Choosing Your Temco Fremont: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for temco fremont

In the ever-evolving landscape of global commerce, sourcing high-quality industrial tools and equipment from TEMCo Fremont presents a unique challenge for international B2B buyers. As businesses seek reliable suppliers to meet their operational demands, understanding the intricacies of product types, applications, and supplier vetting becomes essential. This comprehensive guide delves into the diverse offerings from TEMCo, from advanced hydraulic jacks to precision electrical components, equipping buyers with the knowledge to navigate the complexities of sourcing.

In this guide, we will explore the various product categories available through TEMCo, examining their applications across different industries. We will also provide insights on how to effectively vet suppliers to ensure quality and reliability. Additionally, we will address cost considerations and logistics, offering practical tips for making informed purchasing decisions.

Designed specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Brazil and Vietnam—this guide empowers you to confidently navigate the global market. By leveraging the insights provided, you will be better positioned to establish fruitful partnerships with TEMCo and secure the industrial tools and equipment necessary for your business success.

Understanding temco fremont Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Tools | High durability, precision engineering, extensive range | Manufacturing, construction | Pros: Reliable quality; Cons: Higher initial cost |

| Electrical Components | Broad range of products including transformers and motors | Power generation, automation | Pros: Versatile applications; Cons: Requires expertise |

| Hydraulic Equipment | Robust design, high load capacity, various sizes available | Heavy machinery, automotive | Pros: Excellent reliability; Cons: Maintenance needed |

| Cable Management Tools | Specialized tools for effective cable handling and organization | Telecommunications, data centers | Pros: Enhances efficiency; Cons: Limited to specific tasks |

| Custom Solutions | Tailored products to meet specific client needs | OEM applications, specialized industries | Pros: Perfect fit for unique needs; Cons: Longer lead times |

What Are the Characteristics of Industrial Tools from TEMCo Fremont?

TEMCo Fremont’s industrial tools are known for their high durability and precision engineering. These tools are designed to withstand the rigors of manufacturing and construction environments. B2B buyers looking for reliable equipment will find that these tools often come with extensive warranties and customer support. When purchasing, it’s essential to consider the specific requirements of your operations, including the frequency of use and the types of materials being handled.

How Do Electrical Components from TEMCo Benefit B2B Applications?

TEMCo offers a broad range of electrical components, such as transformers and electric motors, which are integral to various power generation and automation processes. These components are versatile and can be used across multiple industries, including energy, telecommunications, and manufacturing. B2B buyers should evaluate compatibility with existing systems and ensure that they comply with relevant industry standards. The investment in high-quality electrical components can lead to enhanced efficiency and reduced downtime.

What Should Buyers Know About Hydraulic Equipment from TEMCo?

The hydraulic equipment provided by TEMCo is designed for heavy-duty applications, featuring robust designs and high load capacities. This equipment is essential in sectors such as automotive and heavy machinery. Buyers should assess the specific load requirements and operational conditions to ensure the equipment selected meets their needs. While these products are typically reliable, they may require regular maintenance to sustain optimal performance, which is a crucial consideration for long-term operational costs.

How Can Cable Management Tools Improve Efficiency in B2B Environments?

TEMCo’s cable management tools are specialized for effective handling and organization of cables, making them indispensable in telecommunications and data center environments. These tools help streamline operations and improve safety by reducing clutter. B2B buyers should consider the scale of their cable management needs and how these tools can integrate with existing systems. While they enhance operational efficiency, their utility may be limited to specific tasks, so understanding the full scope of needs is vital.

What Are the Advantages of Custom Solutions Offered by TEMCo?

TEMCo’s custom solutions allow businesses to obtain tailored products that meet unique specifications, particularly in OEM applications and specialized industries. This flexibility can lead to improved functionality and performance in specific environments. Buyers should be prepared for longer lead times and potentially higher costs, but the benefits of having a product that perfectly fits their operational requirements often outweigh these considerations. Engaging in thorough discussions with TEMCo representatives can ensure that the final product aligns with business objectives.

