Choosing Your What Is A Chamber Vacuum Sealer: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for what is a chamber vacuum sealer

In the competitive landscape of food preservation and packaging, understanding what a chamber vacuum sealer is and how it can enhance operational efficiency is crucial for international B2B buyers. Sourcing the right chamber vacuum sealer can be a complex task, particularly when balancing quality, cost, and functionality. This guide delves into the intricacies of chamber vacuum sealers, exploring various types, their applications across diverse industries, and essential criteria for supplier vetting.

As businesses from Africa, South America, the Middle East, and Europe seek to optimize their food storage and packaging processes, the need for informed purchasing decisions becomes paramount. This comprehensive resource empowers you with insights into the benefits of chamber vacuum sealers—ranging from their ability to handle liquids without compromising seal integrity to their cost-effectiveness in long-term operations.

Additionally, we will provide a detailed analysis of the market landscape, helping you navigate supplier options and investment considerations. By equipping yourself with this knowledge, you can confidently select the right equipment that meets your business needs, ultimately enhancing your operational efficiency and product quality. In a world where effective packaging can significantly impact your bottom line, understanding chamber vacuum sealers is not just an advantage—it’s a necessity.

Understanding what is a chamber vacuum sealer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Chamber Vacuum Sealers | Full vacuum creation around the bag, suitable for liquids | Food processing, catering, and restaurants | Pros: Versatile for liquids; Cons: Higher initial cost |

| Compact Chamber Vacuum Sealers | Smaller footprint, designed for limited spaces | Small kitchens, food trucks, and cafes | Pros: Space-efficient; Cons: Limited capacity |

| Industrial Chamber Vacuum Sealers | Larger capacity, robust construction, and automation options | Large-scale food production, packaging plants | Pros: High efficiency; Cons: Requires significant investment |

| Tabletop Chamber Vacuum Sealers | Designed for countertop use, user-friendly | Small businesses, home-based food operations | Pros: Affordable and easy to use; Cons: Less durable than industrial models |

| Oil-Free Chamber Vacuum Sealers | No oil pump, lower maintenance, and energy-efficient | Restaurants and food service operations | Pros: Reduced maintenance costs; Cons: May have slower vacuum times |

What Are Standard Chamber Vacuum Sealers and Their B2B Applications?

Standard chamber vacuum sealers are essential tools in the food industry, capable of creating a vacuum around bags, which allows for the sealing of both solids and liquids. These machines are widely used in food processing, catering, and restaurants where food preservation is critical. Their versatility in handling various food types makes them a popular choice among B2B buyers. However, the higher initial investment can be a consideration for businesses operating with tighter budgets.

How Do Compact Chamber Vacuum Sealers Cater to Smaller Businesses?

