Choosing Your Used Scaffolding For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for used scaffolding for sale

Navigating the global market for used scaffolding for sale can be a daunting task for international B2B buyers, especially when balancing quality, cost, and availability. As construction projects ramp up across Africa, South America, the Middle East, and Europe, sourcing reliable and safe scaffolding solutions becomes imperative. This guide addresses key challenges faced by buyers, such as identifying the right types of scaffolding, understanding their applications, and vetting suppliers effectively to ensure compliance with safety standards.

In this comprehensive resource, we delve into the various types of used scaffolding available, from frame scaffolding to elevated platforms, and explore their suitability for different construction projects. We provide insights into cost factors, helping you navigate pricing structures to make informed purchasing decisions. Additionally, this guide outlines essential criteria for supplier selection, emphasizing the importance of quality assurance and after-sales support.

By equipping B2B buyers with actionable insights and a thorough understanding of the used scaffolding market, this guide empowers you to make confident choices that align with your project needs and budget constraints. Whether you are based in Nigeria or Germany, you will find the information necessary to streamline your procurement process and enhance the safety and efficiency of your construction operations.

Understanding used scaffolding for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frame Scaffolding | Modular design, easy assembly, and disassembly. | General construction, maintenance work. | Pros: Cost-effective, versatile. Cons: Limited height; may require additional safety measures. |

| Non-Stop Scaffolding | Continuous platform, crank-up mechanism, and high durability. | Masonry, commercial projects. | Pros: Increases productivity, long-lasting. Cons: Higher initial investment, requires maintenance. |

| Hydraulic Scaffolding | Adjustable height, powered lifting capabilities. | Large-scale industrial projects. | Pros: Efficient for high-rise work, reduces manual labor. Cons: More complex, requires power source. |

| Rolling Scaffolding | Mobile, with wheels for easy relocation. | Interior work, painting, and repairs. | Pros: Flexible use, easy to move. Cons: Stability concerns on uneven surfaces. |

| System Scaffolding | Customizable systems with various components for specific needs. | Specialized construction projects. | Pros: Highly adaptable, suitable for unique structures. Cons: Requires skilled assembly, potentially higher costs. |

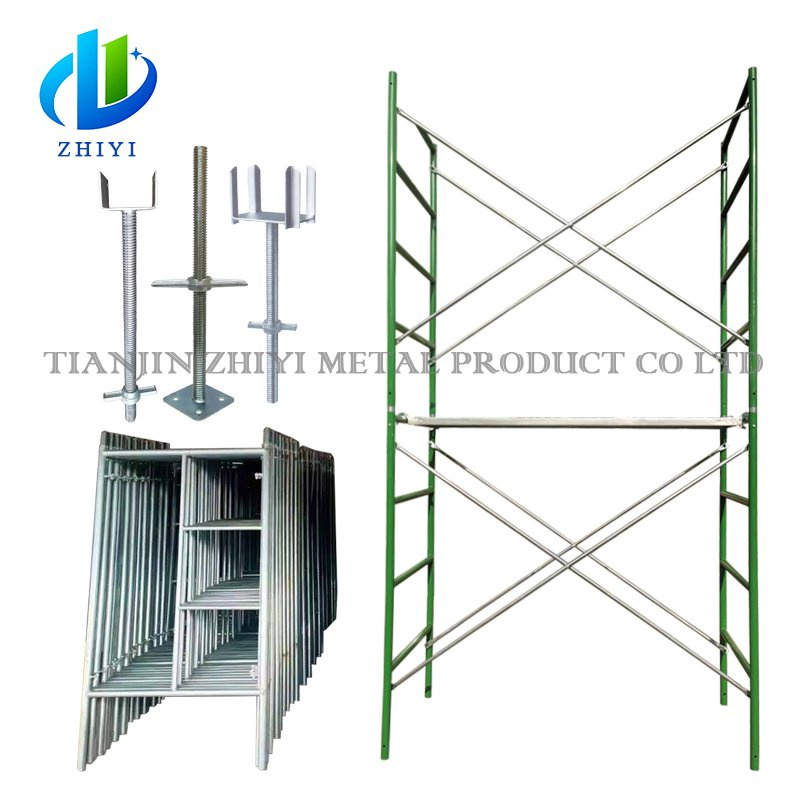

What Are the Key Characteristics of Frame Scaffolding?

Frame scaffolding is characterized by its modular design, which allows for quick assembly and disassembly. This type of scaffolding is commonly used in general construction and maintenance work due to its cost-effectiveness and versatility. B2B buyers should consider the height limitations and the need for additional safety measures when selecting frame scaffolding, especially for projects that require significant elevation.

How Does Non-Stop Scaffolding Enhance Productivity?

Non-Stop scaffolding features a continuous platform and a crank-up mechanism, making it ideal for masonry and commercial projects. Its robust construction ensures durability, allowing it to withstand heavy use over time. For B2B buyers, the primary consideration is the higher initial investment, but the long-term benefits in productivity and reduced labor costs can offset this expense.

