Choosing Your Vacuum Tank: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for vacuum tank

In an increasingly interconnected world, sourcing the right vacuum tank can be a daunting challenge for international B2B buyers. Whether you’re in the bustling markets of Africa, the growing economies of South America, or the resource-rich regions of the Middle East and Europe, understanding the nuances of vacuum tank products is essential. This comprehensive guide delves into various types of vacuum tanks—including portable restroom trucks, septic service vehicles, and customizable slide-in units—catering to diverse operational needs.

Throughout this guide, we will explore key applications, essential components, and the importance of supplier vetting to ensure quality and reliability. Additionally, we will address cost considerations, financing options, and lead times for production, empowering you to make informed purchasing decisions.

Navigating the global market for vacuum tanks requires not just knowledge of products but also an understanding of regional compliance and operational demands. This guide equips you with the insights needed to confidently partner with suppliers who align with your specific requirements, enabling your business to thrive in a competitive landscape. By leveraging the information presented here, you can streamline your procurement processes and enhance your operational efficiency, ensuring that you choose the best solutions for your vacuum tank needs.

Understanding vacuum tank Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Restroom Vacuum Trucks | Designed for transporting waste from portable restrooms | Event management, construction sites | Pros: High capacity, mobility. Cons: Initial investment can be high. |

| Septic Service Trucks | Built for handling liquid waste, often multi-compartment | Waste management, residential services | Pros: Dependable, versatile. Cons: Maintenance can be labor-intensive. |

| Slide-In Vacuum Tanks | Lightweight, customizable units that fit in pickup beds | Small-scale waste collection, service industries | Pros: Flexibility, ease of use. Cons: Limited capacity compared to full trucks. |

| Hydro Excavation Tanks | Specialized for non-destructive digging using high pressure | Utility installations, pipeline projects | Pros: Safe digging, minimal ground disturbance. Cons: Higher operational costs. |

| Vacuum Tank Components | Essential parts for vacuum operations, including pumps and hatches | Repair services, custom builds | Pros: Critical for efficiency, wide variety. Cons: Quality can vary by supplier. |

What Are Portable Restroom Vacuum Trucks and Their Key Features?

Portable restroom vacuum trucks are designed primarily for the efficient collection and transportation of waste from portable toilets. These trucks typically feature high-capacity tanks ranging from 300 to 5,500 gallons, allowing for extensive service runs without frequent emptying. B2B buyers should consider the truck’s mobility and low maintenance needs, making them ideal for events, construction sites, and any location requiring temporary restroom facilities.

How Do Septic Service Trucks Function and Where Are They Used?

Septic service trucks are specifically engineered for liquid waste management, featuring multi-compartment tanks that allow for the separation of different waste types. These trucks are essential in the waste management industry and are commonly used for residential septic services and commercial waste removal. When purchasing, buyers should evaluate the truck’s reliability and capacity, as these factors directly influence service efficiency.

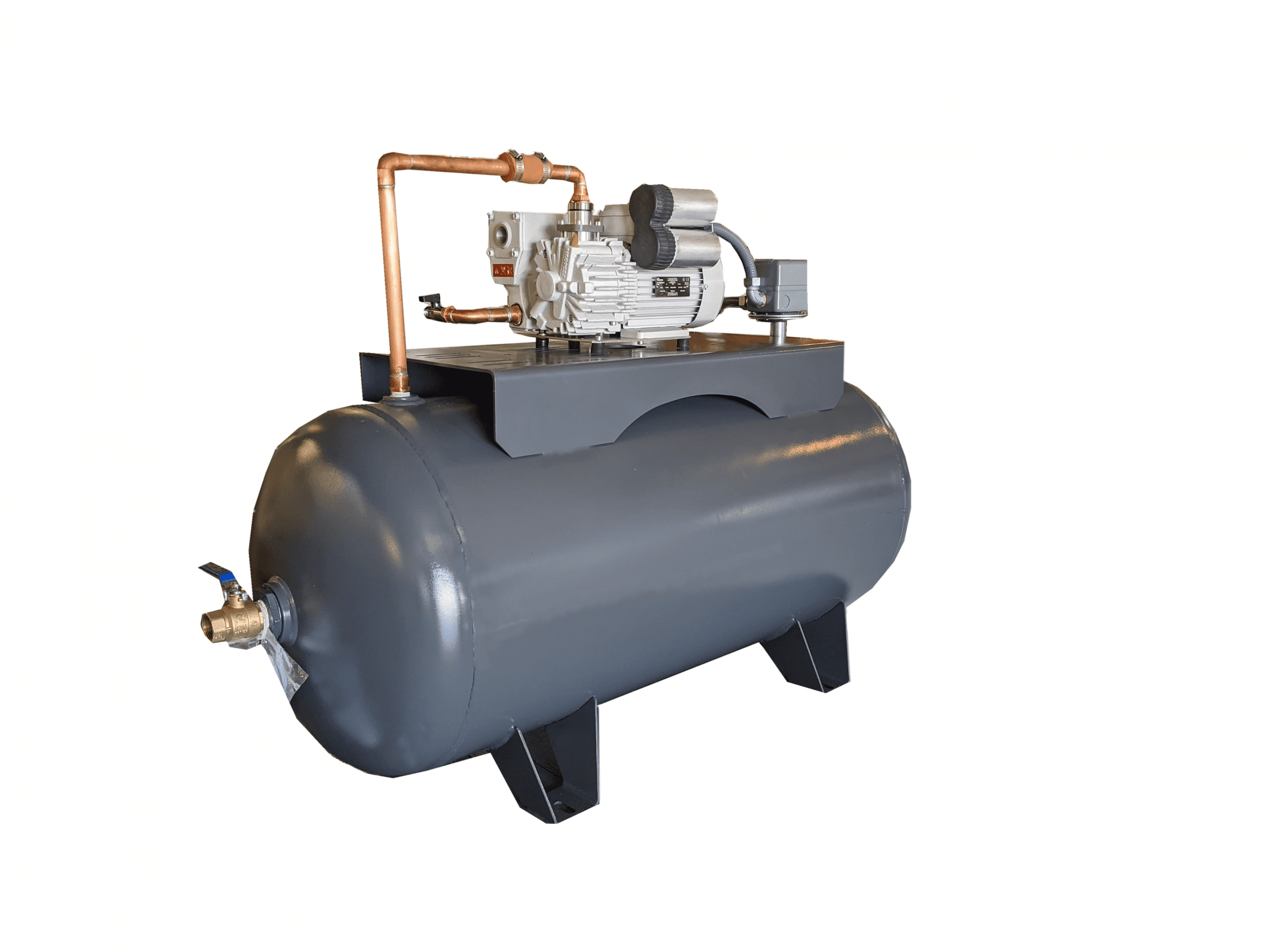

Illustrative image related to vacuum tank

What Are the Advantages of Slide-In Vacuum Tanks?