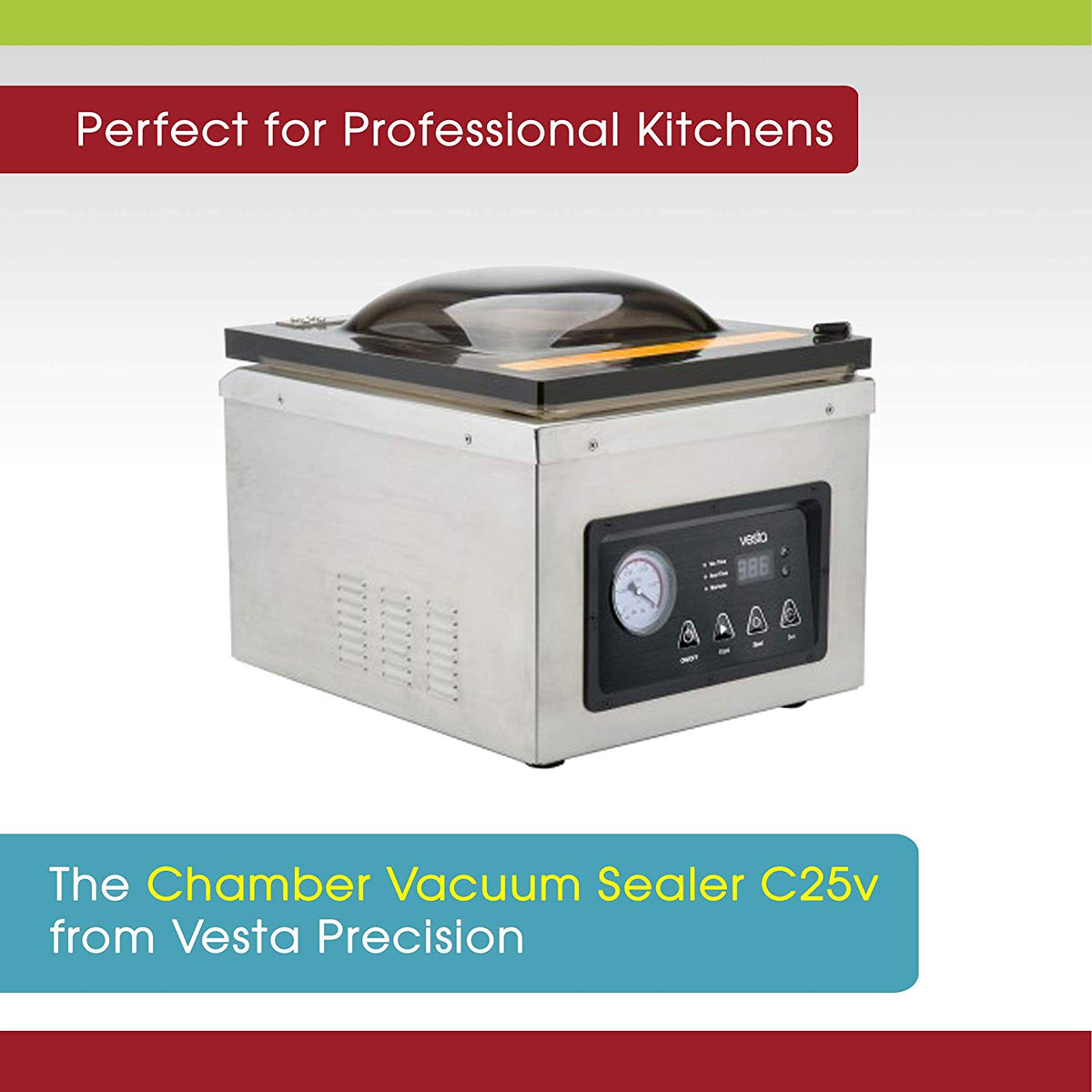

Compact chamber vacuum sealers are designed for businesses with limited space, such as small kitchens, food trucks, and cafes. These units maintain the vacuum sealing capabilities of larger models while offering a smaller footprint. They are particularly useful for small-scale operations that require efficient food preservation without the need for extensive equipment. While they are budget-friendly, buyers should be aware that their capacity may limit large batch processing.

What Makes Industrial Chamber Vacuum Sealers Ideal for Large-Scale Operations?

Industrial chamber vacuum sealers are robust machines designed to meet the demands of large-scale food production and packaging plants. They often feature automation options for high efficiency and can handle larger volumes, making them suitable for big businesses. While they offer significant productivity benefits, the initial investment can be substantial, necessitating careful consideration of ROI for B2B buyers.

Why Choose Tabletop Chamber Vacuum Sealers for Small Operations?

Tabletop chamber vacuum sealers provide an affordable and user-friendly option for small businesses and home-based food operations. Their design allows for easy use in compact spaces, making them ideal for entrepreneurs starting in the food industry. While they are generally less durable than industrial models, their lower cost and ease of use make them appealing for small-scale operations looking to enhance food preservation techniques.

What Are the Advantages of Oil-Free Chamber Vacuum Sealers?

Oil-free chamber vacuum sealers represent a modern advancement in vacuum sealing technology, eliminating the need for oil pumps and reducing maintenance requirements. They are particularly suitable for restaurants and food service operations, where efficiency and cleanliness are paramount. Although they may have slightly slower vacuum times compared to traditional models, their energy efficiency and lower maintenance costs can provide long-term savings for B2B buyers.

Key Industrial Applications of what is a chamber vacuum sealer

| Industry/Sector | Specific Application of what is a chamber vacuum sealer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Vacuum sealing meats, seafood, and prepared meals | Extends shelf life, reduces spoilage, and saves costs | Capacity for liquid sealing; energy efficiency; durability |

| Pharmaceutical | Sealing vials and medical supplies | Ensures sterility and extends product shelf life | Compliance with health regulations; size compatibility; reliability |

| Agriculture | Packaging seeds and fertilizers | Protects against moisture and pests, enhancing viability | Material compatibility; environmental resistance; cost-effectiveness |

| Culinary Arts | Sous-vide cooking and marinating | Enhances flavors and textures while preserving freshness | Temperature control; ease of use; size for commercial kitchens |

| Electronics | Protecting sensitive components | Prevents corrosion and damage during storage | Vacuum strength; bag compatibility; anti-static options |

How is Chamber Vacuum Sealer Used in Food Processing?

In the food processing industry, chamber vacuum sealers play a crucial role in preserving perishable goods such as meats, seafood, and prepared meals. By sealing these items in a vacuum environment, businesses can significantly extend their shelf life, reduce spoilage, and ultimately save costs associated with waste. International buyers should consider the machine’s capacity for liquid sealing, energy efficiency, and durability, especially when sourcing equipment that can handle high volumes.

What Role Does Chamber Vacuum Sealing Play in Pharmaceuticals?

Chamber vacuum sealers are essential in the pharmaceutical sector for sealing vials and medical supplies. The ability to create a sterile environment ensures that products maintain their integrity and effectiveness over time. For B2B buyers in this field, compliance with health regulations is paramount, along with ensuring size compatibility with existing packaging processes and the reliability of the sealing mechanism to prevent contamination.

How Does Chamber Vacuum Sealing Benefit Agriculture?

In agriculture, chamber vacuum sealers are utilized for packaging seeds and fertilizers, protecting them from moisture and pests. This method enhances the viability of seeds and ensures that fertilizers remain effective. Buyers from regions like Africa and South America should focus on material compatibility, environmental resistance, and cost-effectiveness when sourcing these sealers, as they often deal with diverse climatic conditions.

Why is Chamber Vacuum Sealing Important in Culinary Arts?

For culinary professionals, chamber vacuum sealers are indispensable tools for sous-vide cooking and marinating. They allow chefs to enhance flavors and textures while preserving the freshness of ingredients. Sourcing considerations include temperature control capabilities, ease of use, and the size of the machine to fit commercial kitchen requirements, especially in high-demand environments across Europe and the Middle East.

How is Chamber Vacuum Sealing Used in Electronics?

In the electronics industry, chamber vacuum sealers are vital for protecting sensitive components from corrosion and physical damage during storage. By creating a vacuum-sealed environment, businesses can prolong the lifespan of electronic parts. When sourcing equipment, buyers should prioritize vacuum strength, bag compatibility, and the availability of anti-static options to safeguard delicate components effectively.

