Choosing Your What Is A Parallel Plug: Key Specs to Compare in 2025

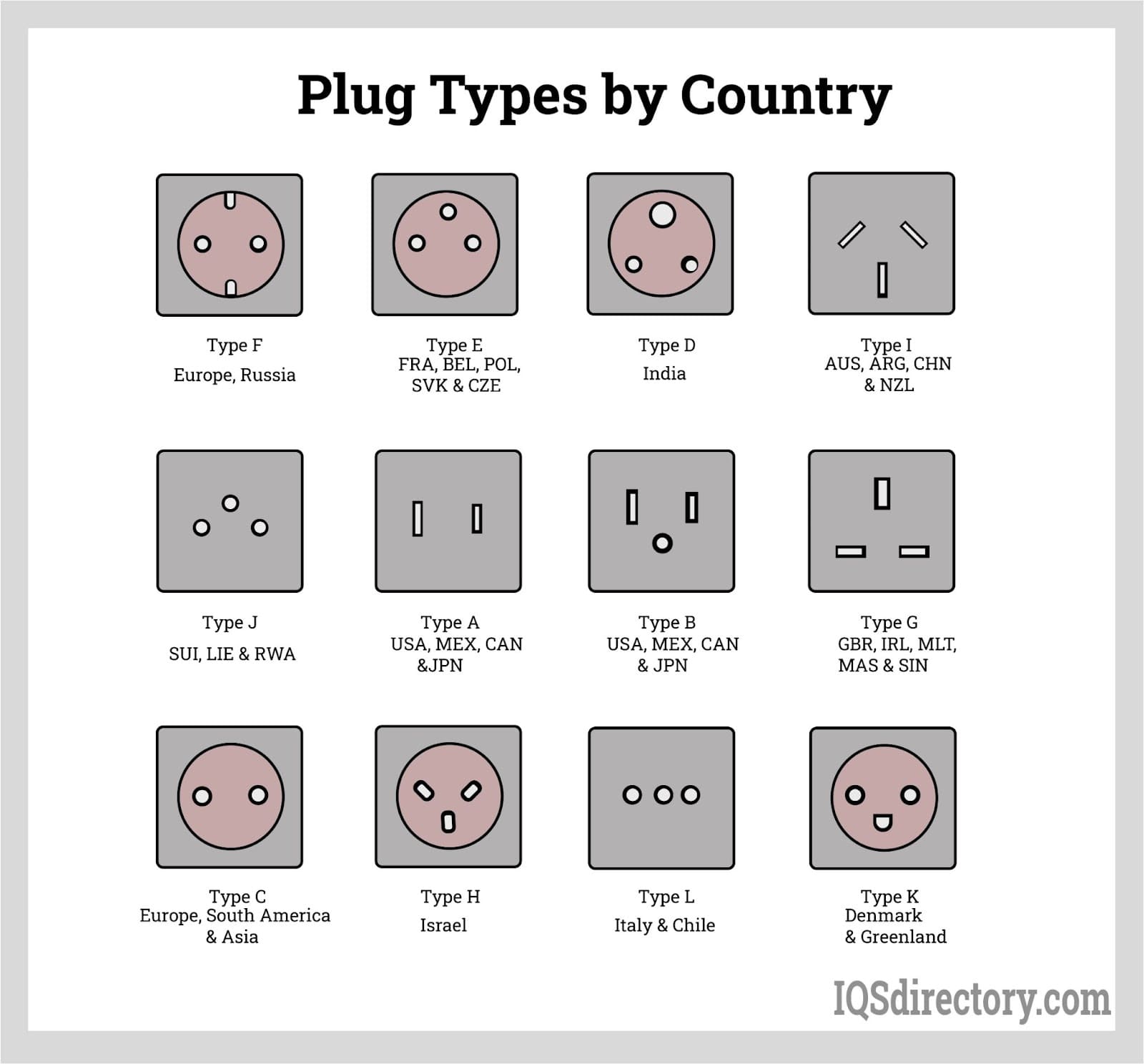

Introduction: Navigating the Global Market for what is a parallel plug

In the dynamic realm of global commerce, understanding the nuances of components like parallel plugs is essential for B2B buyers seeking reliable solutions for their operations. Sourcing parallel plugs that meet specific requirements can pose challenges, particularly when navigating diverse markets across Africa, South America, the Middle East, and Europe, including key players like Germany and Nigeria. This comprehensive guide demystifies parallel plugs, detailing their types, applications, and the materials best suited for various industries, empowering you to make informed purchasing decisions.

Throughout this guide, we will explore the critical distinctions between parallel plugs and other types, such as tapered plugs, while highlighting their unique applications in sectors ranging from automotive to electronics. Additionally, we will provide actionable insights into supplier vetting processes, cost considerations, and best practices for ensuring product compatibility with your specific needs.

By equipping you with this knowledge, we aim to enhance your sourcing strategy and streamline the procurement process, ultimately leading to improved operational efficiency and product reliability. Whether you are looking to protect electrical components, seal openings, or maintain equipment integrity, understanding the role of parallel plugs in your supply chain is crucial for success in today’s competitive marketplace.

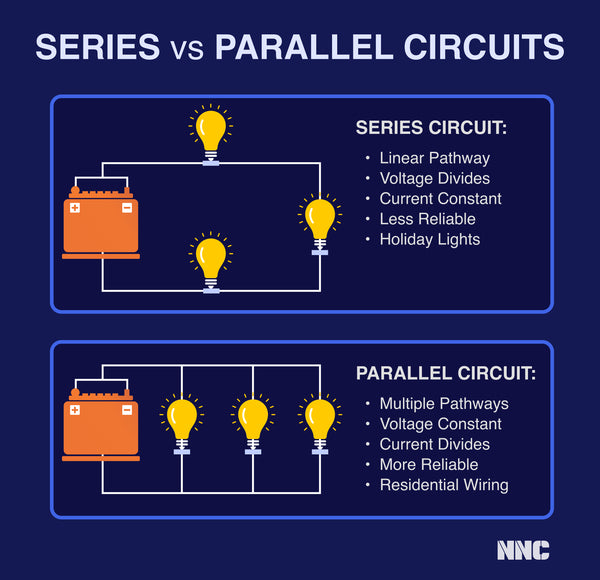

Understanding what is a parallel plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Parallel Plug | Straight cylindrical shape, often with a flange | Protecting electrical connectors, threaded holes | Pros: Easy installation, effective sealing. Cons: Limited to specific hole diameters. |

| Wide-Flange Parallel Plug | Wider flange for enhanced grip and stability | Automotive, industrial machinery | Pros: Superior protection, prevents accidental push-in. Cons: May be bulkier than standard plugs. |

| High-Temperature Parallel Plug | Made from materials like silicone or EPDM | High-temp masking applications | Pros: Resilient in extreme conditions, reusable. Cons: Higher cost compared to standard materials. |

| PVC Parallel Plug | Resistant to shredding, ideal for threaded applications | Electrical and electronic industries | Pros: Durable, cost-effective for high-volume use. Cons: Limited temperature resistance compared to silicone. |

| TPR Parallel Plug | Acid-resistant thermoplastic rubber | Masking in chemical processing | Pros: Excellent chemical resistance, versatile. Cons: May not fit all hole sizes due to rigidity. |

