Cnc Machining: The Ultimate 2025 B2B Sourcing Guide

Top 9 Cnc Machining Suppliers List

1. Hubs – CNC Machining Solutions

Domain: hubs.com

Registered: 1998 (27 years)

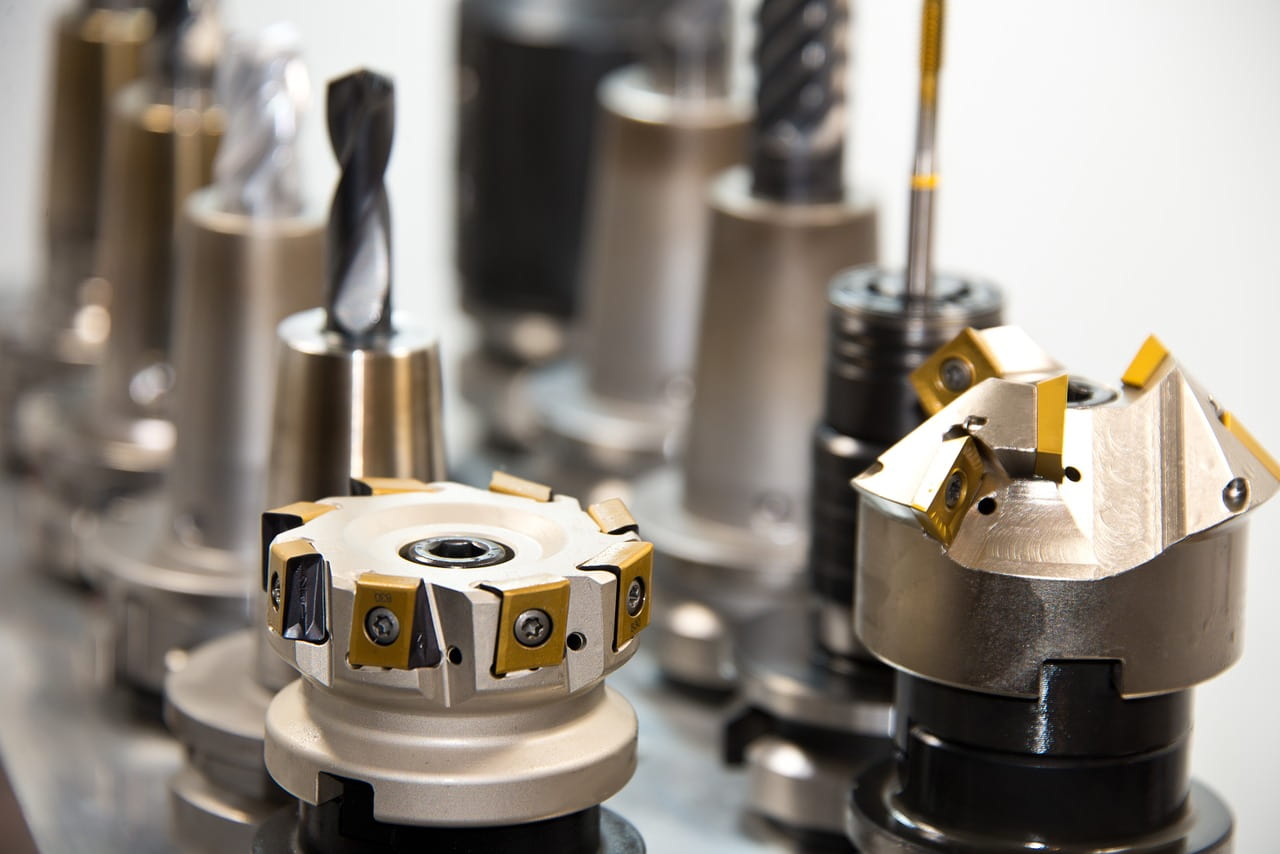

CNC machining is a subtractive manufacturing technology that creates parts by removing material from a solid block using various cutting tools. It produces high-accuracy parts directly from a CAD file and is suitable for both one-off custom parts and medium-volume productions. Common materials for CNC machining include metals (aluminum, steel alloys, brass) and plastics (ABS, Delrin, Nylon). The b…

2. Xometry – Custom CNC Machining Services

Domain: xometry.com

Registered: 2015 (10 years)

Custom Online CNC Machining Services for metal and plastic parts; instant quotes available; quick-turn prototypes and production parts in days; free standard shipping on all US orders; international pricing includes tariffs; certifications include ISO 9001:2015, ISO 13485, IATF 16949:2016, AS9100D; ITAR registered; services include CNC milling, CNC turning, CNC routing, and high-volume production;…

3. Build Submarines – CNC Machining Solutions

Domain: buildsubmarines.com

Registered: 2020 (5 years)

CNC machining is a process that employs computer-controlled machines to precisely shape and cut materials, ranging from polymers to metals. It translates CAD designs into G-Code instructions for accurate movement and cutting. Key benefits include: ensuring precision with minimal human error, producing complex geometries for submarine structures, replicating consistent results across production run…

4. Protolabs – CNC Machining Services

Domain: protolabs.com

Registered: 2006 (19 years)

Online CNC Machining Service offering cost-efficient machined parts at any quantity. Capabilities include CNC Milling (3-axis and 5-axis indexed milling) and CNC Turning (with live tooling for cylindrical features). Fast turnaround for prototypes and production parts in as fast as 1 day. Materials available include various grades of plastics and an extensive library of metals such as Aluminum, Bra…

5. PCBWay – CNC Machining & Prototyping Services

Domain: pcbway.com

Registered: 2012 (13 years)

CNC Machining Service includes precision CNC machining and rapid prototyping parts. Key features include CNC milling (3-, 4-, & full 5-axis), CNC turning, and various 3D printing services (SLA, DLP, FDM, SLM, SLS, PolyJet). Materials used for CNC machining include metals (aluminum, stainless steel, brass, copper, titanium, mild steel, alloy steel, tool steel, spring steel) and plastics (ABS, polyc…

6. 3DS – CNC Machining Solutions

Domain: 3ds.com

Registered: 1995 (30 years)

CNC Machining is a subtractive manufacturing process that uses computerized controls and machine tools to remove layers of material from a blank to produce custom parts. It is characterized by high precision and cost-effectiveness for medium-scale production. The main steps include: 1. CAD model designing, 2. CAD file conversion to generate programming code (G-code), 3. Machine configuration, and …

7. Geomiq – CNC Machining Services

Domain: geomiq.com

Registered: 2019 (6 years)

CNC Machining Service, CNC Milling, CNC Turning, CNC Drilling, CNC Routing, CNC Cutting, Electrical Discharge Machining (EDM), 3-axis CNC milling, 5-axis CNC milling, CNC lathes, CNC turning centres, Laser cutting, Waterjet cutting, Plasma cutting, Materials: Aerospace components, Automotive components, Medical implants, Everyday tech like smartphones, Rapid prototyping, Mass production, Surface f…

8. Practical Machinist – Metalworking Hub

Domain: practicalmachinist.com

Registered: 2000 (25 years)

With over 950k monthly visits, Practical Machinist is the go-to hub for metalworking professionals. Whether you’re learning new techniques, finding solutions, …

9. Roland – CNC Mill MDX-40

Domain: instructables.com

Registered: 2005 (20 years)

CNC Mill: Tabletop MDX-40 by Roland; Software: Modela Player 4, Inventor, Autodesk Fusion 360, Creo, SolidWorks, Blender; Materials: Soft polypropylene, stainless steel, acrylic, aluminum; End Mills: Ball end mill, square end mill; Process: 3D modeling, setting up the mill, design with tolerances, milling workflow.

