Copper Sheathing: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for copper sheathing

Navigating the complexities of sourcing copper sheathing can be a daunting challenge for B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe. The demand for high-quality copper sheathing is driven by its extensive applications in marine, construction, and electrical industries, yet finding reliable suppliers who can meet specific project requirements in terms of quality, cost, and delivery can complicate the purchasing process. This comprehensive guide aims to simplify that journey by providing actionable insights into the various types of copper sheathing available, their applications, and critical factors to consider when vetting suppliers.

From understanding the nuances of different copper alloys to evaluating the cost implications of various thicknesses and finishes, this guide equips international buyers with the knowledge needed to make informed purchasing decisions. We delve into essential topics, including supplier certifications, shipping logistics, and market trends, ensuring that you are well-prepared to navigate the global copper sheathing landscape. Whether you’re operating in bustling markets like Vietnam or Nigeria, this resource is designed to empower your sourcing strategy, helping you secure the best materials for your projects while maximizing value and minimizing risk. With the right insights, you can confidently approach your copper sheathing needs and ensure the success of your operations.

Understanding copper sheathing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Copper Sheathing | High conductivity, excellent corrosion resistance | Electrical applications, marine uses | Pros: High purity, versatile. Cons: Higher cost compared to alloys. |

| Copper-Nickel Alloys | Enhanced resistance to corrosion and biofouling | Shipbuilding, offshore structures | Pros: Durable, effective in saline environments. Cons: More expensive than pure copper. |

| Copper Foil | Very thin, flexible sheets | Crafting, electronics, decorative uses | Pros: Lightweight, easy to manipulate. Cons: Less durable for structural applications. |

| Patina Copper Sheathing | Unique aesthetic due to oxidation | Architectural applications, art projects | Pros: Attractive appearance, customizable. Cons: Requires maintenance to preserve patina. |

| Hammered Copper Sheets | Textured surface, enhanced aesthetic appeal | Interior design, custom artwork | Pros: Distinctive look, adds value to projects. Cons: Labor-intensive to produce. |

What are the Characteristics and Suitability of Pure Copper Sheathing?

Pure copper sheathing is known for its high electrical and thermal conductivity, making it ideal for electrical applications and marine environments. Its excellent corrosion resistance ensures longevity, especially in harsh conditions. B2B buyers should consider the purity level, as higher purity translates to better performance in specialized applications. However, the cost may be a concern, as pure copper is generally more expensive than alloys. It is suitable for projects requiring high-quality materials, such as electrical wiring and marine sheathing.

How Do Copper-Nickel Alloys Enhance Performance in Marine Applications?

Copper-nickel alloys offer superior resistance to corrosion and biofouling, making them an excellent choice for shipbuilding and offshore structures. The addition of nickel enhances the mechanical properties and durability of the copper, especially in saline environments. B2B buyers should evaluate the specific alloy composition to ensure it meets their operational requirements. While these alloys provide long-term benefits, they come at a higher price point, which may impact budget considerations for large-scale projects.

What Advantages Does Copper Foil Offer for B2B Buyers?

Copper foil is characterized by its thinness and flexibility, making it a popular choice for crafting, electronics, and decorative applications. Its lightweight nature allows for easy handling and installation, which is advantageous for projects requiring intricate designs or detailed work. However, its lower durability compared to thicker sheathing may limit its use in structural applications. B2B buyers should assess the intended use to determine if the benefits of copper foil align with their project needs.

Why is Patina Copper Sheathing a Unique Choice for Architectural Projects?

Patina copper sheathing develops a distinctive aesthetic due to the oxidation process, resulting in a range of beautiful color variations. This makes it a favored option for architectural applications and artistic projects where visual appeal is paramount. B2B buyers should consider the maintenance required to preserve the patina, as it may change over time. While patina sheathing can enhance the overall value of a project, it may necessitate additional care to maintain its appearance.

How Do Hammered Copper Sheets Add Value to Design Projects?

Hammered copper sheets feature a textured surface that enhances their aesthetic appeal, making them ideal for interior design and custom artwork. The unique patterns created during the hammering process add a distinct character to projects, elevating their overall value. However, the production of hammered sheets can be labor-intensive, which may increase costs. B2B buyers should weigh the artistic benefits against budget constraints when considering this option for their design needs.

Key Industrial Applications of copper sheathing

| Industry/Sector | Specific Application of Copper Sheathing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Shipbuilding | Hull protection for ships and boats | Extends the lifespan of vessels by preventing marine growth and corrosion | Quality of copper, thickness, and corrosion resistance standards |

| Electrical Engineering | RFI shielding in electronic devices | Enhances performance and reliability of sensitive electronics | Purity of copper, thickness, and compliance with international standards |

| Construction and Architecture | Decorative elements and roofing materials | Provides aesthetic appeal along with durability and weather resistance | Sourcing from reputable suppliers, availability of various thicknesses and finishes |

| Art and Craftsmanship | Artistic installations and sculptures | Offers malleability for creative designs while maintaining durability | Availability of various sheet sizes and custom thickness options |

| Renewable Energy | Components in solar panel frames and wind turbine systems | Enhances efficiency and longevity of renewable energy systems | Sourcing high-purity copper for optimal conductivity and corrosion resistance |