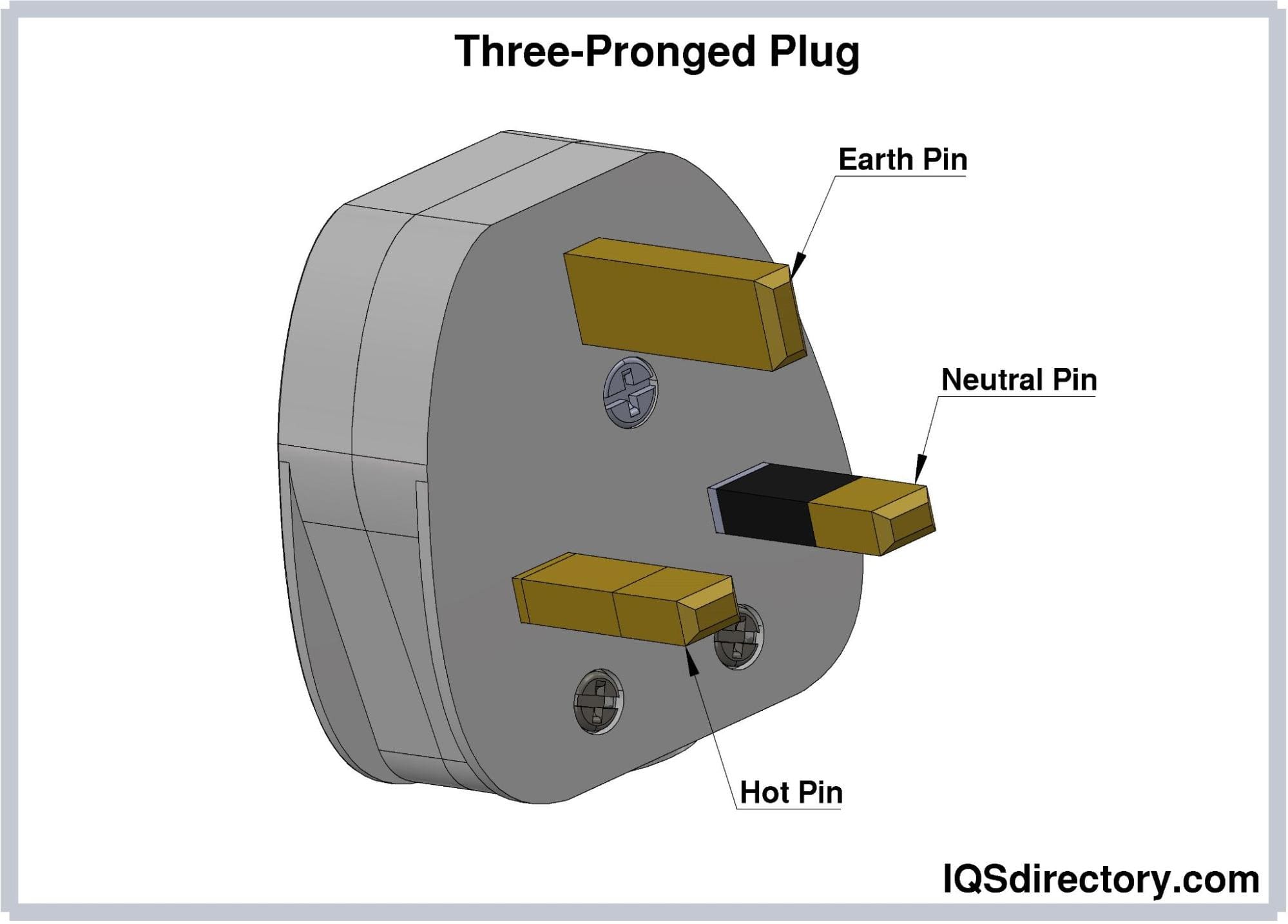

What are the Characteristics of Standard Parallel Plugs?

Standard parallel plugs feature a straight cylindrical design, often equipped with a flange for easy handling. These plugs are primarily used for protecting electrical connectors and sealing threaded holes from dust and moisture. When purchasing, buyers should consider the specific hole diameter, as these plugs are designed for a precise fit. Their ease of installation and effectiveness in sealing make them a go-to choice for many applications, though their limited adaptability can be a drawback.

How Do Wide-Flange Parallel Plugs Enhance Protection?

Wide-flange parallel plugs are designed with a broader flange, providing enhanced grip and stability during insertion. This design is particularly beneficial in automotive and industrial machinery applications where protection against dirt, moisture, and accidental dislodgement is crucial. Buyers should note that while these plugs offer superior protection, their bulkier design may not be suitable for all spaces. They are ideal for environments where the plug may be subjected to movement or vibration.

Why Choose High-Temperature Parallel Plugs?

High-temperature parallel plugs are made from durable materials such as silicone or EPDM, making them suitable for applications that involve extreme temperatures. They are particularly useful in high-temp masking situations, where a reusable and resilient option is necessary. Buyers should consider their specific temperature requirements and the frequency of reuse when selecting these plugs, as they typically come at a higher price point compared to standard options. Their long-term cost-effectiveness can outweigh the initial investment in demanding environments.

What Advantages Do PVC Parallel Plugs Offer?

PVC parallel plugs are known for their resistance to shredding, making them ideal for threaded applications in electrical and electronic industries. Their durability and cost-effectiveness make them a popular choice for high-volume uses. However, buyers should be aware of their limitations in temperature resistance when selecting materials for specific applications. PVC plugs provide a reliable solution for protecting components during storage and transport, balancing performance with affordability.

How Do TPR Parallel Plugs Stand Out in Chemical Applications?

TPR parallel plugs are made from thermoplastic rubber, offering excellent resistance to acids and other chemicals. This makes them particularly suited for masking in chemical processing environments. When purchasing TPR plugs, buyers should assess the specific chemical exposure and compatibility with their applications. While these plugs provide versatility and durability, their rigidity may limit their fit in varying hole sizes, making it essential to choose the correct dimensions for effective sealing.

Key Industrial Applications of what is a parallel plug

| Industry/Sector | Specific Application of what is a parallel plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Protecting threaded components during assembly | Reduces risk of contamination and damage | Material durability, compatibility with assembly processes |

| Automotive | Sealing ports and access points in vehicle assembly | Enhances product integrity and reduces rework costs | Temperature and chemical resistance, ease of installation |

| Electrical & Electronics | Protecting electrical connectors during storage and transport | Prevents damage and ensures reliability | Compliance with electrical standards, size and fit specifications |

| Chemical Processing | Masking applications in chemical processing environments | Minimizes contamination and ensures safety | Resistance to chemicals, temperature ratings |

| HVAC | Protecting air conditioner plugs during installation and transport | Ensures operational efficiency and safety | Voltage and amperage specifications, compliance with local regulations |

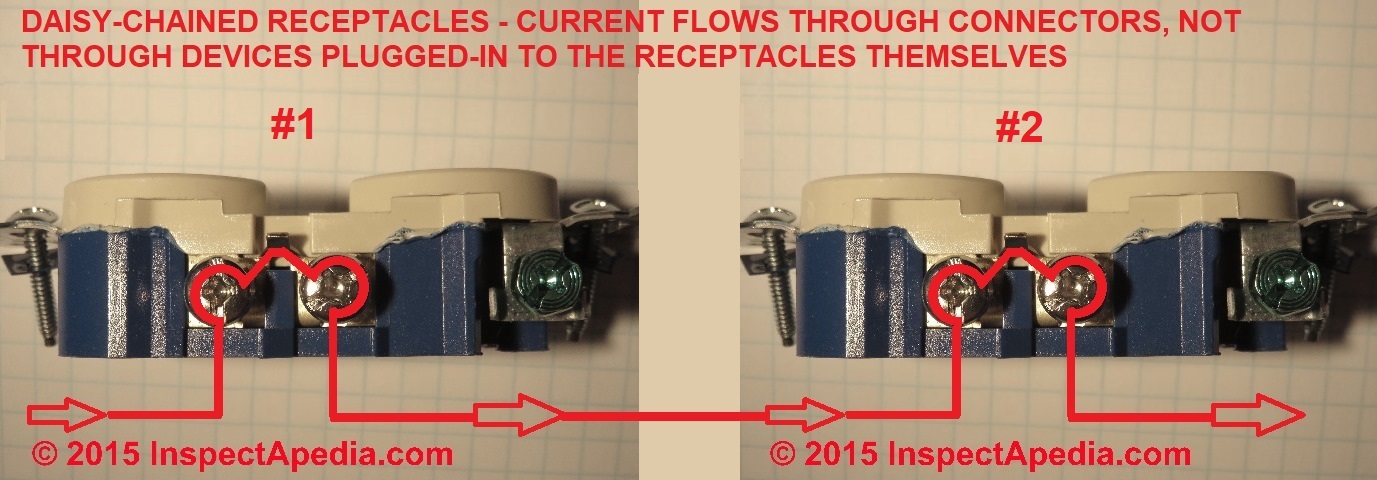

In the manufacturing sector, parallel plugs are crucial for protecting threaded components during assembly. These plugs safeguard against contaminants and physical damage, which can lead to costly rework and delays in production. Buyers should prioritize materials that offer durability and compatibility with various assembly processes to ensure seamless integration.

