Crocs No Holes: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for crocs no holes

In the ever-evolving global market, sourcing high-quality footwear like Crocs without holes can pose significant challenges for B2B buyers. From ensuring comfort and functionality to meeting the specific demands of various industries, the task can seem daunting. This comprehensive guide aims to address these challenges by providing an in-depth exploration of Crocs no holes, covering essential topics such as product types, applications across different sectors, supplier vetting processes, and cost considerations.

Understanding the unique needs of international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and Vietnam—this guide equips decision-makers with the insights necessary for informed purchasing. Whether you’re catering to the hospitality industry, healthcare, or casual wear markets, the guide offers actionable strategies to identify reliable suppliers and evaluate product quality effectively.

By the end of this guide, you will be empowered to navigate the complexities of sourcing Crocs without holes, ensuring that your purchasing decisions align with both your business objectives and the preferences of your end customers. From understanding market trends to leveraging supplier relationships, this resource is designed to enhance your competitive edge in the global footwear market.

Understanding crocs no holes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Work Clog | Slip-resistant tread, adjustable backstrap, waterproof design | Food service, healthcare, hospitality | Pros: Exceptional comfort and support for long shifts; easy to clean. Cons: Limited style options may not appeal to all. |

| Classic Lined Clog | Fleece lining for added warmth, enclosed toe design | Winter wear, healthcare, casual use | Pros: Provides warmth and comfort; suitable for colder climates. Cons: Higher maintenance due to lining. |

| Classic Sandal | Open-toe design, lightweight, and flexible | Casual wear, outdoor activities | Pros: Breathable and suitable for warm climates; easy to wear. Cons: Less foot protection compared to clogs. |

| Calzuro Classic Clog | Fully enclosed, professional-grade materials, available in various colors | Healthcare, food service | Pros: Durable and stylish; offers excellent support. Cons: Higher price point may deter budget-conscious buyers. |

| Baya Clog | Sleek design, slightly narrower fit, various color options | Retail, casual wear | Pros: Trendy design appealing to younger demographics; lightweight. Cons: May not offer the same level of support as work clogs. |

What Are the Key Characteristics of the Classic Work Clog?

The Classic Work Clog is designed for professionals in demanding environments. Its features include a slip-resistant tread, adjustable backstrap, and waterproof upper, making it an ideal choice for food service and healthcare workers. When considering bulk purchases, buyers should evaluate the durability and ease of cleaning, as these factors significantly impact long-term value.

How Does the Classic Lined Clog Suit Different B2B Needs?

The Classic Lined Clog offers warmth and comfort with its fleece lining, making it suitable for colder climates and professionals who work in chilly environments. Its enclosed toe design also provides additional protection. B2B buyers should consider the maintenance requirements of lined footwear, as they may need more frequent cleaning compared to non-lined models, potentially affecting operational costs.

Why Choose the Classic Sandal for Outdoor Applications?

The Classic Sandal features an open-toe design that enhances breathability, making it perfect for casual wear and outdoor activities. Its lightweight and flexible build cater to those in warmer climates. However, B2B buyers should weigh the need for foot protection against the benefits of comfort and style, especially in industries where safety is paramount.

Illustrative image related to crocs no holes

What Makes Calzuro Classic Clogs a Professional Choice?

Calzuro Classic Clogs are made from professional-grade materials and come in various colors, appealing to a wide range of industries, particularly healthcare and food service. Their fully enclosed design ensures foot protection while maintaining comfort. Buyers should consider the initial investment, as these clogs are priced higher but offer durability and style that can enhance workplace professionalism.

How Does the Baya Clog Appeal to Retail and Casual Markets?

The Baya Clog features a sleek design and a slightly narrower fit, making it a trendy option for casual wear. Its various color options appeal to younger demographics, making it a popular choice in retail environments. While the Baya Clog is lightweight and stylish, B2B buyers should consider whether it meets the specific comfort and support needs of their workforce, especially for extended wear.

Key Industrial Applications of crocs no holes

| Industry/Sector | Specific Application of crocs no holes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Footwear for healthcare professionals | Enhanced comfort during long shifts, slip-resistant | Compliance with safety standards, ease of cleaning, bulk ordering options |

| Food Service | Non-slip footwear for kitchen staff | Reduces the risk of slips and falls, easy to clean | Durability, waterproof features, style variety for branding |

| Hospitality | Comfortable shoes for hotel staff | Improves employee satisfaction and productivity | Customization options, bulk discounts, availability of sizes |

| Retail | Casual footwear for employees in retail environments | Promotes comfort while standing for extended hours | Style diversity, seasonal collections, flexibility in order size |

| Agriculture | Protective footwear for farm workers | Offers protection against spills and contaminants | Durability, ease of maintenance, availability in various sizes |

How Are ‘Crocs No Holes’ Used in Healthcare Settings?

