Dc Motor Parts Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for dc motor parts

Navigating the global market for DC motor parts presents unique challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The task of sourcing reliable components, such as replacement carbon brushes and brush holders, can be daunting, especially when considering factors like quality, cost, and supplier reliability. This guide aims to demystify the complexities involved in procuring DC motor parts by providing a comprehensive overview that covers various types of components, their applications, and the intricacies of supplier vetting.

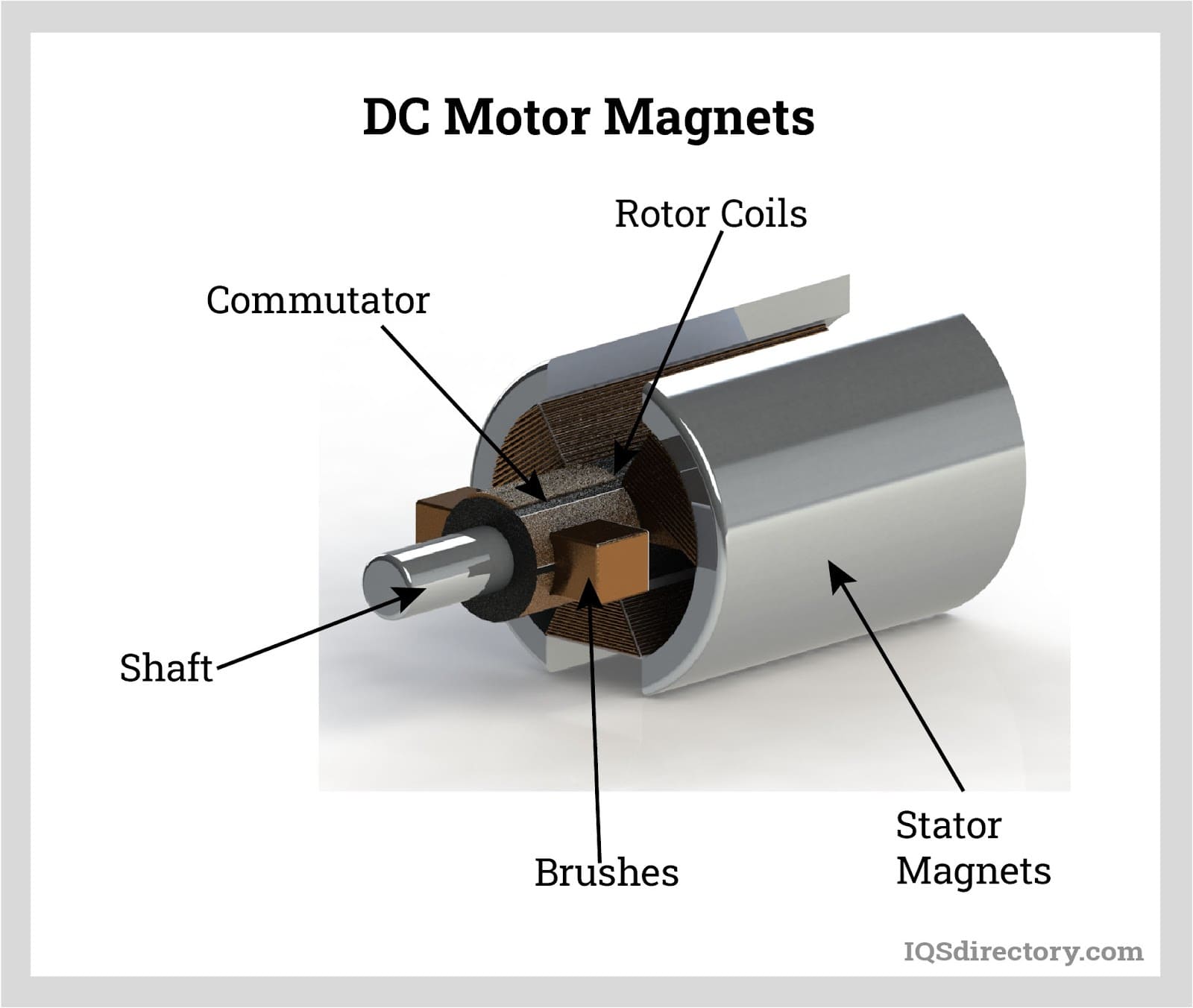

In this guide, you will find detailed insights into the essential parts of DC motors, including the armature, field coils, commutators, and brushes, as well as their specific uses across different industries. We will also explore the critical factors influencing pricing and how to effectively assess suppliers to ensure you are making informed purchasing decisions. Whether you are looking to enhance the efficiency of industrial machinery or seeking components for innovative electric vehicle designs, this resource empowers B2B buyers to navigate the market with confidence. By leveraging the information provided, you can streamline your sourcing process and secure high-quality DC motor parts that meet your operational needs.

Understanding dc motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brushed DC Motors | Uses brushes for current transfer; simple design. | Electric vehicles, robotics, industrial machinery. | Pros: Cost-effective, easy to control. Cons: Higher maintenance due to brush wear. |

| Brushless DC Motors | No brushes; uses electronic controllers for commutation. | HVAC systems, drones, electric bicycles. | Pros: Longer lifespan, higher efficiency. Cons: More complex and expensive. |

| Shunt Wound Motors | Field winding in parallel with armature; stable speed. | CNC machines, conveyor systems, fans. | Pros: Consistent speed under varying loads. Cons: Lower starting torque. |

| Series Wound Motors | Field winding in series with armature; high starting torque. | Elevators, cranes, traction applications. | Pros: High starting torque, variable speed. Cons: Speed varies with load. |

| Compound Wound Motors | Combination of shunt and series; versatile performance. | Heavy machinery, industrial drives, shears. | Pros: High torque and speed control. Cons: More complex design, potentially higher cost. |

What Are the Key Characteristics of Brushed DC Motors?