Table Of Contents

- Top 9 Cnc Machining Suppliers List

- Introduction: Navigating the Market for cnc machining

- Understanding cnc machining Types

- Industrial Applications of cnc machining

- 3 Common User Pain Points for ‘cnc machining’

- Material Selection Guide for cnc machining

- Manufacturing & Quality Assurance for cnc machining

- Sourcing Checklist for ‘cnc machining’

- Cost and Pricing Analysis for cnc machining

- Alternatives to cnc machining

- Technical Properties and Trade Terms

- Market Dynamics and Sourcing Trends

- FAQs for B2B Buyers of cnc machining

- Disclaimer

- Conclusion for cnc machining

Introduction: Navigating the Market for cnc machining

In today’s competitive global landscape, B2B buyers face the daunting challenge of sourcing reliable CNC machining solutions that meet their precise specifications while ensuring cost efficiency and timely delivery. As the demand for high-quality manufacturing escalates across industries—from aerospace and automotive to consumer goods—understanding the intricacies of CNC machining becomes paramount. This guide is designed to equip international buyers from Nigeria, Saudi Arabia, and Brazil with the essential knowledge needed to navigate the complexities of the CNC machining market.

Throughout this guide, we will explore the fundamental principles of CNC machining, including its operational mechanics, various machine types, and the programming languages that drive precision manufacturing. We will also address common pitfalls and considerations when selecting a CNC machining partner, helping you to mitigate risks and make informed purchasing decisions.

By the end of this guide, you will have a comprehensive understanding of the CNC machining landscape, empowering you to identify the best suppliers and technologies for your needs. Whether you are looking to streamline production processes or enhance product quality, this resource will serve as your roadmap to successful sourcing in the dynamic world of CNC machining.

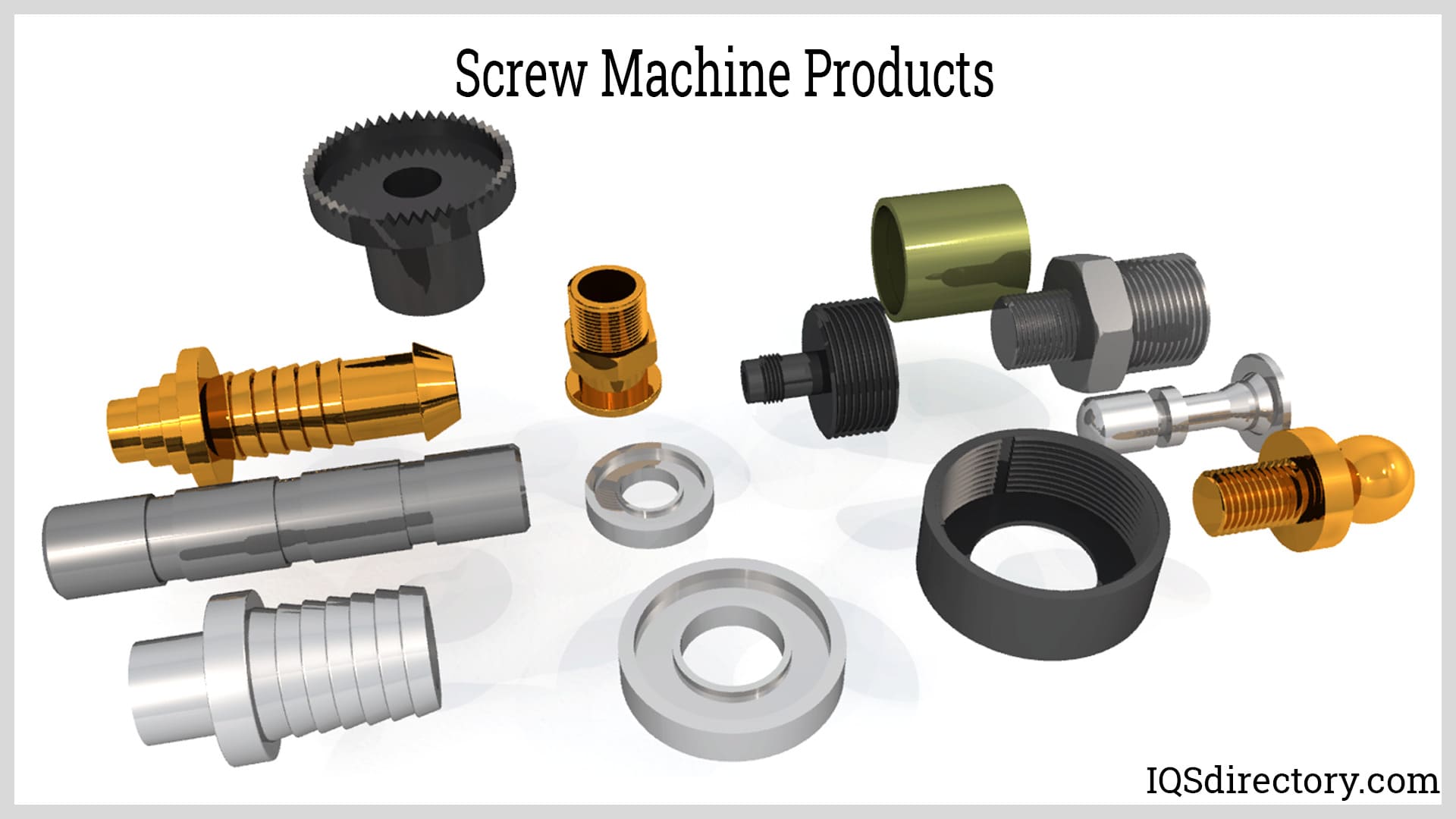

Understanding cnc machining Types

| Type Name | Key Features | B2B Applications | Pros & Cons |

|---|---|---|---|

| CNC Mills | Multi-axis movement, high precision cutting | Aerospace, automotive, electronics | Pros: Versatile, high accuracy Cons: High initial cost, requires skilled operators |

| CNC Lathes | Rotational cutting, ideal for cylindrical shapes | Manufacturing of shafts, bolts, and fittings | Pros: Efficient for cylindrical parts Cons: Limited to rotational shapes |

| Plasma Cutters | High-speed cutting with plasma torch | Metal fabrication, automotive parts | Pros: Fast, efficient for thick materials Cons: Limited to conductive materials |

| Electric Discharge Machines (EDM) | Uses electrical sparks for intricate shapes | Aerospace, mold making | Pros: High precision, can cut complex shapes Cons: Slow process, requires conductive materials |

| Water Jet Cutters | Cuts with high-pressure water, ideal for heat-sensitive materials | Aerospace, stone cutting | Pros: No heat distortion, versatile Cons: Slower than other methods, higher operational costs |

CNC Mills

CNC mills are equipped with multi-axis capabilities, allowing for intricate and precise cutting of materials. They can work on various materials, including metals and plastics, and are ideal for applications in industries such as aerospace, automotive, and electronics. The versatility of CNC mills makes them suitable for producing complex geometries and components, although they require skilled operators and involve a significant initial investment.