In the healthcare sector, Crocs without holes serve as essential footwear for professionals who spend long hours on their feet, such as nurses and doctors. These clogs are designed with slip-resistant soles and waterproof materials, which help prevent slips in wet environments and maintain hygiene. For international buyers, especially in regions like Africa and the Middle East, sourcing must consider local healthcare regulations and the specific needs of healthcare workers, such as comfort and ease of cleaning.

What Role Do ‘Crocs No Holes’ Play in Food Service?

In food service, Crocs without holes are invaluable for kitchen staff, where safety and hygiene are paramount. The slip-resistant tread minimizes the risk of accidents in busy kitchen environments, while the waterproof design allows for easy cleanup after spills. For businesses in South America and Europe, sourcing should focus on bulk purchasing options and compliance with food safety standards to ensure the footwear meets industry requirements.

Illustrative image related to crocs no holes

How Are ‘Crocs No Holes’ Beneficial in Hospitality?

For the hospitality industry, Crocs without holes provide hotel staff with comfortable footwear that can withstand the demands of long shifts. Employees benefit from the lightweight, supportive design, which enhances comfort and productivity. B2B buyers in Europe and Africa should prioritize sourcing options that offer customization for branding and bulk discounts, ensuring that staff are both comfortable and presentable.

Why Are ‘Crocs No Holes’ Ideal for Retail Environments?

In retail, employees often stand for extended periods, making comfortable footwear essential. Crocs without holes offer a blend of style and comfort, allowing staff to remain on their feet without discomfort. For international retailers, sourcing considerations should include style variety to match branding and seasonal trends, as well as options for bulk orders to equip entire teams efficiently.

What Advantages Do ‘Crocs No Holes’ Provide in Agriculture?

In agriculture, Crocs without holes provide protective footwear that shields workers from spills and contaminants while offering comfort during long hours outdoors. The lightweight and durable design makes them suitable for various farming activities. Buyers in regions like Africa and South America should focus on sourcing footwear that meets local agricultural safety standards, ensuring durability and ease of maintenance in rugged environments.

3 Common User Pain Points for ‘crocs no holes’ & Their Solutions

Scenario 1: Managing Hygiene Standards in Food Service

The Problem: For B2B buyers in the food service industry, maintaining hygiene standards is paramount. Traditional footwear with holes can harbor bacteria and allow contaminants to enter, posing health risks. Buyers often face challenges in sourcing footwear that not only meets hygiene regulations but also provides comfort for long shifts. Employees may refuse to wear clogs that are not fully enclosed, leading to compliance issues and potential health inspections.

The Solution: When sourcing ‘crocs no holes’, prioritize models specifically designed for the food service sector, such as the Classic Work Clog. These clogs feature an enclosed toe design and waterproof upper, which are essential for preventing spills and contamination. Additionally, the Crocs Lock™ slip-resistant tread ensures safety in wet environments, reducing the risk of slips and falls. Educate staff on the importance of wearing enclosed footwear and implement a uniform policy that mandates ‘crocs no holes’ for all kitchen and service staff. By promoting a culture of hygiene and safety, you can enhance compliance and employee comfort.

Scenario 2: Ensuring Comfort for Healthcare Workers

The Problem: Healthcare professionals spend long hours on their feet, leading to fatigue and discomfort. B2B buyers in the healthcare sector need to provide footwear that offers support and comfort without compromising on safety. A common issue arises when staff report pain or discomfort from inadequate footwear, which can lead to decreased productivity and increased turnover rates.

The Solution: Invest in ‘crocs no holes’ designed with healthcare in mind, such as the Classic Work Clog. These clogs are lightweight yet durable, featuring a fully molded design that conforms to the foot for maximum comfort. They also include an adjustable backstrap for a customized fit, catering to individual preferences. To address the pain points of healthcare workers, conduct trials to allow staff to test different models and provide feedback. By fostering an environment where employees can choose their preferred footwear, you can significantly improve morale and reduce fatigue-related complaints.

Illustrative image related to crocs no holes

Scenario 3: Balancing Style and Functionality in Retail Environments

The Problem: In retail environments, employees often desire footwear that looks professional yet remains comfortable for all-day wear. B2B buyers face the challenge of sourcing footwear that meets aesthetic standards while also providing the functional benefits of ‘crocs no holes’. Employees may feel that clogs are unattractive, leading to reluctance in wearing them, which can affect their performance and confidence on the job.

The Solution: When selecting ‘crocs no holes’ for retail staff, look for options that blend style with functionality. Encourage buyers to consider models that offer customizable elements, such as color choices and the ability to add accessories like charms. Additionally, emphasize the importance of comfort features, such as cushioned footbeds and ergonomic design, which are crucial for employees who are on their feet for extended periods. Conduct a fashion-forward approach by showcasing how these clogs can be styled with the retail uniform, promoting them as not just functional but also a fashionable choice. By aligning employee preferences with company standards, you can enhance job satisfaction and create a more cohesive brand image.