Key Industrial Applications of temco fremont

| Industry/Sector | Specific Application of temco fremont | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Hydraulic jacks for machinery lifting and positioning | Increases operational efficiency and safety | Verify load capacity, ensure compliance with safety standards, and check warranty terms. |

| Electrical Engineering | Custom electrical components for power distribution | Enhances system reliability and performance | Confirm compatibility with existing systems and inquire about lead times for custom orders. |

| Construction | Cable strippers and fittings for electrical installations | Reduces installation time and labor costs | Assess the range of tools available and check for local support and availability of spare parts. |

| Renewable Energy | Phase converters for solar and wind energy systems | Optimizes energy conversion and usage | Evaluate the efficiency ratings and ensure they meet regional energy regulations. |

| Automotive | Electric motors for hybrid and electric vehicle applications | Improves vehicle performance and sustainability | Ensure compliance with automotive standards and inquire about bulk purchasing options. |

How Are Hydraulic Jacks Used in Manufacturing by temco fremont?

In the manufacturing sector, hydraulic jacks supplied by temco fremont play a crucial role in the lifting and positioning of heavy machinery. These jacks enhance operational efficiency by allowing for quick and safe adjustments during assembly or maintenance processes. For international buyers, particularly in regions with stringent safety regulations, it is essential to ensure that the jacks meet local compliance standards and can handle the specific load capacities required for their operations. Additionally, considering the warranty and support services available can significantly impact the long-term value of the investment.

What Role Do Custom Electrical Components Play in Electrical Engineering?

Temco fremont’s custom electrical components are vital for power distribution in electrical engineering applications. These components ensure that systems operate reliably and efficiently, which is particularly important in projects where downtime can lead to significant losses. International B2B buyers should focus on the compatibility of these components with their existing systems and inquire about customization options to meet specific project requirements. Understanding lead times for delivery is also critical to prevent project delays, especially in regions where supply chain logistics can be challenging.

How Are Cable Strippers and Fittings Beneficial in Construction?

In the construction industry, cable strippers and fittings from temco fremont streamline the electrical installation process. By reducing the time and labor required for electrical setups, these tools help contractors complete projects more efficiently. For businesses sourcing these tools internationally, it’s important to assess the range of products available and their adaptability to local electrical standards. Additionally, confirming the availability of support and spare parts can enhance long-term operational reliability.

How Do Phase Converters Optimize Renewable Energy Systems?

Temco fremont’s phase converters are essential for optimizing solar and wind energy systems. They facilitate the conversion of energy, allowing businesses to maximize their renewable energy investments. For international buyers, particularly in regions focused on sustainability, evaluating the efficiency ratings of these converters is crucial. Furthermore, understanding regional energy regulations can help ensure compliance and enhance the project’s viability.

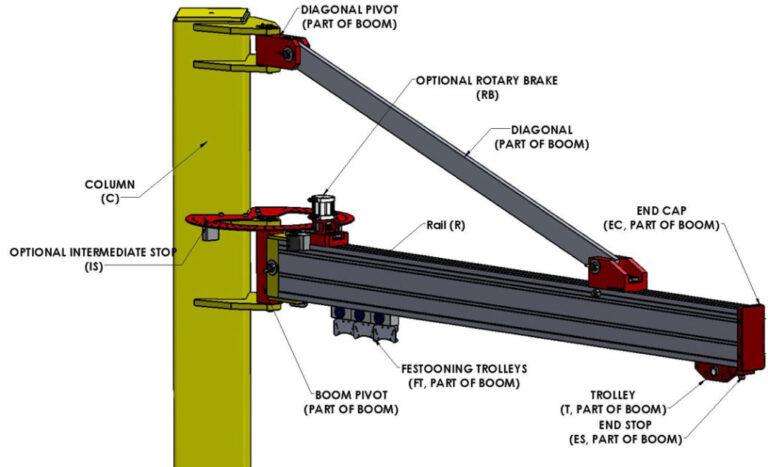

Illustrative image related to temco fremont

What Advantages Do Electric Motors Offer in the Automotive Sector?

