Choosing Your Wood Burn Barrel: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for wood burn barrel

In the dynamic landscape of international trade, sourcing a wood burn barrel can present unique challenges, particularly for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe. These specialized cooking tools, often essential for high-volume charcoal production and authentic barbecue experiences, require careful consideration of material quality, design specifications, and supplier reliability. This comprehensive guide delves into the multifaceted world of wood burn barrels, exploring various types, applications, and the critical factors for vetting suppliers.

Buyers will gain valuable insights into the construction and functionality of wood burn barrels, including their role in producing consistent heat for long-duration cooking. Furthermore, we will address the importance of understanding regional regulations, shipping logistics, and cost implications that affect the purchasing process. By equipping international B2B buyers with the necessary knowledge and tools to navigate these complexities, this guide empowers them to make informed decisions that enhance their operational efficiency and culinary offerings. Whether you are in Brazil, Germany, or elsewhere, understanding the nuances of sourcing a wood burn barrel will enable you to capitalize on its advantages, ensuring quality and reliability in your cooking operations.

Understanding wood burn barrel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Commercial BBQ Burn Barrel | Large capacity, carbon steel construction, designed for high-volume cooking | Catering, restaurants, large events | Pros: High efficiency, durable, ideal for large-scale cooking. Cons: Higher initial investment, longer lead time for custom orders. |

| Modified 55-Gallon Drum | Repurposed steel, open top for easy loading, crisscrossed rods for airflow | Small-scale catering, backyard events | Pros: Cost-effective, easy to construct. Cons: Limited capacity, may require DIY assembly. |

| Portable Burn Barrel | Compact design, lightweight materials, easy transport | Outdoor events, festivals, pop-up kitchens | Pros: Mobility, versatile usage. Cons: Smaller cooking area, less stable in windy conditions. |

| Eco-Friendly Burn Barrel | Made from recycled materials, designed for sustainability | Eco-conscious businesses, organic farms | Pros: Environmentally friendly, attractive to green businesses. Cons: May have lower durability compared to steel models. |

| Multi-Function Burn Barrel | Includes additional features like grilling grates or smoke boxes | Versatile food service operations | Pros: Multifunctional, can replace multiple cooking tools. Cons: More complex design may lead to higher maintenance. |

What are the characteristics of a Commercial BBQ Burn Barrel?

Commercial BBQ burn barrels are engineered for high-capacity cooking, often constructed from robust carbon steel. These barrels can handle whole logs, producing consistent embers ideal for large-scale cooking, such as catering events or restaurant use. When considering a purchase, buyers should evaluate the lead time for custom orders and shipping logistics, as these units typically require a longer production period. The investment is justified by the efficiency and durability that these barrels offer, making them a staple for serious culinary operations.

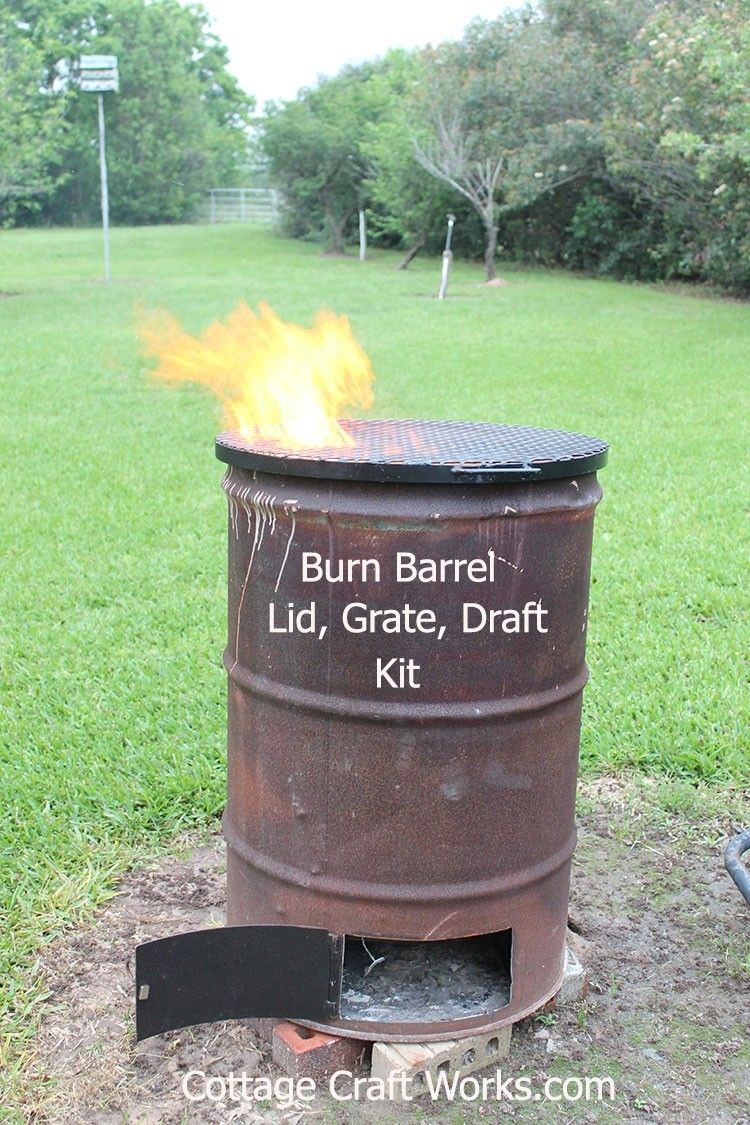

How does a Modified 55-Gallon Drum serve B2B needs?

The modified 55-gallon drum is a popular choice among small-scale caterers and backyard event hosts due to its affordability and ease of construction. This type features an open top for easy loading of hardwood logs and utilizes crisscrossed rods for optimal airflow, promoting efficient combustion. B2B buyers should consider the DIY aspect of this option, as it may require some assembly, but the cost savings can be significant. Its limited capacity is suitable for smaller gatherings, making it a flexible choice for various occasions.

