Coupling Shaft Motor: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for coupling shaft motor

In the ever-evolving landscape of industrial machinery, sourcing the right coupling shaft motor can pose a significant challenge for B2B buyers. As businesses strive to enhance operational efficiency and minimize downtime, understanding the nuances of coupling shaft motors becomes essential. This guide offers a comprehensive exploration of various coupling types, their applications across different industries, and the critical factors to consider when selecting suppliers. From flexible couplings designed for high-performance applications to rigid couplings that provide superior torsional stiffness, we cover the spectrum of options available in the market.

For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, making informed purchasing decisions is crucial. This guide empowers you with actionable insights on vetting suppliers, assessing product quality, and understanding cost implications, ensuring that you can confidently navigate the global market. By leveraging this information, you can optimize your sourcing strategies, align your operational needs with the best coupling solutions, and ultimately drive your business’s success. Whether you are in Brazil, Germany, or beyond, our guide serves as your trusted resource for mastering the complexities of coupling shaft motors in a competitive marketplace.

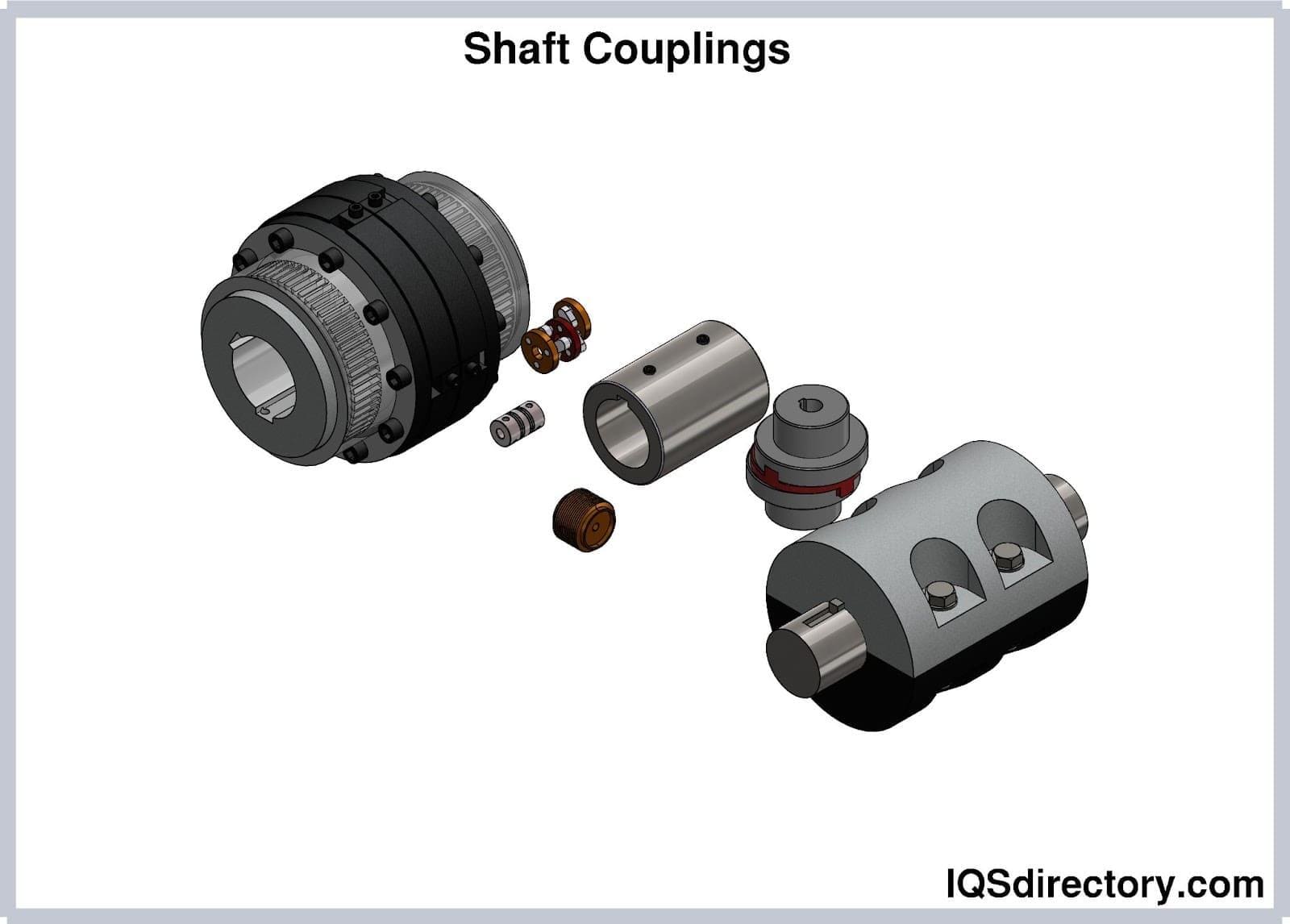

Understanding coupling shaft motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Disc Couplings | Flexible disc elements, high torsional rigidity, low inertia | Machine tools, semiconductor manufacturing | Pros: High precision, minimal backlash. Cons: May be more expensive than alternatives. |

