Choosing Your Vav Plastics: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for vav plastics

In today’s dynamic global marketplace, sourcing vav plastics can be a daunting challenge for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. The need for high-quality, sustainable plastic solutions is paramount, with industries ranging from food and beverage to pharmaceuticals and cosmetics relying heavily on effective packaging. This guide serves as a comprehensive resource, addressing the complexities of sourcing vav plastics by providing insights into various types, applications, and supplier vetting processes.

With a focus on the intricacies of blow molding and custom design options, this guide empowers international buyers to make informed decisions, ensuring that they select the right materials for their specific needs. Key considerations such as cost analysis, sustainability practices, and the importance of establishing long-term partnerships with reliable suppliers will be thoroughly explored.

By navigating this guide, B2B buyers will not only gain a deeper understanding of the vav plastics landscape but also enhance their procurement strategies, ultimately leading to improved operational efficiency and product quality. Whether you’re based in Saudi Arabia, Nigeria, or any other region, this resource is designed to equip you with the knowledge needed to thrive in the competitive market of vav plastics.

Understanding vav plastics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PET (Polyethylene Terephthalate) | High clarity, excellent barrier properties, lightweight | Food and beverage packaging, personal care products | Pros: Recyclable, strong; Cons: Can be sensitive to heat. |

| PETE (Polyethylene Terephthalate – Enhanced) | Enhanced performance over standard PET, improved chemical resistance | Pharmaceuticals, cosmetics | Pros: Superior durability; Cons: Higher cost than standard PET. |

| LDPE (Low-Density Polyethylene) | Flexible, low-density structure, good chemical resistance | Bags, containers, and packaging films | Pros: Cost-effective, versatile; Cons: Less rigid than other plastics. |

| HDPE (High-Density Polyethylene) | Strong, stiff, and resistant to impact | Household products, industrial containers | Pros: High strength-to-density ratio; Cons: Limited transparency. |

| PP (Polypropylene) | High melting point, excellent chemical resistance | Automotive parts, food containers | Pros: Durable, lightweight; Cons: Can be more expensive than other plastics. |

What Are the Characteristics and Suitability of PET Plastics for B2B Buyers?

PET, or Polyethylene Terephthalate, is widely recognized for its high clarity and excellent barrier properties, making it a preferred choice for food and beverage packaging. Its lightweight nature facilitates transportation and storage, which is crucial for B2B buyers looking to optimize logistics. Additionally, PET is recyclable, aligning with sustainability goals, yet it can be sensitive to heat, necessitating careful handling in production and storage.

How Does PETE Differ from Standard PET and Its Applications?

PETE, or Enhanced Polyethylene Terephthalate, offers improved performance characteristics over standard PET, particularly in terms of chemical resistance. This makes it suitable for sensitive applications like pharmaceuticals and cosmetics where product integrity is paramount. B2B buyers should consider the potential for higher costs associated with PETE, but the benefits of increased durability and protection against contamination may justify the investment.

Why Choose LDPE for Flexible Packaging Solutions?

Low-Density Polyethylene (LDPE) is characterized by its flexibility and low-density structure, making it ideal for applications such as bags and packaging films. Its chemical resistance enhances its usability across various industries, including food and consumer goods. While LDPE is cost-effective and versatile, buyers should be aware that its less rigid nature may not be suitable for all applications, particularly those requiring structural integrity.

What Advantages Does HDPE Offer for Industrial Applications?

High-Density Polyethylene (HDPE) is known for its strength and stiffness, making it a robust option for household products and industrial containers. With a high strength-to-density ratio, HDPE provides durability without excessive weight, which is advantageous for shipping and handling. However, its limited transparency may be a drawback for products requiring visibility, and buyers should assess whether its physical properties align with their specific needs.

How Can PP Benefit Buyers Looking for Durable Packaging?

Polypropylene (PP) is distinguished by its high melting point and excellent chemical resistance, making it suitable for automotive parts and food containers. Its lightweight yet durable nature offers significant advantages in terms of shipping costs and product longevity. While it may be more expensive than other plastic types, the long-term benefits of enhanced performance and reduced breakage can provide a solid return on investment for B2B buyers.

Key Industrial Applications of vav plastics

| Industry/Sector | Specific Application of vav plastics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Custom PET and PETE bottles for beverages | Enhanced product shelf life and brand visibility | Compliance with food safety regulations and certifications |

| Pharmaceutical | PET bottles for medicines and health supplements | Ensured product integrity and safety | Need for precise specifications and quality assurance |

| Cosmetics & Personal Care | Custom-designed packaging for beauty products | Differentiation in a competitive market | Consideration of design aesthetics and material safety |

| Household Products | HDPE containers for cleaning supplies | Durability and chemical resistance | Availability of various sizes and customization options |

| Recycling and Waste Management | Supply of recycled LDPE, PP, and HDPE materials | Sustainable sourcing and reduced environmental impact | Consistency in material quality and reliable supply chain |

How Are vav Plastics Used in the Food & Beverage Industry?

In the food and beverage sector, vav plastics specializes in manufacturing custom PET and PETE bottles that are crucial for packaging drinks. These materials not only enhance the shelf life of beverages but also contribute to brand visibility through customizable designs. International buyers, particularly from regions like Africa and the Middle East, must ensure that their suppliers meet stringent food safety regulations and certifications to avoid compliance issues.