In the automotive industry, parallel plugs serve to seal ports and access points effectively during vehicle assembly. This application enhances product integrity by preventing foreign materials from entering sensitive areas, thereby reducing the likelihood of assembly defects. When sourcing, businesses must consider the temperature and chemical resistance of the plugs to ensure they can withstand the automotive environment.

For the electrical and electronics sector, parallel plugs are essential for protecting electrical connectors during storage and transport. This application prevents dust and moisture ingress, which can compromise the functionality and reliability of electrical components. Buyers should focus on sourcing plugs that comply with international electrical standards and fit specifications to guarantee proper protection.

In chemical processing, parallel plugs are utilized for masking applications to prevent contamination during production. This is particularly important in environments where strict safety and quality standards must be met. Buyers need to ensure that the plugs are resistant to the specific chemicals involved and that they meet the temperature ratings necessary for their processes.

Illustrative image related to what is a parallel plug

Lastly, in the HVAC industry, parallel plugs protect air conditioner plugs during installation and transport. This application is critical for ensuring operational efficiency and safety. B2B buyers should verify the voltage and amperage specifications of the plugs, as well as their compliance with local regulations, to ensure they meet the necessary performance standards.

3 Common User Pain Points for ‘what is a parallel plug’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Parallel Plug Size

The Problem: B2B buyers often face challenges in determining the correct size of parallel plugs for their applications. Given the diverse range of hole diameters across various industries, selecting a plug that fits perfectly can be complex. An incorrect size can lead to inadequate sealing, allowing dust and debris to enter sensitive components, which can compromise product integrity and lead to costly repairs or replacements.

The Solution: To overcome this challenge, buyers should conduct thorough measurements of the hole diameters where the plugs will be used. Creating a detailed specification sheet that outlines the exact dimensions, tolerances, and application requirements can streamline the selection process. Additionally, collaborating with suppliers who offer customizable parallel plugs can provide tailored solutions. Many manufacturers also offer sample products, allowing buyers to test fit and performance before making bulk purchases. This proactive approach minimizes risks associated with improper fitment and enhances overall operational efficiency.

Scenario 2: Inadequate Protection Against Environmental Contaminants

The Problem: Many B2B buyers are concerned about the protection of critical components from environmental contaminants such as moisture, dust, and chemicals. For instance, in the automotive and manufacturing industries, exposed holes can lead to corrosion or damage, significantly affecting product lifespan and performance. Buyers often struggle to find effective plugs that can withstand harsh environmental conditions while providing a reliable seal.

Illustrative image related to what is a parallel plug

The Solution: Buyers should focus on sourcing parallel plugs made from materials specifically designed for their application environments. For instance, plugs made from thermoplastic rubber (TPR) offer excellent acid resistance, while those crafted from PVC provide superior protection against shredding and general wear. It’s advisable to consult with suppliers to understand the material properties and select plugs that align with the specific environmental challenges they face. Additionally, implementing a regular maintenance and inspection schedule can help identify any wear and tear on the plugs, allowing for timely replacements and sustained protection.

Scenario 3: Challenges with Automated Assembly Processes

The Problem: In industries that rely on automated assembly lines, such as electronics or automotive manufacturing, using parallel plugs can present unique challenges. Ensuring that the plugs are inserted correctly and securely during automated processes is crucial for maintaining production efficiency. Misalignment or incorrect insertion can lead to downtime, increased labor costs, and the risk of damaging components.

The Solution: To address these challenges, buyers should work closely with their equipment manufacturers to ensure that their assembly systems are compatible with the chosen parallel plugs. Adopting plugs designed for easy handling and automated insertion can enhance efficiency. For instance, selecting plugs with a wider flange can improve grip and facilitate proper alignment during assembly. Additionally, providing training for assembly line staff on the importance of correct plug installation can further mitigate risks. Regularly reviewing the assembly process and making adjustments based on performance data can lead to continuous improvements in efficiency and product quality.

Strategic Material Selection Guide for what is a parallel plug

What Materials Are Commonly Used for Parallel Plugs?

When selecting materials for parallel plugs, it is crucial to consider their properties, advantages, and limitations to ensure optimal performance in various applications. Below, we analyze four common materials used in the manufacturing of parallel plugs, focusing on their suitability for different industries and environments.

Illustrative image related to what is a parallel plug

What Are the Key Properties of LDPE in Parallel Plugs?

Low-Density Polyethylene (LDPE) is a widely used material for parallel plugs due to its excellent flexibility and impact resistance. LDPE typically operates effectively in temperatures ranging from -50°C to 80°C. It offers basic protection against moisture and dust, making it suitable for general-purpose applications.

Pros & Cons: LDPE is cost-effective and easy to manufacture, which makes it an attractive option for bulk production. However, it may not withstand high temperatures or aggressive chemicals, limiting its use in demanding environments.

Impact on Application: LDPE is ideal for applications that require basic protection from dust and moisture during storage and transportation. However, it is not suitable for applications involving corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with local standards, such as ASTM or DIN, especially in regions like Europe and South America, where regulations may be stricter.

Illustrative image related to what is a parallel plug

How Does Silicone Perform as a Material for Parallel Plugs?

Silicone is another popular choice for parallel plugs, particularly in high-temperature applications. It can withstand temperatures up to 316°C and offers excellent chemical resistance, making it suitable for various industrial applications.

Pros & Cons: The key advantage of silicone is its durability and reusability, which can lead to cost savings in the long run. However, silicone plugs tend to be more expensive than alternatives like LDPE, which may deter some buyers.

Impact on Application: Silicone parallel plugs are perfect for environments that experience high temperatures or require frequent plugging and unplugging. They are commonly used in the automotive and aerospace industries.

Considerations for International Buyers: Buyers in regions with demanding industrial standards, such as Germany, should verify that silicone products meet the necessary compliance requirements, including safety certifications.

What Are the Advantages of Using EPDM for Parallel Plugs?

Ethylene Propylene Diene Monomer (EPDM) is a synthetic rubber known for its excellent weather resistance and durability. It can handle temperatures from -40°C to 120°C and exhibits strong resistance to a variety of chemicals.

Pros & Cons: EPDM is highly durable and cost-effective, making it suitable for a wide range of applications. However, its manufacturing process can be more complex than that of simpler materials like LDPE, potentially increasing production costs.

Impact on Application: EPDM is ideal for applications exposed to harsh environmental conditions, such as construction and automotive industries. Its chemical resistance makes it suitable for applications involving oils and solvents.

Illustrative image related to what is a parallel plug

Considerations for International Buyers: Buyers should ensure that EPDM products comply with local regulations and standards, particularly in regions like Africa and the Middle East, where material quality can vary significantly.

