Dc Ups: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for dc ups

In today’s rapidly evolving global market, ensuring consistent power supply is critical for operational efficiency, particularly in sectors where uninterrupted service is non-negotiable. For international B2B buyers, sourcing reliable DC uninterruptible power supplies (DC UPS) can pose significant challenges, from understanding the myriad types available to evaluating supplier reliability. This comprehensive guide aims to illuminate the complexities of the DC UPS landscape, addressing key considerations such as types, applications, supplier vetting, and cost implications.

Understanding the different configurations of DC UPS—ranging from those with integrated batteries to those utilizing capacitor storage—enables buyers to make informed decisions tailored to their specific operational needs. Each application, whether in manufacturing, telecommunications, or data centers, presents unique demands that require careful assessment. This guide not only outlines the functional attributes and benefits of various DC UPS systems but also provides insights into how to effectively vet suppliers, ensuring that buyers can establish partnerships with manufacturers who meet stringent quality and reliability standards.

By equipping B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, with actionable insights and strategic frameworks, this guide empowers them to navigate the complexities of sourcing DC UPS systems. Ultimately, informed purchasing decisions can lead to enhanced system availability, reduced downtime, and significant cost savings, positioning businesses for success in an increasingly competitive environment.

Understanding dc ups Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Capacitor-Based DC UPS | Uses electrochemical double-layer capacitors for short-term backup | Industrial automation, telecommunications | Pros: Quick response time, compact size. Cons: Limited backup duration (seconds). |

| VRLA Battery DC UPS | Utilizes Valve Regulated Lead Acid (VRLA) batteries for extended backup | Critical infrastructure, data centers | Pros: Long backup duration (hours to days). Cons: Requires maintenance and battery management. |

| Integrated Battery DC UPS | Features built-in batteries for seamless integration | Robotics, control systems | Pros: Simplified installation, reliable performance. Cons: Limited customization options. |

| Modular DC UPS | Offers customizable configurations with external battery options | Renewable energy systems, large facilities | Pros: Flexible capacity, tailored solutions. Cons: Potentially higher initial costs. |

| Micro-UPS | Compact design suitable for low-power applications | IoT devices, edge computing | Pros: Space-saving, easy installation. Cons: Limited to lower power outputs. |

What Are the Characteristics of Capacitor-Based DC UPS?

Capacitor-based DC UPS systems utilize electrochemical double-layer capacitors to provide immediate backup power during short outages. Typically offering backup durations measured in seconds, these systems excel in applications requiring rapid response to power fluctuations, such as industrial automation and telecommunications. Buyers should consider their need for quick buffering versus longer backup times, as these units are not suitable for critical processes needing extended power supply.

How Do VRLA Battery DC UPS Systems Operate?

VRLA battery DC UPS systems are designed for longer backup durations, making them ideal for critical infrastructure and data centers. These units can maintain power for several hours to days, depending on battery size. However, they require regular maintenance and careful battery management to ensure longevity and performance. When purchasing, businesses should evaluate their power requirements and the frequency of potential outages to determine the appropriate capacity and configuration.

What Are the Advantages of Integrated Battery DC UPS?

Integrated battery DC UPS systems come with built-in batteries, simplifying installation and making them a convenient option for robotics and control systems. These units offer reliable performance with minimal setup time. Buyers should assess their power needs and consider the trade-off between ease of use and the potential limitations in customization when selecting these systems.

Why Choose a Modular DC UPS?

Modular DC UPS systems provide customizable configurations that allow businesses to scale their power solutions according to specific demands. Often used in renewable energy systems and large facilities, these systems can adapt to varying power needs. While they offer flexibility, potential buyers should weigh the advantages of tailored solutions against the possibility of higher initial costs and complexity in setup.

How Do Micro-UPS Systems Fit into B2B Applications?

Micro-UPS systems are compact and designed for low-power applications, making them suitable for IoT devices and edge computing environments. Their space-saving design allows for easy installation in constrained spaces. However, they are limited to lower power outputs, which may not meet the requirements of larger equipment. Businesses should consider their specific power needs and space constraints when evaluating micro-UPS solutions.

Key Industrial Applications of dc ups

| Industry/Sector | Specific Application of dc ups | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Backup power for cell towers | Ensures continuous service during power outages, reducing downtime and maintaining customer satisfaction. | Voltage requirements, battery capacity, and maintenance options. |

| Manufacturing | Control systems for production lines | Prevents production halts due to power failures, safeguarding revenue and operational efficiency. | Compatibility with existing systems, battery life, and monitoring features. |

| Data Centers | Power supply for servers and networking equipment | Protects against data loss and hardware damage, ensuring uninterrupted service and reliability. | Scalability, energy efficiency, and integration capabilities. |

| Transportation & Logistics | Power supply for automated systems in warehouses | Maintains operational continuity for inventory management systems, enhancing efficiency and reducing errors. | Load capacity, backup duration, and environmental factors. |

| Healthcare | Power supply for critical medical equipment | Prevents loss of critical patient data and equipment functionality during outages, enhancing patient care. | Compliance with health regulations, backup duration, and reliability under load. |

How Are DC UPS Solutions Applied in Telecommunications?

In telecommunications, DC UPS systems are critical for ensuring uninterrupted service at cell towers. These units provide backup power during outages, which is essential for maintaining connectivity and customer satisfaction. Buyers must consider voltage requirements, battery capacity, and maintenance options, especially in regions like Africa and South America, where power reliability can be a significant concern.

