Choosing Your U Flat Spring: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for u flat spring

In the fast-paced world of manufacturing and engineering, sourcing reliable u flat springs can present significant challenges for international B2B buyers. With varying quality standards, diverse applications, and fluctuating costs, it is crucial to navigate this complex market effectively. This guide aims to equip you with the knowledge needed to make informed purchasing decisions regarding u flat springs, whether you are operating in Africa, South America, the Middle East, or Europe, including key markets like Brazil and Saudi Arabia.

Throughout this comprehensive resource, we will explore the different types of u flat springs available, their wide-ranging applications across industries—from automotive to aerospace—and essential considerations for supplier vetting. Understanding the nuances of material selection, manufacturing processes, and compliance standards is vital for ensuring that the springs you choose meet your specific operational requirements. Additionally, we will provide insights into pricing strategies and cost-effective sourcing methods to help you optimize your procurement process.

By the end of this guide, you will be empowered with actionable insights and expert recommendations to confidently navigate the global market for u flat springs. This will not only enhance your purchasing strategy but also contribute to the overall efficiency and reliability of your operations.

Understanding u flat spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Anti-Wrap U Flat Spring | Designed to prevent axle wrap, reinforced with skid plates | Off-road vehicles, trailers | Pros: Enhances durability, reduces maintenance needs. Cons: Higher initial cost due to added features. |

| Heavy-Duty U Flat Spring | Thicker steel construction, angled ends for lateral strength | Heavy machinery, automotive applications | Pros: Superior strength, customizable sizes. Cons: May be overkill for lighter applications. |

| Trailer U-Bolt Tie Plates | Designed for specific axle sizes, often zinc-coated | Trailers, agricultural equipment | Pros: Cost-effective, easy installation. Cons: Limited to specific applications and sizes. |

| Flat Strip Spring | Thin, rectangular design, versatile for various loads | Electronics, automotive, aerospace | Pros: Lightweight, flexible design. Cons: May require custom manufacturing for specific applications. |

| Custom U Flat Spring | Tailored dimensions and materials based on specific needs | Specialized machinery, niche automotive parts | Pros: Perfect fit for unique applications. Cons: Longer lead times and potentially higher costs. |

What are the Characteristics of Anti-Wrap U Flat Springs?

Anti-wrap U flat springs are specifically engineered to mitigate axle wrap in off-road vehicles and trailers. These springs often come with integrated skid plates that protect the U-bolt components from damage during rugged use. B2B buyers should consider their durability and the ability to enhance vehicle performance, especially in demanding environments. However, the initial investment may be higher compared to standard springs, making it essential to evaluate the long-term benefits.

How Do Heavy-Duty U Flat Springs Stand Out?

Heavy-duty U flat springs are characterized by their thicker steel construction and angled ends, which provide exceptional lateral strength. These springs are ideal for heavy machinery and automotive applications where reliability is crucial. B2B purchasers should note that while these springs offer superior strength and customization options, they may be excessive for lighter applications. The focus should be on matching the spring’s capabilities with the intended use case.

Why Choose Trailer U-Bolt Tie Plates?

Trailer U-bolt tie plates are designed for specific axle sizes and often feature a zinc coating for corrosion resistance. They are commonly used in trailers and agricultural equipment, providing a cost-effective solution for securing leaf springs. Buyers will appreciate the ease of installation and the competitive pricing; however, it’s important to ensure compatibility with existing axle specifications to avoid operational issues.

