Dc Motor Wiring Diagram: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for dc motor wiring diagram

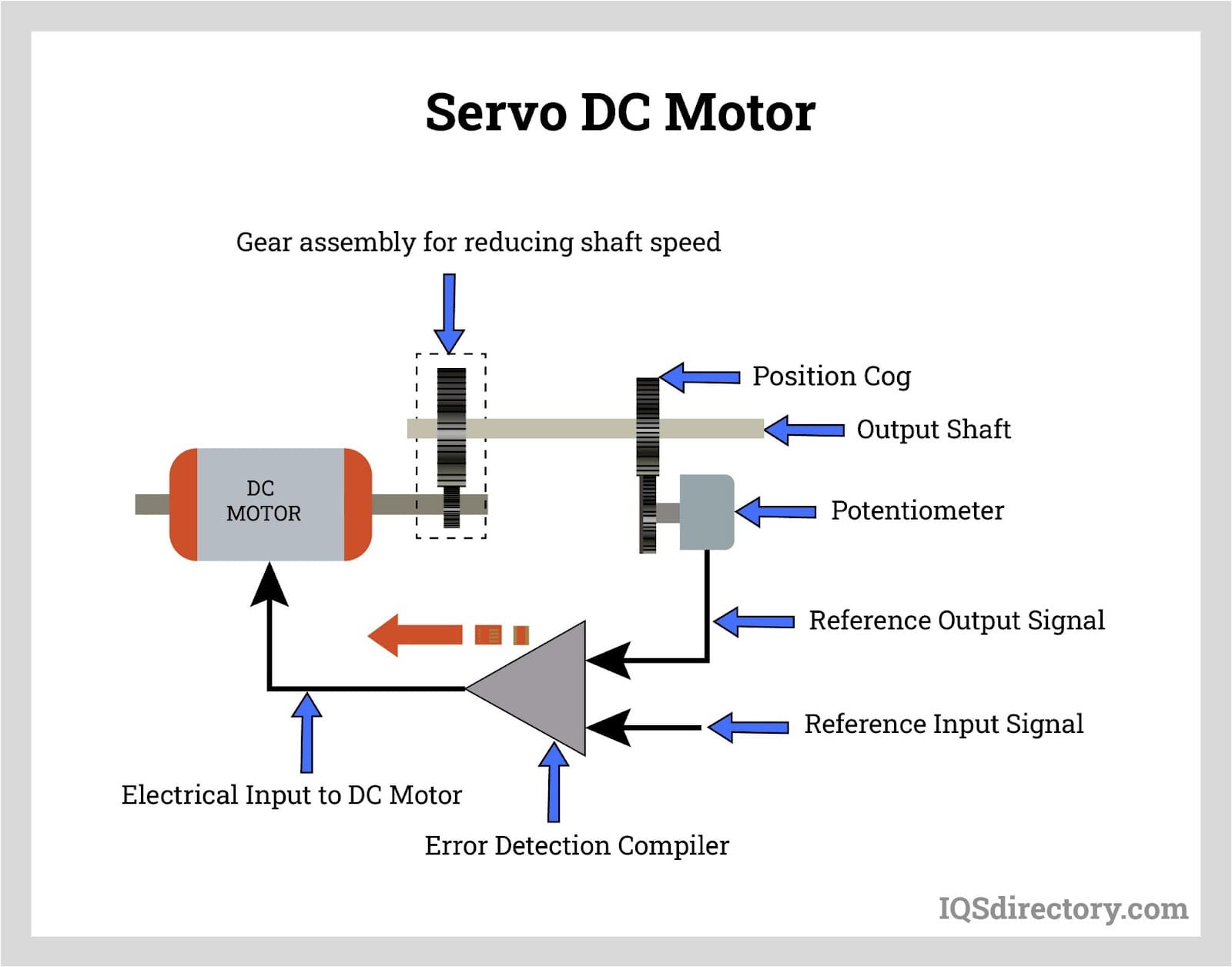

In the fast-evolving landscape of industrial applications, sourcing an accurate and reliable DC motor wiring diagram can present a significant challenge for international B2B buyers. Understanding the intricate connections and configurations of various DC motor types—including shunt, series, and compound motors—is crucial for ensuring optimal performance in applications ranging from robotics to automotive systems. This guide aims to demystify the complexities of DC motor wiring diagrams by providing comprehensive insights into different motor types, their applications, and best practices for installation and maintenance.

Throughout this resource, readers will gain valuable knowledge on how to effectively vet suppliers, assess costs, and navigate the global market for DC motors. With a focus on the needs of businesses in Africa, South America, the Middle East, and Europe—particularly in countries like Brazil and Germany—this guide empowers decision-makers to make informed purchasing choices. By equipping B2B buyers with the expertise needed to understand and utilize wiring diagrams, we facilitate improved operational efficiency and reduced downtime, ultimately driving greater success in their projects.

Understanding dc motor wiring diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Externally-Excited DC Motor | Field is independent of the armature; less common. | Specialized industrial applications | Pros: Flexible control; Cons: Complexity and cost. |

| Shunt DC Motor | Field winding in parallel with armature; stable speed. | Conveyor systems, fans, pumps | Pros: Good speed regulation; Cons: Lower starting torque. |

| Series DC Motor | Field winding in series with armature; high starting torque. | Electric traction systems, cranes | Pros: High torque at startup; Cons: Poor speed regulation. |

| Compound DC Motor | Combines shunt and series; can be cumulatively or differentially compounded. | Heavy machinery, robotics | Pros: Versatile performance; Cons: More complex wiring. |

| Brushless DC Motor | Uses electronic commutation; no brushes; high efficiency. | Electric vehicles, drones, HVAC systems | Pros: Low maintenance; Cons: Higher initial cost. |

What Are the Characteristics of Externally-Excited DC Motors?