Illustrative image related to wood burn barrel

Why choose a Portable Burn Barrel for events?

Portable burn barrels are designed for mobility, allowing businesses to set up cooking stations at outdoor events, festivals, or pop-up kitchens easily. These barrels are typically lightweight and compact, making them easy to transport and store. While they offer the advantage of versatility, potential buyers should be aware of the smaller cooking area and the stability issues that can arise in windy conditions. This type is ideal for businesses that prioritize convenience and adaptability in their food service operations.

What makes an Eco-Friendly Burn Barrel appealing to buyers?

Eco-friendly burn barrels are constructed from recycled materials and are designed with sustainability in mind. These barrels appeal to eco-conscious businesses, such as organic farms and green restaurants, looking to reduce their environmental footprint. When purchasing, businesses should assess the durability of these units, as they may not withstand high heat as well as traditional steel models. However, the positive brand image associated with eco-friendly practices can be a significant advantage in attracting customers.

How does a Multi-Function Burn Barrel enhance cooking operations?

Multi-function burn barrels come equipped with additional features like grilling grates or smoke boxes, making them versatile tools for food service operations. These barrels can replace multiple cooking devices, streamlining the cooking process and saving space. B2B buyers should consider the complexity of the design, as it may require more maintenance than simpler models. However, the multifunctionality can lead to increased efficiency and creativity in menu offerings, making this an attractive option for diverse culinary applications.

Illustrative image related to wood burn barrel

Key Industrial Applications of wood burn barrel

| Industry/Sector | Specific Application of wood burn barrel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Barbecue and Cooking Equipment | Produces high-quality coals for consistent cooking, enhancing flavor and efficiency. | Look for durability, ease of use, and capacity for large-scale cooking. |

| Agriculture | Waste Management and Biomass Conversion | Efficiently burns agricultural waste, reducing landfills while producing energy. | Ensure compliance with local environmental regulations and assess the burning capacity. |

| Hospitality | Outdoor Cooking Facilities | Provides a unique cooking experience that attracts customers, enhancing the venue’s appeal. | Consider design aesthetics, safety features, and ease of maintenance. |

| Manufacturing & Industry | Heat Source for Industrial Processes | Offers a cost-effective and sustainable heating solution for various manufacturing processes. | Evaluate material quality, size, and heat output to meet specific industrial needs. |

| Construction & Demolition | Debris Disposal and Site Preparation | Facilitates the quick disposal of wood waste on-site, reducing cleanup time and costs. | Assess compliance with local waste disposal regulations and ensure adequate safety features. |

How is the Wood Burn Barrel Used in the Food & Beverage Industry?

In the food and beverage sector, wood burn barrels are primarily utilized for barbecue and cooking, especially in large-scale outdoor events and restaurants. They produce high-quality coals essential for consistent cooking, which enhances the flavor of grilled meats. For B2B buyers, it is crucial to source barrels made from durable materials that can withstand high temperatures and have sufficient capacity to handle large volumes of food, particularly in regions like Brazil and South Africa where barbecue culture is prevalent.

What Role Does the Wood Burn Barrel Play in Agriculture?

Agriculture relies on wood burn barrels for efficient waste management and biomass conversion. They allow farmers to burn agricultural residues, reducing landfill use while generating heat energy that can be utilized for various applications. Buyers in this sector must ensure that the burn barrels comply with local environmental regulations and possess adequate burning capacity to handle the volume of waste produced, particularly in regions where agricultural practices are intensive.

How Can Hospitality Businesses Benefit from Wood Burn Barrels?

In the hospitality industry, wood burn barrels enhance outdoor cooking facilities, offering a unique culinary experience that attracts customers. They serve as a focal point for events and gatherings, providing flavorful cooking options. When sourcing, hospitality buyers should consider the design aesthetics, safety features, and maintenance requirements of the barrels, as these factors directly impact the customer experience and operational efficiency in venues across Europe and the Middle East.

What Advantages Do Wood Burn Barrels Offer to Manufacturing Industries?

Wood burn barrels serve as a sustainable heat source for various manufacturing processes, providing an economical alternative to conventional heating methods. They can be utilized in facilities that require consistent heat output for production processes. B2B buyers should evaluate the material quality, size, and heat output of the barrels to ensure they meet specific industrial needs, particularly in regions with a strong emphasis on sustainability and energy efficiency.

Illustrative image related to wood burn barrel

How Are Wood Burn Barrels Used in Construction and Demolition?

In construction and demolition, wood burn barrels facilitate the quick disposal of wood waste on-site, significantly reducing cleanup time and associated costs. They allow for efficient burning of debris, making site preparation faster and more effective. Buyers should assess compliance with local waste disposal regulations and ensure that the barrels have adequate safety features to prevent accidents, especially in urban areas where regulations may be stringent.

3 Common User Pain Points for ‘wood burn barrel’ & Their Solutions

Scenario 1: Sourcing Reliable Burn Barrels for High-Volume Production

The Problem: B2B buyers, especially those in regions such as Africa and South America, often struggle to find reliable suppliers for burn barrels that can handle high-volume charcoal production or large-scale cooking. The challenge is exacerbated by inconsistent quality from local fabricators and the risk of equipment failing during critical cooking periods. This inconsistency can lead to production delays, impacting business operations and customer satisfaction.

The Solution: To mitigate these risks, buyers should prioritize sourcing from reputable manufacturers that specialize in industrial-grade burn barrels. Conduct thorough research by looking for suppliers with proven track records and positive customer reviews. Request samples or visit production facilities if possible to evaluate the quality of materials used, such as the thickness of steel and design features that ensure durability. Furthermore, consider suppliers that offer customization options to tailor barrels for specific cooking needs, ensuring they meet the operational demands of your business. Establishing a long-term partnership with a reliable supplier can also help secure favorable pricing and consistent supply.