What Role Do DC UPS Systems Play in Manufacturing?

In the manufacturing sector, DC UPS units support control systems for production lines. They prevent costly production halts caused by power failures, protecting both revenue and operational efficiency. When sourcing, businesses need to evaluate compatibility with existing systems, battery life, and monitoring features to ensure seamless integration into their operations.

Why Are DC UPS Systems Essential for Data Centers?

Data centers rely heavily on DC UPS systems to protect servers and networking equipment from power disruptions. These systems safeguard against data loss and hardware damage, ensuring that services remain reliable. Key sourcing considerations include scalability to accommodate growth, energy efficiency to reduce operational costs, and integration capabilities with existing infrastructure.

How Do DC UPS Systems Enhance Transportation and Logistics?

In the transportation and logistics industry, DC UPS solutions provide power to automated systems within warehouses. This continuity is vital for inventory management, as it minimizes errors and maximizes efficiency. Buyers should assess load capacity, backup duration, and environmental factors to ensure that the UPS can handle the specific demands of their operations.

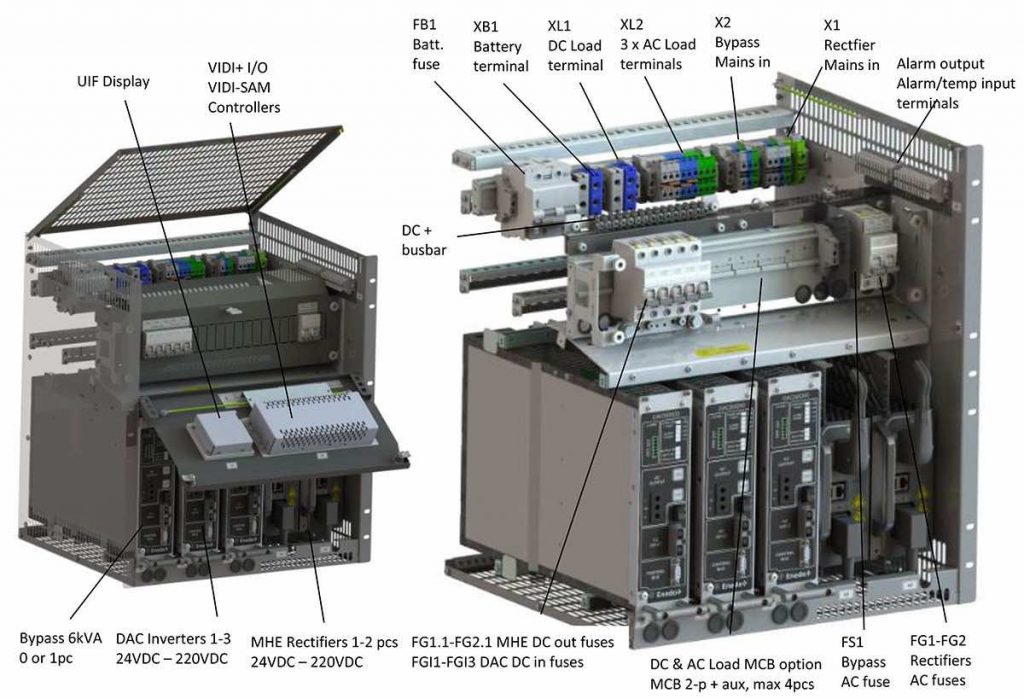

Illustrative image related to dc ups

What Is the Importance of DC UPS in Healthcare Settings?

In healthcare, DC UPS systems are crucial for powering critical medical equipment. They prevent data loss and ensure the functionality of essential devices during power outages, which is vital for patient care. When sourcing these systems, compliance with health regulations, backup duration, and reliability under load are primary considerations, particularly in regions where power stability is uncertain.

3 Common User Pain Points for ‘dc ups’ & Their Solutions

Scenario 1: Ensuring Continuous Operations During Power Outages

The Problem: In regions with unreliable power supply, such as parts of Africa and South America, businesses face significant risks from power outages. These interruptions can halt production lines, lead to data loss, and damage sensitive equipment. For B2B buyers in manufacturing or data centers, the challenge becomes not just about maintaining power but ensuring that critical systems remain operational during these outages. The fear of losing productivity and revenue is a constant concern, leading to heightened anxiety about power stability.

The Solution: To address this challenge, businesses should invest in a robust DC UPS solution tailored to their specific operational needs. When selecting a DC UPS, buyers should consider systems with integrated electrochemical double-layer capacitors that can provide immediate power during outages, ensuring seamless operation for critical processes. Additionally, opting for models featuring the 1-Battery-Concept allows for independent charging and monitoring of batteries, thus prolonging battery life and reliability. Conducting a thorough analysis of the system’s power requirements—such as voltage, current, and necessary backup duration—will help ensure that the selected UPS can handle the specific demands of the business. Engaging with a supplier that offers ongoing support and maintenance services can further enhance operational reliability.

Scenario 2: Managing Battery Life and Maintenance Efficiently

The Problem: One of the most significant pain points for B2B buyers of DC UPS systems is the ongoing maintenance and management of battery life. Traditional UPS systems often require matched batteries for optimal performance, which complicates replacements and can lead to unexpected downtime. Buyers are often frustrated by the lack of clarity on when batteries need replacement or how to monitor their health effectively, leading to potential system failures.