Externally-excited DC motors feature a field winding that is not connected to the armature, allowing for independent control of the magnetic field. This design is less common but is utilized in specialized industrial applications where precise control is paramount. Buyers should consider the complexity and potential costs associated with these motors, as they often require advanced control systems.

Why Choose a Shunt DC Motor for Your Application?

Shunt DC motors are characterized by their field windings that are connected in parallel with the armature. This configuration provides stable speed under varying load conditions, making them ideal for applications such as conveyor systems and pumps. However, while they offer good speed regulation, buyers should note that their starting torque is generally lower compared to series motors.

How Do Series DC Motors Excel in Heavy-Duty Applications?

Series DC motors have their field windings connected in series with the armature, resulting in high starting torque. This makes them particularly suitable for electric traction systems and heavy machinery like cranes. However, buyers should be aware that series motors can struggle with speed regulation, which may limit their use in applications requiring precise speed control.

What Makes Compound DC Motors Versatile?

Compound DC motors integrate both shunt and series field windings, allowing for a balance between high starting torque and speed stability. This versatility makes them suitable for applications in heavy machinery and robotics. However, the complexity of their wiring can be a consideration for buyers, as it may lead to increased installation and maintenance costs.

Why Are Brushless DC Motors Gaining Popularity?

Brushless DC motors utilize electronic commutation instead of mechanical brushes, resulting in higher efficiency and lower maintenance needs. These motors are increasingly used in electric vehicles, drones, and HVAC systems due to their reliability and performance. However, buyers should consider the higher initial costs associated with brushless technology, which may be offset by lower long-term maintenance expenses.

Key Industrial Applications of dc motor wiring diagram

| Industry/Sector | Specific Application of dc motor wiring diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation systems for assembly lines | Increased efficiency and reduced labor costs | Quality and reliability of components; local regulations |

| Agriculture | Irrigation control systems | Enhanced crop yield through precise control | Compatibility with existing systems; voltage specifications |

| Automotive | Electric vehicle (EV) drive systems | Sustainable transport solutions | Battery compatibility; motor efficiency ratings |

| Robotics | Motion control in robotic arms | Improved precision and repeatability | Customization options; technical support availability |

| Renewable Energy | Wind turbine pitch control systems | Optimized energy production | Environmental impact; sourcing of sustainable materials |

How is the ‘dc motor wiring diagram’ utilized in manufacturing automation systems?

In the manufacturing sector, dc motor wiring diagrams are crucial for designing and implementing automation systems, particularly on assembly lines. These diagrams provide clear instructions on connecting the motor’s armature and field circuits, ensuring that the motor operates efficiently and reliably. By using these diagrams, businesses can troubleshoot issues quickly, reducing downtime and improving overall productivity. Key considerations include sourcing high-quality components that comply with local manufacturing standards, especially in regions like Africa and South America, where local regulations may vary.

What role does the ‘dc motor wiring diagram’ play in agricultural applications?

In agriculture, dc motor wiring diagrams are employed in irrigation control systems, allowing for automated water management. These diagrams help farmers to wire motors that control pumps, ensuring that water is delivered precisely when and where it is needed. This automation leads to enhanced crop yields and resource efficiency. Buyers in this sector should prioritize compatibility with existing irrigation systems and specific voltage requirements to ensure seamless integration, particularly in diverse markets across the Middle East and Europe.

How is the ‘dc motor wiring diagram’ relevant to the automotive industry?

In the automotive industry, particularly with the rise of electric vehicles (EVs), dc motor wiring diagrams are essential for the design of drive systems. These diagrams aid in the configuration of motors that provide propulsion and regenerative braking. The benefit lies in creating sustainable transport solutions that meet increasing environmental regulations. International buyers must consider battery compatibility and motor efficiency ratings to ensure optimal performance, especially in competitive markets like Germany and Brazil.

What is the significance of ‘dc motor wiring diagrams’ in robotics?

Robotics heavily relies on dc motor wiring diagrams for motion control in robotic arms and other automated systems. These diagrams guide the connection of motors that enable precise movement and positioning, which is critical for tasks requiring high accuracy. The value here is in improved precision and repeatability, which can significantly enhance production quality. Buyers should look for customization options to meet specific application needs and ensure robust technical support is available during the implementation phase.

How do ‘dc motor wiring diagrams’ support renewable energy initiatives?

In renewable energy, particularly in wind turbine technology, dc motor wiring diagrams are vital for pitch control systems that adjust the blade angle to optimize energy production. These diagrams help engineers to wire the motors that control the pitch, ensuring maximum efficiency. The value to businesses lies in increased energy output and sustainability. When sourcing components, organizations should consider the environmental impact of materials used and the feasibility of sourcing sustainable components to align with global green initiatives.

3 Common User Pain Points for ‘dc motor wiring diagram’ & Their Solutions

Scenario 1: Wiring Complexity Leading to Operational Delays

The Problem: Many B2B buyers encounter significant challenges when interpreting complex DC motor wiring diagrams, which can lead to operational delays. For instance, manufacturers in regions like Africa or South America often work with diverse motor types—such as shunt, series, and compound motors—each with unique wiring requirements. Misinterpretation of these diagrams can result in incorrect installations, leading to equipment malfunction or even damage. This complexity can be further exacerbated by language barriers or the availability of clear, localized instructional materials.