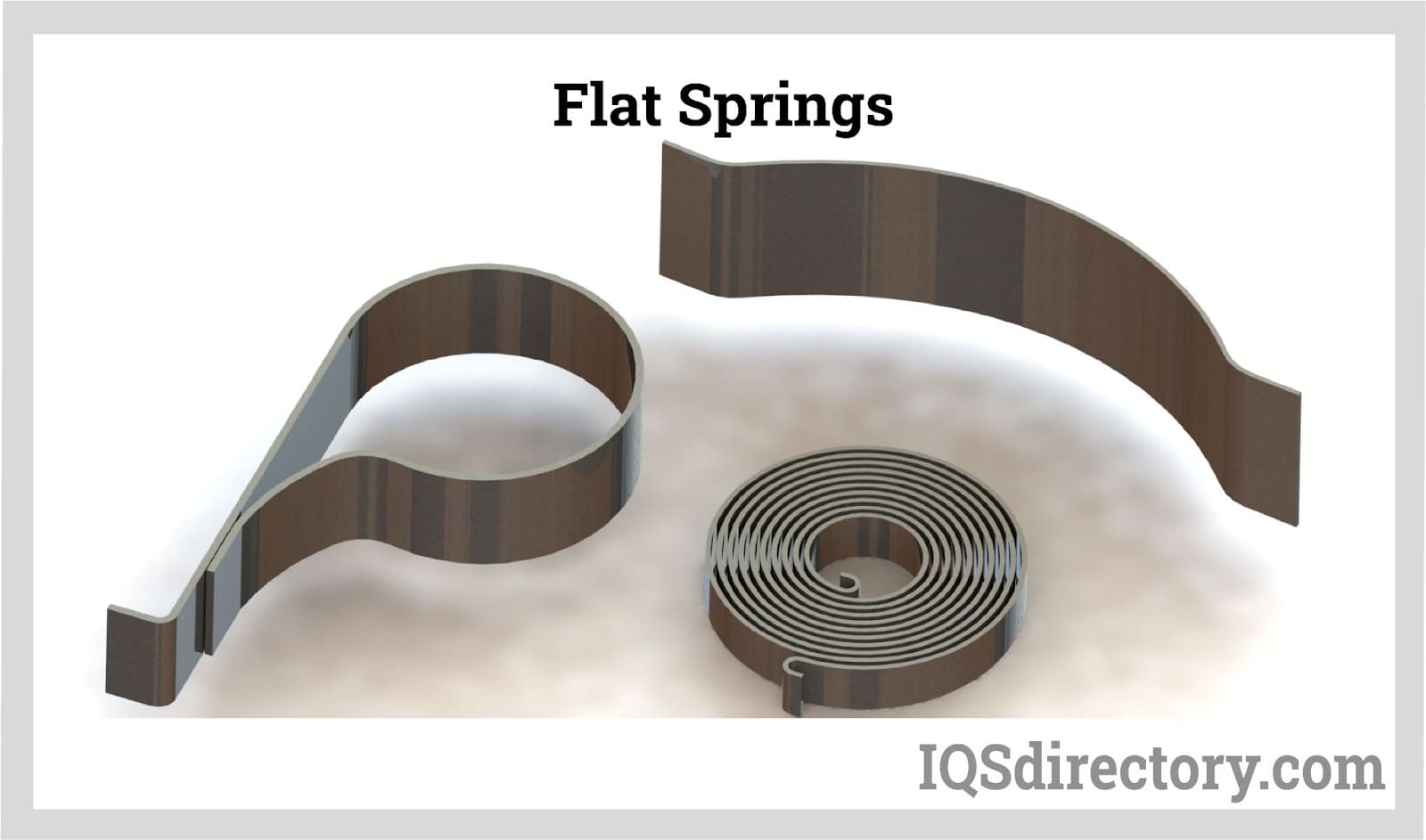

Illustrative image related to u flat spring

What Makes Flat Strip Springs Versatile?

Flat strip springs are thin, rectangular metal pieces that can flex under load, making them suitable for a wide range of applications, including electronics and aerospace. Their lightweight design allows for versatility in various mechanical systems. B2B buyers should consider the need for custom manufacturing to meet specific dimensions or load requirements, as this can affect lead times and costs.

When to Opt for Custom U Flat Springs?

Custom U flat springs are tailored to meet the unique specifications of specialized machinery or niche automotive parts. They offer the advantage of a perfect fit, which can significantly enhance performance in specific applications. However, buyers should be prepared for longer lead times and potentially higher costs, making it essential to assess whether the benefits outweigh the investment.

Key Industrial Applications of u flat spring

| Industry/Sector | Specific Application of u flat spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems in vehicles | Enhances ride quality and vehicle stability | Material durability, precision engineering, and compliance with safety standards. |

| Aerospace | Landing gear and control systems | Critical for safety and performance in flight operations | Aerospace-grade materials, weight considerations, and rigorous testing protocols. |

| Industrial Machinery | Machinery components in stamping and packaging machines | Improves operational efficiency and reduces downtime | Custom designs, compatibility with existing machinery, and high-volume production capabilities. |

| Electronics | Connectors and switches | Ensures reliability and longevity of electronic devices | Electrical conductivity, corrosion resistance, and precise dimensions. |

| Construction Equipment | Spring-loaded safety mechanisms in heavy machinery | Enhances safety and operational efficiency | Compliance with industry safety standards and ability to withstand harsh environments. |

How Are u Flat Springs Used in Automotive Applications?

In the automotive sector, u flat springs are integral to suspension systems, providing essential support that enhances ride quality and vehicle stability. They absorb shocks from uneven surfaces, ensuring a smoother ride for passengers and improved handling for drivers. Buyers in this field must consider the durability of materials, precision engineering to fit specific vehicle models, and adherence to safety standards, particularly when sourcing from international suppliers in regions like Africa and South America.

What Role Do u Flat Springs Play in Aerospace Applications?

In aerospace, u flat springs are crucial components in landing gear and control systems, where reliability is paramount. These springs must perform under extreme conditions, contributing to the safety and efficiency of flight operations. Buyers in this sector should prioritize aerospace-grade materials, weight considerations, and the implementation of rigorous testing protocols to ensure compliance with stringent safety regulations.

How Are u Flat Springs Utilized in Industrial Machinery?

Within industrial machinery, u flat springs are employed in stamping and packaging machines to maintain consistent operational efficiency. They play a vital role in the movement of components and the overall function of machines, reducing downtime caused by mechanical failures. Buyers should look for custom designs that fit their specific machinery, ensuring compatibility and high-volume production capabilities, especially when sourcing from global suppliers.

Illustrative image related to u flat spring

Why Are u Flat Springs Important in Electronics?

In the electronics industry, u flat springs are commonly used in connectors and switches, where they provide reliable and long-lasting performance. These springs help maintain the integrity of electrical connections, ensuring devices function optimally over time. Buyers should focus on sourcing springs with excellent electrical conductivity, corrosion resistance, and precise dimensions to meet the demands of various electronic applications, particularly when engaging with suppliers across different continents.

How Do u Flat Springs Enhance Safety in Construction Equipment?