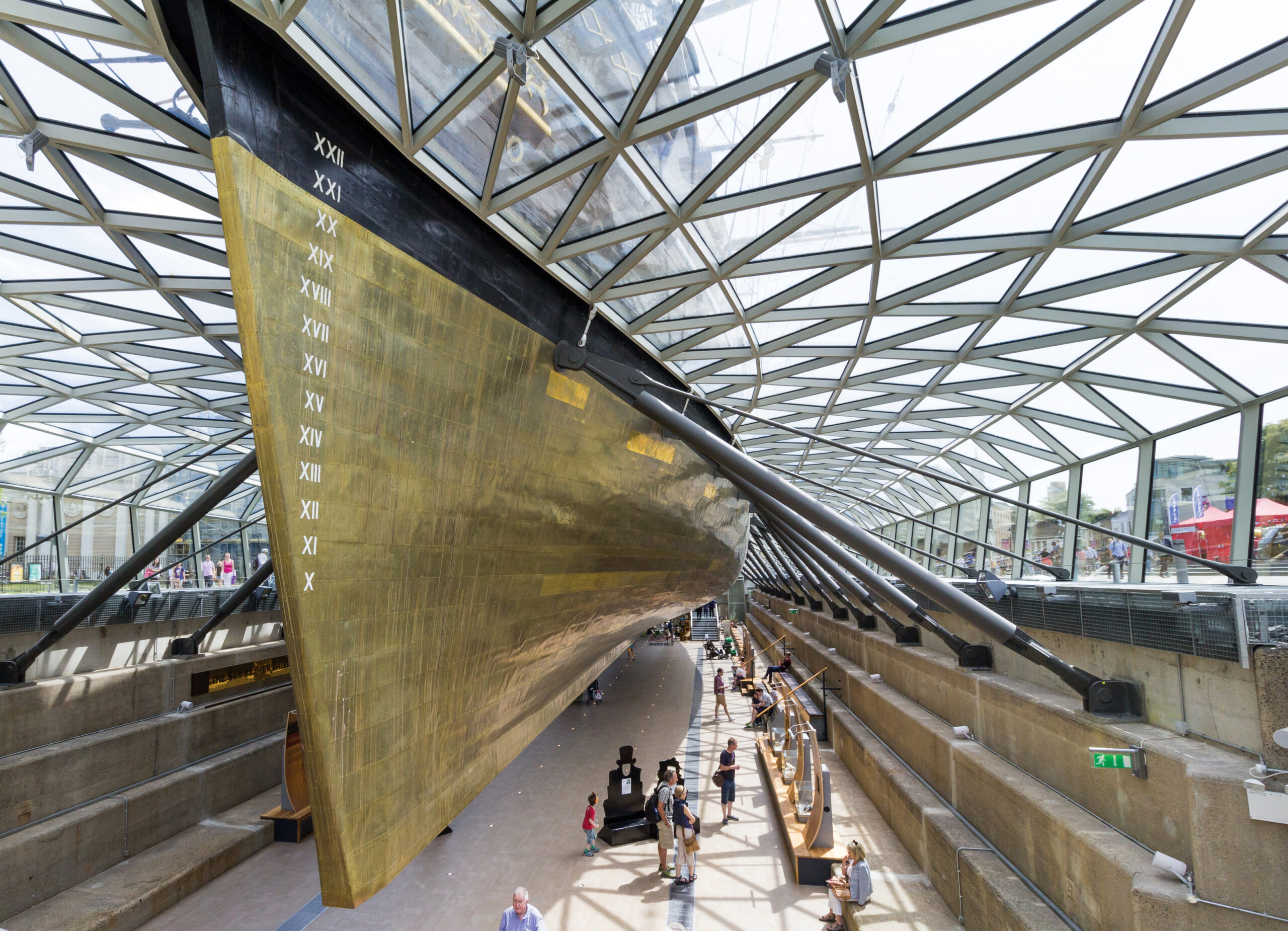

How is Copper Sheathing Used in Marine and Shipbuilding?

Copper sheathing is extensively utilized in marine applications, particularly for the protection of ship hulls. By preventing marine organisms like barnacles and mollusks from adhering to the hull, copper sheathing significantly extends the lifespan of vessels. For B2B buyers in regions such as Africa and South America, it is crucial to consider the quality and thickness of copper sheathing, as these factors directly influence durability and performance in various marine environments.

What Role Does Copper Sheathing Play in Electrical Engineering?

In the field of electrical engineering, copper sheathing is employed for radio frequency interference (RFI) shielding in sensitive electronic devices. This application ensures that devices operate reliably without interference from external signals. International buyers must prioritize sourcing high-purity copper that meets stringent electrical conductivity standards, ensuring optimal performance in their applications.

How is Copper Sheathing Applied in Construction and Architecture?

Copper sheathing serves as a versatile material in construction and architecture, particularly for roofing and decorative elements. Its natural corrosion resistance and aesthetic appeal make it a preferred choice among architects and builders. When sourcing copper sheathing for construction projects in the Middle East or Europe, buyers should focus on the supplier’s reputation and the availability of various finishes and thicknesses to meet specific design requirements.

Why is Copper Sheathing Important for Art and Craftsmanship?

Artists and craftsmen utilize copper sheathing for creating intricate sculptures and decorative installations. Its malleability allows for detailed designs while maintaining structural integrity. For B2B buyers in markets like Nigeria and Vietnam, it is essential to consider the availability of different sheet sizes and custom thickness options to meet artistic needs and project specifications.

How Does Copper Sheathing Benefit Renewable Energy Systems?

In renewable energy applications, copper sheathing is used in the frames of solar panels and components of wind turbines. This material enhances the efficiency and longevity of energy systems by providing excellent conductivity and corrosion resistance. Buyers in emerging markets should ensure they source high-purity copper to maximize performance and comply with international standards in renewable energy technologies.

3 Common User Pain Points for ‘copper sheathing’ & Their Solutions

Scenario 1: Sourcing Quality Copper Sheathing for Marine Applications

The Problem:

B2B buyers in the marine industry often struggle with sourcing high-quality copper sheathing that meets stringent industry standards. Issues may arise from inconsistent product quality, leading to concerns about corrosion resistance and durability. For instance, a shipbuilding company in South America may find that the copper sheathing they received does not withstand marine conditions, causing delays in projects and increased costs for replacements. The challenge is further compounded by the need to ensure that the copper is sourced from reputable suppliers who can guarantee the required specifications, such as thickness and alloy composition.