Brushed DC motors are characterized by their straightforward design, which includes brushes that transfer current to the rotor. They are widely used in applications such as electric vehicles and industrial machinery due to their cost-effectiveness and ease of control. However, buyers should consider the maintenance aspect, as the brushes wear over time and require replacement, potentially leading to increased operational costs.

How Do Brushless DC Motors Stand Out in the Market?

Brushless DC motors utilize electronic controllers for commutation, eliminating the need for brushes. This design leads to longer lifespans and higher efficiency, making them suitable for applications like HVAC systems and drones. While they offer significant advantages, the complexity and higher initial costs may deter some buyers. Understanding the specific application requirements can help in making an informed purchasing decision.

Why Choose Shunt Wound Motors for Stability?

Shunt wound motors feature a field winding connected in parallel with the armature, providing stable speed across various loads. This makes them ideal for applications like CNC machines and conveyor systems where consistent performance is crucial. However, they typically have lower starting torque, which may not be suitable for all industrial applications. Buyers should assess torque requirements before selection.

What Advantages Do Series Wound Motors Offer?

Series wound motors are distinguished by their field winding being connected in series with the armature, resulting in high starting torque. They are commonly used in elevators and cranes where significant initial force is necessary. While they provide variable speed control, the downside is that their speed fluctuates with load, which may not suit every application. Buyers should consider load profiles when evaluating these motors.

How Do Compound Wound Motors Provide Versatility?

Compound wound motors combine features of both shunt and series motors, offering a balance of high torque and speed control. They are particularly useful in heavy machinery and industrial drives where varying load conditions are encountered. The complexity of their design may lead to higher costs, but their adaptability in diverse applications can justify the investment. Buyers should consider the operational environment and load characteristics when choosing this type of motor.

Key Industrial Applications of dc motor parts

| Industry/Sector | Specific Application of dc motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced productivity through efficient material handling | Quality of parts, compatibility with existing systems |

| Automotive | Electric Vehicles (EV) | Improved energy efficiency and reduced emissions | Compliance with international standards, durability |

| Mining | Hoists and Elevators | Increased safety and efficiency in material transport | Reliability under heavy loads, maintenance support |

| Agriculture | Irrigation Systems | Optimized water usage and crop yield | Energy efficiency, adaptability to various environments |

| Robotics | Automated Assembly Lines | Precision manufacturing and reduced labor costs | Customization options, integration capabilities |

How Are DC Motor Parts Utilized in Manufacturing Conveyor Systems?

In the manufacturing sector, DC motor parts play a critical role in conveyor systems, which are essential for material handling. These motors provide the necessary torque and speed control to ensure smooth operation. By using high-quality carbon brushes and commutators, businesses can enhance the longevity and efficiency of their conveyor systems. For international buyers, especially from regions like Africa and South America, it is crucial to ensure that the sourced parts comply with local standards and are suitable for the specific environmental conditions they will operate in.

What Are the Benefits of DC Motor Parts in Electric Vehicles?

In the automotive industry, particularly with the rise of electric vehicles (EVs), DC motor parts are integral for performance and efficiency. These motors convert electrical energy from batteries into mechanical energy, allowing for smooth acceleration and deceleration. Sourcing durable and efficient components is vital, as they directly impact the vehicle’s range and reliability. Buyers from Europe, such as Germany, should prioritize suppliers that meet stringent quality standards and can provide parts that are compatible with advanced EV technologies.

How Do DC Motor Parts Enhance Safety in Mining Applications?

DC motor parts are essential in the mining industry, particularly in hoists and elevators used for transporting materials and personnel. These motors provide high starting torque and robust performance, ensuring safety and reliability under heavy loads. International buyers must consider the harsh operating environments typical in mining, requiring parts that are not only durable but also easy to maintain. Sourcing from reputable suppliers who offer comprehensive support and warranties can mitigate operational risks.

In What Ways Do DC Motor Parts Optimize Agricultural Irrigation Systems?

In agriculture, DC motor parts are utilized in irrigation systems to optimize water distribution and enhance crop yield. These motors enable precise control over water flow, ensuring efficient use of resources. Buyers in regions like the Middle East, where water scarcity is a concern, should focus on sourcing energy-efficient motors that can operate effectively in varying climatic conditions. Additionally, the ability to customize these parts for specific irrigation needs can further enhance agricultural productivity.

How Are DC Motor Parts Essential for Robotics in Automated Assembly Lines?

DC motor parts are pivotal in robotics, especially in automated assembly lines. They provide the necessary precision and control for tasks such as picking, placing, and assembling components. This precision leads to reduced labor costs and improved manufacturing efficiency. For international buyers, particularly those in Europe and South America, it is vital to consider the integration capabilities of these motors with existing robotic systems. Ensuring that sourced parts offer customization options can significantly enhance operational flexibility.