What Role Does PVC Play in the Production of Parallel Plugs?

Polyvinyl Chloride (PVC) is a versatile plastic used in various applications, including parallel plugs. It offers good resistance to abrasion and can withstand temperatures up to 60°C.

Pros & Cons: PVC is relatively inexpensive and easy to mold, making it a popular choice for manufacturers. However, it has lower flexibility compared to other materials, which can limit its applications.

Impact on Application: PVC parallel plugs are commonly used for protecting threaded applications and electrical connectors. They provide adequate protection against dust and moisture.

Considerations for International Buyers: Buyers should be aware of the environmental regulations surrounding PVC, particularly in Europe, where there is increasing scrutiny on the use of certain plastics.

Summary of Material Selection for Parallel Plugs

| Material | Typical Use Case for what is a parallel plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| LDPE | General-purpose protection during storage and transport | Cost-effective and flexible | Limited high-temperature and chemical resistance | Low |

| Silicone | High-temperature applications in automotive and aerospace | Durable and reusable | Higher cost compared to other materials | High |

| EPDM | Harsh environmental conditions in construction and automotive | Excellent weather and chemical resistance | More complex manufacturing process | Med |

| PVC | Protecting threaded applications and electrical connectors | Inexpensive and easy to mold | Lower flexibility limits applications | Low |

This analysis provides B2B buyers with essential insights into material selection for parallel plugs, helping them make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a parallel plug

What Are the Main Stages in the Manufacturing Process of Parallel Plugs?

The manufacturing of parallel plugs involves several critical stages, each designed to ensure the final product meets the rigorous demands of various industries. The process generally includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for Parallel Plug Production?

Material selection is the first step in the manufacturing process. Common materials for parallel plugs include Low-Density Polyethylene (LDPE), Thermoplastic Rubber (TPR), Polyvinyl Chloride (PVC), and Silicone. Each material is chosen based on specific application requirements such as temperature resistance, chemical exposure, and mechanical strength.

Once the materials are selected, they undergo preparation, which may involve compounding to enhance properties like flexibility and durability. This stage often includes the addition of colorants or stabilizers to meet aesthetic and functional requirements. Material preparation is crucial for ensuring consistent quality in the final products.

What Forming Techniques Are Used in Parallel Plug Manufacturing?

Forming is a pivotal stage where the prepared materials are transformed into the desired plug shapes. Common techniques include injection molding and compression molding.

Illustrative image related to what is a parallel plug

-

Injection Molding: This is the most prevalent method, where molten plastic is injected into a mold cavity to form the parallel plug. The process allows for high precision and the ability to produce complex shapes quickly, making it ideal for large-scale production.

-

Compression Molding: This technique involves placing pre-measured material into a mold and applying heat and pressure. It is commonly used for materials like rubber and silicone, particularly when producing plugs that require specific physical properties.

These forming techniques ensure that the plugs have the correct dimensions and surface finishes necessary for effective sealing and protection.

How Are Parallel Plugs Assembled and Finished?

After forming, the plugs may require assembly, particularly if they have multiple components or features like flanges. This can involve manual or automated processes, depending on the complexity and volume of production.

Finishing processes often include trimming excess material, surface polishing, and applying coatings to enhance durability and resistance to environmental factors. Additionally, any necessary labeling or branding is applied at this stage to ensure traceability and compliance with international standards.

What Quality Assurance Practices Are Essential for Parallel Plug Manufacturing?

Quality assurance (QA) is crucial in the manufacturing of parallel plugs to ensure they meet both industry standards and customer specifications. Various international and industry-specific standards guide these practices.

Illustrative image related to what is a parallel plug

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international standards is ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with ISO 9001 ensures that the manufacturer has processes in place for consistent quality control, customer satisfaction, and continuous improvement.

In addition to ISO standards, industry-specific certifications such as CE marking (for European markets) and API standards (for the oil and gas industry) may apply, depending on the application of the parallel plugs. B2B buyers should inquire about these certifications to verify compliance.

What Are the Key Quality Control Checkpoints in Parallel Plug Production?

Quality control (QC) in parallel plug manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint examines raw materials for defects or inconsistencies before they are used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are tested for dimensional accuracy and material properties to ensure ongoing compliance with quality standards.

-

Final Quality Control (FQC): After production, finished plugs undergo rigorous testing to check for functionality, durability, and compliance with specifications. This may include visual inspections, dimension checks, and performance testing under simulated conditions.

What Testing Methods Are Commonly Used for Quality Assurance?

B2B buyers should be aware of common testing methods used to ensure the quality of parallel plugs:

-

Mechanical Testing: This includes tensile strength tests, impact resistance tests, and compression tests to assess the material’s performance under stress.

-

Environmental Testing: Plugs may undergo exposure to various environmental conditions, such as high temperatures or chemical environments, to ensure they will perform as expected in real-world applications.

-

Dimensional Verification: Precision measuring tools are used to ensure that the plugs meet specified dimensions, which is critical for ensuring a proper fit in applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliability and product integrity. Here are several methods to consider:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their QMS documentation and observing production processes firsthand.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation related to their QC processes, including inspection reports, testing results, and certifications. These documents can provide reassurance regarding the quality of the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s capabilities and product quality. This is particularly valuable for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe must navigate various challenges related to quality assurance. These can include differing regulatory requirements, language barriers, and varying levels of manufacturing expertise.

It is crucial for buyers to establish clear communication with suppliers regarding quality expectations and standards. Understanding local manufacturing practices and regulations can also help mitigate risks associated with quality control.

In summary, the manufacturing processes and quality assurance practices for parallel plugs are integral to ensuring product performance and reliability. By understanding these processes and leveraging effective QA strategies, B2B buyers can make informed decisions and foster successful supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a parallel plug’

In the realm of B2B procurement, understanding the specifics of products such as parallel plugs is essential for ensuring compatibility and functionality in various applications. This guide provides a practical checklist for international buyers looking to source parallel plugs effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Consider factors such as the plug’s dimensions, material compatibility, and environmental resistance (e.g., moisture, dust). Understanding these requirements will help you narrow down options and ensure that the plugs meet the needs of your specific application.

- Dimensions: Specify the exact diameter and length required.

- Material: Identify if you need materials like LDPE, PVC, or silicone based on environmental factors.

Step 2: Research Industry Standards and Compliance

Before making a purchase, it’s crucial to understand the relevant industry standards and compliance requirements for parallel plugs. This may vary by region and application, impacting safety and performance.

- Certifications: Look for products that meet international standards such as ISO, ASTM, or regional certifications pertinent to your market.

- Testing: Ensure the plugs have undergone appropriate testing for durability and performance under expected conditions.

Step 3: Evaluate Potential Suppliers

Thorough supplier evaluation is vital to mitigate risks and ensure quality. Research suppliers’ reputations, asking for company profiles, case studies, and references from similar industries.

Illustrative image related to what is a parallel plug

- Experience: Consider suppliers with a proven track record in manufacturing parallel plugs.

- Customer Feedback: Look for reviews or testimonials from other businesses to gauge reliability and service quality.

Step 4: Request Samples for Testing

Before committing to a large order, request samples of the parallel plugs. Testing samples allows you to assess the product’s fit and functionality within your application.

- Fitment Tests: Ensure the samples fit perfectly into the intended holes or components.

- Performance Testing: Evaluate how the plugs perform under real-world conditions, including exposure to various elements.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Understanding the cost implications will help you make an informed decision without compromising on quality.

- Bulk Pricing: Inquire about discounts for bulk orders or long-term contracts.

- Payment Flexibility: Look for suppliers who offer favorable payment terms that align with your budget and cash flow needs.

Step 6: Negotiate Delivery and Lead Times

Discuss delivery options and lead times with your chosen supplier. Timely delivery is crucial in B2B operations, particularly if the plugs are needed for a specific project or production schedule.