The Solution:

To mitigate these risks, buyers should establish relationships with trusted suppliers who provide comprehensive product specifications and quality certifications. It is advisable to request samples before placing bulk orders, enabling buyers to assess the material’s quality firsthand. Additionally, using a standardized specification guide, such as ASTM B370 for copper sheets, can help ensure that the copper sheathing meets the necessary performance criteria for marine applications. Engaging in regular communication with suppliers about quality control processes and sourcing practices is also essential to ensure ongoing compliance with industry standards.

Scenario 2: Managing Installation Challenges for Copper Sheathing

The Problem:

Installing copper sheathing presents unique challenges, especially when dealing with complex hull shapes in shipbuilding or architectural projects. For example, a construction firm in Europe may encounter difficulties aligning and securing copper sheets on a curved surface, which can lead to improper installation and reduced effectiveness. Misalignment can also cause water ingress, ultimately compromising the integrity of the structure and leading to costly repairs.

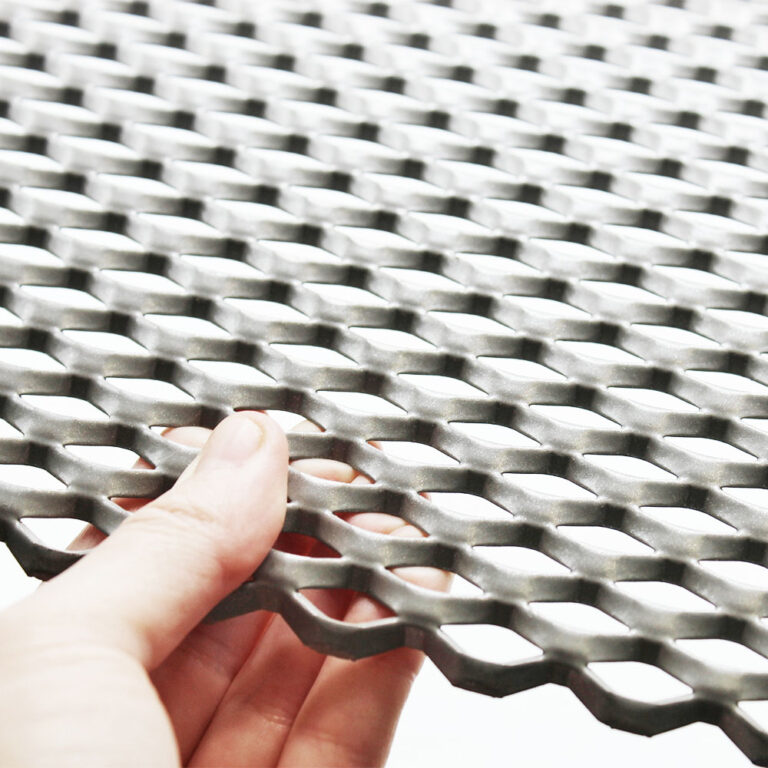

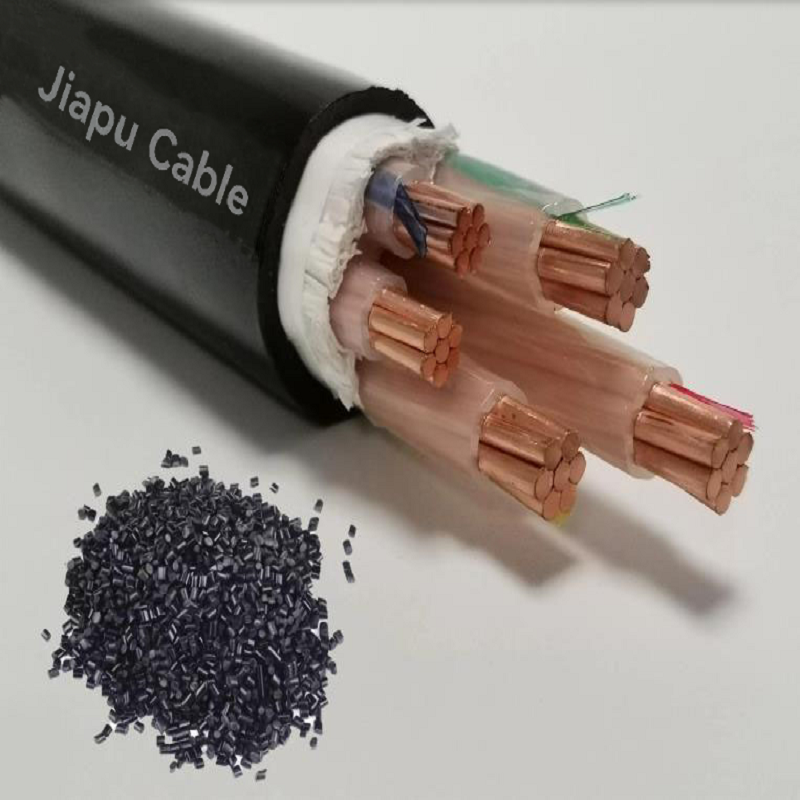

Illustrative image related to copper sheathing

The Solution:

To address installation challenges, it is crucial to employ a skilled workforce trained in working with copper sheathing. Providing training sessions on best practices for installation techniques, such as the “goring belt” method used in historical contexts, can significantly enhance installation accuracy. Additionally, using specialized tools like pneumatic nailers designed for metal sheathing can facilitate more efficient and precise installation. Buyers should also consider investing in installation guides or consulting with industry experts to ensure that their teams are equipped with the knowledge needed to tackle complex installation scenarios effectively.

Scenario 3: Dealing with Environmental and Regulatory Compliance Issues

The Problem:

International buyers often face challenges related to environmental regulations and compliance when using copper sheathing. For instance, a buyer in Africa might be unaware of local regulations regarding the use of copper, which may restrict certain applications due to environmental concerns. Failure to comply with these regulations can lead to fines, project delays, and reputational damage.