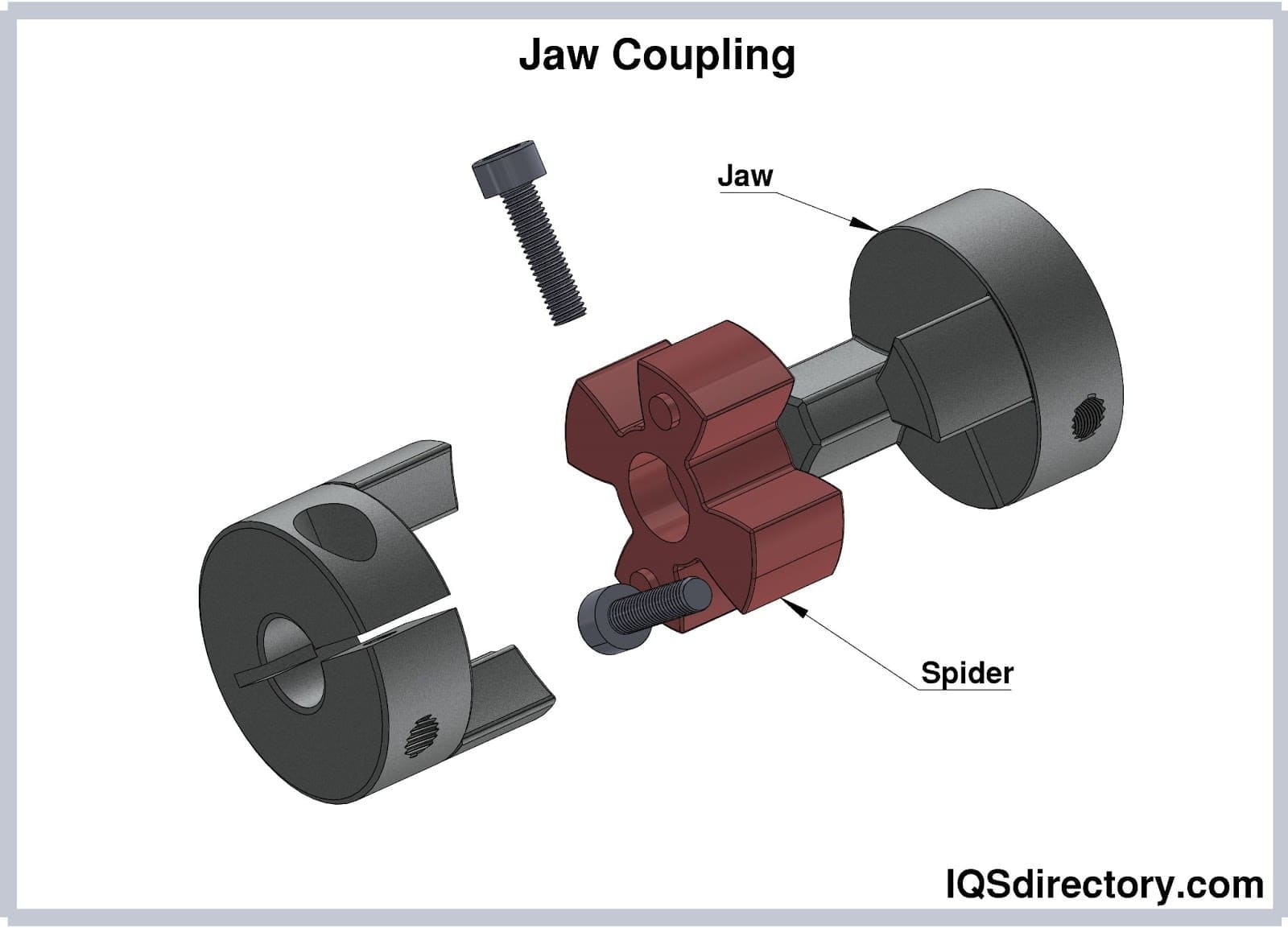

| Jaw & Spider Couplings | Simple design with elastomer elements for shock absorption | General-purpose machinery, packaging equipment | Pros: Cost-effective, excellent vibration dampening. Cons: Limited misalignment tolerance. |

| Bellow Couplings | High elasticity, zero backlash, compact design | Stepper motors, encoders | Pros: Lightweight, easy installation. Cons: Limited torque capacity compared to rigid types. |

| Rigid Couplings | High torsional stiffness, no flexibility | Servo motors, high-performance applications | Pros: Superior torque transmission. Cons: Cannot accommodate misalignment. |

| Magnetic Couplings | Non-contact operation, significant misalignment tolerance | Medical equipment, vacuum applications | Pros: Zero wear, noise, and dust generation. Cons: Generally higher cost and complexity. |

What Are the Key Characteristics of Metal Disc Couplings?

Metal disc couplings feature flexible disc elements that allow for some misalignment while maintaining high torsional rigidity. They are particularly suitable for applications requiring precise power transmission, such as machine tools and semiconductor manufacturing equipment. When considering a purchase, buyers should evaluate the specific torque requirements and potential cost implications, as these couplings tend to be pricier but offer long-term reliability and performance.

How Do Jaw & Spider Couplings Benefit General-Purpose Applications?

Jaw and spider couplings utilize a straightforward design that incorporates elastomer elements to absorb shock and vibrations. These couplings are widely used in general-purpose machinery and packaging equipment due to their cost-effectiveness and ability to dampen vibrations effectively. However, buyers should be mindful of their limited tolerance for misalignment, which could lead to increased wear in demanding environments.

What Advantages Do Bellow Couplings Offer for Compact Applications?

Bellow couplings are designed with high elasticity and zero backlash, making them ideal for applications where space is a constraint, such as stepper motors and encoders. Their lightweight and compact design facilitate easy installation in tight spaces. Buyers should consider the torque capacity of these couplings, as they may not be suitable for heavy-duty applications.

Why Choose Rigid Couplings for High-Performance Needs?

Rigid couplings are characterized by their high torsional stiffness and inability to accommodate misalignment. They are ideal for high-performance applications, such as servo motors, where precise torque transmission is critical. While they provide superior performance, buyers must ensure that their application can tolerate the lack of flexibility, as this could lead to issues if misalignment occurs.

What Makes Magnetic Couplings Unique in Various Applications?

Magnetic couplings operate without physical contact, using magnetic attraction and repulsion to transmit power. This design allows for significant misalignment tolerance and is particularly advantageous in medical and vacuum applications, where cleanliness and minimal wear are paramount. While they offer numerous benefits, including reduced maintenance, buyers should weigh the higher costs and complexity against the specific needs of their application.

Key Industrial Applications of coupling shaft motor

| Industry/Sector | Specific Application of coupling shaft motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision machinery and robotics | Enhanced operational efficiency and reduced downtime | Compatibility with existing machinery and torque ratings |

| Oil & Gas | Pump and compressor systems | Improved reliability in harsh environments | Material durability and resistance to extreme conditions |

| Automotive | Electric vehicle drivetrains | Optimized power transmission and reduced wear | Lightweight design and high torque capacity |

| Food & Beverage | Conveying systems for processing and packaging | Increased productivity and minimized maintenance costs | Hygiene standards and ease of cleaning |

| Mining | Equipment in mineral extraction and processing | Enhanced performance and safety in rugged conditions | Resistance to dust, moisture, and heavy loads |

How is ‘Coupling Shaft Motor’ Utilized in Manufacturing?

In the manufacturing sector, coupling shaft motors are critical in precision machinery and robotics. They connect various components, ensuring smooth power transmission while accommodating misalignments. This technology helps solve common issues such as vibration and shock absorption, leading to enhanced operational efficiency and reduced downtime. For international buyers, particularly from regions like Europe and South America, sourcing these motors requires attention to compatibility with existing machinery and the specific torque ratings necessary for optimal performance.

What Role Do Coupling Shaft Motors Play in Oil & Gas?

In the oil and gas industry, coupling shaft motors are essential for pump and compressor systems. They ensure efficient power transfer in environments that often experience extreme temperatures and pressures. The reliability of these couplings is paramount, as failures can lead to costly downtimes and safety hazards. Buyers in Africa and the Middle East should prioritize sourcing motors made from durable materials that can withstand harsh conditions, ensuring long-term operational reliability.

How Are Coupling Shaft Motors Important in Automotive Applications?