What Role Do vav Plastics Play in the Pharmaceutical Sector?

The pharmaceutical industry relies heavily on vav plastics for producing PET bottles that safeguard medicines and health supplements. These bottles are designed to maintain product integrity while ensuring safety for consumers. Buyers must focus on precise specifications and robust quality assurance processes to meet the rigorous standards of pharmaceutical packaging, which is essential for international trade.

How Are vav Plastics Beneficial in Cosmetics & Personal Care?

In the cosmetics and personal care industry, vav plastics offers custom-designed packaging solutions that help brands stand out in a competitive marketplace. The ability to tailor designs to specific brand identities adds value, making products more appealing to consumers. For international buyers, considerations around design aesthetics, material safety, and compliance with local regulations are vital to ensure successful market entry.

Illustrative image related to vav plastics

Why Choose vav Plastics for Household Products?

For household products, vav plastics provides HDPE containers that are known for their durability and chemical resistance, making them ideal for cleaning supplies. These containers can withstand various household chemicals while maintaining structural integrity. Buyers should consider the availability of different sizes and customization options to meet specific market demands, ensuring that their products are both functional and appealing.

How Does vav Plastics Contribute to Recycling and Waste Management?

Vav plastics plays a significant role in recycling and waste management by supplying high-quality recycled materials such as LDPE, PP, and HDPE flakes and pellets. This sustainable sourcing option not only reduces environmental impact but also helps businesses meet their sustainability goals. Buyers must prioritize consistency in material quality and establish a reliable supply chain to ensure that recycled materials meet production needs effectively.

3 Common User Pain Points for ‘vav plastics’ & Their Solutions

Scenario 1: Challenges in Custom Bottle Design and Engineering

The Problem: B2B buyers often face hurdles when trying to develop custom bottle designs that align with their brand identity and product requirements. This is especially true for industries like food and beverage, pharmaceuticals, and cosmetics where the packaging must not only be aesthetically pleasing but also functional and compliant with regulations. Buyers may struggle with the complexities of translating their ideas into practical designs, leading to delays in product launches and increased costs.

The Solution: To effectively navigate the custom design process, buyers should partner with Vav Plastics, which specializes in custom bottle manufacturing. Begin by engaging in a detailed consultation with Vav’s design team to discuss your vision, including specific requirements such as neck diameter, body shape, and capacity. Utilize their CAD/CAM design capabilities to visualize the product through 2D renderings and 3D mock-ups before moving to production. By involving Vav Plastics early in the conceptual phase, buyers can leverage their expertise in compliance and material selection, ensuring that the final product meets both aesthetic and regulatory standards. This proactive approach not only streamlines the design process but also reduces the likelihood of costly revisions later.

Scenario 2: Sourcing High-Quality Recycled Plastics

The Problem: With an increasing emphasis on sustainability, B2B buyers are often challenged by the need to source high-quality recycled plastics that meet their production standards. Many suppliers offer recycled materials, but the quality can vary significantly, impacting product integrity and brand reputation. Buyers may find themselves receiving inconsistent batches, leading to production delays and quality control issues.

The Solution: Buyers should consider establishing a partnership with Vav Plastics, which specializes in the recycling and production of high-quality LDPE, PP, and HDPE flakes and pellets. When sourcing materials, request detailed specifications about the recycling process and quality control measures employed by Vav Plastics. Conducting an initial order with a smaller batch can also help assess the quality before committing to larger quantities. Furthermore, Vav’s commitment to maintaining high standards ensures that the recycled materials provided will be clean, consistent, and suitable for diverse applications, thereby enhancing the sustainability profile of your products without compromising on quality.

Illustrative image related to vav plastics

Scenario 3: Navigating Compliance and Regulatory Requirements

The Problem: B2B buyers in industries such as pharmaceuticals and food packaging often grapple with stringent compliance and regulatory requirements concerning materials used in packaging. This complexity can lead to concerns about whether the packaging meets local and international standards, potentially resulting in costly recalls or legal issues.

The Solution: To alleviate these compliance concerns, buyers should work closely with Vav Plastics, whose expertise in the manufacturing of PET and PETE bottles is well-aligned with industry regulations. Begin by consulting with their team about the specific compliance requirements relevant to your industry and region. Vav Plastics can provide documentation and certifications related to their materials, ensuring they meet necessary safety standards. Additionally, consider involving Vav in the early stages of product development to ensure that all packaging solutions are designed with compliance in mind. This collaborative approach will not only streamline the approval process but also instill confidence in your supply chain management, protecting your business from regulatory pitfalls.

Strategic Material Selection Guide for vav plastics

When selecting materials for vav plastics, it is essential to understand the properties, advantages, and limitations of each option. The following analysis covers four common materials used in vav plastics manufacturing: PET, PETE, LDPE, and HDPE. Each material has unique characteristics that can significantly impact product performance and suitability for various applications.

What Are the Key Properties of PET and PETE in vav Plastics?

Polyethylene Terephthalate (PET) and Polyethylene Terephthalate Glycol (PETE) are widely used in the production of bottles and jars. They are known for their excellent clarity, strength, and resistance to impact and moisture. PET has a temperature rating of up to 60°C, making it suitable for various applications, including food and beverage packaging. Additionally, both materials exhibit good chemical resistance, particularly against alcohols and acids.