Scenario 2: Efficient Use of Burn Barrels in Various Cooking Conditions

The Problem: Many B2B buyers are uncertain about how to effectively use burn barrels in different environmental conditions. For instance, buyers in the Middle East may face extreme heat, while those in Europe may deal with cold and damp weather. These conditions can impact the burn efficiency and the quality of the coals produced, leading to inconsistent cooking results and wasted resources.

The Solution: To optimize burn barrel performance across various climates, buyers should invest in additional accessories that enhance airflow and heat retention. For hot climates, consider using insulated jackets or thermal blankets that can help regulate the temperature inside the barrel. In colder regions, ensure that the burn barrel is elevated off the ground to prevent heat loss through contact with cold surfaces. Additionally, buyers should experiment with different types of wood and loading techniques to find the most effective combinations for their specific environment. This adaptability not only improves coal production but also enhances the overall cooking experience, ensuring consistent results regardless of external conditions.

Scenario 3: Safety Concerns During Operation of Burn Barrels

The Problem: Safety is a paramount concern for B2B buyers using burn barrels, especially in commercial settings where multiple employees are involved. Risks include burns, fires, and exposure to harmful fumes. Buyers may find it challenging to implement adequate safety protocols, which can lead to serious accidents and liabilities.

The Solution: To enhance safety during the operation of burn barrels, buyers should develop comprehensive safety training programs for all employees involved in the cooking process. This training should cover proper handling techniques, emergency procedures, and the importance of using personal protective equipment (PPE) like gloves and goggles. Additionally, installing safety features such as spark arrestors and proper ventilation systems can significantly reduce risks associated with smoke inhalation and fire hazards. Regular maintenance checks should also be scheduled to ensure that all equipment is functioning properly and any potential hazards are addressed proactively. By creating a culture of safety and awareness, businesses can minimize risks and protect their employees while maximizing operational efficiency.

Strategic Material Selection Guide for wood burn barrel

What Materials Are Commonly Used for Wood Burn Barrels?

When selecting materials for wood burn barrels, it is essential to consider their properties, advantages, disadvantages, and how they align with international standards. The most common materials used for constructing wood burn barrels include carbon steel, stainless steel, aluminum, and cast iron. Each material has unique characteristics that influence performance, manufacturing complexity, and suitability for various applications.

Illustrative image related to wood burn barrel

How Does Carbon Steel Perform in Wood Burn Barrels?

Carbon steel is a prevalent choice for wood burn barrels due to its excellent heat resistance and structural integrity. With a typical temperature rating exceeding 1,000°F (537°C), carbon steel can withstand the high temperatures generated during combustion. Its corrosion resistance is moderate, often requiring protective coatings to enhance durability against rust, especially in humid environments.

Pros: Carbon steel is relatively cost-effective, making it an attractive option for manufacturers. It offers good weldability, allowing for complex designs and modifications.

Cons: Without proper treatment, carbon steel can corrode over time, particularly in outdoor settings. Additionally, its weight can complicate transportation and handling.

For international buyers, particularly in regions like Africa and South America, compliance with local standards such as ASTM or DIN is crucial. Buyers should ensure that the materials used meet local regulations regarding emissions and safety.

What Are the Benefits of Using Stainless Steel for Burn Barrels?

Stainless steel is another popular material for wood burn barrels, known for its superior corrosion resistance and aesthetic appeal. With a temperature rating similar to carbon steel, stainless steel can endure high heat without compromising structural integrity.

Pros: The primary advantage of stainless steel is its resistance to rust and staining, making it ideal for outdoor use. It also requires minimal maintenance and offers a longer lifespan compared to carbon steel.

Cons: The primary drawback is the higher cost associated with stainless steel, which can impact the overall pricing of the burn barrel. Additionally, its manufacturing process is more complex, requiring specialized equipment.

Illustrative image related to wood burn barrel

International buyers, particularly in Europe, may prefer stainless steel due to its compliance with stringent environmental regulations. Ensuring that the stainless steel used meets standards like EN 10088 can be an essential consideration.

Why Choose Aluminum for Wood Burn Barrels?

Aluminum is a lightweight alternative for wood burn barrels, offering good thermal conductivity and resistance to corrosion. While its temperature rating is lower than that of steel (around 800°F or 427°C), aluminum can still perform adequately in many applications.

Pros: The lightweight nature of aluminum makes it easy to transport and handle. It is also resistant to rust, reducing maintenance needs.

Cons: The lower temperature resistance may limit its use in high-heat applications. Additionally, aluminum can be more expensive than carbon steel, affecting cost-effectiveness.

Illustrative image related to wood burn barrel

For buyers in the Middle East, where high temperatures are common, aluminum may not be the best choice for prolonged use. However, its lightweight nature can be advantageous for portable applications.

What Advantages Does Cast Iron Offer for Burn Barrels?

Cast iron is known for its exceptional heat retention and durability, making it a suitable material for wood burn barrels that require consistent heat output. With a high-temperature rating, cast iron can withstand extreme conditions.

Pros: Cast iron provides excellent thermal stability, allowing for even heat distribution. Its durability ensures a long lifespan with proper care.

Illustrative image related to wood burn barrel

Cons: The weight of cast iron can be a significant disadvantage, making it cumbersome to transport. Additionally, it is prone to cracking under thermal shock if not handled properly.

International buyers should consider the weight and handling implications of cast iron, especially in regions where transport logistics are challenging. Compliance with local standards is also important to ensure safety and performance.