The Solution:

To navigate these regulatory landscapes, B2B buyers should conduct thorough research into local environmental laws and regulations regarding copper usage. Engaging with local industry associations or regulatory bodies can provide valuable insights into compliance requirements. Furthermore, considering eco-friendly alternatives or finishes for copper sheathing that minimize environmental impact can be beneficial. Collaborating with suppliers who are knowledgeable about compliance issues can also ensure that the materials used are not only high quality but also adhere to local environmental standards, thus safeguarding the buyer’s operations and reputation.

Illustrative image related to copper sheathing

Strategic Material Selection Guide for copper sheathing

What Are the Key Properties of Different Copper Sheathing Materials?

When selecting copper sheathing materials for various applications, it is crucial to consider the specific properties that affect performance. The most common materials include pure copper, copper alloys, tin-coated copper, and copper-nickel. Each material has unique characteristics that influence their suitability for different environments and applications.

What Are the Key Properties of Pure Copper for Sheathing?

Pure copper, known for its excellent electrical and thermal conductivity, is often the go-to choice for sheathing in marine and electrical applications. Its high corrosion resistance makes it particularly effective in preventing biofouling in marine environments. Pure copper can withstand temperatures up to 200°C (392°F) and pressures up to 10,000 psi, making it suitable for various demanding applications.

Pros:

– Exceptional conductivity and corrosion resistance.

– Malleable and easy to work with, allowing for intricate designs.

– Long lifespan due to natural patina formation that protects the metal.

Cons:

– Higher cost compared to some alloys.

– Can be prone to oxidation if not sealed or maintained properly.

How Do Copper Alloys Compare for Sheathing Applications?

Copper alloys, such as brass (copper-zinc) and bronze (copper-tin), offer enhanced strength and durability compared to pure copper. These alloys are particularly effective in applications requiring greater mechanical strength and resistance to wear. They are also more resistant to corrosion from seawater, making them ideal for marine applications.

Pros:

– Increased strength and durability.

– Better resistance to certain corrosive environments.

– Potentially lower cost than pure copper.

Illustrative image related to copper sheathing

Cons:

– Reduced electrical conductivity compared to pure copper.

– May require more complex manufacturing processes.

What Are the Benefits of Tin-Coated Copper Sheathing?

Tin-coated copper is another option that combines the benefits of copper with the corrosion resistance of tin. This material is particularly suitable for electrical applications and environments where moisture is a concern. The tin layer protects the copper from oxidation and enhances its durability.

Pros:

– Excellent corrosion resistance due to the tin coating.

– Maintains good conductivity.

– Suitable for both electrical and decorative applications.

Cons:

– The tin layer can wear off over time, exposing the copper beneath.

– Generally more expensive than pure copper.

Why Consider Copper-Nickel for Sheathing?

Copper-nickel alloys are well-regarded in marine applications due to their exceptional resistance to corrosion and biofouling. They perform well in seawater environments and can withstand higher pressures, making them ideal for shipbuilding and offshore structures.

Pros:

– Outstanding corrosion resistance in saline environments.

– Strong mechanical properties, suitable for high-pressure applications.

– Less maintenance required due to resistance to fouling.

Illustrative image related to copper sheathing

Cons:

– Higher initial cost compared to pure copper.

– More complex manufacturing processes involved.

What Should International B2B Buyers Consider?

When sourcing copper sheathing materials, international buyers, particularly from Africa, South America, the Middle East, and Europe, should consider compliance with local and international standards such as ASTM, DIN, and JIS. Understanding the specific requirements for corrosion resistance, mechanical properties, and environmental conditions in their region is crucial. Additionally, buyers should evaluate the availability of materials and suppliers in their local markets to ensure timely delivery and support.

Summary Table of Copper Sheathing Materials

| Material | Typical Use Case for Copper Sheathing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Pure Copper | Electrical applications, marine sheathing | Exceptional conductivity and corrosion resistance | Higher cost, prone to oxidation | High |

| Copper Alloys | Marine applications, structural components | Increased strength and durability | Reduced conductivity, complex manufacturing | Medium |

| Tin-Coated Copper | Electrical connections, decorative sheathing | Excellent corrosion resistance | Tin layer can wear off, higher cost | Medium |

| Copper-Nickel | Shipbuilding, offshore structures | Outstanding corrosion resistance in seawater | Higher initial cost, complex manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for copper sheathing

What Are the Main Stages of the Copper Sheathing Manufacturing Process?

The manufacturing of copper sheathing involves several critical stages that ensure the final product meets the stringent requirements of various applications, particularly in marine and construction industries.

-

Material Preparation

The process begins with the selection of high-purity copper, typically C110 grade, known for its excellent conductivity and corrosion resistance. The raw copper is sourced from reputable suppliers, and material properties are verified through certificates of analysis. This stage may involve melting and casting copper into slabs or billets, which are then cooled and further processed into sheets. -

Forming

Once the copper is prepared, it undergoes forming processes such as rolling and stamping. In rolling, the copper is passed through a series of rollers to achieve the desired thickness. The thickness of the sheets can vary, depending on end-use requirements. For example, thinner sheets are often used for decorative applications, while thicker sheets are essential for structural integrity in marine environments. Advanced techniques, such as cold working and hot rolling, may be employed to enhance the metal’s properties, including its strength and ductility. -

Assembly

In some cases, copper sheathing is assembled with other components, such as fasteners or insulation materials. This assembly may involve precision cutting, welding, or riveting to ensure a secure fit. Attention to detail is crucial, especially when preparing sheets for installation on vessels or structures, where water and environmental exposure are concerns. -

Finishing

The finishing stage includes surface treatment processes such as cleaning, polishing, and patination. A protective layer may also be applied to enhance corrosion resistance. This is especially important for applications like ship hulls, where the copper is exposed to harsh marine environments.

How Is Quality Assurance Implemented in Copper Sheathing Production?