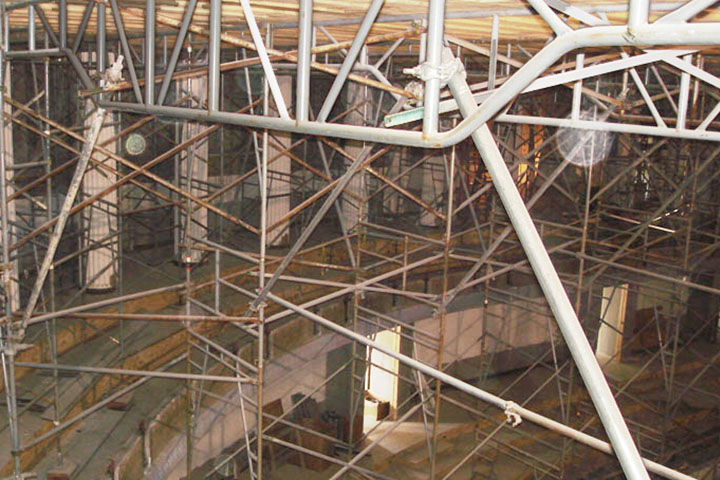

Illustrative image related to used scaffolding for sale

What Advantages Does Hydraulic Scaffolding Offer for Large Projects?

Hydraulic scaffolding stands out with its adjustable height and powered lifting capabilities, making it particularly beneficial for large-scale industrial projects. This type enhances efficiency by reducing manual labor and allowing for quick adjustments. However, B2B buyers must be aware of the complexity and the requirement for a power source, which can add to operational costs.

When Should You Consider Rolling Scaffolding?

Rolling scaffolding is designed for mobility, featuring wheels that enable easy relocation from one site to another. It is particularly useful for interior work, such as painting and repairs, where flexibility is paramount. While rolling scaffolding offers the advantage of ease of movement, buyers should be cautious of stability issues on uneven surfaces, which can pose safety risks.

What Makes System Scaffolding a Unique Choice?

System scaffolding provides a customizable solution with various components that cater to specific project needs. This adaptability makes it suitable for specialized construction projects that require unique structural solutions. B2B buyers should consider the necessity for skilled assembly, as well as the potential for higher costs, when evaluating system scaffolding for their operations.

Illustrative image related to used scaffolding for sale

Key Industrial Applications of used scaffolding for sale

| Industry/Sector | Specific Application of used scaffolding for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Building and Renovation Projects | Cost savings on equipment, quick setup for ongoing projects | Assess structural integrity, ensure compliance with local regulations, and verify load capacity. |

| Oil and Gas | Maintenance of Refineries and Platforms | Enhanced safety during maintenance, reduced downtime | Check for corrosion resistance and suitability for hazardous environments. |

| Infrastructure | Bridge and Highway Construction | Increased efficiency in project timelines | Ensure compatibility with existing structures and compliance with engineering standards. |

| Event Management | Temporary Structures for Events and Festivals | Flexibility and cost-effectiveness for short-term projects | Consider ease of assembly/disassembly and transportation logistics. |

| Industrial Manufacturing | Access Platforms for Machinery Maintenance | Improved worker safety and productivity | Verify load ratings and ensure availability of necessary accessories for specific machinery. |

How is Used Scaffolding Applied in Construction Projects?

In the construction sector, used scaffolding is essential for building and renovation projects. It provides a stable platform for workers to access different heights safely. By opting for used scaffolding, companies can significantly cut costs while maintaining the necessary safety standards. However, international buyers must ensure that the scaffolding meets local safety regulations and is structurally sound to support the specific load requirements of their projects.

What Role Does Used Scaffolding Play in Oil and Gas Maintenance?

In the oil and gas industry, used scaffolding is frequently employed for maintenance tasks on refineries and offshore platforms. It allows workers to safely reach high-risk areas for inspection and repair, thereby minimizing downtime and enhancing operational safety. Buyers in this sector should prioritize scaffolding that is corrosion-resistant and suitable for hazardous environments to ensure the safety of their personnel and compliance with industry regulations.

How is Used Scaffolding Beneficial for Infrastructure Projects?

Infrastructure projects, such as bridge and highway construction, benefit from the versatility of used scaffolding. It facilitates efficient project timelines by providing necessary access to various construction areas. For international buyers, it is crucial to ensure that the scaffolding can be integrated with existing structures and complies with engineering standards, which can vary significantly from one region to another.

What Advantages Does Used Scaffolding Offer Event Management?

In the realm of event management, used scaffolding is often utilized to create temporary structures for festivals and large gatherings. Its flexibility allows for quick assembly and disassembly, making it a cost-effective solution for short-term events. Buyers should consider the logistics of transporting and setting up the scaffolding, as well as its structural integrity to withstand the demands of large crowds.

How Does Used Scaffolding Enhance Industrial Manufacturing Processes?

Used scaffolding serves a vital role in industrial manufacturing by providing access platforms for machinery maintenance. This enhances worker safety and productivity, allowing for efficient inspections and repairs. When sourcing used scaffolding for this purpose, companies must verify load ratings and ensure that they have the necessary accessories to accommodate specific machinery, which can vary by industry.

3 Common User Pain Points for ‘used scaffolding for sale’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Used Scaffolding Purchases

The Problem: B2B buyers often face uncertainty regarding the quality and safety of used scaffolding. When purchasing used equipment, the stakes are high, particularly in construction and industrial environments where worker safety is paramount. Buyers worry about potential defects, structural integrity, and whether the scaffolding will meet local safety standards. This concern is heightened when sourcing from international markets, where regulations may differ significantly from those in the buyer’s home country.