Summary Table of Material Options for Wood Burn Barrels

| Material | Typical Use Case for wood burn barrel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Commercial and backyard cooking | Cost-effective and durable | Moderate corrosion resistance | Low |

| Stainless Steel | High-end outdoor cooking | Superior corrosion resistance | Higher cost and complex mfg | High |

| Aluminum | Portable burn barrels | Lightweight and rust-resistant | Lower temperature resistance | Medium |

| Cast Iron | High-heat cooking applications | Excellent heat retention | Heavy and prone to cracking | Medium |

This analysis provides B2B buyers with a comprehensive understanding of material options for wood burn barrels, enabling informed decisions that align with their operational needs and compliance requirements.

Illustrative image related to wood burn barrel

In-depth Look: Manufacturing Processes and Quality Assurance for wood burn barrel

The manufacturing process for wood burn barrels involves several critical stages, each designed to ensure the production of a high-quality, durable product. For B2B buyers, understanding these processes can help in selecting reliable suppliers and ensuring that the products meet specific performance requirements.

What Are the Main Stages in the Manufacturing Process of Wood Burn Barrels?

1. Material Preparation

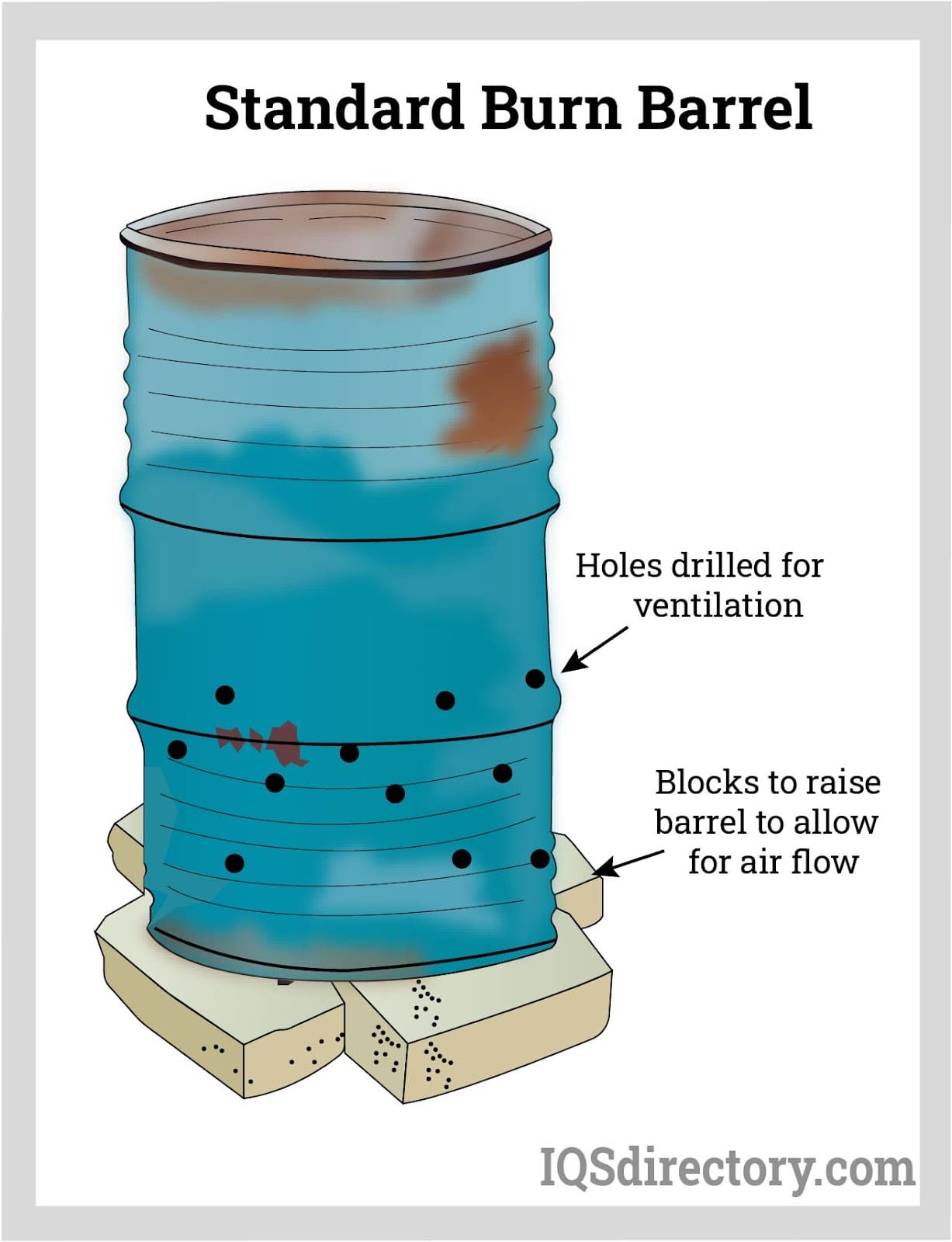

The foundation of any burn barrel is its materials. Typically, manufacturers use carbon steel due to its excellent heat resistance and durability. The first step involves sourcing high-quality steel, often in the form of repurposed 55-gallon drums. The drums are inspected for integrity, and any rust or damage is addressed before they are processed. This initial quality check is crucial, as the performance of the burn barrel heavily relies on the material’s structural soundness.

2. Forming the Burn Barrel

Once the materials are prepared, the forming process begins. This involves cutting the steel drum to create an open top and a shovel opening at the bottom. Advanced cutting techniques, such as plasma cutting or laser cutting, may be employed to achieve precise dimensions. The cut edges are then smoothed to ensure safety and prevent sharp edges that could pose a risk during handling. Additionally, ventilation holes may be created to enhance airflow, which is essential for efficient combustion.

3. Assembly of Components

After forming, the next stage is assembly. The burn barrel is constructed with critical components, including crisscrossed rods or stakes that support the wood during burning. These rods are often made from rebar or concrete stakes, strategically positioned to allow for optimal airflow and combustion. The assembly process must ensure that all parts fit securely, as any loose components can affect performance and safety.