In construction equipment, u flat springs are often integrated into spring-loaded safety mechanisms, enhancing the overall safety and operational efficiency of heavy machinery. These springs help prevent accidents by ensuring that safety features engage properly under load. Buyers in this sector must ensure that their sourced springs comply with industry safety standards and can withstand the harsh environments typical of construction sites, especially when dealing with international suppliers in regions like the Middle East and Europe.

3 Common User Pain Points for ‘u flat spring’ & Their Solutions

Scenario 1: Managing Inventory for Diverse Applications

The Problem: B2B buyers often face the challenge of maintaining adequate inventory levels of u flat springs that cater to various applications across different industries, such as automotive, aerospace, and electronics. The complexity arises from the need to balance stock levels against fluctuating demand, which can lead to either excess inventory or shortages. Excess inventory ties up capital and increases storage costs, while shortages can disrupt production schedules and harm customer relationships.

The Solution: To effectively manage inventory, buyers should implement a just-in-time (JIT) inventory system that aligns stock levels with actual production schedules. This involves collaborating closely with manufacturers to forecast demand accurately and establish a reliable supply chain. Utilizing data analytics tools can help buyers predict trends based on historical usage and seasonal fluctuations. Additionally, maintaining a small buffer stock of critical sizes or types of u flat springs can safeguard against unexpected demand spikes. Engaging in strategic partnerships with suppliers can also facilitate quicker restocking, ensuring that buyers are never caught off guard.

Scenario 2: Ensuring Quality and Compliance Standards

The Problem: Quality assurance is a significant concern for B2B buyers sourcing u flat springs, especially in industries like automotive and aerospace, where compliance with stringent regulations is mandatory. Buyers may struggle to find suppliers who can consistently meet quality and compliance standards, which can lead to defective products, costly recalls, and potential legal ramifications.

The Solution: Buyers should prioritize suppliers that adhere to internationally recognized quality management systems, such as ISO 9001. Requesting detailed certifications and quality control documentation can provide assurance of a supplier’s commitment to maintaining high standards. Additionally, conducting regular audits and quality checks on incoming shipments can help catch any issues early. Establishing a collaborative relationship with the supplier can also facilitate open communication regarding quality expectations, allowing for adjustments in production processes if necessary. Finally, leveraging technology, such as automated inspection systems, can enhance quality assurance efforts by ensuring consistent monitoring of product specifications.

Scenario 3: Customization Challenges for Unique Applications

The Problem: Many B2B buyers require customized u flat springs to meet specific application needs. This can be particularly challenging when the required specifications are outside the standard offerings of suppliers, leading to delays in production and increased costs. Buyers may find themselves frustrated when suppliers are unable or unwilling to accommodate custom requests, which can stall project timelines.

The Solution: To overcome customization challenges, buyers should clearly define their specifications and requirements before initiating discussions with suppliers. Providing detailed drawings, material requirements, and performance expectations can help suppliers understand the exact needs. Engaging with manufacturers that specialize in custom solutions can also be beneficial; these suppliers often have the expertise and flexibility to adapt their processes to meet unique demands. Furthermore, conducting feasibility studies and prototyping can allow buyers to test the custom u flat springs before full-scale production, ensuring that they meet performance criteria without incurring significant costs or delays. Building a strong relationship with a responsive supplier can also facilitate a smoother customization process, fostering innovation and responsiveness to changing needs.

Strategic Material Selection Guide for u flat spring

What Are the Key Properties of Common Materials for U Flat Springs?

When selecting materials for u flat springs, it is crucial to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials: carbon steel, stainless steel, spring steel, and plastic composites.

How Does Carbon Steel Perform in U Flat Spring Applications?

Carbon steel is a widely used material for manufacturing u flat springs due to its excellent strength-to-weight ratio and affordability. It exhibits good tensile strength and can withstand moderate pressure and temperature variations. However, carbon steel is prone to corrosion, which can limit its application in environments exposed to moisture or chemicals.

Pros: Cost-effective, readily available, and easy to manufacture.

Cons: Limited corrosion resistance, which can lead to premature failure in harsh environments.

Impact on Application: Suitable for general-purpose applications but may require protective coatings or treatments for enhanced durability.

Considerations for International Buyers: Compliance with ASTM standards is common; however, buyers in regions like Africa and South America may need to consider local environmental conditions that affect material longevity.

What Advantages Does Stainless Steel Offer for U Flat Springs?

Stainless steel is renowned for its corrosion resistance and durability, making it ideal for applications that require exposure to moisture or chemicals. It maintains its strength over a wide temperature range and is less likely to deform under stress compared to carbon steel.

Pros: Excellent corrosion resistance and longevity.

Cons: Higher cost compared to carbon steel and may require more complex manufacturing processes.

Impact on Application: Ideal for automotive and aerospace applications where exposure to harsh conditions is expected.

Considerations for International Buyers: Standards such as DIN and JIS are critical for ensuring quality; buyers should verify that suppliers meet these standards.

Why Choose Spring Steel for U Flat Springs?

Spring steel, a type of carbon steel, is specifically designed for high-stress applications. It has superior yield strength and elasticity, allowing it to return to its original shape after deformation. This material is particularly effective in applications requiring repeated cycling.

Pros: High tensile strength and fatigue resistance.

Cons: More expensive than standard carbon steel and may require specialized heat treatment.

Impact on Application: Highly suitable for automotive suspension systems and heavy machinery where durability is paramount.