The Solution: To navigate these challenges, businesses should invest in high-quality, standardized wiring diagrams that clearly delineate the connections for various DC motor types. Suppliers should provide diagrams with both visual representations and step-by-step instructions, accompanied by multilingual support to cater to diverse teams. Additionally, utilizing digital platforms that allow for interactive diagrams can enhance understanding. Training sessions or webinars focusing on common wiring configurations can also empower teams to troubleshoot and correctly implement wiring, reducing downtime and improving operational efficiency.

Scenario 2: Inconsistent Quality of Wiring Diagrams

The Problem: Buyers often find that the quality and clarity of DC motor wiring diagrams vary significantly across manufacturers. Inconsistent diagrams can lead to confusion, miswiring, and, ultimately, expensive repairs or replacements. This is particularly problematic in industries such as automotive or manufacturing, where precision is critical. A lack of standardization means that even experienced technicians may struggle with unfamiliar diagrams, leading to costly errors.

The Solution: To combat this issue, companies should prioritize sourcing wiring diagrams from reputable manufacturers known for their commitment to quality and standardization. Establishing partnerships with suppliers that adhere to industry standards can ensure that the diagrams provided are clear, accurate, and user-friendly. Additionally, implementing a quality control process where technicians verify wiring diagrams against operational requirements before installation can minimize errors. Creating a centralized repository of reliable diagrams for different motor types can also serve as a valuable reference for teams, enhancing overall productivity and reducing risk.

Scenario 3: Challenges with Motor Reversibility

The Problem: A common pain point for B2B buyers is understanding how to implement motor reversibility in their applications effectively. Many industries, such as logistics and automated manufacturing, require motors to operate in both forward and reverse directions. However, without a proper understanding of the wiring configuration needed to achieve this—such as using relay systems to switch polarity—buyers can face significant operational hurdles, including motor stalling or failure to respond to commands.

The Solution: To address these challenges, businesses should invest in comprehensive training and resources that explain the principles of motor reversibility in depth. Wiring diagrams should explicitly illustrate how to set up the necessary relay configurations and highlight the importance of correctly managing power inputs. Implementing simulation software that allows teams to visualize and practice wiring configurations before actual implementation can also be beneficial. Moreover, collaborating with engineering experts or consultants who specialize in DC motors can provide tailored guidance, ensuring that the wiring setup is both functional and efficient. This proactive approach not only enhances operational reliability but also optimizes the overall performance of motor-driven systems.

Strategic Material Selection Guide for dc motor wiring diagram

What Are the Key Materials for DC Motor Wiring Diagrams?

When selecting materials for DC motor wiring diagrams, it is essential to consider the properties, advantages, and limitations of various materials. This analysis focuses on copper, aluminum, thermoplastic, and silicone rubber, which are commonly used in the construction and wiring of DC motors.

How Does Copper Perform in DC Motor Wiring Applications?

Copper is the most widely used material for electrical wiring due to its excellent conductivity and thermal properties. It has a high melting point (around 1,984°F or 1,085°C) and is resistant to corrosion, making it suitable for various environments.

Pros: Copper wires are durable and provide low resistance, which enhances the efficiency of DC motors. They are also easy to work with and can be manufactured into various shapes and sizes.

Cons: The primary drawback of copper is its cost, which can be higher than alternative materials like aluminum. Additionally, copper is heavier, which may be a consideration in applications where weight is a critical factor.

Impact on Application: Copper’s high conductivity makes it ideal for applications requiring rapid power transfer, such as in automotive and industrial motors.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and South America should also consider local availability and pricing fluctuations.

What Role Does Aluminum Play in DC Motor Wiring?

Aluminum is often used as a cost-effective alternative to copper. It has a lower conductivity than copper but is significantly lighter, which can be advantageous in certain applications.

Pros: Aluminum wiring is less expensive and offers good resistance to corrosion, particularly in humid environments. Its lightweight nature makes it easier to handle and install.

Cons: The main limitation is its lower electrical conductivity, which means larger gauge wires are required to achieve the same performance as copper. This can lead to increased manufacturing complexity.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as in aerospace or portable devices, but may not be ideal for high-performance industrial motors.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards and assess the impact of local market conditions on aluminum pricing.

How Do Thermoplastics Enhance DC Motor Wiring Diagrams?

Thermoplastics, such as PVC and nylon, are commonly used for insulation and protection in DC motor wiring. They offer excellent dielectric properties and are resistant to moisture and chemicals.

Pros: Thermoplastics are lightweight, flexible, and can withstand a wide temperature range. They are also cost-effective and can be easily molded into complex shapes.

Cons: While thermoplastics are durable, they may not withstand high temperatures as effectively as metals. Their mechanical strength can also degrade over time when exposed to UV light.

Impact on Application: Thermoplastics are ideal for applications requiring insulation and protection from environmental factors, making them suitable for consumer electronics and automotive applications.

Considerations for International Buyers: Compliance with material safety standards is vital, especially in regions with strict regulations. Buyers should also consider the availability of specific thermoplastics in their local markets.

What Advantages Do Silicone Rubber Materials Offer in DC Motor Wiring?