Pros: PET and PETE are lightweight, recyclable, and cost-effective. Their clarity enhances product visibility, which is crucial for consumer appeal.

Cons: They have lower temperature resistance compared to some other plastics, which may limit their use in high-temperature applications.

Impact on Application: PET and PETE are ideal for food and beverage industries due to their safety and compatibility with consumables.

Illustrative image related to vav plastics

Considerations for International Buyers: Compliance with international standards such as FDA regulations for food safety is critical. Buyers from regions like Europe and the Middle East should ensure that their suppliers adhere to these standards to avoid regulatory issues.

How Do LDPE and HDPE Compare in Terms of Performance and Cost?

Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) are both versatile materials used in various applications. LDPE is known for its flexibility and low-density structure, making it ideal for applications requiring a softer touch, such as squeeze bottles. It has a temperature rating of up to 80°C but is less resistant to UV radiation.

Pros: LDPE is highly resistant to impact and moisture, making it suitable for packaging applications. It is also relatively inexpensive, which is advantageous for large-scale production.

Illustrative image related to vav plastics

Cons: Its lower strength compared to HDPE can be a limitation for applications requiring structural integrity.

Impact on Application: LDPE is often used in packaging for food and personal care products, while HDPE is preferred for more robust applications, such as containers for chemicals and cleaning products.

Considerations for International Buyers: Buyers should be aware of the different recycling codes associated with LDPE and HDPE, as these can impact logistics and compliance with local regulations. For instance, HDPE is often preferred in regions with stringent recycling mandates.

Summary Table of Material Selection for vav Plastics

| Material | Typical Use Case for vav plastics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PET | Beverage bottles, food containers | Excellent clarity and strength | Limited temperature resistance | Medium |

| PETE | Food and beverage packaging | Good chemical resistance | Lower temperature tolerance | Medium |

| LDPE | Squeeze bottles, flexible packaging | High moisture resistance | Lower structural strength | Low |

| HDPE | Chemical containers, robust packaging | High strength and durability | Less flexible than LDPE | Medium |

In conclusion, understanding the properties and applications of these materials will enable international B2B buyers to make informed decisions based on their specific needs. By considering the advantages and limitations of each material, buyers can select the most suitable options for their products while ensuring compliance with relevant standards in their respective regions.

Illustrative image related to vav plastics

In-depth Look: Manufacturing Processes and Quality Assurance for vav plastics

What Are the Key Stages in the Manufacturing Process for VAV Plastics?

The manufacturing process at VAV Plastics involves several critical stages that ensure the production of high-quality PET and PETE plastic bottles and jars. Understanding these stages can help B2B buyers make informed decisions when sourcing plastic products.

Material Preparation: How Are Raw Materials Processed?

The first step in the manufacturing process is material preparation, which involves sourcing high-grade PET and PETE resins. These materials are selected based on their properties to meet specific industry requirements, such as food safety or chemical resistance. Once sourced, the resins undergo a drying process to eliminate moisture, which is crucial for preventing defects during molding.

Following drying, the materials are often pre-processed into small pellets, making them easier to handle during the blow molding process. VAV Plastics ensures that only the highest quality materials are utilized, which is fundamental for achieving the desired clarity, strength, and durability in the final product.

What Techniques Are Used in Forming Plastic Bottles?