The Solution: To mitigate quality concerns, buyers should prioritize sourcing from reputable suppliers who provide detailed inspection reports and certifications for their used scaffolding. Conduct thorough research on the supplier’s reputation and customer feedback, focusing on their history with used scaffolding sales. Request to see any testing certifications or maintenance records for the scaffolding in question. Additionally, consider arranging a site visit to inspect the scaffolding before purchase. If this isn’t feasible, utilize video conferencing tools to conduct a virtual inspection. Ensure that the scaffolding complies with local regulations and standards by checking if the supplier is familiar with the specific requirements of your region. This proactive approach will help ensure that the purchased scaffolding is safe, reliable, and suitable for your project needs.

Scenario 2: Managing Inventory Turnover and Availability

The Problem: B2B buyers frequently encounter challenges with inventory turnover when looking for used scaffolding. Due to the fluctuating nature of the used equipment market, available stock can change rapidly. This can lead to frustration when a buyer finds the ideal scaffolding only to discover it has already been sold. For businesses with tight project timelines, this unpredictability can result in delays and increased costs, impacting overall project efficiency and profitability.

Illustrative image related to used scaffolding for sale

The Solution: To effectively manage inventory turnover, buyers should establish a proactive relationship with scaffolding suppliers. Sign up for inventory alerts or newsletters from suppliers that specialize in used scaffolding to stay informed about new arrivals. Additionally, consider using digital platforms that aggregate listings from multiple suppliers to broaden your search and increase your chances of finding the right scaffolding in a timely manner. Implementing a just-in-time inventory system can also help by allowing you to purchase scaffolding as needed, thereby reducing excess inventory and storage costs. Lastly, consider developing a contingency plan that includes alternative scaffolding options or rental solutions, ensuring that project timelines remain on track even in the face of inventory challenges.

Scenario 3: Cost-Effectiveness vs. Quality Trade-offs in Used Scaffolding

The Problem: One of the most pressing dilemmas for B2B buyers is balancing cost-effectiveness with quality when purchasing used scaffolding. While used scaffolding is often significantly cheaper than new options, buyers must weigh the potential risks associated with lower-priced items against the long-term benefits of investing in higher-quality equipment. This decision can be particularly complex for buyers operating on tight budgets or in regions where the cost of construction materials is rising.

The Solution: To navigate this challenge, buyers should adopt a strategic approach to their scaffolding purchases. Start by setting a clear budget, but also consider the total cost of ownership, which includes maintenance, potential repair costs, and safety implications over the scaffolding’s lifespan. When evaluating used options, focus on well-known brands with a track record of durability and reliability. It may be worthwhile to pay slightly more for scaffolding that has been properly maintained or refurbished, as this can reduce the risk of costly repairs or replacements down the line. Additionally, engage in discussions with suppliers about the potential for buy-back programs or trade-ins, which can mitigate costs when upgrading to new equipment in the future. Lastly, consider collaborating with other contractors to pool resources and share costs, thereby increasing your purchasing power and access to higher-quality scaffolding.

Strategic Material Selection Guide for used scaffolding for sale

What Are the Common Materials Used in Scaffolding and Their Key Properties?

When considering used scaffolding for sale, the material used in its construction is paramount for ensuring safety, durability, and cost-effectiveness. Below, we analyze four common materials used in scaffolding, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Steel

Key Properties:

Steel scaffolding is known for its high strength-to-weight ratio, making it capable of supporting heavy loads. It typically exhibits excellent corrosion resistance when galvanized, and it can withstand high temperatures and pressures.

Pros & Cons:

Steel is highly durable and can last for decades with proper maintenance. However, its initial cost is relatively high, and it can be heavy, which may complicate transportation and assembly. Additionally, steel scaffolding requires periodic inspections for rust and structural integrity.

Impact on Application:

Steel is suitable for a wide range of construction applications, including heavy industrial projects. Its strength makes it ideal for situations where high load-bearing capacity is essential.

Considerations for International Buyers:

Buyers in regions like Europe and the Middle East often prefer steel due to its compliance with standards such as DIN and EN. In contrast, buyers in Africa and South America may need to assess local regulations regarding material specifications and safety standards.

2. Aluminum

Key Properties:

Aluminum scaffolding is lightweight and resistant to corrosion, making it ideal for use in environments with high humidity or exposure to chemicals. It has a lower load-bearing capacity compared to steel but is still robust enough for many applications.

Illustrative image related to used scaffolding for sale

Pros & Cons:

The primary advantage of aluminum scaffolding is its ease of handling and transport due to its lightweight nature. However, it is generally less durable than steel and may have a shorter lifespan under heavy use. The cost can be moderate, depending on the alloy used.

Impact on Application:

Aluminum is particularly effective for residential and light commercial projects where portability and ease of assembly are critical. Its corrosion resistance also makes it suitable for coastal areas.

Considerations for International Buyers:

In Europe, aluminum scaffolding must meet specific safety standards, such as EN 1004. Buyers from Africa and South America should verify local availability and compliance with regional safety regulations.

3. Fiberglass

Key Properties:

Fiberglass scaffolding is non-conductive, making it an excellent choice for electrical work. It is resistant to corrosion and chemicals, and it has a lower weight compared to steel.

Pros & Cons:

The non-conductive nature is a significant advantage for electrical and maintenance work. However, fiberglass scaffolding is generally more expensive than both steel and aluminum and can be less robust under heavy loads.

Impact on Application:

Ideal for jobs involving electrical installations or in environments where chemical exposure is a concern, fiberglass scaffolding provides safety and durability.

Considerations for International Buyers:

International buyers should consider the availability of fiberglass scaffolding and ensure that it meets relevant safety standards in their region, such as ASTM standards in the U.S. or equivalent standards in Europe.