3 Common User Pain Points for ‘what is a chamber vacuum sealer’ & Their Solutions

Scenario 1: Difficulty in Sealing Liquids Without Spills

The Problem: Many businesses, particularly in the food and beverage sector, struggle with vacuum sealing liquids. Traditional suction vacuum sealers often fail to create a proper seal when sealing soups, sauces, or marinades, leading to messy spills and wasted products. This not only affects operational efficiency but can also result in increased costs due to product loss and the need for additional cleaning efforts.

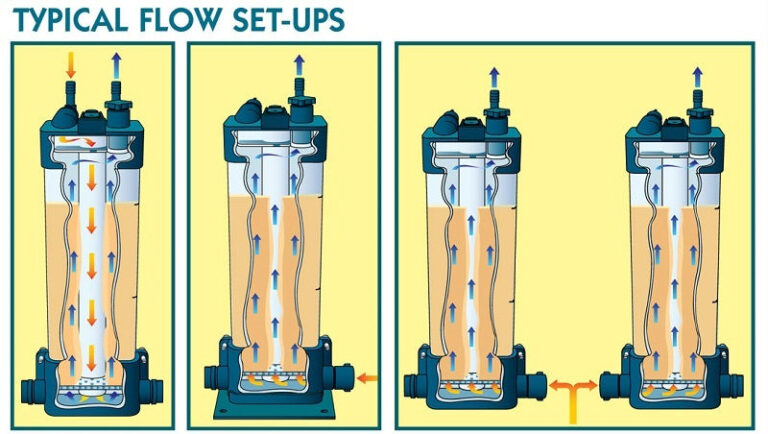

The Solution: A chamber vacuum sealer is specifically designed to address this issue by creating a vacuum around the entire pouch, allowing for the sealing of liquids without any risk of spillage. When sourcing a chamber vacuum sealer, look for models with adjustable vacuum levels to accommodate different liquid densities. Ensure the device is compatible with full mesh vacuum bags, which are better suited for liquids. For optimal results, fill the bags with the liquid to about three-quarters full, allowing room for the vacuum process, and then place them inside the chamber. This way, air is evacuated evenly, preventing spills and ensuring a tight seal every time.

Scenario 2: High Operating Costs Due to Expensive Bags

The Problem: B2B buyers often face high operating costs associated with vacuum sealing because of the expensive proprietary bags required by traditional suction sealers. This is particularly challenging for businesses that require frequent sealing, such as restaurants or food processors, where the cumulative cost of bags can significantly impact the bottom line.

The Solution: Chamber vacuum sealers can utilize more affordable vacuum bags, which do not have the ribbed structure required for suction sealers. When selecting a chamber vacuum sealer, prioritize models that allow for the use of both regular and chamber-specific bags. This flexibility not only reduces bag costs but also enables businesses to take advantage of bulk purchasing options. Additionally, consider investing in a sealer that offers programmable settings for different products, enhancing efficiency and reducing waste. Over time, the savings on bags can help offset the initial investment in a chamber vacuum sealer.

Scenario 3: Inefficient Packaging Leading to Food Waste

The Problem: Food businesses often encounter challenges related to food waste due to improper vacuum sealing techniques. Foods that are not vacuum-sealed correctly can spoil quickly, leading to significant losses. This is particularly problematic for suppliers in regions with limited access to refrigeration, where maintaining food quality is crucial.

The Solution: A chamber vacuum sealer can significantly mitigate this issue by ensuring a complete vacuum seal, which is vital for extending the shelf life of perishable goods. When selecting a chamber vacuum sealer, look for models with features like double sealing bars and adjustable sealing time, which can enhance the sealing quality. Additionally, train staff on how to properly load the machine and adjust settings based on the type of food being sealed. For instance, packaging fatty foods may require a longer sealing time to ensure a secure seal. Implementing these best practices not only reduces waste but also improves overall product quality, leading to higher customer satisfaction and reduced operational costs.

Strategic Material Selection Guide for what is a chamber vacuum sealer

What Materials are Commonly Used in Chamber Vacuum Sealers?

Chamber vacuum sealers utilize various materials to ensure optimal performance and durability. The selection of materials impacts the functionality, lifespan, and cost-effectiveness of the equipment. Below, we analyze four common materials used in chamber vacuum sealers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to what is a chamber vacuum sealer

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 500°F (260°C), making it suitable for various food processing applications.

Pros & Cons:

Stainless steel is highly durable and resistant to rust and staining, which is crucial for maintaining hygiene in food processing environments. However, it can be more expensive than other materials, and its manufacturing process can be complex, leading to higher initial costs.

Impact on Application:

Stainless steel is ideal for components that come into direct contact with food, ensuring compliance with health regulations. Its robustness allows it to handle both solid and liquid contents without compromising the integrity of the seal.

Illustrative image related to what is a chamber vacuum sealer

Considerations for International Buyers:

Buyers should ensure that the stainless steel used meets international standards such as ASTM A240 or equivalent. The availability of stainless steel in local markets may vary, affecting procurement costs.

2. Plastic (Nylon and Polyethylene)

Key Properties:

Nylon and polyethylene are commonly used in vacuum bags and pouches. These materials are lightweight, flexible, and have good barrier properties against moisture and gases.

Pros & Cons:

Plastic materials are generally cost-effective and easy to manufacture, making them suitable for high-volume production. However, they may not withstand high temperatures as effectively as metals, limiting their use in certain applications.

Impact on Application:

These materials are suitable for vacuum sealing a variety of food items, including liquids, due to their flexibility. However, they may not be ideal for high-temperature processing applications.

Illustrative image related to what is a chamber vacuum sealer

Considerations for International Buyers:

International buyers should verify that the plastic materials comply with food safety regulations such as FDA standards or equivalent local regulations. The recyclability of these materials can also be a concern in regions focused on sustainability.