4. Finishing Touches

Finishing processes enhance the durability and aesthetics of the burn barrel. This may include applying heat-resistant coatings or paints that can withstand high temperatures. Some manufacturers also opt for rust-proof finishes to extend the product’s lifespan, especially in humid or coastal regions. Final inspections are conducted to ensure that the barrel meets all design specifications and quality standards before it is packaged for shipping.

Illustrative image related to wood burn barrel

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for wood burn barrels. International standards such as ISO 9001 play a significant role in ensuring consistent product quality. Compliance with these standards indicates that manufacturers have established quality management systems that govern their production processes.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of materials received from suppliers. Steel drums and other components are inspected for defects or inconsistencies before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints are established to monitor the assembly and forming stages. This includes verifying dimensions, ensuring proper alignment of components, and checking for any signs of defects during assembly.

-

Final Quality Control (FQC): Before the burn barrels are packaged, a comprehensive inspection is conducted to assess the finished product. This includes testing for structural integrity, ensuring that all openings are cut to specifications, and verifying that any finishes applied are uniform and intact.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, especially those operating in diverse international markets such as Africa, South America, the Middle East, and Europe, understanding the relevant standards and certifications is crucial.

-

ISO 9001: This standard focuses on quality management systems and is widely recognized globally. Suppliers with ISO 9001 certification demonstrate their commitment to maintaining high-quality production processes.

-

CE Marking: Particularly relevant for buyers in the European market, CE marking indicates that a product complies with EU safety, health, and environmental protection standards.

-

API Standards: While primarily associated with the oil and gas industry, API standards can also apply to the manufacturing processes of metal products, ensuring they meet specific safety and performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain rigorous quality control standards, buyers can implement several verification strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place. This firsthand observation can provide valuable insights into the supplier’s commitment to quality.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the specific measures taken during production. These reports should outline IQC, IPQC, and FQC processes, as well as any testing methods used.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing practices. This is especially important for international transactions where buyers may not have the ability to conduct audits themselves.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must navigate additional complexities when it comes to quality control. For instance, understanding local regulations and standards can be challenging, especially in regions with less stringent requirements. Buyers should be proactive in researching the specific standards applicable to their target markets and ensure that their suppliers comply with these regulations.

Illustrative image related to wood burn barrel

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, written agreements that outline quality standards, testing methods, and penalties for non-compliance can help mitigate these risks.

By understanding the manufacturing processes and quality assurance protocols of wood burn barrels, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wood burn barrel’

In the competitive landscape of sourcing wood burn barrels, it is essential for B2B buyers to follow a structured approach to ensure they select the right product for their needs. This guide outlines the critical steps involved in procuring wood burn barrels, enabling you to make informed decisions that align with your operational requirements.

Illustrative image related to wood burn barrel

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. Consider factors such as size, material, and heat resistance. For instance, a burn barrel made from carbon steel with a specified thickness can significantly impact durability and performance.

- Dimensions: Determine the size that fits your space and production capacity.

- Material: Look for high-quality steel that can withstand intense heat and frequent use.

Step 2: Research Potential Suppliers

Take the time to identify and research suppliers that specialize in wood burn barrels. A thorough supplier evaluation can help you find reliable partners.

- Reputation: Look for suppliers with positive reviews and a strong market presence, especially in your target regions.

- Experience: Consider suppliers with a proven track record in producing burn barrels tailored to your industry’s needs.

Step 3: Evaluate Supplier Certifications

Ensuring that your chosen supplier meets industry standards is vital for safety and quality. Verify that they hold relevant certifications, which can indicate adherence to manufacturing and safety regulations.

Illustrative image related to wood burn barrel

- ISO Certification: This demonstrates a commitment to quality management systems.

- Safety Standards: Check for compliance with local and international safety standards relevant to your market.

Step 4: Request Detailed Product Information

Gather comprehensive product information from potential suppliers. This should include specifications, usage guidelines, and warranty details.

- Product Specs: Ensure the burn barrel meets your defined technical specifications.

- Warranties: Understand the warranty coverage to protect your investment against defects or failures.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, obtain quotes and compare pricing. Be sure to consider payment terms that suit your cash flow requirements.

- Total Cost: Look beyond the initial purchase price; include shipping, handling, and potential customs duties.

- Payment Flexibility: Evaluate payment terms to ensure they align with your financial strategy.

Step 6: Assess Shipping and Delivery Options

Shipping logistics can significantly affect your procurement timeline. Confirm that suppliers can deliver to your location in a timely manner.

- Lead Time: Ask about the production and shipping lead times, especially if you require custom orders.

- Shipping Methods: Understand the available shipping options and associated costs to avoid unexpected expenses.

Step 7: Establish Communication Channels

Effective communication with your supplier is essential throughout the sourcing process. Ensure that you have clear lines of communication for any inquiries or updates.

- Point of Contact: Designate a specific representative for your account to streamline communication.

- Response Times: Assess how quickly the supplier responds to inquiries, which can be indicative of their customer service quality.

By following these steps, B2B buyers can navigate the complexities of sourcing wood burn barrels more effectively, ensuring that they select the best product to meet their operational needs.

Illustrative image related to wood burn barrel

Comprehensive Cost and Pricing Analysis for wood burn barrel Sourcing

When sourcing wood burn barrels, understanding the cost structure and pricing dynamics is essential for B2B buyers. This analysis will outline the various cost components involved, the influencers on pricing, and provide actionable tips for negotiating and optimizing costs.

What Are the Key Cost Components in Wood Burn Barrel Manufacturing?

-

Materials: The primary material for wood burn barrels is steel, typically sourced from recycled or new steel drums. The cost of raw materials fluctuates based on market conditions, which can significantly impact the final price. Additionally, if custom features like thicker walls or specific finishes are required, this will also affect material costs.

-

Labor: Labor costs can vary widely depending on the region of production and the complexity of the manufacturing process. Skilled labor is often necessary for welding and assembly, particularly for custom designs, which may increase labor costs.