3 Common User Pain Points for ‘dc motor parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality DC Motor Parts

The Problem: Many B2B buyers struggle with finding reliable suppliers for DC motor parts, particularly in regions like Africa and South America where local options may be limited. Issues such as inconsistent product quality, long lead times, and high shipping costs can lead to operational delays and increased costs. Buyers often feel overwhelmed by the variety of suppliers and parts available, making it difficult to select the right components for their specific applications.

The Solution: To effectively source quality DC motor parts, buyers should start by conducting thorough research to identify reputable suppliers that specialize in DC motors and their components. This involves checking online reviews, asking for references, and verifying certifications. Engaging with suppliers who offer a wide range of parts, such as carbon brushes and brush holders, can also simplify the sourcing process. Additionally, consider forming long-term partnerships with suppliers who can guarantee consistent quality and timely delivery. It’s also beneficial to request samples before making bulk purchases to ensure that the parts meet your specific requirements. Utilizing local distributors can help reduce shipping times and costs, making it easier to maintain production schedules.

Scenario 2: Understanding the Technical Specifications of DC Motor Parts

The Problem: Buyers often face confusion regarding the technical specifications required for DC motor parts, leading to mismatches and performance issues. For instance, selecting the wrong type or size of carbon brushes can result in decreased efficiency or even damage to the motor. This is particularly critical in sectors like manufacturing and mining, where the reliability of equipment is paramount.

The Solution: To mitigate this issue, buyers should invest time in understanding the specific requirements of their DC motors. This includes consulting technical documentation and manufacturers’ specifications for parameters such as voltage ratings, current ratings, and physical dimensions of components. Engaging with technical experts or engineers can provide additional insights into selecting the right parts. Buyers can also leverage online resources and forums dedicated to electric motors to gain knowledge from industry peers. When in doubt, don’t hesitate to reach out to suppliers for guidance. Many reputable suppliers offer technical support services that can assist in clarifying specifications and ensuring the right components are chosen for your application.

Scenario 3: Managing Maintenance and Replacement Schedules for DC Motor Parts

The Problem: A common pain point for B2B buyers is the challenge of managing maintenance and replacement schedules for DC motor parts. Without a proper strategy, businesses can experience unexpected downtimes due to worn-out components, leading to costly interruptions in production. This is especially true for industries that rely heavily on continuous operation, like manufacturing and logistics.

The Solution: Implementing a proactive maintenance strategy can significantly reduce the risk of unexpected failures. Buyers should develop a comprehensive maintenance schedule based on the operational demands of their equipment. Regular inspections of critical components, such as brushes and commutators, can help identify wear and tear before it leads to a breakdown. Additionally, keeping an inventory of commonly used parts can facilitate quick replacements, minimizing downtime. Establishing a partnership with suppliers who offer quick delivery options can further enhance your ability to respond to maintenance needs. Lastly, investing in training for maintenance staff on the proper handling and replacement of DC motor parts can lead to more efficient operations and longer lifespans for the equipment.

Strategic Material Selection Guide for dc motor parts

When selecting materials for DC motor parts, it is crucial to consider various factors that influence performance, durability, and cost-effectiveness. The following analysis explores four common materials used in DC motor components, examining their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Copper for DC Motor Parts?

Copper is widely used in DC motor parts, particularly for windings and brushes, due to its excellent electrical conductivity. Key properties include a high melting point (approximately 1,984°F or 1,085°C) and good thermal conductivity, which helps in heat dissipation during operation. Copper also exhibits resistance to corrosion, particularly when coated or alloyed.

Pros & Cons: Copper’s high conductivity ensures efficient energy transfer, making it ideal for applications requiring minimal energy loss. However, it is relatively expensive compared to other materials like aluminum, and its density can lead to increased weight in applications where weight savings are critical.

Impact on Application: Copper is compatible with various media and performs well in high-temperature environments, making it suitable for industrial applications. However, buyers should be aware of potential supply chain issues, especially in regions like Africa and South America, where copper mining and processing may face challenges.

How Does Steel Perform in DC Motor Components?

Steel, particularly carbon steel and stainless steel, is commonly used for structural components such as the motor casing and shafts. Key properties include high tensile strength, good wear resistance, and the ability to withstand high pressures and temperatures.

Pros & Cons: Steel’s durability makes it suitable for heavy-duty applications. However, it is prone to corrosion, which can lead to failure in humid or corrosive environments unless properly treated or coated. Additionally, the manufacturing complexity can increase costs, particularly for precision components.

Impact on Application: Steel components are often favored in industries that require robust machinery, such as mining and manufacturing. Buyers in regions like the Middle East and Europe should consider compliance with standards like ASTM and DIN for material specifications.

What Are the Advantages of Using Graphite in DC Motor Parts?

Graphite is primarily used for brushes in DC motors due to its excellent electrical conductivity and self-lubricating properties. It can operate effectively at high temperatures (up to 1,832°F or 1,000°C) and has good wear resistance.

Pros & Cons: The main advantage of graphite is its ability to maintain performance under high-load conditions, reducing wear on both the brushes and the commutator. However, graphite is brittle and can break under excessive mechanical stress, limiting its use in high-impact applications.

Impact on Application: Graphite brushes are particularly suitable for applications requiring frequent start-stop cycles, such as in electric vehicles. International buyers should ensure compliance with relevant standards and consider the availability of high-quality graphite sources in their regions.