3. Glass

Key Properties:

Glass is non-reactive and can withstand high temperatures, making it suitable for vacuum sealing applications where chemical interaction is a concern. It is also transparent, allowing for easy visibility of contents.

Pros & Cons:

The use of glass provides an excellent barrier against oxygen and moisture, enhancing the shelf life of sealed products. However, glass is fragile and can be heavy, increasing shipping costs and the risk of breakage during handling.

Impact on Application:

Glass is particularly beneficial for vacuum sealing liquids and delicate items, ensuring that the integrity of the product is maintained. Its non-reactive nature makes it suitable for sensitive applications, such as storing fermented products.

Considerations for International Buyers:

Buyers should consider the weight and fragility of glass when shipping internationally. Compliance with packaging regulations and standards for glass materials is essential, especially in markets with strict import regulations.

Illustrative image related to what is a chamber vacuum sealer

4. Rubber

Key Properties:

Rubber is often used in seals and gaskets within chamber vacuum sealers. It offers flexibility and resilience, with the ability to withstand varying temperatures and pressures.

Pros & Cons:

Rubber seals provide excellent airtightness, which is crucial for effective vacuum sealing. However, rubber can degrade over time, especially when exposed to extreme temperatures or certain chemicals, leading to potential leaks.

Impact on Application:

The use of rubber in seals enhances the overall performance of the vacuum sealer by ensuring that air is effectively removed from the chamber. However, the lifespan of rubber components can affect the long-term reliability of the equipment.

Considerations for International Buyers:

Buyers should ensure that rubber components meet relevant standards, such as ASTM D2000, to guarantee performance and safety. Variations in rubber quality can also affect the durability of seals, making it important to source from reputable suppliers.

Summary Table

| Material | Typical Use Case for what is a chamber vacuum sealer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Structural components, vacuum chambers | High durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic (Nylon/Polyethylene) | Vacuum bags and pouches | Cost-effective and flexible | Limited high-temperature resistance | Low |

| Glass | Storage containers for liquids and delicate items | Excellent barrier properties | Fragile and heavy | Medium |

| Rubber | Seals and gaskets | Provides airtight sealing | Degrades over time | Low |

This analysis provides B2B buyers with essential insights into material selection for chamber vacuum sealers, enabling informed purchasing decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for what is a chamber vacuum sealer

What Are the Main Stages of Manufacturing a Chamber Vacuum Sealer?

Manufacturing a chamber vacuum sealer involves a series of stages that ensure the final product meets the necessary standards for performance and reliability. Each stage plays a critical role in the overall quality and functionality of the device.

What Materials Are Used in the Manufacturing Process of Chamber Vacuum Sealers?

The manufacturing process begins with material preparation. Chamber vacuum sealers typically utilize high-quality stainless steel for the chamber and durable plastics for the components. Stainless steel is favored for its resistance to corrosion and ease of cleaning, making it ideal for food-related applications. In addition, components like motors and pumps are sourced from specialized suppliers to ensure reliability and longevity.

How Are Chamber Vacuum Sealers Formed During Manufacturing?

Following material preparation, the forming stage involves shaping the materials into the necessary parts. This may include cutting, molding, and machining stainless steel and plastic components. CNC (Computer Numerical Control) machining is often employed for precision in producing parts such as chambers, lids, and seals. The use of advanced forming techniques ensures that each component meets the dimensional specifications necessary for optimal performance.

What Assembly Techniques Are Used in Chamber Vacuum Sealer Production?

Assembly is the next crucial stage in the manufacturing process. Here, components are brought together to form the complete vacuum sealing unit. Skilled technicians typically assemble the units, ensuring that all electrical connections, seals, and mechanical parts are properly fitted. Automated assembly lines may also be utilized for efficiency, particularly in large-scale production. During this stage, attention to detail is vital to ensure that the seals are airtight, which is critical for the vacuum sealing process.

How Does Finishing Impact the Quality of Chamber Vacuum Sealers?

The finishing stage involves final touches that enhance both the aesthetics and functionality of the chamber vacuum sealers. This can include surface treatments such as polishing, coating, or painting to protect against wear and corrosion. Additionally, quality checks are performed to ensure that the product meets all specifications and standards before it is packaged for shipment.

What International Quality Assurance Standards Apply to Chamber Vacuum Sealers?

Quality assurance is paramount in the manufacturing of chamber vacuum sealers, particularly for B2B buyers who expect high standards of reliability and performance. International standards such as ISO 9001 provide a framework for a quality management system that helps manufacturers ensure consistent quality throughout their processes. Compliance with these standards demonstrates a commitment to quality and customer satisfaction.

Illustrative image related to what is a chamber vacuum sealer

Which Industry-Specific Certifications Should Buyers Look for?

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and FDA (Food and Drug Administration) approval for food safety may be crucial for B2B buyers. The CE mark indicates that the product complies with European health, safety, and environmental protection standards, while FDA approval signifies that the materials used are safe for food contact.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is a multi-faceted process that occurs at various checkpoints throughout the manufacturing stages.

What Are the Key QC Checkpoints in the Manufacturing Process?

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components before they enter the production line. Ensuring that materials meet quality specifications is critical for the integrity of the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring occurs to identify any defects or variances in production. This includes checking dimensions, functionality, and assembly accuracy.

-

Final Quality Control (FQC): Once the assembly is complete, FQC involves thorough testing of the finished chamber vacuum sealers. This includes performance tests, leak tests, and safety checks to ensure the product operates as intended.

What Testing Methods Are Commonly Used for Chamber Vacuum Sealers?