Strategic Material Selection Guide for crocs no holes

What Materials Are Commonly Used in Crocs No Holes and Their Key Properties?

In the production of Crocs without holes, several materials are commonly employed, each offering unique properties that affect performance, durability, and overall suitability for various applications. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse climates and regulatory environments.

What Are the Key Properties of Croslite Material?

Croslite is the primary material used in Crocs footwear. It is a proprietary closed-cell resin that provides a lightweight, flexible, and cushioned experience. Croslite exhibits excellent thermal insulation properties, making it suitable for various temperature conditions. It is also resistant to water and easy to clean, which is beneficial for industries like healthcare and food service.

Illustrative image related to crocs no holes

Pros:

– Lightweight and comfortable, reducing fatigue for users on their feet for long periods.

– Resistant to odors and bacteria, enhancing hygiene.

– Easy to manufacture and mold into different styles.

Cons:

– Limited resistance to extreme temperatures, which may affect performance in very hot or cold environments.

– May not provide the same level of durability as traditional rubber or leather.

Impact on Application: Croslite is ideal for environments where comfort and hygiene are paramount, such as hospitals and kitchens. However, it may not be suitable for high-impact industrial applications.

Considerations for International Buyers: Compliance with ASTM and ISO standards is crucial, particularly in the healthcare sector. Buyers from regions like Africa and South America should ensure that the material meets local regulations regarding safety and environmental impact.

How Does EVA Compare as a Material for Crocs No Holes?

Ethylene Vinyl Acetate (EVA) is another material frequently used in the production of Crocs. EVA is known for its flexibility and shock-absorbing properties, making it a popular choice for footwear.

Pros:

– Excellent cushioning and comfort, ideal for prolonged wear.

– Good resistance to UV radiation, which helps maintain color and integrity over time.

Cons:

– Less durable than Croslite, particularly in abrasive environments.

– Can become less effective in extreme temperatures, leading to potential deformation.

Impact on Application: EVA is suitable for casual wear and light-duty applications but may not hold up well in more demanding environments, such as industrial settings.

Illustrative image related to crocs no holes

Considerations for International Buyers: Buyers should check for compliance with international standards like EN ISO 20347, especially in sectors like hospitality and healthcare where safety is critical.

What Role Does Rubber Play in Crocs No Holes?

Rubber is often used in the soles of Crocs to enhance grip and durability. It provides excellent traction, making it suitable for environments where slip resistance is essential.

Pros:

– Highly durable and resistant to wear, making it suitable for high-traffic areas.

– Offers superior slip resistance, which is critical in food service and healthcare.

Illustrative image related to crocs no holes

Cons:

– Heavier than Croslite or EVA, which may affect overall comfort.

– Higher manufacturing complexity can lead to increased costs.

Impact on Application: Rubber soles are crucial in environments where safety is a priority, such as kitchens and hospitals. Their durability makes them suitable for long-term use.

Considerations for International Buyers: Compliance with slip-resistance standards (e.g., ASTM F2913) is essential for buyers in sectors that require high safety standards.

What Are the Benefits of Using Thermoplastic Polyurethane (TPU) in Crocs No Holes?

Thermoplastic Polyurethane (TPU) is sometimes utilized for its flexibility and resistance to abrasion. TPU provides a balance between comfort and durability, making it a versatile choice.

Pros:

– Excellent abrasion resistance, extending the lifespan of the footwear.

– Flexible and lightweight, offering comfort similar to Croslite.

Cons:

– More expensive than other materials, which could affect pricing strategies.

– Manufacturing processes can be more complex, potentially leading to longer lead times.

Impact on Application: TPU is suitable for various applications, including outdoor and industrial environments, where durability is essential.

Illustrative image related to crocs no holes

Considerations for International Buyers: Buyers should ensure that TPU products comply with local regulations regarding chemical safety and environmental impact.

Summary Table of Material Properties for Crocs No Holes

| Material | Typical Use Case for crocs no holes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Croslite | Healthcare, Food Service | Lightweight and comfortable | Limited durability in extreme conditions | Medium |

| EVA | Casual Wear | Excellent cushioning | Less durable in abrasive environments | Low |

| Rubber | Industrial, Food Service | Superior slip resistance | Heavier, higher manufacturing complexity | High |

| TPU | Outdoor, Industrial | Excellent abrasion resistance | Higher cost, complex manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions when sourcing Crocs without holes. Understanding the properties, advantages, and limitations of each material will help buyers align their choices with specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for crocs no holes

What Are the Key Stages in the Manufacturing Process of Crocs No Holes?