Slide-in vacuum tanks are lightweight units that can fit into the bed of a standard pickup truck, providing a flexible solution for small-scale waste collection. They are customizable in size and configuration, making them suitable for various service industries, including plumbing and small waste management operations. Buyers should consider their specific capacity needs and the ease of installation, as these factors will affect operational efficiency.

Why Choose Hydro Excavation Tanks for Your Projects?

Hydro excavation tanks utilize high-pressure water to safely excavate soil without damaging underground utilities. This method is particularly beneficial for utility installations and pipeline projects where precision is crucial. B2B buyers should weigh the benefits of reduced ground disturbance against the higher operational costs associated with hydro excavation, ensuring it aligns with project budgets and timelines.

What Should You Know About Vacuum Tank Components?

Vacuum tank components are crucial for the effective operation of various vacuum systems, including pumps, hatches, and valves. These components are essential for ensuring the safe and efficient transportation of liquids and waste materials. When sourcing components, buyers should focus on the quality and reliability of parts, as subpar components can lead to operational inefficiencies and increased maintenance costs.

Key Industrial Applications of vacuum tank

| Industry/Sector | Specific Application of Vacuum Tank | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Waste Management | Septic Service Trucks | Efficient liquid waste collection and disposal | Tank capacity, material durability, and maintenance support |

| Construction | Hydro Excavation Units | Safe and effective soil removal | Pump efficiency, tank size, and customization options |

| Event Management | Portable Restroom Trucks | Reliable sanitation solutions for large events | Tank mobility, ease of cleaning, and service frequency |

| Oil and Gas | Frac Tanks | Safe transportation of liquids in drilling operations | Compliance with safety standards and material specifications |

| Food and Beverage | Grease Trap Trucks | Effective waste management for food processing | Tank design for easy access, maintenance, and cleaning capabilities |

How Are Vacuum Tanks Used in Waste Management?

In the waste management sector, vacuum tanks are primarily utilized in septic service trucks. These tanks facilitate the efficient collection and transportation of liquid waste from residential and commercial properties. The critical requirements for buyers in this sector include tank capacity (typically ranging from 300 to 5,500 gallons), material durability to withstand corrosive waste, and reliable maintenance support. For international buyers, especially in regions like Africa and South America, understanding local regulations regarding waste disposal is essential to ensure compliance and operational efficiency.

What Role Do Vacuum Tanks Play in Construction?

Vacuum tanks are integral to hydro excavation units used in the construction industry. These units employ high-pressure water and vacuum technology to safely excavate soil without damaging underground utilities. For B2B buyers, key considerations include pump efficiency, tank size, and the availability of customization options to meet specific project requirements. In regions like the Middle East, where ground conditions can be challenging, the ability to adapt vacuum tanks for various soil types is particularly valuable.

How Are Portable Restroom Trucks Beneficial for Event Management?

In event management, portable restroom trucks equipped with vacuum tanks provide essential sanitation solutions for large gatherings. These tanks ensure reliable waste storage and facilitate easy cleaning and maintenance. Buyers should prioritize tank mobility, ease of cleaning, and the frequency of service when sourcing these units. For international buyers, especially in Europe, understanding the cultural expectations around sanitation can influence purchasing decisions, making it vital to offer high-quality, aesthetically pleasing options.

How Are Vacuum Tanks Used in Oil and Gas Operations?

In the oil and gas industry, vacuum tanks are commonly used as frac tanks for the safe transportation of liquids involved in drilling operations. These tanks must comply with stringent safety standards and material specifications to handle potentially hazardous substances. B2B buyers should focus on sourcing tanks that meet local regulations and industry best practices, particularly in regions like Saudi Arabia, where regulatory compliance is critical for operational success.

What Are the Applications of Vacuum Tanks in Food and Beverage?

In the food and beverage sector, vacuum tanks are crucial for grease trap trucks that manage waste from food processing facilities. These tanks need to be designed for easy access, maintenance, and cleaning to ensure hygiene standards are met. Buyers should evaluate the tank’s design and capacity to ensure it aligns with their operational needs. In regions with strict food safety regulations, such as Europe, compliance with health standards is a significant consideration when sourcing vacuum tanks.

3 Common User Pain Points for ‘vacuum tank’ & Their Solutions

Scenario 1: Inconsistent Performance of Vacuum Tanks in Harsh Environments

The Problem: B2B buyers often face challenges with vacuum tanks that underperform in extreme conditions, such as high temperatures or corrosive environments. For instance, a company in Saudi Arabia may need to transport waste in sweltering heat, leading to tank failures or reduced efficiency. This can result in downtime, increased operational costs, and a negative impact on service reliability.

The Solution: To mitigate these issues, it’s crucial for buyers to select vacuum tanks that are specifically designed for harsh environments. Buyers should prioritize materials that resist corrosion, such as stainless steel or high-grade aluminum. Additionally, investing in vacuum tanks with robust insulation can help maintain performance in extreme temperatures. It’s also advisable to consult with manufacturers about the specific environmental conditions the tanks will face and request tanks that have been tested under similar circumstances. Regular maintenance and inspections can further enhance durability and performance.