The Solution: To alleviate these concerns, businesses should look for DC UPS systems that incorporate advanced battery management features, such as those provided by the PULS 1-Battery-Concept. This system allows for independent charging and monitoring of batteries, mitigating the issues associated with matched battery requirements. Buyers should prioritize systems that provide clear indicators for battery health, including alerts for replacements, which can significantly reduce the risk of unexpected failures. Regular training for staff on how to monitor and manage battery health is also essential, ensuring that they can proactively address any maintenance needs. By establishing a routine check-up schedule and utilizing battery management software, businesses can optimize the lifespan of their UPS batteries and enhance overall system reliability.

Scenario 3: Adapting UPS Solutions to Diverse Operational Needs

The Problem: Many B2B buyers encounter difficulties when trying to adapt UPS solutions to various operational environments, particularly in industries with diverse equipment requirements. For instance, a company may need to power not only critical servers but also less sensitive equipment, complicating the selection process. This challenge is exacerbated in multi-national operations where voltage and frequency standards may vary.

The Solution: To effectively address this issue, businesses should take a holistic approach when evaluating their DC UPS needs. They should start by conducting a detailed assessment of all equipment that requires backup power, categorizing them based on their sensitivity and power requirements. A versatile DC UPS system that offers adjustable output voltage and current can cater to various applications, from critical server operations to less sensitive equipment. Buyers should also consider systems that allow for load sharing, enabling efficient power distribution across multiple devices. Consulting with a supplier that understands the specific regional power challenges and can provide tailored solutions will be invaluable. By implementing modular UPS systems, businesses can scale their power supply based on fluctuating demands, ensuring resilience and adaptability in their operations.

Strategic Material Selection Guide for dc ups

What Are the Key Materials Used in DC UPS Manufacturing?

When selecting materials for DC uninterruptible power supplies (UPS), several factors come into play, including performance, durability, cost, and compliance with international standards. Below, we analyze four common materials used in the construction of DC UPS systems.

Illustrative image related to dc ups

How Do Different Metals Impact the Performance of DC UPS?

1. Aluminum

Aluminum is frequently used in the housing and structural components of DC UPS systems due to its lightweight and corrosion-resistant properties.

- Key Properties: Excellent thermal conductivity, low density, and good resistance to corrosion.

- Pros: Lightweight, which aids in reducing overall system weight; excellent thermal management; cost-effective compared to other metals.

- Cons: Lower strength compared to steel; may require additional coatings for enhanced corrosion resistance in harsh environments.

- Impact on Application: Suitable for applications requiring lightweight solutions, particularly in mobile or compact setups.

- Considerations for International Buyers: Aluminum components should comply with ASTM standards for structural integrity, especially in regions with varying environmental conditions.

2. Steel

Steel is often used for its strength and durability, making it suitable for the chassis and support structures of DC UPS systems.

- Key Properties: High tensile strength, good impact resistance, and excellent durability.

- Pros: Very strong and durable; can withstand high-pressure environments; relatively low cost.

- Cons: Heavier than aluminum; susceptible to corrosion unless treated or coated.

- Impact on Application: Ideal for stationary installations where weight is less of a concern but strength is critical.

- Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material strength and corrosion resistance, particularly in humid or coastal regions.

3. Polycarbonate

Polycarbonate is commonly used for protective covers and enclosures in DC UPS systems due to its excellent impact resistance.

- Key Properties: High impact resistance, good thermal stability, and transparency.

- Pros: Lightweight and shatter-resistant; allows for visibility of internal components; good electrical insulation properties.

- Cons: Can be more expensive than traditional plastics; may yellow over time when exposed to UV light.

- Impact on Application: Suitable for environments where visibility of internal components is beneficial, such as in monitoring applications.

- Considerations for International Buyers: Ensure that polycarbonate materials meet relevant safety standards (e.g., UL) to avoid issues in markets with stringent regulations.

4. Copper

Copper is primarily used in the wiring and circuitry of DC UPS systems due to its excellent electrical conductivity.

- Key Properties: High electrical conductivity, good thermal conductivity, and corrosion resistance.

- Pros: Superior performance in electrical applications; reliable and efficient for power transmission.

- Cons: Higher cost compared to aluminum; heavier, which may affect overall system weight.

- Impact on Application: Essential for applications requiring high efficiency and reliability in power transfer.

- Considerations for International Buyers: Compliance with international electrical standards (e.g., IEC) is crucial, especially in regions with strict electrical safety regulations.

Summary Table of Material Selection for DC UPS

| Material | Typical Use Case for dc ups | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Housing and structural components | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Steel | Chassis and support structures | High strength and durability | Heavier and corrosion-prone | Low |

| Polycarbonate | Protective covers and enclosures | Shatter-resistant and lightweight | Expensive and UV degradation potential | High |

| Copper | Wiring and circuitry | Excellent electrical conductivity | Higher cost and weight | High |

This strategic material selection guide provides essential insights for B2B buyers looking to optimize their DC UPS systems. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to dc ups

In-depth Look: Manufacturing Processes and Quality Assurance for dc ups

The manufacturing process and quality assurance protocols for DC uninterruptible power supplies (UPS) are critical components that directly impact product reliability and performance. For B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, understanding these processes can enhance their purchasing decisions and supplier evaluations.

What Are the Main Stages of Manufacturing DC UPS?

The manufacturing of DC UPS typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets high-quality standards.

How is Material Prepared for DC UPS Manufacturing?