In the automotive sector, particularly with the rise of electric vehicles, coupling shaft motors are used in drivetrains to optimize power transmission. They enhance the efficiency of electric motors by minimizing energy loss during operation. This is crucial for improving vehicle performance and extending battery life. B2B buyers in regions such as Germany and Brazil should focus on lightweight designs with high torque capacity to meet stringent performance standards in the automotive industry.

Why Are Coupling Shaft Motors Essential in Food & Beverage Processing?

In the food and beverage industry, coupling shaft motors facilitate conveying systems used in processing and packaging. Their design allows for seamless operation, which increases productivity while minimizing maintenance costs. Additionally, these motors must adhere to strict hygiene standards, making it essential for buyers to consider materials that are easy to clean and resistant to contamination. This is particularly important for international buyers looking to comply with regional food safety regulations.

What Benefits Do Coupling Shaft Motors Offer in Mining Operations?

In mining, coupling shaft motors are employed in various equipment for mineral extraction and processing. They enhance performance and safety by providing reliable power transmission in rugged conditions. The ability to resist dust, moisture, and heavy loads is crucial for operational efficiency. Buyers from the Middle East and Africa should seek couplings designed for durability and high performance, ensuring that their equipment can withstand the demanding environments typical in mining operations.

3 Common User Pain Points for ‘coupling shaft motor’ & Their Solutions

Scenario 1: Misalignment Leading to Downtime and Increased Costs

The Problem: Many B2B buyers experience operational disruptions due to misalignment issues between the motor and the driven equipment. Misalignment can lead to excessive wear and tear on the coupling shaft motor, increased vibration, and ultimately, equipment failure. This situation not only results in costly repairs but also leads to unplanned downtime, disrupting production schedules and impacting overall profitability. Buyers often struggle to accurately assess alignment during installation or maintenance, resulting in recurring issues.

The Solution: To mitigate misalignment challenges, it is essential to implement precise alignment techniques and utilize high-quality coupling shaft motors designed to accommodate misalignment. Investing in laser alignment tools can provide accurate measurements and help ensure that shafts are aligned within manufacturer specifications. Additionally, selecting couplings with flexible elements, such as bellows or spider couplings, can allow for some degree of misalignment without sacrificing performance. Regular maintenance schedules should include alignment checks, and staff should be trained on the importance of proper installation and monitoring techniques to prevent future issues.

Scenario 2: Inadequate Torque Transmission Causing Performance Issues

The Problem: Another common pain point for B2B buyers is the inability of their coupling shaft motor to transmit the required torque effectively. This can occur when the chosen coupling does not match the application’s torque requirements or when the coupling is subjected to conditions beyond its designed capacity. Inadequate torque transmission can lead to inefficient operation, increased energy costs, and a higher risk of component failure, which can be particularly problematic in high-demand industries such as manufacturing and processing.

The Solution: Buyers should conduct a thorough analysis of their application’s torque requirements before selecting a coupling shaft motor. Utilizing torque calculators can assist in determining the appropriate size and type of coupling needed. Additionally, consider employing couplings designed for high-torque applications, such as metal disc or rigid couplings, which can handle greater loads without slipping. It is also beneficial to consult with manufacturers or suppliers who can provide insights into the best coupling solutions tailored to specific operational needs. Regularly monitoring performance and making adjustments based on real-time data can further enhance efficiency and mitigate risks.

Scenario 3: Difficulty in Sourcing Compatible Coupling Shaft Motors

The Problem: Many international B2B buyers face challenges when sourcing coupling shaft motors that are compatible with their existing systems. This issue is exacerbated by a lack of standardization across manufacturers and geographical differences in product availability. Buyers may find themselves overwhelmed by the numerous specifications, types, and configurations of coupling shaft motors, leading to decision fatigue and potential mismatches that can cause operational inefficiencies.