Silicone rubber is increasingly used in wiring applications due to its flexibility and resistance to extreme temperatures and environmental conditions.

Pros: Silicone rubber can withstand temperatures ranging from -76°F to 500°F (-60°C to 260°C) and provides excellent insulation properties. It is also resistant to UV light, ozone, and moisture.

Cons: The main limitation is its higher cost compared to other insulating materials. Additionally, silicone rubber can be less durable in mechanical applications where abrasion resistance is critical.

Impact on Application: Silicone rubber is particularly beneficial in applications exposed to extreme temperatures or harsh environments, making it suitable for outdoor motors and industrial applications.

Considerations for International Buyers: Buyers should ensure that silicone rubber products meet international standards and consider the implications of sourcing costs and availability in their respective regions.

Summary Table of Material Selection for DC Motor Wiring Diagrams

| Material | Typical Use Case for dc motor wiring diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance industrial motors | Excellent conductivity and durability | Higher cost and weight | High |

| Aluminum | Lightweight applications and portable devices | Cost-effective and lightweight | Lower conductivity requires larger gauge | Medium |

| Thermoplastics | Insulation in consumer electronics | Flexible, cost-effective, and durable | Limited high-temperature performance | Low |

| Silicone Rubber | Extreme temperature applications | High-temperature resistance and flexibility | Higher cost and lower mechanical durability | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in DC motor wiring diagrams, helping them make informed purchasing decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for dc motor wiring diagram

What Are the Main Stages of Manufacturing DC Motor Wiring Diagrams?

The manufacturing process for DC motor wiring diagrams involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical for ensuring that the final product meets the specified design requirements and quality standards.

-

Material Preparation: The first step is selecting the appropriate materials, such as copper wire for windings, insulation materials, and connectors. Suppliers must ensure that these materials comply with international standards, such as those set by ISO and other industry-specific certifications. Quality assurance begins with Incoming Quality Control (IQC), where materials are inspected for defects and conformity to specifications.

-

Forming: In this stage, the raw materials are shaped into the necessary components. Techniques may include winding copper wire into coils for the armature and field windings, as well as creating the necessary connectors and terminal blocks. Precision is crucial; manufacturers often use automated machines for winding to ensure consistent coil dimensions and tight tolerances.

-

Assembly: This stage involves integrating all the components into a complete motor. The assembly process for DC motors typically includes mounting the armature and field coils, connecting the brushes, and securing all components within the motor housing. Attention to detail is critical, as improper assembly can lead to performance issues or motor failure.

-

Finishing: The finishing stage includes applying protective coatings, insulation treatments, and labeling. This ensures durability and compliance with safety standards. Manufacturers may also perform visual inspections and functional tests to verify that the motor operates correctly before it moves on to the next quality control phase.

How Is Quality Control Implemented in the Manufacturing of DC Motors?

Quality control (QC) is an integral part of the manufacturing process for DC motors, particularly in the wiring diagrams. Adherence to international standards, like ISO 9001, ensures that the manufacturing process is efficient and that the final product is reliable.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001 for quality management systems. This certification requires companies to consistently provide products that meet customer and regulatory requirements, ensuring a high level of quality in their operations.

-

Industry-Specific Standards: Depending on the application, additional certifications may be necessary. For instance, CE marking is essential for products sold within the European market, while API standards may apply to motors used in the oil and gas industry. Understanding the regulatory landscape is crucial for B2B buyers in different regions.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint ensures that all incoming materials meet specified quality standards. Verification includes material certifications and testing for defects.

– In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC monitors various parameters such as winding tension and insulation resistance to ensure that all components are being produced to specification.

– Final Quality Control (FQC): At this stage, the finished product undergoes rigorous testing to ensure functionality. Tests may include electrical performance, thermal behavior, and mechanical stability. -

Common Testing Methods: Various testing methods are employed to ensure quality:

– Electrical Testing: This includes checking for insulation resistance and continuity in the wiring.

– Functional Testing: The motor is run under load conditions to verify performance characteristics, including speed, torque, and direction.

– Durability Testing: Simulations are conducted to assess how the motor will perform under extreme conditions, including temperature and humidity variations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating across international borders, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance.

-

Supplier Audits: Conducting regular audits of suppliers can provide insight into their quality management systems. These audits should assess compliance with international standards, production processes, and quality control measures.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the quality assurance processes in place. These reports should include data on defect rates, testing outcomes, and corrective actions taken for non-compliance.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality control measures. This is particularly important for buyers in regions with varying standards of quality assurance.

-

Understanding Regional QC Nuances: B2B buyers from Africa, South America, the Middle East, and Europe should be aware of regional differences in quality standards. For example, the requirements for CE certification in Europe may differ significantly from those in other markets. Familiarity with local regulations can help buyers make informed decisions when selecting suppliers.

Conclusion: Importance of Robust Manufacturing and QC Processes

In summary, the manufacturing processes and quality assurance for DC motor wiring diagrams are integral to delivering reliable and efficient products. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed purchasing decisions that align with their operational needs and regional standards. Ensuring that suppliers adhere to stringent quality measures not only mitigates risk but also enhances the overall value proposition of the products being sourced.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc motor wiring diagram’

In the world of DC motors, understanding wiring diagrams is essential for ensuring optimal performance and reliability. This guide provides a step-by-step checklist for B2B buyers aiming to procure accurate and effective DC motor wiring diagrams. By following these steps, you can streamline your sourcing process and secure the best solutions for your operational needs.

