Deburrer Machine Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for deburrer machine

In today’s competitive manufacturing landscape, sourcing a reliable deburrer machine is essential for ensuring the quality and safety of metal parts. With the rise of global supply chains, B2B buyers face the challenge of finding machines that not only meet their production needs but also comply with international standards and regulations. This guide serves as a comprehensive resource, exploring various types of deburring machines, their applications across different industries, and key considerations for supplier vetting. From automated solutions designed for high-volume production to specialized machines for intricate tasks, we delve into the features that can enhance operational efficiency.

International buyers from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Germany—will benefit from our insights on cost factors, maintenance support, and the latest technological advancements in deburring. Understanding these elements empowers businesses to make informed purchasing decisions that align with their operational goals and budget constraints. By leveraging the information in this guide, you can navigate the complexities of the global market and invest in deburring solutions that elevate your manufacturing processes, ensuring that your products consistently meet the highest standards of quality and safety.

Understanding deburrer machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wet Deburring Machines | Utilize water or coolant to remove burrs; integrated drying systems. | Ideal for processing metal parts requiring a high-quality finish. | Pros: Superior finish, reduced dust. Cons: Requires water management. |

| Dry Deburring Machines | Operate without liquids; suitable for various materials; often faster. | Suitable for high-volume production of small parts. | Pros: Minimal maintenance, versatile. Cons: May produce dust, less effective on certain materials. |

| Slag Grinders | Specifically designed for removing heavy dross from plasma-cut parts. | Heavy-duty applications in metal fabrication. | Pros: High performance on tough materials. Cons: Requires significant power and maintenance. |

| Edge Rounding Machines | Focus on rounding sharp edges; often combined with deburring functions. | Used in industries where safety and aesthetics are critical. | Pros: Enhances safety, improves product quality. Cons: May require additional adjustments for different materials. |

| Manual Deburring Machines | Operated by hand; versatile and cost-effective for small operations. | Suitable for small workshops and custom projects. | Pros: Low initial cost, flexibility. Cons: Labor-intensive, inconsistent results. |

What Are Wet Deburring Machines and Their Applications?

Wet deburring machines leverage water or coolant to effectively remove burrs while providing a superior surface finish. These machines often come equipped with integrated drying systems to ensure that parts emerge dry and ready for further processing. They are particularly suited for applications requiring high-quality finishes, such as automotive and aerospace components. Buyers should consider water management systems and the machine’s capacity for continuous operation, as these factors can influence overall efficiency and maintenance costs.

How Do Dry Deburring Machines Differ from Wet Machines?

Dry deburring machines operate without the use of liquids, making them ideal for high-volume production environments. They are versatile enough to handle a variety of materials and can often complete deburring tasks more quickly than their wet counterparts. While they are easier to maintain and do not require water management, buyers should be aware that they may produce dust and could be less effective on certain materials. Evaluating the specific materials and production volumes will help buyers determine if a dry machine is the right choice.

Illustrative image related to deburrer machine

What Are Slag Grinders and Their Benefits?

Slag grinders are specialized machines designed to tackle heavy dross and burrs created during plasma cutting. Their robust construction allows them to handle tough materials and thick slag with ease, making them a staple in metal fabrication facilities. While they deliver high performance, buyers should consider the power requirements and maintenance needs associated with these machines, as they can be significant. Companies engaged in heavy-duty metal processing will find slag grinders particularly beneficial for maintaining efficiency and product quality.

What Are Edge Rounding Machines Used For?

Edge rounding machines focus on rounding sharp edges, which is crucial for both safety and aesthetic purposes. These machines often combine deburring and edge conditioning functions, making them versatile tools in manufacturing settings. Industries such as construction and consumer goods frequently utilize these machines to ensure that their products meet safety standards. Buyers should consider the machine’s adaptability to different materials and the ease of adjustment for various edge profiles when making a purchasing decision.

Why Choose Manual Deburring Machines?

Manual deburring machines offer a cost-effective solution for small workshops and custom projects. They provide flexibility and can be adapted to various tasks, making them suitable for businesses that require a personalized approach. However, they are labor-intensive and may yield inconsistent results compared to automated solutions. Businesses with limited budgets or those just starting out may find manual machines to be a practical entry point into the deburring process, but they should weigh the potential trade-offs in efficiency and labor costs.

Key Industrial Applications of deburrer machine

| Industry/Sector | Specific Application of deburrer machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Deburring of metal parts for engines and chassis | Ensures safety and enhances the aesthetic quality of components | Machine compatibility with various metal types and production volumes |

| Aerospace | Edge finishing of aircraft components | Reduces weight while maintaining strength and safety standards | Compliance with stringent aerospace regulations and quality control |

| Electronics | Deburring of circuit boards and metal enclosures | Improves product reliability and prevents short-circuit issues | Precision requirements for intricate designs and small parts |

| Construction & Heavy Machinery | Deburring of steel beams and plates | Enhances structural integrity and safety in construction projects | Durability to handle heavy-duty materials and high throughput |

| Metal Fabrication | Processing laser-cut or punched metal parts | Increases efficiency and reduces manual labor costs | Versatility for different deburring processes and material types |

How is a Deburrer Machine Used in the Automotive Industry?

In the automotive sector, deburring machines play a critical role in processing engine and chassis components. These machines remove sharp edges and imperfections that could pose safety hazards or affect the aesthetic quality of parts. For B2B buyers in regions like Nigeria or Germany, sourcing deburring machines that can accommodate various metal types and production volumes is essential. This ensures that automotive manufacturers can maintain high safety standards while optimizing production efficiency.

What is the Role of Deburring Machines in Aerospace Applications?