- Shipping Options: Evaluate different shipping methods for cost-effectiveness and speed.

- Production Lead Times: Understand how long it will take for the supplier to fulfill your order.

Step 7: Finalize the Order and Confirm Details

Once all terms are agreed upon, finalize your order. Ensure that all specifications, quantities, and delivery details are clearly documented to avoid any misunderstandings.

- Written Confirmation: Obtain a written confirmation of the order, including all agreed-upon details.

- Follow-Up: Schedule follow-ups with the supplier to ensure adherence to timelines and quality expectations.

By following these steps, B2B buyers can confidently source parallel plugs that meet their technical needs and industry standards, ensuring optimal performance in their applications.

Comprehensive Cost and Pricing Analysis for what is a parallel plug Sourcing

What Are the Key Cost Components for Sourcing Parallel Plugs?

When sourcing parallel plugs, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s profit margin.

-

Materials: The choice of material significantly impacts the cost. Common materials for parallel plugs include low-density polyethylene (LDPE), thermoplastic rubber (TPR), polyvinyl chloride (PVC), and silicone. Each material has different price points based on its properties, such as chemical resistance or temperature tolerance.

-

Labor: Labor costs vary depending on the region and the complexity of the production process. For instance, countries with lower labor costs might offer competitive pricing, but the quality and reliability of the manufacturing process should also be considered.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: Custom tooling for specific designs or sizes can be a significant upfront cost. B2B buyers should evaluate whether the investment in tooling is justified based on their expected order volume.

-

Quality Control (QC): Investing in robust QC processes ensures that the parallel plugs meet the required specifications and standards. This may increase initial costs but can save money in the long run by reducing defects and returns.

-

Logistics: Shipping costs can vary widely based on the destination, shipping method, and volume of the order. Buyers should consider the total logistics costs when sourcing from international suppliers.

-

Margin: The supplier’s profit margin will also influence the final pricing. Margins can vary based on market conditions, competition, and the supplier’s value proposition.

What Influences the Pricing of Parallel Plugs?

Several factors influence the pricing of parallel plugs, which B2B buyers should be aware of:

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs. Negotiating minimum order quantities (MOQs) can yield better pricing.

-

Specifications/Customization: Customized plugs with specific dimensions, materials, or features will incur additional costs. Buyers must weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials or certified products may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation, reliability, and service level can influence pricing. Established suppliers may charge a premium for their experience and quality assurance.

-

Incoterms: The choice of Incoterms can affect overall costs. Different terms dictate who bears the risk and responsibility for shipping, impacting the final price.

How Can Buyers Negotiate Effectively for Parallel Plugs?

To achieve cost efficiency when sourcing parallel plugs, buyers should adopt strategic negotiation tactics:

-

Research and Benchmarking: Understand market prices and supplier offerings to negotiate effectively. Benchmarking against competitors can provide leverage in negotiations.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the initial purchase price. Consider factors such as durability, maintenance, and replacement costs over time.

-

Long-term Partnerships: Establishing long-term relationships with suppliers can lead to better pricing, improved service, and preferential treatment in terms of stock availability.

-

Flexibility in Specifications: If possible, maintain flexibility in product specifications to allow suppliers to propose cost-effective alternatives.

What Should International Buyers Consider When Sourcing Parallel Plugs?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, there are additional nuances to consider:

-

Currency Fluctuations: Keep an eye on exchange rates, as they can significantly affect pricing. Locking in prices through contracts can mitigate this risk.

-

Import Duties and Taxes: Be aware of import tariffs and taxes that may apply when bringing products into your country. These can add to the overall cost and should be factored into the budget.

-

Cultural Considerations: Different regions may have varying expectations regarding communication, negotiation styles, and business practices. Understanding these cultural nuances can facilitate smoother transactions.

Conclusion

Sourcing parallel plugs involves a comprehensive understanding of the cost structure and pricing influences. By considering the outlined components and employing effective negotiation strategies, B2B buyers can optimize their sourcing decisions, ensuring they secure high-quality products at competitive prices. Always remember to request indicative prices and samples from suppliers to ensure the products meet your requirements before making a commitment.

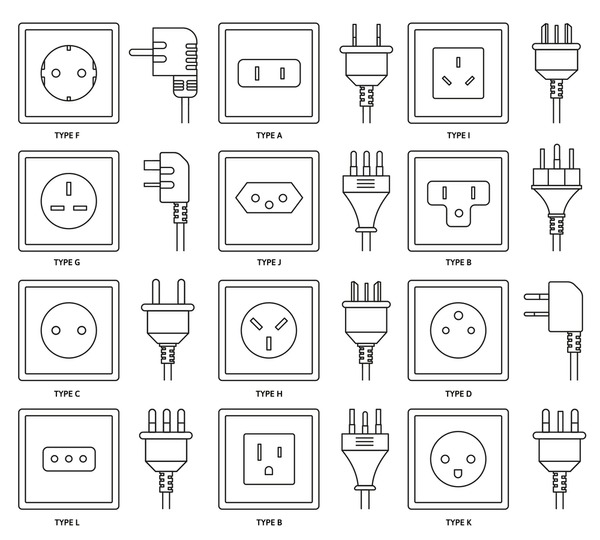

Alternatives Analysis: Comparing what is a parallel plug With Other Solutions

When considering the best solution for protecting holes and preventing ingress in various applications, B2B buyers often face multiple options. Among these, parallel plugs stand out for their unique characteristics. However, it’s essential to compare them with alternative solutions to determine the most suitable choice for specific applications. Below, we explore how parallel plugs stack up against tapered plugs and blanking plugs, two viable alternatives.

| Comparison Aspect | What Is A Parallel Plug | Alternative 1: Tapered Plug | Alternative 2: Blanking Plug |

|---|---|---|---|

| Performance | High grip, prevents dust and moisture ingress | Excellent for variable hole sizes, creates a tight seal | Provides a complete closure for ports or unused holes |

| Cost | Generally affordable | Slightly higher due to versatility | Typically low-cost, depending on material |

| Ease of Implementation | Easy push-fit design, available in various sizes | Requires specific sizing for optimal fit | Simple installation but may need custom sizing |

| Maintenance | Minimal, disposable or reusable options available | Reusable, but may require cleaning | Generally disposable, less maintenance required |

| Best Use Case | Protecting electrical connectors or threaded holes | Masking during painting or protecting threaded components | Temporary closure of ports in machinery or plumbing |

What Are the Pros and Cons of Tapered Plugs Compared to Parallel Plugs?

Tapered plugs offer unique advantages, particularly in their ability to adapt to slightly varying hole sizes due to their conical shape. This flexibility makes them ideal for applications where tolerances may not be uniform, such as in manufacturing and automotive industries. Their tapered design provides a secure fit that can effectively seal against dust and moisture. However, this adaptability comes at a slightly higher cost, and they may require more precise measurements for optimal performance. Additionally, while tapered plugs can serve dual purposes as caps, their installation can be less intuitive compared to the straightforward push-fit mechanism of parallel plugs.

How Do Blanking Plugs Serve as an Alternative to Parallel Plugs?

Blanking plugs provide a complete seal for ports or unused holes, making them an effective solution for preventing contamination and damage. They are particularly advantageous in applications requiring a temporary closure, such as in plumbing or machinery during maintenance. The installation process is generally simple, as most blanking plugs are designed for quick insertion. However, they may not offer the same level of grip or versatility as parallel plugs, especially in dynamic environments where movement could dislodge the plug. Additionally, blanking plugs are typically disposable, which may lead to higher long-term costs if frequent replacements are necessary.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate plug solution ultimately depends on the specific application and the operational environment. For applications requiring a high level of adaptability and sealing capability, tapered plugs may be the best choice, despite their higher cost. Conversely, for straightforward applications focused on protecting electrical connectors or threaded holes, parallel plugs provide an excellent balance of performance and affordability. Blanking plugs serve well for temporary closures but may fall short in environments needing durable, reusable solutions. By carefully considering the performance characteristics, costs, and specific use cases, B2B buyers can make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for what is a parallel plug

What are the Key Technical Properties of a Parallel Plug?