Several testing methods are employed to validate the quality and functionality of chamber vacuum sealers:

-

Leak Testing: To ensure that the vacuum seal is effective, leak testing is performed, which may involve submerging the unit in water or using electronic leak detection methods.

-

Performance Testing: This assesses the operational efficiency of the vacuum sealer, including vacuum speed, sealing integrity, and the ability to handle liquids.

-

Durability Testing: Manufacturers may conduct stress tests to evaluate the unit’s performance under various conditions, ensuring long-term reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can include:

-

Supplier Audits: Conducting on-site audits of the manufacturing facility allows buyers to assess compliance with quality standards and manufacturing practices.

-

Quality Reports: Requesting detailed quality reports that outline QC procedures, testing results, and certifications can provide insight into a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspectors to evaluate products before shipment can help ensure that they meet agreed-upon specifications and standards.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of certain nuances when it comes to quality control.

-

Regulatory Compliance: Different regions may have specific regulatory requirements that must be met. Understanding these regulations is crucial for ensuring compliance and avoiding potential issues.

-

Cultural Considerations: Communication and cultural differences can impact the QC process. Establishing clear guidelines and expectations can help bridge any gaps.

-

Logistics and Shipping: Quality assurance does not end at the factory door. Buyers should consider how products are handled during shipping and ensure that appropriate measures are in place to prevent damage.

By understanding the manufacturing processes and quality assurance measures associated with chamber vacuum sealers, B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is a chamber vacuum sealer’

To assist B2B buyers in navigating the procurement process for chamber vacuum sealers, this guide provides a step-by-step checklist. Chamber vacuum sealers are essential tools for food preservation, packaging, and culinary innovation, making them vital for businesses in food service, manufacturing, and retail. Understanding how to source the right machine can lead to improved efficiency and reduced costs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. Consider factors such as the size of the chamber, the types of materials you’ll be sealing (liquids, solids), and the volume of products you expect to process. This clarity ensures you select a machine that meets your operational needs without overspending on unnecessary features.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers that specialize in chamber vacuum sealers. Look for companies with a strong reputation in the industry, positive customer reviews, and a history of serving businesses similar to yours. Consider reaching out to industry contacts or using B2B marketplaces to gather recommendations.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet each supplier carefully. Request company profiles, product catalogs, and case studies that demonstrate their experience and success in your specific industry. Engage in discussions to understand their customer service approach and warranty policies, as these will impact your long-term satisfaction with the equipment.

Illustrative image related to what is a chamber vacuum sealer

Step 4: Verify Compliance and Certifications

Ensure that the chamber vacuum sealers you’re considering comply with international safety and quality standards. Check for certifications such as CE, ISO, or FDA approval, which indicate that the equipment meets specific regulatory requirements. This step is crucial to avoid potential legal issues and ensure product safety.

Step 5: Assess After-Sales Support and Maintenance

Inquire about the after-sales support offered by the suppliers, including warranty terms, availability of spare parts, and technical support. A reliable support system can minimize downtime and keep your operations running smoothly. Ask about the maintenance requirements of the machines to gauge the total cost of ownership.

Step 6: Request Samples and Demonstrations

Whenever possible, request samples or demonstrations of the chamber vacuum sealers. This hands-on experience allows you to assess the machine’s performance and ease of use firsthand. Evaluate the sealing quality, speed, and versatility in handling different types of products.

Step 7: Compare Pricing and Payment Terms

Finally, compare the pricing structures of the shortlisted suppliers, taking into account the total cost of ownership rather than just the initial purchase price. Evaluate payment terms and financing options that might be available, as these can significantly affect your cash flow and budgeting. Negotiate where possible to secure the best deal while ensuring that quality is not compromised.

By following this checklist, B2B buyers can make informed decisions when sourcing chamber vacuum sealers, ensuring that their investment aligns with their operational goals and enhances their business capabilities.

Comprehensive Cost and Pricing Analysis for what is a chamber vacuum sealer Sourcing

What Are the Key Cost Components of a Chamber Vacuum Sealer?

When sourcing chamber vacuum sealers, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The main materials involved in manufacturing chamber vacuum sealers are stainless steel for the body, high-quality pumps, and vacuum bags. These materials are essential for ensuring durability and functionality, especially when sealing liquids.

-

Labor: Labor costs encompass the wages of workers involved in the assembly, quality control, and testing of the machines. Skilled labor is often required to ensure precision in manufacturing, which can drive up costs.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. A well-managed overhead can significantly affect the final pricing of the product.

-

Tooling: The initial setup for production, including molds and specialized tools, can be substantial. Custom tooling for specialized features or designs increases the initial investment but can lead to higher quality outputs.

-

Quality Control (QC): Given the critical nature of vacuum sealing in food preservation, rigorous QC processes are essential. This may involve additional testing and validation, which can contribute to the overall cost.

-

Logistics: Transportation and warehousing costs for moving finished products to distributors or direct customers add to the total expenses. These can vary significantly based on the destination, especially for international shipments.

-

Margin: Suppliers typically add a profit margin on top of the total production costs. This margin can vary widely depending on the supplier’s positioning in the market and their brand reputation.

How Do Price Influencers Affect Chamber Vacuum Sealer Costs?

Several factors influence the pricing of chamber vacuum sealers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs. Buyers should consider negotiating bulk purchasing agreements to achieve better pricing.

-

Specifications and Customization: Custom features or enhanced specifications can lead to higher costs. Buyers should assess the necessity of these features against their operational needs.

-

Material Quality and Certifications: Higher quality materials and certifications (like food safety standards) can increase costs but are essential for compliance in many markets, particularly in Europe and North America.

-

Supplier Factors: Supplier reputation, reliability, and experience can influence pricing. Established suppliers may charge a premium but can offer assurances regarding quality and service.