Material preparation involves sourcing and selecting high-quality components such as capacitors, batteries, circuit boards, and enclosures. Manufacturers often rely on standardized suppliers to ensure component reliability. The materials undergo rigorous inspections to verify their compliance with specifications. This stage may include:

- Supplier Qualification: Ensuring that suppliers meet quality standards and have certifications like ISO 9001.

- Incoming Quality Control (IQC): Conducting inspections on materials upon arrival to detect any defects or non-conformities.

What Forming Techniques Are Used in DC UPS Production?

Forming is the next step, where raw materials are shaped into functional components. Common techniques include:

- Injection Molding: Used for plastic enclosures and components, ensuring precision and durability.

- Sheet Metal Fabrication: For metal parts, this process may involve cutting, bending, and assembling sheet metal to create robust structures.

- PCB Manufacturing: Printed circuit boards are fabricated using photolithography, etching, and soldering techniques to create the electronic backbone of the UPS.

These techniques are chosen based on the specific design requirements and expected operational environments of the UPS units.

How Is Assembly Conducted for DC UPS Systems?

Assembly is where all the manufactured components come together to form the final product. This stage typically includes:

- Component Integration: Attaching capacitors, batteries, and circuit boards to the main chassis.

- Wiring and Connectivity: Ensuring all electrical connections are secure and meet safety standards.

- Functional Testing: Early-stage testing to confirm that basic functionalities are operational before proceeding to final assembly.

Automated assembly lines are often utilized to enhance efficiency and precision, though manual assembly is still common for more complex or customized units.

What Finishing Processes Are Involved in DC UPS Production?

Finishing processes aim to enhance the durability and appearance of the DC UPS. These may include:

- Coating and Painting: To protect against corrosion and improve aesthetics.

- Quality Inspections: Conducting thorough checks for defects, including visual inspections and functional tests to ensure compliance with specifications.

What Quality Assurance Standards Are Relevant for DC UPS Manufacturing?

Quality assurance is paramount in the manufacturing of DC UPS systems. B2B buyers should be aware of both international standards and industry-specific certifications that govern these processes.

Illustrative image related to dc ups

Which International Standards Should Buyers Be Aware Of?

- ISO 9001: This international standard focuses on quality management systems and is essential for manufacturers to demonstrate their commitment to quality and continuous improvement.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

What Industry-Specific Certifications Are Important?

Depending on the application, additional certifications may be relevant, such as:

- UL Certification: Particularly for products used in North America, ensuring compliance with safety standards.

- IEC Standards: International Electrotechnical Commission standards apply to electrical equipment, ensuring reliability and safety.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure adherence to specifications.

What Are the Key QC Checkpoints?

- Incoming Quality Control (IQC): As mentioned, this is performed on incoming materials to confirm compliance with specifications.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this involves regular inspections and testing of components and assemblies.

- Final Quality Control (FQC): This is the last line of defense before products are shipped, involving comprehensive testing of the final product to ensure it meets all operational requirements.

What Common Testing Methods Are Used for DC UPS?

Testing methods for DC UPS systems typically include:

- Functional Testing: Ensuring all features operate correctly under normal and extreme conditions.

- Load Testing: Verifying that the UPS can handle the specified load without failure.

- Environmental Testing: Assessing performance under varying temperatures and humidity levels to ensure reliability in diverse conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets, ensuring supplier quality is vital. Here are several strategies:

What Methods Can Buyers Use to Assess Supplier QC?

- Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing processes and quality control measures.

- Requesting Quality Reports: Buyers should request documentation of quality control processes, including inspection results and compliance certifications.

- Third-Party Inspections: Engaging independent inspectors can provide unbiased assessments of a supplier’s quality practices and product reliability.

What QC and Certification Nuances Should International Buyers Consider?

International buyers must navigate varying standards and practices across regions. For instance:

- Understanding Regional Standards: Different countries may have unique regulatory requirements; thus, familiarity with local standards is essential for compliance.

- Language Barriers: Documentation and communication may present challenges; buyers should ensure clear understanding and translation of quality certifications.

- Cultural Differences: The approach to quality assurance can vary by region, so establishing strong communication channels with suppliers is crucial for clarity and consistency.

In conclusion, the manufacturing processes and quality assurance protocols for DC UPS systems are intricate and vital for ensuring product reliability. B2B buyers, especially those in developing markets, should prioritize understanding these processes to make informed purchasing decisions and establish strong supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc ups’

Introduction

In today’s fast-paced business environment, ensuring uninterrupted power supply is critical for operational continuity. This guide provides a step-by-step checklist for B2B buyers looking to procure DC uninterruptible power supplies (UPS). By following these actionable steps, you can make informed decisions, minimize risks, and enhance the reliability of your power systems.

Illustrative image related to dc ups

Step 1: Define Your Technical Specifications

Begin by clearly outlining your technical requirements. This includes determining the necessary output voltage, current capacity, and backup time needed for your specific applications. Understanding these specifications will help you choose a UPS that effectively meets your operational demands and prevents costly downtime.

- Voltage and Current: Identify the voltage levels (commonly 24V DC) and the current (measured in Amperes) that your systems require.

- Backup Duration: Assess how long you need the UPS to maintain power during an outage, which could range from seconds to several hours.

Step 2: Research Different UPS Types

Explore the various types of DC UPS systems available. There are models with capacitor storage and those with external batteries. Each type has unique features suitable for different applications, such as buffering time and capacity.