Scenario 2: Difficulty in Sourcing Replacement Parts and Accessories

The Problem: A common pain point for businesses utilizing vacuum tanks is the challenge of sourcing replacement parts and accessories when repairs are needed. For instance, a septic service company in Brazil may find that the lead time for crucial components like pumps or valves is excessively long, leading to service interruptions and lost revenue.

The Solution: To ensure a steady supply of replacement parts, buyers should establish relationships with reliable manufacturers or suppliers who offer comprehensive inventories of vacuum tank components. It’s advisable to consider companies that provide aftermarket parts as well, as they often have more flexible sourcing options. Buyers can also benefit from creating a maintenance inventory, stocking essential components based on usage patterns. Additionally, utilizing a vendor who can provide expedited shipping options can minimize downtime in critical situations.

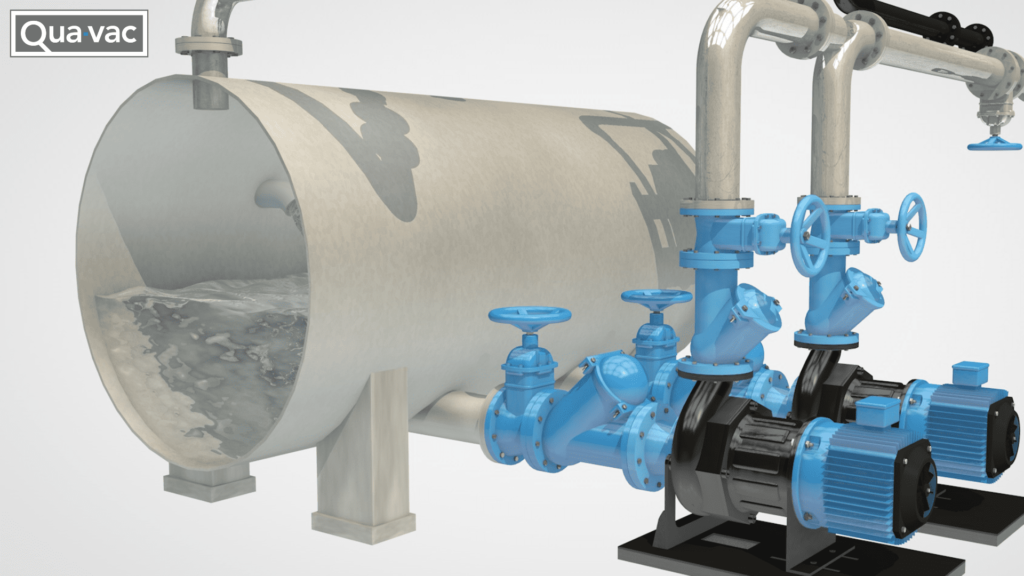

Illustrative image related to vacuum tank

Scenario 3: Compliance with Environmental Regulations

The Problem: B2B buyers frequently grapple with stringent environmental regulations concerning waste management and transportation. A vacuum tank used for septic services in Europe, for example, must comply with local laws regarding emissions and waste disposal. Non-compliance can lead to hefty fines and damage to a company’s reputation.

The Solution: To navigate these regulatory challenges, businesses should conduct thorough research on the environmental standards applicable in their regions. Engaging with legal experts or environmental consultants can provide insights into compliance requirements. When purchasing vacuum tanks, buyers should select models that are certified to meet or exceed these standards. Additionally, working closely with manufacturers who are knowledgeable about regulatory compliance can ensure that the tanks are equipped with the necessary technology to minimize environmental impact, such as advanced filtration systems or low-emission engines. Regular training for staff on compliance practices is also essential to uphold standards consistently.

By addressing these common pain points with strategic solutions, B2B buyers can enhance the efficiency and reliability of their vacuum tank operations, leading to improved service delivery and customer satisfaction.

Strategic Material Selection Guide for vacuum tank

What Are the Key Properties of Common Materials Used in Vacuum Tanks?

When selecting materials for vacuum tanks, the choice often hinges on several critical properties such as temperature and pressure ratings, corrosion resistance, and overall durability. The most common materials used in vacuum tank construction include aluminum, mild steel, stainless steel, and composite materials. Each material has its unique characteristics that influence its performance and suitability for specific applications.

How Does Aluminum Compare as a Material for Vacuum Tanks?

Aluminum is a popular choice for vacuum tanks due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 300°F (149°C) and can handle moderate pressure levels. The primary advantage of aluminum is its resistance to rust, making it ideal for applications involving liquid waste and other corrosive substances. However, aluminum can be more expensive than mild steel and may require specialized welding techniques, which can complicate manufacturing.

For international buyers, especially in regions like Africa and the Middle East, aluminum tanks may align with local preferences for lightweight and efficient solutions. Compliance with standards such as ASTM can also be a consideration, as many manufacturers adhere to these guidelines for quality assurance.

What Are the Benefits and Limitations of Mild Steel in Vacuum Tanks?

Mild steel is often chosen for its strength and cost-effectiveness. It can withstand high pressures and has a temperature rating of around 400°F (204°C). However, mild steel is prone to rust and corrosion, which necessitates protective coatings or regular maintenance. This material is suitable for applications where the tank will be used for non-corrosive media.

Illustrative image related to vacuum tank

For B2B buyers in regions like South America and Europe, the lower cost of mild steel may be appealing, but they must also consider the implications of corrosion in their specific environments. Compliance with local standards, such as DIN in Europe, is crucial to ensure safety and reliability.

How Does Stainless Steel Stand Out in Vacuum Tank Applications?

Stainless steel is renowned for its exceptional corrosion resistance and durability, making it suitable for a wide range of applications, including those involving harsh chemicals. With a temperature rating that can exceed 600°F (316°C), stainless steel tanks can handle high-pressure environments effectively. The primary drawback is the higher cost and complexity in manufacturing, which can lead to longer lead times.

For international buyers, particularly in the Middle East and Europe, stainless steel tanks may be preferred for their longevity and compliance with stringent safety standards. Buyers should ensure that their suppliers meet relevant certifications, such as ISO standards, to guarantee quality.