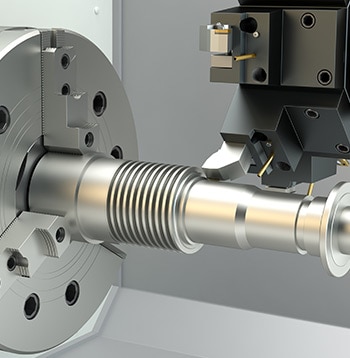

CNC Lathes

CNC lathes are designed for rotational cutting, which makes them optimal for creating cylindrical components like shafts, bolts, and fittings. They operate by rotating the workpiece against a stationary cutting tool, allowing for efficient production of round parts. While CNC lathes excel in speed and efficiency for cylindrical shapes, their limitations include a narrower range of shapes compared to mills, making them less versatile for complex geometries.

Plasma Cutters

Plasma cutters utilize a high-speed jet of ionized gas to cut through conductive materials like metal. This method is particularly favored in metal fabrication and automotive industries for its speed and efficiency, especially when working with thicker materials. While plasma cutting is advantageous for its rapid processing, it is limited to conductive materials and may not provide the same level of precision as other CNC methods.

Electric Discharge Machines (EDM)

EDM employs electrical discharges to remove material and create intricate shapes, making it an excellent choice for applications in aerospace and mold-making industries. This method is capable of achieving high precision and can work on complex geometries that are difficult to achieve with traditional machining. However, EDM can be a slower process and is limited to electrically conductive materials, which may restrict its applicability in certain manufacturing scenarios.

Water Jet Cutters

Water jet cutters utilize high-pressure water to slice through materials, making them ideal for applications involving heat-sensitive materials like certain plastics and composites. This method is particularly useful in industries such as aerospace and stone cutting, where precision and the absence of heat distortion are crucial. Despite their versatility, water jet cutters can operate at slower speeds compared to other CNC methods and may incur higher operational costs.

Industrial Applications of cnc machining

| Industry | Application | Business Value | Sourcing Considerations |

|---|---|---|---|

| Aerospace | Precision components manufacturing | Ensures safety and reliability in flight operations. | Evaluate supplier certifications, machining capabilities, and lead times. |

| Automotive | Engine and transmission parts | Enhances performance and durability of vehicles. | Consider material quality, production volume, and cost efficiency. |

| Medical Devices | Surgical instruments production | Vital for patient safety and effectiveness in medical procedures. | Look for compliance with health regulations and precision standards. |

| Electronics | Custom circuit boards | Facilitates advanced technology integration and miniaturization. | Assess design capabilities and turnaround time for prototypes. |

| Defense | Military equipment components | Supports national security through reliable manufacturing. | Verify security clearances and material sourcing practices. |

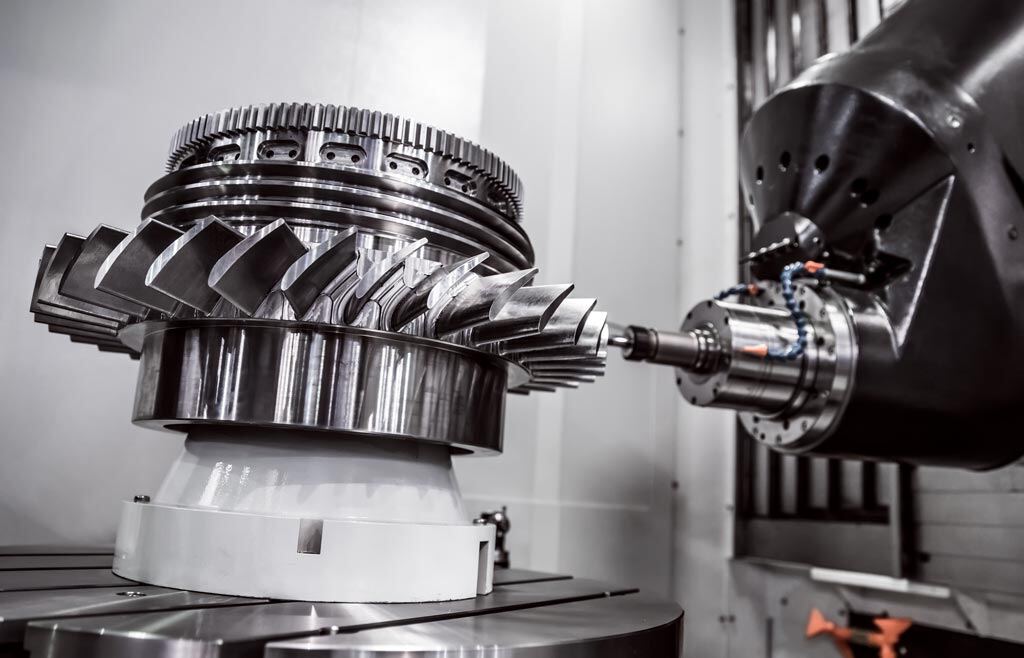

Aerospace

CNC machining plays a critical role in the aerospace industry, where precision and reliability are paramount. Components such as turbine blades, fuselage parts, and landing gear require exacting tolerances to ensure safety and performance during flight. The ability to produce lightweight yet strong materials through CNC processes allows aerospace manufacturers to enhance fuel efficiency and overall aircraft performance. When sourcing CNC machining services for aerospace applications, it is essential to evaluate supplier certifications, such as AS9100, and their capability to meet stringent industry standards.

Automotive

In the automotive sector, CNC machining is integral to the production of engine and transmission parts, which require high precision to optimize vehicle performance and longevity. Components like camshafts, crankshafts, and gear sets are often machined to ensure they meet exact specifications for fit and functionality. As manufacturers increasingly focus on electric and hybrid vehicles, CNC machining enables the production of complex components that support advanced technologies. When sourcing for automotive applications, businesses should consider the quality of materials used, the supplier’s production volume capabilities, and cost efficiency to maintain competitive pricing.

Medical Devices

The medical device industry relies heavily on CNC machining for the production of surgical instruments and implants. The precision offered by CNC technology is crucial in ensuring that these devices perform effectively and safely during medical procedures. Components must meet stringent regulatory requirements, including biocompatibility and sterilization standards. When sourcing CNC machining services for medical applications, it is important to look for suppliers who comply with health regulations such as ISO 13485 and can demonstrate a commitment to precision manufacturing.