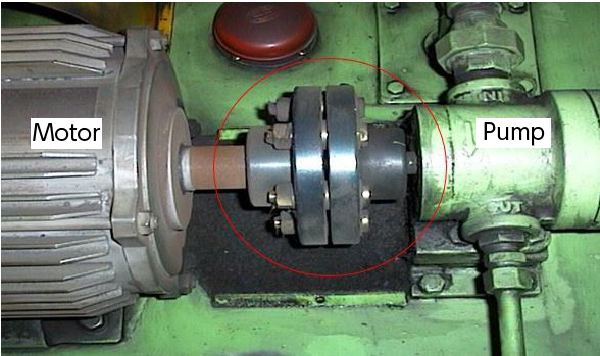

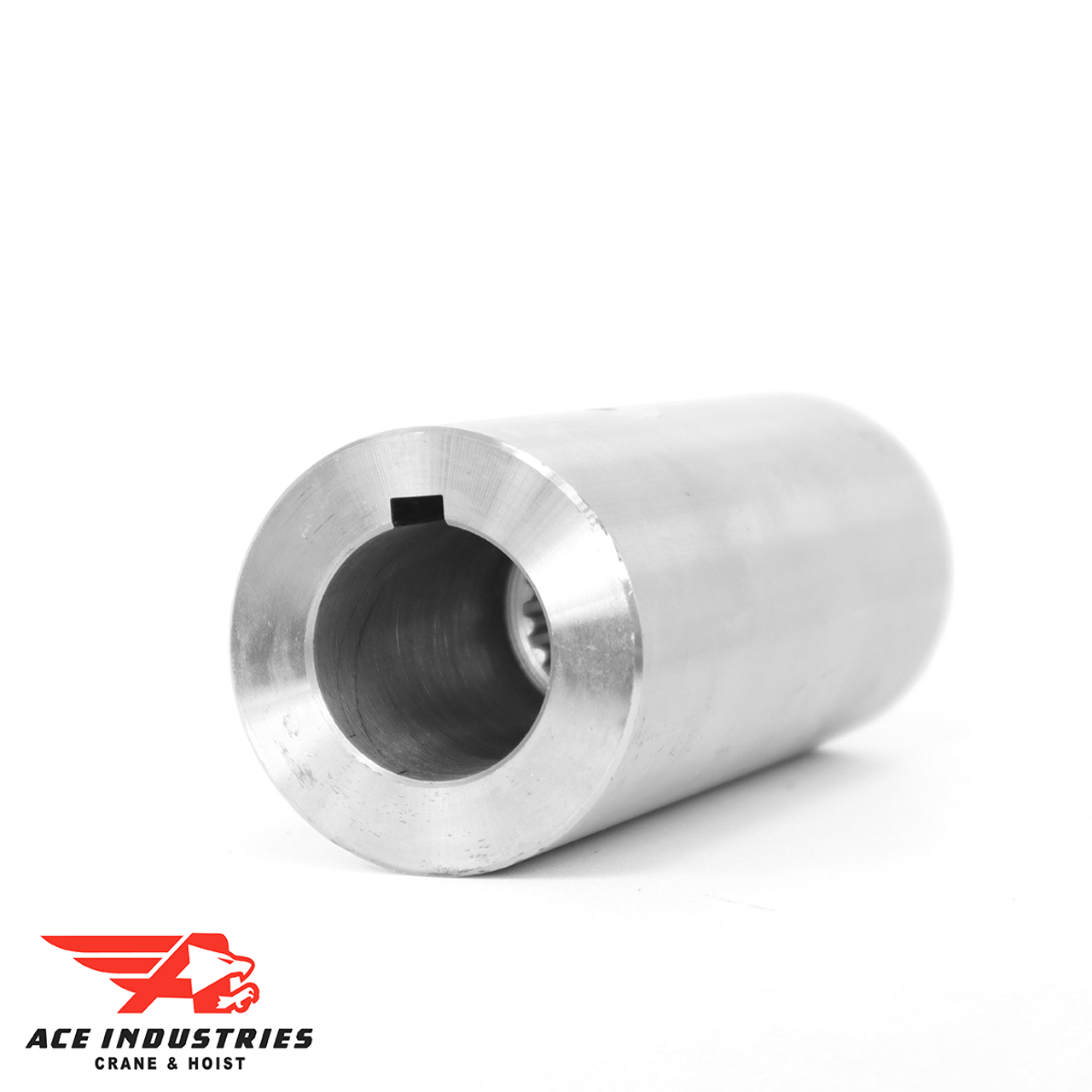

Illustrative image related to coupling shaft motor

The Solution: To streamline the sourcing process, buyers should establish a clear set of criteria based on their specific operational needs. Creating a checklist that includes compatibility factors such as size, torque ratings, and environmental conditions can help narrow down options. Engaging with reputable suppliers who have a diverse inventory and offer customization options can further simplify the process. Leveraging online platforms and directories that specialize in industrial components can also aid in finding the right products more efficiently. Finally, initiating direct communication with manufacturers can clarify compatibility questions and foster long-term partnerships that may lead to better pricing and support services.

Strategic Material Selection Guide for coupling shaft motor

What Are the Key Materials Used in Coupling Shaft Motors?

When selecting materials for coupling shaft motors, it is essential to consider the performance characteristics, durability, and compatibility with specific applications. Below, we analyze four common materials used in the manufacturing of coupling shaft motors, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Aluminum Perform in Coupling Shaft Motors?

Aluminum is a widely used material for coupling shafts due to its excellent strength-to-weight ratio and corrosion resistance. Key properties include a temperature rating up to 150°C and good fatigue resistance.

Pros: Aluminum is lightweight, making it ideal for applications where reducing weight is crucial. It is also relatively cost-effective and easy to machine, which simplifies manufacturing processes.

Cons: While aluminum is resistant to corrosion, it may not withstand high temperatures or extreme environments as well as other materials like steel. Additionally, it can be less durable under heavy loads compared to more robust materials.

Impact on Application: Aluminum is suitable for applications with moderate torque requirements and where weight savings are essential, such as in automotive or aerospace industries.

Considerations for International Buyers: Buyers in regions like Europe and South America should ensure compliance with relevant standards such as DIN and ASTM for aluminum quality, especially when used in critical applications.

Illustrative image related to coupling shaft motor

What Are the Advantages of Using Stainless Steel for Coupling Shaft Motors?

Stainless steel is another popular choice for coupling shaft motors, known for its high strength, corrosion resistance, and ability to perform in extreme temperatures (up to 800°C).

Pros: The durability of stainless steel makes it ideal for heavy-duty applications. It is also resistant to rust and corrosion, which is crucial in industries like food processing and marine applications.

Cons: The primary drawback is the higher cost compared to aluminum and other materials. Additionally, stainless steel can be more challenging to machine, leading to increased manufacturing complexity.

Illustrative image related to coupling shaft motor

Impact on Application: Stainless steel is ideal for applications that involve harsh environments or where high torque is required, such as in industrial machinery or chemical processing.

Considerations for International Buyers: Buyers in the Middle East and Africa should be aware of local regulations regarding stainless steel grades and certifications to ensure compliance with international standards.

How Does Plastic Compare as a Material for Coupling Shaft Motors?

Plastic materials, such as polyamide (nylon) and polyurethane, are increasingly used in coupling shaft motors for their lightweight and flexibility.

Pros: Plastics are resistant to corrosion and can operate in a wide range of temperatures. They are also cost-effective and can be produced in various colors and shapes.

Illustrative image related to coupling shaft motor

Cons: The main limitation is their lower strength and stiffness compared to metals, which may restrict their use in high-torque applications. They can also be susceptible to wear and tear over time.

Impact on Application: Plastic couplings are suitable for light-duty applications, such as in consumer electronics or small machinery, where weight and cost are more critical than strength.

Considerations for International Buyers: Buyers should ensure that the plastic materials meet specific industry standards, such as JIS for Japan or ASTM for the U.S., particularly for applications requiring food-grade materials.

What Role Does Rubber Play in Coupling Shaft Motors?

Rubber, particularly in the form of elastomers, is often used in flexible coupling designs to absorb shocks and vibrations.

Illustrative image related to coupling shaft motor

Pros: Rubber couplings provide excellent flexibility and damping characteristics, which can prolong the life of connected components. They are also relatively inexpensive and easy to install.

Cons: Rubber has a lower temperature and chemical resistance compared to metals, which can limit its use in certain applications. Over time, rubber can degrade due to environmental factors such as UV exposure and ozone.

Impact on Application: Rubber couplings are ideal for applications that require vibration dampening, such as in HVAC systems or automotive engines.

Considerations for International Buyers: Buyers should consider local climate conditions when selecting rubber materials, as extreme temperatures can affect performance. Compliance with international standards for rubber quality is also essential.

Summary of Material Properties for Coupling Shaft Motors

| Material | Typical Use Case for coupling shaft motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive, aerospace applications | Lightweight and cost-effective | Limited high-temperature performance | Low |

| Stainless Steel | Industrial machinery, chemical processing | High strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Consumer electronics, small machinery | Corrosion-resistant and cost-effective | Lower strength and wear susceptibility | Low |

| Rubber | HVAC systems, automotive engines | Excellent vibration dampening | Limited temperature resistance and durability | Low |

This analysis provides a comprehensive overview of the materials commonly used in coupling shaft motors, helping B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for coupling shaft motor

What Are the Main Stages of Manufacturing Coupling Shaft Motors?

The manufacturing of coupling shaft motors involves several critical stages that ensure the final product meets performance standards and customer requirements. Understanding these processes can aid B2B buyers in selecting reliable suppliers.