When considering parallel plugs for your applications, several technical specifications are critical for ensuring optimal performance and compatibility. Here are some essential properties to consider:

-

Material Grade: Parallel plugs are made from various materials such as Low-Density Polyethylene (LDPE), Thermoplastic Rubber (TPR), Polyvinyl Chloride (PVC), and Silicone. Each material offers unique properties; for instance, LDPE is cost-effective and versatile, while Silicone provides high-temperature resistance. Understanding the material grade is vital for selecting plugs that will withstand specific environmental conditions and chemical exposures.

-

Tolerance: This refers to the permissible limit of variation in the dimensions of the plug. A tighter tolerance ensures a snug fit in the designated hole, preventing ingress of dust and moisture. In industries where precision is crucial, such as automotive or electronics, selecting plugs with the right tolerance can prevent damage and improve the longevity of the equipment.

-

Flange Size: The flange, or the wider rim at one end of the parallel plug, is essential for providing a secure grip and preventing the plug from being pushed too far into the hole. The size of the flange can impact the ease of installation and removal, making it a critical consideration for applications requiring frequent access.

-

Temperature Resistance: Different applications may expose parallel plugs to varying temperatures. Knowing the temperature resistance of the plug material helps in choosing the right product for applications in high-heat environments, such as manufacturing processes or electrical equipment.

-

Chemical Resistance: For industries that deal with harsh chemicals, selecting plugs that resist corrosion and degradation is essential. Materials like EPDM and TPR offer excellent chemical resistance, ensuring that the plugs maintain their integrity and functionality over time.

What are Common Trade Terminologies Related to Parallel Plugs?

Understanding industry-specific terminology is crucial for effective communication in B2B transactions. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. For buyers, knowing whether a parallel plug is made by an OEM can affect warranty considerations and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is important for budget planning and inventory management, especially for businesses that may not need large quantities of plugs regularly.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specified products. This is a common practice in B2B transactions, allowing buyers to compare costs and negotiate better deals.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms helps businesses understand their liabilities regarding shipping, insurance, and customs clearance when sourcing parallel plugs from international suppliers.

-

Lead Time: This refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for supply chain planning, especially in industries where delays can lead to significant operational disruptions.

-

Certification: This term refers to the process by which a product is tested and verified to meet specific standards or regulations. Certifications can provide assurance regarding the quality and safety of parallel plugs, which is particularly important in regulated industries such as healthcare and automotive.

By understanding these technical properties and industry terminologies, B2B buyers can make informed decisions when sourcing parallel plugs, ensuring they meet the specific requirements of their applications.

Illustrative image related to what is a parallel plug

Navigating Market Dynamics and Sourcing Trends in the what is a parallel plug Sector

What Are the Key Market Drivers for Parallel Plugs?

The global market for parallel plugs is driven by the increasing demand for effective protection of components in various industries, including manufacturing, automotive, and electronics. As manufacturers focus on improving product quality and reducing downtime, the need for reliable sealing solutions has surged. Additionally, the rise of automation and advanced manufacturing technologies is pushing for more efficient sourcing strategies, with an emphasis on plug types that offer easy assembly and removal.

In regions such as Africa and South America, where industrial growth is rapidly evolving, parallel plugs are becoming essential in sectors like construction and agriculture. This trend is mirrored in Europe, particularly in Germany, where sustainability and efficiency are central to manufacturing processes. The Middle East also presents opportunities due to ongoing infrastructure projects that require robust protective solutions for machinery and equipment.

Emerging technologies, such as 3D printing and smart manufacturing, are also influencing sourcing trends. These advancements facilitate the production of customized parallel plugs, allowing manufacturers to meet specific application requirements more effectively. As a result, international B2B buyers are increasingly looking for suppliers that can provide both standard and tailored solutions to enhance operational efficiency.

How Are Sustainability and Ethical Sourcing Impacting the Parallel Plug Industry?

Sustainability is becoming a critical consideration for B2B buyers in the parallel plug sector. The environmental impact of manufacturing processes, particularly regarding plastic waste, has prompted companies to seek alternative materials and production methods. Eco-friendly options, such as biodegradable plastics and recycled materials, are gaining traction among buyers who prioritize green certifications and ethical sourcing.

In addition to material choices, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ practices to ensure compliance with international labor standards and environmental regulations. This shift is fostering a culture of transparency and accountability in the industry, encouraging manufacturers to adopt sustainable practices.

Illustrative image related to what is a parallel plug

Certifications such as ISO 14001 for environmental management and other green credentials are becoming essential for suppliers to demonstrate their commitment to sustainability. As international B2B buyers from regions like Africa and South America continue to grow, they are also more likely to favor suppliers who align with their sustainability goals. This trend is not only beneficial for the environment but also enhances brand reputation and customer loyalty.

What Is the Evolution of Parallel Plugs in the B2B Market?

The evolution of parallel plugs has been closely tied to advancements in material science and manufacturing technology. Initially developed for simple sealing applications, parallel plugs have transformed into sophisticated protective solutions suitable for a diverse range of industries. The introduction of high-performance materials, such as thermoplastic rubber and PVC, has expanded their application scope, making them more versatile and durable.

Over the years, the design of parallel plugs has also evolved to incorporate features that enhance usability, such as flanges for improved grip and sealing capabilities. This evolution reflects the growing demand for products that not only meet functional requirements but also align with modern sustainability practices. As the market continues to grow, innovations in design and materials will play a pivotal role in shaping the future of parallel plugs, positioning them as indispensable components in the global B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a parallel plug