Electronics

CNC machining is essential in the electronics industry, particularly for the production of custom circuit boards and enclosures. As technology continues to advance and the demand for miniaturized components increases, CNC machining allows for the intricate designs necessary for modern electronics. This capability enables manufacturers to integrate advanced technologies and meet consumer demands for smaller, more efficient devices. When sourcing CNC machining services for electronics, businesses should assess the supplier’s design capabilities and turnaround time for prototypes, ensuring they can meet fast-paced market demands.

Defense

In the defense sector, CNC machining is vital for producing components used in military equipment, such as weapon systems, vehicles, and communication devices. The reliability and accuracy of these components directly impact national security and operational effectiveness. CNC machining allows for the production of parts that can withstand extreme conditions and rigorous use. When sourcing CNC machining services for defense applications, it is crucial to verify suppliers’ security clearances and their practices regarding material sourcing to ensure compliance with government regulations and standards.

3 Common User Pain Points for ‘cnc machining’

Scenario 1: Inconsistent Quality Control

Problem:

B2B buyers often face challenges with the quality consistency of CNC machined parts. Variations in the manufacturing process can lead to parts that do not meet specified tolerances, resulting in costly rework and delays. This issue can stem from inadequate machine calibration, programming errors, or variations in raw materials.

Solution:

To mitigate quality inconsistencies, it is essential to establish a robust quality control (QC) process. Buyers should collaborate closely with their CNC machining suppliers to implement regular inspection protocols, including statistical process control (SPC) techniques. This involves setting up a feedback loop where data on part quality is continuously monitored and analyzed. Additionally, investing in advanced CNC machines with built-in precision monitoring and error-correction capabilities can enhance overall output quality. Establishing clear communication regarding quality expectations and tolerances before production begins can also help ensure that the final products meet the required standards.

Scenario 2: Long Lead Times

Problem:

Another common pain point for international B2B buyers is extended lead times for CNC machining projects. Factors such as machine availability, complexity of the parts, and supply chain delays can contribute to longer-than-expected production times. This can disrupt project timelines and lead to missed market opportunities.

Solution:

To address lead time issues, buyers should engage in proactive planning with their CNC machining partners. This can include discussing project timelines in detail and exploring options for expedited services if needed. Implementing a just-in-time (JIT) inventory strategy can also be beneficial, allowing buyers to minimize stock levels while ensuring that parts are produced and delivered as needed. Additionally, maintaining a reliable relationship with multiple suppliers can provide flexibility and options for faster production if one source encounters delays. Utilizing digital tools for real-time tracking of orders can further enhance transparency and keep all parties informed throughout the manufacturing process.

Scenario 3: High Production Costs

Problem:

B2B buyers often grapple with the high costs associated with CNC machining. Factors such as complex designs, material waste, and machine downtime can inflate production expenses, impacting overall project budgets. This is particularly concerning for companies operating in competitive markets where cost efficiency is crucial.

Solution:

To combat high production costs, buyers should focus on optimizing their designs for manufacturability (DFM). This involves collaborating with engineering teams to simplify designs where possible, which can reduce machining time and material waste. Implementing advanced software tools for simulation and analysis can help identify potential inefficiencies early in the design phase. Additionally, negotiating bulk purchasing agreements with suppliers can lead to cost savings on raw materials. Investing in automation technologies within CNC machining processes can also lower long-term operational costs by reducing labor needs and minimizing errors. Finally, conducting a thorough cost-benefit analysis of different machining methods can help buyers choose the most cost-effective solution for their specific needs.

Material Selection Guide for cnc machining

When selecting materials for CNC machining, understanding the properties, advantages, and limitations of each material is crucial for meeting specific project requirements. Below, we analyze four common materials used in CNC machining: aluminum, stainless steel, plastic, and titanium. Each material has unique characteristics that impact its suitability for various applications.

1. Aluminum

Properties:

Aluminum is a lightweight, corrosion-resistant metal known for its excellent machinability. It has a high strength-to-weight ratio and is often used in applications where weight reduction is essential.

Pros:

– Lightweight: Easy to handle and reduces shipping costs.

– Corrosion Resistance: Ideal for outdoor applications or environments with moisture.

– Excellent Machinability: Can be easily shaped and cut with CNC machines.

– Versatile: Suitable for a wide range of applications, from automotive to aerospace.

Cons:

– Lower Strength: Not as strong as steel or titanium, which may limit its use in high-stress applications.

– Thermal Conductivity: High thermal conductivity can lead to warping if not managed properly during machining.

B2B Considerations: Aluminum is often favored in industries like aerospace and automotive due to its lightweight nature. However, buyers should ensure they select the appropriate alloy (e.g., 6061, 7075) based on strength and corrosion resistance needs.

2. Stainless Steel

Properties:

Stainless steel is an alloy known for its strength, durability, and resistance to corrosion. It is available in various grades, each with different properties, making it suitable for a wide range of applications.

Pros:

– Corrosion Resistance: Suitable for harsh environments and food processing applications.

– High Strength: Provides excellent tensile strength, making it ideal for structural components.

– Durability: Long lifespan due to resistance to wear and tear.

Cons:

– Difficult to Machine: Requires specialized tools and techniques, which can increase production time and costs.

– Weight: Heavier than aluminum, which may not be suitable for weight-sensitive applications.

B2B Considerations: Industries such as medical, food processing, and construction often require stainless steel for its hygienic properties and strength. Buyers should consider the specific grade of stainless steel based on the application (e.g., 304, 316) to ensure compliance with industry standards.

3. Plastic (e.g., ABS, Nylon)

Properties:

Plastics are versatile materials that can be molded into complex shapes. Common types used in CNC machining include Acrylonitrile Butadiene Styrene (ABS) and Nylon, both known for their durability and lightweight characteristics.

Pros:

– Lightweight: Reduces shipping costs and is easier to handle.

– Good Machinability: Easier to machine than metals, allowing for more intricate designs.

– Cost-Effective: Generally lower material costs compared to metals.

Cons:

– Lower Strength: Not suitable for high-stress applications.

– Thermal Sensitivity: Can warp or melt under high temperatures.

B2B Considerations: Plastic is widely used in consumer goods, automotive parts, and electronic housings. Buyers should evaluate the specific type of plastic based on required mechanical properties and environmental resistance.

4. Titanium

Properties:

Titanium is a lightweight metal known for its exceptional strength and corrosion resistance. It is often used in high-performance applications, such as aerospace and medical devices.

Pros:

– High Strength-to-Weight Ratio: Offers superior strength without the added weight.

– Corrosion Resistance: Ideal for applications in harsh environments, including marine and chemical processing.

– Biocompatibility: Safe for medical applications due to its non-reactive nature.

Cons:

– Cost: Generally more expensive than aluminum or stainless steel.

– Difficult to Machine: Requires specialized equipment and techniques, increasing production complexity.

B2B Considerations: Titanium is essential in aerospace, military, and medical industries. Buyers must consider the high material costs and machining challenges, making it suitable primarily for applications where performance justifies the investment.