How Does Aluminum Compare for DC Motor Parts?

Aluminum is increasingly used for various DC motor components, including housings and heat sinks, due to its lightweight nature and good thermal conductivity. Key properties include a melting point of approximately 1,221°F (660°C) and excellent corrosion resistance when anodized.

Pros & Cons: The primary advantage of aluminum is its low weight, which can enhance the efficiency of portable applications. However, its lower tensile strength compared to steel may limit its use in high-load scenarios. Additionally, aluminum can be more expensive than steel, depending on market conditions.

Impact on Application: Aluminum is well-suited for applications in automotive and aerospace industries where weight reduction is critical. Buyers from Europe and the Middle East should consider local regulations regarding aluminum sourcing and processing.

Summary Table of Material Selection for DC Motor Parts

| Material | Typical Use Case for dc motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings, brushes | Excellent electrical conductivity | High cost, increased weight | High |

| Steel | Casings, shafts | High tensile strength | Prone to corrosion, complex mfg | Medium |

| Graphite | Brushes | Self-lubricating, good wear resistance | Brittle, limited mechanical stress | Medium |

| Aluminum | Housings, heat sinks | Lightweight, good thermal conductivity | Lower tensile strength than steel | Medium |

This material selection guide provides actionable insights for international B2B buyers looking to optimize their DC motor parts procurement strategies. By understanding the properties and implications of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for dc motor parts

What Are the Key Stages in the Manufacturing Process of DC Motor Parts?

The manufacturing of DC motor parts involves several critical stages, each contributing to the overall quality and functionality of the final product. Understanding these stages is essential for B2B buyers, especially when sourcing parts from international suppliers.

1. Material Preparation: What Materials Are Used and How Are They Prepared?

The manufacturing process begins with the selection of appropriate materials. Common materials for DC motor parts include high-grade carbon for brushes, copper for windings, and various alloys for the rotor and stator components.

Material preparation involves several steps:

– Material Selection: Choosing materials based on electrical conductivity, thermal resistance, and mechanical strength.

– Cutting and Shaping: Raw materials are cut into specific shapes and sizes using techniques such as laser cutting or CNC machining. This precision ensures that parts fit together correctly in later stages.

2. Forming: How Are Parts Shaped and Assembled?

Once the materials are prepared, they undergo forming processes. This stage is critical for creating the essential components of the DC motor, including the rotor, stator, and commutator.

- Machining: Parts are shaped using various machining techniques, including turning, milling, and grinding. These processes are crucial for achieving the desired dimensions and surface finishes.

- Winding: For the armature, copper wire is wound around the core to create electromagnetic fields. This step requires precision to ensure optimal performance.

- Assembly: Once individual components are fabricated, they are assembled. This may involve the use of jigs and fixtures to ensure accuracy during assembly.

3. Finishing: What Techniques Are Used for Surface Treatment?

Finishing processes enhance the performance and longevity of DC motor parts. These processes may include:

- Surface Treatment: Techniques such as anodizing, plating, or coating may be applied to enhance corrosion resistance and electrical conductivity.

- Balancing: Rotors are often balanced to minimize vibrations during operation, which is crucial for the motor’s efficiency and lifespan.

What Quality Assurance Practices Are Common in DC Motor Parts Manufacturing?

Quality assurance (QA) is integral to the manufacturing of DC motor parts, ensuring that products meet international standards and customer expectations.

International Standards: What Certifications Should Buyers Look For?

B2B buyers should be aware of relevant international quality standards, such as:

- ISO 9001: This standard outlines a framework for quality management systems, emphasizing customer satisfaction and continual improvement.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For specific applications in the oil and gas industry, adherence to API standards may be necessary.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process to ensure that defects are identified and addressed promptly.

1. Incoming Quality Control (IQC): How Is Material Quality Assessed?

IQC involves inspecting raw materials upon arrival at the manufacturing facility. Key activities include:

- Visual Inspection: Checking for physical defects or inconsistencies in the materials.

- Material Testing: Conducting tests to verify material properties, such as electrical conductivity and tensile strength.

2. In-Process Quality Control (IPQC): How Is Quality Monitored During Production?

IPQC focuses on monitoring the manufacturing process itself to catch defects early. Techniques include:

- Process Audits: Regular audits of production processes to ensure compliance with established protocols.

- Statistical Process Control (SPC): Utilizing statistical methods to monitor and control the production process.

3. Final Quality Control (FQC): What Happens Before Products Leave the Facility?

FQC is the final checkpoint before products are shipped to customers. This stage includes:

- Functional Testing: Testing the assembled DC motor parts to ensure they meet performance specifications.

- Documentation Review: Ensuring that all necessary documentation, such as compliance certificates and test reports, is complete and accurate.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers can take several steps to verify the quality assurance practices of their suppliers:

1. Conducting Supplier Audits: What Should Buyers Look For?

Auditing potential suppliers is a critical step in ensuring quality. Buyers should assess:

- Facility Conditions: Evaluate the cleanliness and organization of the manufacturing facility.

- QC Procedures: Review the supplier’s quality control processes and ensure they align with international standards.

2. Requesting Quality Reports and Certifications: What Documentation Is Essential?

Buyers should request documentation that demonstrates compliance with quality standards, including:

- Certificates of Compliance: Proof that products meet specified standards.

- Test Reports: Detailed reports of the testing conducted on the products.