Step 1: Define Your Technical Specifications

Before initiating your search for a wiring diagram, clearly outline your technical requirements. Consider factors such as motor type (shunt, series, or compound), voltage ratings, and specific application needs. Having a detailed specification will help you communicate effectively with potential suppliers and ensure that you receive diagrams that meet your operational standards.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers known for their expertise in DC motor wiring diagrams. Look for companies with a proven track record in your industry, preferably those that cater to international markets. This step is crucial as it sets the foundation for sourcing high-quality diagrams that are both accurate and reliable.

- Check online reviews and testimonials.

- Evaluate their experience with similar projects.

Step 3: Request Sample Wiring Diagrams

Once you have shortlisted potential suppliers, request sample wiring diagrams. This will allow you to evaluate the clarity, detail, and accuracy of their diagrams. Ensure that the samples cover various motor types and configurations relevant to your needs.

- Assess the level of detail provided.

- Check for compliance with international standards.

Step 4: Verify Supplier Certifications

Before finalizing any procurement, it’s essential to verify that your chosen suppliers hold relevant certifications. Look for certifications that indicate adherence to industry standards, such as ISO or IEC. This ensures that the wiring diagrams are not only accurate but also meet safety and quality benchmarks.

- Request copies of certifications.

- Inquire about their quality assurance processes.

Step 5: Evaluate the Technical Support Provided

Technical support is a critical factor when sourcing wiring diagrams. Assess whether the supplier offers comprehensive support, including clarification on diagrams and troubleshooting assistance. A supplier that provides ongoing support can help mitigate issues and enhance operational efficiency.

- Inquire about available support channels (phone, email, chat).

- Check if they offer training or additional resources.

Step 6: Negotiate Terms and Conditions

Once you have identified a supplier that meets your criteria, discuss the terms and conditions of procurement. This includes pricing, delivery timelines, and payment terms. A clear agreement will help prevent misunderstandings and ensure a smooth transaction.

- Be clear about your budget constraints.

- Discuss potential volume discounts or long-term partnership agreements.

Step 7: Finalize Your Order and Monitor Delivery

After negotiating terms, finalize your order and ensure that you have a tracking mechanism in place for delivery. Monitoring the shipment will help you stay informed about any potential delays and allow for timely adjustments in your operations.

- Keep communication lines open with the supplier.

- Prepare for receipt and inspection of the diagrams upon arrival.

By following this checklist, B2B buyers can effectively navigate the procurement of DC motor wiring diagrams, ensuring that they receive the best products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for dc motor wiring diagram Sourcing

When sourcing DC motor wiring diagrams, understanding the comprehensive cost structure and pricing components is crucial for international B2B buyers. This analysis will help you make informed decisions and optimize procurement strategies.

What Are the Key Cost Components for DC Motor Wiring Diagrams?

-

Materials: The primary materials involved in producing DC motor wiring diagrams include high-quality copper wiring, insulation materials, and connectors. The choice of materials significantly affects the durability and efficiency of the motor, impacting both the initial cost and long-term performance.

-

Labor: Skilled labor is essential for creating accurate and reliable wiring diagrams. Labor costs may vary based on geographical location, expertise level, and the complexity of the diagrams required. In regions with high labor costs, such as Germany, this can significantly influence overall pricing.

-

Manufacturing Overhead: Overhead costs encompass utilities, facility maintenance, and administrative expenses. These costs can vary widely depending on the supplier’s operational efficiency and location. Buyers should inquire about how these overheads are calculated to understand their impact on the final price.

-

Tooling: The cost of tooling for producing wiring diagrams can vary based on the complexity and customization required. For example, specialized software or equipment may be necessary for unique designs, which can add to the initial investment.

-

Quality Control (QC): Ensuring the reliability of the wiring diagrams through rigorous QC processes is essential. This can involve testing and validation procedures that add to the overall cost but are crucial for maintaining high standards.

-

Logistics: Shipping costs, particularly for international buyers, can fluctuate based on distance, shipping method, and compliance with import/export regulations. Understanding logistics costs is vital for evaluating the total cost of ownership.

-

Margin: Suppliers typically apply a markup to cover costs and generate profit. Understanding the supplier’s margin helps buyers negotiate better deals and assess the fairness of pricing.

What Influences the Pricing of DC Motor Wiring Diagrams?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounted pricing. Buyers should consider their needs carefully, as higher volumes can reduce per-unit costs significantly.

-

Specifications and Customization: Customized wiring diagrams tailored to specific motor types or applications can incur additional costs. Buyers should be clear about their specifications to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and compliance with international standards (such as ISO certifications) can raise costs but also improve product reliability and longevity. Buyers in regions like Europe may prioritize certified products.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers with proven track records may charge higher rates but offer better service and assurance of quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total cost.

What Tips Should Buyers Consider for Cost-Efficiency?

-

Negotiate Wisely: Leverage your purchasing power and market knowledge to negotiate better terms. Discussing bulk orders, long-term partnerships, or flexible payment options can lead to favorable pricing.

-

Evaluate Total Cost of Ownership: Consider not just the initial purchase price but also the maintenance, efficiency, and lifespan of the wiring diagrams. Cheaper options may lead to higher costs in the long run.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local regulations that can affect pricing. Buyers from regions like Africa and South America should factor in these variables when budgeting.

-

Conduct Supplier Assessments: Regularly evaluate suppliers based on performance, delivery times, and product quality. This ensures that you are getting the best value for your investment.