Summary Table

| Material | Use Case | Advantage | Disadvantage | Relative Cost |

|---|---|---|---|---|

| Aluminum | Aerospace, automotive, consumer goods | Lightweight, corrosion-resistant | Lower strength compared to steel | Moderate |

| Stainless Steel | Medical, food processing, construction | High strength, durable, corrosion-resistant | Difficult to machine | Moderate to High |

| Plastic (ABS, Nylon) | Consumer goods, automotive parts | Lightweight, cost-effective, good machinability | Lower strength, thermal sensitivity | Low |

| Titanium | Aerospace, medical devices | High strength-to-weight ratio, corrosion-resistant | High cost, difficult to machine | High |

In conclusion, the choice of material for CNC machining should align with the specific requirements of the application, taking into account factors such as strength, weight, cost, and machinability. Understanding these aspects will help B2B buyers make informed decisions that enhance the efficiency and effectiveness of their manufacturing processes.

Manufacturing & Quality Assurance for cnc machining

CNC machining stands at the forefront of modern manufacturing, offering precision and efficiency that traditional methods cannot match. However, ensuring quality throughout the CNC machining process is crucial for maintaining product integrity and meeting industry standards. This section explores the manufacturing stages involved in CNC machining, the key quality control (QC) standards like ISO 9001, and how international buyers can verify the quality assurance practices of their suppliers.

Manufacturing Stages in CNC Machining

The CNC machining process involves several distinct stages, each contributing to the overall quality of the finished product. Understanding these stages is essential for buyers looking to ensure that their suppliers adhere to high manufacturing standards.

1. Design and Prototyping

The manufacturing process begins with the design phase, where engineers create a Computer-Aided Design (CAD) model of the part to be produced. This model is critical as it dictates the specifications, dimensions, and tolerances required for the final product.

Prototyping may follow, where a sample part is created to evaluate the design’s feasibility and functionality. This stage allows for adjustments before mass production begins, reducing the risk of costly errors.

2. Programming

Once the design is finalized, CNC programmers convert the CAD model into G-code, a language that directs CNC machines on how to operate. This code includes detailed instructions regarding tool movements, feed rates, and cutting paths.

Program validation is crucial at this stage to ensure that the code accurately reflects the intended design. This step often involves simulations to preemptively identify potential issues.

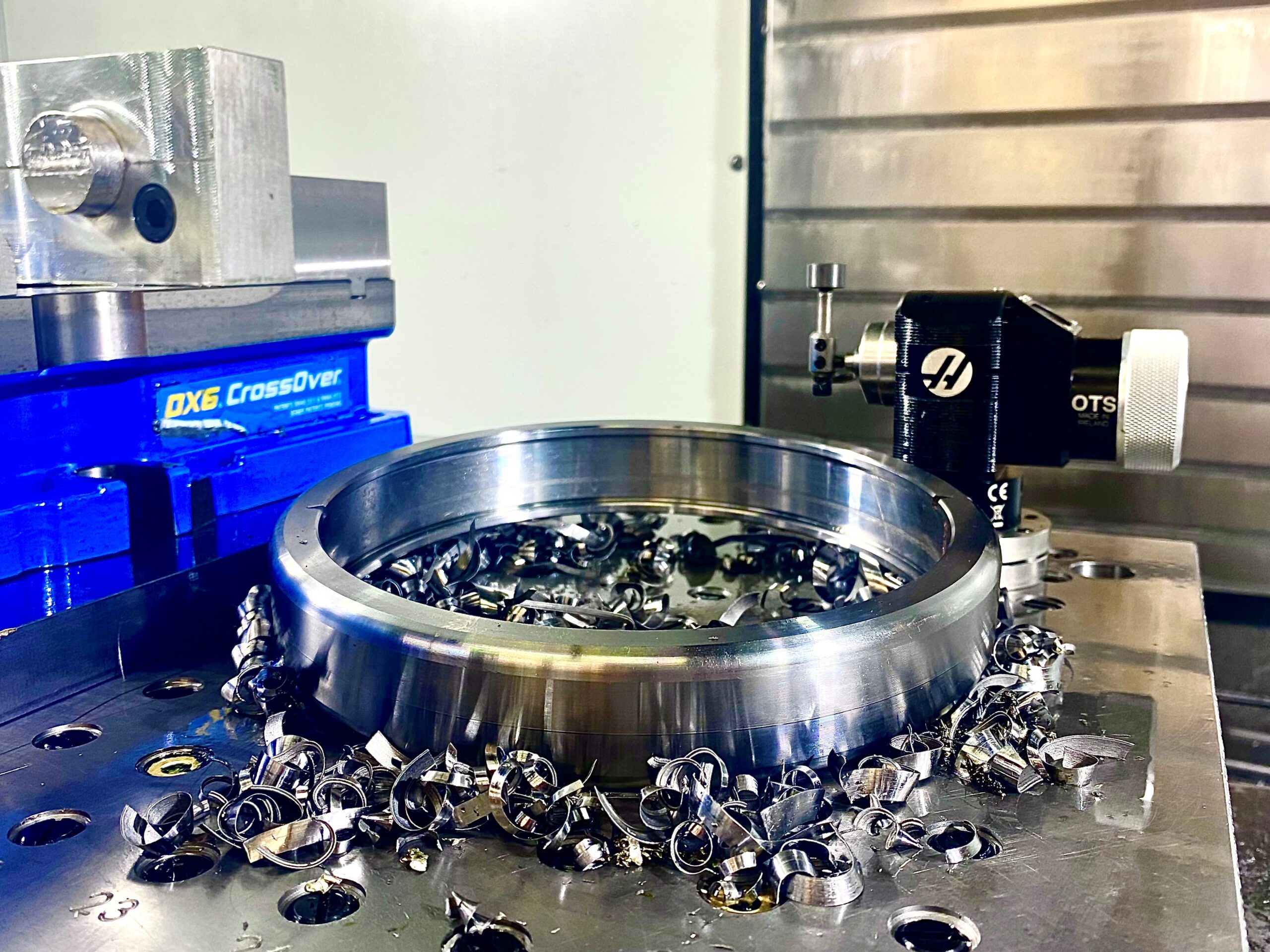

3. Machining

The actual machining process involves loading the raw material into a CNC machine and executing the programmed instructions. Various types of CNC machines—such as mills, lathes, and plasma cutters—can be employed depending on the complexity and requirements of the part.

During machining, operators monitor the process to ensure that it adheres to the specified tolerances. Automated systems often control multiple machines, allowing for increased efficiency and reduced labor costs.

4. Post-Processing

After machining, parts may require post-processing treatments such as deburring, polishing, or surface finishing to enhance their aesthetic appeal and functionality. This stage is crucial for ensuring that parts are free of sharp edges and imperfections that could affect their performance.

5. Inspection and Testing

Quality assurance culminates in the inspection and testing phase. Here, parts undergo rigorous assessments to ensure they meet the required specifications. Techniques such as Coordinate Measuring Machines (CMM) or laser scanning may be employed to verify dimensional accuracy.

Key Quality Control Standards

Quality control in CNC machining is guided by various standards that provide frameworks for maintaining product quality. One of the most recognized standards is ISO 9001.