The production of Crocs without holes involves a meticulous manufacturing process designed to ensure both comfort and durability. This process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to crocs no holes

-

Material Preparation:

The primary material used in the production of Crocs is Croslite, a proprietary foam resin known for its lightweight and cushioning properties. During this stage, the resin is formulated and mixed with color additives to achieve the desired aesthetic. Quality control begins here, as the raw materials are tested for consistency and compliance with safety standards. -

Forming:

Once the materials are ready, they are subjected to a molding process. The Croslite material is heated and injected into molds that shape the clogs. This is a critical stage, as the molding temperature and pressure must be precisely controlled to ensure uniformity and structural integrity. Advanced techniques, such as computer numerical control (CNC) machining, may be employed to optimize the mold designs for efficiency and performance. -

Assembly:

After the molded parts are cooled and ejected from the molds, they undergo assembly. This includes attaching components such as backstraps and insoles. The assembly process is often automated but may involve manual labor for quality-sensitive tasks. Each clog is checked for alignment and fit before moving to the next stage. -

Finishing:

The final stage includes surface treatments, quality checks, and packaging. Crocs are typically subjected to a cleaning process to remove any residues from manufacturing. They may also receive additional coatings for aesthetic or protective purposes. At this point, products are inspected for defects and packaged for shipment.

How is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of manufacturing Crocs without holes, ensuring that each product meets international standards and customer expectations. The QA process can be divided into several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC):

This checkpoint occurs at the beginning of the manufacturing process. Raw materials are inspected for quality, consistency, and compliance with specifications. Only materials passing these criteria are allowed to proceed to the next stage, ensuring that potential defects are identified early on. -

In-Process Quality Control (IPQC):

During the forming and assembly stages, periodic inspections are conducted to monitor the production process. This includes checking the temperature and pressure of the molding process, as well as verifying assembly accuracy. Any deviations from established protocols are addressed immediately to prevent defects from propagating through the production line. -

Final Quality Control (FQC):

The final inspection occurs before packaging. Each pair of Crocs is examined for aesthetic and functional quality, such as checking for defects in color, shape, and comfort. This stage often includes wear tests to assess durability and performance under various conditions.

What International Standards and Certifications Are Relevant to Crocs No Holes?

B2B buyers must be aware of the various international standards that govern the manufacturing of footwear, particularly for Crocs without holes. Compliance with these standards not only ensures product quality but also enhances marketability in different regions.

-

ISO 9001:

This standard focuses on quality management systems and is applicable across various industries, including footwear manufacturing. Companies that achieve ISO 9001 certification demonstrate their commitment to quality and continuous improvement. -

CE Marking:

In Europe, the CE marking signifies that products meet EU safety, health, and environmental protection standards. Crocs targeting the European market must comply with relevant regulations to ensure market access. -

ASTM Standards:

In the United States, ASTM International provides a set of standards for footwear, including slip resistance and other performance criteria. Manufacturers of Crocs may need to adhere to these standards, particularly if their products are marketed for work environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to partner with suppliers for Crocs without holes should take proactive steps to verify the quality control practices of potential manufacturers. Here are several strategies to ensure supplier integrity:

Illustrative image related to crocs no holes

-

Supplier Audits:

Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This provides insight into the supplier’s operational standards and compliance with international regulations. -

Quality Control Reports:

Requesting documentation of quality control procedures, including inspection reports and compliance certifications, can help buyers evaluate the reliability of a supplier. This information should outline the QA processes and any third-party testing conducted. -

Third-Party Inspections:

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management systems. These inspections can cover everything from material sourcing to final product checks, ensuring that suppliers adhere to agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing Crocs without holes, international buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that may affect their purchasing decisions:

-

Cultural Differences in Quality Expectations:

Different markets may have varying expectations regarding product quality and durability. Understanding local preferences and standards can help buyers select suitable suppliers. -

Logistical Challenges:

Shipping and customs regulations can impact product quality during transit. Buyers should ensure that suppliers have robust packaging and handling practices to minimize damage during transportation. -

Regulatory Compliance:

Buyers must be aware of local regulations that could affect product compliance. This includes ensuring that all necessary certifications are in place to avoid issues at customs or within local markets.

By understanding these manufacturing processes, quality assurance practices, and verification methods, B2B buyers can make informed decisions when sourcing Crocs without holes, ensuring high-quality products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crocs no holes’

Introduction

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing ‘Crocs No Holes’ footwear. As the demand for comfortable and functional footwear grows, understanding the nuances of procurement can help you make informed decisions. This checklist outlines essential steps to ensure you find reliable suppliers who meet your specific needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your product requirements. Specify the desired styles, sizes, colors, and features, such as slip-resistance or waterproof capabilities. This clarity will streamline communication with suppliers and help ensure that the products meet your market’s demands.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in Crocs No Holes. Utilize online platforms, industry directories, and trade shows to gather a list of candidates. Look for suppliers with a proven track record and positive customer reviews, as this can indicate reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ASTM or CE marks, which demonstrate compliance with safety and quality standards. Certifications provide assurance that the products meet specific industry requirements. Additionally, inquire about their manufacturing practices to ensure ethical and sustainable operations.