Conclusion

In summary, a thorough understanding of the cost structure and price influencers for DC motor wiring diagrams is essential for B2B buyers. By considering all cost components and employing strategic negotiation tactics, you can optimize your sourcing strategy and enhance your overall procurement efficiency. Always remember to seek detailed quotations and clarify all terms to avoid any surprises down the line.

Alternatives Analysis: Comparing dc motor wiring diagram With Other Solutions

Exploring Alternatives to DC Motor Wiring Diagrams: A Comparative Analysis

In the realm of motor control and automation, understanding the various wiring options available can significantly impact operational efficiency and performance. While DC motor wiring diagrams are prevalent, several alternative solutions exist that can offer distinct advantages or cater to specific applications. This analysis compares DC motor wiring diagrams with brushless DC motors and AC motors, highlighting key performance indicators and use cases.

| Comparison Aspect | Dc Motor Wiring Diagram | Brushless DC Motor Wiring | AC Motor Wiring |

|---|---|---|---|

| Performance | Good torque at low speeds | High efficiency, longer lifespan | Reliable for high power applications |

| Cost | Generally lower initial cost | Higher upfront cost due to complexity | Moderate cost, depending on type |

| Ease of Implementation | Relatively straightforward | More complex, requires specialized controllers | Straightforward for basic applications |

| Maintenance | Moderate; brushes require replacement | Low; no brushes to replace | Varies; generally low maintenance |

| Best Use Case | Low to moderate power applications | Robotics, automotive, and applications needing precise control | Industrial applications requiring high power |

What Are the Advantages and Disadvantages of Brushless DC Motor Wiring?

Brushless DC motors (BLDC) utilize electronic commutation instead of mechanical brushes, offering significant advantages such as higher efficiency and reduced wear and tear. This technology enables longer lifespans and lower maintenance costs compared to traditional brushed motors. However, the initial investment for BLDC motors and their controllers is generally higher, which may deter some buyers. They are ideal for applications in robotics and automotive sectors where precision and efficiency are paramount.

How Does AC Motor Wiring Compare to DC Motor Wiring Diagrams?

AC motors are widely used in industrial settings due to their reliability and ability to handle high power loads. They are typically easier to implement for basic applications, as they often require less complex wiring than DC motors. However, the performance of AC motors can be less efficient at lower speeds compared to DC motors. Additionally, maintenance needs can vary based on the specific type of AC motor used. For applications that require robust and reliable power, AC motors are often the preferred choice.

Conclusion: How Can B2B Buyers Choose the Right Motor Solution?

When selecting between DC motor wiring diagrams and alternative motor solutions, B2B buyers should consider factors such as performance requirements, cost constraints, and maintenance capabilities. For applications demanding high efficiency and longevity, brushless DC motors may present a compelling option despite their higher initial costs. Conversely, for straightforward industrial applications, AC motors offer reliability and ease of use. Ultimately, understanding the specific needs of the application will guide buyers in making informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for dc motor wiring diagram

Understanding the essential technical properties and terminology associated with DC motor wiring diagrams is crucial for international B2B buyers, especially when sourcing components from diverse regions such as Africa, South America, the Middle East, and Europe. This knowledge not only facilitates effective communication with suppliers but also ensures that the right specifications are met for applications across various industries.

What Are the Key Technical Specifications to Consider for DC Motor Wiring Diagrams?

-

Material Grade

– Definition: Refers to the quality and type of materials used in motor components, such as copper for windings and steel for the frame.

– B2B Importance: Higher-grade materials can improve performance and longevity, which is vital for industrial applications where reliability is paramount. Buyers should ensure that materials meet industry standards relevant to their specific applications. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension, often crucial for parts that must fit precisely within a system.

– B2B Importance: Tighter tolerances are essential in high-performance applications to prevent failures. Buyers should specify tolerance levels in their RFQs (Requests for Quotation) to ensure compatibility and performance. -

Voltage Rating

– Definition: The maximum voltage that the motor can handle safely without risk of failure.

– B2B Importance: Selecting the correct voltage rating is critical for operational safety and efficiency. Buyers should confirm that the motors they procure match the voltage requirements of their systems to avoid costly damages. -

Current Rating

– Definition: The maximum current the motor can draw under normal operating conditions.

– B2B Importance: This specification is vital for ensuring that power supplies are appropriately sized. Overrating can lead to overheating, while underrating can result in insufficient power delivery. -

Insulation Class

– Definition: Indicates the thermal resistance of the insulation material used in the motor.

– B2B Importance: Higher insulation classes allow for higher operating temperatures, which can be essential in harsh environments. Buyers should consider this when sourcing motors for high-temperature applications. -

Speed Rating

– Definition: The operational speed at which the motor is designed to run, usually measured in RPM (revolutions per minute).

– B2B Importance: Understanding the speed requirements is crucial for applications that require precise control. Buyers should specify speed ratings to ensure that the motors align with their operational needs.

What Are the Common Trade Terms Related to DC Motor Wiring Diagrams?

-

OEM (Original Equipment Manufacturer)

– Explanation: Refers to companies that manufacture products that are sold under another company’s brand.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers that provide quality components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– Explanation: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers should be aware of MOQs to plan their procurement strategies effectively, especially when dealing with international suppliers. -

RFQ (Request for Quotation)

– Explanation: A document sent to suppliers requesting a price estimate for specific products or services.