- Capacitor Storage: Ideal for short-term outages, providing immediate power for seconds to complete critical processes.

- Battery-Based Systems: Suitable for longer outages, capable of maintaining power for hours or even days, depending on battery size.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Look for established companies with a strong reputation in the industry. Request detailed company profiles, case studies, and references from other businesses that have utilized their products.

- Supplier Reputation: Check online reviews and testimonials to gauge customer satisfaction.

- Experience: Ensure the supplier has experience in your industry and understands the specific challenges you face.

Step 4: Verify Certifications and Compliance

Ensure that the DC UPS you are considering complies with international standards and certifications. This is crucial for ensuring safety, reliability, and performance in your operations.

- Safety Standards: Look for certifications like CE, UL, or ISO that indicate compliance with safety regulations.

- Quality Assurance: Confirm that the supplier follows rigorous quality control processes during manufacturing.

Step 5: Assess Battery Management Features

If opting for a battery-powered UPS, evaluate the battery management system. Advanced battery management features can significantly extend battery life and enhance reliability.

Illustrative image related to dc ups

- Charging and Monitoring: Choose systems that offer individual battery monitoring and charging capabilities to prevent mismatching and ensure optimal performance.

- Deep Discharge Protection: Look for features that protect batteries from deep discharge, which can lead to premature failure.

Step 6: Request Detailed Quotes and Compare

Gather quotes from multiple suppliers and compare them based on price, features, and after-sales support. This will provide insight into the market rates and help you identify the best value for your investment.

- Total Cost of Ownership: Consider not just the initial purchase price but also installation, maintenance, and potential operational savings.

- Warranty and Support: Check the warranty terms and the level of technical support offered by each supplier.

Step 7: Finalize Your Purchase and Plan for Installation

Once you have selected a supplier, finalize your purchase and plan for the installation of the DC UPS. Proper installation is critical to ensure optimal performance and reliability.

- Installation Guidelines: Follow the manufacturer’s guidelines for installation to avoid operational issues.

- Training: Consider training your staff on the UPS operation and maintenance to maximize uptime and efficiency.

By following this checklist, B2B buyers can confidently navigate the procurement process for DC UPS systems, ensuring they choose the right solution to meet their power reliability needs.

Comprehensive Cost and Pricing Analysis for dc ups Sourcing

What Are the Key Cost Components in DC UPS Manufacturing?

When sourcing DC uninterruptible power supplies (UPS), understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to dc ups

-

Materials: The cost of raw materials, such as capacitors, batteries (VRLA or lithium-ion), and electronic components, significantly influences the overall price. High-quality materials can ensure reliability and longevity but may come at a premium.

-

Labor: Labor costs can vary based on the region and the level of expertise required. Skilled labor for assembly and quality control will typically incur higher costs, particularly in developed markets.

-

Manufacturing Overhead: This encompasses utilities, facility costs, and other indirect expenses associated with production. Companies with efficient operations often achieve better pricing.

-

Tooling: The initial setup costs for manufacturing machinery and molds can be substantial, especially for custom designs. These costs are typically amortized over large production runs.

-

Quality Control (QC): Implementing stringent QC processes adds to costs but is essential for ensuring product reliability, especially in critical applications where DC UPS systems are deployed.

-

Logistics: Transportation and warehousing costs are significant, particularly for international shipments. The choice of shipping methods and routes can influence delivery times and costs.

-

Margin: Suppliers will add a profit margin to cover their operational costs and risks. This margin can vary widely among manufacturers based on their market positioning and brand reputation.

How Do Price Influencers Affect DC UPS Sourcing?

Several factors can influence the pricing of DC UPS systems:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs with suppliers to optimize their purchasing strategy.

-

Specifications and Customization: Customized solutions that meet specific application requirements can incur higher costs. It’s crucial to balance the need for customization with budget constraints.

-

Material Quality and Certifications: High-quality materials and compliance with international standards can increase costs but may enhance product reliability and reduce total cost of ownership.

-

Supplier Factors: The reputation, reliability, and service level of suppliers can impact pricing. Established suppliers may charge more due to their proven track record and customer support.

-

Incoterms: Understanding shipping terms is vital for managing costs. Incoterms define the responsibilities of buyers and sellers in international shipping, affecting the final cost.

What Are Effective Buyer Tips for Negotiating DC UPS Prices?

To secure favorable pricing and terms when sourcing DC UPS systems, consider the following strategies:

-

Leverage Total Cost of Ownership (TCO): Analyze the long-term costs associated with the UPS, including maintenance, energy efficiency, and potential downtime costs. A higher upfront investment in quality can yield lower TCO.

-

Negotiate Terms Based on Volume: Engage suppliers in discussions about pricing based on projected order volumes. Suppliers may offer discounts or flexible payment terms for larger commitments.

-

Request Detailed Quotations: Ensure that suppliers provide itemized quotes that break down the costs. This transparency can facilitate better negotiations and help identify areas for potential savings.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Comparing offerings from various suppliers can reveal significant price differences and provide leverage in negotiations.

-

Stay Informed About Market Trends: Being aware of the latest developments in DC UPS technology and pricing trends can enhance negotiation power. This knowledge can help buyers understand what constitutes a fair price.

Are There Pricing Nuances for International Buyers in Regions Like Africa and South America?

