Cylinder Brush Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for cylinder brush

Navigating the complexities of sourcing the right cylinder brush for your business can be a daunting challenge, especially in a global market where quality, compatibility, and supplier reliability vary significantly. Whether you are looking for brushes for industrial cleaning, specialized applications, or routine maintenance, understanding the diverse types available and their specific functions is crucial for making informed purchasing decisions. This guide aims to demystify the cylinder brush market by providing insights into various brush types, their applications across different sectors, and essential criteria for vetting suppliers.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe—including key markets such as Brazil and Germany—this comprehensive resource is designed to empower you with the knowledge needed to navigate supplier landscapes effectively. We will explore factors influencing pricing, the importance of compatibility with existing equipment, and tips for establishing long-term partnerships with reliable manufacturers. By equipping yourself with this information, you can streamline your procurement process, ensure product quality, and ultimately enhance operational efficiency in your business.

Join us as we delve into the world of cylinder brushes, uncovering the essential insights that will help you make strategic purchasing decisions tailored to your unique needs and market demands.

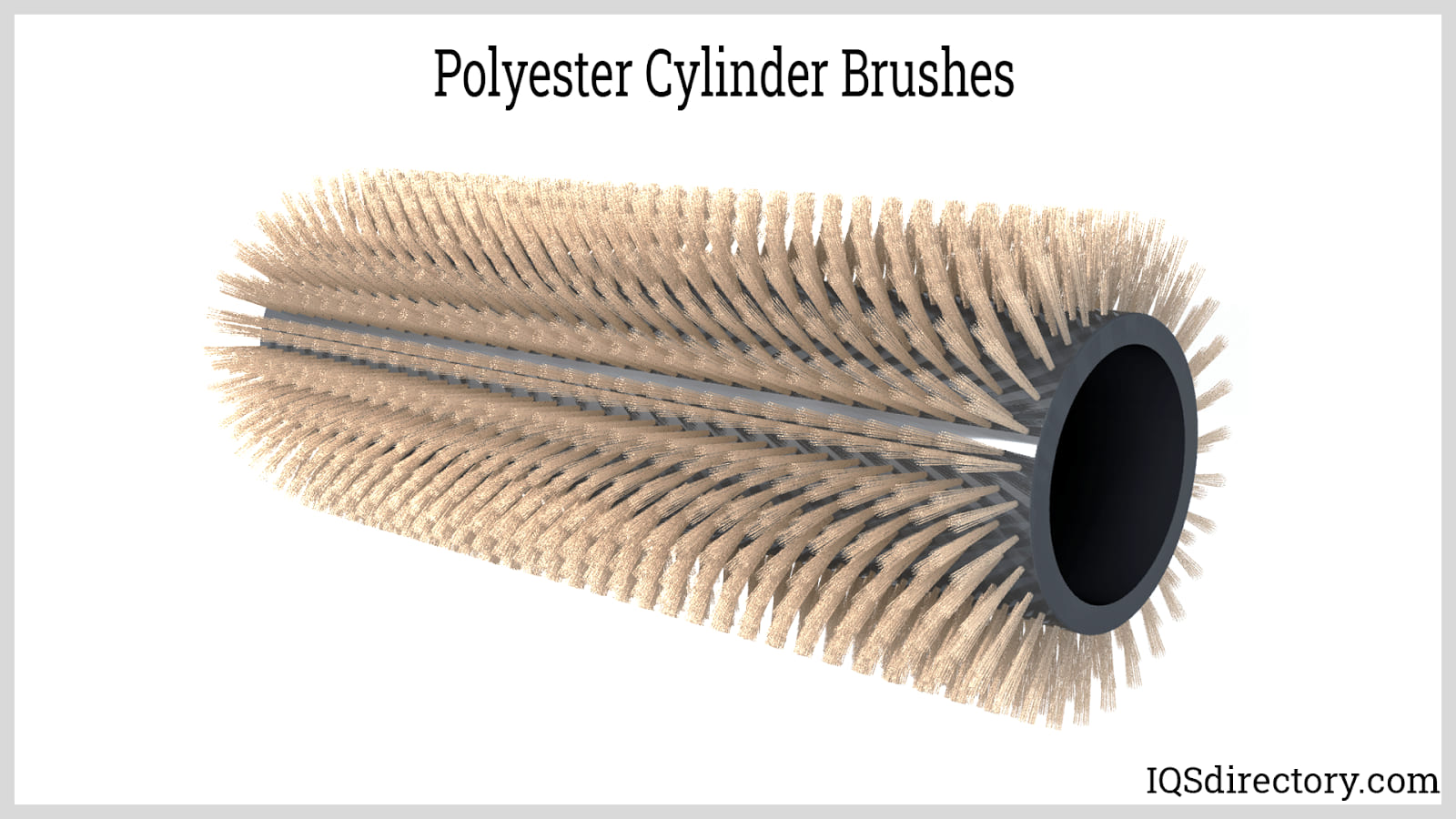

Understanding cylinder brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard Bristle Brush | Durable bristles designed for tough scrubbing tasks | Heavy-duty cleaning in industrial settings | Pros: Effective on tough stains; Cons: May damage softer surfaces. |

| Soft Bristle Brush | Gentle bristles suitable for delicate surfaces | Maintenance of polished or tiled floors | Pros: Safe for sensitive surfaces; Cons: Less effective on heavy grime. |

| Grit Brush | Abrasive surface for enhanced scrubbing power | Cleaning heavily soiled areas | Pros: Excellent for tough jobs; Cons: Can wear down quickly. |

| Escalator Cleaner Brush | Specialized design for cleaning escalator steps | Transportation hubs and commercial areas | Pros: Tailored for specific use; Cons: Limited application elsewhere. |

| Medium Duty Brush | Balanced bristle stiffness for versatile cleaning | General cleaning in various environments | Pros: Versatile and effective; Cons: May not excel in specialized tasks. |

What Are the Characteristics of Hard Bristle Brushes?

Hard bristle brushes are built with sturdy bristles that can withstand rigorous scrubbing, making them ideal for heavy-duty cleaning tasks. They are particularly effective in industrial settings where tough stains and grime are prevalent. When considering a hard bristle brush, B2B buyers should evaluate the surfaces they will be cleaning, as these brushes can potentially damage softer materials.

How Do Soft Bristle Brushes Differ in Application?

Soft bristle brushes feature gentler bristles that are perfect for maintaining delicate surfaces, such as polished floors and tiles. They are commonly used in environments where surface integrity is crucial, such as in retail spaces or hotels. B2B buyers should consider the balance between cleaning effectiveness and surface safety when selecting soft bristle brushes for their operations.

What Makes Grit Brushes Suitable for Heavy-Duty Cleaning?

Grit brushes are designed with an abrasive surface that enhances their scrubbing capability, making them suitable for cleaning heavily soiled areas. They are often utilized in industrial cleaning operations where stubborn dirt and grime are a concern. Buyers should be aware that while grit brushes are effective for tough jobs, they may wear down more quickly than other types, necessitating more frequent replacements.