Quality assurance (QA) is vital throughout the manufacturing process to guarantee that the copper sheathing meets international standards and customer specifications.

-

What International Standards Govern Copper Sheathing Quality?

The manufacturing process is often guided by international standards such as ISO 9001, which outlines requirements for a quality management system. Additional certifications, such as CE marking for products sold in Europe or API standards for oil and gas applications, may also apply. These certifications ensure that the products are safe, reliable, and of high quality. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of production:

– Incoming Quality Control (IQC): This initial stage involves inspecting incoming raw materials for compliance with specified standards. This includes checks for purity, thickness, and mechanical properties.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to ensure that operations are within specified tolerances. This includes monitoring temperature during rolling processes and verifying dimensional accuracy.

– Final Quality Control (FQC): Once production is complete, a final inspection assesses the finished product against the required specifications. This may involve visual inspection, dimensional checks, and performance testing. -

What Common Testing Methods Are Used?

Several testing methods are employed to ensure quality, including:

– Tensile Testing: Measures the strength and ductility of the copper.

– Hardness Testing: Assesses the material’s resistance to deformation.

– Corrosion Resistance Testing: Evaluates how well the copper can withstand environmental factors.

– Visual Inspection: Ensures there are no defects such as cracks or surface imperfections.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in diverse international markets, verifying the quality control processes of suppliers is essential. Here are key strategies:

-

Conduct Supplier Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality assurance protocols. These audits should assess compliance with relevant international standards and the effectiveness of their QC checkpoints. -

Request Quality Assurance Documentation

Buyers should request and review quality assurance documentation, including certificates of compliance, test reports, and inspection records. This documentation should detail the results of tests performed at various stages of production. -

Engage Third-Party Inspectors

Utilizing third-party inspection services can further validate the quality of copper sheathing. These independent experts can conduct inspections and testing, ensuring that products meet the required specifications before shipping.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers must navigate various quality control and certification nuances specific to their regions:

-

Understanding Regional Standards

Different regions may have unique quality standards. For instance, European buyers may need to ensure CE compliance, while buyers in the Middle East may be subject to local regulations that dictate material properties and testing methods. -

Dealing with Language and Documentation Barriers

Buyers should be prepared to address language barriers in documentation. It is crucial to ensure that all quality assurance documents are available in a language that is understandable to the buyer, as this can prevent misinterpretations. -

Building Relationships with Suppliers

Establishing strong relationships with suppliers can facilitate better communication about quality standards and expectations. Regular interactions can help clarify any ambiguities regarding QC processes and certifications.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing copper sheathing for their specific applications, ensuring they obtain high-quality materials that meet international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘copper sheathing’

To assist international B2B buyers in sourcing copper sheathing effectively, this practical guide outlines essential steps that ensure a successful procurement process. With copper’s unique properties and applications spanning various industries, understanding the specifics of sourcing is crucial for making informed decisions.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly define the technical specifications for the copper sheathing you require. Consider factors such as thickness, purity (e.g., C110 grade), and dimensions. Specific applications may demand certain attributes, like corrosion resistance or conductivity, making this step vital for aligning your needs with product offerings.

Step 2: Identify Reputable Suppliers

Research and compile a list of potential suppliers who specialize in copper sheathing. Focus on those with a proven track record in the industry. Look for suppliers with certifications such as ISO, which can indicate quality assurance and reliability. Engaging with established suppliers minimizes risks and enhances the potential for successful transactions.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps confirm the supplier’s credibility and past performance, ensuring they can meet your specific requirements.

- Check Product Quality: Request samples to assess the quality of the copper sheathing, verifying its physical and chemical properties.

- Review Client Feedback: Look for testimonials or reviews from previous customers to gauge satisfaction levels.

Step 4: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers, initiate discussions around pricing and payment terms. Copper prices can fluctuate, so obtaining quotes from multiple suppliers will aid in securing competitive pricing. Ensure to clarify payment terms, delivery schedules, and any additional costs that might be incurred.

- Consider Bulk Discounts: If your project requires large quantities, inquire about bulk pricing options.

- Review Terms of Sale: Ensure you understand the warranty and return policies.

Step 5: Verify Compliance with Standards

Ensure that the copper sheathing complies with relevant local and international standards, particularly if you’re operating in regulated industries. This step is critical to avoid potential legal and operational issues down the line.

Illustrative image related to copper sheathing

- Confirm Certifications: Request documentation that verifies compliance with standards such as ASTM or EN for materials.

- Assess Environmental Impact: Inquire about the supplier’s sustainability practices, especially if your company prioritizes eco-friendly sourcing.

Step 6: Establish a Communication Plan

Effective communication with your supplier is key throughout the procurement process. Establish a clear line of communication to discuss timelines, delivery schedules, and any issues that may arise.

- Designate Points of Contact: Identify who will manage communications on both sides to streamline the process.

- Set Regular Check-ins: Schedule updates to ensure the project remains on track and address any concerns promptly.

Step 7: Plan for Logistics and Delivery

Finally, outline a logistics plan that details how the copper sheathing will be transported from the supplier to your location. Consider factors such as shipping methods, customs clearance, and delivery timelines.

- Assess Shipping Costs: Include potential shipping fees in your budget to avoid unexpected expenses.

- Track Shipments: Utilize tracking systems to monitor the shipment’s progress and anticipate delivery.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing copper sheathing with confidence, ensuring that they acquire quality materials that meet their project specifications.

Comprehensive Cost and Pricing Analysis for copper sheathing Sourcing

What Are the Key Cost Components in Sourcing Copper Sheathing?

When sourcing copper sheathing, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of copper itself is influenced by market fluctuations and the purity level of the metal. High-purity copper (C110) is often preferred for its conductivity and corrosion resistance, but it may come at a premium. Additional costs may arise from any necessary alloys or special treatments, like patina development, which can also affect pricing.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor is required for cutting, shaping, and installing copper sheathing, especially in custom applications.