Step 4: Request Samples

Before placing a bulk order, request samples of the Crocs No Holes to evaluate quality firsthand. Testing the comfort, durability, and fit of the samples is crucial for ensuring they align with your standards and customer expectations. Use this opportunity to assess the supplier’s responsiveness and willingness to accommodate your requests.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in discussions regarding pricing and payment terms. Be transparent about your budget and explore volume discounts or favorable payment options that can enhance your cash flow. Ensure that all terms are documented to prevent misunderstandings later.

Illustrative image related to crocs no holes

Step 6: Confirm Shipping and Logistics

Discuss logistics with your chosen supplier, including shipping methods, lead times, and delivery terms. Understanding these aspects is vital for planning inventory levels and meeting customer demand. Additionally, inquire about customs documentation and any potential tariffs that may apply to your order.

Step 7: Establish a Communication Plan

Effective communication is essential throughout the sourcing process. Set up regular check-ins with your supplier to monitor order progress and address any issues promptly. A clear communication strategy helps build a strong partnership and ensures that both parties are aligned on expectations.

By following this step-by-step checklist, you can navigate the complexities of sourcing Crocs No Holes effectively. This structured approach will help you identify the right suppliers, secure quality products, and ultimately enhance your business’s competitive edge in the footwear market.

Comprehensive Cost and Pricing Analysis for crocs no holes Sourcing

What Are the Key Cost Components for Sourcing Crocs Without Holes?

When sourcing Crocs without holes, understanding the cost structure is essential for effective budgeting and pricing strategy. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials account for a significant portion of the overall cost. Crocs are typically made from Croslite, a proprietary foam resin that provides comfort and durability. The price of this material fluctuates based on market demand and supply chain dynamics.

Labor costs vary widely depending on the country of production. Regions with lower labor costs, such as certain areas in Southeast Asia, may offer more competitive pricing, but this can come with trade-offs in terms of quality and ethical standards.

Manufacturing overhead includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these costs.

Tooling is another critical factor; the initial investment in molds and machinery can be substantial, but it is amortized over the production volume.

Quality control measures are essential to ensure product consistency and safety, particularly for industries such as healthcare and food service, where Crocs are commonly used.

Logistics costs encompass transportation, warehousing, and customs duties, which can vary significantly based on the shipping route and Incoterms used.

Lastly, the margin required by suppliers can vary, impacting the final pricing for buyers.

How Do Price Influencers Affect the Cost of Crocs Without Holes?

Several factors influence the pricing of Crocs without holes, which are crucial for international buyers to consider.

Volume and minimum order quantity (MOQ) play a significant role. Larger orders often result in lower per-unit costs due to economies of scale. It is advisable for buyers to negotiate for favorable terms based on expected purchase volumes.

Specifications and customization also affect pricing. Customized designs or specific color requests may incur additional costs. Buyers should evaluate whether these customizations are necessary for their market to avoid unnecessary expenditures.

Material quality and certifications can significantly impact costs. Premium materials or certifications (such as ASTM compliance for workplace safety) may raise the price but are essential for certain industries. Buyers should assess their target market’s needs to determine the appropriate balance between cost and quality.

Supplier factors, including reputation and reliability, can influence pricing. Established suppliers may charge a premium for their proven track record, while emerging suppliers may offer lower prices to gain market share. Conducting thorough due diligence on suppliers is vital.

Incoterms dictate the responsibilities of buyers and sellers in international transactions, affecting logistics costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers estimate total landed costs accurately.

What Are the Best Practices for Negotiating Costs and Ensuring Cost-Efficiency?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential.

First, establish clear communication with suppliers regarding expectations for pricing, delivery times, and quality standards. Building a strong relationship can lead to better negotiation outcomes.

Second, analyze the total cost of ownership rather than just the initial purchase price. Consider factors such as durability, maintenance costs, and potential returns or warranty claims. Investing in higher-quality products can lead to savings in the long run.

Lastly, be aware of pricing nuances in different regions. For example, import duties and taxes can vary greatly, impacting the overall cost structure. Familiarizing oneself with local regulations and market conditions will aid in making informed purchasing decisions.

Conclusion

Understanding the comprehensive cost and pricing analysis for sourcing Crocs without holes is crucial for B2B buyers. By considering the various cost components, price influencers, and effective negotiation strategies, buyers can make informed decisions that align with their business goals. Note that prices can fluctuate based on market conditions, so ongoing market research and supplier engagement are vital for securing the best deals.