3. Utilizing Third-Party Inspection Services: How Can Independent Verification Help?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These services can conduct:

- Pre-shipment Inspections: Verifying that products meet specifications before they leave the supplier’s facility.

- Random Sampling: Inspecting a random sample of products to ensure quality consistency.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding regional regulations and standards is crucial. Buyers from Africa, South America, the Middle East, and Europe may encounter different certification requirements and quality expectations.

- Regional Standards: Buyers should familiarize themselves with local standards and regulations that may impact product compliance.

- Cultural Considerations: Building strong relationships with suppliers can facilitate better communication regarding quality expectations.

By understanding the manufacturing processes and quality assurance practices associated with DC motor parts, international B2B buyers can make informed sourcing decisions that ensure product reliability and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dc motor parts’

The following guide serves as a comprehensive checklist for B2B buyers looking to procure DC motor parts. It is designed to streamline the sourcing process and ensure that buyers make informed decisions that align with their technical and operational needs.

Step 1: Define Your Technical Specifications

Before beginning your procurement process, clearly outline your technical requirements. This includes the type of DC motor parts you need, such as brushes, armatures, or field coils, as well as their specific dimensions and material specifications. Understanding these details is crucial for ensuring compatibility with your existing systems and avoiding costly mistakes.

- Consider Application Needs: Identify the specific applications for which the DC motor parts will be used, such as industrial machinery or automotive components.

- Performance Criteria: Determine the performance characteristics required, including voltage ratings, current capacity, and operational environment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in DC motor parts. Look for suppliers with a proven track record and extensive product offerings. This step is vital to ensuring that you partner with reliable manufacturers that can meet your demands.

- Industry Reputation: Investigate online reviews, ratings, and testimonials from other B2B buyers to gauge supplier reliability.

- Product Range: Ensure that the supplier offers a comprehensive range of parts, including various brands and types, to facilitate future procurement.

Step 3: Verify Supplier Certifications

Before finalizing any agreements, verify that potential suppliers hold relevant certifications and comply with industry standards. Certifications can indicate a commitment to quality and safety, which is essential when sourcing critical components like DC motor parts.

- Quality Assurance: Look for ISO 9001 or similar quality management certifications.

- Safety Standards: Confirm compliance with international safety standards relevant to your industry, such as CE or UL certifications.

Step 4: Request Samples and Technical Documentation

Obtaining samples of the DC motor parts you intend to purchase is a crucial step in the sourcing process. Samples allow you to evaluate quality firsthand and ensure that specifications are met.

- Documentation: Request technical data sheets, installation manuals, and maintenance guides to understand the parts’ compatibility and performance requirements.

- Testing: Conduct tests on samples to confirm they meet your operational needs before placing a bulk order.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier and evaluated samples, initiate negotiations regarding pricing and terms of purchase. This step is critical to ensuring that you receive the best value for your investment.

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts.

- Payment Terms: Discuss payment options, delivery schedules, and warranty conditions to protect your interests.

Step 6: Establish a Communication Plan

Effective communication with your supplier is vital throughout the procurement process and beyond. Establish a clear communication plan to ensure that both parties are aligned on expectations and timelines.

- Point of Contact: Designate a specific contact person for all communications to streamline the process.

- Regular Updates: Schedule regular check-ins to discuss order status, potential issues, and future needs.

Step 7: Evaluate Supplier Performance Post-Purchase

After receiving your DC motor parts, it’s important to assess the supplier’s performance. This evaluation will help you determine whether to continue the relationship for future purchases.

- Quality Control: Inspect the received parts for quality and adherence to specifications.

- Feedback Loop: Provide feedback to the supplier regarding any issues or areas for improvement to foster a collaborative relationship.

By following this checklist, B2B buyers can effectively navigate the procurement process for DC motor parts, ensuring that they make informed decisions that support their operational goals.

Comprehensive Cost and Pricing Analysis for dc motor parts Sourcing

What Are the Key Cost Components in Sourcing DC Motor Parts?

When sourcing DC motor parts, understanding the cost structure is crucial for effective budgeting and financial planning. The primary cost components include:

-

Materials: The raw materials used in manufacturing DC motor parts, such as copper for windings, carbon for brushes, and various metals for housings, significantly impact overall costs. Prices can fluctuate based on market demand and availability.

-

Labor: Labor costs encompass the wages of skilled workers involved in manufacturing, assembly, and quality control. Regions with higher labor costs, such as Western Europe, may require buyers to factor in these expenses when comparing suppliers.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, equipment maintenance, and facility expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Custom tooling for specific parts can be a significant upfront cost. Buyers should inquire about tooling costs, especially for specialized components or low-volume orders.

-

Quality Control (QC): Ensuring that parts meet quality standards is essential. Costs associated with quality assurance processes should be factored into the total cost of sourcing.

-

Logistics: Transportation and warehousing costs can vary widely depending on the supplier’s location and the buyer’s destination. International shipping, customs duties, and insurance are all aspects that can add to logistics expenses.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margins within the industry can help buyers gauge whether a quote is competitive.

How Do Price Influencers Affect DC Motor Parts Sourcing?

Several factors influence the pricing of DC motor parts, and recognizing these can help buyers negotiate better deals:

-

Volume/MOQ: Larger order volumes often lead to reduced per-unit costs. Suppliers may offer tiered pricing, so understanding the Minimum Order Quantity (MOQ) can be advantageous for bulk purchases.