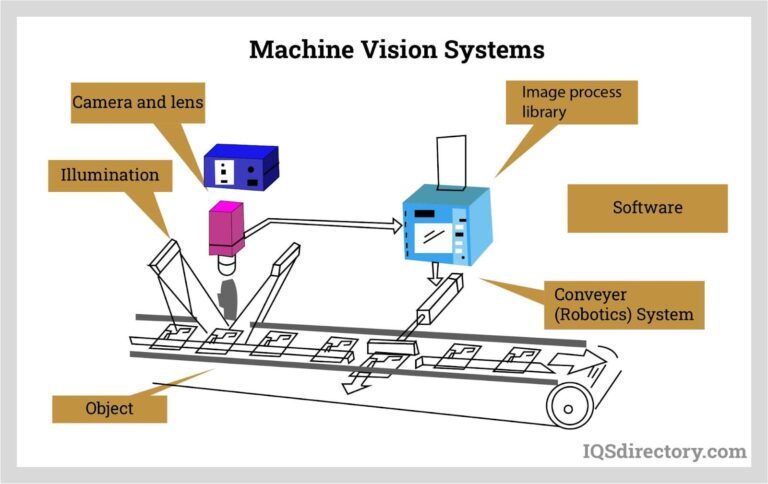

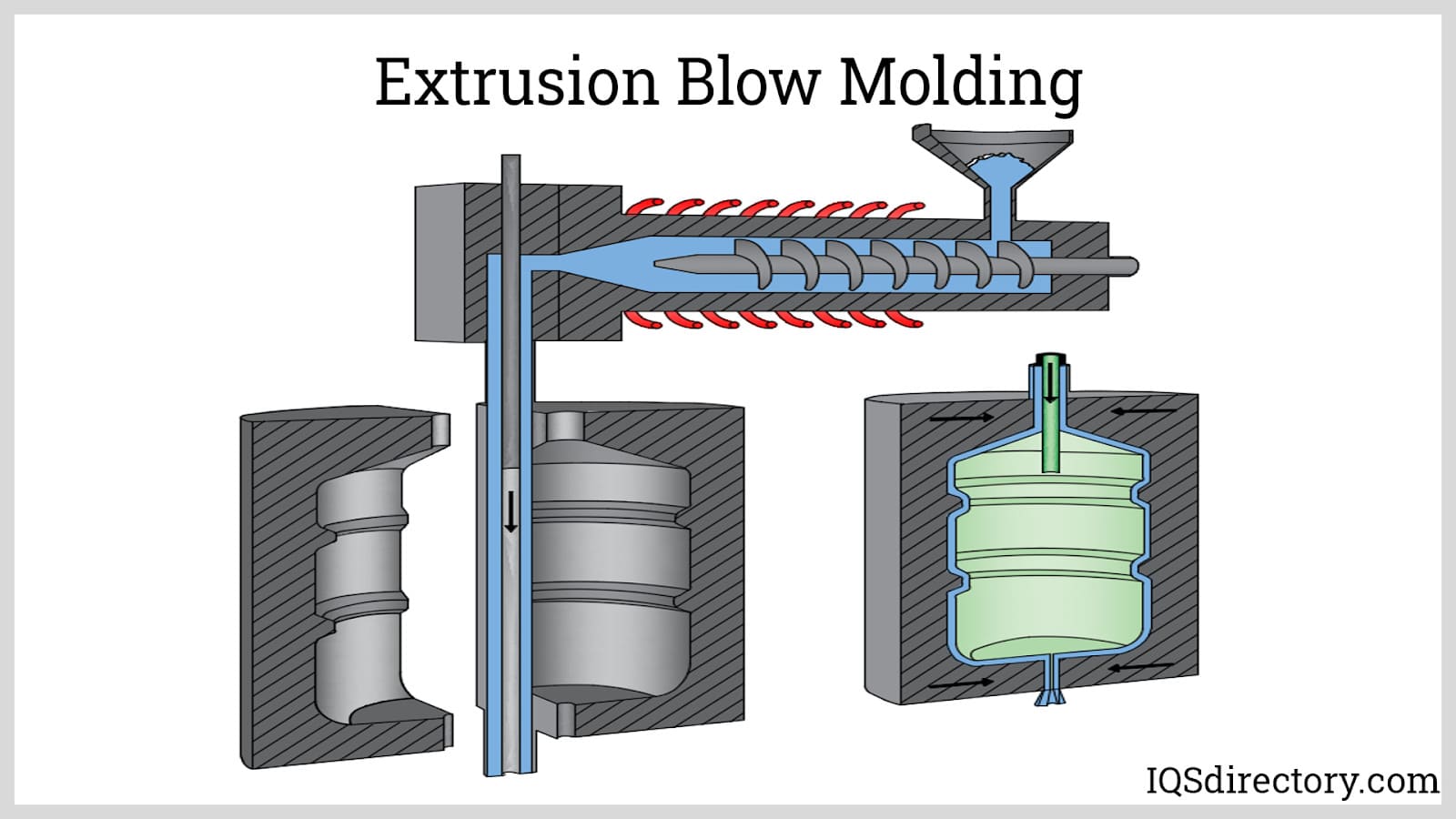

The primary technique employed by VAV Plastics for forming bottles is blow molding. This method is particularly effective for producing hollow plastic parts, such as bottles and jars, with consistent wall thickness.

-

Blow Molding Process: The process begins with the creation of a parison, a hollow tube of plastic that is heated and then inflated within a mold to form the desired shape. VAV Plastics offers both client-supplied molds and custom-made options, allowing flexibility in design.

-

Custom Design Capabilities: VAV Plastics specializes in taking concepts from initial design to final product. This includes CAD/CAM design, prototype creation, and custom mold making, ensuring that each product meets the specific needs of its intended market.

-

Quality of Production: The manufacturing facility is equipped with advanced machinery that ensures precision in the blow molding process. This technology not only enhances efficiency but also minimizes waste, contributing to sustainability efforts.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process at VAV Plastics, aimed at ensuring that every product meets stringent quality standards. This is particularly vital for B2B buyers who require reliability and consistency in their supply chains.

Illustrative image related to vav plastics

What International Standards Guide VAV Plastics’ Quality Control?

VAV Plastics adheres to several international quality standards, including ISO 9001, which focuses on effective quality management systems. This certification demonstrates the company’s commitment to continuous improvement and customer satisfaction. In addition, industry-specific certifications such as CE and API may be applicable depending on the product’s end use, especially in sectors like pharmaceuticals and food packaging.

What Are the Key Quality Control Checkpoints?

The quality control process at VAV Plastics includes several checkpoints throughout the manufacturing cycle:

-

Incoming Quality Control (IQC): This initial step involves inspecting raw materials upon delivery to ensure they meet the required specifications. Any discrepancies can lead to immediate corrective actions.

-

In-Process Quality Control (IPQC): During production, real-time monitoring is conducted to catch any defects early in the manufacturing cycle. This includes checking the dimensions, weight, and visual appearance of the bottles.