4. Wood

Key Properties:

Wood scaffolding, typically made from high-grade timber, is lightweight and offers good load-bearing capacity. It is also relatively inexpensive compared to metal options.

Pros & Cons:

Wood is easy to work with and can be sourced locally, reducing transportation costs. However, it is susceptible to rot, insect damage, and weathering, which can limit its lifespan. Regular maintenance is required to ensure safety.

Impact on Application:

Wood scaffolding is often used in residential construction and restoration projects where the aesthetic of wood is desired. It is less suitable for heavy industrial applications.

Considerations for International Buyers:

Buyers should verify the quality of the wood and ensure it complies with local building codes. In regions like Africa and South America, sourcing locally can be advantageous, but care must be taken to ensure sustainability.

Summary Table of Material Selection for Used Scaffolding

| Material | Typical Use Case for used scaffolding for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy industrial projects requiring high load capacity | High strength and durability | Heavy and requires maintenance | High |

| Aluminum | Residential and light commercial projects | Lightweight and portable | Less durable than steel | Medium |

| Fiberglass | Electrical installations and chemical environments | Non-conductive and corrosion-resistant | More expensive and less robust | High |

| Wood | Residential construction and restoration | Cost-effective and locally sourced | Susceptible to rot and weathering | Low |

This analysis provides a comprehensive overview of the materials used in scaffolding, aiding international buyers in making informed decisions tailored to their specific project needs and local regulations.

In-depth Look: Manufacturing Processes and Quality Assurance for used scaffolding for sale

What Are the Key Stages in the Manufacturing Process of Used Scaffolding?

The manufacturing process for used scaffolding involves several critical stages that ensure safety and durability. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on sourcing high-quality materials, typically steel, that meet industry specifications for strength and durability. Suppliers often prefer galvanized steel for its corrosion resistance, which is crucial for scaffolding exposed to various weather conditions. The materials are inspected to ensure they are free from defects before moving to the next stage.

-

Forming: In this phase, raw materials are shaped into scaffolding components using techniques such as bending, cutting, and welding. Automated machinery is frequently employed to ensure precision and consistency. Techniques like hot-dip galvanization may be used at this stage to enhance the longevity of the scaffolding by providing a protective layer against rust and corrosion.

-

Assembly: After forming, the components are assembled into scaffolding systems. This process involves connecting various parts, such as frames, boards, and braces, ensuring they fit together securely. A focus on modular design allows for flexibility in construction and easy transport, which is particularly beneficial for international buyers who may require scaffolding for diverse applications.

-

Finishing: The final stage includes surface treatments such as powder coating or painting to provide additional protection and improve aesthetics. Quality checks are performed to confirm that all components meet safety standards and are free from any defects.

How Is Quality Assurance Implemented in Used Scaffolding Manufacturing?

Quality assurance (QA) is vital in ensuring that used scaffolding meets international safety standards. Various international and industry-specific standards guide the QA process, including ISO 9001 for quality management systems and CE marking for products sold in the European Economic Area.

-

International Standards: Compliance with ISO 9001 indicates that the manufacturing process adheres to quality management principles, including a strong customer focus, the involvement of top management, and a process approach. CE marking signifies that the scaffolding complies with EU safety, health, and environmental protection standards.

-

Industry-Specific Standards: In addition to ISO and CE, scaffolding manufacturers may also follow standards set by organizations like the American Petroleum Institute (API) or the Occupational Safety and Health Administration (OSHA). These standards provide guidelines for design, construction, and performance, ensuring that scaffolding is safe for use in various industries.

What Are the Key Quality Control Checkpoints in Scaffolding Production?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Typically, these checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This step involves inspecting the raw materials upon arrival at the manufacturing facility. Suppliers are required to provide certification of material quality, and samples are often tested for compliance with specified standards. This initial QC step is crucial in preventing defects from entering the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to ensure that components are being produced according to design specifications. This includes checking dimensions, weld integrity, and surface finishes. Automated systems may be used to monitor production variables, allowing for immediate adjustments when deviations are detected.

-

Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection of the completed scaffolding is performed. This includes load testing to verify structural integrity and adherence to safety standards. Documentation of these tests is crucial for B2B buyers, as it provides evidence of compliance with safety regulations.

What Testing Methods Are Commonly Used in Scaffolding Quality Assurance?

Several testing methods are employed to ensure the reliability and safety of used scaffolding. These include mechanical testing, non-destructive testing (NDT), and load testing.

-

Mechanical Testing: This involves evaluating the material properties of scaffolding components, such as tensile strength, yield strength, and ductility. Samples are subjected to standardized tests to determine their performance under various conditions, ensuring they can withstand the loads expected in real-world applications.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle testing are utilized to detect internal defects or structural weaknesses without damaging the scaffolding. NDT is essential for identifying potential issues that could compromise safety and performance.

-

Load Testing: This critical test involves applying a specified load to the scaffolding to ensure it can support the weight it is designed to carry. Load testing is typically performed in accordance with international standards, and the results are documented for verification purposes.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers need to conduct due diligence when selecting suppliers for used scaffolding. Several strategies can help buyers verify the quality control practices of potential suppliers.

-

Supplier Audits: Conducting on-site audits of suppliers can provide valuable insights into their manufacturing processes and quality control measures. Audits allow buyers to evaluate the facilities, equipment, and practices used in production.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the QC measures in place. These reports should include documentation of testing methods, results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the scaffolding before purchase can provide an unbiased assessment of quality and safety. These inspections can verify that the scaffolding meets required standards and is suitable for use.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Understanding these nuances is essential for making informed purchasing decisions.