– Relevance: Crafting a precise RFQ can significantly impact pricing and delivery times, making it a critical tool for B2B negotiations. -

Incoterms (International Commercial Terms)

– Explanation: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is essential for understanding shipping responsibilities, costs, and risk management in international transactions. -

Lead Time

– Explanation: The amount of time from placing an order to receiving the product.

– Relevance: Knowing the lead time can help businesses plan their production schedules and manage inventory more effectively. -

Technical Datasheet

– Explanation: A document that provides detailed information about a product’s specifications and performance.

– Relevance: Reviewing technical datasheets is crucial for making informed purchasing decisions, ensuring that the sourced components meet operational requirements.

By familiarizing themselves with these specifications and terms, B2B buyers can enhance their procurement processes, minimize risks, and ensure that their operations run smoothly and efficiently.

Navigating Market Dynamics and Sourcing Trends in the dc motor wiring diagram Sector

What Are the Current Market Dynamics and Key Trends in the DC Motor Wiring Diagram Sector?

The global demand for DC motors and their associated wiring diagrams is being driven by advancements in automation, robotics, and electric vehicles. Industries across Africa, South America, the Middle East, and Europe are increasingly incorporating DC motors due to their efficiency, reliability, and ease of control. For international B2B buyers, understanding the various types of DC motors—such as shunt, series, and compound motors—is crucial, as each has unique wiring requirements that affect performance in specific applications.

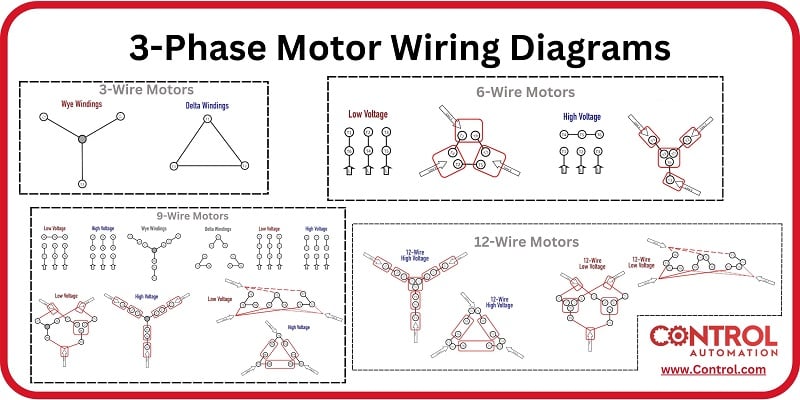

Illustrative image related to dc motor wiring diagram

Emerging trends include the shift towards brushless DC motors, which offer higher efficiency and lower maintenance costs. This transition is particularly relevant for sectors like automotive and renewable energy, where reliability and performance are paramount. Additionally, the integration of IoT technologies is influencing sourcing strategies, as smart motors equipped with sensors are becoming commonplace. Buyers should prioritize suppliers that not only provide quality wiring diagrams but also support the implementation of these advanced technologies.

Supply chain dynamics are also evolving; buyers are encouraged to seek partnerships with manufacturers that can provide comprehensive technical support, including detailed wiring diagrams that facilitate installation and troubleshooting. This trend is essential for reducing downtime and enhancing operational efficiency. As the market continues to grow, B2B buyers must stay informed about emerging technologies and industry standards to make strategic sourcing decisions.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the DC Motor Wiring Diagram Sector?

Sustainability is becoming a critical consideration for B2B buyers in the DC motor sector. The environmental impact of manufacturing processes and material sourcing is under scrutiny, prompting many companies to adopt greener practices. This shift is particularly relevant in regions like Europe, where regulations are stringent, and consumers are increasingly demanding sustainable products. Buyers should prioritize suppliers who demonstrate a commitment to eco-friendly practices, such as using recycled materials and implementing energy-efficient manufacturing processes.

Ethical sourcing is equally important, as it ensures that materials are obtained responsibly, without contributing to social or environmental harm. Buyers can enhance their corporate social responsibility (CSR) profiles by partnering with manufacturers who hold certifications for sustainability, such as ISO 14001 or other relevant environmental certifications. These certifications not only validate the manufacturer’s commitment to sustainable practices but also provide buyers with assurance regarding the quality and ethical implications of their sourcing decisions.

Moreover, incorporating sustainable practices in the supply chain can lead to cost savings in the long run. For example, investing in energy-efficient DC motors can reduce operational costs significantly. As sustainability becomes a central tenet of business operations, B2B buyers in the DC motor wiring diagram sector must align their sourcing strategies with these values to remain competitive.

What Is the Brief Evolution of DC Motors and Their Wiring Diagrams Relevant to B2B Buyers?

The evolution of DC motors dates back to the 19th century, with early designs focusing on simplicity and mechanical efficiency. Over time, advancements in materials and technology have led to the development of various motor types, including brushed and brushless variants. The introduction of electronic controls in the late 20th century revolutionized the sector, allowing for precise speed and torque management, which is crucial for modern applications.

In tandem with motor advancements, the complexity of wiring diagrams has increased. Initially, simple diagrams sufficed for basic connections, but as applications became more sophisticated, detailed schematics became essential for installation and maintenance. Today’s wiring diagrams not only illustrate connections but also incorporate real-time data for diagnostics, reflecting the integration of IoT technologies.

This historical context is vital for B2B buyers as it highlights the importance of understanding both the mechanical and electrical aspects of DC motors. Buyers should seek suppliers who provide comprehensive documentation, including wiring diagrams that are up-to-date with current technologies. This knowledge not only aids in effective sourcing but also enhances operational efficiency and product reliability in the long run.