Why Are Escalator Cleaner Brushes Specialized?

Escalator cleaner brushes are uniquely designed to clean the specific contours of escalator steps effectively. These brushes are essential in high-traffic areas such as airports and shopping centers, where cleanliness is vital. Buyers should consider the specialized nature of these brushes and their limited application in other cleaning tasks, ensuring they meet the specific needs of their facilities.

What Are the Benefits of Using Medium Duty Brushes?

Medium duty brushes offer a balanced bristle stiffness that makes them versatile for various cleaning tasks. They are suitable for general cleaning in commercial environments, providing effective scrubbing without the risk of damaging surfaces. B2B buyers should assess their cleaning needs to determine if a medium duty brush can fulfill multiple roles, providing both efficiency and cost-effectiveness in their operations.

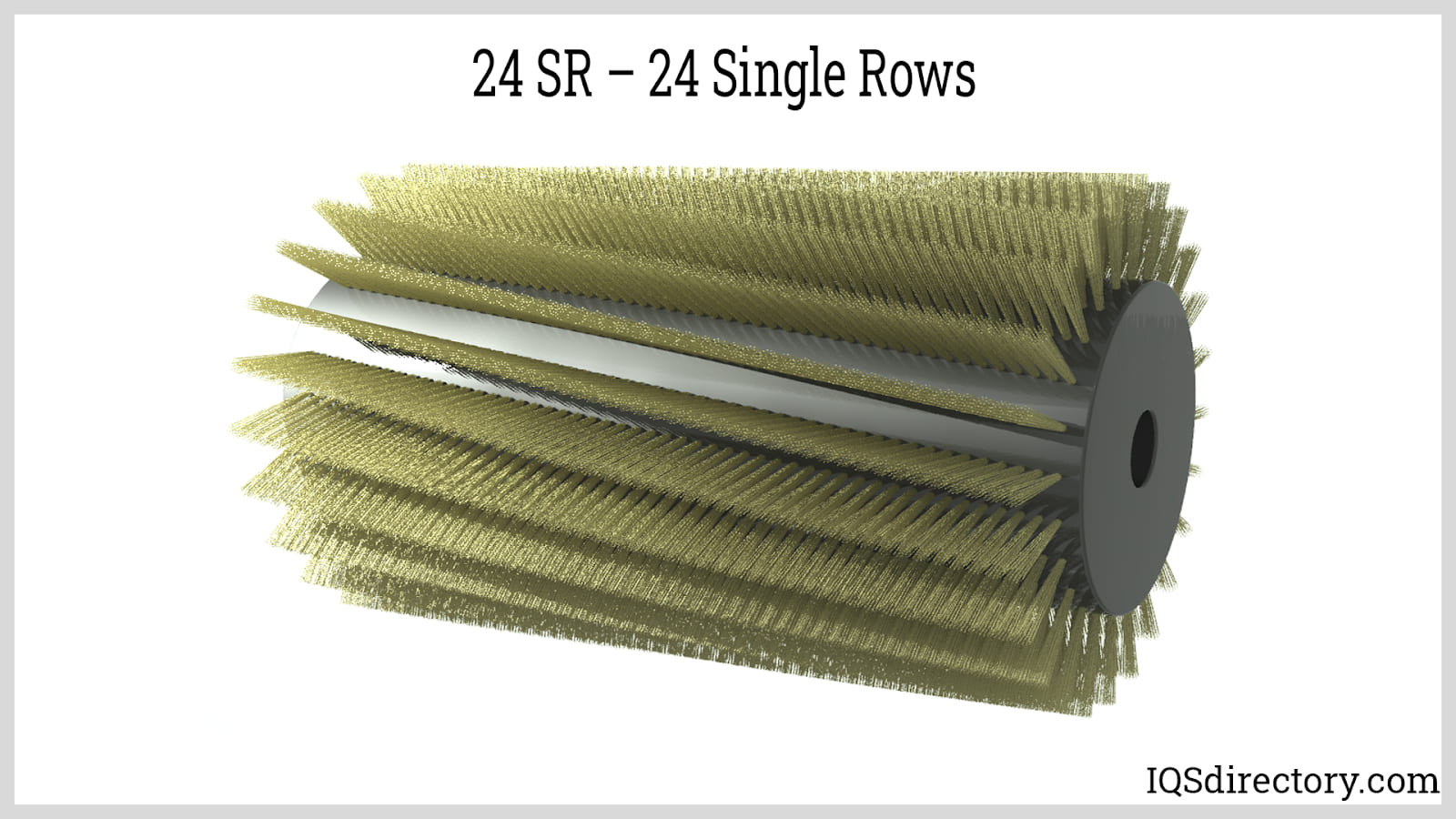

Key Industrial Applications of cylinder brush

| Industry/Sector | Specific Application of Cylinder Brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Cleaning and Maintenance | Floor Scrubbing in Warehouses | Ensures a clean, safe work environment, reducing accidents | Durability of bristles, compatibility with existing equipment |

| Food and Beverage Processing | Equipment Cleaning and Sanitization | Maintains hygiene standards, preventing contamination | Material safety, ease of cleaning, and resistance to chemicals |

| Automotive Manufacturing | Parts Cleaning and Surface Preparation | Enhances product quality and reduces rework costs | Brush stiffness, size, and resistance to wear |

| Mining and Heavy Industry | Conveyor Belt Cleaning | Improves operational efficiency by minimizing downtime | Brush strength, ability to handle abrasive materials |

| Textile Manufacturing | Fabric and Material Cleaning | Enhances fabric quality, reducing defects | Brush material, compatibility with various fabrics |

How is Cylinder Brush Used in Cleaning and Maintenance?

In the cleaning and maintenance sector, cylinder brushes are essential for effective floor scrubbing in warehouses and large facilities. They are designed to remove dirt, grime, and other debris from various surfaces, ensuring a clean and safe work environment. This not only enhances employee safety but also minimizes the risk of accidents caused by slips and falls. Buyers from regions like Africa and South America should prioritize the durability of bristles and ensure compatibility with existing floor scrubbers to maximize efficiency.

What Role Does Cylinder Brush Play in Food and Beverage Processing?

Cylinder brushes are crucial in the food and beverage processing industry for equipment cleaning and sanitization. They help maintain stringent hygiene standards, which are vital for preventing contamination in food products. By effectively removing residues and buildup, these brushes contribute to compliance with health regulations. International buyers, particularly in Europe and the Middle East, should consider sourcing brushes made from food-safe materials that are easy to clean and resistant to harsh chemicals used in sanitization processes.

Why is Cylinder Brush Important in Automotive Manufacturing?

In automotive manufacturing, cylinder brushes are utilized for parts cleaning and surface preparation. They play a critical role in enhancing the quality of finished products by ensuring that surfaces are free from contaminants before assembly or painting. This reduces the likelihood of defects and rework costs. Buyers should focus on brush stiffness and size to ensure they meet the specific cleaning needs of various automotive components, particularly in regions with high manufacturing standards such as Germany.