-

Cultural and Regulatory Differences: Different regions may have varying safety standards and regulations for scaffolding. Buyers must familiarize themselves with local regulations to ensure compliance and avoid potential legal issues.

-

Logistics and Transportation: The condition of scaffolding during transportation can impact its quality. Buyers should verify that suppliers have robust packaging and handling procedures to prevent damage during shipping.

-

Language and Communication Barriers: Clear communication is vital in international transactions. Buyers should ensure that all quality-related discussions, documentation, and contracts are understood by both parties to avoid misunderstandings.

In conclusion, understanding the manufacturing processes and quality assurance measures for used scaffolding is critical for B2B buyers. By focusing on the key stages of production, quality control checkpoints, testing methods, and verification strategies, buyers can make informed decisions that ensure safety and compliance with international standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used scaffolding for sale’

Introduction

In the competitive landscape of construction and industrial projects, sourcing used scaffolding can provide significant cost savings while still meeting operational needs. This guide offers a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring they acquire high-quality scaffolding that aligns with their specific requirements.

1. Identify Your Project Requirements

Before starting your search for used scaffolding, clearly define your project needs. Consider factors such as the type of scaffolding required (frame, system, or suspended), load capacity, and specific dimensions. Understanding these parameters will help you filter options effectively and avoid purchasing equipment that does not meet your needs.

2. Research Reputable Suppliers

Finding reliable suppliers is crucial in the used scaffolding market. Look for companies with a solid reputation, positive reviews, and a history of serving your industry. Utilize platforms such as trade shows, industry associations, and online marketplaces to gather a list of potential suppliers.

- Check for online reviews and testimonials from previous clients.

- Verify their industry experience, particularly in your region.

3. Inspect Equipment Thoroughly

When evaluating used scaffolding, conducting a thorough inspection is essential. Look for signs of wear and tear, rust, or structural integrity issues. If possible, visit the supplier’s location to assess the equipment firsthand, as this will give you a better understanding of its condition.

- Check load capacity ratings to ensure they meet your project’s demands.

- Review maintenance records if available, as they can provide insight into the scaffolding’s history.

4. Request Detailed Pricing Information

Understanding the pricing structure of used scaffolding is vital for budgeting. Request detailed quotes from multiple suppliers, including shipping costs, taxes, and any potential additional fees. This will allow you to compare offers effectively and identify the best value for your investment.

- Inquire about bulk purchase discounts if you need multiple units.

- Ask about warranties or guarantees, even for used equipment, to ensure you are protected against unforeseen issues.

5. Evaluate Compliance with Safety Standards

Safety should be a top priority when sourcing scaffolding. Ensure that the used scaffolding complies with local safety regulations and industry standards. Verify any certifications or compliance documents provided by the supplier.

- Request documentation that confirms safety testing and inspections.

- Consider the supplier’s commitment to safety protocols, including any training they may offer for proper scaffolding use.

6. Negotiate Terms and Conditions

Once you’ve selected a potential supplier, it’s time to negotiate terms. Discuss payment options, delivery schedules, and any return policies. Clear communication during this phase can prevent misunderstandings and ensure a smoother transaction process.

- Clarify who is responsible for shipping and handling costs.

- Establish timelines for delivery and installation to keep your project on track.

7. Finalize Your Purchase and Arrange Logistics

After reaching an agreement, finalize your purchase. Ensure all paperwork is complete, including invoices and contracts. Arrange logistics for delivery, considering the best methods to transport the scaffolding to your project site safely.

- Confirm delivery dates and check on tracking information.

- Prepare your site for the arrival of the scaffolding to facilitate a smooth setup.

By following this checklist, B2B buyers can confidently navigate the procurement process for used scaffolding, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for used scaffolding for sale Sourcing

What Are the Key Cost Components in Sourcing Used Scaffolding?

When sourcing used scaffolding, understanding the underlying cost components is crucial for B2B buyers. The primary cost factors include:

-

Materials: The quality of materials used in scaffolding significantly impacts pricing. Steel scaffolding, for instance, tends to be more durable and is often priced higher than aluminum alternatives. Buyers should assess the condition and grade of the materials to ensure they meet safety standards.

-

Labor: Labor costs associated with the refurbishment of used scaffolding can vary widely. Skilled labor is required for repairs, cleaning, and ensuring the structural integrity of the scaffolding. Suppliers may pass these costs onto buyers, so it’s essential to factor in labor when evaluating total costs.

-

Manufacturing Overhead: This includes the costs associated with the facility where the scaffolding is refurbished or stored. Overhead costs can vary by region and impact overall pricing.

-

Tooling and Quality Control (QC): Tooling costs arise from the necessary equipment used to repair and maintain scaffolding. Quality control processes ensure that all units meet safety and performance standards, which can further influence pricing.

-

Logistics: Shipping and handling costs can be significant, especially for international buyers. Factors such as distance, shipping methods, and local regulations can affect overall logistics costs.

-

Margin: Suppliers typically add a markup to cover their expenses and profit margin. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of Used Scaffolding?

Several factors can influence the pricing of used scaffolding:

-

Volume and Minimum Order Quantity (MOQ): Larger orders may lead to lower per-unit costs. Buyers should inquire about bulk pricing options, especially for ongoing projects.