Material Preparation: What Materials Are Used in Coupling Shaft Motors?

The first stage in manufacturing coupling shaft motors is material preparation. Common materials include high-strength alloys, stainless steel, and plastics, each chosen for their specific mechanical properties. Suppliers often source materials that comply with international standards such as ASTM or ISO specifications to ensure quality and compatibility.

During this phase, materials undergo various treatments such as heat treatment and surface hardening to enhance durability and wear resistance. B2B buyers should inquire about the source and certification of materials, as these factors significantly impact the quality of the final product.

Illustrative image related to coupling shaft motor

How Is the Forming Process Conducted for Coupling Shaft Motors?

Once materials are prepared, the forming process begins. Techniques such as machining, forging, and casting are commonly employed to create the necessary shapes and dimensions.

- Machining: This involves cutting materials to precise specifications using CNC machines, which provide high accuracy and repeatability.

- Forging: A process that enhances material strength through deformation under pressure, ensuring a robust structure.

- Casting: Used for complex shapes, where molten metal is poured into molds and allowed to solidify.

B2B buyers should assess the manufacturing capabilities of suppliers, particularly their machinery and technology, as these directly influence production efficiency and product quality.

What Assembly Techniques Are Used in Coupling Shaft Motors?

The assembly stage involves integrating various components, such as hubs, elastomers, and couplings. Depending on the design, this can require specialized techniques:

- Press-Fitting: Components are tightly fitted together, ensuring minimal backlash and high torque transmission.

- Adhesive Bonding: Often used for non-metal components to provide additional flexibility and dampening.

- Welding: Utilized for metal components to create strong, permanent joints.

Quality during assembly is crucial; any misalignment can lead to operational inefficiencies and increased wear. Buyers should look for suppliers that utilize automated assembly processes to maintain consistency and quality.

What Finishing Processes Are Important for Coupling Shaft Motors?

Finishing processes enhance the surface quality and performance characteristics of coupling shaft motors. Common techniques include:

- Surface Treatment: Processes like anodizing, plating, or painting improve corrosion resistance and aesthetic appeal.

- Balancing: Ensures that the rotating parts do not cause vibrations that could lead to mechanical failure.

- Inspection: Post-finishing inspection is essential to ensure that all specifications are met before products are dispatched.

B2B buyers should request detailed reports on finishing processes and final inspections to confirm that the products meet their operational needs.

Illustrative image related to coupling shaft motor

What Quality Control Measures Are in Place for Coupling Shaft Motors?

Quality control (QC) is integral to the manufacturing process, ensuring that coupling shaft motors meet industry standards and customer expectations.

Which International Standards Apply to Coupling Shaft Motors?

Manufacturers typically adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality and continuously improve their processes.

In addition to ISO certifications, industry-specific standards may apply. For example, CE marking is essential for products sold in Europe, while API standards are critical in the oil and gas industry. Buyers should verify that suppliers hold the necessary certifications for their target markets.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process to catch defects early. These include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, which can include dimensional checks and functional tests.

- Final Quality Control (FQC): A thorough examination of the finished product, including performance testing and dimensional verification.

Understanding these checkpoints allows B2B buyers to ask informed questions about a supplier’s QC processes.

Illustrative image related to coupling shaft motor

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier meets quality standards, B2B buyers can undertake several verification methods:

- Audits: Conducting on-site audits provides firsthand insight into the supplier’s manufacturing processes and quality assurance practices.

- Quality Reports: Requesting detailed quality control reports, including inspection results and compliance certifications, helps verify adherence to standards.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of product quality before shipment.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality.

- Regulatory Compliance: Different regions have varying regulatory requirements that must be understood and adhered to. Buyers should familiarize themselves with local regulations that may impact product use.

- Cultural and Language Barriers: Communication can be a challenge. Buyers should ensure that suppliers can provide documentation and support in languages they understand.

- Logistical Considerations: Shipping and handling can affect product quality. Buyers should inquire about packaging and transport methods to mitigate risks during transit.

By understanding these nuances, B2B buyers can make informed decisions and foster successful partnerships with suppliers of coupling shaft motors.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘coupling shaft motor’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure coupling shaft motors. It provides a systematic checklist to ensure that you make informed decisions throughout the purchasing process. By following these steps, you can identify the right products, evaluate suppliers effectively, and ensure that the motors meet your operational needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the coupling shaft motors you require. This includes parameters such as torque ratings, shaft diameters, material requirements, and environmental conditions. Clearly defined specifications help streamline the selection process and ensure compatibility with your existing systems.

- Torque Ratings: Determine the maximum torque the motor will need to handle to avoid performance issues.

- Shaft Dimensions: Measure the shaft diameter and length to ensure a proper fit.

Step 2: Research Market Options

Conduct thorough market research to identify the different types of coupling shaft motors available. Familiarize yourself with various designs, such as flexible couplings, rigid couplings, and specialized options like magnetic couplings.

- Industry Trends: Look for emerging technologies or advancements in coupling design that may offer enhanced performance or efficiency.

- Supplier Diversity: Consider sourcing from multiple regions, including Europe, Africa, and South America, to access a wider range of products.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a comprehensive evaluation. Review their company profiles, product offerings, and customer testimonials to gauge reliability and expertise.

- Request Documentation: Ask for certifications, quality assurance protocols, and case studies relevant to your industry.

- Check References: Reach out to existing clients to gain insights into their experiences with the supplier.

Step 4: Assess Quality and Compliance Standards

Verify that the coupling shaft motors meet relevant industry standards and regulations. Compliance with international standards ensures product reliability and safety, which is crucial for operational efficiency.

- Quality Certifications: Look for ISO certifications or other industry-specific quality marks.

- Testing Protocols: Inquire about the testing processes the supplier employs to ensure product durability and performance.

Step 5: Consider After-Sales Support and Warranty

Assess the after-sales support offered by potential suppliers, including warranty terms and maintenance services. Strong support can significantly reduce downtime and maintenance costs over the motor’s lifecycle.

Illustrative image related to coupling shaft motor

- Warranty Coverage: Ensure the warranty duration covers potential defects or failures.

- Technical Support: Confirm the availability of technical assistance for installation and troubleshooting.

Step 6: Request Samples or Prototypes

If feasible, request samples or prototypes of the coupling shaft motors. Testing these units in your operational environment can provide valuable insights into performance and compatibility before making a bulk purchase.

- Performance Testing: Evaluate the motor under real operational conditions to verify its suitability.

- Feedback from Technicians: Gather input from your technical team on the ease of installation and functionality.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a suitable supplier, enter into negotiations regarding pricing, delivery timelines, and payment terms. Clear agreements help prevent misunderstandings and ensure a smooth procurement process.

- Volume Discounts: Discuss potential discounts for bulk orders to optimize your budget.