Alternatives Analysis: Comparing crocs no holes With Other Solutions

Exploring Alternatives to Crocs No Holes for Footwear Solutions

In the competitive landscape of footwear solutions, particularly for industries requiring comfort and functionality, it’s essential to explore alternatives to Crocs No Holes. This section provides a comparative analysis of Crocs No Holes against two viable alternatives, highlighting key aspects that B2B buyers should consider when making purchasing decisions.

| Comparison Aspect | Crocs No Holes | Calzuro Classic Clogs Without Holes | Dansko Professional Clogs |

|---|---|---|---|

| Performance | Excellent comfort and support; slip-resistant | Superior durability; high comfort for long hours | Exceptional arch support; slip-resistant |

| Cost | Moderate price point (~$50) | Higher price (~$125) | Premium price (~$130) |

| Ease of Implementation | Widely available; no special ordering needed | Available through select distributors; some lead time | Requires specialized retailers or online order |

| Maintenance | Easy to clean; waterproof | Easy to clean; autoclave safe | Requires more maintenance; can be hand-washed |

| Best Use Case | Ideal for casual and light-duty work | Perfect for healthcare and food service sectors | Best for professional settings requiring all-day wear |

What Are the Advantages and Disadvantages of Calzuro Classic Clogs Without Holes?

Calzuro Classic Clogs Without Holes offer a strong alternative to Crocs No Holes, particularly for professionals in healthcare and food service. Their design emphasizes durability and comfort, making them suitable for long hours of standing. However, they come at a premium price point, which could be a consideration for budget-conscious businesses. Additionally, while they are easy to clean, the need for specific distribution channels may delay acquisition.

How Do Dansko Professional Clogs Compare to Crocs No Holes?

Dansko Professional Clogs are recognized for their exceptional arch support and slip-resistant properties, making them a favorite among healthcare workers. They provide all-day comfort, which is crucial in high-demand environments. However, they are typically more expensive than Crocs No Holes and require more maintenance due to their material composition. This might not be ideal for businesses looking for low-maintenance options.

Illustrative image related to crocs no holes

Conclusion: How to Choose the Right Footwear Solution for Your Business?

When selecting the right footwear solution, B2B buyers should consider their specific industry needs, budget constraints, and the importance of comfort and safety features. Crocs No Holes offers a good balance of comfort and affordability, making them suitable for casual and light-duty use. In contrast, Calzuro and Dansko clogs provide more specialized solutions for demanding professional environments but at a higher cost. Evaluating these aspects will enable buyers to make informed decisions that align with their operational requirements and employee satisfaction.

Essential Technical Properties and Trade Terminology for crocs no holes

What Are the Key Technical Properties of Crocs Without Holes?

1. Material Composition: What Makes Crocs Durable?

Crocs without holes are primarily made from Croslite™, a proprietary closed-cell resin material that is lightweight, flexible, and resistant to odor. This material is critical for B2B buyers as it ensures the longevity of the product, making it suitable for various environments, from healthcare to hospitality. Understanding the material composition helps buyers assess the suitability of Crocs for their specific use cases, particularly in industries where hygiene and comfort are paramount.

2. Slip-Resistance: Why Is It Important?

Many Crocs models feature Crocs Lock™ slip-resistant tread. This property is essential for professionals who spend long hours on their feet, especially in food service and healthcare sectors. The slip-resistant feature minimizes the risk of workplace accidents, a crucial consideration for B2B buyers looking to ensure employee safety and compliance with industry standards.

3. Enclosed Toe Design: What Are the Benefits?

The enclosed toe design of Crocs without holes offers enhanced protection against spills and debris, making them ideal for environments where foot safety is a concern. This design not only meets regulatory requirements in many industries but also provides additional comfort, which can lead to increased employee satisfaction and productivity. Buyers should consider this feature when evaluating options for work footwear.

4. ASTM and CE Certifications: How Do They Affect Quality Assurance?

Crocs without holes often carry certifications such as ASTM F2913-24 and CE marking. These certifications indicate compliance with safety standards in North America and Europe, respectively. For B2B buyers, these certifications serve as a quality assurance measure, ensuring that the products meet rigorous safety and performance criteria, which can influence procurement decisions and liability concerns.

5. Lightweight Design: How Does It Enhance Comfort?

The lightweight nature of Crocs contributes significantly to all-day comfort, reducing fatigue for wearers. This property is particularly appealing for industries with high turnover rates or those requiring extended periods of standing. B2B buyers should prioritize lightweight footwear as it can lead to reduced employee absenteeism and improve overall workplace morale.

What Are Common Trade Terms Related to Crocs Without Holes?

1. OEM (Original Equipment Manufacturer): What Is Its Relevance?

OEM refers to companies that produce products that are sold under another company’s brand. In the context of Crocs, understanding OEM relationships can help buyers identify the source of their footwear and ensure consistency in quality and branding. This is particularly relevant for retailers looking to offer customized or private label options.

2. MOQ (Minimum Order Quantity): Why Is It Crucial for Procurement?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential for budgeting and inventory management. Suppliers may set MOQs to ensure cost efficiency, and understanding these requirements can help buyers negotiate better terms.

3. RFQ (Request for Quotation): How Does It Facilitate Purchasing?

An RFQ is a document that solicits price quotes from suppliers. This process is vital for B2B transactions, allowing buyers to compare costs and services from different suppliers. For Crocs without holes, issuing an RFQ can ensure that buyers receive competitive pricing and understand the terms of sale.