-

Incoterms: The choice of Incoterms can significantly impact the total landed cost. Buyers should be aware of who bears the responsibility for shipping costs, insurance, and import duties.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing Chamber Vacuum Sealers?

To optimize costs when sourcing chamber vacuum sealers, consider the following strategies:

-

Negotiate Pricing: Leverage your purchasing power, especially if you represent a larger organization or are placing bulk orders. Don’t hesitate to negotiate terms and prices with suppliers.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider operational costs, maintenance, and the longevity of the equipment. A cheaper machine may lead to higher operational costs in the long run.

-

Understand Pricing Nuances for International Markets: When sourcing from different regions (e.g., Africa, South America, the Middle East, Europe), be aware of local market conditions, tariffs, and import regulations that can affect pricing.

-

Explore Multiple Suppliers: Diversify your supplier base to compare pricing, quality, and service levels. This can also provide leverage in negotiations.

-

Stay Informed About Market Trends: Understanding shifts in material costs, technological advancements, and competitive pricing can help you make informed purchasing decisions.

In conclusion, a comprehensive understanding of the cost structure and price influencers, coupled with strategic sourcing approaches, can lead to significant savings and value when investing in chamber vacuum sealers. Always request indicative prices and be aware that final costs may vary based on specific requirements and market dynamics.

Alternatives Analysis: Comparing what is a chamber vacuum sealer With Other Solutions

Introduction: Understanding Alternative Solutions to Chamber Vacuum Sealers

In the realm of food preservation and packaging, chamber vacuum sealers stand out for their unique ability to handle a variety of items, including liquids. However, several alternative technologies and methods exist that can achieve similar goals. This analysis will compare chamber vacuum sealers with suction vacuum sealers and food preservation methods such as canning. Each alternative presents its own advantages and challenges, making it essential for B2B buyers to assess their specific needs before making a decision.

Illustrative image related to what is a chamber vacuum sealer

Comparison Table

| Comparison Aspect | What Is A Chamber Vacuum Sealer | Suction Vacuum Sealer | Canning |

|---|---|---|---|

| Performance | Excellent for liquids and solids | Good for solid items | Long-term preservation |

| Cost | Higher initial investment | Lower initial investment | Moderate, with equipment costs |

| Ease of Implementation | Requires some training | User-friendly | Requires more preparation |

| Maintenance | Moderate; may require oil changes | Low maintenance | Moderate; requires sterilization |

| Best Use Case | Commercial kitchens, sous vide | Home use, small-scale | Long-term storage, shelf-stable |

Detailed Breakdown of Alternatives

What Is A Suction Vacuum Sealer?

Suction vacuum sealers operate by extracting air from the bag and sealing it tightly. This method is user-friendly and widely available, making it a popular choice for home users and small businesses. The lower initial cost is a significant advantage, allowing users to start preserving food without a hefty investment. However, suction sealers are less effective with liquids, as they can lead to spills and compromised seals. They are best suited for solid foods and short-term storage, which may limit their applicability in commercial settings.

What Is Canning?

Canning is a traditional preservation method that involves sealing food in jars and heating them to kill bacteria and enzymes that cause spoilage. This method provides excellent long-term storage and ensures that food remains shelf-stable for extended periods. While the initial setup costs can be moderate, the process requires careful preparation, including sterilization of jars and precise timing during heating. Canning is labor-intensive and may not be ideal for businesses needing quick turnaround times for perishable items. However, it offers a robust solution for long-term storage, particularly for fruits, vegetables, and sauces.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a food preservation method, B2B buyers must consider their specific operational requirements, budget constraints, and the types of products they intend to store. Chamber vacuum sealers offer unparalleled versatility, especially for liquid and solid items, making them ideal for commercial kitchens and catering businesses. Suction vacuum sealers provide a cost-effective solution for smaller-scale operations, while canning is an excellent option for long-term preservation. Ultimately, the right choice will depend on the unique needs of each business, including the types of food being preserved and the volume of production.

Illustrative image related to what is a chamber vacuum sealer

Essential Technical Properties and Trade Terminology for what is a chamber vacuum sealer

What Key Specifications Should You Consider for a Chamber Vacuum Sealer?

When evaluating chamber vacuum sealers for your business, it’s crucial to understand several technical specifications that can impact performance and suitability for your specific needs. Here are some critical properties:

-

Vacuum Pressure (mmHg or inHg)

The vacuum pressure indicates how effectively the machine can remove air from the chamber. A higher vacuum pressure (typically between 25 to 30 inHg) allows for better preservation of food and other products, as it minimizes oxidation and spoilage. For businesses dealing with perishable goods or sensitive materials, understanding vacuum pressure is essential for ensuring product longevity. -

Chamber Size (L x W x H)

The dimensions of the chamber directly affect the volume of items that can be sealed at one time. Larger chambers can accommodate bulkier items or multiple smaller items, making them ideal for restaurants, catering services, or food production facilities. For B2B buyers, selecting the appropriate chamber size can optimize workflow and efficiency. -

Sealing Bar Length

The length of the sealing bar determines the size of the bags that can be used. Most commercial chamber vacuum sealers have sealing bars ranging from 12 inches to 20 inches. Understanding this specification helps businesses choose a model that can handle their typical packaging sizes, thus improving operational efficiency. -

Material Grade of Construction

Chamber vacuum sealers are typically constructed from stainless steel or high-grade plastics. Stainless steel models are more durable and resistant to corrosion, making them suitable for high-volume or industrial applications. For buyers, material grade impacts not only the longevity of the machine but also maintenance costs over time. -

Pump Type (Oil vs. Oil-free)

The type of vacuum pump influences the maintenance requirements and operating costs of the sealer. Oil pumps require regular maintenance and replacement of oil, while oil-free models reduce maintenance time and costs. Choosing the right pump type can significantly affect total cost of ownership, making it a critical consideration for B2B buyers. -

Power Consumption (Watts)

Understanding the power consumption helps in evaluating operational costs. Chamber vacuum sealers typically range from 200 to 1000 watts. Selecting an energy-efficient model can lead to lower electricity bills, which is an important factor for businesses aiming to maintain profitability.