- Delivery Schedules: Set clear expectations for delivery times to align with your project timelines.

By following this checklist, you can ensure a thorough and effective sourcing process for coupling shaft motors, ultimately leading to enhanced operational performance and reliability.

Illustrative image related to coupling shaft motor

Comprehensive Cost and Pricing Analysis for coupling shaft motor Sourcing

When sourcing coupling shaft motors, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Coupling Shaft Motors?

-

Materials: The primary cost driver in coupling shaft motors is the materials used. High-performance couplings often incorporate advanced materials such as stainless steel or specialized polymers, which can significantly impact pricing. Variations in material quality can lead to substantial differences in durability and performance, influencing the overall cost.

-

Labor: Labor costs are inherently variable, depending on the region of manufacture. Countries with higher labor costs may see increased prices for coupling shaft motors. Conversely, manufacturers in regions with lower labor costs may offer competitive pricing but might compromise on quality or certification standards.

-

Manufacturing Overhead: This encompasses costs related to production facilities, machinery, and technology. Efficient manufacturing processes can help keep these costs down, allowing for more competitive pricing.

-

Tooling: Custom tooling for specific applications can elevate costs. Buyers needing tailored solutions should be aware that initial tooling investments can be significant, but they can lead to cost savings in the long run through optimized production processes.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and performance. While stringent QC measures can raise manufacturing costs, they are essential for minimizing defects and ensuring longevity in high-stress applications.

-

Logistics: Transportation costs, including shipping and handling, can vary greatly based on distance, shipping method, and Incoterms. For international buyers, understanding the logistics costs associated with sourcing from different regions can greatly affect the total cost.

-

Margin: Supplier margins can differ based on brand reputation, market demand, and exclusivity of the product. Buyers should evaluate whether the markup reflects the value provided, especially when considering long-term partnerships.

What Influences Pricing for Coupling Shaft Motors?

-

Volume/MOQ: Bulk purchases often qualify for discounts. Buyers should negotiate minimum order quantities (MOQ) to leverage better pricing, especially in markets where suppliers are eager to secure large contracts.

-

Specifications and Customization: Customization can significantly influence pricing. Specific requirements may lead to higher costs due to specialized manufacturing processes. Buyers should carefully assess whether customization is necessary or if standard products can meet their needs.

-

Material Quality and Certifications: Certifications (e.g., ISO, CE) can also affect pricing. Products that meet higher standards typically come at a premium but may provide better performance and reliability, justifying the cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing strategies. Established suppliers may offer better warranties and after-sales support, which can mitigate long-term costs, making them worth the higher upfront price.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost structure.

What Tips Should Buyers Consider for Cost-Efficiency?

-

Negotiation: Always negotiate pricing and terms. Suppliers may be willing to adjust prices based on factors like volume and payment terms, especially in competitive markets.

-

Total Cost of Ownership (TCO): Evaluate the TCO, not just the upfront price. Consider factors like maintenance, energy efficiency, and downtime to make informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that may affect pricing. Establishing relationships with local distributors can also mitigate some of these costs.

-

Research and Compare: Conduct thorough research on various suppliers and products. Comparing specifications, prices, and reviews can provide valuable insights into the best options available.

In conclusion, sourcing coupling shaft motors involves a nuanced understanding of costs and pricing dynamics. By considering these factors, international buyers can make informed decisions that enhance their operational efficiency and profitability. Always remember that prices can vary significantly based on the aforementioned factors, so it’s advisable to seek multiple quotes and conduct due diligence before finalizing purchases.

Alternatives Analysis: Comparing coupling shaft motor With Other Solutions

Exploring Alternatives to Coupling Shaft Motors

In the realm of industrial machinery and equipment, coupling shaft motors serve as a pivotal component for transmitting power and motion between shafts. However, several alternative solutions can achieve similar objectives, each with unique advantages and limitations. This analysis will compare coupling shaft motors against two viable alternatives: Flexible Couplings and Magnetic Couplings.

Comparison Table

| Comparison Aspect | Coupling Shaft Motor | Flexible Couplings | Magnetic Couplings |

|---|---|---|---|

| Performance | High torque transmission; stable operation | Good flexibility for misalignment; moderate torque | Zero contact; high misalignment tolerance |

| Cost | Generally higher initial investment | Moderate cost; varies by type | Typically higher due to advanced technology |

| Ease of Implementation | Requires precise alignment; installation can be complex | Easier to install; versatile configurations | Simple setup; no need for precise alignment |

| Maintenance | Moderate; requires periodic checks | Low; minimal maintenance needed | Very low; no wear components |

| Best Use Case | Heavy machinery requiring precise torque | Applications with misalignment concerns | Sensitive applications needing minimal wear |

Detailed Breakdown of Alternatives

Flexible Couplings

Flexible couplings are designed to connect two shafts while accommodating misalignment, making them suitable for applications where shafts may not be perfectly aligned. They allow for angular, parallel, and axial misalignment, thus reducing stress on machinery components. Their moderate cost and ease of installation make them an attractive option for many industries. However, they may not transmit as much torque as coupling shaft motors, which could be a limitation in high-demand applications.

Magnetic Couplings

Magnetic couplings employ magnetic fields to transmit torque without any physical contact between the driving and driven shafts. This non-contact method minimizes wear and eliminates the need for lubrication, leading to a significantly longer operational lifespan and reduced maintenance. Their ability to handle significant misalignment makes them ideal for sensitive applications where precision is paramount. However, the initial cost can be higher due to the advanced technology involved, and they may not be suitable for all types of machinery.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate coupling solution, B2B buyers should assess their specific operational requirements, including the level of torque needed, tolerance for misalignment, maintenance capabilities, and budget constraints. Coupling shaft motors are ideal for heavy-duty applications that demand high torque and stability. In contrast, flexible couplings provide a cost-effective solution for moderate torque needs with misalignment capabilities. Meanwhile, magnetic couplings offer cutting-edge technology for applications where wear reduction and minimal maintenance are critical. By carefully evaluating these factors, buyers can make informed decisions that align with their operational goals and enhance overall efficiency.

Illustrative image related to coupling shaft motor

Essential Technical Properties and Trade Terminology for coupling shaft motor

What Are the Key Technical Properties of Coupling Shaft Motors?

When selecting a coupling shaft motor, understanding its technical properties is crucial for ensuring optimal performance in your machinery. Here are several critical specifications to consider:

1. Material Grade

The material grade of a coupling shaft motor significantly impacts its durability and performance. Common materials include steel, aluminum, and various polymers. Steel couplings offer high strength and resistance to wear, making them suitable for heavy-duty applications. In contrast, aluminum provides a lightweight alternative, ideal for applications requiring reduced inertia. Selecting the right material can lead to longer service life and lower maintenance costs, enhancing overall operational efficiency.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. High precision in tolerance is essential for ensuring the proper alignment and functioning of the coupling. Tight tolerances reduce the risk of misalignment, which can lead to increased wear and tear or even system failure. For B2B buyers, understanding tolerance levels is vital in selecting couplings that meet the specific requirements of their machinery, ensuring reliability and performance.