Aerospace manufacturers utilize deburring machines to edge-finish components that are crucial for flight safety and performance. By smoothing out sharp edges, these machines help reduce the weight of parts while ensuring they meet stringent safety regulations. For international buyers, particularly in Europe and the Middle East, it is vital to ensure that the chosen deburring equipment complies with aerospace standards and offers robust quality control features.

How Do Deburring Machines Enhance Electronics Manufacturing?

In electronics manufacturing, deburring machines are employed to process circuit boards and metal enclosures. This application is essential for preventing short-circuit issues and improving the overall reliability of electronic devices. Buyers from South America and Africa should consider machines that provide high precision for intricate designs, as well as the capability to handle small parts effectively, ensuring consistent quality across production runs.

Why are Deburring Machines Important in Construction and Heavy Machinery?

Deburring machines are indispensable in the construction and heavy machinery industries, where they process steel beams and plates. The removal of burrs enhances structural integrity and safety, crucial for construction projects. For businesses sourcing deburring machines, durability to withstand heavy-duty materials and high throughput capabilities are key considerations, especially in regions with growing infrastructure demands.

What Benefits Do Deburring Machines Offer in Metal Fabrication?

In metal fabrication, deburring machines streamline the processing of laser-cut or punched metal parts. By automating the deburring process, manufacturers can significantly increase efficiency and reduce labor costs. For international buyers, especially in fast-developing markets, selecting machines that offer versatility for different deburring processes and material types will be essential for maintaining competitive production capabilities.

3 Common User Pain Points for ‘deburrer machine’ & Their Solutions

Scenario 1: Difficulty Achieving Consistent Quality in Production Runs

The Problem: B2B buyers often face challenges in maintaining consistent quality across production runs due to variations in deburring processes. When using manual deburring methods, the potential for human error increases, leading to inconsistencies in the surface finish of metal parts. This inconsistency not only affects the aesthetic appeal but can also compromise the functionality and safety of the components, resulting in increased rework and scrap rates.

The Solution: To address these quality control issues, companies should invest in automated deburring machines tailored to their specific production requirements. When sourcing a deburring machine, buyers should look for features that enhance precision, such as adjustable settings for different materials and thicknesses. Additionally, investing in machines equipped with advanced technology, like robotic arms for loading and unloading, can further reduce human error and ensure uniformity. Regular training for operators on the machine’s capabilities will also help maximize its potential, contributing to a consistent quality output.

Scenario 2: High Operating Costs Due to Inefficient Processes

The Problem: Many manufacturers struggle with high operating costs associated with inefficient deburring processes. Manual deburring not only consumes significant labor hours but can also lead to higher material wastage due to imprecise handling. For companies in competitive markets, these inefficiencies can hinder profitability and scalability, creating a pressing need for a more cost-effective solution.

The Solution: Buyers should consider investing in modern, automated deburring machines that offer both efficiency and cost savings. When evaluating options, it’s crucial to assess the total cost of ownership, including maintenance, energy consumption, and labor savings. Machines with multi-functional capabilities can further reduce costs by combining multiple processes, such as deburring and edge rounding, into one operation. Additionally, exploring leasing or financing options can make acquiring high-quality machines more feasible without upfront financial strain.

Scenario 3: Safety Concerns from Manual Deburring Operations

The Problem: Safety is a significant concern in environments that rely heavily on manual deburring. Workers are often exposed to sharp edges and heavy machinery, increasing the risk of accidents and injuries. This not only affects employee morale but can also lead to costly downtime and potential liabilities for the company.

The Solution: Transitioning to automated deburring machines can significantly enhance workplace safety. Buyers should prioritize machines designed with safety features, such as enclosed operating areas and emergency shut-off systems. Furthermore, investing in training programs that emphasize the safe operation of these machines will empower employees and reduce the likelihood of accidents. By creating a safer work environment, companies can improve productivity while also demonstrating a commitment to employee well-being, ultimately benefiting their overall reputation and operational efficiency.

Illustrative image related to deburrer machine

In summary, addressing these common pain points through strategic investments in deburring technology and training can lead to improved quality, reduced costs, and enhanced safety in manufacturing operations.

Strategic Material Selection Guide for deburrer machine

What Are the Key Materials for Deburrer Machines?

When selecting materials for deburrer machines, understanding their properties and how they impact performance is crucial for international B2B buyers. Here, we analyze four common materials used in the manufacturing of deburring machines: stainless steel, aluminum, cast iron, and high-strength plastics. Each material has unique characteristics that influence durability, cost, and suitability for specific applications.

How Does Stainless Steel Benefit Deburrer Machines?

Stainless steel is renowned for its excellent corrosion resistance and high strength. It can withstand elevated temperatures and pressures, making it suitable for heavy-duty applications. Its durability ensures a long lifespan for deburring machines, reducing maintenance costs over time.

Pros: Stainless steel offers superior durability and resistance to corrosion, making it ideal for environments with moisture or chemicals. It also maintains structural integrity under high temperatures, ensuring consistent performance.

Illustrative image related to deburrer machine

Cons: The primary downside is its cost, as stainless steel is generally more expensive than other materials. Additionally, its weight can complicate the machine’s mobility and installation.

Impact on Application: Stainless steel is compatible with a wide range of deburring media, including abrasive materials and liquid coolants, enhancing its versatility in different industrial settings.

Considerations for International Buyers: Buyers in regions like Germany and Nigeria should ensure compliance with local standards such as DIN or ASTM, particularly for food or medical applications where material safety is paramount.

Why Choose Aluminum for Deburrer Machines?

Aluminum is lightweight and offers good corrosion resistance, making it a popular choice for deburring machines that require mobility and ease of handling. Its thermal conductivity allows for efficient heat dissipation during operation.