Considerations for International Buyers: Buyers should ensure compliance with local regulations and standards, especially in Europe, where quality control is stringent.

Are Plastic Composites a Viable Option for U Flat Springs?

Plastic composites are increasingly being used in applications where weight reduction is essential. These materials offer good corrosion resistance and are lightweight, making them suitable for specific applications in electronics and automotive sectors.

Pros: Lightweight, corrosion-resistant, and can be molded into complex shapes.

Cons: Lower strength compared to metals and may not withstand high temperatures or pressures.

Impact on Application: Best for low-stress applications or where weight savings are critical.

Considerations for International Buyers: Compliance with relevant safety and performance standards is essential, particularly in the electronics sector, where certifications can vary by region.

Summary of Material Selection for U Flat Springs

| Material | Typical Use Case for u flat spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General-purpose applications | Cost-effective and readily available | Prone to corrosion | Low |

| Stainless Steel | Automotive and aerospace | Excellent corrosion resistance | Higher cost | High |

| Spring Steel | Heavy machinery and automotive | High tensile strength | More expensive | Med |

| Plastic Composites | Electronics and lightweight applications | Lightweight and corrosion-resistant | Lower strength | Med |

This guide provides a comprehensive overview of material options for u flat springs, helping international B2B buyers make informed decisions based on performance, cost, and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for u flat spring

What Are the Key Stages in the Manufacturing Process of U Flat Springs?

The manufacturing of U flat springs involves several critical stages that ensure precision, durability, and reliability. Each stage is designed to convert raw materials into finished products that meet specific performance standards.

1. Material Preparation

The first step in manufacturing U flat springs is material preparation. Typically, high-quality steel or stainless steel is chosen for its strength and elasticity. The material is sourced from reputable suppliers, and the first quality check occurs at this stage, known as Incoming Quality Control (IQC). The raw materials are then cut into strips of the required width and length, which are crucial for the final dimensions of the flat springs.

2. Forming Techniques

Once the material is prepared, it undergoes various forming techniques. Common methods include:

- Stamping: This technique uses dies to cut and shape the flat strips into the desired form. Stamping is efficient for high-volume production and ensures uniformity across multiple pieces.

- Bending: After stamping, the strips may be bent to create the U shape. Precision bending machines are used to achieve the exact angles and radii required for specific applications.

- Coiling: For certain designs, coiling may be employed to create tension in the spring. This involves winding the flat strip into a coil shape, which is then heat-treated to enhance its strength.

These forming techniques are often conducted in a controlled environment to minimize the risk of defects.

3. Assembly

In some cases, U flat springs may require assembly with other components, such as U-bolts or mounting plates. This stage may involve welding or bolting, depending on the design specifications. Assembly is usually done under strict quality control measures to ensure that all components fit correctly and operate as intended.

4. Finishing Processes

The finishing stage is essential for enhancing the durability and aesthetic appeal of the U flat springs. Common finishing processes include:

- Heat Treatment: This process strengthens the springs by altering their microstructure, improving elasticity and fatigue resistance.

- Surface Treatment: Options such as powder coating, galvanization, or plating are employed to protect the springs from corrosion and wear. This is particularly important for applications in harsh environments.

- Quality Inspection: Before the final product is shipped, a thorough quality inspection is performed to ensure that all specifications are met.

How Is Quality Assurance Implemented in U Flat Spring Manufacturing?

Quality assurance is critical in maintaining the integrity and performance of U flat springs. This involves adherence to international standards and industry-specific regulations.

Relevant International Standards for Quality Assurance

Manufacturers of U flat springs often comply with ISO 9001, a globally recognized standard for quality management systems. This standard emphasizes continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the end-use of the springs.

Illustrative image related to u flat spring

Quality Control Checkpoints: What Should B2B Buyers Look For?

Quality control is integrated into every stage of the manufacturing process, with specific checkpoints established to ensure compliance with standards:

- Incoming Quality Control (IQC): This initial check verifies the quality of raw materials before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is crucial. This includes assessing dimensional accuracy and ensuring that each stage meets predefined standards.

- Final Quality Control (FQC): The final inspection before shipment is essential. This includes functional testing, dimensional checks, and visual inspections to catch any defects.

What Common Testing Methods Are Used for U Flat Springs?

Testing methods for U flat springs are essential to validate their performance under various conditions. Common testing methods include:

- Tensile Testing: This measures the strength of the material and its ability to withstand pulling forces without breaking.

- Fatigue Testing: This assesses how well the spring can endure repeated cycles of loading and unloading, simulating real-world usage.

- Dimensional Inspection: Precision measuring tools are used to ensure that the springs meet the specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital. Here are several strategies:

- Supplier Audits: Conducting audits allows buyers to assess the manufacturing processes and quality control systems directly. This can help identify any potential issues before placing large orders.

- Requesting Quality Reports: Buyers should ask for documentation that outlines the quality assurance processes, including test results and compliance certifications.

- Third-party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures.

What Are the Nuances of Quality Control and Certification for International B2B Buyers?

International buyers must navigate various regulatory and quality standards that may differ from their local practices. Understanding these nuances is crucial for successful procurement:

Illustrative image related to u flat spring

- Regional Compliance: Different regions may have unique requirements for product certifications. For example, European buyers might require CE marking, while buyers in the Middle East might look for API certifications for oil and gas applications.