-

Manufacturing Overhead: This encompasses fixed costs such as utilities, rent, and administrative expenses associated with the production facility. Efficient operations can help mitigate these costs, impacting overall pricing.

-

Tooling: Specialized tools for cutting and processing copper sheathing can add to the initial costs. Buyers should inquire about whether these costs are included in the quoted price or if they will be passed on as additional charges.

-

Quality Control: Ensuring that products meet industry standards and certifications can incur extra expenses. Buyers should verify the quality assurance processes of suppliers to avoid costly rejections or returns.

-

Logistics: Transportation costs can vary significantly based on the origin and destination of the copper sheathing. Factors such as shipping method, distance, and tariffs must be considered, especially for international transactions.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding market rates can help buyers gauge whether they are receiving a fair price.

How Do Pricing Influencers Impact the Cost of Copper Sheathing?

Several factors can influence the pricing of copper sheathing, particularly for international buyers:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often qualify for bulk discounts, reducing the per-unit cost. Buyers should assess their needs to negotiate favorable terms.

-

Specifications and Customization: Customized copper sheathing, such as specific thicknesses or finishes, can significantly affect pricing. Suppliers may charge more for bespoke orders, so clarity on specifications is essential.

-

Material Quality and Certifications: Copper sheathing that meets higher standards or comes with certifications will likely cost more. Buyers should prioritize quality to ensure longevity and performance, especially for critical applications.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge higher prices due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the Incoterms agreed upon in the contract can affect the total landed cost. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, thus influencing overall pricing.

What Buyer Tips Can Help in Negotiating Copper Sheathing Costs?

International B2B buyers should consider several strategies to optimize their sourcing of copper sheathing:

-

Negotiate Effectively: Engage in discussions about pricing and be prepared to leverage bulk orders or long-term commitments for better rates. Understanding the supplier’s cost structure can provide leverage during negotiations.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes logistics, installation, and maintenance costs associated with the copper sheathing.

-

Understand Pricing Nuances for Different Regions: Factors such as local tariffs, shipping routes, and regional demand can impact prices. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to identify the best sourcing options.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability for specific applications. This can prevent costly mistakes down the line.

-

Stay Informed on Market Trends: Keeping abreast of copper market trends and potential supply chain disruptions can provide insights into pricing fluctuations, allowing for timely purchasing decisions.

By carefully considering these cost components and pricing influencers, B2B buyers can make informed decisions when sourcing copper sheathing, ensuring they achieve the best value for their investments.

Alternatives Analysis: Comparing copper sheathing With Other Solutions

When evaluating materials for marine applications, particularly for hull protection, it’s essential to consider various alternatives to copper sheathing. Each solution comes with its own set of advantages and disadvantages that can significantly impact performance, cost, and maintenance requirements. This section explores copper sheathing alongside two viable alternatives: fiberglass sheathing and epoxy coatings.

| Comparison Aspect | Copper Sheathing | Fiberglass Sheathing | Epoxy Coatings |

|---|---|---|---|

| Performance | Excellent corrosion resistance, durable, effective against marine growth | Good durability, resistant to impact but less effective against marine growth | High adhesion, customizable, good for various surfaces |

| Cost | Higher initial investment but long lifespan | Moderate initial cost; less expensive than copper | Lower initial cost; varies based on type and application |

| Ease of Implementation | Requires skilled labor for installation | Relatively straightforward installation, DIY-friendly | Easy application, can be done by unskilled labor |

| Maintenance | Low maintenance, resistant to fouling | Requires regular inspections and repairs | Moderate maintenance, may require reapplication |

| Best Use Case | Long-term marine vessels, historical restorations | Small boats, recreational vessels | Quick fixes, temporary solutions |

What are the Advantages and Disadvantages of Fiberglass Sheathing?

Fiberglass sheathing is a popular alternative known for its lightweight properties and impact resistance. It is often used in smaller vessels where weight is a critical factor. The installation process can be more straightforward than copper sheathing, allowing for DIY applications. However, while fiberglass is durable, it is less effective at preventing marine growth compared to copper, necessitating more frequent cleaning and maintenance. Additionally, its longevity might not match that of copper, leading to potentially higher replacement costs over time.

How Does Epoxy Coating Compare to Copper Sheathing?

Epoxy coatings provide an affordable and versatile solution for hull protection. They offer excellent adhesion and can be tailored to various substrates, making them suitable for a wide range of applications. The application process is relatively easy, allowing businesses to minimize labor costs. However, epoxy coatings may require periodic reapplication to maintain their protective qualities, especially in harsh marine environments. While they serve as a good short-term solution, they do not offer the same long-term durability as copper sheathing, which could result in higher costs over time due to maintenance and replacement.

How Should B2B Buyers Choose the Right Solution?

In selecting the most appropriate solution, B2B buyers must evaluate their specific needs, including the type of vessel, the marine environment, and budget constraints. Copper sheathing is ideal for long-term investments in durability and low maintenance, particularly for larger or historic vessels. Conversely, fiberglass sheathing may suit smaller boats that prioritize weight and ease of installation. Epoxy coatings can be an excellent choice for businesses seeking a cost-effective, short-term solution with flexibility in application. Ultimately, understanding the unique requirements of each project will guide buyers to the best solution for their maritime needs.

Essential Technical Properties and Trade Terminology for copper sheathing

What Are the Key Technical Properties of Copper Sheathing?

When evaluating copper sheathing for industrial applications, several technical properties are crucial for ensuring performance and longevity. Understanding these specifications can aid B2B buyers in making informed purchasing decisions.

Illustrative image related to copper sheathing

1. Material Grade

Copper sheathing is commonly categorized by its material grade, typically denoted as C110 or C101. Grade C110 is known for its high electrical and thermal conductivity, making it suitable for applications requiring efficient heat transfer. This grade is particularly relevant for marine applications, where corrosion resistance and conductivity are paramount. Selecting the appropriate grade ensures that the sheathing will withstand environmental stresses while maintaining functionality.