Pros: The lightweight nature of aluminum facilitates easier transportation and installation. It is also less expensive than stainless steel, making it a cost-effective option for many manufacturers.

Cons: However, aluminum is not as strong as stainless steel and may not withstand heavy-duty applications as effectively. It is also more susceptible to scratching and denting.

Illustrative image related to deburrer machine

Impact on Application: Aluminum is suitable for lighter applications where high precision is required, but it may not be ideal for heavy or abrasive materials that can damage softer surfaces.

Considerations for International Buyers: Buyers should be aware of the varying standards for aluminum alloys in different regions, ensuring they select grades that meet local compliance requirements.

What Are the Advantages of Cast Iron in Deburring Machines?

Cast iron is known for its exceptional stability and vibration-dampening properties, making it ideal for deburring machines that operate at high speeds. Its rigidity contributes to precision in the deburring process.

Illustrative image related to deburrer machine

Pros: The durability of cast iron ensures longevity and consistent performance, particularly in heavy-duty applications. Its ability to absorb vibrations enhances the quality of the finished product.

Cons: The main drawbacks of cast iron include its weight and susceptibility to rust if not properly maintained. Additionally, it can be more challenging to machine and fabricate compared to other materials.

Impact on Application: Cast iron is particularly effective for heavy-duty deburring tasks, especially in industries where precision and durability are critical.

Considerations for International Buyers: Buyers should consider the maintenance requirements for cast iron, especially in humid climates prevalent in regions like Africa, to prevent rust and degradation.

How Do High-Strength Plastics Fit into Deburring Machine Design?

High-strength plastics, such as polycarbonate and nylon, are increasingly being used in deburring machines due to their lightweight nature and resistance to corrosion. These materials can be engineered for specific applications, providing flexibility in design.

Illustrative image related to deburrer machine

Pros: High-strength plastics are lightweight, reducing the overall weight of the machine and enhancing mobility. They also offer good chemical resistance, making them suitable for various environments.

Cons: However, they may not provide the same level of durability as metals and can be prone to wear over time, particularly under heavy loads.

Impact on Application: These materials are ideal for applications where weight is a concern, and they can be used in conjunction with metal components for a hybrid solution.

Considerations for International Buyers: Buyers should ensure that the selected plastics meet industry standards for strength and chemical resistance, particularly in sectors like automotive or aerospace.

Summary Table of Material Selection for Deburrer Machines

| Material | Typical Use Case for deburrer machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty industrial applications | Superior corrosion resistance | Higher cost and weight | High |

| Aluminum | Lightweight, portable machines | Cost-effective and easy to handle | Less durable than steel | Medium |

| Cast Iron | High-speed, precision tasks | Excellent stability and durability | Heavy and prone to rust | Medium |

| High-Strength Plastics | Lightweight applications | Lightweight and corrosion-resistant | Less durable under heavy loads | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their deburring machine investments while considering performance, cost, and compliance factors specific to their regions.

In-depth Look: Manufacturing Processes and Quality Assurance for deburrer machine

What Are the Key Stages in the Manufacturing Process of Deburrer Machines?

The manufacturing process of deburrer machines involves several critical stages, each designed to ensure that the final product meets the highest quality standards for functionality and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Raw Materials Are Used?

The journey of a deburrer machine begins with material preparation. Manufacturers typically use high-grade steel and aluminum for the machine’s frame and components to ensure strength and longevity. Stainless steel is often selected for parts that come into contact with various metal workpieces, as it provides resistance to corrosion and wear. During this stage, materials are sourced from certified suppliers who adhere to international standards, ensuring consistency and reliability in the quality of raw materials.

Forming: How Are Deburrer Components Shaped?

Once the raw materials are prepared, they undergo forming processes. Techniques such as laser cutting, bending, and machining are commonly employed to create the precise shapes required for each component of the deburrer machine. Advanced CNC (Computer Numerical Control) technology is often utilized for machining operations, allowing for high accuracy and repeatability. This precision is vital, as it directly impacts the machine’s performance and the quality of the deburring process itself.

Assembly: What Are the Key Considerations?

The assembly stage involves integrating all components into a cohesive unit. Skilled technicians meticulously assemble the machines, ensuring that all parts fit together seamlessly. This stage may include installing motors, belts, and control systems that dictate the machine’s operation. Quality checks are performed at various points during assembly to catch any defects early in the process. Ensuring that the assembly is conducted in a clean and controlled environment helps to prevent contamination and maintain quality.

Finishing: What Techniques Are Used to Enhance Performance?

Finishing processes are critical for enhancing both the aesthetic appeal and the functional performance of deburrer machines. This can involve surface treatments like powder coating or anodizing to improve corrosion resistance and durability. Additionally, precise calibration is performed to ensure that the machine operates within specified tolerances. This stage also often includes testing the machines under load conditions to verify their performance before they are shipped to customers.

How Is Quality Assurance Implemented in Deburrer Machine Manufacturing?

Quality assurance (QA) is an integral aspect of the manufacturing process, ensuring that each deburrer machine meets international standards and customer expectations. B2B buyers should pay close attention to the QA processes employed by manufacturers.

What International Standards Should B2B Buyers Look For?

Manufacturers of deburrer machines often adhere to international quality standards such as ISO 9001. This standard outlines requirements for a quality management system and emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE marking (for compliance with European safety standards) or API certification (for equipment used in the oil and gas industry) can provide assurance of quality and safety.

Illustrative image related to deburrer machine

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage assesses the quality of raw materials upon delivery. Materials that do not meet predefined specifications are rejected or returned.

-

In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to ensure that components are being produced according to specifications. This includes measuring dimensions and testing for defects.