-

Specifications and Customization: Custom scaffolding solutions may come at a premium. Buyers should clearly define their requirements to avoid unexpected costs.

-

Quality and Certifications: Scaffolding that meets specific safety certifications (e.g., OSHA in the U.S.) may command higher prices due to added assurance of quality and compliance.

-

Supplier Factors: Established suppliers with a reputation for quality may charge more. However, they often offer better warranties and customer service, which can be beneficial in the long run.

-

Incoterms: Understanding the terms of trade (e.g., FOB, CIF) is crucial for international buyers. These terms can significantly affect the final landed cost of the scaffolding.

What Buyer Tips Can Help in Negotiating Prices for Used Scaffolding?

For B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are key:

-

Conduct Thorough Research: Familiarize yourself with market prices and suppliers. Utilize platforms like IronPlanet or local suppliers to compare prices and quality.

-

Negotiate Terms: Don’t hesitate to negotiate payment terms, delivery schedules, and warranties. Suppliers may be willing to adjust these factors to secure a sale.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront cost but also potential maintenance, repair, and resale value of the scaffolding. This holistic view will provide a clearer picture of the investment.

-

Understand Pricing Nuances: Be aware of regional pricing differences. For instance, used scaffolding may be more readily available and cheaper in regions with high construction activity compared to others.

-

Request for Quotes (RFQs): Submit RFQs to multiple suppliers to gauge competitive pricing and terms. This approach can also foster relationships with suppliers for future purchases.

Final Thoughts on Sourcing Used Scaffolding

While prices for used scaffolding can vary significantly, understanding the cost components and influential factors will empower buyers to make informed decisions. Always remember that prices are indicative and can fluctuate based on market conditions, availability, and specific supplier circumstances. Engaging in thorough due diligence will yield better pricing outcomes and ultimately enhance project efficiency.

Illustrative image related to used scaffolding for sale

Alternatives Analysis: Comparing used scaffolding for sale With Other Solutions

Exploring Alternatives to Used Scaffolding for Sale

When considering scaffolding solutions, buyers often face the dilemma of choosing between used scaffolding for sale and various alternative methods. Each option presents its own set of advantages and disadvantages, impacting performance, cost, and ease of implementation. Understanding these alternatives is crucial for B2B buyers looking to make informed decisions that align with their project requirements.

| Comparison Aspect | Used Scaffolding For Sale | Modular Scaffolding Systems | Scaffolding Rental Services |

|---|---|---|---|

| Performance | Reliable for standard tasks | High adaptability and strength | Variable performance based on quality |

| Cost | Lower upfront cost | Higher initial investment but reusable | Ongoing costs can exceed purchase |

| Ease of Implementation | Requires manual assembly | Quick setup with pre-fabricated parts | Quick access without storage needs |

| Maintenance | May require repairs and inspections | Minimal maintenance; durable materials | No maintenance required, but subject to rental terms |

| Best Use Case | Short-term projects or budget constraints | Long-term projects needing flexibility | Projects with fluctuating requirements |

What Are the Advantages and Disadvantages of Modular Scaffolding Systems?

Modular scaffolding systems are designed for high adaptability and strength. These systems consist of pre-fabricated components that can be assembled quickly, allowing for efficient use on various job sites. The initial investment is typically higher than purchasing used scaffolding, but the durability and reusability can lead to cost savings over time. However, the requirement for skilled labor for assembly may present challenges for some companies, especially in regions where trained personnel are limited.

How Do Scaffolding Rental Services Compare?

Scaffolding rental services provide a flexible solution for projects that have unpredictable timelines or varying scaffolding needs. These services eliminate the upfront purchase costs and the burden of maintenance, making them an appealing choice for companies that require short-term scaffolding solutions. However, as projects extend, the ongoing rental fees can accumulate, potentially exceeding the cost of purchasing scaffolding outright. Additionally, the quality of rented scaffolding can vary by provider, which may impact safety and performance.

Conclusion: Which Scaffolding Solution Is Right for Your Business?

Selecting the appropriate scaffolding solution hinges on your project’s specific requirements, budget constraints, and long-term goals. Used scaffolding for sale may provide immediate cost savings for short-term projects, while modular systems are ideal for long-term use and adaptability. On the other hand, rental services offer convenience and flexibility but may incur higher costs over time. B2B buyers must weigh these options against their operational needs to determine the best scaffolding solution that aligns with their business strategy.

Essential Technical Properties and Trade Terminology for used scaffolding for sale

What Are the Key Technical Properties of Used Scaffolding?

When evaluating used scaffolding for sale, understanding the essential technical properties is critical for making informed purchasing decisions. Here are several key specifications:

Illustrative image related to used scaffolding for sale

Material Grade

The material grade of scaffolding typically refers to the type and quality of steel used in its construction. Common grades include ASTM A36 and ASTM A992, which are known for their strength and durability. For B2B buyers, selecting scaffolding made from high-grade materials ensures structural integrity, safety, and longevity, which can significantly affect project costs and timelines.

Load Capacity

Load capacity indicates the maximum weight that scaffolding can safely support, often expressed in pounds or kilograms per square meter. This specification is crucial for construction projects, as it dictates the types of materials and equipment that can be used on the scaffolding. Understanding load capacity helps buyers ensure compliance with safety regulations and prevents accidents on the job site.

Tolerance

Tolerance refers to the allowable deviation in dimensions of scaffolding components. It is crucial for ensuring that parts fit together correctly and that the scaffolding can be assembled without issues. For B2B buyers, knowing the tolerance levels helps in planning installations and maintaining the overall stability of the structure.