-

Specifications and Customization: Customized parts that require specific engineering or design can lead to higher prices. Clear communication about specifications can help suppliers provide more accurate quotes.

-

Materials: The choice of materials directly affects pricing. Higher quality or specialty materials typically come at a premium, while standard materials may offer cost savings.

-

Quality and Certifications: Parts with certifications (e.g., ISO, CE) may command higher prices due to the assurance of quality and reliability. Buyers should assess whether such certifications are necessary for their applications.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers with a track record of reliability may charge more but can save costs in the long run through reduced risk.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for cost estimation. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of goods.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing DC Motor Parts?

To ensure cost-efficiency in sourcing DC motor parts, buyers can implement the following strategies:

-

Negotiation: Engage in negotiations to secure better pricing. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price, but the total cost of ownership, which includes maintenance, durability, and operational costs. This broader perspective can lead to more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be mindful of currency fluctuations, import duties, and taxes when sourcing from different countries. Local market conditions can significantly impact pricing, especially in regions like Africa and South America.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better service, priority in production schedules, and potential discounts.

-

Market Research: Regularly conduct market research to stay informed about material costs and industry trends. This information can help buyers anticipate price changes and make strategic sourcing decisions.

Disclaimer

The prices discussed herein are indicative and can vary based on market conditions, supplier negotiations, and individual buyer requirements. Always consult multiple suppliers and conduct thorough cost analyses to ensure the best sourcing decisions.

Alternatives Analysis: Comparing dc motor parts With Other Solutions

Exploring Alternatives to DC Motor Parts for B2B Applications

In the quest for efficient and reliable power solutions, businesses often face the challenge of selecting the right components for their machinery. While DC motor parts are a popular choice due to their versatility and ease of control, several alternative technologies can achieve similar objectives. Understanding these alternatives can help international B2B buyers make informed decisions tailored to their specific operational needs.

| Comparison Aspect | Dc Motor Parts | Brushless DC Motors | Stepper Motors |

|---|---|---|---|

| Performance | High torque and precise speed control. | Higher efficiency and lower heat generation. | Excellent for precise positioning and control. |

| Cost | Generally affordable with low initial investment. | Higher upfront costs but lower operational costs. | Moderate cost, varies based on precision and torque requirements. |

| Ease of Implementation | Simple installation and integration into existing systems. | Requires specialized controllers, adding complexity. | Requires proper driver integration for optimal performance. |

| Maintenance | Requires regular maintenance, particularly of brushes. | Minimal maintenance; no brushes to replace. | Low maintenance, but calibration may be needed. |

| Best Use Case | Ideal for applications needing variable speed and torque. | Best suited for applications requiring efficiency and low noise. | Perfect for applications needing precise control over motion. |

What Are the Pros and Cons of Brushless DC Motors?

Brushless DC motors (BLDC) are gaining popularity in various industries due to their efficiency and reduced maintenance requirements. Unlike traditional brushed DC motors, BLDC motors utilize electronic controllers, which eliminate the need for brushes and commutators. This design leads to less mechanical wear and tear, resulting in longer lifespans and lower operational costs. However, the complexity of installation and the need for specialized controllers can deter some buyers, especially in regions where technical expertise is limited.

How Do Stepper Motors Compare in Precision Applications?

Stepper motors are another alternative that excels in applications requiring high precision and control. They operate by dividing a full rotation into a series of discrete steps, allowing for precise positioning. This makes them ideal for robotics, CNC machines, and 3D printers. While they provide excellent control, they may struggle with high-speed applications and can experience resonance issues. Additionally, the cost can vary significantly based on the required torque and precision, making them a more tailored solution for specific needs.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate motor technology, B2B buyers should consider their specific application requirements, budget constraints, and maintenance capabilities. DC motor parts are a solid choice for those needing variable speed and torque in a straightforward package. In contrast, brushless DC motors offer enhanced efficiency and reduced maintenance but may require additional expertise. Stepper motors shine in precision applications but may not be suitable for all scenarios. By evaluating these aspects, businesses can make informed decisions that align with their operational goals and maximize their investment.

Essential Technical Properties and Trade Terminology for dc motor parts

What Are the Key Technical Properties of DC Motor Parts?

When sourcing DC motor parts, understanding their technical properties is crucial for ensuring compatibility and performance. Here are several essential specifications that B2B buyers should consider:

-

Material Grade

– Definition: The material grade indicates the type and quality of materials used in the construction of motor parts, such as carbon for brushes or copper for windings.

– Importance: High-quality materials enhance durability and performance, reducing the likelihood of failures. This is particularly vital in industrial applications where uptime is critical. -

Tolerance

– Definition: Tolerance refers to the permissible limit of variation in a physical dimension of a part.

– Importance: Precise tolerances ensure that parts fit together correctly, which is essential for efficient motor operation. Poor tolerance can lead to increased wear and decreased efficiency, impacting overall performance. -

Voltage Rating

– Definition: The voltage rating specifies the maximum voltage that a motor part can safely handle.

– Importance: Matching voltage ratings between parts is essential for optimal performance and preventing electrical failures. Overvoltage can damage components and lead to costly downtime. -

Current Rating

– Definition: Current rating indicates the maximum continuous current a component can handle without overheating.