-

Final Quality Control (FQC): After assembly and finishing, the complete machine undergoes rigorous testing. This may include performance tests, safety checks, and operational assessments to verify that the machine functions as intended.

What Common Testing Methods Are Employed for Deburrer Machines?

Manufacturers employ various testing methods to ensure the reliability and performance of deburrer machines:

- Functional Testing: This verifies that the machine operates correctly under different conditions and meets performance specifications.

- Load Testing: Machines are subjected to their maximum operational loads to ensure they can handle stress without failure.

- Visual Inspections: A thorough visual check for any surface imperfections or assembly errors is conducted before final shipment.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to ensure the quality of deburrer machines from suppliers can take several steps:

-

Conduct Supplier Audits: Visiting the manufacturing facility to review processes, quality control measures, and overall operational standards can provide valuable insights into the supplier’s commitment to quality.

-

Request Quality Reports: Suppliers should be able to provide documentation that outlines their quality control processes and results from testing procedures. This transparency is crucial for building trust.

-

Engage Third-Party Inspectors: Hiring independent inspectors to evaluate the machines before shipment can further ensure that the equipment meets the required standards and specifications.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Different regions may have varying compliance requirements, and it’s crucial to ensure that the machines meet both local and international standards. Additionally, language barriers and differing business practices can complicate communication regarding quality expectations.

Buyers should establish clear lines of communication with suppliers and consider using third-party consultants familiar with local regulations and standards to bridge any gaps. This diligence can help mitigate risks associated with importing equipment that may not meet local compliance standards.

Conclusion

The manufacturing processes and quality assurance measures for deburrer machines are critical for ensuring that these machines deliver consistent performance and quality. By understanding the key stages of production, the importance of quality control checkpoints, and how to verify supplier practices, B2B buyers can make informed decisions that will contribute to their operational success and safety in metalworking applications. Investing in high-quality deburring machines is not just a purchase; it’s a strategic decision that can enhance production efficiency and product quality in the long run.

Illustrative image related to deburrer machine

Practical Sourcing Guide: A Step-by-Step Checklist for ‘deburrer machine’

In the competitive landscape of metalworking, acquiring the right deburring machine is crucial for ensuring product quality and operational efficiency. This checklist serves as a comprehensive guide for B2B buyers seeking to procure deburring machines, tailored for various needs and budgets.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first step in sourcing a deburring machine. Consider factors such as the types of materials you will be processing (e.g., aluminum, steel, or composites), the size and shape of your workpieces, and the expected production volume.

– Material Compatibility: Ensure the machine can handle the thickness and type of materials you typically work with.

– Production Capacity: Assess your operational needs to determine the machine’s throughput requirements.

Step 2: Research Available Technologies

Deburring machines come in various configurations, including wet and dry systems, each suited for different applications. Familiarize yourself with the technologies available, such as automated systems that enhance efficiency and precision.

– Wet vs. Dry: Wet deburring machines often provide better cooling and finish quality, while dry machines are typically more versatile and require less maintenance.

– Automation Features: Look for machines with advanced automation capabilities that can streamline your operations and reduce labor costs.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers to ensure they meet your operational and quality standards.

– Supplier Reputation: Request company profiles, case studies, and references from other buyers in similar industries or regions.

– Service and Support: Investigate the level of customer support and maintenance services offered, as these can significantly impact long-term machine performance.

Step 4: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotes that include all costs associated with the purchase, such as installation, training, and maintenance.

– Transparent Pricing: Ensure that quotes break down costs to avoid hidden fees later.

– Value vs. Cost: Consider the machine’s capabilities and expected lifespan when evaluating the overall value, not just the initial price.

Step 5: Check for Compliance and Certifications

Verify that the deburring machines comply with international and local industry standards, especially if you operate in regulated markets.

– Safety Standards: Look for machines that meet safety regulations to protect your workforce.

– Quality Certifications: Suppliers with ISO or similar certifications often indicate a commitment to quality and reliability.

Step 6: Assess After-Sales Support and Maintenance Options

A reliable after-sales support system is essential for minimizing downtime and ensuring your machine operates optimally.

– Parts Availability: Confirm that the supplier maintains an inventory of spare parts to facilitate quick repairs.

– Maintenance Services: Inquire about training for your staff and the availability of maintenance contracts to keep the machine in top condition.

Step 7: Finalize Your Purchase and Installation Plan

Once you have selected a machine and supplier, finalize your order and discuss the installation process.

– Installation Timeline: Agree on a clear timeline for installation to minimize disruptions to your operations.

– Training Requirements: Ensure that your team is adequately trained to operate the new machine efficiently, maximizing its potential from day one.

This checklist is designed to guide you through the essential steps of sourcing a deburring machine, enabling you to make an informed decision that aligns with your production needs and quality standards.

Comprehensive Cost and Pricing Analysis for deburrer machine Sourcing

What Are the Key Cost Components for Sourcing Deburring Machines?

When sourcing deburring machines, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used in the manufacturing of deburring machines significantly impacts pricing. High-grade steel, advanced composites, and durable components increase initial costs but enhance the machine’s lifespan and performance.

-

Labor: Skilled labor is essential for assembling and testing deburring machines. Labor costs vary by region, with countries like Germany often experiencing higher wages compared to those in Africa or South America. This can influence the final price of the machine.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: The investment in specialized tools for production can add to the overall cost. Custom tooling for specific machine configurations or specifications may be necessary, impacting pricing.

-

Quality Control (QC): Rigorous QC processes ensure that machines meet industry standards. This involves testing, inspections, and certifications, which contribute to the overall cost but are crucial for ensuring reliability and performance.