2. Thickness Tolerance

Thickness tolerance refers to the permissible deviation in the thickness of the copper sheets. Common thicknesses range from thin foils (around 0.5 mm) to thicker plates (up to 10 mm or more). Tighter tolerances are essential in applications where the fit is critical, such as in shipbuilding or electrical connections. For B2B buyers, understanding thickness specifications helps ensure that the copper sheathing will integrate seamlessly into existing systems or designs.

3. Corrosion Resistance

Copper sheathing is renowned for its natural corrosion resistance, particularly when exposed to marine environments. The formation of a protective patina, which develops over time, enhances this resistance. Buyers should consider the environmental conditions the sheathing will face and select products that meet specific corrosion resistance requirements to prolong the life of their investments.

Illustrative image related to copper sheathing

4. Mechanical Properties

The mechanical properties of copper sheathing, such as tensile strength and malleability, determine its workability and durability. Higher tensile strength allows for better performance under stress, while malleability enables easy shaping and forming. For B2B applications, understanding these properties ensures that the sheathing can be effectively utilized in various manufacturing processes, from shipbuilding to architectural applications.

5. Electrical Conductivity

Copper is one of the best conductors of electricity, making its electrical conductivity a critical property for applications in electrical components and systems. The conductivity is often measured in percent IACS (International Annealed Copper Standard). High conductivity is essential in electrical installations to minimize energy loss and ensure efficient operation, which is particularly important for manufacturers and electrical contractors.

What Trade Terminology Should B2B Buyers Know for Copper Sheathing?

Familiarizing yourself with industry jargon is essential for effective communication and negotiation in the B2B copper sheathing market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of copper sheathing, OEMs often supply custom sheets tailored for specific applications. Understanding the role of OEMs can help buyers identify reliable suppliers who can meet their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of product that a supplier is willing to sell. This term is crucial for B2B buyers, as it can impact inventory management and cost efficiency. Knowing the MOQ helps in planning purchases and negotiating terms with suppliers, particularly for bulk orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For buyers in the copper sheathing market, issuing an RFQ can lead to competitive pricing and better terms. It’s an essential step in the procurement process, allowing for informed decision-making based on comprehensive supplier responses.

4. Incoterms

Incoterms (International Commercial Terms) are predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is crucial for understanding shipping costs, responsibilities, and risks involved in the procurement of copper sheathing from global suppliers.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. In the copper sheathing industry, lead times can vary significantly based on the complexity of the order and supplier capabilities. Understanding lead times is vital for project planning and inventory management, allowing buyers to synchronize their production schedules with material availability.

Illustrative image related to copper sheathing

By comprehending these technical properties and industry terms, B2B buyers can navigate the copper sheathing market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the copper sheathing Sector

What are the Key Market Drivers and Trends in the Copper Sheathing Sector?

The copper sheathing market is experiencing dynamic shifts influenced by several global drivers. Demand for copper sheathing has surged in maritime applications, particularly for shipbuilding and restoration, as its properties prevent marine biofouling and extend the lifespan of vessels. Emerging economies in Africa and South America are witnessing increased investment in infrastructure and shipbuilding, which are significant drivers for copper sheathing products. Furthermore, the push towards sustainable practices is making copper a preferred choice due to its recyclability and durability.

Technological advancements are also reshaping the sourcing landscape. The integration of digital platforms for procurement is streamlining supply chains and enhancing transparency for international buyers. This is especially relevant for B2B buyers in regions like the Middle East and Europe, where efficient sourcing is critical due to varying regulations and standards. Additionally, the customization of copper sheathing products, such as varied thicknesses and alloys, is gaining traction, enabling buyers to meet specific project requirements.

How is Sustainability and Ethical Sourcing Addressed in the Copper Sheathing Sector?

Sustainability has become a cornerstone in the procurement strategies of B2B buyers. The environmental impact of copper extraction and processing is significant, prompting a shift towards ethical sourcing practices. Buyers are increasingly demanding transparency in supply chains to ensure that the copper they procure is sourced responsibly. This includes adherence to international standards and certifications that verify sustainable practices.

Copper sheathing products that are certified as “green” or “eco-friendly” are becoming more prevalent, reflecting a growing market preference for materials that minimize environmental impact. For instance, certifications such as the Responsible Minerals Initiative (RMI) provide assurance that the copper is sourced from conflict-free and environmentally sustainable mines. By prioritizing ethical sourcing, businesses not only enhance their brand reputation but also contribute positively to global sustainability efforts.

Illustrative image related to copper sheathing

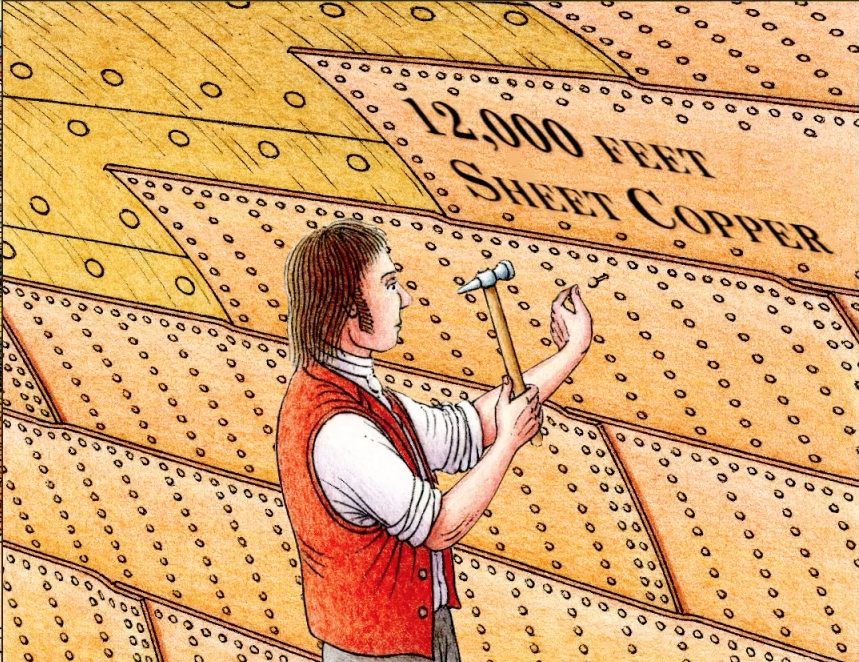

What is the Historical Context of Copper Sheathing in Maritime Applications?