- Cultural Considerations: Establishing strong relationships with suppliers can facilitate better communication regarding quality expectations and standards.

By understanding the manufacturing processes and quality assurance practices associated with U flat springs, B2B buyers can make informed decisions, ensuring they source reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘u flat spring’

Introduction

This guide provides a structured approach for B2B buyers looking to procure U flat springs, ensuring that you make informed decisions throughout the sourcing process. By following this checklist, you can efficiently navigate supplier selection, quality assurance, and cost considerations tailored to your specific needs.

1. Define Your Technical Specifications

Before you start sourcing U flat springs, it’s essential to clearly define your technical requirements. Specifications should include dimensions, materials, load capacities, and any specific design features needed for your application.

– Material Selection: Determine if you need standard steel, stainless steel, or a specialized alloy based on environmental conditions.

– Load Requirements: Specify the spring’s load capacity to ensure it meets your operational demands.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in U flat springs. Look for manufacturers with a solid reputation in your industry and region.

– Online Directories: Utilize platforms like ThomasNet or Alibaba to find credible suppliers.

– Industry Recommendations: Seek referrals from industry peers or trade associations that can point you toward reputable manufacturers.

3. Evaluate Supplier Certifications

Verify that potential suppliers hold necessary certifications and quality standards relevant to your industry, such as ISO 9001 or ASTM certifications.

– Quality Assurance: These certifications indicate a commitment to quality and reliability in manufacturing processes.

– Compliance: Ensure that the supplier adheres to international safety and environmental regulations, which can be particularly important for industries like automotive or aerospace.

4. Request Samples for Testing

Before making a bulk purchase, request samples of the U flat springs. Testing samples will help you assess the product’s quality and performance in real-world applications.

– Performance Testing: Evaluate how the springs perform under load and check for any signs of deformation or failure.

– Compatibility: Ensure that the samples fit your equipment or assembly line specifications seamlessly.

5. Negotiate Terms and Pricing

Once you have identified a suitable supplier, initiate negotiations on pricing, lead times, and payment terms.

– Volume Discounts: Inquire about bulk pricing or long-term contracts that could reduce costs.

– Flexible Payment Options: Discuss payment terms that align with your financial strategy, considering options like net 30 or net 60.

6. Establish a Communication Plan

Clear communication with your supplier is crucial for a successful partnership. Set up a plan for regular updates on production status and delivery timelines.

– Point of Contact: Designate a primary contact person for both parties to streamline communication.

– Feedback Mechanism: Establish a process for providing feedback on the product quality and service, allowing for continuous improvement.

7. Plan for Logistics and Delivery

Finally, consider the logistics involved in receiving your U flat springs. Coordinate with your supplier to ensure timely delivery that aligns with your project timelines.

– Shipping Options: Evaluate the most cost-effective shipping methods based on urgency and budget.

– Customs and Duties: If sourcing internationally, be aware of customs regulations and potential duties that may affect the overall cost.

By following this checklist, you can ensure a streamlined procurement process for U flat springs, maximizing both quality and value for your business.

Comprehensive Cost and Pricing Analysis for u flat spring Sourcing

In the world of B2B sourcing for u flat springs, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. This analysis delves into the various components that contribute to the total cost of these essential components, along with factors influencing pricing, particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for U Flat Springs?

Materials: The primary cost driver in u flat spring manufacturing is the raw materials used. Typically, these springs are made from high-carbon steel or stainless steel, with prices fluctuating based on global steel market conditions. The choice of material significantly impacts durability and performance, affecting the overall cost.

Labor: Labor costs can vary significantly based on the region where the springs are manufactured. Countries with lower labor costs may offer more competitive pricing, but this can come at the expense of quality. Skilled labor is essential for precision manufacturing, particularly in custom or complex designs.

Manufacturing Overhead: This includes costs related to utilities, maintenance, and facility expenses. Overhead costs are often factored into the price per unit, especially for manufacturers with advanced equipment and technology.

Tooling: The initial setup and tooling costs can be substantial, particularly for custom spring designs. These costs are typically amortized over the production run, meaning larger orders can help reduce the per-unit cost.

Quality Control (QC): Ensuring that each u flat spring meets specific standards is vital. Rigorous QC processes can add to costs but are essential for maintaining product integrity and compliance with industry standards, especially for applications in sectors like automotive and aerospace.

Logistics: Shipping and handling costs can vary based on the destination, shipping method, and size of the order. For international buyers, understanding Incoterms is critical as they dictate who bears the costs and risks during transportation.

Margin: Supplier margins will also influence the final price. These margins can differ based on competition, brand reputation, and market demand.

How Do Volume and Customization Affect U Flat Spring Pricing?

Volume/MOQ: Pricing is often tiered based on order volume. Higher quantities typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to maximize cost efficiency.

Specifications and Customization: Custom-designed springs that require unique specifications will generally incur higher costs. Buyers should carefully assess whether the benefits of customization justify the additional expense.

What Buyer Tips Can Help Reduce Costs?

Negotiation: Effective negotiation is essential in securing the best price. Buyers should be prepared to discuss volume discounts, payment terms, and other factors that could lead to cost reductions.

Total Cost of Ownership (TCO): When evaluating suppliers, it’s crucial to consider not just the upfront costs but also the total cost of ownership. This includes maintenance, longevity, and performance of the springs, which can significantly impact long-term costs.