What Role Do Composite Materials Play in Vacuum Tank Construction?

Composite materials, often a blend of resin and fiberglass, are gaining traction due to their lightweight properties and resistance to corrosion. They can handle moderate temperatures and pressures, making them suitable for specific applications. The main advantage is their resistance to chemical degradation, but they can be more expensive and less durable compared to metals.

For B2B buyers in emerging markets, the use of composite materials may be limited by availability and higher costs. However, as industries evolve, these materials may become more common, especially for specialized applications.

Summary Table of Material Options for Vacuum Tanks

| Material | Typical Use Case for Vacuum Tank | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Liquid waste transport | Lightweight and corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Mild Steel | Non-corrosive media transport | Cost-effective and strong | Prone to rust, requires maintenance | Low |

| Stainless Steel | Harsh chemical transport | Exceptional durability and corrosion resistance | High cost, complex manufacturing | High |

| Composite | Specialized applications (e.g., chemicals) | Corrosion-resistant and lightweight | Higher cost, less durable | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used in vacuum tanks, enabling informed decisions that align with their operational needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for vacuum tank

What Are the Key Stages in the Manufacturing Process of Vacuum Tanks?

The manufacturing of vacuum tanks involves a series of well-defined stages that ensure the final product meets the necessary standards for quality and functionality. The main stages typically include:

1. Material Preparation

The initial stage focuses on selecting and preparing the materials, which are primarily aluminum or steel. These materials are chosen for their strength, durability, and corrosion resistance. Suppliers must provide certificates of compliance and material test reports to verify that the materials meet international standards. Proper inventory management is crucial at this stage to ensure that only high-quality materials are used.

2. Forming

Once materials are prepared, they undergo various forming techniques. This includes processes such as cutting, bending, and welding. Advanced technologies like CNC machining and robotic welding are increasingly utilized for their precision and efficiency. Forming ensures that the components are shaped accurately to fit together seamlessly during assembly. It’s essential to maintain tolerances as specified in the design blueprints to avoid issues in later stages.

3. Assembly

During the assembly stage, individual components are brought together to form the vacuum tank. This process often involves bolting, welding, and sealing various parts, such as the tank body, manways, and shutoff valves. Skilled technicians must follow detailed assembly instructions to ensure that all components fit correctly and function as intended. Additionally, the assembly area should be kept clean and organized to prevent contamination and defects.

4. Finishing

The finishing stage involves applying protective coatings, such as paint or anodization, to enhance corrosion resistance and aesthetics. This step may also include polishing and cleaning the tank to ensure it meets visual and functional standards. Inspections are conducted to confirm that the finishing process adheres to specifications and that the tank is ready for delivery.

What Quality Assurance Practices Are Commonly Followed in Vacuum Tank Manufacturing?

Quality assurance is critical in the manufacturing of vacuum tanks, as it ensures that products meet both international and industry-specific standards. Key practices include:

International Standards

Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with ISO standards demonstrates a commitment to quality and customer satisfaction. Other relevant standards may include CE marking for products sold in Europe and API standards for tanks used in the oil and gas industry.

Industry-Specific Standards

Specific industries may require additional certifications. For example, tanks used in hazardous environments may need to meet regulations set forth by organizations such as the National Fire Protection Association (NFPA) or the Occupational Safety and Health Administration (OSHA).

What Are the Key Quality Control Checkpoints in Vacuum Tank Manufacturing?

Quality control (QC) is embedded throughout the manufacturing process with several critical checkpoints:

Incoming Quality Control (IQC)

Before production begins, materials and components undergo inspection to ensure they meet specified standards. This includes verifying material certifications, dimensional checks, and visual inspections for defects. Only materials that pass this inspection are approved for use.

In-Process Quality Control (IPQC)

During manufacturing, various inspections are conducted at different stages to monitor compliance with established standards. This may involve checking weld integrity, dimensional accuracy, and functionality of components. Any discrepancies must be addressed immediately to prevent defects in the final product.

Final Quality Control (FQC)

Once the vacuum tank is fully assembled, a comprehensive final inspection is performed. This includes pressure testing to ensure that the tank can withstand operational demands, as well as functional testing of valves and pumps. FQC is crucial for confirming that the tank meets all specifications before it is shipped to customers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to conduct due diligence to ensure their suppliers maintain rigorous quality control practices. Here are several actionable steps:

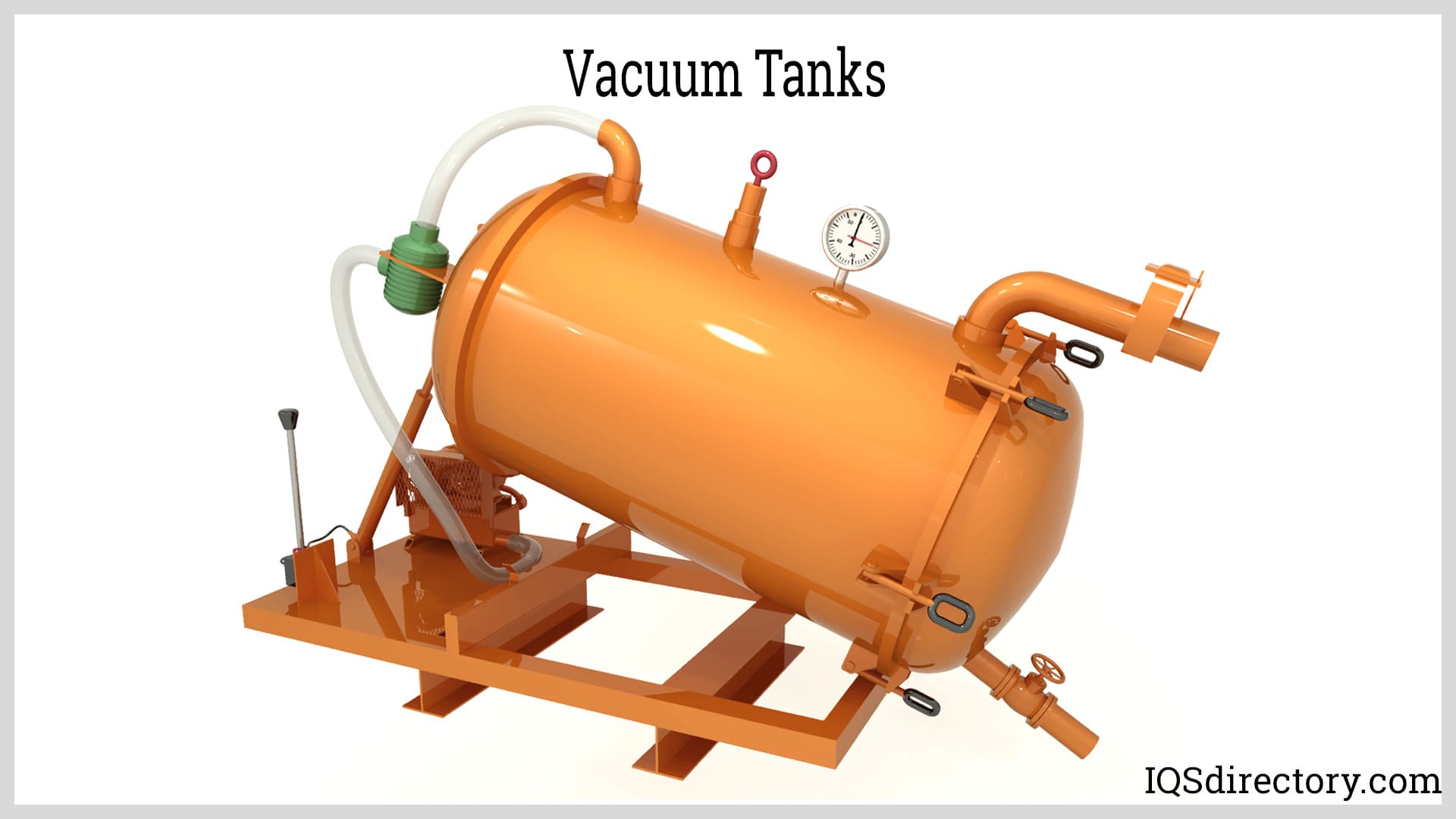

Illustrative image related to vacuum tank

Supplier Audits

Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Auditors should check for compliance with international standards and evaluate the effectiveness of their quality management systems.

Requesting Quality Reports

Buyers should request detailed quality reports, including results from IQC, IPQC, and FQC. These documents provide transparency regarding the supplier’s quality assurance processes and any issues encountered during manufacturing.

Third-Party Inspections

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. This is particularly important for buyers in regions with stringent regulations, such as Europe and the Middle East, where compliance with local standards is essential.

What Are the Quality Control Nuances for International Buyers in Regions Like Africa and South America?

International B2B buyers must be aware of specific nuances when dealing with suppliers from different regions. Buyers in Africa and South America may encounter challenges related to:

Regulatory Compliance

Understanding the regulatory landscape in the supplier’s country is crucial. Different regions may have varying compliance requirements, which can affect the quality and certification of vacuum tanks. Buyers should ensure that suppliers are familiar with the regulations applicable in their target markets.

Cultural and Communication Differences

Effective communication is key in international transactions. Buyers should establish clear expectations regarding quality standards and certifications. Additionally, language barriers may hinder understanding, so it may be beneficial to engage local representatives who can bridge these gaps.

Conclusion

The manufacturing processes and quality assurance practices for vacuum tanks are intricate and essential for ensuring reliability and performance. By understanding these processes and implementing thorough verification methods, B2B buyers can make informed decisions when sourcing vacuum tanks from international suppliers. This diligence not only safeguards investments but also helps build long-lasting partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vacuum tank’

When sourcing a vacuum tank, a methodical approach is essential to ensure you select a product that meets your operational needs and complies with industry standards. This guide provides a checklist of critical steps to facilitate informed purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of a successful procurement process. Consider the intended use of the vacuum tank, such as for septic services or portable restroom operations, and determine the necessary capacity, usually ranging from 300 to 5,500 gallons. Additionally, identify whether you need a single or multi-compartment tank based on the type of waste you will be handling.

Step 2: Research Potential Suppliers

Start by compiling a list of reputable manufacturers and suppliers. Look for companies with a solid track record in producing high-quality vacuum tanks, such as Robinson Vacuum Tanks or Slide In Queen. Pay attention to their market presence, customer reviews, and case studies to gauge reliability and performance.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers adhere to relevant industry standards and possess necessary certifications. This includes compliance with safety regulations, environmental standards, and quality management systems. Verified certifications indicate a supplier’s commitment to quality and safety, which is crucial for the safe handling of liquid waste.

Step 4: Request Detailed Quotes

Once you have identified potential suppliers, request detailed quotes that outline the costs, lead times, and included features. Compare these quotes not only on price but also on the value offered, such as warranties, maintenance services, and customization options. Understanding the total cost of ownership will help in making a more informed decision.

Illustrative image related to vacuum tank

Step 5: Inspect Product Quality

Before finalizing your purchase, it’s important to inspect product quality. If possible, arrange for a factory visit or request samples of the vacuum tanks. Look for signs of durability, such as the material used (aluminum vs. steel), welding quality, and the overall design of the tank and its components, which can significantly impact long-term performance.

Step 6: Assess After-Sales Support and Maintenance

Inquire about the after-sales support offered by the supplier. A reliable supplier should provide comprehensive maintenance services, access to spare parts, and technical support. This is particularly important for vacuum tanks that require regular maintenance to ensure optimal operation and longevity.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, carefully review and finalize the purchase agreement. Ensure that all terms, including delivery schedules, payment terms, and warranty details, are clearly outlined. A well-defined contract protects both parties and ensures that expectations are met throughout the procurement process.

By following these steps, you can confidently source a vacuum tank that meets your operational requirements and adheres to industry standards, ultimately contributing to the efficiency and safety of your operations.