-

Final Quality Control (FQC): Once production is complete, a thorough final inspection is conducted. This includes testing the bottles for strength, clarity, and any potential leaks, ensuring they meet both client specifications and regulatory standards.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods employed by VAV Plastics are critical for verifying the quality and safety of their products. Some common testing techniques include:

-

Mechanical Testing: This involves assessing the tensile strength and impact resistance of the bottles, ensuring they can withstand handling and transportation.

-

Chemical Testing: For industries like food and pharmaceuticals, chemical compatibility testing ensures that the materials do not leach harmful substances into their contents.

-

Visual Inspection: A thorough visual inspection is performed to check for any defects, such as bubbles, discoloration, or irregularities in shape.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of suppliers like VAV Plastics is crucial for maintaining product integrity in their own supply chains. Here are several actionable steps:

-

Audits: Requesting regular audits of the manufacturing facilities can provide insight into the quality assurance processes in place. These audits can be performed by third-party organizations to ensure impartiality.

-

Quality Reports: Suppliers should be able to provide detailed quality reports that outline testing results, compliance with standards, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspectors to conduct random checks on products can help verify that the supplier’s quality claims are consistent with the actual products delivered.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, need to be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions have varying regulations regarding packaging materials, particularly in the food and pharmaceutical sectors. Understanding these regulations is essential for compliance and market entry.

-

Sustainability Considerations: As global emphasis on sustainability grows, buyers should inquire about the supplier’s practices regarding recyclable materials and waste management.

-

Cultural Differences: Communication styles and business practices may vary significantly across regions. Building strong relationships with suppliers can facilitate better understanding and adherence to quality standards.

In summary, the manufacturing processes and quality assurance systems at VAV Plastics are designed to meet the high standards expected by B2B buyers across various industries. By understanding these processes and implementing effective verification strategies, buyers can ensure they receive reliable and high-quality products that meet their specific needs.

Illustrative image related to vav plastics

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vav plastics’

To assist international B2B buyers in procuring ‘vav plastics’, particularly PET and PETE products, this practical sourcing guide outlines essential steps to ensure a successful and efficient procurement process.

Step 1: Identify Your Specific Needs

Before reaching out to suppliers, clarify what you need in terms of product specifications, quantity, and delivery timelines. Understanding your requirements helps streamline communication and ensures you receive the most suitable options.

– Considerations:

– Types of plastics (e.g., PET, PETE, LDPE, PP, HDPE)

– Required bottle sizes, shapes, and capacities.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers like Vav Plastics. Look for companies with a solid reputation in the industry, especially those that specialize in custom designs and engineering for bottles.

– Key Factors:

– Years of experience and client testimonials.

– Product range and manufacturing capabilities.

Step 3: Evaluate Supplier Certifications

Verify that your chosen suppliers hold relevant certifications and comply with industry standards. This step is crucial to ensure the quality and safety of the products you will be sourcing.

– Look For:

– ISO certifications or equivalent.

– Compliance with local and international regulations regarding packaging materials.

Step 4: Request Samples

Always request product samples before finalizing an order. This allows you to assess the quality, design, and functionality of the plastics you intend to purchase.

– Important Aspects to Test:

– Durability and material quality.

– Compatibility with your products (e.g., food-grade certifications for food and beverage packaging).

Step 5: Negotiate Pricing and Terms

Once you are satisfied with the samples, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements can prevent misunderstandings and ensure a smooth transaction.

– Considerations:

– Bulk order discounts.

– Shipping costs and lead times.

Step 6: Establish Communication Channels

Ensure that there are clear communication lines with your supplier. Regular updates on production and delivery timelines can help manage expectations and address potential issues proactively.

– Best Practices:

– Designate a point of contact for seamless communication.

– Utilize project management tools for tracking progress.

Step 7: Plan for Sustainability

Consider the environmental impact of your sourcing decisions. Partner with suppliers that offer recyclable materials and sustainable practices, aligning with global trends toward sustainability.

– Key Points:

– Inquire about the supplier’s recycling processes.

– Assess their commitment to reducing carbon footprints during production and transport.

By following this checklist, B2B buyers can navigate the complexities of sourcing vav plastics effectively, ensuring they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for vav plastics Sourcing

Understanding the cost structure and pricing dynamics for sourcing Vav Plastics products is essential for B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This analysis provides insight into the key cost components, price influencers, and practical tips for buyers to enhance their procurement strategies.

What Are the Key Cost Components in Vav Plastics Sourcing?

-

Materials: The primary materials used in the production of Vav Plastics products include PET, PETE, LDPE, HDPE, and PP. Fluctuations in the prices of these raw materials can significantly impact overall costs. Buyers should monitor market trends and negotiate fixed pricing agreements when possible to mitigate risks associated with price volatility.

-

Labor Costs: Labor is a significant component in manufacturing processes, especially in custom designs and engineering. Skilled labor for blow molding and custom mold-making can lead to variations in pricing. Understanding local labor market conditions can provide leverage in negotiations.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. For international buyers, understanding the overhead cost structures in different regions can lead to more informed sourcing decisions.