What Common Trade Terms Should You Know When Purchasing Chamber Vacuum Sealers?

Navigating the procurement process for chamber vacuum sealers also involves familiarity with certain trade terminology. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce equipment or components that are used in another company’s product. When sourcing a chamber vacuum sealer, understanding if it is an OEM product can help ensure quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

This term indicates the smallest number of units that a supplier is willing to sell. For businesses, knowing the MOQ is vital for budgeting and inventory planning, especially if you require a specific quantity for operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products or services. It is a critical step in the procurement process, allowing businesses to compare costs and features of different chamber vacuum sealers before making a purchasing decision. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B transactions involving chamber vacuum sealers, as they clarify shipping costs and liability. -

Lead Time

The lead time is the time it takes from placing an order to receiving the product. Understanding lead time is essential for operational planning, especially for businesses that rely on timely deliveries to maintain inventory levels. -

Warranty Period

The warranty period defines the duration for which the manufacturer guarantees the product against defects. Knowing the warranty terms can provide peace of mind and help businesses assess the long-term value of their investment in a chamber vacuum sealer.

By understanding these key specifications and trade terms, B2B buyers can make informed decisions when purchasing chamber vacuum sealers, ensuring they choose the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the what is a chamber vacuum sealer Sector

What Are the Key Market Drivers for Chamber Vacuum Sealers?

The chamber vacuum sealer market is witnessing significant growth due to various global drivers. The increasing demand for food preservation, particularly in regions like Africa, South America, and the Middle East, is fueled by a rise in food waste awareness and the need for longer shelf-life products. In Europe and Asia, the trend towards sous-vide cooking and gourmet food preparations has driven culinary professionals and home cooks alike to invest in more advanced sealing technologies. Additionally, the rise of e-commerce platforms has made it easier for international buyers to access high-quality chamber vacuum sealers, expanding market reach.

Emerging B2B technology trends include the integration of smart features in chamber vacuum sealers, such as IoT capabilities that allow for remote monitoring and control. Suppliers are increasingly focusing on providing customized solutions that cater to specific industries, whether it be food processing, pharmaceuticals, or even electronics. The shift towards automation in manufacturing processes is also influencing sourcing trends, as businesses look for equipment that enhances efficiency and reduces labor costs.

How Is Sustainability Influencing the Chamber Vacuum Sealer Market?

Sustainability is becoming a critical consideration in the procurement of chamber vacuum sealers. The environmental impact of packaging waste, particularly in the food industry, is prompting buyers to seek out suppliers who prioritize ethical sourcing and sustainable materials. Manufacturers are responding by developing vacuum sealers that use biodegradable or recyclable materials for packaging, as well as energy-efficient machines that lower carbon footprints during operation.

Buyers are increasingly favoring companies that can demonstrate commitment to ethical supply chains, often seeking certifications such as ISO 14001 (Environmental Management) or certifications for sustainable materials. This trend not only aligns with consumer preferences but also mitigates risks associated with regulatory compliance. As a result, international buyers are encouraged to conduct thorough due diligence on suppliers to ensure they meet sustainability standards that resonate within their markets.

What Has Been the Evolution of Chamber Vacuum Sealers?

Chamber vacuum sealers have evolved significantly over the past few decades. Initially, these machines were primarily used in high-end restaurants and food processing facilities due to their high cost and maintenance requirements, including oil pumps for operation. However, advancements in technology have led to the development of more compact and affordable models, making them accessible to a broader audience, including small businesses and home chefs.

The introduction of oil-free models has further enhanced their appeal, allowing for easier maintenance and lower operational costs. Today, chamber vacuum sealers are not just tools for preservation; they are essential equipment for culinary innovation, enabling techniques such as sous-vide cooking and efficient fermentation processes. As the market continues to grow, ongoing innovations will likely focus on enhancing user experience and sustainability, ensuring that chamber vacuum sealers remain a vital asset across various industries.

Frequently Asked Questions (FAQs) for B2B Buyers of what is a chamber vacuum sealer

-

How do I choose the right chamber vacuum sealer for my business needs?

Selecting the right chamber vacuum sealer involves assessing your specific requirements, such as production volume, types of products to be sealed (liquids, solids, or both), and available space. Consider the machine’s sealing capacity, cycle time, and ease of use. Additionally, evaluate the quality and durability of the unit, particularly if you operate in a high-demand environment like restaurants or food processing facilities. Consulting with suppliers about customization options can also help ensure the sealer meets your unique operational needs. -

What is the best chamber vacuum sealer for small-scale food producers?

For small-scale food producers, a compact and user-friendly chamber vacuum sealer is ideal. Look for models that offer versatility in sealing both solids and liquids, as well as efficiency in cycle time. Brands like Avid Armor and VacMaster offer affordable options without compromising on performance. Ensure that the sealer can accommodate your specific bag sizes and has features like adjustable vacuum levels to suit various food items. Investing in a reliable unit can enhance your packaging quality and prolong product shelf life. -

What are the typical minimum order quantities (MOQs) for chamber vacuum sealers?