How Does Cylinder Brush Improve Efficiency in Mining and Heavy Industry?

In mining and heavy industry, cylinder brushes are employed for conveyor belt cleaning. These brushes help remove debris and materials that can accumulate on belts, which is essential for maintaining operational efficiency and minimizing downtime. By ensuring that conveyor systems run smoothly, businesses can significantly reduce operational costs. Buyers should consider the strength and durability of brushes, especially in harsh environments that involve abrasive materials, to ensure longevity and performance.

Illustrative image related to cylinder brush

What is the Application of Cylinder Brush in Textile Manufacturing?

In textile manufacturing, cylinder brushes are vital for cleaning fabrics and materials during production. They help enhance the quality of textiles by removing loose fibers and contaminants, which can lead to defects in the final product. This attention to detail is crucial for maintaining quality standards in competitive markets. Buyers should look for brushes that are compatible with various fabric types and made from materials that will not damage delicate textiles, ensuring optimal performance in their manufacturing processes.

3 Common User Pain Points for ‘cylinder brush’ & Their Solutions

Scenario 1: Sourcing the Right Brush for Specific Cleaning Applications

The Problem: B2B buyers often struggle to find the right cylindrical brush that meets the unique requirements of their cleaning tasks. For instance, a company in the food processing industry may need a brush that is safe for use on delicate surfaces while also being effective at removing stubborn debris. Misjudging the bristle material or brush hardness can lead to inadequate cleaning results or damage to surfaces, causing operational disruptions and increased costs.

The Solution: To address this sourcing challenge, buyers should conduct a thorough needs assessment before making a purchase. Start by evaluating the surfaces that require cleaning—are they hard, soft, or sensitive materials? Next, consult with suppliers to understand the specifications of different brush types, including bristle stiffness and material composition. For example, polypropylene brushes are suitable for tough scrubbing jobs, while softer bristles are ideal for sensitive surfaces. Creating a checklist of requirements based on specific applications can streamline the selection process, ensuring the chosen brushes enhance operational efficiency and reduce the risk of damage.

Scenario 2: Managing Inventory and Lead Times

The Problem: International buyers often face challenges related to inventory management and long lead times, especially when sourcing cylindrical brushes from overseas manufacturers. Delays in receiving essential cleaning equipment can halt operations and impact service delivery, particularly in industries where cleanliness is non-negotiable, such as healthcare or hospitality.

Illustrative image related to cylinder brush

The Solution: To mitigate these risks, buyers should establish a proactive inventory management system that includes safety stock levels for critical items like cylindrical brushes. Communicate with suppliers about their lead times and consider implementing a just-in-time (JIT) inventory approach to ensure brushes arrive as needed without overstocking. Additionally, maintaining relationships with multiple suppliers can provide alternatives if one source experiences delays. It’s also beneficial to inquire about expedited shipping options and possible local distributors to enhance supply chain flexibility, allowing for quicker access to necessary cleaning tools.

Scenario 3: Training Staff on Effective Brush Usage

The Problem: Another common pain point is the lack of proper training for staff on how to effectively use cylindrical brushes, which can lead to inefficient cleaning practices. Inadequate training can result in improper brush application, causing premature wear and tear, ineffective cleaning, or even safety hazards. This is particularly critical in environments such as factories where cleanliness standards are stringent.

The Solution: To resolve this issue, companies should invest in comprehensive training programs for their staff that cover the proper techniques for using cylindrical brushes. This can include practical demonstrations and instructional materials outlining the correct usage for different brushes and surfaces. Consider collaborating with manufacturers who often provide training resources or workshops. Additionally, creating a user manual specific to the types of brushes used in your operation can serve as a quick reference guide for employees. Regular training refreshers can also help maintain high standards and ensure that all staff are updated on best practices, ultimately enhancing cleaning effectiveness and extending the lifespan of the brushes.

Strategic Material Selection Guide for cylinder brush

What Are the Key Materials for Cylinder Brushes?

When selecting materials for cylinder brushes, it is crucial to consider their properties, advantages, limitations, and how they align with specific applications. Here, we analyze four common materials used in the manufacturing of cylinder brushes: polypropylene, nylon, natural bristle, and steel.

Illustrative image related to cylinder brush

How Does Polypropylene Perform in Cylinder Brushes?

Polypropylene is a synthetic polymer known for its resilience and versatility. It boasts excellent resistance to chemicals, moisture, and UV rays, making it suitable for various cleaning applications, especially in environments with harsh chemicals. The temperature resistance of polypropylene typically ranges from -20°C to 80°C (-4°F to 176°F), which is adequate for most industrial cleaning tasks.

Pros: Polypropylene brushes are durable, lightweight, and cost-effective, making them a popular choice for general scrubbing tasks. They are also easy to manufacture, allowing for quicker production times.

Cons: While polypropylene is resistant to many chemicals, it may not withstand extreme temperatures or abrasive environments as well as other materials. Additionally, its rigidity can limit its effectiveness on uneven surfaces.

Impact on Application: Polypropylene brushes are ideal for cleaning floors in warehouses and commercial spaces, where chemical exposure is common. However, they may not be suitable for delicate surfaces that require softer bristles.

Illustrative image related to cylinder brush

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic use. In Europe, adherence to standards like REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is essential.

What Are the Benefits of Nylon in Cylinder Brushes?

Nylon is a synthetic material known for its strength and flexibility. It can handle a wide range of temperatures, typically from -40°C to 90°C (-40°F to 194°F), making it suitable for various industrial applications. Nylon brushes also exhibit good abrasion resistance and can endure high-pressure cleaning processes.

Pros: The flexibility of nylon allows it to conform to surfaces, making it effective for scrubbing uneven or textured areas. It is also resistant to oils and chemicals, which enhances its longevity.

Illustrative image related to cylinder brush

Cons: Nylon brushes can be more expensive than polypropylene options, and they may wear out faster when used in extremely abrasive conditions. Additionally, they can absorb moisture, which may lead to bacterial growth if not properly maintained.

Impact on Application: Nylon brushes are commonly used in food processing and pharmaceutical industries due to their ability to withstand cleaning chemicals and high temperatures.

Considerations for International Buyers: Buyers in the Middle East and Europe should ensure that nylon brushes meet food safety standards, such as FDA regulations in the U.S. or EU food safety directives.

Why Choose Natural Bristle for Cylinder Brushes?

Natural bristle brushes, typically made from animal hair, offer a unique combination of softness and durability. They are particularly effective for delicate cleaning tasks, such as polishing surfaces or cleaning fine materials. Natural bristles can handle temperatures up to 70°C (158°F) but are less resistant to moisture and chemicals.

Pros: The softness of natural bristles makes them ideal for applications requiring gentle cleaning, such as on painted surfaces or delicate machinery. They also provide a high level of absorbency, which can enhance cleaning performance.

Cons: Natural bristle brushes are generally more expensive and may require more maintenance than synthetic options. Their susceptibility to moisture can lead to mold and degradation over time.

Impact on Application: These brushes are well-suited for high-end cleaning applications in industries like automotive detailing or fine furniture care.