– Importance: Understanding current ratings helps prevent overheating and potential burnout of motor parts, ensuring longevity and reliability in operation. -

Insulation Class

– Definition: This class categorizes the thermal resistance of the insulation material used in motor components.

– Importance: Selecting parts with appropriate insulation ratings is critical in high-temperature environments, as it affects safety and performance. Higher insulation classes allow for operation in more demanding conditions. -

Weight

– Definition: The weight of a motor part can influence its application and installation.

– Importance: For applications requiring portability or specific load-bearing capacities, knowing the weight is vital. It also affects shipping costs and logistical planning.

What Are the Common Trade Terms Used in DC Motor Parts Procurement?

Navigating the procurement landscape for DC motor parts involves familiarity with industry jargon. Here are several key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Significance: Sourcing from OEMs often ensures higher quality and compatibility, as these parts are designed specifically for the intended machinery. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding MOQs helps buyers plan their purchases effectively and avoid excess inventory or stockouts, which can impact production schedules. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document used to invite suppliers to bid on specific products or services.

– Significance: Issuing an RFQ allows buyers to compare pricing and terms from multiple suppliers, ensuring they receive the best value for their procurement needs. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Significance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost implications, which is crucial for international transactions. -

Lead Time

– Definition: Lead time is the amount of time it takes from placing an order to receiving the goods.

– Significance: Knowing lead times is essential for planning production schedules and managing inventory levels, particularly in industries where timely delivery is critical. -

Warranty Period

– Definition: The warranty period is the time frame during which a manufacturer guarantees the quality and performance of a product.

– Significance: A longer warranty period can indicate higher confidence in product reliability, providing buyers with peace of mind and protection against defects.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the successful integration of DC motor parts into their operations.

Navigating Market Dynamics and Sourcing Trends in the dc motor parts Sector

What Are the Key Trends Driving the DC Motor Parts Market?

The global DC motor parts market is experiencing significant growth, driven by advancements in automation, electric vehicles (EVs), and renewable energy applications. The increasing demand for energy-efficient solutions is prompting manufacturers to innovate and enhance the performance of DC motors. Key trends influencing sourcing strategies include the integration of smart technologies, such as Internet of Things (IoT) capabilities, which enable real-time monitoring and predictive maintenance of motor systems.

In regions like Africa and South America, there is a surge in infrastructure development projects, increasing the need for reliable and efficient DC motors in various applications, including mining, agriculture, and transportation. In the Middle East, investments in smart cities and industrial automation are driving demand for high-quality DC motor parts. European countries, particularly Germany, are focusing on sustainability and energy efficiency, leading to a preference for suppliers that offer advanced and eco-friendly motor solutions.

Moreover, international B2B buyers are increasingly favoring suppliers who can provide customized solutions tailored to specific applications. The emergence of digital marketplaces is transforming the sourcing landscape, making it easier for buyers to compare suppliers and streamline procurement processes. As competition intensifies, companies are prioritizing long-term partnerships with reliable manufacturers who can ensure quality, timely delivery, and after-sales support.

How Does Sustainability and Ethical Sourcing Impact the DC Motor Parts Sector?

Sustainability and ethical sourcing have become critical factors for B2B buyers in the DC motor parts sector. Environmental considerations are paramount, as the production and disposal of motor components can significantly impact ecological systems. Buyers are increasingly seeking suppliers who demonstrate a commitment to minimizing their environmental footprint through sustainable practices, such as using recycled materials and reducing waste in the manufacturing process.

The importance of ethical supply chains cannot be overstated. International buyers are now scrutinizing the sourcing of raw materials to ensure that they are obtained responsibly and do not contribute to human rights abuses or environmental degradation. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential for suppliers to gain credibility in the market.

Additionally, the rise of green materials, such as eco-friendly carbon brushes and recyclable components, is reshaping product offerings. Buyers are encouraged to look for suppliers who prioritize these materials, as they not only contribute to sustainability goals but can also enhance brand reputation and marketability in an increasingly eco-conscious consumer landscape.

What Is the Historical Context of the DC Motor Parts Market for B2B Buyers?

The evolution of DC motors can be traced back to the early 19th century, with significant advancements occurring throughout the Industrial Revolution. Initially, DC motors were primarily used in industrial applications due to their ability to provide variable speed control, which was essential for machinery operations. Over the decades, the introduction of brushless DC motors has enhanced efficiency and reduced maintenance needs, making them popular in various applications, including consumer electronics and automotive industries.

As technology progressed, the integration of digital controls and automation systems revolutionized the DC motor parts market. Today, buyers benefit from a rich history of innovation that has led to improved performance, reliability, and efficiency in DC motors. Understanding this historical context allows B2B buyers to appreciate the advancements in technology and the ongoing trends that are shaping the future of the DC motor parts sector, helping them make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of dc motor parts

-

How do I solve compatibility issues with DC motor parts?

To address compatibility issues with DC motor parts, start by confirming the specifications of your existing equipment, including voltage, current ratings, and physical dimensions. When sourcing parts, consult with suppliers to ensure they provide components that match your motor’s requirements. It’s advisable to request detailed datasheets and, if possible, samples for testing. Additionally, engaging in open communication with your supplier regarding your specific needs can help avoid mismatches, ensuring smooth integration into your operations. -

What is the best type of DC motor for industrial applications?