Comprehensive Cost and Pricing Analysis for vacuum tank Sourcing

What Are the Key Cost Components in Vacuum Tank Manufacturing?

When sourcing vacuum tanks, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Aluminum tanks tend to be lighter and more corrosion-resistant than steel, but they can be more expensive. High-quality components, such as pumps and valves, also contribute to the overall material costs.

-

Labor: Labor costs vary based on geographic location and the complexity of the manufacturing process. Skilled labor is often required for assembly and quality control, particularly for custom units.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment maintenance. Manufacturers with advanced facilities may have higher overhead costs, which can influence pricing.

-

Tooling: The initial investment in tooling for custom designs can be substantial. These costs are often amortized over the production run, impacting unit pricing, especially for low-volume orders.

-

Quality Control (QC): Rigorous QC processes ensure that tanks meet safety and performance standards. This is essential for compliance, especially in regulated markets, but it also adds to the cost.

-

Logistics: Shipping costs vary based on the tank’s size and weight, as well as the distance to the destination. International shipping may incur additional fees such as tariffs and insurance.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Vacuum Tank Costs?

Several factors influence the pricing of vacuum tanks, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be beneficial for businesses looking to reduce costs.

-

Specifications and Customization: Custom tanks tailored to specific applications can incur additional costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials and Quality Certifications: Tanks constructed from higher-grade materials or those that meet specific industry certifications (e.g., ISO, ASME) typically command higher prices. Buyers should ensure that the materials align with their operational requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and service quality can influence costs. Established manufacturers may charge a premium, but they often provide better warranties and customer support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for managing logistics costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and responsibility for shipping costs.

What Are Effective Buyer Tips for Negotiating Vacuum Tank Prices?

International B2B buyers should consider the following strategies to enhance cost-efficiency:

-

Negotiation: Build strong relationships with suppliers. Engaging in open discussions about pricing can lead to discounts or favorable payment terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, and operational costs. Investing in higher-quality tanks may reduce long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of fluctuating exchange rates and potential import duties, which can affect the overall cost. Consider sourcing from local suppliers in regions like Africa or South America to mitigate these expenses.

-

Research and Compare Suppliers: Conduct thorough research on various suppliers. Request quotes from multiple manufacturers to understand market pricing and identify the best value.

-

Standardization: Whenever possible, opt for standardized tank designs. Custom builds can significantly increase costs, while standard models offer more predictable pricing.

Disclaimer on Indicative Prices

The prices for vacuum tanks can vary widely based on specifications, supplier, and market conditions. Buyers are encouraged to obtain detailed quotes and consider the total cost implications before making purchasing decisions.

Alternatives Analysis: Comparing vacuum tank With Other Solutions

Exploring Alternative Solutions to Vacuum Tanks

When it comes to liquid waste management and transportation, vacuum tanks are a popular choice due to their efficiency and reliability. However, there are alternative solutions that businesses can consider. This section will compare vacuum tanks against other viable options, helping B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Vacuum Tank | Portable Restroom Truck | Slide-In Tank |

|---|---|---|---|

| Performance | High suction power, suitable for various liquids and waste types. | Designed primarily for portable restroom services, limited in scope. | Flexible for different applications, can be customized. |

| Cost | Moderate to high initial investment, but durable and long-lasting. | Generally lower upfront costs but may require more frequent replacements. | Cost-effective, especially for existing pickup trucks. |

| Ease of Implementation | Requires specialized installation; may need additional equipment. | Ready-to-use upon delivery, minimal setup required. | Easy to install in compatible vehicles, no specialized equipment needed. |

| Maintenance | Regular maintenance is necessary to ensure optimal performance. | Requires periodic cleaning and servicing. | Low maintenance if properly designed; depends on usage. |

| Best Use Case | Ideal for septic services, industrial waste, and large-scale operations. | Best suited for events and locations needing portable sanitation. | Excellent for smaller operations or when flexibility is needed. |

What Are the Benefits and Drawbacks of Portable Restroom Trucks?

Portable restroom trucks, while primarily designed for sanitation services, present a cost-effective alternative for businesses focused on event management or construction sites. These trucks can efficiently service multiple portable restrooms, making them a practical choice for temporary setups. However, their limitations arise when dealing with non-sanitary waste, as they are not built for handling a broader range of liquids, which can restrict their usability in diverse applications.

How Do Slide-In Tanks Serve as a Versatile Alternative?

Slide-in tanks are an innovative solution that can be fitted into the beds of standard pickup trucks, offering flexibility and ease of use. They are particularly appealing for businesses that already possess compatible vehicles, thus minimizing additional investments. Their customizable options allow for varying capacities and configurations, making them suitable for both light and heavy-duty tasks. However, their performance may not match the suction power of dedicated vacuum tanks, especially for larger-scale operations or highly viscous materials.

Conclusion: How to Choose the Right Solution for Your Needs?

Selecting the appropriate liquid waste management solution depends on several factors, including the specific requirements of your operation, budget constraints, and the types of waste you will be handling. Vacuum tanks are ideal for businesses that require robust performance and versatility across various waste types, particularly in industrial settings. In contrast, portable restroom trucks and slide-in tanks may be more suitable for companies that prioritize cost-effectiveness and ease of use in more targeted applications. By evaluating these alternatives against your operational needs, you can make a well-informed choice that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for vacuum tank

What Are the Essential Technical Properties of a Vacuum Tank?