Surface Treatment

The surface treatment of scaffolding, such as galvanization or powder coating, protects against corrosion and extends the life of the equipment. This property is particularly important for scaffolding used in harsh environments or for long-term projects. Buyers should assess surface treatment options to ensure that their investment remains durable over time.

Dimensions and Compatibility

Dimensions refer to the size of scaffolding components, including height, width, and length. Compatibility with existing scaffolding systems is also a critical consideration. For international buyers, understanding these specifications ensures that the used scaffolding can be seamlessly integrated into their current setups, minimizing disruptions.

What Are Common Trade Terms in Scaffolding Procurement?

Familiarizing yourself with industry jargon can streamline the procurement process and enhance communication. Here are some essential trade terms:

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the scaffolding industry, buyers often seek OEM products to ensure quality and compatibility. Knowing this term helps buyers identify reliable suppliers and negotiate better deals.

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. In the context of used scaffolding, understanding MOQ is vital for B2B buyers to ensure they can meet their project needs without overcommitting financially. It also facilitates better inventory management.

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. In scaffolding procurement, sending an RFQ can help buyers obtain competitive pricing and terms from multiple vendors, allowing for informed decision-making.

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risk management, particularly when importing used scaffolding from different countries.

Bid and Auction Terms

In the used scaffolding market, buyers often encounter bidding and auction formats. Familiarity with terms like “reserve price,” “starting bid,” and “buy now” can enhance a buyer’s ability to navigate auctions effectively, ensuring they secure the best possible deals.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding their used scaffolding purchases, ultimately leading to safer and more efficient construction projects.

Navigating Market Dynamics and Sourcing Trends in the used scaffolding for sale Sector

What Are the Current Market Dynamics and Key Trends in the Used Scaffolding Sector?

The global used scaffolding market is influenced by a variety of factors, including economic growth in developing regions, increased construction activity, and the rising cost of new materials. In regions such as Africa and South America, rapid urbanization is driving demand for scaffolding as infrastructure projects proliferate. For international B2B buyers, understanding the dynamics of this market is essential for making informed purchasing decisions. The trend towards digital platforms for sourcing used scaffolding is gaining momentum, with online marketplaces allowing buyers to access a wider range of products and vendors, streamlining the procurement process.

Emerging technologies, such as inventory management systems and predictive analytics, are reshaping how companies in the scaffolding sector operate. These tools enable suppliers to optimize their inventory based on real-time demand forecasts, ensuring that buyers have access to the scaffolding they need when they need it. Additionally, sustainability is becoming a crucial consideration, with buyers increasingly favoring suppliers who adopt eco-friendly practices and materials. As the market evolves, international buyers must remain vigilant about fluctuations in supply chains, regulatory changes, and evolving safety standards that could impact their sourcing strategies.

How Does Sustainability Influence Sourcing Decisions in the Used Scaffolding Market?

Sustainability has become a cornerstone of sourcing strategies in the used scaffolding sector. The environmental impact of construction activities, including the use of scaffolding, has prompted many companies to adopt greener practices. This includes sourcing materials that are either recycled or have a lower carbon footprint. Ethical sourcing is also gaining traction, as businesses look for suppliers who adhere to responsible labor practices and environmental regulations.

Buyers are increasingly seeking scaffolding that comes with certifications indicating that it meets specific sustainability standards. These may include green certifications that validate the materials used or the processes followed in manufacturing. Such certifications not only enhance a company’s reputation but also align with corporate social responsibility goals that many firms are now prioritizing. For international buyers, particularly in regions with stringent environmental regulations, choosing suppliers with verified sustainability practices can mitigate risks and enhance compliance.

What Is the Evolution of the Used Scaffolding Market?

The used scaffolding market has evolved significantly over the decades, transitioning from a niche segment to a vital component of the global construction industry. Initially, used scaffolding was primarily a cost-saving option for smaller contractors. However, as the construction landscape became more competitive, larger companies began to recognize the value of sourcing used scaffolding for both economic and operational advantages.

Illustrative image related to used scaffolding for sale

With the advent of online marketplaces and auction platforms, access to used scaffolding has expanded dramatically. Buyers can now easily compare prices, specifications, and supplier reputations, making informed decisions that were previously challenging. The increased focus on sustainability and ethical sourcing has also transformed buyer expectations, pushing suppliers to innovate and improve their offerings. As this market continues to mature, it stands to benefit from advancements in technology and a growing emphasis on responsible business practices.

Frequently Asked Questions (FAQs) for B2B Buyers of used scaffolding for sale

-

1. How do I assess the quality of used scaffolding before purchasing?

To evaluate the quality of used scaffolding, inspect the materials for signs of wear, rust, or damage. Request detailed photographs and descriptions from suppliers, focusing on load capacities and compliance with safety standards. It’s advisable to ask for maintenance records or any certifications that demonstrate the scaffolding has been tested for safety. If possible, visit the supplier’s yard to conduct a physical inspection. Ensure you have a checklist of criteria to assess, including structural integrity and compatibility with your project requirements. -

2. What is the best type of used scaffolding for my construction needs?

The best type of used scaffolding depends on your specific project requirements, such as height, load capacity, and type of work being performed. Frame scaffolding is versatile for general construction, while system scaffolding offers flexibility for complex structures. If you need to work at height for extended periods, consider non-stop scaffolding for its efficiency. Always match the scaffolding type with the materials you will be using and the conditions of the site, ensuring safety and productivity. -