Minimum order quantities for chamber vacuum sealers can vary significantly by supplier and region. Generally, MOQs range from a single unit for smaller suppliers to dozens or more for larger manufacturers. When dealing with international suppliers, it’s advisable to inquire about bulk pricing, as larger orders may yield cost savings. Always clarify the MOQ during negotiations to align your purchasing strategy with your production needs. -

How can I vet suppliers of chamber vacuum sealers effectively?

To effectively vet suppliers, start by researching their reputation and customer reviews in the market. Look for certifications that demonstrate compliance with international standards, such as ISO or CE marks. Request references from previous clients and evaluate their responsiveness during initial communications. Additionally, consider visiting manufacturing facilities if possible, or utilizing third-party inspection services to ensure the quality of the products before placing an order. -

What payment terms should I expect when sourcing chamber vacuum sealers internationally?

Payment terms can vary based on the supplier, transaction size, and buyer-seller relationship. Common terms include a deposit upon order confirmation, followed by the balance before shipment. Some suppliers may offer net terms (e.g., net 30 or net 60 days) for established customers. It’s essential to negotiate clear payment terms upfront and consider using secure methods like letters of credit or escrow services to protect your investment, especially in international transactions. -

What quality assurance measures should I look for when buying chamber vacuum sealers?

Quality assurance is crucial when purchasing chamber vacuum sealers. Look for suppliers that conduct rigorous testing and quality control processes, including performance evaluations and durability tests. Inquire about warranties and after-sales support, as these can indicate the manufacturer’s confidence in their product. Additionally, consider requesting samples or demonstration units to assess performance before committing to a larger order. -

How do logistics impact the purchase of chamber vacuum sealers from overseas suppliers?

Logistics play a significant role in the procurement of chamber vacuum sealers, particularly when dealing with international suppliers. Factors such as shipping costs, delivery times, and customs regulations can affect overall expenses and timelines. Ensure that you understand the supplier’s shipping methods and terms of delivery. Collaborating with a freight forwarder can help navigate the complexities of international shipping, ensuring that your equipment arrives safely and on schedule. -

What are the benefits of using chamber vacuum sealers in food processing?

Chamber vacuum sealers offer numerous advantages in food processing, including the ability to seal liquids without spillage, which is ideal for soups and marinades. They create a consistent vacuum environment, enhancing product preservation and extending shelf life. Additionally, using chamber vacuum sealers can reduce food waste and improve portion control, making them a valuable investment for businesses looking to optimize their packaging and storage processes.

Top 4 What Is A Chamber Vacuum Sealer Manufacturers & Suppliers List

1. Anova – Precision Chamber Vacuum Sealer

Domain: anovaculinary.com

Registered: 2013 (12 years)

Introduction: Anova Precision™ Chamber Vacuum Sealer features a powerful pump that removes air from the entire chamber, creating an equally pressurized environment inside and outside the bag. It allows for sealing of liquids without risk of mess, with adjustable vacuum and sealing times. The sealer has pre-programmed settings for infusion, extraction, compression, pickling, and rapid cooling. Chamber vacuum pou…

2. Vacmaster – Chamber Vacuum Sealers

Domain: vacmasterfresh.com

Registered: 2015 (10 years)

Introduction: Chamber Vacuum Sealers: Used to store solid and liquid items; utilize regular vacuum sealer pouches and full mesh vacuum sealer bags; control vacuum amount; evacuate air from the chamber, equalizing pressure inside and outside the pouch; suitable for liquids like soups and marinades; available in smaller countertop models for home use and larger commercial models for restaurants. Suction Vacuum Se…

3. Dr. Mike Kuna – Chamber Vacuum Sealers

Domain: drmikekuna.com

Registered: 2014 (11 years)

Introduction: Chamber vacuum sealers are designed to create a partial vacuum in a thick plastic bag, sealing its contents in a low-oxygen environment to extend food shelf life. They differ from external vacuum sealers, which are more common for home use. Chamber sealers can keep meats and cheeses fresh 3-5 times longer than refrigeration alone, and they are effective for freezing foods without degradation. They…

4. JVR – Vac100 Chamber Vacuum Sealer

Domain: jvrinc.com

Registered: 1997 (28 years)

Introduction: JVR Vac100 Chamber Vacuum Sealer: A robust, self-serviceable vacuum sealing machine with a shatterproof tempered glass lid and a removable seal bar. Features user-friendly programmable controls and a sleek stainless steel body. It removes up to 99.8% of air for an airtight seal, promoting longer-lasting food storage and reducing food waste. Suitable for sealing dry goods, meats, vegetables, and li…

Strategic Sourcing Conclusion and Outlook for what is a chamber vacuum sealer

Chamber vacuum sealers represent a significant advancement in food preservation and packaging, offering unique benefits that cater to diverse industry needs. By enabling the vacuum sealing of both solid and liquid items, these machines outperform traditional suction sealers, ensuring the integrity of products while reducing waste and improving shelf life. As international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances between chamber and suction vacuum sealers can lead to more informed purchasing decisions and ultimately enhance operational efficiency.

Strategic sourcing of chamber vacuum sealers allows businesses to capitalize on cost savings from cheaper vacuum bags and increased durability of packaged goods. Investing in these technologies not only streamlines food processing operations but also opens doors to innovative culinary techniques, such as quick pickling and reliable fermentation.

Looking ahead, the demand for efficient food preservation solutions is set to grow. Now is the time to evaluate your procurement strategies and consider integrating chamber vacuum sealers into your operations. By doing so, you can position your business to leverage advancements in food technology, maximize profitability, and meet the evolving needs of your customers.

Illustrative image related to what is a chamber vacuum sealer

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.