-

Logistics: Shipping costs, including freight and handling, vary based on distance and mode of transport. International buyers should consider these factors, as they can significantly affect the total cost.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary based on market conditions, competition, and the supplier’s business model.

How Do Price Influencers Affect Deburring Machine Costs?

Several factors influence the pricing of deburring machines, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in bulk typically reduces the unit cost. Suppliers often offer discounts for larger orders, making it advantageous for businesses with high production needs.

-

Specifications/Customization: Custom-built machines tailored to specific requirements can lead to higher costs. Buyers should clearly define their needs to avoid unnecessary expenditures on features that may not be utilized.

-

Materials and Quality/Certifications: Machines made from premium materials and those that comply with international quality standards or certifications often command higher prices. Buyers should weigh the benefits of these features against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established manufacturers with a track record of quality may charge more but offer better support and warranty options.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost.

What Tips Can Help Buyers Optimize Costs When Sourcing Deburring Machines?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can benefit from strategic approaches to cost management:

Illustrative image related to deburrer machine

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially for larger orders. Leveraging relationships and exploring multiple quotes can lead to better deals.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the purchase price. Consider long-term operating costs, maintenance, and energy efficiency, which can significantly affect your return on investment.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local taxes, and import duties that can affect the final price. Establishing clear communication with suppliers about these factors can prevent unexpected costs.

-

Research and Due Diligence: Conduct thorough research on potential suppliers and their offerings. Understanding the market landscape can help identify the best value propositions.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always request detailed quotes and consider all cost components when making purchasing decisions.

Alternatives Analysis: Comparing deburrer machine With Other Solutions

When considering the best solutions for metal deburring, businesses often evaluate multiple options to find the most effective method for their specific needs. While deburring machines are widely recognized for their efficiency and effectiveness, it is essential to explore alternative solutions that might also meet production requirements. This analysis compares deburring machines with manual deburring processes and robotic deburring systems, providing insights for B2B buyers seeking optimal performance.

| Comparison Aspect | Deburrer Machine | Manual Deburring Process | Robotic Deburring System |

|---|---|---|---|

| Performance | High, consistent quality finish | Variable quality; depends on operator skill | High, but may require programming adjustments |

| Cost | Higher initial investment, lower long-term costs | Low upfront cost, high labor costs | High initial investment, potential long-term savings |

| Ease of Implementation | Requires training, but straightforward operation | Simple to start, but labor-intensive | Requires technical knowledge for setup and programming |

| Maintenance | Regular maintenance needed, but parts support available | Minimal, but labor-intensive and slow | High maintenance due to complexity, but fewer operator errors |

| Best Use Case | High-volume production with consistent quality | Small-scale or prototype work | Complex shapes and designs requiring precision |

What Are the Pros and Cons of Manual Deburring Processes?

Manual deburring is a traditional method where operators use hand tools to remove burrs from workpieces. The primary advantage of this approach is its low initial cost, making it accessible for small operations or businesses that do not require high-volume production. However, manual deburring relies heavily on the skill and consistency of the operator, leading to variability in the quality of finished parts. Additionally, it can be labor-intensive and time-consuming, which may not be sustainable for larger production runs.

How Do Robotic Deburring Systems Compare to Deburrer Machines?

Robotic deburring systems represent a sophisticated alternative that integrates automation with advanced programming to perform deburring tasks. These systems can be highly effective for complex shapes and intricate designs, providing a consistent finish with minimal human intervention. While the initial investment is significant, robotic systems can lead to long-term savings by reducing labor costs and increasing throughput. However, they require a skilled technician for setup and maintenance, which can complicate implementation, especially for businesses with limited technical resources.

Conclusion: How Should B2B Buyers Choose the Right Deburring Solution?

Selecting the right deburring solution hinges on various factors, including production volume, budget constraints, and the complexity of parts being processed. For businesses focused on high-volume production with a need for consistent quality, investing in a deburring machine is often the most beneficial choice. In contrast, companies with lower production volumes or those just starting may find manual deburring to be a cost-effective solution. Finally, for operations requiring precision on complex geometries, robotic deburring systems could be the ideal solution, albeit at a higher initial cost. By carefully assessing these alternatives, B2B buyers can make informed decisions that align with their operational goals and financial capabilities.

Essential Technical Properties and Trade Terminology for deburrer machine

What Are the Key Technical Properties of a Deburrer Machine?

When considering the procurement of a deburrer machine, understanding its technical specifications is vital. Here are several critical properties that B2B buyers should evaluate:

-

Material Grade: The construction material of the deburring machine affects its durability and performance. Common materials include steel and aluminum, with high-quality steel offering better longevity and resistance to wear. For buyers, investing in a machine with superior material grade can lead to lower maintenance costs and extended operational life.

-

Tolerance Levels: This specification indicates the precision with which the machine can operate. A tighter tolerance ensures that the deburring process produces parts with minimal deviation from the desired dimensions. For manufacturers, maintaining tight tolerances is crucial to meet industry standards and customer expectations, enhancing product quality and reducing waste.

-

Processing Speed: Measured in parts per minute (PPM), processing speed reflects the machine’s efficiency in handling deburring tasks. Higher speeds can significantly improve throughput, which is essential for businesses aiming to meet high-volume production demands. Faster machines can lead to better ROI by maximizing output without compromising quality.

-

Power Requirements: This specification indicates the electrical consumption of the machine, often expressed in kilowatts (kW). Understanding the power requirements is critical for ensuring compatibility with existing facilities and estimating operational costs. Machines with lower power consumption can be more economical in the long run, especially in regions where energy costs are high.

-

Automation Features: Many modern deburrer machines come equipped with automated functionalities, such as robotic loading and unloading systems. Automation enhances operational efficiency by reducing manual labor and minimizing human error. For B2B buyers, investing in automation can lead to significant labor cost savings and increased production consistency.