3. How can I verify the legitimacy of a scaffolding supplier?

To verify a scaffolding supplier’s legitimacy, check their business credentials, including registrations and certifications. Look for customer reviews and testimonials, and inquire about their history in the market. A reliable supplier should provide references from past clients and details on their quality assurance processes. Additionally, consider visiting their facility or requesting a virtual tour to assess their inventory and operations. Engaging with industry associations can also provide insights into reputable suppliers. -

4. What are the typical payment terms for purchasing used scaffolding internationally?

Payment terms for international purchases of used scaffolding can vary widely. Standard practices include a deposit upfront, followed by the balance upon delivery or before shipping. Some suppliers may offer financing options or letter of credit arrangements for larger orders. Always clarify payment methods accepted, including wire transfers, credit cards, or escrow services, to ensure security. It’s crucial to have a written agreement detailing payment schedules and conditions to avoid misunderstandings. -

5. How do I handle logistics and shipping for used scaffolding?

Managing logistics for used scaffolding involves coordinating with your supplier and shipping company to ensure safe transportation. Discuss shipping options, including container sizes and freight methods, to find the most cost-effective solution. Verify that the supplier can provide necessary export documentation and comply with customs regulations in your country. Planning for potential delays in customs clearance and ensuring proper insurance coverage for the shipment are also critical steps in the logistics process. -

6. What should I know about minimum order quantities (MOQ) when sourcing used scaffolding?

Minimum order quantities (MOQ) for used scaffolding can vary based on the supplier and the type of scaffolding needed. Some suppliers may have an MOQ to ensure cost-effectiveness, while others might be flexible depending on your specific requirements. When negotiating, consider your project size and timeline. It’s beneficial to communicate your needs clearly and explore options for combining different types of scaffolding to meet MOQ requirements without excess inventory. -

7. Can I customize used scaffolding to meet my project specifications?

Customization of used scaffolding is often possible, depending on the supplier’s capabilities. Many suppliers offer modifications such as resizing or adding accessories to fit specific project needs. Discuss your requirements upfront and inquire about any additional costs or lead times associated with customization. Ensure that any alterations comply with safety standards and that you receive documentation confirming the modifications made to the scaffolding. -

8. What quality assurance measures should I expect when buying used scaffolding?

Quality assurance measures for used scaffolding should include thorough inspections and certifications from the supplier. Look for suppliers who provide detailed reports on the condition of the scaffolding, including any repairs made. It’s important to ask whether the scaffolding has undergone testing for safety and compliance with local regulations. Additionally, some suppliers may offer warranties or guarantees on their used equipment, which can provide peace of mind regarding your investment.

Top 4 Used Scaffolding For Sale Manufacturers & Suppliers List

1. Facebook – Scaffolding for Sale

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Scaffolding for Sale, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Metaltech – Job Site Series Scaffold

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Top rated products include: 1. Metaltech I-IMIS Job Site Series 5′ Scaffold – $260.61, 100% recommend. 2. Werner 92-88 Cable Hook and V-Rung Assembly – $55.99, 100% recommend. 3. Louisville PK100C Rung Lock Kit – $12.16, 100% recommend. 4. Metaltech I-IBSJP12H4 Leveling Jack Pack of 4 – $89.99, 100% recommend. 5. Metaltech I-CISO4 14″ Outrigger Set for Maxi Square Baker Scaffold – $170.24, 88% rec…

3. IronPlanet – Scaffolding Models for Sale

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Scaffolding for sale includes various models such as Burke, Hydro-Mobile, INSTANT UPRIGHT (12 models), Lissamc, and others. Available models include F Series, F-300, M2, MAB3040, and SPAN 300. Locations include Europe (Germany, France, Netherlands) and the United States (California, Minnesota, New York, Texas, Washington) as well as Canada (Alberta, British Columbia, Quebec). The price range varie…

4. Scaffolding Rental & Sales – Used Scaffolding

Domain: scaffoldingrentalandsales.com

Registered: 2012 (13 years)

Introduction: Used scaffolding available for sale, including frames, scaffold boards, accessories, and used elevated platform (crank-up) scaffolding. Inventory changes daily, and items are sold as-is. Pricing varies based on availability. Used Non-Stop scaffolding is often restored, with repairs and repainting done. Buy back procedures available for used scaffolding. New scaffolding also offered at competitive …

Strategic Sourcing Conclusion and Outlook for used scaffolding for sale

In conclusion, the strategic sourcing of used scaffolding presents a unique opportunity for international B2B buyers to optimize construction costs while ensuring safety and reliability. Key takeaways include the importance of assessing inventory availability, understanding the condition and quality of used items, and leveraging buy-back programs to maintain cost efficiency. Buyers should prioritize suppliers that offer transparent information regarding the performance and history of used scaffolding to make informed purchasing decisions.

As the demand for scaffolding continues to grow globally, especially in emerging markets across Africa, South America, the Middle East, and Europe, strategic sourcing will play a crucial role in enhancing operational efficiency. By establishing strong supplier relationships and staying informed on market trends, businesses can secure high-quality scaffolding solutions that align with their project needs.

Looking forward, we encourage international buyers to engage with reputable suppliers, explore diverse inventory options, and consider the long-term value of used scaffolding. This proactive approach will not only drive project success but also contribute to sustainable construction practices in your region.

Illustrative image related to used scaffolding for sale

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to used scaffolding for sale