Illustrative image related to crocs no holes

4. Incoterms: What Do They Mean for International Shipping?

Incoterms are a set of international commercial terms that define the responsibilities of buyers and sellers in shipping. Familiarity with Incoterms is crucial for B2B buyers engaging in international trade, as they dictate who bears the risk and costs at each stage of the shipping process. This knowledge is particularly beneficial when sourcing Crocs from manufacturers in different countries.

5. Lead Time: Why Is It Important for Supply Chain Management?

Lead time refers to the time taken from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for inventory planning and ensuring that products are available when needed. This is especially relevant for businesses that rely on Crocs for seasonal promotions or specific projects.

By understanding these technical properties and trade terminology, B2B buyers can make informed purchasing decisions that align with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the crocs no holes Sector

What Are the Key Market Dynamics Driving the Crocs No Holes Sector?

The market for Crocs no holes footwear is experiencing robust growth, driven by several global factors. Increased demand for comfortable and functional footwear across various sectors, including healthcare, hospitality, and food service, is propelling this trend. The rise of remote work and a shift towards casual attire in professional settings have led to greater acceptance of leisure-oriented footwear, making Crocs a popular choice among employees seeking comfort during long hours.

Technological advancements in manufacturing and materials are also shaping the sourcing landscape. Innovations such as 3D printing and eco-friendly materials are making it easier for manufacturers to produce customizable and sustainable footwear options. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding these technological trends is crucial for making informed purchasing decisions.

Another emerging trend is the integration of e-commerce platforms and digital supply chains, which facilitate easier access to global suppliers. This is particularly beneficial for buyers in emerging markets, where traditional retail infrastructure may be limited. As such, leveraging online marketplaces and digital tools for sourcing Crocs no holes products can enhance supply chain efficiency and reduce lead times, meeting the growing consumer demand for immediate availability.

How Is Sustainability and Ethical Sourcing Influencing the Crocs No Holes Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the Crocs no holes market. Environmental impacts associated with footwear production, such as waste generation and carbon emissions, are prompting businesses to seek suppliers that prioritize sustainable practices. Ethical sourcing is no longer just a value-added proposition; it has become a necessity for companies aiming to align with consumer expectations and regulatory requirements.

Buyers should look for suppliers that utilize environmentally friendly materials, such as recycled plastics and bio-based components, which significantly lower the ecological footprint of Crocs no holes footwear. Certifications like Global Recycled Standard (GRS) and OEKO-TEX® Standard 100 serve as indicators of a supplier’s commitment to sustainability.

Illustrative image related to crocs no holes

Furthermore, many manufacturers are adopting transparent supply chains to enhance accountability. For international buyers, particularly in regions like Nigeria and Vietnam, ensuring that suppliers adhere to ethical labor practices is essential. This not only mitigates risks associated with supply chain disruptions but also enhances brand reputation in increasingly eco-conscious markets.

What Is the Brief Evolution and History of Crocs No Holes Footwear?

Crocs was founded in 2002, initially gaining fame for its innovative clogs featuring ventilation holes. However, recognizing the demand for more versatile and professional footwear, the company introduced the no holes design, which quickly gained traction in various industries. The no holes model not only provides a sleek aesthetic but also enhances functionality, making it suitable for environments where foot protection from spills and hazards is essential.

Over the years, Crocs has expanded its offerings, introducing a variety of styles and colors to cater to diverse consumer preferences. This evolution reflects the brand’s adaptability to market demands and its commitment to providing comfort and practicality across different sectors. Today, Crocs no holes footwear is a staple in workplaces around the world, particularly in healthcare and hospitality, where comfort and safety are paramount.

In summary, understanding the market dynamics, sustainability practices, and historical context of Crocs no holes footwear can empower B2B buyers to make strategic sourcing decisions that align with current trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of crocs no holes

-

1. How do I ensure the quality of Crocs no holes when sourcing?

To guarantee the quality of Crocs no holes, it is essential to conduct thorough supplier vetting. Request samples and review certifications such as ASTM or CE compliance, which ensure the shoes meet safety and durability standards. Additionally, consider third-party quality assurance inspections prior to shipment. Establish clear quality expectations in your purchase agreements, and maintain open lines of communication with suppliers to address any issues promptly. -

2. What is the best strategy for negotiating payment terms with suppliers?

When negotiating payment terms, start by researching industry standards and understanding the supplier’s position. Propose terms that are mutually beneficial, such as a percentage upfront and the balance upon delivery. For larger orders, consider establishing a letter of credit to secure your interests. Building a strong relationship with suppliers can also lead to more favorable terms, including extended payment periods or discounts for early payments. -

3. What are the minimum order quantities (MOQs) for Crocs no holes?

MOQs for Crocs no holes can vary significantly between suppliers. Typically, manufacturers may set MOQs based on production costs and material availability. It’s advisable to inquire directly with potential suppliers about their MOQs and see if they offer flexibility for first-time buyers or smaller businesses. Some suppliers may allow lower MOQs in exchange for a higher price per unit, which can be beneficial for testing market demand before committing to larger orders. -