Considerations for International Buyers: Buyers from Europe may need to consider animal welfare regulations when sourcing natural bristle products, ensuring compliance with local ethical standards.

How Does Steel Compare in Cylinder Brush Applications?

Steel brushes are known for their durability and strength, making them ideal for heavy-duty applications. They can withstand high temperatures and pressures, typically rated for use up to 400°C (752°F). Steel bristles are effective for removing rust, paint, and other tough residues.

Pros: Steel brushes are highly durable and can handle abrasive cleaning tasks that other materials cannot. They are also relatively inexpensive compared to synthetic options.

Cons: The rigidity of steel can damage softer surfaces, making them unsuitable for delicate applications. Additionally, steel is prone to corrosion if not properly maintained, which can limit its lifespan.

Impact on Application: Steel brushes are commonly used in metalworking and heavy industrial applications where tough cleaning is required.

Considerations for International Buyers: Buyers in regions with high humidity, such as parts of Africa and South America, should consider corrosion resistance and maintenance requirements when selecting steel brushes.

Illustrative image related to cylinder brush

Summary of Material Selection for Cylinder Brushes

| Material | Typical Use Case for cylinder brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | General scrubbing in commercial spaces | Durable, lightweight, cost-effective | Limited temperature resistance | Low |

| Nylon | Food processing and pharmaceutical industries | Flexible, good abrasion resistance | Higher cost, moisture absorption | Medium |

| Natural Bristle | Automotive detailing and fine furniture care | Soft, effective for delicate tasks | Expensive, moisture susceptibility | High |

| Steel | Heavy-duty industrial cleaning | Extremely durable | Can damage soft surfaces, prone to corrosion | Medium |

This guide provides a comprehensive overview of material options for cylinder brushes, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

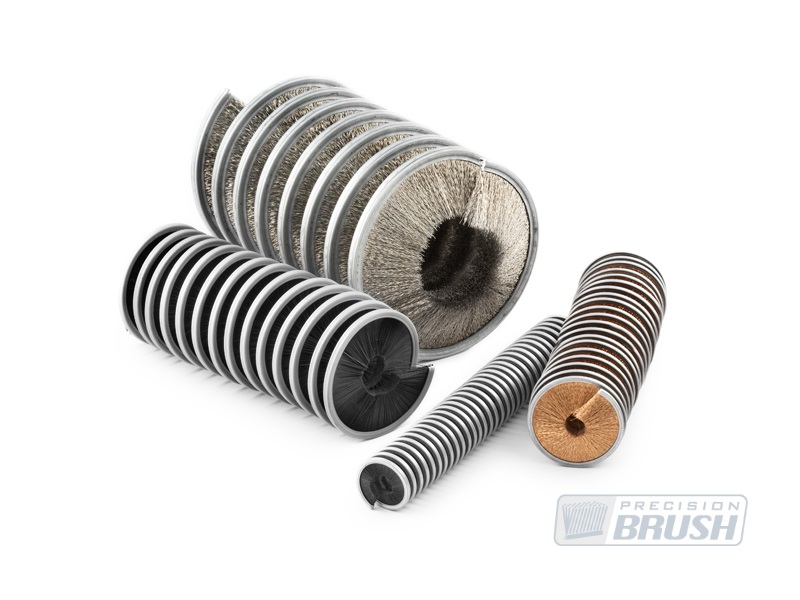

In-depth Look: Manufacturing Processes and Quality Assurance for cylinder brush

What Are the Key Stages in the Manufacturing Process of Cylinder Brushes?

The manufacturing of cylinder brushes involves several critical stages that ensure the final product meets the high standards required in various industries. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: What Materials Are Used and How Are They Processed?

The first step in the manufacturing process is material preparation. Cylinder brushes can be made from various materials, including natural and synthetic fibers, plastics, and metals. Common bristle materials include polypropylene, nylon, and natural fibers like horsehair or sisal. Each material has its own properties that suit different applications, such as durability, flexibility, and resistance to chemicals.

Once the materials are selected, they undergo a series of processes. For synthetic fibers, extrusion is a common technique where the raw material is melted and shaped into long strands. Natural fibers may require washing and conditioning to enhance their performance. Quality control measures at this stage often include verifying the material specifications and conducting preliminary tests for strength and durability.