3. Torque Capacity

The torque capacity of a coupling indicates the maximum torque it can handle without failure. This specification is critical for applications with variable loads, as exceeding the torque capacity can lead to mechanical failure. B2B buyers should ensure that the selected coupling can accommodate the peak torque of their application to avoid costly downtimes and repairs.

Illustrative image related to coupling shaft motor

4. Misalignment Capability

Shaft couplings are designed to accommodate certain degrees of misalignment (parallel, axial, or angular). Understanding the misalignment capabilities of a coupling is essential, especially in applications where precise alignment is challenging. Couplings with higher misalignment tolerance can absorb shocks and vibrations, leading to smoother operation and reduced mechanical stress.

5. Backlash

Backlash is the play between the coupling components that can affect the precision of power transmission. In applications requiring high accuracy, such as robotics or CNC machinery, minimizing backlash is crucial. Buyers should seek couplings designed to provide zero or minimal backlash to maintain the integrity of their operations.

What Are Common Trade Terms Related to Coupling Shaft Motors?

Familiarity with industry jargon can enhance communication and negotiation between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of coupling shaft motors, understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing equipment.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it affects inventory management and procurement strategies. Knowing the MOQ can help businesses plan their purchases to optimize costs and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal request for price proposals from suppliers. Buyers use RFQs to compare pricing and terms from multiple vendors, making it an essential tool for procurement. A well-prepared RFQ can lead to better pricing and contract terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Familiarity with Incoterms can help B2B buyers navigate shipping costs, risks, and responsibilities, ensuring smooth transactions across borders.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is critical for project planning and inventory management. Buyers should consider lead times when selecting suppliers to ensure timely delivery and avoid production delays.

Illustrative image related to coupling shaft motor

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing coupling shaft motors, ultimately enhancing their operational efficiency and competitiveness in the market.

Navigating Market Dynamics and Sourcing Trends in the coupling shaft motor Sector

What Are the Key Trends Influencing the Coupling Shaft Motor Market?

The coupling shaft motor market is witnessing dynamic shifts driven by several global factors. Increased demand for automation across various industries, such as manufacturing, automotive, and energy, is propelling the market forward. Emerging technologies like Industry 4.0 and the Internet of Things (IoT) are also reshaping how businesses approach motor coupling solutions. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking advanced coupling solutions that offer enhanced performance, reliability, and flexibility.

Sourcing trends are leaning towards customized solutions that cater to specific operational requirements. Buyers are prioritizing suppliers who can provide high-quality, durable couplings designed for various applications, including high-torque environments and environments with significant misalignment challenges. Furthermore, the rising interest in predictive maintenance technologies allows businesses to reduce downtime and improve operational efficiency. Buyers are encouraged to align themselves with manufacturers who leverage advanced engineering techniques, such as finite element analysis (FEA), to optimize product performance.

Additionally, globalization is influencing sourcing strategies, with buyers seeking suppliers that can offer competitive pricing without compromising quality. This trend is particularly relevant in emerging markets where cost-effectiveness is paramount. As international trade barriers continue to diminish, the ability to source from diverse suppliers will be crucial for businesses aiming to maintain a competitive edge.

How Does Sustainability and Ethical Sourcing Impact the Coupling Shaft Motor Sector?

Sustainability and ethical sourcing have become central considerations for B2B buyers in the coupling shaft motor sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, has led companies to adopt greener practices. Buyers are increasingly seeking suppliers that utilize sustainable materials and processes, such as recycled metals and eco-friendly manufacturing techniques, which reduce carbon footprints.

The importance of ethical supply chains cannot be overstated, especially in regions like Africa and South America, where social and environmental issues may be more pronounced. Buyers are encouraged to partner with suppliers who demonstrate transparency in their sourcing practices and adhere to international labor standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are valuable indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the growing focus on sustainability is pushing manufacturers to innovate, leading to the development of ‘green’ coupling solutions that incorporate biodegradable materials and energy-efficient designs. This trend not only enhances corporate social responsibility but also meets the increasing consumer demand for environmentally conscious products. By prioritizing sustainable sourcing, B2B buyers can enhance their brand reputation and appeal to a broader customer base.

What Is the Historical Context of the Coupling Shaft Motor Market?

The coupling shaft motor sector has evolved significantly over the past few decades. Initially, couplings were primarily mechanical devices designed to connect two shafts and transmit power. Early designs focused on basic functionality, with limited consideration for factors like misalignment and torque variations.

As technology advanced, the introduction of flexible couplings allowed for greater tolerance of misalignments, which became crucial as industries expanded and machinery became more complex. The late 20th century saw the rise of computer-aided design (CAD) and finite element analysis (FEA), enabling manufacturers to create more sophisticated coupling solutions tailored to specific applications. This evolution has led to the diverse range of coupling types available today, including metal disc couplings, jaw and spider couplings, and magnetic couplings, each designed to meet unique operational demands.

Today, the coupling shaft motor market is characterized by a blend of traditional engineering and cutting-edge technology, reflecting the ongoing need for efficiency, reliability, and sustainability. This historical perspective underscores the importance of aligning with suppliers who are not only aware of past innovations but are also forward-thinking in their approach to product development and market responsiveness.

Frequently Asked Questions (FAQs) for B2B Buyers of coupling shaft motor

-

1. How do I solve alignment issues with coupling shaft motors?

Alignment issues can lead to premature wear and operational inefficiencies in coupling shaft motors. To address this, ensure that both shafts are aligned within the manufacturer’s specified tolerance levels. Utilize alignment tools like laser alignment systems or dial indicators for precision. Additionally, consider flexible couplings that can accommodate minor misalignments. Regular maintenance checks are crucial to identify and rectify alignment issues before they escalate. -

2. What is the best coupling type for high-torque applications?

For high-torque applications, metal disc couplings are often the best choice due to their superior torsional rigidity and ability to handle misalignments. These couplings minimize backlash and provide reliable power transmission. Other options include jaw and spider couplings, which also offer high torque capacity and shock absorption. The right choice depends on specific application requirements, including load type and environmental factors. -

3. How do I vet suppliers for coupling shaft motors internationally?

When vetting suppliers, prioritize those with a proven track record in your industry. Check for certifications like ISO 9001, which indicates a commitment to quality management. Request references from previous clients and evaluate their responsiveness and customer service. It’s also beneficial to visit their manufacturing facilities if possible, or request a virtual tour, to ensure their production capabilities meet your standards. -