When considering the purchase of vacuum tanks, understanding key technical specifications is crucial for making informed decisions. Here are some vital properties to evaluate:

Illustrative image related to vacuum tank

-

Material Grade

Vacuum tanks are commonly constructed from materials like aluminum, mild steel, or stainless steel. Each material offers distinct advantages—aluminum is lightweight and corrosion-resistant, while stainless steel provides enhanced durability. Selecting the right material is essential for ensuring the tank’s longevity and performance, particularly in harsh operating environments. -

Capacity

The capacity of a vacuum tank typically ranges from 300 to 5,500 gallons. This specification is critical for B2B buyers, as it determines the volume of liquid or waste the tank can effectively handle. Understanding your operational needs can help in selecting a tank that optimally balances capacity with vehicle compatibility. -

Compartmentalization

Many vacuum tanks come in single- and multi-compartment designs. Multi-compartment tanks allow for the separation of different types of waste or liquids, which can enhance operational efficiency and compliance with waste management regulations. Knowing your requirements for compartmentalization can influence both functionality and cost. -

Pump Specifications

Vacuum tanks are often equipped with pumps that vary in size and power. The pump’s capacity and efficiency directly affect the speed and effectiveness of waste removal. B2B buyers should evaluate pump specifications to ensure they meet the demands of their operational environment and can handle the required waste volumes. -

Tolerance Levels

Tolerance refers to the acceptable limits of variation in the tank’s dimensions and performance metrics. High tolerance levels are essential for ensuring that the vacuum tank operates effectively under varying conditions. This is particularly important for maintaining system integrity and preventing leaks or failures during operation. -

Weight and Dimensions

The weight and physical dimensions of a vacuum tank influence its compatibility with various vehicle chassis. Understanding the weight distribution and overall size is vital for ensuring compliance with local transport regulations and maximizing vehicle performance.

What Are Common Trade Terms in the Vacuum Tank Industry?

Familiarity with industry terminology can greatly enhance communication and negotiation in B2B transactions. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce the original components that are later used in vacuum tanks. Understanding OEM relationships can be crucial for sourcing quality parts and ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ can help businesses manage inventory costs and avoid overcommitting to purchases that may exceed immediate operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This is a fundamental step in procurement, allowing buyers to compare options and negotiate better deals. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps in clarifying shipping responsibilities, costs, and risk management. -

Lead Time

Lead time refers to the duration from placing an order to receiving the product. In the vacuum tank industry, understanding lead times is crucial for planning operational schedules and ensuring timely service delivery. -

Aftermarket Parts

These are replacement parts that are not sourced from the original manufacturer. For B2B buyers, knowing about aftermarket parts can provide options for cost-effective maintenance and repairs, often with competitive pricing and availability.

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of purchasing vacuum tanks more effectively, ensuring they make choices that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the vacuum tank Sector

What Are the Key Drivers and Trends Influencing the Global Vacuum Tank Market?

The vacuum tank market is witnessing significant growth driven by various global factors. Increasing urbanization and infrastructure development, particularly in emerging economies in Africa, South America, the Middle East, and Europe, are propelling the demand for efficient waste management solutions. The growing awareness of environmental sustainability is leading businesses to invest in advanced vacuum tank technologies that minimize waste and enhance operational efficiency.

Emerging technologies, including the integration of IoT and automation, are transforming traditional vacuum tank operations. IoT-enabled vacuum tanks allow for real-time monitoring of tank levels, optimizing routing and reducing operational costs. Additionally, advancements in materials science are leading to lighter, more durable vacuum tanks, which can enhance fuel efficiency and reduce overall lifecycle costs for buyers.

International B2B buyers should also be aware of the fluctuating costs of raw materials and the impact of global supply chain disruptions. The COVID-19 pandemic underscored the importance of agile sourcing strategies, prompting companies to diversify their supplier base and consider local suppliers to mitigate risks. As businesses navigate these dynamics, it is crucial to stay informed about market trends to make strategic purchasing decisions.

How Can B2B Buyers Emphasize Sustainability and Ethical Sourcing in Vacuum Tank Procurement?

Sustainability is becoming a cornerstone of procurement strategies in the vacuum tank sector. The environmental impact of waste management practices is under scrutiny, and companies are seeking vacuum tanks that align with eco-friendly standards. Buyers are encouraged to look for manufacturers that utilize sustainable materials, such as recycled aluminum or low-carbon steel, in their tank construction.

Illustrative image related to vacuum tank

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers should prioritize suppliers who demonstrate transparency in their sourcing practices and adhere to ethical labor standards. Certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as indicators of a supplier’s commitment to sustainability.

Incorporating ‘green’ certifications into purchasing criteria is essential for businesses aiming to bolster their brand reputation. By choosing vacuum tanks from suppliers that prioritize eco-friendly practices, companies can reduce their carbon footprint while meeting regulatory requirements and enhancing their market position.

What is the Historical Context of the Vacuum Tank Industry?

The vacuum tank industry has evolved significantly since its inception in the early 20th century. Originally designed for basic waste removal, advancements in engineering and technology have transformed vacuum tanks into sophisticated, multi-functional vehicles capable of handling various liquid waste types. Innovations such as compartmentalized tanks and enhanced pump systems have improved efficiency and safety in waste management operations.

As environmental concerns gained prominence over the decades, the industry adapted by integrating greener technologies and materials. Today, vacuum tanks are not only pivotal in the sanitation sector but also play a crucial role in industrial applications, including hydro excavation and oilfield services. Understanding this evolution is vital for B2B buyers as they navigate a market that continues to innovate in response to changing environmental and operational demands.

Frequently Asked Questions (FAQs) for B2B Buyers of vacuum tank

-

How do I select the right vacuum tank for my needs?

Selecting the right vacuum tank involves assessing your specific requirements, such as capacity, material, and application. Consider whether you need a portable restroom truck, septic service truck, or a slide-in tank. Evaluate the tank’s compatibility with your existing vehicle, including cab and chassis options. It’s also essential to check for customization options that may cater to your unique operational needs. Consulting with manufacturers or suppliers can provide valuable insights into the best choices for your business. -

What capacity vacuum tank should I choose for my operations?

The capacity of the vacuum tank you choose should align with your operational demands. Tanks typically range from 300 to 5,500 gallons. For smaller jobs or more frequent service calls, a tank in the lower range may suffice. Conversely, larger operations, such as municipal waste management, may require tanks that can handle higher volumes. Assess your average waste collection volume and frequency to determine the most efficient capacity for your requirements. -

What are the key features to look for in a vacuum tank?