International buyers, particularly from regions like Africa and South America, must navigate specific pricing nuances:

-

Import Duties and Taxes: Understand the applicable tariffs and taxes in your country, as these can significantly affect the landed cost of the UPS systems.

-

Currency Fluctuations: Be aware of currency exchange rates, which can impact pricing, especially in long-term contracts.

-

Local Regulations: Compliance with local standards may necessitate additional certifications or modifications, influencing overall costs.

-

Supplier Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms, as they may prioritize loyal customers for discounts or favorable payment terms.

Conclusion

In summary, sourcing DC UPS systems involves a complex interplay of cost components, pricing influencers, and negotiation strategies. By understanding these elements, international B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember to consider the total cost of ownership and the specific nuances of your market to achieve the best value.

Alternatives Analysis: Comparing dc ups With Other Solutions

Understanding Alternative Solutions to DC UPS

In the realm of uninterruptible power supply systems, DC UPS solutions are widely recognized for their efficiency and reliability. However, various alternative technologies exist that can also provide backup power and system stability. This analysis will explore how DC UPS systems compare with other viable options, enabling B2B buyers to make informed decisions based on their unique operational requirements.

| Comparison Aspect | DC UPS | Capacitor-Based Systems | Generator Solutions |

|---|---|---|---|

| Performance | Provides continuous power for seconds to hours, depending on the battery size. | Offers instantaneous power but typically only for short durations (seconds). | Can provide power for extended periods, depending on fuel supply. |

| Cost | Moderate initial investment with ongoing battery maintenance costs. | Lower upfront costs; however, limited to short-term applications. | Higher initial investment and ongoing fuel and maintenance costs. |

| Ease of Implementation | Generally easy to integrate into existing DC systems. | Simple installation but may require specialized knowledge for larger systems. | Installation can be complex, often needing site preparation and permits. |

| Maintenance | Requires regular battery checks and replacements based on usage. | Minimal maintenance; capacitors have long lifespans. | Regular maintenance and fuel supply management are necessary. |

| Best Use Case | Ideal for critical systems needing reliability and longer backup times. | Best for applications requiring short bursts of power for immediate load stabilization. | Suitable for large-scale operations needing long-term power continuity, especially in remote areas. |

In-Depth Examination of Alternatives

Capacitor-Based Systems

Capacitor-based solutions, such as those using electrochemical double-layer capacitors, offer quick response times and can handle immediate power needs effectively. They are particularly beneficial in applications where short power interruptions occur frequently, as they provide instantaneous backup. However, their limited energy storage capacity means they are not suitable for long-term outages, making them less versatile than DC UPS systems for critical applications.

Generator Solutions

Generators are a traditional alternative to UPS systems, providing backup power over extended periods. They are particularly advantageous in locations with unreliable grid power, offering a robust solution for industries like manufacturing or agriculture. However, they come with higher upfront costs and ongoing fuel expenses, along with the complexity of installation and maintenance. Additionally, generators may not offer the immediate response needed for sensitive electronic equipment, potentially leading to data loss or equipment damage.

Making the Right Choice for Your Business

When evaluating the best power backup solution for your organization, consider the specific needs of your operations. If your business relies on critical systems that require consistent and reliable power for extended periods, a DC UPS is likely the best fit. On the other hand, if your application involves managing short power fluctuations, capacitor-based systems may suffice. For businesses operating in remote areas with frequent outages, a generator might be the most practical solution despite its higher costs.

Ultimately, understanding the performance, cost, maintenance requirements, and ideal use cases of each option will empower B2B buyers to select the most suitable solution tailored to their operational demands.

Essential Technical Properties and Trade Terminology for dc ups

What Are the Essential Technical Properties of DC UPS Systems?

In the realm of uninterruptible power supplies (UPS), especially for DC applications, understanding the technical specifications is crucial for decision-makers. Here are some essential properties that B2B buyers should consider:

1. Output Voltage and Current Ratings

Output voltage and current ratings are fundamental specifications that define the operational capacity of a DC UPS. These ratings ensure compatibility with the connected equipment and determine how much load can be supported. For instance, common outputs are 24 V and 48 V with current ratings ranging from 10 A to 40 A. Understanding these specifications helps buyers select a UPS that meets their specific power requirements without risk of overload.

2. Backup Time

Backup time indicates how long a UPS can sustain power during an outage. This duration can range from seconds to several hours, depending on the battery size and load demands. For B2B applications, knowing the required backup time is vital to prevent operational interruptions and data loss during power failures, which can lead to significant financial repercussions.

3. Battery Technology

The type of battery used in a DC UPS significantly influences its performance and maintenance needs. Common technologies include Valve Regulated Lead Acid (VRLA) batteries and supercapacitors. VRLA batteries offer longer backup times but require regular maintenance, while supercapacitors provide quick discharge and recharge cycles with less maintenance. B2B buyers must weigh the trade-offs between backup duration, maintenance, and cost when choosing battery technology.

4. Efficiency Ratings

Efficiency ratings indicate how effectively a UPS converts input power to output power. Higher efficiency ratings lead to lower energy costs and reduced heat generation, which can prolong the lifespan of the UPS and connected equipment. For businesses focused on sustainability and operational costs, selecting a UPS with high efficiency is crucial.

5. Form Factor and Dimensions

The physical dimensions and mounting options of a DC UPS are essential for compatibility with existing installations. Compact designs save space, while DIN rail mounting options offer flexibility in various setups. Buyers should evaluate their installation environment to ensure the selected UPS fits seamlessly into their infrastructure.