The best type of DC motor for industrial applications often depends on the specific requirements of your project. For applications needing high starting torque, such as cranes or conveyors, a series wound DC motor is ideal. Conversely, for applications requiring speed consistency, a shunt wound DC motor is preferable. Brushless DC motors are also gaining popularity due to their efficiency and reduced maintenance needs. Assess your operational demands, including load characteristics and speed control requirements, to make an informed choice. -

What factors should I consider when vetting a supplier for DC motor parts?

When vetting a supplier for DC motor parts, consider their industry experience, product quality certifications, and customer reviews. Verify their manufacturing capabilities and whether they can provide customized solutions to meet your specifications. Assess their logistics and delivery timelines, especially for international shipping, to ensure timely supply. Additionally, inquire about their after-sales support, warranty policies, and return procedures to safeguard your investment and ensure a reliable partnership. -

Are there minimum order quantities (MOQs) for DC motor parts?

Yes, many suppliers impose minimum order quantities (MOQs) for DC motor parts, which can vary significantly based on the type of part and the supplier’s policies. It’s essential to clarify MOQs during your initial discussions with potential suppliers, especially if you’re a smaller business or testing new components. Some suppliers may offer flexibility on MOQs for first-time orders or samples, while others may have strict requirements. Understanding these terms upfront can help you budget and plan your procurement strategy effectively. -

What payment terms are typically offered by suppliers of DC motor parts?

Payment terms for DC motor parts can vary widely among suppliers. Common options include upfront payment, net 30 or net 60 days, and letter of credit arrangements for larger orders. It’s crucial to discuss and negotiate payment terms that align with your cash flow and purchasing strategy. Ensure you understand any implications of late payments, discounts for early payments, and the security of your transactions. Establishing clear terms can foster a smoother relationship and facilitate ongoing transactions. -

How can I ensure quality assurance (QA) for DC motor parts?

To ensure quality assurance (QA) for DC motor parts, establish a clear set of standards and specifications that suppliers must meet. Request documentation such as quality certifications (ISO, CE) and test reports for critical components. Additionally, consider conducting periodic audits of suppliers’ manufacturing processes and quality control systems. Engaging in regular communication about quality expectations and potential issues can foster a collaborative approach to maintaining high standards throughout your supply chain. -

What are the logistics considerations when importing DC motor parts?

When importing DC motor parts, logistics considerations include shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with your destination country’s import laws to ensure compliance and avoid delays. Assess the costs associated with shipping, duties, and taxes, and factor these into your overall budget. It’s also wise to establish clear communication with your supplier regarding shipping schedules and tracking to manage your inventory effectively and avoid production interruptions. -

How do I customize DC motor parts for my specific needs?

Customizing DC motor parts typically involves working closely with your supplier to define your specific requirements, such as size, material, or performance characteristics. Provide detailed specifications and any relevant data about your application to guide the design process. Many suppliers offer engineering support to assist with modifications. Be prepared for potential lead times associated with custom orders and ensure that you have clear agreements regarding pricing, delivery schedules, and quality checks before finalizing your order.

Top 3 Dc Motor Parts Manufacturers & Suppliers List

1. DB Electrical – DC Motors Replacement Parts

Domain: dbelectrical.com

Registered: 2000 (25 years)

Introduction: DC Motors Replacement Parts available at DB Electrical. Free Same Day Shipping over $50 in the USA/48 states. Various models include:

1. Item #: 430-22044 – Pump Motor, Replaces Hino X2772302, Bosch 0-204-788-062, Prestolite HYL5006, Price: $157.13

2. Item #: 430-20094 – P56SX401 12V, 1/2HP Scott DC Reel Motor for Hannay Reels, Various CCW Rotation, Price: $153.18

3. Item #: SCO-P56SX401 – 12V …

2. Cart Parts R Us – AMD Traction Motor Bearing

Domain: cartpartsrus.com

Registered: 2009 (16 years)

Introduction: This company, Cart Parts R Us – AMD Traction Motor Bearing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. EEPowerschool – DC Machine Components

Domain: eepowerschool.com

Registered: 2018 (7 years)

Introduction: DC Machine: Basic Components and Function

1. **Field Winding**: The stationary part of a DC motor, constructed from magnetic poles, producing a uniform magnetic field for the armature to rotate in.

2. **Armature Winding**: The moving part of a DC motor that completes the electro-mechanical energy conversion, typically a copper coil spinning in the magnetic field.

3. **Commutator**: A mechanical…

Strategic Sourcing Conclusion and Outlook for dc motor parts

In the evolving landscape of DC motor parts, strategic sourcing emerges as a pivotal component for international B2B buyers. By understanding the intricate components of DC motors—including brushes, commutators, and armatures—buyers can make informed decisions that enhance operational efficiency and reduce costs. Establishing strong relationships with reliable suppliers not only ensures the availability of high-quality parts but also fosters innovation and adaptability in a competitive market.

Furthermore, as industries across Africa, South America, the Middle East, and Europe increasingly rely on advanced technologies, the demand for optimized sourcing practices will only grow. By leveraging data-driven insights and engaging with suppliers who prioritize quality and efficiency, businesses can navigate supply chain complexities and mitigate risks associated with sourcing.

Looking ahead, it is essential for B2B buyers to remain proactive. Evaluate your sourcing strategies regularly, embrace technological advancements, and explore partnerships that align with your operational goals. The future of DC motor parts sourcing is promising; take the initiative today to secure a competitive edge in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.