-

Tooling Costs: Custom mold creation can require substantial initial investments. Buyers should consider these costs when assessing pricing, especially if they require unique bottle designs. Long-term partnerships can help in spreading these costs over larger production runs.

-

Quality Control (QC): Ensuring product quality is non-negotiable, and associated QC costs should be factored into pricing. Certifications for quality and sustainability may also affect pricing structures, as suppliers with certifications may charge a premium for their products.

-

Logistics: Transportation costs can vary widely based on the shipping method, distance, and Incoterms. International buyers should consider logistics as a critical cost component, particularly when sourcing from regions with higher shipping rates.

-

Margin: Suppliers typically include a margin in their pricing to ensure profitability. Understanding the typical margins for similar products in the market can help buyers negotiate better deals.

What Influences Pricing for Vav Plastics Products?

-

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with higher order volumes. Buyers should assess their needs and consider bulk purchasing to achieve better pricing.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. Clear communication of specifications can help avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and recognized certifications may come at a premium. Buyers should weigh the benefits of quality against costs, especially in regulated industries like pharmaceuticals and food & beverage.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Long-term partnerships with established suppliers can offer better pricing stability.

-

Incoterms: Understanding the implications of Incoterms is crucial for pricing. Different terms can shift the responsibility for shipping and insurance costs, impacting total expenses.

What Tips Can Help Buyers in Negotiation and Cost-Efficiency?

-

Negotiate Wisely: Prepare for negotiations by understanding market prices and the supplier’s cost structure. Leverage your purchasing power by committing to larger orders or longer contracts.

-

Consider Total Cost of Ownership (TCO): Look beyond initial pricing. Consider logistics, storage, and potential quality issues that could arise over time. A lower upfront price may lead to higher TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and local regulations that may affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Build Long-Term Relationships: Cultivating strong relationships with suppliers can lead to better pricing, priority service, and access to innovative products.

Disclaimer

The prices and cost structures discussed herein are indicative and may vary based on real-time market conditions, specific buyer requirements, and supplier negotiations. Always conduct thorough market research and consult with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing vav plastics With Other Solutions

Understanding Alternative Solutions to Vav Plastics

In the rapidly evolving landscape of packaging solutions, businesses are increasingly seeking alternatives to traditional materials like PET and PETE plastic bottles manufactured by Vav Plastics. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational needs and sustainability goals. This analysis compares Vav Plastics with two viable alternatives: recycled paperboard packaging and glass bottles, providing insights into their respective advantages and drawbacks.

| Comparison Aspect | Vav Plastics | Recycled Paperboard Packaging | Glass Bottles |

|---|---|---|---|

| Performance | Excellent durability and lightweight; good barrier properties for many products | Moderate durability; suitable for dry goods and some liquids | High durability and excellent barrier properties; reusable |

| Cost | Competitive manufacturing costs; variable based on custom designs | Generally lower production costs; eco-friendly options may have a premium | Higher initial costs due to material and transport; potential for reuse savings |

| Ease of Implementation | Custom designs require engineering input; established supply chains available | Easier to source and implement; less technical design required | Requires careful handling and specific logistics for transport |

| Maintenance | Low maintenance; recyclable; offers various customization options | Requires proper storage to maintain structural integrity; recyclable | Can break easily; requires proper cleaning for reuse |

| Best Use Case | Ideal for beverages, pharmaceuticals, and personal care products | Best for dry goods, snacks, and lightweight items | Excellent for beverages, high-end cosmetics, and specialty foods |

Pros and Cons of Alternative Solutions

Recycled Paperboard Packaging

Recycled paperboard is an eco-friendly alternative that appeals to brands focused on sustainability. Its lightweight nature reduces transportation costs and carbon footprint. However, it lacks the durability of plastic and is not suitable for all liquid products. For dry goods and non-perishable items, it provides a cost-effective solution but may not offer the same level of protection as Vav Plastics’ offerings.

Illustrative image related to vav plastics

Glass Bottles

Glass bottles are renowned for their premium feel and excellent barrier properties, making them a preferred choice for high-end products. Their reusability also adds to their sustainability credentials, appealing to eco-conscious consumers. However, the higher production and transport costs can be a significant drawback, especially for larger-scale operations. Additionally, the risk of breakage during handling and transport requires careful logistics management.

How to Choose the Right Solution for Your Business Needs

When selecting a packaging solution, B2B buyers should consider their specific product requirements, target market, and sustainability goals. Vav Plastics offers custom PET and PETE solutions that provide excellent durability and design flexibility, making them ideal for a wide range of industries. However, if sustainability is a primary concern, exploring recycled paperboard or glass may be worthwhile, especially for products that can benefit from eco-friendly branding. Ultimately, the decision should align with the operational strategy, budget constraints, and long-term goals of the business.

Essential Technical Properties and Trade Terminology for vav plastics

What Are the Critical Technical Properties of Vav Plastics?