-

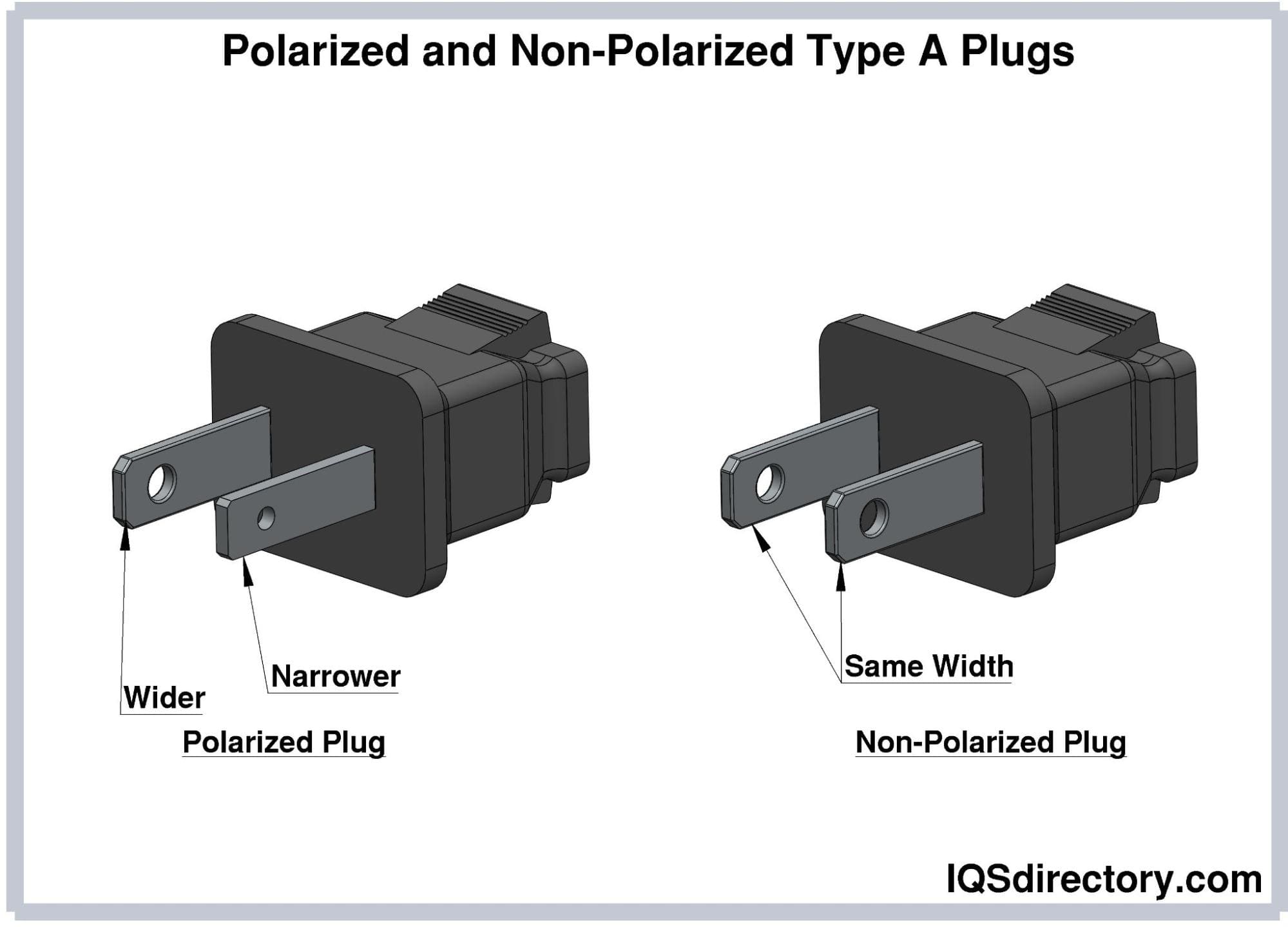

What is a parallel plug and how is it used?

A parallel plug, also known as a straight-wall plug, is designed to fill holes and protect applications from dust, debris, moisture, and potential damage. Its cylindrical shape allows for a snug fit in a specific hole diameter, making it suitable for various applications across industries such as manufacturing, automotive, and electronics. The plug often features a flange that enhances grip and provides a more secure seal, ensuring reliable protection during storage and transport. -

How do I determine the right size of parallel plug for my application?

To select the correct size of a parallel plug, measure the diameter of the hole you intend to protect. It’s essential to choose a plug that matches this diameter closely for optimal sealing. Many suppliers offer detailed specifications and charts that can guide you in finding the appropriate size. Additionally, consider the material of the plug, as different materials provide varying levels of resistance to environmental factors like moisture, chemicals, and temperature. -

What materials are commonly used for parallel plugs, and how do they differ?

Parallel plugs are typically made from materials such as LDPE, PVC, thermoplastic rubber (TPR), and vinyl. LDPE offers basic protection against dust and moisture, while PVC is resistant to shredding and ideal for threaded applications. TPR provides acid resistance, and vinyl is effective against oils and greases. The choice of material should align with your specific application requirements, including environmental exposure and durability needs. -

What are the advantages of using parallel plugs in industrial applications?

Using parallel plugs in industrial applications provides several benefits, including enhanced protection against contaminants, reduced risk of damage during transport, and improved efficiency in assembly processes. Their design allows for easy installation and removal, making them suitable for automated systems. Furthermore, their ability to fit tightly into designated holes minimizes the chances of accidental dislodgment, ensuring that components remain secure throughout their lifecycle. -

What should I consider when vetting suppliers for parallel plugs?

When vetting suppliers for parallel plugs, assess their manufacturing capabilities, material quality, and compliance with industry standards. Look for suppliers who can provide samples for testing and have a proven track record in your specific industry. Additionally, evaluate their customer service, delivery times, and flexibility in meeting your customization needs. It’s also beneficial to read reviews and request references to gauge their reliability and reputation. -

Are there customization options available for parallel plugs?

Yes, many manufacturers offer customization options for parallel plugs to meet specific application requirements. Customizations can include variations in size, material, color, and flange design. When discussing customization with suppliers, provide detailed specifications regarding your needs, including environmental factors and any specific performance criteria. This ensures that the final product aligns perfectly with your operational requirements. -

What are the typical minimum order quantities (MOQs) for parallel plugs?

Minimum order quantities (MOQs) for parallel plugs can vary significantly between suppliers and are often influenced by the type of plug, material, and level of customization. Generally, standard plugs may have lower MOQs, while customized options might require higher quantities. It’s advisable to discuss MOQs upfront with potential suppliers to understand their policies and to negotiate terms that align with your purchasing strategy. -

What payment terms are commonly offered by suppliers for parallel plugs?

Payment terms for parallel plugs can differ based on the supplier’s policies and your business relationship. Common terms include upfront payment, net 30, or net 60 days after delivery. Some suppliers may also offer discounts for early payment or larger orders. It’s essential to discuss payment terms during the negotiation phase to ensure they are favorable for your cash flow and to establish a clear agreement before placing an order.