The use of copper sheathing dates back to the 18th century, with the British Royal Navy pioneering its application on warships to combat marine biofouling. The introduction of copper sheathing allowed for easier maintenance of ship hulls and significantly extended the lifespan of wooden vessels. Historical accounts indicate that the USS Constitution, launched in 1797, required substantial amounts of copper sheathing, showcasing its importance in naval engineering.

Over the years, the methods of applying copper sheathing have evolved, adapting to the unique shapes of modern vessels. Innovations in installation techniques and the introduction of advanced alloys have improved the performance and aesthetics of copper sheathing. This historical significance not only emphasizes copper’s long-standing utility but also highlights its continuing relevance in contemporary maritime applications, making it a key consideration for B2B buyers in the sector.

Conclusion

As the copper sheathing market continues to evolve, understanding the key drivers, sourcing trends, and sustainability practices will empower international B2B buyers to make informed procurement decisions. By embracing these insights, businesses can enhance their operational efficiency while contributing to a more sustainable future.

Frequently Asked Questions (FAQs) for B2B Buyers of copper sheathing

-

How do I choose the right thickness of copper sheathing for my project?

Selecting the appropriate thickness of copper sheathing depends on your specific application. Thicker sheets are ideal for structural applications requiring durability, while thinner sheets are better suited for decorative uses or intricate designs. It’s important to consider the environmental conditions, such as exposure to moisture or chemicals, which may affect the longevity of thinner materials. Consulting with your supplier for a thickness guide can also aid in making an informed decision. -

What are the key factors to consider when sourcing copper sheathing suppliers?

When sourcing suppliers, prioritize their reputation, quality certifications, and experience in the industry. Look for suppliers who specialize in B2B transactions and have a history of reliability in international shipping. Request samples to assess quality and ensure they can meet your specifications. Additionally, inquire about their customer service responsiveness and support for logistics, as these factors can significantly impact your procurement process. -

What customization options are available for copper sheathing?

Many suppliers offer customization options, including specific dimensions, thicknesses, and finishes such as patinas or protective coatings. If you have unique project requirements, discuss them with potential suppliers to determine their capabilities. Customization may involve additional costs and lead times, so ensure you communicate your needs clearly and confirm production timelines. -

What is the minimum order quantity (MOQ) for copper sheathing?

MOQs can vary significantly among suppliers, often influenced by the type of sheathing and your location. Some suppliers may offer flexible MOQs for first-time buyers or smaller projects, while others might have strict minimums to ensure cost-effectiveness. Always clarify the MOQ before finalizing your order and explore potential alternatives if your needs do not meet the specified quantity. -

How can I ensure the quality of copper sheathing before making a purchase?

To ensure quality, request certifications and test reports from your supplier, confirming that the copper meets industry standards. Additionally, consider ordering samples to inspect the material firsthand. Establishing a quality assurance process, including visual inspections and testing upon receipt, will help mitigate risks and ensure that the sheathing meets your project’s requirements. -

What payment terms are typically offered for international purchases of copper sheathing?

Payment terms can vary widely based on the supplier and the buyer’s location. Common terms include upfront payments, letters of credit, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow and budget. Always ensure that payment methods are secure, and consider using escrow services for large transactions to protect both parties. -

What logistics considerations should I keep in mind when importing copper sheathing?

Logistics play a crucial role in international procurement. Consider shipping methods, lead times, and customs regulations specific to your country. Ensure that your supplier provides adequate packaging to prevent damage during transit. It’s advisable to work with a logistics partner experienced in handling metal products to streamline customs clearance and delivery processes. -

How do I handle customs and import duties when purchasing copper sheathing internationally?

When importing copper sheathing, familiarize yourself with the customs regulations and tariffs applicable in your country. Duties can vary based on the origin of the product, so it’s beneficial to consult with a customs broker to ensure compliance. Prepare all necessary documentation, including invoices and certificates of origin, to facilitate a smooth customs process and avoid unexpected fees.

A Look at Copper Sheathing Manufacturers & Suppliers

Could not verify enough suppliers for copper sheathing to create a list at this time.

Strategic Sourcing Conclusion and Outlook for copper sheathing

In navigating the complexities of sourcing copper sheathing, international buyers must prioritize quality, cost-effectiveness, and supplier reliability. The versatility of copper—renowned for its malleability, conductivity, and corrosion resistance—underscores its importance across various applications, from maritime to architectural needs. Leveraging strategic sourcing practices enables companies to mitigate risks associated with fluctuating prices and supply chain disruptions, ensuring a steady flow of high-quality materials.

Illustrative image related to copper sheathing

As buyers from regions like Africa, South America, the Middle East, and Europe explore their options, it is crucial to establish relationships with reputable suppliers who can provide not only premium copper sheathing but also invaluable industry insights. Engaging with suppliers that offer customizable solutions and excellent customer service can enhance project outcomes and foster innovation.

Looking ahead, the demand for copper sheathing is expected to grow as industries increasingly recognize its benefits. By actively pursuing strategic partnerships and remaining informed about market trends, international buyers can position themselves advantageously in this evolving landscape. Take the initiative now to evaluate your sourcing strategy and connect with trusted suppliers to secure the best copper sheathing for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to copper sheathing

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.