-

Machine Configuration: This refers to the number of heads, types of abrasives, and the machine’s adaptability to various materials and processing techniques. A versatile configuration allows manufacturers to customize the machine for different applications, making it a more flexible investment. Buyers should consider machines that can handle multiple processes to maximize their utility.

What Are Common Trade Terms Related to Deburrer Machines?

Understanding industry terminology is equally important for effective communication and decision-making. Here are some common terms relevant to the deburring machine market:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the deburring machine industry, working with reputable OEMs ensures that the machines meet high-quality standards and are supported by reliable service.

-

MOQ (Minimum Order Quantity): This term specifies the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge their purchasing power and negotiate better terms. For companies looking to scale production, knowing the MOQ can help in planning inventory and budget.

-

RFQ (Request for Quotation): An RFQ is a document that buyers use to solicit price quotes from suppliers. It typically includes detailed specifications and requirements. Crafting a thorough RFQ helps ensure that suppliers understand the buyer’s needs, leading to more accurate and competitive pricing.

-

Incoterms: Short for International Commercial Terms, these are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms is essential for B2B transactions, as they clarify shipping, insurance, and delivery obligations, reducing the risk of disputes.

-

Lead Time: This refers to the amount of time from placing an order to receiving the machine. It is a critical factor for planning production schedules. Buyers should inquire about lead times to align their procurement with operational timelines and avoid production delays.

-

Service Level Agreement (SLA): An SLA outlines the expected level of service between a supplier and a buyer, detailing aspects like maintenance, support response times, and warranty conditions. For B2B buyers, a well-defined SLA ensures that they receive the necessary support and reliability from their deburring machine suppliers.

Understanding these technical properties and trade terms can empower B2B buyers to make informed decisions when investing in deburring machines, ensuring they meet their operational needs effectively.

Illustrative image related to deburrer machine

Navigating Market Dynamics and Sourcing Trends in the deburrer machine Sector

What are the Current Market Dynamics and Key Trends in the Deburrer Machine Sector?

The global deburrer machine market is witnessing robust growth, driven by the increasing demand for high-quality finished metal products across various industries, including automotive, aerospace, and manufacturing. Key factors such as the rise of automation and Industry 4.0 are reshaping procurement strategies for international B2B buyers. Automated deburring solutions are now favored for their efficiency, consistency, and ability to minimize labor costs, which is particularly beneficial for businesses in regions like Africa, South America, the Middle East, and Europe.

Emerging technologies, such as robotic-assisted deburring and advanced sensor systems, are enhancing machine capabilities and offering greater precision. The demand for customized solutions tailored to specific materials and processing methods is also on the rise, with manufacturers focusing on developing versatile machines that can handle various thicknesses and types of burrs. For instance, machines that can accommodate both wet and dry deburring processes are increasingly popular, as they provide flexibility and cater to diverse operational needs.

In regions like Nigeria and Germany, buyers are increasingly prioritizing machines that not only meet production requirements but also align with sustainability goals. As the market matures, the integration of smart technologies and data analytics into deburring machines is expected to further streamline operations, allowing companies to optimize their sourcing strategies while enhancing product quality.

How is Sustainability and Ethical Sourcing Impacting Deburrer Machine Procurement?

Sustainability has emerged as a central theme in the sourcing of deburrer machines, reflecting the growing awareness of environmental impacts across the manufacturing sector. B2B buyers are increasingly seeking equipment that adheres to sustainable practices, including energy-efficient operations and the use of eco-friendly materials. Machines that incorporate features such as reduced water consumption in wet deburring processes or recyclable components are gaining traction.

The importance of ethical supply chains is also paramount. International buyers are scrutinizing their suppliers for compliance with ethical labor practices and environmental regulations. Manufacturers that can demonstrate a commitment to sustainable sourcing—through certifications such as ISO 14001 for environmental management—are more likely to secure contracts in competitive markets.

Moreover, green certifications and the use of sustainable materials in the production of deburrer machines not only enhance brand reputation but also help businesses meet regulatory requirements. As industries pivot toward greener practices, suppliers that integrate sustainability into their operations will find themselves better positioned to meet the demands of conscientious buyers.

What is the Brief History and Evolution of Deburrer Machines?