4. What customization options are available for coupling shaft motors?

Most manufacturers offer various customization options, including material selection, size, and specific design features tailored to your application. Discuss your requirements early in the sourcing process to determine available options. Custom solutions can enhance performance, especially in specialized industries like automotive or robotics, where unique operational demands exist. -

5. What are the minimum order quantities (MOQs) for coupling shaft motors?

MOQs can vary significantly among suppliers, often influenced by the type of coupling and the manufacturing process. Some suppliers may offer lower MOQs for standard products, while custom solutions typically have higher MOQs due to setup costs. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms that align with your project requirements. -

6. What payment terms should I expect when sourcing coupling shaft motors?

Payment terms can vary widely based on supplier policies and your negotiation power. Common arrangements include a percentage upfront, with the remainder due upon delivery or after a specified period. Always clarify payment terms before finalizing contracts, and consider utilizing secure payment methods or trade finance options to mitigate risks, especially in international transactions. -

7. How can I ensure quality assurance (QA) for coupling shaft motors?

To ensure quality assurance, request detailed product specifications and certifications from your supplier. Consider implementing a third-party inspection service to evaluate the products before shipment. Establish clear quality metrics and communicate them to your supplier. Additionally, conducting regular audits of your supplier’s production processes can help maintain high standards throughout the manufacturing cycle. -

8. What are the logistics considerations when importing coupling shaft motors?

When importing coupling shaft motors, consider shipping methods, customs regulations, and potential tariffs. Choose logistics partners experienced in handling industrial equipment to ensure timely delivery. Verify that the supplier provides necessary shipping documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. Additionally, assess the total landed cost, which includes shipping, duties, and taxes, to accurately budget for your purchase.

Top 9 Coupling Shaft Motor Manufacturers & Suppliers List

1. McMaster – Flexible and Rigid Shaft Couplings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Flexible and Rigid Shaft Couplings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Miki Pulley – Motor Drive Shaft Couplings

Domain: mikipulley-us.com

Registered: 2013 (12 years)

Introduction: Motor Drive Shaft Couplings: High performance shaft couplings used to join two shafts to transmit power and rotational motion, allowing for some degree of parallel, axial, or angular misalignment. Specific models with torque limiting capabilities permit slipping or automatic disconnection when a specified torque limit is reached. Miki Pulley’s shaft coupling lineup includes: Metal Disc Couplings, …

3. Phidgets – Spiral Beam Coupling 4mm

Domain: phidgets.com

Registered: 2002 (23 years)

Introduction: Shaft Couplers – Phidgets offers a variety of shaft couplers designed to connect two differently sized rotary shafts with flexibility to account for misalignment. Key products include:

1. Spiral Beam Coupling 4mm – 4mm: Aluminium, connects two 4mm shafts, set screws, 378 in stock, $3.50.

2. Spiral Beam Coupling 5-5mm: Aluminium, connects two 5mm shafts, set screws, 220 in stock, $7.50, clearance …

4. Palmer’s Electric – Motor Couplings

Domain: palmerselectric.com

Registered: 1999 (26 years)

Introduction: Electric Motor Couplings are connection components used to transmit torque between a drive shaft and a driven part, such as a motor shaft and a ball screw. They introduce mechanical flexibility to eliminate misalignment issues, preventing vibration, uneven wear, and other mechanical troubles. Available products include Flex Type Couplings and StarFlex Couplings from brands like Maska and Baldor Do…

5. Motion – Shaft Couplings

Domain: motion.com

Registered: 1994 (31 years)

Introduction: Motion supplies a vast inventory of shaft couplings, including elastomeric flexible couplings and fluid couplings. Elastomeric flexible couplings compensate for shaft misalignment and deformation and do not require lubrication. Fluid couplings use hydraulic fluid to transmit rotational power between shafts. The product categories include: Fluid Couplings, Jaw and Wrap Type Couplings, Metallic Chai…

6. IQS Directory – Shaft Couplings

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Shaft couplings are components that join two shafts to transmit power while accommodating alignment challenges. They reduce impact, wear, vibrations, and noise, and are used in motors, generators, pumps, compressors, turbines, and engines. Key types include rigid and flexible couplings. They allow for efficient power transmission and torque handling, accommodating minor misalignments and promoting…

7. OMC – Shaft Couplings

Domain: omc-stepperonline.com

Registered: 2013 (12 years)

Introduction: Shaft Coupling Types: Beam Shaft Coupling, Disc Shaft Coupling, Jaw Shaft Coupling, Rigid Shaft Coupling. Matching Shaft Diameter Options: 5 – 6 mm, 5 – 6.35 mm, 5 – 5 mm, 5 – 8 mm, 6 – 8 mm, 6 – 6.35 mm, 6 – 10 mm.

8. WorldWide Electric – Vertical Hollow Shaft Couplings

Domain: worldwideelectric.com

Registered: 1999 (26 years)

Introduction: WorldWide Electric offers Vertical Hollow Shaft Couplings as an accessory. A standard coupling, sized for your Vertical Hollow Shaft Motor is included with the purchase of the motor. Compatible model numbers include: MC5006/8P-2.5, MC5006/8P-2.251, MC5006/8P-2.1875, MC5006/8P-2.001, MC5006/8P-1.9375, MC5006/8P-1.8125, MC5006/8P-1.75, MC5006/8P-1.6875, MC5006/8P-1.5, MC440-2.1875, MC440-1.9375, MC4…

9. Ato – Shaft Couplings

Domain: ato.com

Registered: 1997 (28 years)

Introduction: This company, Ato – Shaft Couplings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for coupling shaft motor

How Can Strategic Sourcing Enhance Your Procurement of Coupling Shaft Motors?

In conclusion, the strategic sourcing of coupling shaft motors is essential for optimizing operational efficiency and driving long-term cost savings. By understanding the diverse range of coupling types—such as flex, jaw, and magnetic couplings—international B2B buyers can make informed decisions that align with their specific application needs. Sourcing high-quality components not only minimizes downtime but also enhances the performance and reliability of machinery, a critical factor for industries across Africa, South America, the Middle East, and Europe.

As buyers navigate the complexities of global supply chains, forging strong partnerships with reputable manufacturers can yield significant advantages, including access to innovative technologies and competitive pricing. Emphasizing quality and performance in procurement strategies is paramount for sustaining a competitive edge in the marketplace.

Looking ahead, the demand for advanced coupling solutions is expected to rise, driven by technological advancements and the evolving needs of various industries. Now is the time to reevaluate your sourcing strategies and engage with trusted suppliers who can provide tailored solutions for your coupling shaft motor requirements. Take action today to secure your competitive advantage and ensure your operations run smoothly and efficiently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.