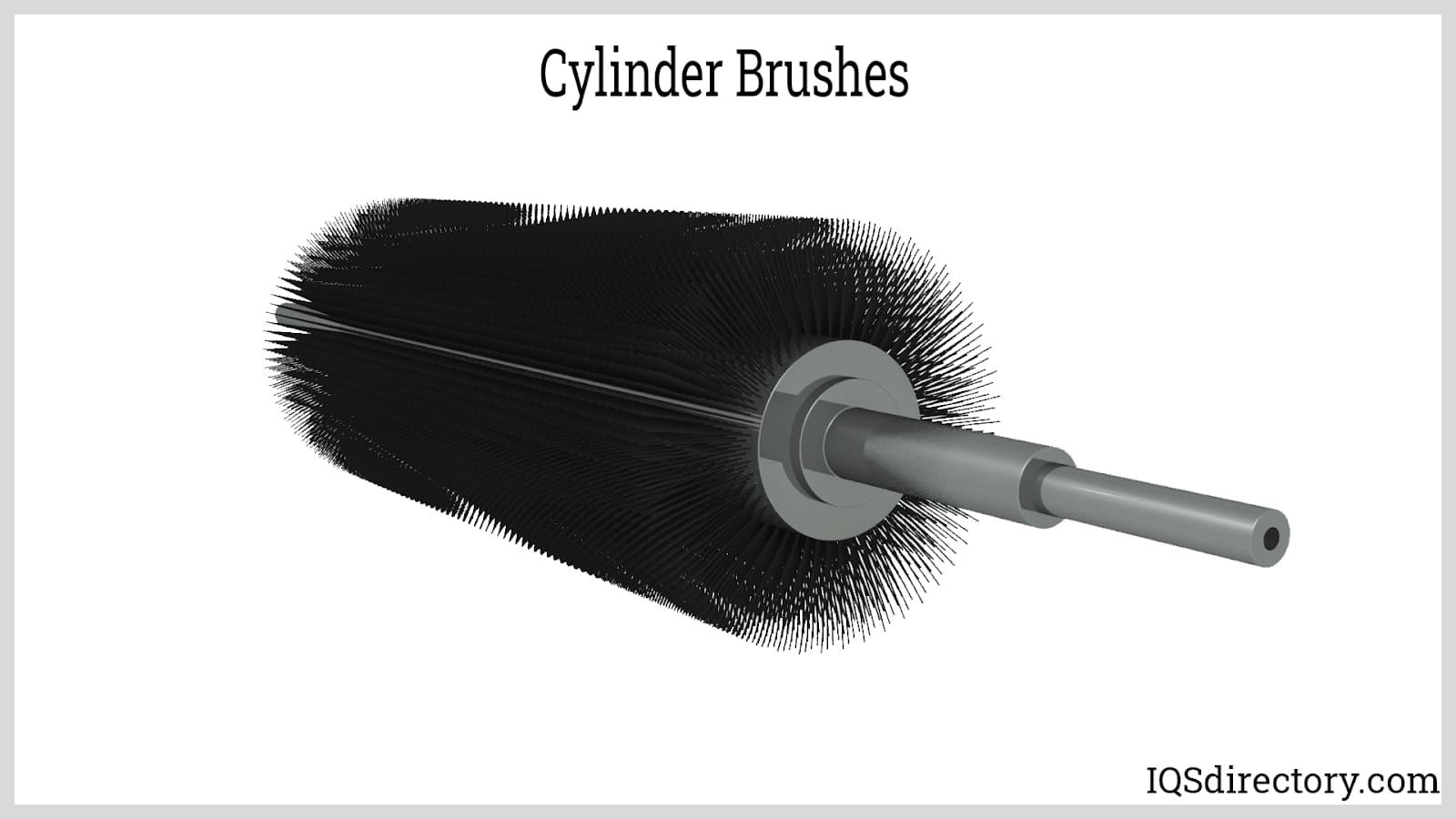

How Are Cylinder Brushes Formed and Assembled?

After material preparation, the next stage is forming. This involves cutting the bristles to the desired length and shaping the brush core, which can be made from plastic or metal, depending on the application. The bristles are then inserted into the core using various methods, such as tufting or embedding.

Illustrative image related to cylinder brush

In tufting, bristles are inserted into holes in the core and secured using adhesive or mechanical fasteners. The assembly process may also involve adding features such as a mounting hub or a protective casing. During this stage, manufacturers must ensure that bristle density and alignment are consistent to guarantee optimal performance.

What Finishing Techniques Are Commonly Used for Cylinder Brushes?

Finishing is the final stage of the manufacturing process. This includes processes such as trimming, shaping, and surface treatment. For instance, brushes may be trimmed to achieve a specific profile that enhances their cleaning efficiency. Surface treatments may involve coating the brush with materials that improve its resistance to wear or chemical exposure.

At this stage, quality assurance teams conduct final inspections to ensure that the brushes meet specifications. This can include visual inspections, dimensional checks, and functional tests to confirm that the brushes perform as intended.

What Quality Assurance Standards Are Relevant for Cylinder Brushes?

Quality assurance is vital in the manufacturing of cylinder brushes to ensure they meet international standards and customer requirements. For B2B buyers, understanding these standards is crucial for supplier evaluation.

Which International Standards Should Buyers Look For?

ISO 9001 is one of the most recognized quality management standards globally. Compliance with this standard indicates that the manufacturer has established a quality management system (QMS) that meets customer and regulatory requirements. In addition to ISO 9001, industry-specific certifications like CE marking for products sold in Europe and API standards for industrial applications may also be relevant.

For buyers in Africa, South America, the Middle East, and Europe, understanding local regulations and standards is essential. Compliance with these standards not only ensures product quality but also facilitates smoother importation and distribution processes.

How Is Quality Control Implemented Throughout the Manufacturing Process?

Quality control (QC) is implemented at multiple checkpoints throughout the manufacturing process. These checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

Illustrative image related to cylinder brush

What Are the Main QC Checkpoints?

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications. This may involve testing material properties, dimensions, and any certifications provided by suppliers.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself. Regular checks during the forming and assembly stages ensure that any deviations from specifications are caught early. This can include dimensional checks and assessments of bristle alignment and density.

-

Final Quality Control (FQC): Before the products are shipped, FQC ensures that the final product meets all specifications and quality standards. This may include functionality tests, such as scrubbing performance and durability assessments.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should conduct thorough due diligence. This can include:

- Supplier Audits: Regular audits of manufacturing facilities can provide insights into the supplier’s quality management practices and adherence to standards.

- Quality Reports: Requesting detailed quality reports, including test results and compliance certifications, can help verify that the supplier meets required standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control processes and product quality.

What Are the Common Testing Methods Used for Cylinder Brushes?

Testing methods for cylinder brushes can vary based on their intended application. Common testing methods include:

- Mechanical Testing: Assessing the strength and elasticity of bristles to ensure they can withstand operational stresses.

- Chemical Resistance Testing: Evaluating how well the materials hold up against various cleaning agents and chemicals.

- Performance Testing: This includes simulating actual cleaning scenarios to determine the effectiveness of the brushes.

How Do Quality Control Nuances Affect International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control can be a key differentiator in supplier selection. Factors such as local regulations, certification requirements, and the reliability of logistics and supply chains can impact the overall quality of the products received.

Buyers should also consider the implications of cultural differences in manufacturing practices. For instance, suppliers in regions like Africa and South America may have different approaches to quality assurance compared to those in Europe. Establishing clear communication and setting expectations can help mitigate potential issues related to quality.

Illustrative image related to cylinder brush

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance standards for cylinder brushes enables B2B buyers to make informed decisions when selecting suppliers. By focusing on material preparation, forming, assembly, finishing, and rigorous quality control measures, buyers can ensure that they procure high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cylinder brush’

Introduction

Sourcing the right cylinder brush is critical for ensuring efficient cleaning and maintenance operations across various industries. This guide provides a comprehensive checklist to assist B2B buyers in navigating the procurement process, ensuring they select a product that meets their specific needs while fostering strong supplier relationships.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it’s essential to clearly outline your technical requirements. Consider the type of surfaces the cylinder brush will be used on, the level of abrasiveness required, and the compatibility with your existing equipment.

– Material Considerations: Different materials (polypropylene, nylon, etc.) offer varying durability and cleaning capabilities.

– Size and Shape: Ensure the brush dimensions align with your cleaning machinery for optimal performance.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is crucial in securing quality products. Conduct thorough research to compile a list of potential vendors.

– Industry Experience: Look for suppliers with a proven track record in supplying cylinder brushes to your specific sector.

– Customer Reviews: Explore online reviews and testimonials to gauge the reliability and service levels of potential suppliers.

Illustrative image related to cylinder brush

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is a key step in ensuring product quality and compliance with industry standards.

– Quality Assurance: Request documentation related to ISO or other relevant certifications to ensure the supplier adheres to high-quality manufacturing processes.

– Environmental Compliance: Check for certifications that demonstrate adherence to environmental regulations, which can be particularly important in certain markets.

Step 4: Request Samples for Testing

Before finalizing your order, requesting product samples is a prudent practice. Testing samples allows you to assess the performance of the cylinder brush in real-world conditions.

– Performance Evaluation: Evaluate the brush’s effectiveness on the surfaces you intend to clean.

– Durability Testing: Monitor how the brush holds up over time under your specific operational conditions.

Step 5: Negotiate Pricing and Terms

Once you have identified a preferred supplier, engage in pricing negotiations to secure the best deal.

– Bulk Purchase Discounts: Inquire about pricing tiers based on order volume, which can significantly reduce costs.

– Payment Terms: Establish clear payment terms to manage cash flow effectively.