Frequently Asked Questions (FAQs) for B2B Buyers of dc motor wiring diagram

-

How do I solve wiring issues with DC motors?

To address wiring issues with DC motors, first review the motor’s wiring diagram to ensure all connections match the specifications. Check for loose or corroded connections, as these can disrupt power flow. If the motor does not operate as expected, verify that the power supply is sufficient and correctly wired. For troubleshooting, consider using a multimeter to test voltage at various points. If problems persist, consult with the manufacturer or a technical expert for further guidance. -

What is the best wiring diagram for different types of DC motors?

The best wiring diagram depends on the type of DC motor you are using. For shunt motors, the field windings are connected in parallel with the armature, while series motors connect the field in series with the armature. Compound motors combine both configurations. It’s crucial to match the wiring diagram to your specific motor type to ensure optimal performance and efficiency, particularly in industrial applications. -

How can I customize a DC motor wiring diagram for my specific needs?

Customizing a DC motor wiring diagram involves understanding your operational requirements and the motor’s specifications. Begin by defining the application, voltage requirements, and control methods (e.g., forward/reverse). Collaborate with your motor supplier to modify existing diagrams or create new ones that reflect your needs. Providing detailed specifications will help ensure that the customized wiring diagram meets your operational expectations. -

What are the minimum order quantities (MOQs) for DC motor wiring diagrams?

Minimum order quantities (MOQs) for DC motor wiring diagrams can vary widely depending on the supplier and the complexity of the diagrams. Generally, suppliers may require a minimum order to cover production costs, especially for customized diagrams. It is advisable to discuss MOQs upfront with potential suppliers and explore options for bulk orders or tiered pricing structures to optimize your procurement strategy. -

What payment terms should I expect when purchasing DC motor wiring diagrams?

Payment terms for purchasing DC motor wiring diagrams often vary by supplier and region. Common terms include net 30, where payment is due within 30 days after invoicing, or upfront payment for customized services. It is essential to clarify payment options, including any discounts for early payment or specific payment methods accepted (e.g., bank transfer, credit card). Establishing clear terms in the contract can help prevent misunderstandings. -

How do I vet suppliers for DC motor wiring diagrams?

Vetting suppliers involves conducting thorough research to ensure they have a solid reputation and expertise in DC motor technology. Start by checking their certifications and industry experience. Request references or case studies from previous clients, particularly in your region. Additionally, assess their ability to provide technical support and customization options, as well as their responsiveness to inquiries. Engaging in direct communication can also give insights into their customer service standards. -

What quality assurance measures should I consider for DC motor wiring diagrams?

Quality assurance for DC motor wiring diagrams includes verifying that the diagrams adhere to industry standards and regulations. Ensure that the supplier has a quality management system in place, such as ISO certification. Request samples of previous work to evaluate clarity and accuracy. Additionally, consider implementing a review process where technical experts assess the diagrams before use, ensuring they meet your operational requirements. -

What logistics considerations should I keep in mind when sourcing DC motor wiring diagrams internationally?

When sourcing DC motor wiring diagrams internationally, consider shipping times, customs regulations, and potential tariffs. Work with suppliers who have experience in international shipping to streamline the logistics process. Additionally, clarify delivery timelines and ensure that digital formats are available for immediate access. Establishing a reliable communication channel with the supplier can help address any logistical challenges that may arise during the procurement process.

Top 3 Dc Motor Wiring Diagram Manufacturers & Suppliers List

1. Pinterest – DC Motor Wiring Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: How to wire a DC motor on battery with switch and relay, basic wiring for DC current, DC electric motor wiring, parallel and serial battery connection, how to use switches, relays, basic electrical symbols.

2. Nidec – Brushless DC Motor Connection Methods

Domain: nidec.com

Registered: 1997 (28 years)

Introduction: The wire connection methods for brushless DC motors include two types: 1) Delta (Δ) connection, where coils are connected in a loop, and 2) Star (Y) connection, where three coils (U, V, W) are connected in a block with a neutral point. The choice of connection type depends on the operating voltage and application, with star connection being the general preference unless special motors are used.

3. Facebook – 1800W Brushless DC Motor Wiring Diagram

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: A wiring diagram for an 1800W brushless DC motor and controller setup, detailing connections for throttle, key on/off, forward/reverse switch.

Strategic Sourcing Conclusion and Outlook for dc motor wiring diagram

In conclusion, understanding the intricacies of DC motor wiring diagrams is essential for international B2B buyers seeking to optimize their operations. The choice of motor type—be it shunt, series, or compound—affects not only performance but also compatibility with existing systems. Moreover, recognizing the significance of connection methods, such as delta and star configurations for brushless motors, can lead to enhanced efficiency and reliability in applications across various sectors.

Strategic sourcing plays a pivotal role in this context, enabling buyers to access high-quality components and expert suppliers who understand local market nuances in regions like Africa, South America, the Middle East, and Europe. By leveraging these insights, businesses can reduce costs, improve operational performance, and foster long-term partnerships.

As the global market continues to evolve, it is crucial for B2B buyers to stay informed about advancements in motor technology and sourcing strategies. We encourage you to take proactive steps in evaluating your current suppliers and exploring innovative solutions that align with your operational goals. The future is bright for those who invest in knowledge and strategic partnerships in the ever-expanding field of DC motor applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.