When evaluating vacuum tanks, consider features such as material durability, ease of maintenance, and safety mechanisms. Aluminum tanks are lightweight and corrosion-resistant, while steel tanks offer strength for heavy-duty applications. Look for design elements like manways, shutoff valves, and efficient pump systems that enhance usability. Moreover, ensure that the tank meets local regulatory standards for waste transportation, especially in international markets. -

How can I ensure the quality of the vacuum tank I purchase?

To ensure quality, source vacuum tanks from reputable manufacturers with a proven track record. Check for certifications and compliance with industry standards. Request product specifications and warranty information to understand the durability and lifespan of the tank. Conducting inspections or requesting samples can also provide assurance of quality before making a bulk purchase. Engaging with suppliers that offer after-sales support can further enhance your confidence in the investment. -

What customization options are available for vacuum tanks?

Many manufacturers offer customization options to cater to specific business needs. This can include variations in tank size, compartmentalization, and additional features like pump upgrades or specialized fittings. Custom designs can also be tailored to fit specific vehicle models. Discuss your requirements with suppliers during the procurement process to explore available options and ensure the tank meets your operational needs. -

What are the typical payment terms when purchasing a vacuum tank?

Payment terms can vary significantly between suppliers and regions. Common practices include upfront payments, partial deposits, or payment upon delivery. In international transactions, consider factors such as currency fluctuations and import duties that may affect pricing. It’s advisable to negotiate clear terms before finalizing the purchase, including timelines for payments and any financing options available for larger orders. -

How do I handle logistics and shipping for vacuum tanks?

Logistics for vacuum tanks typically involve coordinating with suppliers for shipping arrangements, which can include freight forwarding and customs clearance. Ensure that the supplier has experience in international shipping, particularly if you’re sourcing from different continents. Discuss delivery timelines, packaging requirements, and insurance options to protect your investment during transit. Additionally, consider the local regulations regarding the import of such equipment to avoid compliance issues. -

What should I know about supplier vetting for vacuum tank purchases?

When vetting suppliers for vacuum tanks, assess their industry reputation, customer reviews, and experience in international trade. Request references from past clients, particularly those in your region, to gauge reliability and service quality. Verify certifications and compliance with international standards to ensure safety and performance. Finally, consider engaging suppliers that offer comprehensive support, including maintenance services and spare parts, to ensure a long-term partnership.

Top 5 Vacuum Tank Manufacturers & Suppliers List

1. Robinson Tanks – Vacuum & Septic Trucks

Domain: robinsontanks.com

Registered: 2012 (13 years)

Introduction: Robinson Vacuum Tanks offers a range of products including:

– Portable Restroom Trucks (PRTs) with capacities of 1200, 1500, and 2000 gallons, all made of aluminum.

– Septic Service Trucks with tank capacities ranging from 2000 to 5500 gallons.

– Slide-In Tanks available in SC Series and FD Series, customizable and lightweight aluminum units.

– The tanks accommodate single- and multi-compartmental…

2. McMaster-Carr – Vacuum Tanks

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: Vacuum Tanks | McMaster-Carr

1. Vacuum Containers: Also known as vacuum degassing chambers, these containers remove trapped air from mixtures such as paint and mold resins. (23 products)

2. Pressurized Liquid Dispensing Tanks: Attach a compressed air source to pressurize liquids for dispensing and spraying. (26 products)

3. Sanitary Pressurized Liquid Dispensing Tanks: Store and dispense liquid…

3. Vacuum Tank Sales – Custom Vacuum Tanks

Domain: vacuumtanksales.com

Registered: 2023 (2 years)

Introduction: Vacuum Tank Sales (VTS) offers a range of vacuum tanks and custom builds, including:

– Slide-Ins: Dome and Flathead Series

– Portable Services: 450 to 2500 gallons

– Commercial Units: 2000 to 5000 gallons

– Truck Packages

– Add-Ons

VTS is known for its craftsmanship and reliability, serving operators across the U.S. and beyond, with products designed for efficiency and quality.

4. Wastecorp – Vacuum Tanks

Domain: wastecorp.com

Registered: 1998 (27 years)

Introduction: Vacuum Tanks are made with steel or optional stainless steel for durability and reliability. Customizable components include volume gauges, inspection ports, and manways. Available manway options include three sizes for easier cleaning and inspection. Two types of tanks are offered: waste only tanks and tanks with both waste and fresh water compartments. Vacuum Tank configurations include: 1) Slid…

5. Leybold – 69 CFM Vacuum Tank System

Domain: avac.com

Registered: 1996 (29 years)

Introduction: 69 CFM 200 Gallon Single Pump Vacuum Tank System | SKU: 76.00015.01 | Brand: Leybold | Level of Vacuum: Rough Vacuum: 29 Inches Atmospheric Pressure (760 Torr) to 7.5 x 10E-1 Torr | CFM / L/M (Displacement): 174 | Inlet / Exhaust: 1 1/2″ | Motor: 6.2 HP | Power Options: Voltage 230V 3ph 50/60 hz, Voltage 460V 3ph 50/60 hz | Features: Direct-drive pump, ASME-approved vacuum vessels, brass construct…

Strategic Sourcing Conclusion and Outlook for vacuum tank

In the realm of vacuum tanks, strategic sourcing is pivotal for international B2B buyers seeking to optimize operational efficiency and reduce costs. By understanding the diverse offerings—from portable restroom trucks to customizable slide-in tanks—buyers can align their procurement strategies with their specific needs. Emphasizing quality, reliability, and adaptability is essential; selecting manufacturers that provide durable products and comprehensive support ensures long-term satisfaction and operational success.

Moreover, buyers in regions like Africa, South America, the Middle East, and Europe should consider the advantages of local suppliers who understand regional regulations and market demands. Establishing relationships with reputable manufacturers can lead to better pricing, enhanced service, and quicker access to parts and maintenance.

As the market evolves, embracing innovative technologies and sustainable practices will be crucial. By prioritizing strategic sourcing, businesses can not only meet current demands but also position themselves for future growth. Take the first step today—assess your vacuum tank needs, explore suppliers, and request quotes to ensure your operations remain robust and competitive in the global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to vacuum tank