-

Manufacturing Overhead: This includes expenses related to the production facility, utilities, equipment maintenance, and administrative costs. Efficient operations can help reduce overhead costs, benefiting the final pricing.

-

Tooling: If a manufacturer needs to create specific tools or molds for customized barrels, this adds to the initial investment. Tooling costs are often amortized over the production run, so larger orders can help reduce the per-unit cost.

-

Quality Control (QC): Implementing quality assurance processes ensures that the barrels meet safety and performance standards. While this incurs additional costs, it can prevent future liabilities and enhance customer satisfaction.

-

Logistics: Transportation costs are influenced by the distance from the manufacturing site to the buyer’s location, shipping method, and volume. International shipping can add complexities such as customs duties and tariffs.

-

Margin: Manufacturers typically mark up their prices to ensure profitability. The margin can vary based on competition and the perceived value of the product.

What Factors Influence Pricing for Wood Burn Barrels?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounted pricing. Suppliers may have set MOQs that, if met, can provide additional savings.

-

Specifications and Customization: Custom features, such as specific dimensions or additional ventilation, may increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Quality Certifications: Compliance with international quality standards can affect pricing. Certifications provide assurance of product reliability but may also add to manufacturing costs.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices due to perceived quality and reliability. Conversely, new or less reputable suppliers may offer lower prices but come with risks.

-

Incoterms: Understanding the terms of shipping and delivery can significantly impact total costs. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) terms can shift responsibility and costs between the buyer and seller.

How Can Buyers Optimize Costs When Sourcing Wood Burn Barrels?

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or longer-term contracts. Leverage market research to understand competitive pricing.

-

Evaluate Total Cost of Ownership: Consider not just the purchase price, but also shipping, potential duties, and the lifespan of the product. A higher-quality barrel may have a higher upfront cost but could save money in the long run due to durability.

-

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local tariffs, shipping logistics, and currency fluctuations. Partnering with local distributors might ease some of these complexities.

-

Request Sample Products: Before committing to a large order, request samples to assess quality and suitability. This helps ensure that the investment aligns with your needs.

Disclaimer on Pricing

It is important to note that prices for wood burn barrels can vary significantly based on the aforementioned factors. The prices mentioned in various references are indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and engage directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing wood burn barrel With Other Solutions

Exploring Alternatives to Wood Burn Barrels: Effective Solutions for Cooking and Charcoal Production

In the competitive landscape of B2B solutions for cooking and charcoal production, understanding alternatives to wood burn barrels is crucial for informed decision-making. While wood burn barrels are renowned for their efficient heat generation and ember production, various other methods and technologies can also meet similar needs. This section delves into a comparative analysis of wood burn barrels against two viable alternatives: charcoal grills and traditional wood-fired ovens.

| Comparison Aspect | Wood Burn Barrel | Charcoal Grill | Traditional Wood-Fired Oven |

|---|---|---|---|

| Performance | Produces high-quality, consistent embers for long cooking times, ideal for barbecuing large cuts of meat. | Offers good heat retention and flavor; however, charcoal quality can vary. | Provides even cooking with a unique smoky flavor, but requires more time to heat up. |

| Cost | Higher initial investment (around $5,700) but durable and long-lasting. | Generally lower cost, with options ranging from budget to high-end models. | Significant upfront cost and installation expenses, especially for brick ovens. |

| Ease of Implementation | Requires some assembly and a learning curve for optimal use. | Quick setup and easy to use, suitable for both beginners and experienced cooks. | Requires more complex installation and a longer learning curve for efficient use. |

| Maintenance | Low maintenance; occasional cleaning of ash and embers needed. | Moderate maintenance; regular cleaning of grates and ash disposal is necessary. | High maintenance; requires regular cleaning and occasional repairs due to heat exposure. |

| Best Use Case | Best suited for large-scale barbecuing and cooking whole animals, ideal for events and catering. | Great for casual grilling and small gatherings; versatile for various cooking styles. | Perfect for pizzerias and restaurants looking to offer authentic wood-fired dishes. |

In-Depth Analysis of Alternatives

Charcoal Grill

Charcoal grills are a popular choice for many due to their relatively low cost and ease of use. They provide a decent flavor profile and are suitable for various cooking methods, from grilling to smoking. The primary drawback is that the quality of charcoal can vary, affecting flavor and heat consistency. Additionally, while they are ideal for smaller gatherings, they may not provide the same level of heat or cooking time as a wood burn barrel, especially for large cuts of meat.

Traditional Wood-Fired Oven

Wood-fired ovens offer a unique cooking experience, delivering even heat distribution and a distinct smoky flavor that enhances the taste of dishes. They are ideal for baking pizzas and roasting meats, making them a favorite in restaurants and catering businesses. However, the initial investment can be significant, and installation may require professional assistance. Moreover, they demand more time to heat up and maintain than wood burn barrels, making them less suitable for quick cooking needs.

Making the Right Choice: Key Considerations for B2B Buyers

When selecting the right solution for cooking and charcoal production, B2B buyers should evaluate their specific needs and operational context. Consider factors such as the scale of cooking operations, budget constraints, and desired flavor profiles. A wood burn barrel is an excellent choice for high-volume cooking and long-duration events, while charcoal grills offer versatility and lower costs for casual settings. Traditional wood-fired ovens cater to niche markets requiring authentic flavors but come with higher initial and maintenance costs. Ultimately, the best solution aligns with your business goals and operational capabilities.

Illustrative image related to wood burn barrel

Essential Technical Properties and Trade Terminology for wood burn barrel

What Are the Key Technical Properties of a Wood Burn Barrel?