4. How can I customize Crocs no holes for my business?

Many suppliers offer customization options for Crocs no holes, such as color choices, branding, or adding unique design features. To initiate the process, communicate your specific requirements and request a catalog of available customization options. Be aware of any additional costs associated with customization and lead times, as these may extend the overall delivery schedule. Confirm the minimum order quantities for customized products to ensure alignment with your business needs. -

5. What logistics considerations should I keep in mind when importing Crocs no holes?

Logistics plays a crucial role in the timely delivery of imported Crocs no holes. Evaluate shipping methods based on cost, speed, and reliability. Ensure compliance with import regulations in your country, including customs duties and tariffs. Partnering with a reputable freight forwarder can facilitate smoother logistics management and provide guidance on documentation requirements. Additionally, track shipments regularly to address potential delays proactively. -

6. How can I assess the reputation of a supplier for Crocs no holes?

To assess a supplier’s reputation, start by checking online reviews and testimonials from other businesses. Look for case studies or references from previous clients that demonstrate successful partnerships. Engaging in direct conversations with the supplier can reveal insights into their operational practices. Additionally, consider visiting the supplier’s facility if possible or utilizing third-party audits to gain a comprehensive understanding of their capabilities. -

7. What are the best practices for managing returns and exchanges with suppliers?

Establishing clear return and exchange policies with suppliers is crucial for managing any discrepancies or defects in Crocs no holes. Clearly outline the conditions under which returns are accepted, the timeframe for initiating a return, and who bears the shipping costs. Maintain open communication with your supplier to facilitate a smooth return process. Document all transactions and agreements regarding returns to ensure both parties are aligned. -

8. How do I stay informed about the latest trends in footwear, particularly Crocs no holes?

To stay updated on the latest trends in footwear, including Crocs no holes, subscribe to industry newsletters, follow trade publications, and participate in relevant trade shows and exhibitions. Engage with industry groups on social media platforms to connect with other buyers and suppliers. Networking with professionals in the footwear industry can provide insights into emerging trends, consumer preferences, and innovative designs, helping you make informed purchasing decisions.

Top 5 Crocs No Holes Manufacturers & Suppliers List

1. Reddit – Classic Work Clog & Overpuffs

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Classic Work Clog: Described as essentially a classic clog with no holes, featuring rubber tread on the bottom and an adjustable strap. 2. Overpuffs: Mentioned as a comfortable option, though the style may not appeal to everyone.

2. Crocs – New Fall Collection

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: The new Crocs without holes are perfect for fall. Available in multiple colors.

3. Etsy – Custom Crocs No Holes

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Custom Crocs No Holes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Crocs – Footwear Collection

Domain: us.sportsdirect.com

Registered: 1996 (29 years)

Introduction: Crocs provide comfort for everyone with a range of footwear including slippers and shoes. The collection features classic Baya Clogs and fluffy-lined options, designed for incredible underfoot cushioning suitable for everyday wear. Ideal for holidays and daily use, Crocs are a staple in any wardrobe.

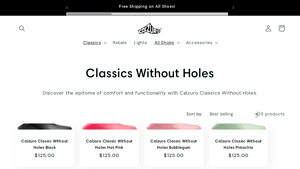

5. Calzuro – Classic Clogs

Domain: calzuro.com

Registered: 2000 (25 years)

Introduction: Calzuro Classic Clogs Without Holes | Slip-On Work Shoes | 100% MADE IN ITALY | Regular price: $125.00 | Available colors: Black, Hot Pink, Bubblegum, Pistachio, Metallic Grey, Green, Maroon, Metallic Blue, Purple, Lavender, Light Blue, Red, Orange, Yellow, Royal Blue, Brown, Teal, White, Peach, Metallic Turquoise | Designed for comfort and functionality, suitable for healthcare workers, chefs, an…

Strategic Sourcing Conclusion and Outlook for crocs no holes

In conclusion, the strategic sourcing of Crocs without holes presents a compelling opportunity for international B2B buyers. The unique features of these clogs—including their lightweight design, slip-resistant soles, and easy-to-clean materials—make them an ideal choice for industries such as healthcare, hospitality, and food service. By focusing on the comfort and functionality that these products offer, businesses can enhance employee satisfaction and productivity while reducing costs associated with workplace injuries and footwear replacements.

Additionally, leveraging strategic sourcing practices allows buyers to tap into competitive pricing and secure reliable supply chains, crucial for markets in Africa, South America, the Middle East, and Europe. As demand for comfortable, versatile footwear continues to rise, especially in diverse working environments, now is the time to consider integrating Crocs no holes into your inventory.

Looking ahead, international B2B buyers should explore partnerships with reputable suppliers to ensure they meet the evolving needs of their customers. Embrace the opportunity to provide your workforce with unparalleled comfort and support—invest in Crocs no holes today and position your business for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.