ISO 9001

ISO 9001 is an international standard that outlines the criteria for a quality management system (QMS). It is applicable to any organization, regardless of size or industry. Key components of ISO 9001 relevant to CNC machining include:

- Customer Focus: Ensuring that products meet customer needs and expectations.

- Leadership: Establishing a clear direction and creating an environment that encourages participation from all employees.

- Process Approach: Understanding and managing interrelated processes to enhance efficiency and effectiveness.

- Continuous Improvement: Committing to ongoing enhancements in processes, products, and services.

Adhering to ISO 9001 ensures that a CNC machining company has established a robust QMS that promotes consistent quality and customer satisfaction.

Other Relevant Standards

While ISO 9001 is the cornerstone of quality management, other standards may also apply depending on the specific industry. For instance:

- AS9100: A quality standard specifically for the aerospace industry.

- IATF 16949: A standard for automotive quality management systems.

- ISO 13485: A standard applicable to medical device manufacturing.

Verifying Supplier Quality Assurance

For international B2B buyers, verifying the quality assurance practices of CNC machining suppliers is essential to ensure product reliability. Here are key steps to take:

1. Request Documentation

Ask suppliers for documentation demonstrating their compliance with quality standards such as ISO 9001. This documentation should include quality manuals, certifications, and audit reports.

2. Conduct Audits

If feasible, conduct on-site audits of potential suppliers. This allows buyers to evaluate the manufacturing processes, equipment, and quality control measures in place. During the audit, pay attention to how the supplier handles quality checks and their responsiveness to quality issues.

3. Review Previous Work

Request samples of previous work or case studies that illustrate the supplier’s capabilities and quality standards. Analyzing past projects can provide insights into the supplier’s reliability and adherence to specifications.

4. Seek References

Contact other clients who have worked with the supplier. Their experiences can provide valuable information regarding the supplier’s quality assurance practices, delivery times, and overall reliability.

5. Use Technology for Monitoring

Leverage technology to monitor the quality of ongoing production. Tools like real-time data tracking and quality management software can provide insights into the manufacturing process and alert buyers to potential quality issues.

Conclusion

In the realm of CNC machining, manufacturing and quality assurance are intricately linked to ensure that products meet the high standards demanded by today’s industries. By understanding the manufacturing stages, adhering to recognized quality standards like ISO 9001, and actively verifying supplier practices, international B2B buyers can confidently partner with CNC machining suppliers that prioritize quality and excellence. This commitment to quality not only enhances product reliability but also strengthens business relationships in the global market.

Sourcing Checklist for ‘cnc machining’

-

Define Your Project Requirements

Before beginning the sourcing process, clearly outline the specifications of your CNC machining project. Consider factors such as materials, dimensions, tolerances, and production volume. Having a comprehensive understanding of your project will help you communicate effectively with potential suppliers and ensure they can meet your needs. -

Research Potential Suppliers

Conduct thorough research to identify potential CNC machining suppliers that operate within your target regions, such as Nigeria, Saudi Arabia, and Brazil. Utilize online platforms, industry directories, and trade shows to compile a list of manufacturers with a solid reputation and relevant experience in your industry. Pay attention to customer reviews and case studies to gauge their reliability and capabilities. -

Evaluate Capabilities and Technologies

Assess the machining capabilities and technologies offered by your shortlisted suppliers. Look for advanced CNC equipment, such as multi-axis machines and specialized tooling that can handle your project’s complexity. Understanding the technological strengths of each supplier will enable you to choose one that can deliver precision and quality consistently. -

Request Quotes and Compare Costs

Reach out to your selected suppliers to request detailed quotes based on your project specifications. Ensure that the quotes include all relevant costs, such as tooling, production, and shipping. By comparing costs, you can identify the best value proposition, but remember that the lowest price isn’t always the best option—consider quality and service as well. -

Assess Quality Assurance Processes

Quality assurance is critical in CNC machining to ensure that the final products meet your specifications. Inquire about the supplier’s quality control measures, including certifications (such as ISO 9001), inspection processes, and testing methods. A supplier with robust quality assurance practices is more likely to deliver consistent, high-quality results. -

Examine Lead Times and Production Flexibility

Understanding the lead times for production is crucial for your project’s timeline. Discuss the supplier’s ability to meet your deadlines and their capacity for handling fluctuations in order volume. A supplier who can demonstrate flexibility and responsiveness to your needs will be invaluable in maintaining smooth operations. -

Establish Communication and Support Channels

Effective communication is essential for a successful partnership. Ensure that your chosen supplier has reliable communication channels and a dedicated support team that can address any questions or concerns throughout the production process. Building a strong line of communication will foster a collaborative relationship and facilitate timely problem resolution.

By following this sourcing checklist, B2B buyers can make informed decisions when selecting a CNC machining supplier, ultimately leading to successful project outcomes.

Cost and Pricing Analysis for cnc machining

When it comes to CNC machining, understanding the cost structure is crucial for B2B buyers looking to make informed purchasing decisions. The pricing of CNC machining services can vary widely based on several key components. This analysis will explore the cost components, price influencers, and provide tips for effective negotiation.

Cost Components of CNC Machining

-

Material Costs: The type of material being machined significantly impacts overall costs. Metals such as aluminum and steel are typically less expensive than exotic materials like titanium or certain plastics. Buyers should consider the material’s availability and market price fluctuations.

-

Machine Setup and Programming: CNC machining requires precise setup and programming, which can incur substantial labor costs. The complexity of the part being manufactured will dictate the time and expertise needed for programming. Simpler parts may require less setup time, while intricate designs will demand more attention.

-

Labor Costs: Skilled labor is essential in CNC machining. The expertise of operators, programmers, and engineers can influence costs. More experienced personnel may command higher wages, but their proficiency can lead to greater efficiency and quality.

-

Production Volume: The scale of production plays a critical role in pricing. Generally, larger volumes lead to lower per-unit costs due to economies of scale. However, initial setup costs remain constant, which can make small batch runs disproportionately expensive.

-

Overhead Costs: This includes costs related to facility maintenance, utilities, equipment depreciation, and administrative expenses. These costs are typically distributed across all projects and can impact the final pricing.

-

Post-Processing: Additional processes such as finishing, assembly, or quality assurance checks add to the overall cost. Buyers should clarify the extent of post-processing required for their products to avoid unexpected expenses.

Price Influencers

Several factors can influence CNC machining prices:

-

Complexity of Design: More complex geometries or tighter tolerances require advanced machining techniques and longer machining times, driving up costs.

-

Lead Time: Rush orders may incur additional fees. Buyers should consider how flexible their timelines are to optimize costs.

-

Supplier Location: Shipping costs and tariffs can affect pricing, especially for international buyers. Local suppliers may offer lower shipping costs, while overseas suppliers might provide competitive pricing but at the expense of longer lead times.

-

Technology and Equipment: The type of CNC machines used can influence pricing. Advanced machines with higher precision capabilities may lead to higher costs but can also improve quality and reduce material waste.

Buyer Tips for Negotiation

-

Get Multiple Quotes: Requesting quotes from several suppliers can provide a clearer picture of the market rate and help identify competitive pricing.