Understanding the technical specifications of vav plastics is essential for B2B buyers, especially when selecting materials for manufacturing and packaging. Here are some of the most critical properties to consider:

-

Material Grade

Vav plastics are primarily manufactured from PET (Polyethylene Terephthalate) and PETE (Polyethylene Terephthalate Ester). These materials are known for their strength, lightweight nature, and recyclability. Material grade is vital because it affects the durability, clarity, and safety of the final product, particularly in food and pharmaceutical applications. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during the manufacturing process. For instance, a neck diameter tolerance of ±0.5mm ensures that closures fit securely. Maintaining strict tolerances is crucial for B2B buyers to ensure compatibility with existing machinery and reduce product waste. -

Container Capacity

The capacity of vav plastic bottles can range from 50ml to 1500ml. Understanding the required capacity is essential for buyers to meet market demand and optimize storage and transportation. This specification also helps in ensuring that the packaging meets regulatory requirements for specific industries, such as pharmaceuticals or beverages. -

Color Options and Customization

Vav plastics offer various color options, including clear, blue, and purple. The ability to customize colors and designs allows brands to differentiate their products in competitive markets. This flexibility is particularly important for B2B buyers looking to enhance brand visibility and consumer appeal. -

Recyclability

Sustainability is a growing concern in global markets. Vav plastics are produced from recyclable materials, which not only meet environmental regulations but also appeal to eco-conscious consumers. B2B buyers should prioritize recyclability as it can enhance brand reputation and align with corporate social responsibility goals.

What Are the Common Trade Terms in the Vav Plastics Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the plastics sector. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of vav plastics, understanding OEM relationships can help buyers identify reliable suppliers and assess the quality of components used in their products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchasing strategies effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to provide pricing for specific products or services. For B2B buyers, issuing an RFQ is a strategic step to compare prices and ensure they are getting the best deal for their required plastic products. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers for the delivery of goods under sales contracts. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and responsibilities, ensuring smooth transactions across borders. -

Blow Molding

This is a manufacturing process used to create hollow plastic parts, such as bottles. Understanding blow molding techniques is vital for buyers as it influences product design, material selection, and production efficiency.

By grasping these essential properties and terms, B2B buyers can make more informed decisions when sourcing vav plastics, ensuring that they select products that meet their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the vav plastics Sector

What are the Current Market Dynamics and Key Trends Affecting the Vav Plastics Sector?

The vav plastics sector is experiencing significant transformation driven by global economic shifts, evolving consumer preferences, and technological advancements. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek competitive advantages, understanding these market dynamics is crucial. Notably, the demand for PET and PETE plastic bottles is surging across industries, including food and beverage, pharmaceuticals, and cosmetics. This trend is fueled by the growing need for lightweight, durable packaging solutions that offer convenience and safety.

Emerging B2B tech trends include the adoption of digital supply chain platforms and advanced manufacturing technologies such as automation and 3D printing. These innovations facilitate faster production cycles, reduce costs, and enhance customization capabilities. Buyers are increasingly looking for manufacturers that can provide tailored solutions, reflecting a shift towards more personalized service in sourcing strategies. Additionally, the rise of e-commerce is pushing companies to invest in packaging that not only protects products during transit but also enhances brand visibility on digital platforms.

Furthermore, geopolitical factors, such as trade regulations and tariffs, are influencing sourcing strategies. International buyers must remain agile, adapting to changes in supply chain dynamics while ensuring compliance with local regulations. As the market continues to evolve, staying informed about these trends will enable B2B buyers to make strategic decisions that align with their business objectives.

Illustrative image related to vav plastics

How is Sustainability and Ethical Sourcing Reshaping the Vav Plastics Market?

Sustainability has become a pivotal concern in the vav plastics sector, affecting sourcing decisions and operational strategies. The environmental impact of plastic waste is prompting companies to prioritize ethical sourcing and sustainable practices. For B2B buyers, partnering with manufacturers who adhere to eco-friendly principles is not only a responsible choice but also a competitive advantage. The demand for recyclable materials, particularly PET and PETE, is on the rise as businesses seek to align with consumer expectations for sustainability.

Ethical supply chains are gaining importance, with buyers increasingly scrutinizing their suppliers’ practices. Certifications such as ISO 14001 for environmental management and materials that meet recycling standards are becoming essential criteria in supplier selection. Moreover, the push for circular economy models encourages companies to source recycled plastics, thus reducing their carbon footprint and promoting resource efficiency.

Investing in sustainable packaging solutions not only mitigates environmental impact but can also enhance brand loyalty. Companies that communicate their commitment to sustainability effectively can differentiate themselves in crowded marketplaces. Therefore, B2B buyers should prioritize partnerships with suppliers who demonstrate a genuine commitment to sustainable practices and ethical sourcing.

What is the Evolution of the Vav Plastics Sector?

The vav plastics sector has undergone significant evolution since its inception, marked by technological advancements and shifts in consumer behavior. Established in 2008, companies like Vav Plastics have played a pivotal role in the development of customized plastic solutions, primarily focusing on PET and PETE manufacturing. Initially, the sector was characterized by standard product offerings, but as market demands evolved, so did the need for customization and innovation.

The introduction of advanced manufacturing techniques, such as blow molding and CAD/CAM design, has revolutionized the production process, allowing for greater flexibility and efficiency. As global awareness of environmental issues grew, the sector began to shift towards more sustainable practices, including the use of recycled materials and the implementation of ethical sourcing strategies. This evolution reflects a broader trend within the plastics industry, where adaptability and sustainability are becoming key drivers of success in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of vav plastics

-

How do I ensure the quality of vav plastics products?