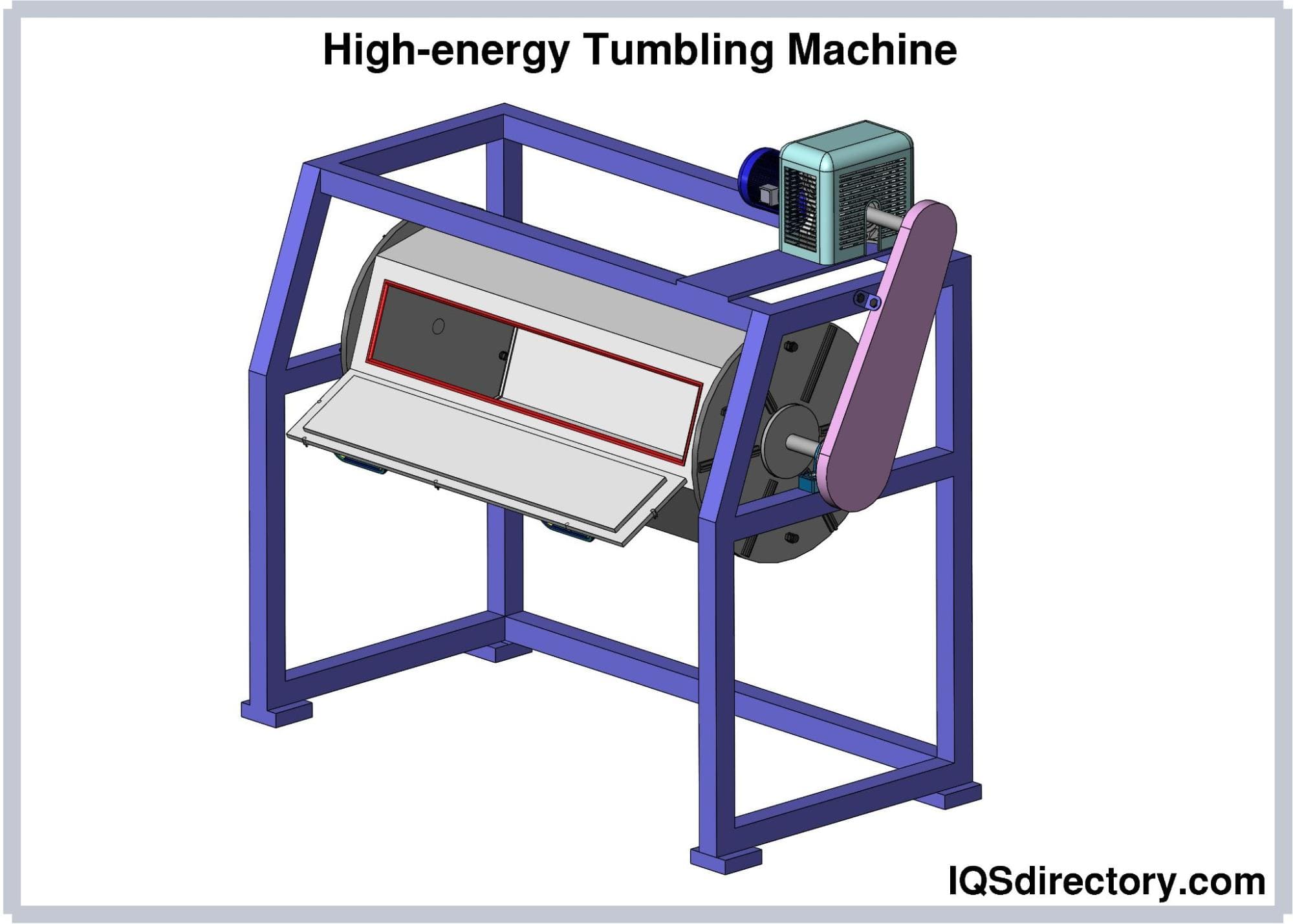

The evolution of deburrer machines dates back to the mid-20th century when the need for high-quality finishes in metalworking became increasingly critical. Initially, deburring was a manual process, often labor-intensive and time-consuming. However, as industrialization advanced, the introduction of automated systems revolutionized the deburring process, significantly enhancing efficiency and precision.

By the 1970s and 1980s, manufacturers began developing specialized machines that could handle various deburring methods, including wet and dry processes. This innovation allowed for greater versatility in handling different materials and production requirements. Today, the market has expanded to include sophisticated automated solutions that incorporate smart technologies, enabling real-time monitoring and adjustments to optimize performance.

As the industry continues to evolve, B2B buyers are presented with a plethora of options that cater to diverse operational needs, thus driving the demand for advanced deburring solutions in a competitive global market.

Frequently Asked Questions (FAQs) for B2B Buyers of deburrer machine

-

How do I choose the right deburring machine for my needs?

Choosing the right deburring machine involves assessing your specific production requirements, including the type of materials you work with, the size of the parts, and the volume of production. Consider whether you need a wet or dry deburring system, as each has its advantages. Evaluate the machine’s capabilities in handling various burr sizes and shapes. Additionally, consult with manufacturers to understand customization options that can tailor the machine to your unique specifications. -

What are the key features to look for in a deburring machine?

Key features to consider include automation level, processing speed, versatility for different materials, and ease of operation. Look for machines with advanced abrasive technology that can provide a consistent finish and high-quality results. Features like adjustable settings for different burr types and sizes, integrated dust extraction systems, and low maintenance requirements can significantly enhance productivity and reduce downtime. -

What is the typical lead time for ordering a deburring machine?

Lead times can vary significantly based on the manufacturer, customization level, and order volume. Generally, standard machines may have a lead time of 4 to 12 weeks, while custom solutions could take longer. It’s advisable to communicate your timeline requirements upfront and confirm with the supplier to ensure they can meet your production schedules. -

What payment terms should I expect when purchasing a deburring machine?

Payment terms can vary by supplier and region, but common practices include a deposit upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer financing options or leasing arrangements, which can be beneficial for managing cash flow. Always clarify payment terms, including any potential discounts for early payment or specific terms for international transactions. -

How do I vet suppliers for deburring machines?

To vet suppliers, start by researching their reputation and industry experience. Look for customer testimonials, case studies, and reviews. Check if they have certifications and quality assurance processes in place, such as ISO standards. Request references from other B2B buyers and inquire about their after-sales support and availability of spare parts to ensure long-term reliability. -

Can I customize my deburring machine?

Yes, many manufacturers offer customization options to meet specific production needs. This can include modifications in machine size, additional tooling for various materials, or integration with existing production lines. Discuss your requirements with the supplier during the initial consultation to explore the available customization features and their associated costs. -

What are the logistics considerations for importing deburring machines?

Logistics considerations include shipping costs, import duties, and compliance with local regulations. Ensure that the supplier provides detailed shipping information and documentation required for customs clearance. It’s also wise to work with a logistics partner who understands international trade, as they can help navigate potential challenges and ensure timely delivery. -

What should I know about ongoing maintenance and support for my deburring machine?