Step 6: Confirm Shipping and Delivery Timelines

Understanding shipping logistics is vital to ensure timely product availability.

– Lead Times: Confirm the expected delivery timeframes, especially if you’re working with suppliers located internationally.

– Shipping Costs: Factor in shipping costs to your overall budget, as these can vary significantly based on the supplier’s location and shipping methods.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your supplier for ongoing support and future orders.

– Regular Check-ins: Schedule periodic updates to discuss product performance and address any issues.

– Feedback Mechanism: Encourage feedback on the products received to foster a collaborative relationship that can lead to improved offerings in the future.

Illustrative image related to cylinder brush

By following this detailed checklist, B2B buyers can streamline their sourcing process for cylinder brushes, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for cylinder brush Sourcing

What Are the Key Cost Components in Cylinder Brush Manufacturing?

When analyzing the cost structure of cylinder brushes, several core components contribute to the overall pricing. Materials typically account for a significant portion of expenses, as the type of bristles (e.g., polypropylene, nylon, or natural fibers) and the brush core material can vary widely in cost. Labor costs are also essential, including the wages of workers involved in both assembly and quality control.

Manufacturing overhead encompasses utilities, facility costs, and equipment maintenance, which can fluctuate based on production volume. Tooling expenses are incurred for specialized equipment and molds needed for customized brushes. Additionally, quality control (QC) processes ensure that products meet industry standards, adding to the cost. Finally, logistics—including transportation, warehousing, and customs duties—play a crucial role, especially for international buyers. The desired profit margin is added on top of these costs to determine the final price.

How Do Price Influencers Impact Cylinder Brush Costs?

Several factors can influence the pricing of cylinder brushes significantly. Volume and Minimum Order Quantity (MOQ) are critical; larger orders often qualify for discounts, thus lowering the per-unit cost. Specifications and customization can also impact price; specialized brushes designed for unique applications generally command higher prices due to the additional resources required.

The materials used in production affect cost variably, with high-performance or specialty materials costing more. Furthermore, the quality and certifications of the brushes can influence pricing, as products that meet higher standards or certifications (e.g., ISO, CE) are typically more expensive. Supplier factors, such as reliability and reputation, can also play a role; established suppliers may charge a premium for their products. Lastly, understanding Incoterms is crucial for international transactions, as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect the total cost.

What Tips Can Help Buyers Negotiate Better Pricing for Cylinder Brushes?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider several strategies to negotiate better pricing on cylinder brushes. First, emphasizing volume purchases can lead to substantial discounts, so consolidating orders may be beneficial.

It’s also wise to be transparent about cost-efficiency goals. By discussing long-term partnerships, buyers may secure better pricing and terms. Understanding the Total Cost of Ownership (TCO)—including maintenance, lifespan, and operational costs—can provide leverage during negotiations.

Buyers should also be aware of pricing nuances specific to their regions. For example, currency fluctuations can significantly impact costs, so negotiating prices in a stable currency may mitigate risks. Additionally, factoring in local tariffs and import duties is essential for accurate budgeting.

What Should Buyers Keep in Mind Regarding Pricing?

While it is crucial to consider these factors, buyers should be mindful that the prices provided by suppliers are often indicative and can fluctuate based on market conditions. Therefore, requesting quotes from multiple suppliers and comparing offers is prudent.

Establishing a robust relationship with suppliers can lead to better terms and insights into upcoming price changes. Ultimately, being informed about the cost structure and pricing influencers will empower buyers to make strategic sourcing decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing cylinder brush With Other Solutions

Understanding Alternative Solutions to Cylinder Brushes

In the realm of industrial cleaning and maintenance, cylinder brushes have established themselves as a reliable solution for various scrubbing and cleaning tasks. However, businesses must often evaluate alternative technologies or methods that may offer unique advantages depending on their specific needs. This section explores cylinder brushes alongside two viable alternatives: rotary floor scrubbers and microfiber mops, providing a comprehensive comparison to help B2B buyers make informed decisions.

Comparison of Cylinder Brush and Alternative Solutions

| Comparison Aspect | Cylinder Brush | Rotary Floor Scrubber | Microfiber Mop |

|---|---|---|---|

| Performance | Effective for tough scrubbing on uneven surfaces | High-efficiency on flat surfaces | Good for light cleaning and dusting |

| Cost | Moderate initial investment, long-term durability | Higher upfront costs, but efficient | Low cost, but needs frequent replacement |

| Ease of Implementation | Requires compatible machines, but easy to install | Usually comes as a complete unit | Simple to use, no setup required |

| Maintenance | Requires regular replacement of brushes | Needs routine maintenance and parts replacement | Minimal maintenance, wash and reuse |

| Best Use Case | Ideal for industrial settings with heavy soil | Suitable for large, flat areas like warehouses | Great for light-duty cleaning in offices and homes |

Pros and Cons of Alternative Solutions

Rotary Floor Scrubber

Rotary floor scrubbers use a rotating disk to clean surfaces efficiently. They excel in large commercial environments, like warehouses and supermarkets, due to their ability to cover extensive areas quickly. The downside is the higher initial investment and maintenance costs associated with the machinery. Additionally, they may not perform as well on uneven surfaces compared to cylinder brushes.

Microfiber Mop

Microfiber mops are an economical choice for light cleaning tasks. They are easy to use and maintain, making them popular in office environments and smaller facilities. The major limitation is their effectiveness; they may not handle heavy soil or grime as efficiently as cylinder brushes. Frequent replacement of mop heads can also add to long-term costs, particularly in high-traffic areas.

Making the Right Choice for Your Business Needs

When choosing between cylinder brushes, rotary floor scrubbers, and microfiber mops, B2B buyers should carefully consider their specific cleaning requirements and operational contexts. Cylinder brushes are optimal for industrial settings where robust scrubbing power is essential, while rotary floor scrubbers can streamline cleaning processes in larger, flat areas. On the other hand, microfiber mops offer a cost-effective solution for lighter cleaning tasks in less demanding environments. By assessing performance, cost, and maintenance needs, businesses can select the most suitable cleaning solution to enhance their operational efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for cylinder brush

What Are the Key Technical Properties of a Cylinder Brush?

When sourcing cylinder brushes, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

Illustrative image related to cylinder brush

-

Material Composition

Cylinder brushes are commonly made from materials like polypropylene, nylon, or natural fibers. The choice of material affects durability, flexibility, and cleaning effectiveness. For instance, polypropylene brushes are excellent for heavy-duty scrubbing, while softer materials are more suitable for delicate surfaces. Selecting the right material ensures that the brush meets the specific cleaning needs of various floor types. -

Bristle Hardness

Bristle hardness is categorized as soft, medium, or hard. This specification determines the aggressiveness of the brush during cleaning. Soft bristles are ideal for sensitive surfaces, while hard bristles are better for tough, soiled areas. Understanding bristle hardness helps businesses select the appropriate brush for their cleaning applications, enhancing operational efficiency. -

Diameter and Length

The diameter and length of a cylinder brush can significantly impact its performance. A larger diameter often allows for greater surface coverage, while the length can influence maneuverability. Businesses should assess the dimensions required for their specific equipment and cleaning tasks to ensure optimal performance. -

Operating Temperature Range

Some applications may expose brushes to extreme temperatures. Knowing the operating temperature range helps in selecting a brush that maintains its integrity under various conditions. This is particularly important for industries where heat is a factor, ensuring that brushes do not degrade or lose effectiveness over time. -

Compatibility with Equipment

It’s essential to ensure that the selected cylinder brush is compatible with existing equipment, such as floor scrubbers. Compatibility affects installation ease and operational efficiency. Buyers should verify specifications like SKU numbers or model compatibility to avoid purchasing errors that could lead to increased costs.