-

Be Clear About Specifications: Clearly defining the required specifications and tolerances can prevent misunderstandings that lead to increased costs later in the project.

-

Discuss Volume Discounts: If planning for larger orders, discuss potential discounts for bulk purchases. Suppliers may offer lower rates for increased volume commitments.

-

Consider Long-Term Partnerships: Establishing a long-term relationship with a supplier can lead to better pricing and improved service, as suppliers may be more inclined to offer favorable terms to repeat customers.

-

Negotiate on Lead Times: If your timeline allows, negotiating longer lead times may result in cost savings, as suppliers can schedule production more efficiently.

In conclusion, understanding the cost structure of CNC machining is essential for B2B buyers. By considering material costs, labor, production volume, and other influencing factors, buyers can make more informed decisions. Additionally, employing strategic negotiation techniques can help secure the best possible pricing for CNC machining services.

Alternatives to cnc machining

When considering manufacturing processes, CNC machining is often the go-to solution for precision and automation. However, various alternative methods can also fulfill specific production needs. Below is a comparison of CNC machining against other popular alternatives, including traditional machining and additive manufacturing (3D printing).

| Aspect | CNC Machining | Traditional Machining | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High precision and repeatability | Moderate precision; manual skill-dependent | Variable precision; depends on technology used |

| Cost | Higher initial investment; lower long-term costs for large volumes | Lower initial costs; higher labor costs for manual processes | Lower setup costs; material costs can be high |

| Best Use Case | Complex parts with tight tolerances | Simple designs or one-off projects | Prototyping and complex geometries that are difficult to machine |

Detailed Breakdown

Performance

CNC machining is renowned for its high precision and repeatability, making it ideal for producing complex parts with tight tolerances. The automated nature of CNC systems allows for consistent output, significantly reducing the chances of human error. In contrast, traditional machining methods rely heavily on the skill of the operator, which can lead to variability in quality and performance. While traditional machining can be effective for simpler designs, it may struggle with intricate components.

Additive manufacturing, or 3D printing, offers a different performance profile. The precision of 3D printing depends on the technology used (e.g., FDM, SLA, SLS) and the materials involved. While some advanced 3D printers can achieve high accuracy, they may not match the repeatability of CNC machining for mass production. However, 3D printing excels in creating complex geometries that would be challenging or impossible to achieve with traditional machining techniques.

Cost

In terms of cost, CNC machining typically involves a higher initial investment due to the machinery, software, and setup required. However, for large production runs, the cost per unit decreases significantly, making it cost-effective in the long term. Traditional machining, on the other hand, has lower upfront costs but can incur higher labor costs over time, especially if skilled operators are required for complex tasks.

Additive manufacturing often has lower setup costs, as it does not require extensive tooling or machining setups. However, the material costs can be high, particularly for specialized filaments or resins. For low-volume production and prototyping, 3D printing can be more economical, but the cost per unit may rise substantially for larger quantities.

Best Use Case

CNC machining is best suited for producing complex parts that require high precision, such as components in the aerospace, automotive, and medical industries. Its efficiency and accuracy make it the preferred choice for manufacturers needing reliable output on a large scale.

Traditional machining is often employed for simpler designs or one-off projects where the cost and complexity of CNC machining are not justified. It is still widely used in small-scale operations or for repairs where custom solutions are needed.

Additive manufacturing shines in prototyping and creating intricate designs that are challenging to machine. It is particularly advantageous for industries like consumer goods, medical devices, and aerospace, where rapid iteration and customization are vital.

Conclusion

While CNC machining offers unmatched precision and efficiency for complex parts, traditional machining and additive manufacturing serve their unique purposes in the manufacturing landscape. The choice between these methods should be guided by the specific requirements of the project, including performance needs, budget constraints, and the intended use case. Understanding these alternatives allows B2B buyers to make informed decisions that align with their production goals.

Technical Properties and Trade Terms

CNC machining is a highly specialized manufacturing process characterized by several technical properties and trade terms that are essential for B2B decision-makers to understand. Below are key technical properties and common trade terms relevant to CNC machining.

Key Technical Properties

-

Precision and Tolerance:

CNC machining is renowned for its ability to produce parts with exceptional precision. Tolerance levels can be as tight as ±0.005 mm (0.0002 inches), making it ideal for industries such as aerospace and automotive where exact specifications are critical. This precision ensures that components fit perfectly within larger assemblies. -

Material Compatibility:

CNC machines can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics (ABS, nylon), and composites. This versatility allows manufacturers to tailor parts to specific applications, ensuring optimal performance and durability. -

Surface Finish:

The surface finish produced by CNC machining can vary based on the machining process and tooling used. Finishes can range from rough (as-machined) to smooth (polished or anodized). A high-quality surface finish not only enhances aesthetic appeal but also affects the part’s performance, particularly in reducing friction and wear. -

Scalability:

CNC machining is highly scalable, allowing for both low-volume and high-volume production runs. This scalability is beneficial for businesses that require prototypes as well as mass production, enabling them to respond quickly to market demands without compromising quality. -

Automation and Efficiency:

CNC machines operate with minimal human intervention, thanks to automated programming and operation. This automation leads to higher efficiency, reduced lead times, and lower labor costs, making it a cost-effective solution for manufacturing needs. -

Multi-Axis Machining:

Many CNC machines operate on multiple axes (typically 3, 4, or 5), allowing for complex geometries and intricate designs. Multi-axis machining enhances the capability to produce parts that would be challenging or impossible to create with traditional methods, increasing design flexibility.

Common Trade Terms

-

OEM (Original Equipment Manufacturer):

Refers to companies that produce parts or components that are used in another company’s end product. In CNC machining, OEMs often require precise specifications and high-quality standards. -

MOQ (Minimum Order Quantity):

The smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they meet the supplier’s requirements while aligning with their own production needs. -

RFQ (Request for Quotation):

A formal document sent to suppliers requesting pricing, terms, and conditions for a specific quantity of parts. An RFQ allows buyers to compare offers and make informed purchasing decisions. -

Lead Time:

The amount of time required to manufacture a part after an order is placed. Lead time is critical for planning and inventory management, affecting how quickly a company can respond to customer demands. -

CAD/CAM:

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are software tools used to design parts and control CNC machines, respectively. CAD software facilitates design visualization, while CAM software translates these designs into machine instructions. -

Takt Time:

The maximum allowable time to produce a product in order to meet customer demand. Understanding takt time helps manufacturers optimize their production processes and maintain efficiency.

In summary, comprehending the technical properties and trade terms associated with CNC machining is vital for international B2B buyers in Nigeria, Saudi Arabia, and Brazil. These insights empower decision-makers to navigate supplier relationships effectively and enhance their manufacturing strategies.

Market Dynamics and Sourcing Trends

The CNC machining industry is experiencing robust growth, driven by advancements in technology, increasing demand for precision manufacturing, and the expansion of various end-user industries such as automotive, aerospace, and consumer electronics. As international B2B buyers, particularly from Nigeria, Saudi Arabia, and Brazil, evaluate their sourcing options, understanding the current market dynamics is crucial.