Pricing Nuances for International Buyers: International buyers, particularly from regions such as Africa and South America, should be aware of additional factors like import duties, tariffs, and currency fluctuations that can affect the final cost of u flat springs. Understanding local regulations and compliance standards is also essential to avoid unexpected expenses.

Conclusion

In summary, a comprehensive understanding of the cost structure and pricing influencers for u flat springs can empower B2B buyers to make strategic sourcing decisions. By considering material costs, labor, manufacturing overhead, and logistics, along with negotiating effectively and understanding the total cost of ownership, buyers can optimize their procurement processes. Always remember that prices can fluctuate, and it’s wise to request current quotes and be aware of market trends when planning purchases.

Alternatives Analysis: Comparing u flat spring With Other Solutions

Understanding Alternative Solutions to U Flat Springs

When evaluating the best solution for suspension systems, it’s essential to consider alternatives to U flat springs. Various options exist, each with unique benefits and limitations. This analysis compares U flat springs with two viable alternatives: leaf springs and coil springs. By examining performance, cost, ease of implementation, maintenance, and best use cases, international B2B buyers can make informed decisions tailored to their operational needs.

| Comparison Aspect | U Flat Spring | Leaf Springs | Coil Springs |

|---|---|---|---|

| Performance | High load capacity, rigidity | Excellent for heavy loads, flexibility | Good for shock absorption, adjustable stiffness |

| Cost | Moderate cost | Generally lower cost | Higher initial investment |

| Ease of Implementation | Simple installation | Requires skilled labor | Easy installation with proper tools |

| Maintenance | Low maintenance | Moderate, may require periodic checks | Low maintenance, durable |

| Best Use Case | High-performance vehicles, industrial applications | Trucks, trailers, off-road vehicles | Sports cars, machinery needing precision |

Exploring Alternatives in Detail

Leaf Springs

Leaf springs consist of several layers of metal strips (leaves) that provide support and flexibility. They are commonly used in heavy-duty applications, such as trucks and trailers, due to their ability to handle significant loads. One of the primary advantages of leaf springs is their lower cost compared to U flat springs, making them a budget-friendly choice for many businesses. However, they can be less efficient in terms of performance, as they may not provide the same level of rigidity. Additionally, leaf springs require skilled labor for installation and may need periodic maintenance checks to ensure optimal performance.

Coil Springs

Coil springs are a popular choice for applications requiring superior shock absorption and ride quality. They are designed to compress and expand, allowing for adjustable stiffness based on the load requirements. While coil springs generally offer a higher initial investment, they provide excellent long-term value due to their durability and low maintenance needs. Their installation is relatively straightforward, which can minimize labor costs. However, coil springs may not be suitable for extremely heavy loads, making them less ideal for certain industrial applications compared to U flat springs.

Making the Right Choice for Your Needs

Choosing the right suspension solution for your business depends on various factors, including load requirements, budget constraints, and specific application needs. U flat springs offer a robust solution for high-performance and industrial applications, while leaf springs can be more cost-effective for heavy-duty vehicles. Coil springs excel in applications needing superior ride quality but may come with higher upfront costs.

B2B buyers should carefully assess their operational demands, considering not only the performance and cost but also the ease of implementation and maintenance requirements. By weighing these aspects against the unique needs of their projects, businesses can select the most suitable suspension solution that aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for u flat spring

What Are the Key Technical Properties of U Flat Springs?

Understanding the technical properties of U flat springs is essential for B2B buyers to ensure they meet specific application requirements. Here are several critical specifications:

1. Material Grade

U flat springs are typically made from various materials, including carbon steel, stainless steel, and alloy steel. The choice of material affects durability, flexibility, and resistance to corrosion. For instance, stainless steel offers superior corrosion resistance, making it ideal for outdoor or marine applications. Buyers should consider the operating environment and load requirements when selecting the appropriate material grade.

2. Thickness

The thickness of a U flat spring significantly impacts its load-bearing capacity and flexibility. Thicker springs generally provide greater strength and stiffness but may limit the range of motion. Understanding the required thickness is vital for ensuring the spring performs effectively in its intended application, whether in automotive, aerospace, or industrial machinery.

3. Tolerance

Tolerance refers to the allowable variation in dimensions and performance of the spring. Tight tolerances are crucial in applications where precision is critical, such as in automotive or aerospace components. Poor tolerance can lead to failure or reduced efficiency, making it essential for buyers to specify their tolerance requirements clearly to manufacturers.

4. Yield Strength

Yield strength indicates the maximum stress that a material can withstand without permanent deformation. For U flat springs, a higher yield strength means the spring can endure greater loads and stresses. B2B buyers should assess the yield strength relative to the expected operational loads to ensure optimal performance and longevity.

5. Finish Type

The surface finish of U flat springs can influence their performance and lifespan. Common finishes include galvanized, powder-coated, or oil-treated surfaces. Each finish offers varying levels of corrosion resistance and aesthetic appeal. Buyers must consider the intended application and environmental factors when selecting the appropriate finish type.

What Common Trade Terms Should B2B Buyers Know About U Flat Springs?