Top 2 What Is A Parallel Plug Manufacturers & Suppliers List

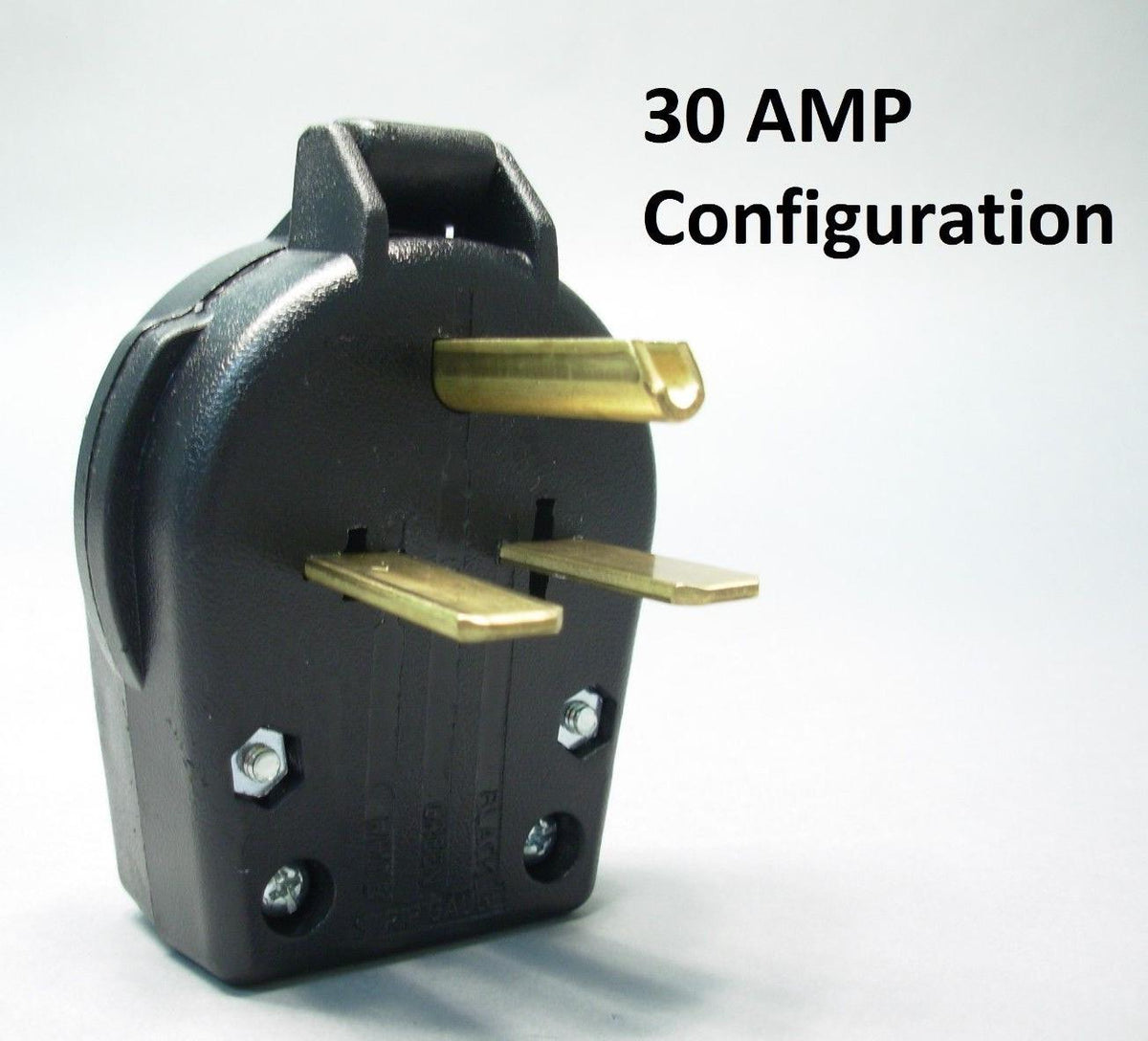

1. GE – Room/Window Air Conditioners

Domain: products.geappliances.com

Registered: 1996 (29 years)

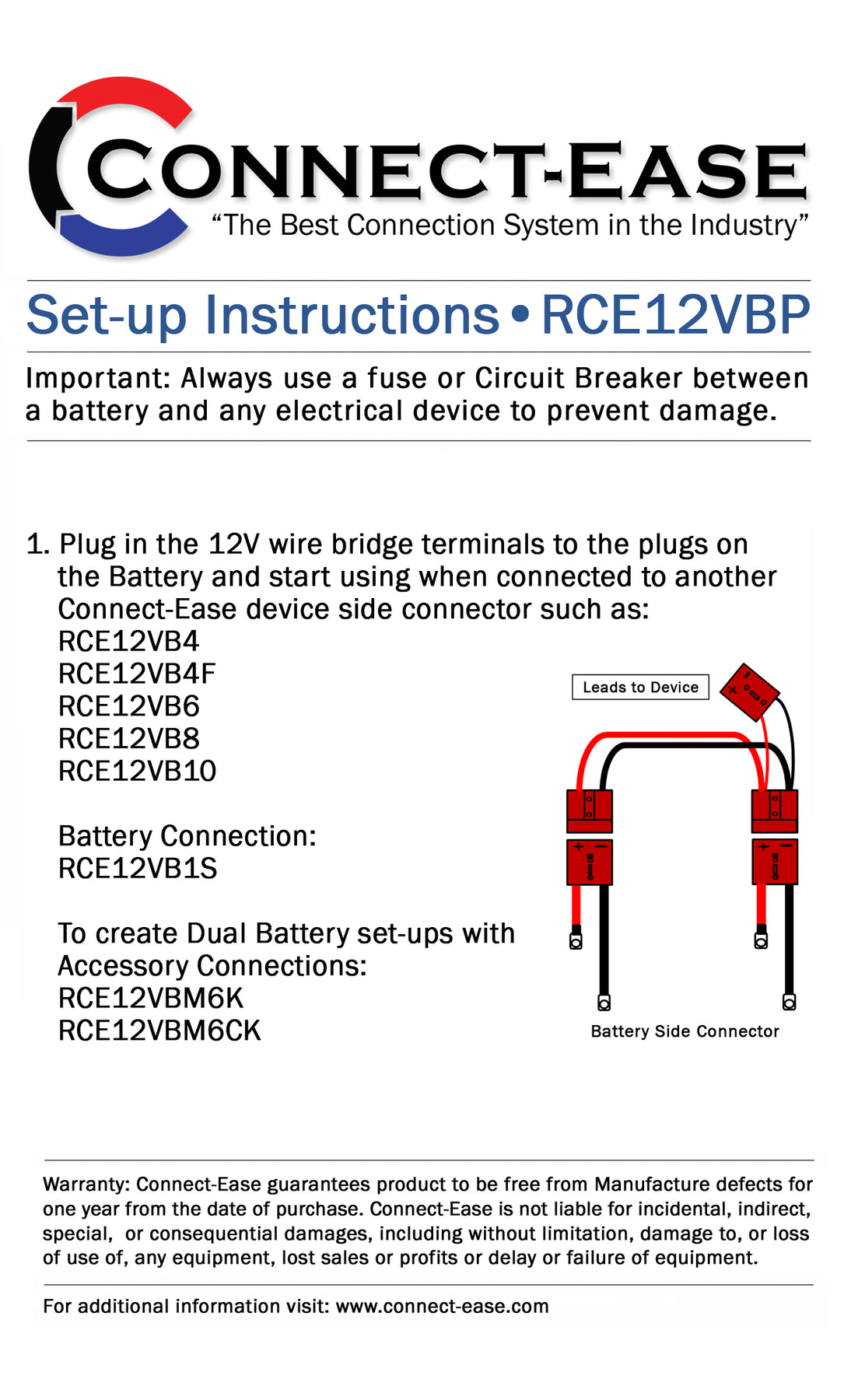

Introduction: Room / Window Air Conditioners have four different power cord plug styles: Parallel, Perpendicular, Tandem, and Large Tandem. Each plug type has specific voltage and amperage requirements. Users can check the product Specs & Details tab for specific models and their plug types, as well as the Installation Instructions for detailed information. It is essential to have the appropriate wall outlet th…

2. HTP AMERICA INC. – Parallel Plug and Receptacle, 50 Amp

Domain: usaweld.com

Registered: 1999 (26 years)

Introduction: {“Product Name”: “Parallel Plug and Receptacle, 50 Amp”, “Brand”: “HTP AMERICA INC.”, “Product Number”: “12542”, “Price”: “$21.95”, “Type”: “Plug and Receptacle”, “Voltage Compatibility”: “208, 220, or 250 volts”, “NEMA Rating”: “NEMA 6-30P/6-50P”, “Description”: “50 amp parallel plug, also known as a dryer plug. The prongs on the plug resemble a large 100 volt plug and are commonly found in newer…

Strategic Sourcing Conclusion and Outlook for what is a parallel plug

What Are the Key Benefits of Utilizing Parallel Plugs in Your Operations?

In summary, parallel plugs serve as essential components in various industries, providing reliable protection against dust, moisture, and damage to critical applications. Their unique straight-walled design ensures a snug fit for specific hole diameters, making them ideal for applications ranging from automotive to electronics. For international B2B buyers, understanding the distinctions between parallel and tapered plugs can lead to more informed purchasing decisions, ultimately enhancing product longevity and operational efficiency.

How Can Strategic Sourcing Enhance Your Supply Chain?

Strategic sourcing is crucial for optimizing procurement processes and ensuring the availability of high-quality parallel plugs tailored to your specific needs. By developing relationships with reputable suppliers across Africa, South America, the Middle East, and Europe, buyers can negotiate better terms and access a wider variety of materials and designs. This proactive approach not only reduces costs but also mitigates risks associated with supply chain disruptions.

What Should You Consider Moving Forward?

As you explore your options for parallel plugs, consider reaching out to suppliers for samples to ensure compatibility with your applications. Engage with industry experts to stay updated on the latest innovations and best practices in plug technology. By prioritizing strategic sourcing, you position your business for success in an increasingly competitive landscape. Start today to secure the components that will drive your operations forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to what is a parallel plug