Illustrative image related to dc ups

6. Integrated Features

Modern DC UPS systems often come with integrated features such as remote monitoring, communication interfaces (like USB or Modbus), and advanced battery management systems. These features enhance usability and enable proactive maintenance, which is especially valuable for B2B operations that rely on uptime and efficiency.

What Are Common Trade Terms in the DC UPS Industry?

Understanding trade terminology is equally important for effective communication and negotiation in the DC UPS market. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand name. In the context of DC UPS, buyers may source components from OEMs to integrate into their systems. Understanding OEM relationships can help buyers ensure product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers, as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing capabilities and storage capacities.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. In the DC UPS sector, submitting an RFQ helps buyers gather competitive offers and make informed purchasing decisions.

Illustrative image related to dc ups

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers clarify shipping costs and risks associated with international transactions.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. In the DC UPS market, shorter lead times can be critical for maintaining operational continuity. Buyers should communicate their lead time expectations to ensure timely delivery.

6. Warranty Period

The warranty period indicates the duration for which a supplier guarantees the product against defects. For DC UPS systems, understanding warranty terms is essential for assessing long-term reliability and planning for potential maintenance costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing DC UPS systems, ultimately leading to enhanced operational efficiency and reliability.

Illustrative image related to dc ups

Navigating Market Dynamics and Sourcing Trends in the dc ups Sector

What Are the Key Global Drivers Affecting the DC UPS Market?

The DC UPS (Uninterruptible Power Supply) market is experiencing significant growth, driven by the increasing reliance on uninterrupted power for critical systems across various industries. Global trends indicate a rising demand for efficient and compact power solutions, especially in regions prone to power fluctuations, such as Africa and parts of South America. The surge in digital transformation, with businesses migrating to cloud services and IoT applications, has intensified the need for reliable power backup systems. Furthermore, the growing emphasis on automation in manufacturing and logistics is propelling the adoption of DC UPS systems, which help prevent costly downtime.

Emerging technologies, including smart grid solutions and energy storage systems, are influencing sourcing trends. Buyers are increasingly looking for DC UPS systems that integrate seamlessly with these technologies, offering advanced features like remote monitoring and predictive maintenance capabilities. Additionally, the rise of renewable energy sources is prompting manufacturers to develop UPS systems that can efficiently manage variable power inputs, thereby enhancing their appeal to international B2B buyers.

How Are Sustainability and Ethical Sourcing Shaping the DC UPS Sector?

Sustainability has become a crucial consideration for businesses worldwide, and the DC UPS sector is no exception. The environmental impact of manufacturing processes and the materials used in DC UPS systems are under scrutiny. Buyers are increasingly prioritizing products that utilize recyclable materials and have a lower carbon footprint. The adoption of ‘green’ certifications, such as ISO 14001 for environmental management, is becoming a key factor in purchasing decisions.

Ethical sourcing practices are also gaining traction, with a growing emphasis on transparency throughout the supply chain. Buyers from regions such as the Middle East and Europe are more likely to choose suppliers who demonstrate a commitment to ethical labor practices and sustainable production methods. This trend is prompting manufacturers to innovate in areas such as battery technology, with a focus on developing maintenance-free, long-lasting batteries that minimize waste and reduce the need for frequent replacements.

Illustrative image related to dc ups

What Is the Evolution of DC UPS Technology and Its Importance for B2B Buyers?

The evolution of DC UPS technology has been marked by significant advancements in efficiency and reliability. Originally, these systems were bulky and limited in their functionality, often relying on lead-acid batteries that required regular maintenance. However, the introduction of advanced battery technologies, such as VRLA (Valve-Regulated Lead Acid) and electrochemical double-layer capacitors, has transformed the landscape. These innovations provide longer battery life, reduced maintenance requirements, and enhanced performance, making DC UPS systems more appealing to international B2B buyers.

Today, the focus has shifted towards integrating smart technologies into DC UPS systems. Features like remote diagnostics, real-time monitoring, and energy management capabilities are now standard, allowing businesses to optimize their power supply and reduce operational costs. For B2B buyers in emerging markets, understanding these advancements is crucial for making informed purchasing decisions that align with their operational needs and sustainability goals.

In summary, the DC UPS market is evolving rapidly, driven by technological advancements and a heightened focus on sustainability. International buyers must navigate these market dynamics to source solutions that not only meet their immediate power needs but also align with broader environmental and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of dc ups

-

1. How do I solve power supply interruptions in critical applications?

To mitigate power supply interruptions, consider investing in a DC uninterruptible power supply (DC-UPS). These systems are designed to provide continuous power during outages, ensuring that critical applications remain operational. Evaluate your specific needs, such as required output voltage and current, to select a suitable DC-UPS. Furthermore, assess the backup time necessary for your operations. By choosing a reliable DC-UPS with features like integrated battery management and monitoring, you can prevent costly downtime and protect essential equipment. -

2. What is the best DC-UPS for industrial applications?

The best DC-UPS for industrial applications typically combines high reliability with robust features. Look for systems that offer flexible battery options, such as built-in batteries or external VRLA batteries, which can provide backup for extended periods. Systems equipped with advanced battery management technology, like PULS’s 1-Battery-Concept, ensure optimal battery life and performance. Additionally, choose a DC-UPS that fits your specific voltage and current requirements, and consider those with maintenance-free options to minimize operational overhead. -