Ongoing maintenance is crucial for the longevity and performance of your deburring machine. Inquire about the manufacturer’s support services, including warranty terms, availability of spare parts, and maintenance schedules. Regular servicing can prevent unexpected breakdowns and ensure the machine operates at peak efficiency, ultimately protecting your investment and minimizing downtime in your production process.

Top 9 Deburrer Machine Manufacturers & Suppliers List

1. Timesavers – Industrial Deburring Machines

Domain: timesaversinc.com

Registered: 1996 (29 years)

Introduction: Timesavers offers a range of industrial deburring machines designed to remove imperfections from machined metal products, ensuring a smooth and high-quality finish. Key product details include: 11 Series (wet, integrated dryer, 9″ conveyor belt), 12 Series (dry, standard in the industry for over 40 years), 21 Series (wet, compact design for lower production), 22 Series (versatile for metal finishi…

2. Trick Tools – Deburring Machines

Domain: trick-tools.com

Registered: 2001 (24 years)

Introduction: This company, Trick Tools – Deburring Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Capital Weld Cleaners – EF-11 Sheet Metal Deburring Machine

Domain: capitalweldcleaners.com

Registered: 2008 (17 years)

Introduction: {‘name’: ‘EF-11 Sheet Metal Deburring Machine’, ‘price’: ‘$2,375.00’, ‘description’: ‘Efficient, Dual-Sided Edge Finishing Built for Industrial Demands’, ‘key_features’: [‘Dual-Sided Deburring in One Pass’, ‘Adjustable Guide Rail System’, ‘Rotatable 90° Vertical Configuration’, ‘Tool-Free Flap Wheel Adjustment’, ‘Safer Alternative to Hand Grinders’, ‘Universal Material Capability’, ‘Built for the …

4. Arku – Deburring Machines & Automated Material Handling

Domain: arku.com

Registered: 1999 (26 years)

Introduction: Deburring Machines for Laser Cut & Punched Parts, Deburring Machines for Plasma & Flame Cut Parts, Automated Material Handling for Deburring, Edgebreaker® for deburring and edge rounding, suitable for various materials and dimensions, robust design for flame cut parts, handles slag or burrs over 0.12″ (3mm) thickness, precision deburring tools, automated loading and unloading solutions, leasing an…

5. CS Unitec – Flat & Sheet Metal Deburring Machines

Domain: csunitec.com

Registered: 1997 (28 years)

Introduction: This company, CS Unitec – Flat & Sheet Metal Deburring Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. LISSMAC – SBM-XS G1E1

Domain: lissmac.com

Registered: 1997 (28 years)

Introduction: LISSMAC offers a range of deburring machines designed for high-quality processing of metal workpieces, ensuring efficient burr removal, edge rounding up to a radius of 2 mm, oxide layer removal, effective slag removal, and precise surface grinding. Key products include:

1. SBM-XS G1E1: Double-sided deburring for small parts, uniform edge rounding on all sides in a single pass.

2. SBM-M S2: Deburr…

7. Techniks USA – Spinner Deburring Machines

Domain: techniksusa.com

Registered: 2000 (25 years)

Introduction: Product Name: Spinner Deburring Machines

Key Features:

– Works best for:

– Surface polishing

– Pre-electroplating processing

– Removing heat treat scaling

– Oxidized grease/film cleaning

– Removing rust/cleaning threads

– Batch deburrs dozens to hundreds of small precision metal parts.

– Eliminates time-consuming hand-deburring, polishing, or finishing processes.

– Effective for irregul…

8. Deburring Machinery – Deburring Machines

Domain: deburringmachinery.com

Registered: 2000 (25 years)

Introduction: Deburring Machinery offers a variety of products including deburring machines, deburring media, deburring tumblers, tumbler polishing equipment, polishing machines, tumbling barrels, tumbling machines, tumbling media, and vibratory finishing equipment. Key manufacturers listed include Otec USA Inc., which specializes in centrifugal disc, drag, and stream finishing machines; ESMA, Inc., known for a…

9. NS Maquinas – DM1100 Z2C EVO

Domain: nsmaquinas.com

Registered: 2010 (15 years)

Introduction: {“product_name”: “DM1100 Z2C EVO”, “category”: “Deburring and Edge Rounding”, “working_capacity_mm”: “1100×120”, “belt_stations”: 1, “cross_belt_stations”: 2, “abrasive_belt_dimensions_mm”: “1100×2200”, “abrasive_belt_speed_m_s”: “8-22”, “cross_belt_speed_m_s”: “2-8”, “feeding_speed_m_m”: “0.6-3.2”, “abrasive_belt_motor_per_head_kW”: 18.5, “cross_belt_motor_kW”: “(2x) 3”, “feeding_motor_kW”: “(3x)…

Strategic Sourcing Conclusion and Outlook for deburrer machine

In today’s competitive manufacturing landscape, the importance of investing in high-quality deburring machines cannot be overstated. These machines are essential for enhancing product quality, ensuring safety, and maximizing operational efficiency. By automating the deburring process, businesses can achieve consistent results while significantly reducing labor costs and the risk of human error. The range of available machines—from compact models for small operations to robust systems designed for heavy-duty use—allows companies to tailor their investments to specific production needs.

Strategic sourcing of deburring machines should be a priority for international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. By partnering with reputable manufacturers, businesses can access cutting-edge technology that not only meets regulatory requirements but also drives long-term savings through durability and low maintenance costs.

Looking ahead, the demand for efficient metal finishing solutions will only grow as industries expand and evolve. We encourage B2B buyers to assess their deburring needs and explore partnerships with trusted manufacturers to secure the right equipment that will propel their operations into the future. Now is the time to invest in technology that enhances production capabilities and delivers superior quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.