In the automotive sector, electric motors from temco fremont are integral to the performance of hybrid and electric vehicles. These motors not only improve vehicle performance but also contribute to sustainability efforts. Buyers should ensure that the motors comply with automotive industry standards and inquire about bulk purchasing options, which can lead to cost savings. Additionally, understanding the support available for installation and maintenance can influence sourcing decisions, particularly in emerging markets.

3 Common User Pain Points for ‘temco fremont’ & Their Solutions

Scenario 1: Delays in Product Delivery Impacting Project Timelines

The Problem: B2B buyers often face challenges with delayed shipments, especially when they are relying on specific industrial tools and equipment to meet project deadlines. For instance, a construction firm in Brazil might order hydraulic jacks from TEMCo Fremont for a critical project, only to find that the delivery is delayed due to unforeseen circumstances. Such delays can stall project timelines, lead to financial losses, and damage client relationships.

The Solution: To mitigate this risk, buyers should proactively communicate with TEMCo about their specific delivery needs at the time of ordering. When placing an order, it’s advisable to request a confirmed shipping timeline and discuss options for expedited shipping if necessary. Buyers can also explore TEMCo’s inventory for items available for immediate dispatch. Establishing a relationship with a dedicated account manager at TEMCo can facilitate more personalized service and quicker response times for urgent requests. Additionally, leveraging tracking tools provided by TEMCo ensures that buyers can monitor their shipments and adjust their project schedules accordingly.

Scenario 2: Navigating Complex Product Specifications

The Problem: Many international buyers may struggle with understanding the technical specifications of industrial tools, leading to the purchase of incompatible or suboptimal equipment. For example, a manufacturing plant in Vietnam might require specific electrical components, but without a clear understanding of the compatibility and specifications, they risk ordering the wrong items, resulting in costly returns and delays.

Illustrative image related to temco fremont

The Solution: To overcome this challenge, B2B buyers should utilize TEMCo’s extensive product resources, including technical datasheets and product guides available on their website. Engaging directly with TEMCo’s technical support team can provide clarity on product specifications and suitability for particular applications. It’s also beneficial to participate in training sessions or webinars offered by TEMCo, as these can offer deeper insights into product capabilities and best practices. Additionally, buyers should ensure to provide detailed descriptions of their needs when inquiring, allowing TEMCo’s experts to recommend the most suitable products.

Scenario 3: Warranty and Return Policy Confusion

The Problem: Warranty and return policies can often be sources of confusion for B2B buyers, particularly when dealing with high-value industrial equipment. A company in South America may invest in a set of crimping tools from TEMCo, but if a defect arises after purchase, uncertainty about the warranty process can lead to frustration and delays in obtaining replacements.

The Solution: Buyers should familiarize themselves with TEMCo’s warranty and return policies before making a purchase. It is advisable to request a detailed explanation of the warranty terms during the buying process. Keeping a record of all transactions and warranty documentation is crucial. In case of issues, buyers should reach out to TEMCo’s customer service promptly, providing evidence such as purchase receipts and images of the defective items. TEMCo’s commitment to customer satisfaction means they are likely to respond quickly to warranty claims, ensuring that replacements are processed efficiently. Establishing a clear understanding of the warranty process can save time and enhance overall satisfaction with the purchasing experience.

Strategic Material Selection Guide for temco fremont

What Are the Key Materials Used in TEMCo Fremont Products?

When selecting materials for industrial tools and equipment, TEMCo Fremont emphasizes durability, performance, and suitability for various applications. Here, we analyze four common materials used in their products: steel, aluminum, plastic, and rubber. Each material has unique properties, advantages, and limitations that international B2B buyers should consider, especially those from Africa, South America, the Middle East, and Europe.