What Are Common Trade Terminologies in the Cylinder Brush Industry?

Familiarity with industry jargon can streamline the procurement process and enhance communication with suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. In the context of cylinder brushes, buyers often seek OEM brushes to ensure compatibility and quality that meets the original equipment standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of product that a supplier is willing to sell. Understanding MOQ is critical for businesses to manage inventory costs effectively. Buyers should negotiate MOQs that align with their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For cylinder brushes, issuing an RFQ allows businesses to compare quotes from multiple suppliers, ensuring competitive pricing and favorable terms. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions, such as shipping costs and risk. Familiarity with these terms helps businesses navigate the complexities of global trade, ensuring clarity in contracts and minimizing disputes. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is received. Understanding lead times is essential for planning and inventory management. Businesses must consider lead times when scheduling cleaning operations to avoid delays. -

Custom Brush Design

Some suppliers offer custom brush designs tailored to specific applications. This term is vital for companies with unique cleaning requirements. Engaging in custom design can lead to enhanced performance and efficiency in cleaning tasks, providing a competitive advantage.

Understanding these technical properties and trade terminologies can empower B2B buyers to make informed decisions, optimize their cleaning processes, and strengthen supplier relationships in the cylinder brush market.

Navigating Market Dynamics and Sourcing Trends in the cylinder brush Sector

What Are the Current Market Dynamics and Key Trends Influencing the Cylinder Brush Sector?

The cylinder brush market is experiencing significant growth, driven by various global factors, including industrial automation, increasing demand for efficient cleaning solutions, and the rise of environmentally-friendly products. As industries worldwide—especially in Africa, South America, the Middle East, and Europe—continue to modernize their cleaning processes, the need for high-quality cylindrical brushes has surged. Key players are investing in advanced manufacturing technologies, such as automation and robotics, to enhance production efficiency and product quality.

Illustrative image related to cylinder brush

Emerging trends indicate a shift towards customization, with manufacturers offering tailored solutions to meet specific industry needs. For instance, businesses in the food processing sector require brushes that can handle abrasive cleaning without damaging surfaces, while those in the automotive sector may prioritize brushes designed for heavy-duty applications. Additionally, the integration of smart technologies in cleaning equipment is becoming more prevalent, enabling better performance tracking and maintenance scheduling, which can appeal to tech-savvy buyers.

International buyers are also navigating complex supply chains, often seeking suppliers who can provide not only quality products but also reliable delivery timelines and competitive pricing. This is particularly vital in markets like Brazil and Germany, where operational efficiency is paramount. As companies increasingly focus on sustainability, the demand for brushes made from recycled or eco-friendly materials is expected to rise, urging manufacturers to innovate their product offerings.

How Are Sustainability and Ethical Sourcing Shaping the Cylinder Brush Industry?

Sustainability is becoming a cornerstone of the cylinder brush industry, with buyers increasingly prioritizing environmentally responsible sourcing practices. This shift is largely driven by regulatory pressures and consumer demand for green products. For international B2B buyers, understanding the environmental impact of their sourcing decisions is crucial. Suppliers that demonstrate a commitment to sustainable practices—such as utilizing recyclable materials or adopting energy-efficient manufacturing processes—are more likely to stand out in the marketplace.

Ethical sourcing is equally important, as businesses strive to ensure their supply chains are free from exploitation and environmental degradation. Certifications such as ISO 14001 (Environmental Management) and other eco-labels can serve as indicators of a manufacturer’s commitment to sustainability. Buyers should look for suppliers who not only comply with these standards but actively participate in initiatives aimed at reducing their carbon footprint.

The cylinder brush sector is witnessing a growing trend towards the use of natural fibers and biodegradable materials, which not only meet cleaning requirements but also align with the values of environmentally-conscious companies. By prioritizing suppliers with sustainable practices, businesses can enhance their brand reputation and appeal to a broader customer base.

What Is the Historical Context Behind the Development of the Cylinder Brush Sector?

The cylinder brush has evolved significantly since its inception, initially being a simple tool for manual cleaning. The industrial revolution marked a turning point, introducing mechanized cleaning equipment that integrated cylindrical brushes for more efficient operations. Over the decades, advancements in materials science and manufacturing techniques have led to the development of specialized brushes that cater to various industries, including automotive, food processing, and commercial cleaning.

As global markets expanded and technological innovations emerged, the cylinder brush sector adapted to meet the changing demands of industrial cleaning. Today, these brushes are engineered with precision, utilizing a range of materials—from synthetic bristles for durability to softer options for sensitive surfaces—allowing for versatile applications across diverse sectors. The ongoing evolution of the cylinder brush reflects broader trends in industrial efficiency and sustainability, positioning it as an essential tool in modern cleaning solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cylinder brush

-

How do I choose the right cylindrical brush for my cleaning equipment?

Choosing the right cylindrical brush depends on several factors, including the type of surface you are cleaning, the level of dirt or grime, and the specific cleaning machine you are using. For hard surfaces like concrete or tile, a medium to hard bristle brush is ideal. Conversely, for softer surfaces or delicate flooring, opt for softer bristles to prevent damage. Always ensure compatibility with your cleaning equipment model to maximize efficiency and cleaning effectiveness. -

What are the advantages of using cylindrical brushes in industrial cleaning?

Cylindrical brushes offer several advantages in industrial cleaning, such as superior dirt removal and effective scrubbing action due to their design. They provide consistent pressure across the surface, ensuring thorough cleaning. Additionally, they can be easily replaced and customized for various tasks, making them versatile for different cleaning applications. This efficiency can lead to reduced labor costs and improved overall cleanliness in facilities. -

What is the typical lead time for ordering cylindrical brushes internationally?

Lead times for international orders of cylindrical brushes can vary based on the manufacturer, shipping method, and destination. Generally, you can expect a lead time ranging from 2 to 8 weeks. It’s crucial to discuss timelines with your supplier upfront and consider factors like customs clearance and potential delays in shipping. Establishing a clear timeline helps in planning your inventory and ensuring your cleaning operations remain uninterrupted. -

How can I vet suppliers for cylindrical brushes?

To vet suppliers, conduct thorough research by checking their company history, customer reviews, and product quality certifications. Request samples to evaluate the brush quality firsthand. Additionally, inquire about their manufacturing processes, material sourcing, and compliance with international standards. Establishing communication and asking for references from other businesses can also provide insights into their reliability and service quality. -

Are cylindrical brushes customizable for specific cleaning applications?