Market Overview & Trends

The global CNC machining market is projected to grow significantly, with a compound annual growth rate (CAGR) of approximately 6% from 2023 to 2030. This growth is primarily fueled by the increasing need for automation in manufacturing processes, which enhances operational efficiency and reduces production costs. The rise of Industry 4.0, characterized by smart manufacturing and the Internet of Things (IoT), is transforming CNC machining, allowing for real-time monitoring and improved production accuracy.

Moreover, the integration of advanced technologies such as artificial intelligence (AI) and machine learning is enabling manufacturers to optimize their CNC machining processes. These technologies facilitate predictive maintenance and enhance the precision of machining operations, leading to higher quality outputs and reduced waste.

Regionally, the demand for CNC machining services is surging in emerging markets like Brazil and Nigeria, where industrialization efforts are gaining momentum. These countries are investing in modern manufacturing technologies to enhance competitiveness in global supply chains. In Saudi Arabia, the government’s Vision 2030 initiative aims to diversify the economy and reduce reliance on oil, further propelling investments in advanced manufacturing sectors, including CNC machining.

As international buyers assess their sourcing strategies, it is essential to consider suppliers that not only provide high-quality CNC machined components but also demonstrate technological capabilities and a commitment to continuous improvement.

Sustainability & Ethical Sourcing

In an era where sustainability is paramount, the CNC machining industry is increasingly focusing on environmentally friendly practices and ethical sourcing. International B2B buyers from Nigeria, Saudi Arabia, and Brazil are recognizing the importance of partnering with manufacturers that prioritize sustainability in their operations.

Sustainable CNC machining practices include the implementation of energy-efficient machinery, waste reduction techniques, and the utilization of recyclable materials. Suppliers are adopting innovative technologies such as additive manufacturing to minimize waste and improve resource efficiency. By sourcing from manufacturers that embrace these practices, buyers can reduce their carbon footprint and contribute to a more sustainable supply chain.

Ethical sourcing is another critical consideration. As buyers expand their supplier networks, they must ensure that their partners adhere to fair labor practices and uphold human rights throughout their operations. This includes transparency in sourcing raw materials and compliance with international labor standards. Establishing strong relationships with suppliers who prioritize ethical practices not only enhances brand reputation but also fosters customer loyalty.

In conclusion, as the CNC machining market evolves, international B2B buyers must stay informed about market trends and prioritize sustainability and ethical sourcing. By doing so, they can secure reliable supply chains that align with their corporate social responsibility goals while capitalizing on the growth opportunities presented by this dynamic industry.

FAQs for B2B Buyers of cnc machining

-

What is CNC machining and how does it work?

CNC machining, or Computer Numerical Control machining, is a manufacturing process where pre-programmed software controls the movement of machinery and tools. The process allows for precise cutting, shaping, and finishing of materials based on a digital design. Operators input a CAD (Computer-Aided Design) model, which is then translated into G-code—a language that CNC machines understand. This enables the machinery to execute complex tasks with high accuracy and consistency, minimizing human error and enhancing production efficiency. -

What are the benefits of using CNC machining for my business?

CNC machining offers several advantages, including high precision, repeatability, and efficiency. It reduces production time and costs by automating complex processes, allowing for rapid prototyping and mass production. Additionally, CNC machines can work with a variety of materials, including metals, plastics, and composites, making them versatile for different industries. The ability to produce intricate designs consistently also enhances product quality, which can lead to greater customer satisfaction and loyalty. -

What types of materials can be processed using CNC machining?

CNC machining is highly versatile and can process a wide range of materials, including metals (such as aluminum, steel, and titanium), plastics (like ABS and nylon), wood, and composites. The choice of material often depends on the specific application and desired properties of the final product. Each material may require different machining strategies and tools, so it’s essential to work with a supplier that has experience in handling the material you intend to use. -

How do I choose the right CNC machining provider?

Selecting the right CNC machining provider involves evaluating several factors. Look for a supplier with a solid reputation and experience in your industry. Assess their capabilities, including the types of machines they operate, their material handling expertise, and their quality control processes. Additionally, consider their production capacity, lead times, and customer service. Request samples or case studies to understand their work quality, and ensure they adhere to relevant industry standards and certifications. -

What is the typical lead time for CNC machining projects?

Lead times for CNC machining can vary significantly based on several factors, including the complexity of the design, the materials used, and the current workload of the provider. Generally, a lead time can range from a few days for simple parts to several weeks for more complex projects. It’s important to discuss your specific timeline with the CNC provider upfront to set realistic expectations and ensure they can meet your deadlines. -

Can CNC machining accommodate custom designs?

Yes, CNC machining is particularly well-suited for custom designs. The process allows for the production of unique parts tailored to specific requirements. By providing detailed CAD drawings or prototypes, businesses can have components manufactured to their exact specifications. This flexibility makes CNC machining an excellent choice for industries requiring bespoke solutions, such as aerospace, automotive, and medical device manufacturing. -

What are the common applications of CNC machining in various industries?

CNC machining is widely used across multiple industries, including aerospace, automotive, electronics, and medical. In aerospace, it is employed to manufacture lightweight components with high precision. The automotive sector utilizes CNC machining for producing engine parts, frames, and custom fittings. In electronics, it is used for creating enclosures and circuit boards. The medical industry relies on CNC machining for producing surgical instruments and implants, highlighting its versatility and precision in critical applications. -

What are the cost factors associated with CNC machining?

The cost of CNC machining can vary based on several factors, including material type, part complexity, production volume, and machining time. High-quality materials and intricate designs may lead to higher costs, while simpler parts can be produced more economically. Additionally, setup fees and tooling costs can impact overall pricing. To obtain an accurate estimate, it is advisable to discuss your project in detail with potential suppliers, who can provide a tailored quote based on your specific requirements.

Disclaimer

⚠️ Important Disclaimer

The information in this guide is for informational purposes only and does not constitute professional procurement advice. B2B buyers must conduct their own thorough due diligence before any purchasing decisions.

Conclusion for cnc machining

CNC machining stands as a pivotal technology in modern manufacturing, offering unparalleled precision, efficiency, and versatility. For international B2B buyers in Nigeria, Saudi Arabia, and Brazil, understanding the nuances of CNC machining can significantly enhance sourcing decisions and streamline production processes. The ability to automate intricate tasks with minimal human intervention not only reduces the potential for errors but also ensures consistent quality across various applications, from automotive components to aerospace parts.

Investing in CNC machining capabilities can lead to substantial cost savings and improved turnaround times, making it an essential consideration for companies aiming to stay competitive in the global marketplace. As industries continue to evolve, embracing advanced manufacturing technologies like CNC will be crucial for achieving operational excellence and meeting the increasing demand for customized products.

Looking ahead, international B2B buyers are encouraged to explore partnerships with CNC machining providers that prioritize innovation and quality. By leveraging these advanced capabilities, businesses can position themselves for growth and success in a rapidly changing economic landscape. The future of manufacturing is here—are you ready to embrace it?