When selecting a wood burn barrel, understanding its technical properties is essential for ensuring optimal performance and longevity. Here are some critical specifications to consider:

-

Material Grade

The most common material used for burn barrels is carbon steel, known for its durability and heat resistance. A higher material grade, such as 1/4″ steel for the body and 3/8″ for doors, enhances structural integrity and allows the barrel to withstand high temperatures without warping. For B2B buyers, material grade impacts not only the initial cost but also the long-term value, as higher-quality materials reduce maintenance and replacement needs. -

Dimensions

Typical dimensions for a burn barrel might be around 18″ wide, 26″ deep, and 65″ tall, including a smokestack. These dimensions are critical for ensuring adequate airflow and heat distribution, which are vital for efficient combustion. Buyers should consider how the barrel’s size will fit into their operational space and whether it can handle the volume of wood necessary for their cooking or charcoal production needs. -

Ventilation Features

Effective ventilation is essential for promoting airflow and combustion efficiency. Burn barrels often include latching doors with ventilation holes or slits that allow air to circulate while keeping the fire contained. For businesses, understanding these features can aid in selecting a product that maximizes fuel efficiency and minimizes smoke output, contributing to a better cooking experience. -

Weight Tolerance

The weight tolerance of a burn barrel, influenced by its construction and material grade, is crucial for safety and performance. A well-constructed barrel should support the weight of the wood and coals without compromising stability. B2B buyers must assess whether the burn barrel can handle their intended load, particularly in high-volume cooking scenarios. -

Lead Time

Custom-made burn barrels often have a lead time ranging from 10-12 weeks. Understanding this timeline is vital for businesses planning their cooking schedules or inventory. It is also important for supply chain management, ensuring that products arrive in time to meet customer demand.

What Are Common Trade Terms Related to Wood Burn Barrels?

Familiarity with industry terminology is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to wood burn barrels:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components that are used in another company’s end product. In the context of wood burn barrels, buyers may seek OEMs for customized parts or modifications, ensuring compatibility with their existing equipment. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For wood burn barrels, understanding MOQ is important for businesses to manage inventory levels and budget constraints while ensuring they meet production needs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and availability for specific products. When sourcing wood burn barrels, businesses use RFQs to compare costs and terms from different manufacturers, helping them make informed purchasing decisions. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations, which are crucial when importing wood burn barrels from overseas suppliers. -

Lead Time

In procurement, lead time refers to the period between placing an order and receiving the goods. For wood burn barrels, knowing the lead time helps businesses plan their operations and manage customer expectations effectively.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and enhance their procurement processes for wood burn barrels.

Navigating Market Dynamics and Sourcing Trends in the wood burn barrel Sector

What Are the Current Market Dynamics and Key Trends in the Wood Burn Barrel Sector?

The wood burn barrel market is witnessing a significant transformation driven by several global factors. Increasing interest in outdoor cooking and barbecuing, particularly in regions like Africa, South America, the Middle East, and Europe, is propelling demand. As consumers become more health-conscious, there is a growing preference for wood-fired cooking, which is perceived as healthier and more flavorful compared to gas or electric options. Furthermore, the rise of culinary tourism and barbecue competitions is enhancing the visibility and desirability of wood burn barrels.

Illustrative image related to wood burn barrel

Emerging technologies such as advanced materials and manufacturing techniques are reshaping sourcing trends. For instance, the use of carbon steel in burn barrel production enhances durability and heat retention, making these products more efficient. Additionally, buyers are increasingly looking for customizable options, allowing them to tailor products to specific cooking styles or aesthetic preferences. The rise of e-commerce platforms is also changing the landscape, enabling international buyers to source products directly from manufacturers, thus reducing costs and lead times.

Market dynamics are also influenced by fluctuating raw material prices and supply chain disruptions. B2B buyers must remain vigilant about sourcing strategies, opting for suppliers who demonstrate agility and reliability in their operations. Establishing long-term partnerships with manufacturers can provide stability in pricing and supply, particularly in regions experiencing economic volatility.

How Is Sustainability and Ethical Sourcing Impacting the Wood Burn Barrel Industry?

Sustainability is becoming a critical factor in purchasing decisions within the wood burn barrel sector. As environmental awareness grows, buyers are increasingly prioritizing products that minimize ecological impact. The sourcing of wood materials is under scrutiny, with a rising demand for certified sustainable wood, such as FSC (Forest Stewardship Council) certified timber, which ensures responsible forest management practices.

Moreover, manufacturers are adopting eco-friendly production processes that reduce waste and energy consumption. This trend aligns with the global shift towards sustainable practices, making it essential for B2B buyers to engage with suppliers who adhere to these principles. Ethical supply chains are not just a moral obligation; they also enhance brand reputation and customer loyalty.

Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming increasingly relevant. Buyers should seek out suppliers who can demonstrate their commitment to sustainability through these certifications. By prioritizing ethical sourcing and sustainable materials, businesses can differentiate themselves in a competitive market, attracting environmentally conscious consumers and enhancing their market position.

What Is the Evolution of the Wood Burn Barrel in a B2B Context?

The wood burn barrel has evolved from a simple DIY tool for backyard cooking to a sophisticated piece of equipment used in commercial barbecue settings. Historically, these barrels were constructed from repurposed steel drums, primarily for personal use. However, with the rise of barbecue culture and culinary innovation, manufacturers began to refine the design and materials used, leading to more durable and efficient products.

In the B2B context, the evolution has included the introduction of customizable features and advanced materials that cater to professional chefs and pitmasters. This has opened new markets, especially in regions where barbecue traditions are deeply rooted. As the demand for high-quality outdoor cooking solutions continues to grow, the wood burn barrel is positioned as a vital tool for both home cooks and commercial establishments, reflecting the broader trends of culinary excellence and sustainability in the food industry.

Frequently Asked Questions (FAQs) for B2B Buyers of wood burn barrel

-

How can I ensure the quality of a wood burn barrel before purchasing?