To ensure the quality of products from Vav Plastics, consider requesting detailed specifications and certifications relevant to your industry, such as ISO or FDA compliance. Additionally, conduct a site visit or request samples to evaluate the material’s integrity and manufacturing processes firsthand. Engaging in a dialogue with the supplier about their quality control measures, such as testing procedures and materials used, can further assure you of the product’s quality. -

What customization options are available for plastic bottles?

Vav Plastics offers extensive customization options for plastic bottles, including shape, color, and size. Buyers can specify dimensions like neck diameter and body diameter, with maximum capacities reaching up to 1500ml. The company provides a full design service, from conceptual sketches to CAD designs and mock-ups, ensuring your vision is realized. Discussing your specific needs early in the process can facilitate a smoother development experience. -

What are the minimum order quantities (MOQs) for vav plastics products?

Minimum order quantities can vary based on the type of product and customization requirements. Typically, Vav Plastics accommodates both small and large orders, but it’s advisable to confirm specific MOQs during initial discussions. Understanding these requirements helps in budgeting and planning your inventory more effectively, especially when catering to diverse markets in regions like Africa and South America. -

What payment terms are available for international buyers?

Vav Plastics generally offers flexible payment terms to accommodate international buyers. Common options include upfront payment, partial payment before shipment, or payment upon delivery. Discussing payment terms early in negotiations ensures clarity and builds trust. Be sure to consider the implications of currency exchange rates and transaction fees when planning your budget. -

How can I effectively vet a supplier like Vav Plastics?

Vetting a supplier involves thorough research and due diligence. Look for reviews and testimonials from existing clients, evaluate their years of experience, and check for industry certifications. It’s also beneficial to assess their manufacturing capabilities and quality control processes. Establishing communication can provide insights into their responsiveness and customer service levels. -

What logistics options are available for shipping vav plastics products?

Vav Plastics offers various logistics options depending on the destination and urgency of the shipment. Common methods include sea freight for bulk orders and air freight for expedited needs. Understanding the logistics options available can help you plan for delivery times and costs, particularly when importing to regions like the Middle East or Europe. -

What sustainability practices does Vav Plastics adhere to?

Vav Plastics is committed to sustainability, utilizing recyclable materials such as PET and PETE in their manufacturing processes. They focus on reducing carbon emissions by producing locally in California, which benefits North American clients. Engaging with suppliers on their sustainability practices can enhance your brand’s image and meet the growing demand for environmentally responsible products. -

How can I address potential supply chain disruptions when sourcing from Vav Plastics?

To mitigate supply chain disruptions, maintain open communication with Vav Plastics regarding production timelines and potential challenges. Implementing a buffer stock strategy can also help manage unexpected delays. Additionally, consider diversifying your supplier base to minimize reliance on a single source, ensuring that you can maintain product availability across different markets.

Top 6 Vav Plastics Manufacturers & Suppliers List

1. Vav Plastics – PET Bottles & Jars

Domain: vavplastics.com

Registered: 2009 (16 years)

Introduction: Vav Plastics specializes in manufacturing PET and PETE plastic bottles and jars for all industries. They utilize blow molding for production. Custom design services are available from concept to completion, and molds can be client-supplied or custom made. The company emphasizes perfect quality and technical execution in their products.

2. Vav Plastics – Recycled Plastic Flakes and Pellets

Domain: vavplastik.com

Registered: 2019 (6 years)

Introduction: Vav Plastics is a licensed and accredited importer of waste plastics and exporter of recycled plastic flakes and pellets. They primarily process LDPE (Low-Density Polyethylene) and also handle some PP (Polypropylene) and HDPE (High-Density Polyethylene).

3. Vav Plastics – PET & PETE Bottles

Domain: vavwater.com

Registered: 2008 (17 years)

Introduction: Vav Plastics specializes in manufacturing PET and PETE plastic bottles and jars for all industries utilizing PET and PETE bottles. Manufacturing is accomplished through blow molding.

4. VAV Plastics – Employee Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, VAV Plastics – Employee Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Vav Plastics – PET & PETE Bottles and Jars

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Vav Plastics – PET & PETE Bottles and Jars, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Vav Plastics – East Coast Expansion

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Vav Plastics – East Coast Expansion, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for vav plastics

In conclusion, the strategic sourcing of vav plastics presents a multitude of opportunities for international B2B buyers seeking high-quality, customizable plastic solutions. With a strong focus on PET and PETE bottle manufacturing, Vav Plastics not only emphasizes perfect quality through precise blow molding techniques but also offers comprehensive design capabilities from concept to completion. This adaptability ensures that businesses across diverse industries—ranging from food and beverage to pharmaceuticals—can find tailored solutions that meet their unique requirements.

As global markets increasingly prioritize sustainability, Vav Plastics stands out by reducing carbon footprints through localized production in California and offering recyclable materials. This commitment to environmental responsibility resonates particularly well with buyers in Africa, South America, the Middle East, and Europe, who are navigating the complexities of modern supply chains.

Looking ahead, the potential for growth and innovation in the plastic manufacturing sector is significant. We encourage international buyers to engage with Vav Plastics to explore strategic partnerships that can enhance their product offerings while ensuring quality and sustainability. Connect today to discover how Vav Plastics can contribute to your success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.