Yes, many manufacturers offer customization options for cylindrical brushes to meet specific cleaning needs. You can adjust factors such as bristle material, length, and stiffness based on the surfaces you intend to clean. Communicate your requirements clearly to the supplier, and they can help design a brush that enhances cleaning efficiency for your particular application, whether it’s for industrial, commercial, or specialized use. -

What are the minimum order quantities (MOQs) for cylindrical brushes?

Minimum order quantities for cylindrical brushes can vary significantly among suppliers. Typically, MOQs range from 10 to 100 units, depending on the brush type and manufacturer. Some suppliers may offer lower MOQs for standard brushes, while custom orders often require larger quantities. It’s advisable to discuss MOQs during your initial negotiations to ensure they align with your purchasing capabilities and budget. -

What payment terms should I expect when sourcing cylindrical brushes?

Payment terms vary by supplier and may include options such as upfront payment, net 30/60/90 days, or letters of credit. It’s essential to discuss and agree on payment terms before placing an order. Some suppliers may require a deposit for large orders, while others may offer flexible terms for established clients. Understanding payment conditions can help manage cash flow and ensure a smooth transaction process. -

How do I ensure quality assurance for cylindrical brushes?

To ensure quality assurance, request detailed specifications and certifications from your supplier regarding the materials and manufacturing processes used for the cylindrical brushes. Implementing a quality control checklist during the ordering process can help you assess the brushes upon arrival. Additionally, consider setting up a quality assurance agreement with the supplier to outline expectations and procedures for addressing any defects or issues that may arise.

Top 8 Cylinder Brush Manufacturers & Suppliers List

1. Tornado – Blue Hard Bristle Floor Scrubbing Brush

Domain: floorscrubbers.com

Registered: 1998 (27 years)

Introduction: Cylindrical Brushes available for various floor scrubbers. Key products include: 1. Blue Hard Bristle Floor Scrubbing Brush (#33857) for Tornado® BR 13/1 Auto Scrubber – Price: $117.99, In Stock, good for tough scrubbing jobs, requires 2 per scrubber. 2. Side Edge Scrubbing Brush (#33858) for Tornado® BR 13/1 – Price: $67.99, In Stock, good for everyday scrubbing, will not harm tiled surfaces. 3. …

2. Justman – Graduated Cylinder Brushes

Domain: justmanbrush.com

Introduction: Graduated Cylinder Brushes are designed for cleaning graduated cylinders and other containers such as bottles, growlers, bowls, and small tanks. Made in the USA with nylon filaments, these brushes are available in various sizes and lengths. The brushes come in diameters from 5/8″ to 4 ¼” and lengths from 12″ to 28″. They can clean graduated cylinders of sizes 10ml, 25ml, 50ml, 100ml, 250ml, 500ml,…

3. Spiral Brushes – Cylinder & Conveyor Cleaning Solutions

Domain: spiralbrushes.com

Registered: 1998 (27 years)

Introduction: Cylinder Brushes and Conveyor Cleaning Brushes: Types include Steel, Stainless Steel, Brass, Bronze, Nylon, Abrasive Nylon, Polyester, Polypropylene, and Tampico. Applications span agriculture, bakery ovens, battery production, concrete cleaning, fiberglass insulation, foundry sand conveyors, glass cleaning, industrial ovens, metal fabricating, paper mills, oil & gas pipeline inspection, primary m…

4. Gordon Brush – Tufted Cylinder Brushes

Domain: gordonbrush.com

Introduction: Tufted Cylinder Brushes

– Type: 6.0 crimped natural Nylon staple set into high grade ABS plastic core.

– Features: Low-density roller brush face helps reduce brush loading.

– Primary Use: Printed circuit board industry.

– Available Sizes: Other cylinder brush sizes are available.

– Fill Materials: Nylon, Polypropylene, Tampico.

– Core Materials: ABS, HDPE, PVC.

– Inner Diameter Options: 0.985″ [25…

5. Precision Brush – Cylinder Brushes

Domain: precisionbrush.com

Registered: 1997 (28 years)

Introduction: Cylinder brushes, also known as rotary brushes, wound brushes, cylindrical brushes, spiral brushes, and coil brushes, are motorized and spin during operation. They are constructed based on operating RPM, quantity, and specifications. Metal channel cylinder brushes are economical, formed by winding straight metal channel brushes around a mandrel, with sizes ranging from 0.75″ to 12″ in diameter. Th…

6. Tanis Brush – Cylindrical Conveyor Brushes

Domain: tanisbrush.com

Registered: 2006 (19 years)

Introduction: Cylindrical conveyor brushes are versatile tools designed for cleaning and material handling on conveyor systems. They help keep production lines smooth and efficient, reducing downtime and increasing productivity. Types include: Spiral Brushes (light to medium-duty applications), Straight Brushes (heavy-duty cleaning and material transport), and Custom Brushes (tailored to specific needs). Applic…

7. Flinn Scientific – Cylinder Cleaning Brush

Domain: flinnsci.com

Registered: 1997 (28 years)

Introduction: {“item_number”:”AP8204″,”price”:”$6.92″,”availability”:”In Stock”,”overall_length”:”20 inches”,”bristle_length”:”7 inches”,”bristle_diameter”:”2.5 inches”,”usage”:”Cleaning cylinders or tubes from 1¼ inch to 2¼ inch inside diameter”}

8. Hach – Cylinder Brush 2-Inch Diameter

Domain: hach.com

Registered: 1995 (30 years)

Introduction: Brush, cylinder, 2-in diameter for general glassware

Strategic Sourcing Conclusion and Outlook for cylinder brush

What Are the Key Takeaways for Strategic Sourcing of Cylinder Brushes?

In the competitive landscape of industrial cleaning solutions, strategic sourcing of cylinder brushes is essential for optimizing operational efficiency and ensuring product quality. Understanding the diverse range of cylindrical brushes available, from varying bristle types to specific applications, allows B2B buyers to select the right products tailored to their unique needs. By leveraging local suppliers, particularly in regions such as Africa, South America, the Middle East, and Europe, businesses can reduce lead times and enhance supply chain resilience.

Illustrative image related to cylinder brush

Why Is Strategic Sourcing Crucial for B2B Buyers?

Effective sourcing strategies not only improve cost-effectiveness but also foster strong supplier relationships, which are vital for consistent quality and innovation. As industries evolve, staying informed about the latest developments in brush technology and cleaning solutions can provide a competitive edge.

How Can International Buyers Prepare for Future Trends?

Looking ahead, B2B buyers should remain proactive in exploring sustainable options and innovations in cleaning technology. Engaging with suppliers who prioritize eco-friendly practices will not only align with global sustainability goals but also meet the increasing demand from customers for greener solutions.

Investing time in strategic sourcing today will pave the way for successful partnerships and a cleaner, more efficient tomorrow. Embrace the opportunity to refine your sourcing strategy, and connect with reliable suppliers who can support your business objectives in the evolving market landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.