3. What should I consider when sourcing DC-UPS suppliers internationally?

When sourcing DC-UPS suppliers internationally, prioritize their reputation and track record in the industry. Check for certifications and compliance with international standards, ensuring they meet safety and quality benchmarks. Evaluate their product range to ensure they offer the specific types of DC-UPS you need. Additionally, consider their responsiveness to inquiries and customer service quality. It may also be beneficial to request references from other international buyers to gauge their reliability and service levels. -

4. How can I customize a DC-UPS for my specific needs?

Customization options for DC-UPS systems often include adjustments to output specifications, battery types, and monitoring features. When discussing your requirements with suppliers, clearly outline the operational parameters, such as voltage, current load, and desired backup time. Many manufacturers offer tailored solutions that can include specific communication interfaces or integration with existing systems. Don’t hesitate to ask for prototypes or samples to evaluate how well the customized DC-UPS meets your operational needs. -

5. What are the minimum order quantities (MOQs) for DC-UPS systems?

Minimum order quantities (MOQs) for DC-UPS systems can vary significantly by supplier and product type. Some manufacturers may have low MOQs for standard models, while custom solutions might require higher quantities. Always inquire about MOQs during the sourcing process, as this will affect your purchasing strategy and inventory management. Understanding the supplier’s production capabilities can also help negotiate better terms or explore bulk order discounts. -

6. What payment terms are commonly accepted for international DC-UPS purchases?

Common payment terms for international DC-UPS purchases include letters of credit, wire transfers, and sometimes payment upon delivery. The choice of payment method can depend on the supplier’s policies and the buyer’s relationship with them. It’s advisable to clarify payment terms upfront to avoid misunderstandings. Additionally, consider utilizing escrow services for larger transactions to protect both parties until the goods are received and inspected. -

7. How do I ensure quality assurance (QA) for DC-UPS systems?

To ensure quality assurance for DC-UPS systems, request detailed documentation of the supplier’s QA processes, including testing protocols and certifications. Look for suppliers who adhere to international quality standards, such as ISO certifications. It’s also beneficial to conduct factory audits or third-party inspections, especially for large orders. Consider establishing a quality agreement that outlines specific performance criteria and warranty terms to safeguard your investment. -

8. What logistics considerations should I keep in mind when importing DC-UPS?

When importing DC-UPS, logistics considerations include shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder experienced in handling electronic equipment to minimize risks during transit. Ensure compliance with local customs regulations to avoid delays or additional costs. Additionally, plan for potential tariffs or import duties that may apply. It’s prudent to maintain open communication with the supplier regarding shipping schedules and tracking to ensure timely delivery.

Top 5 Dc Ups Manufacturers & Suppliers List

1. PULS – Efficient DC-UPS Solutions

Domain: products.pulspower.com

Registered: 2000 (25 years)

Introduction: This company, PULS – Efficient DC-UPS Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mini-Box – DCDC-USB Micro-UPS

Domain: mini-box.com

Registered: 2002 (23 years)

Introduction: micro-UPS, Load Sharing

1. DCDC-USB

– Intelligent buck-boost DC-DC converter with USB interface

– Power: 100 watts

– Input: 6-34V

– Programmable output: 5-24V (default 12V)

– High current: up to 10A

– Applications: power for motherboards, laptops, custom electronics

– Programmable via USB interface

– Modes: DUMB, Automotive, Script, UPS

– 100% Solid Polymer Capacitors

…

3. DC Power Solutions – 24V UPS System for Small Devices

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DC UPS system for small devices, including components like a 24VDC PSU, 24VDC UPS, 24VDC to 12VDC converter, and 24VDC to 5VDC converter. Suggested use of a large 24V sealed lead acid battery with barrel plugs for 12V/5V outputs to power networking gear such as routers, WiFi APs, and home automation hubs.

4. SourceASI – Power Supply & Battery Charger

Domain: sourceasi.com

Registered: 2021 (4 years)

Introduction: This company, SourceASI – Power Supply & Battery Charger, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. CyberPower – Indoor DC UPS 12V

Domain: cyberpower.com

Registered: 1999 (26 years)

Introduction: Indoor DC UPS with 12V, designed to provide reliable power backup for critical devices. Features include a compact design, easy installation, and compatibility with various devices. It offers protection against power surges and outages, ensuring uninterrupted operation. Ideal for use in home and office environments.

Strategic Sourcing Conclusion and Outlook for dc ups

As businesses increasingly rely on uninterrupted power supplies, the strategic sourcing of DC UPS systems becomes paramount. By prioritizing quality and efficiency in their backup power solutions, organizations can mitigate risks associated with power outages, ensuring seamless operations and protecting valuable data. Key considerations include understanding specific power requirements, evaluating the type of backup needed—whether capacitor-based or battery-operated—and leveraging advanced battery management systems like the 1-Battery-Concept for optimized performance and longevity.

Illustrative image related to dc ups

International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, must navigate diverse market conditions and technological advancements. Engaging with reputable suppliers and investing in reliable DC UPS systems can yield significant long-term benefits, including reduced downtime and enhanced productivity.

Looking ahead, the demand for robust power solutions will only grow as industries evolve. Companies are encouraged to assess their current power backup strategies and explore innovative DC UPS options that align with their operational needs. This proactive approach not only secures business continuity but also positions organizations for future growth in an increasingly power-dependent landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.