Familiarity with industry terminology can enhance communication and streamline the procurement process. Here are several common trade terms related to U flat springs:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of U flat springs, buyers may seek OEM suppliers to ensure compatibility with existing machinery or systems. Understanding OEM specifications helps in maintaining quality and performance standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For U flat springs, MOQs can vary significantly among suppliers. Buyers should inquire about MOQs to avoid overcommitting resources while ensuring they meet production needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting price quotes for specific products or services. When seeking U flat springs, an RFQ should detail the required specifications, quantities, and delivery timelines to facilitate accurate pricing and lead time estimates.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risk transfer, and delivery obligations when purchasing U flat springs from international suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order until it is delivered. For U flat springs, lead times can vary based on manufacturing capabilities and material availability. Buyers should consider lead times when planning production schedules to avoid delays in their operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing U flat springs, ensuring that they select the right products for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the u flat spring Sector

What Are the Key Drivers Influencing the U Flat Spring Market?

The global u flat spring market is currently experiencing significant growth, driven by advancements in automotive, aerospace, and industrial applications. As manufacturers increasingly seek lightweight and durable components, u flat springs, made from high-strength materials, are gaining traction. Notably, the rise of electric vehicles (EVs) is reshaping demand patterns, as these vehicles often require innovative suspension systems that utilize advanced spring technologies. In regions like Africa, South America, and the Middle East, the expansion of infrastructure projects and the automotive industry further bolster demand for u flat springs.

Emerging technologies, such as automation and Industry 4.0 practices, are transforming sourcing strategies. B2B buyers are increasingly leveraging digital procurement tools to streamline their supply chain processes. This trend is particularly evident in Europe, where e-commerce platforms are facilitating easier access to suppliers and enabling buyers to compare prices and specifications efficiently. Additionally, the growing emphasis on just-in-time (JIT) manufacturing is pushing businesses to rethink their inventory strategies, opting for suppliers who can ensure timely deliveries without sacrificing quality.

How Can B2B Buyers Address Sustainability and Ethical Sourcing in the U Flat Spring Sector?

The importance of sustainability in manufacturing is more pronounced than ever. B2B buyers are increasingly prioritizing suppliers who implement eco-friendly practices in their production processes. This includes utilizing recycled materials or adopting green certifications, which not only reduces environmental impact but also enhances the brand image of the buyer’s business. In the u flat spring sector, sourcing from suppliers that adhere to sustainable practices can significantly contribute to a company’s overall sustainability goals.

Ethical sourcing is equally crucial, especially in international markets. Buyers are encouraged to conduct thorough due diligence to ensure that their suppliers maintain fair labor practices and comply with environmental regulations. Certifications such as ISO 14001 for environmental management systems and ISO 9001 for quality management can serve as benchmarks for assessing supplier credibility. By aligning procurement strategies with sustainability and ethical sourcing criteria, businesses can build resilient supply chains that resonate with increasingly conscientious consumers.

What Is the Historical Context of U Flat Springs in B2B Markets?

The evolution of u flat springs can be traced back to their early applications in transportation and machinery. Initially, these springs were primarily used in horse-drawn vehicles, providing necessary suspension support. With the advent of the automotive industry in the early 20th century, the design and manufacturing processes of flat springs saw significant advancements. The integration of new materials and manufacturing techniques, such as heat treatment and precision machining, enhanced their performance and durability.

As industries progressed, the application of u flat springs expanded beyond automotive uses to include aerospace and heavy machinery. This diversification has been fueled by ongoing innovations and the need for higher efficiency and reliability in various mechanical systems. Today, u flat springs are essential components in a wide range of applications, reflecting their versatility and the continuous demand for high-performance materials in global markets. B2B buyers should consider this historical context when evaluating suppliers, as experience and expertise can be critical factors in ensuring product quality and reliability.

Frequently Asked Questions (FAQs) for B2B Buyers of u flat spring

-

How do I solve issues with flat springs in my machinery?

To address problems with flat springs, first, identify the specific issue—be it fatigue, deformation, or incorrect sizing. Ensure that you are using the right material and specifications for your application. Regular maintenance checks can help detect wear and tear early. If problems persist, consult with a manufacturer for custom solutions or replacements that meet your precise needs. They can also provide guidance on improving the design or material to enhance longevity and performance. -

What is the best flat spring design for high-stress applications?

For high-stress applications, a flat spring made from high-carbon steel or stainless steel is often ideal due to their superior strength and fatigue resistance. Additionally, consider designs that incorporate reinforcement features, such as thicker sections or curved geometries, to enhance performance under load. Engaging with an experienced supplier can provide insights into the most effective design tailored to your specific requirements, ensuring reliability in demanding environments. -

How can I vet suppliers of u flat springs for international trade?

When vetting suppliers, start by checking their reputation through industry reviews and references. Request samples to evaluate quality and compliance with international standards. Ensure they have experience in your specific market and understand the regulatory requirements of your region. Additionally, verify their manufacturing capabilities and inquire about their quality assurance processes. A reliable supplier should also be willing to provide certifications and have a transparent communication process. -

What are typical minimum order quantities (MOQ) for flat springs?

Minimum order quantities for flat springs can vary significantly by supplier and the specifics of the design. Generally, MOQs can range from 100 to 1,000 units for standard products, while custom designs may require higher quantities. Discussing your needs directly with suppliers can sometimes lead to flexibility, especially if you are willing to pay a premium for smaller runs or if you are a first-time customer looking to establish a relationship. -

What payment terms should I expect when sourcing u flat springs internationally?