To guarantee the quality of a wood burn barrel, request detailed specifications and technical diagrams from the supplier. Verify the materials used, such as carbon steel thickness, and inquire about the manufacturing process. Consider asking for samples or references from previous clients to assess durability and performance. Additionally, check for compliance with international safety standards, especially if you are sourcing from overseas. Conducting a factory visit or utilizing third-party quality inspection services can further assure you of the product’s quality. -

What is the best material for a durable wood burn barrel?

The best material for a wood burn barrel is carbon steel, particularly with a thickness of at least 1/4 inch for the body and 3/8 inch for doors. This material can withstand high temperatures and offers excellent durability. Some manufacturers also provide options with heat-resistant coatings to enhance longevity. When selecting a supplier, prioritize those who emphasize the quality of materials in their products, ensuring that the burn barrel can endure repeated use over time. -

What are the typical lead times for ordering a custom wood burn barrel?

Lead times for custom wood burn barrels can vary significantly based on the manufacturer and order size. Generally, you can expect a production time of 10-12 weeks for made-to-order units. It is crucial to confirm the lead time with your supplier during the negotiation phase, especially if you have specific deadlines or seasonal demands. Additionally, factor in shipping times, which can differ based on your location and the chosen shipping method. -

What are the minimum order quantities (MOQ) for wood burn barrels?

Minimum order quantities (MOQ) for wood burn barrels typically depend on the supplier’s production capabilities and your specific requirements. Some manufacturers may have an MOQ of one unit for custom orders, while others might require larger quantities to optimize production efficiency. When negotiating, express your needs clearly and inquire if they offer flexibility on MOQs, particularly if you are testing the market or launching a new product line. -

How do I vet suppliers for wood burn barrels effectively?

To effectively vet suppliers for wood burn barrels, start by researching their reputation in the industry. Look for online reviews, client testimonials, and case studies. Verify their certifications and compliance with international standards relevant to your market. Request references and follow up with previous clients to gauge their satisfaction. It can also be beneficial to visit the supplier’s facility, if possible, or utilize third-party inspection services to assess their production capabilities and quality control measures. -

What payment terms are commonly accepted when sourcing wood burn barrels?

Common payment terms for sourcing wood burn barrels may include options such as a deposit upfront (typically 30-50%) with the balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for larger transactions. It’s essential to discuss payment terms early in negotiations and ensure they align with your financial processes. Also, consider the impact of currency fluctuations, especially when dealing with international suppliers. -

What logistics considerations should I be aware of when importing wood burn barrels?

When importing wood burn barrels, consider several logistics factors, including shipping methods, customs regulations, and import duties. Choose between sea freight and air freight based on your budget and urgency. Ensure that the supplier provides all necessary documentation, such as invoices and certificates of origin. Familiarize yourself with local import regulations in your country, and consider working with a customs broker to facilitate the process and avoid potential delays. -

Can I customize the design of a wood burn barrel for my specific needs?

Yes, many manufacturers offer customization options for wood burn barrels. You can request modifications in size, material, or additional features such as ventilation systems or specialized coatings. When discussing customization, provide detailed specifications and intended use cases to help the supplier understand your needs. Additionally, inquire about any extra costs associated with customization and the impact on lead times to ensure that the final product meets your operational requirements.

Top 4 Wood Burn Barrel Manufacturers & Suppliers List

1. Millscale – Burn Barrel

Domain: millscale.co

Registered: 2018 (7 years)

Introduction: {“product_name”: “Burn Barrel”, “description”: “The Burn Barrel is designed for efficient and environmentally friendly waste disposal. It features a durable construction that withstands high temperatures and is suitable for burning various types of waste materials. The barrel is equipped with ventilation holes to promote airflow and reduce smoke emissions.”, “features”: [“Durable construction”, “H…

2. Burn Barrel – Wood Shop Scrap Disposal

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Burn barrel used for disposing of wood shop scraps; started crumbling after years of use; purchased a new one.

3. Destination BBQ – Burn Barrel

Domain: destination-bbq.com

Registered: 2012 (13 years)

Introduction: A burn barrel is a modified 55-gallon drum used for creating wood embers for cooking barbecue. It features an open top for loading hardwood logs and crisscrossed rods inside to hold the wood in place. As the logs burn, embers fall to the bottom through a shovel opening, providing coals for long cooks like whole hogs. Burn barrels are typically built using an old steel barrel and concrete stakes or…

4. BBQ Brethren – Burn Barrel Embers

Domain: bbq-brethren.com

Registered: 2003 (22 years)

Introduction: Burn barrel used for making embers for direct smoking. Method involves pre-burning wood splits into coals and shoveling embers into a smoker. Suitable for offset or vertical smokers. Users share tips and experiences, including using a 55-gallon drum with rebar for coal collection. Some users also mention using coals from wood stoves or other grills. The burn barrel method is considered an old-scho…

Strategic Sourcing Conclusion and Outlook for wood burn barrel

The wood burn barrel represents a unique opportunity for international B2B buyers looking to enhance their culinary offerings and operational efficiency. With its robust construction and ability to produce high-quality embers for extended cooking sessions, this tool is indispensable for businesses engaged in barbecue and catering. Strategic sourcing of burn barrels, whether through direct manufacturers or local suppliers, ensures that buyers can secure high-quality products tailored to their specific needs while optimizing costs.

As the market for wood burn barrels continues to grow, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing is vital. Buyers should consider factors such as material quality, lead times, and shipping logistics to make informed decisions. Investing in durable and efficient burn barrels not only enhances cooking capabilities but also elevates brand reputation through superior product offerings.

Looking ahead, the demand for wood burn barrels is poised to increase as culinary trends favor traditional wood-fired cooking methods. B2B buyers are encouraged to explore partnerships with reputable suppliers to capitalize on this trend. By prioritizing strategic sourcing, businesses can position themselves as leaders in the evolving barbecue market, meeting consumer preferences for authentic and flavorful cooking experiences.

Illustrative image related to wood burn barrel

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.