Payment terms can vary widely between suppliers. Common terms include a deposit of 30-50% upfront with the balance due upon delivery or after inspection. Some suppliers may offer net terms (e.g., net 30 or net 60 days), especially for established customers. It’s essential to clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal. Always ensure that the terms are documented in a contract to avoid misunderstandings. -

How do I ensure quality assurance for flat springs sourced internationally?

To ensure quality assurance, request detailed specifications and tolerances from your supplier. Establish a clear quality control process that includes inspections at various stages of production. Consider third-party inspection services to verify compliance with international standards before shipment. Additionally, building a strong relationship with your supplier can facilitate better communication regarding quality expectations and improvements. -

What logistics considerations should I be aware of when importing flat springs?

When importing flat springs, consider shipping methods, lead times, and customs regulations specific to your country. Choose a reliable freight forwarder familiar with importing industrial components. Understanding tariffs and duties applicable to your products is crucial for budgeting. Additionally, ensure proper documentation accompanies your shipment to facilitate smooth customs clearance and avoid delays. -

Can I customize flat springs for specific applications?

Yes, many manufacturers offer customization options for flat springs to meet specific application requirements. You can modify dimensions, materials, and spring characteristics such as stiffness and load capacity. When discussing customization, provide detailed specifications and any relevant application data to the supplier. Collaborating closely with the manufacturer can help ensure that the final product meets your needs effectively.

Top 4 U Flat Spring Manufacturers & Suppliers List

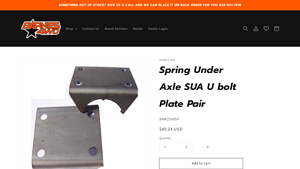

1. Barnes 4WD – Spring Under Axle SUA U Bolt Plate Pair

Domain: barnes4wd.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “Spring Under Axle SUA U bolt Plate Pair”, “brand”: “Barnes 4WD”, “sku”: “B4W25085P”, “price”: “40.24 USD”, “description”: “The Barnes 4WD SUA U bolt plate allows you to set up your spring under suspension in a way that the square u bolt nuts are on top so they are not hanging down low and being damaged. This also removes the chance of your u bolt nuts getting hung on a rock. Thes…

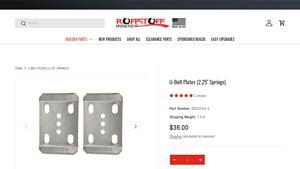

2. Springworks – Trailer U-Bolt Plates

Domain: springworks.com

Registered: 1997 (28 years)

Introduction: [{‘name’: ‘Trailer U-Bolt Plate – 3″ Round Axle – 1-3/4″ And 2″ Wide Spring – 9/16″ U-Bolt – 4201-3’, ‘price’: ‘$9.00’}, {‘name’: ‘Trailer U-Bolt Plate – 2-3/8″ Round Axle – 1-3/4″ Wide Spring – 1/2″ U-Bolt – 4202-3’, ‘price’: ‘$6.12’}, {‘name’: ‘Trailer U-Bolt Plate – 2″ Square Axle – 1-3/4″ And 2″ Wide Springs – 1/2″ U-Bolt – Zinc – 4203-3ZP’, ‘price’: ‘$8.76’}, {‘name’: ‘Trailer U-Bolt Plate – …

3. Ruff Stuff Specialties – R2033-Kit-1

Domain: ruffstuffspecialties.com

Registered: 2005 (20 years)

Introduction: {“Part Number”:”R2033-Kit-1″,”Price”:”$36.00″,”Shipping Weight”:”7.5 lb”,”Fitment”:”Early Ford Bronco 1966–1977, 2.25″ leaf springs”,”Material”:”3/8″ thick HR P&O steel plate with 45-degree angled ends”,”Dimensions”:”2.5″–3.5″ axle tube diameter compatibility”,”Design”:”Three mounting positions for wheelbase adjustment”,”Included Items”:”(2) U-bolt plates with angled ends, U-bolts for 2.25″ spring…

4. Western Spring – Flat Springs

Domain: westernspring.com

Registered: 2000 (25 years)

Introduction: Flat springs, also known as flat strip springs, are thin, rectangular metal pieces made from materials like steel or stainless steel. They store and release energy by flexing or deforming when a force is applied and return to their original shape when the force is removed. Applications include automotive, aerospace, industrial, and electronics. Western Spring Manufacturing offers custom flat sprin…

Strategic Sourcing Conclusion and Outlook for u flat spring

In the dynamic landscape of global manufacturing, the strategic sourcing of u flat springs presents a pivotal opportunity for B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the diverse applications of flat springs—from automotive to aerospace—enables companies to make informed decisions that enhance operational efficiency and product reliability. By prioritizing quality, buyers can mitigate risks associated with supply chain disruptions and ensure the longevity of their products.

Investing in strategic sourcing not only allows for cost-effective procurement but also fosters partnerships with manufacturers who are committed to innovation and quality assurance. As demand for robust and versatile components continues to rise, aligning with trusted suppliers will be crucial for maintaining competitive advantage.

Looking ahead, international buyers should actively seek out manufacturers that offer customization options and demonstrate a commitment to sustainable practices. Engaging with suppliers who understand regional market needs can unlock new avenues for growth and innovation. Take the next step in securing your supply chain by exploring partnerships that emphasize quality and strategic alignment in the sourcing of u flat springs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.