How Does Steel Perform in TEMCo Products?

Steel is a fundamental material in many industrial applications due to its high tensile strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for heavy-duty equipment. Steel’s corrosion resistance can vary based on the alloy used; stainless steel, for example, offers superior resistance compared to carbon steel.

Illustrative image related to temco fremont

Pros: Steel is highly durable and can withstand extreme conditions, making it ideal for heavy machinery and tools. It is also relatively cost-effective compared to other metals.

Cons: However, steel can be heavy, which may complicate transportation and handling. Additionally, it may require protective coatings to prevent rust, increasing manufacturing complexity.

For international buyers, compliance with standards such as ASTM (American Society for Testing and Materials) and EN (European Norm) is crucial, especially when sourcing steel components.

What Advantages Does Aluminum Offer for TEMCo Applications?

Aluminum is known for its lightweight properties and resistance to corrosion, making it a popular choice for applications where weight reduction is essential. It has good thermal and electrical conductivity, which is beneficial for electrical components.

Pros: The primary advantage of aluminum is its lightweight nature, which facilitates easier handling and transportation. It also has a high strength-to-weight ratio, making it suitable for various applications.

Cons: Aluminum is generally more expensive than steel and can be less durable under high-stress conditions. It is also more prone to deformation compared to other metals.

International buyers should be aware of specific standards like JIS (Japanese Industrial Standards) for aluminum components and consider the material’s performance in varying climates, particularly in regions with high humidity.

Illustrative image related to temco fremont

Why Is Plastic Used in TEMCo Products?

Plastic is often utilized in applications where chemical resistance and lightweight properties are essential. It can be molded into complex shapes, allowing for versatile designs in components like fittings and housings.

Pros: Plastic is generally low-cost and offers excellent resistance to chemicals, making it suitable for various environments. Its lightweight nature also reduces shipping costs.

Cons: However, plastic may not withstand high temperatures or pressures, limiting its use in heavy-duty applications. It can also be less durable than metals, leading to potential wear and tear over time.

For B2B buyers, understanding the specific type of plastic (e.g., PVC, polyethylene) is important, as different plastics comply with different international standards.

Illustrative image related to temco fremont

How Does Rubber Contribute to TEMCo’s Product Range?

Rubber is primarily used for seals, gaskets, and cushioning components due to its excellent elasticity and shock-absorbing properties. It can also provide good resistance to various chemicals and environmental factors.

Pros: The main advantage of rubber is its ability to create airtight seals, which is crucial for many industrial applications. It also offers excellent vibration dampening.

Cons: On the downside, rubber can degrade over time when exposed to UV light or extreme temperatures, necessitating regular replacement. Its manufacturing process can also be complex and costly.

International buyers should consider compliance with standards such as ASTM D2000 for rubber materials, ensuring that the products meet specific performance criteria.

Summary of Material Selection for TEMCo Fremont Products

| Material | Typical Use Case for TEMCo Fremont | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery and tools | High durability | Can be heavy and may require coatings | Medium |

| Aluminum | Electrical components and lightweight applications | Lightweight and corrosion-resistant | More expensive and less durable under stress | High |

| Plastic | Fittings and housings | Low-cost and chemical-resistant | Limited high-temperature performance | Low |

| Rubber | Seals and gaskets | Excellent elasticity and shock absorption | Degrades over time with UV exposure | Medium |

This strategic material selection guide provides a comprehensive overview of the materials used in TEMCo Fremont products, helping international B2B buyers make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for temco fremont

What Are the Key Stages in the Manufacturing Process at TEMCo Fremont?

At TEMCo Fremont, the manufacturing process is meticulously structured to ensure efficiency and quality. The main stages of production include material preparation, forming, assembly, and finishing. Each stage employs specific techniques designed to optimize output while adhering to strict quality standards.

-

Material Preparation: This initial stage involves sourcing high-grade raw materials, often certified to meet international standards. The materials undergo rigorous inspections to ensure they meet the specifications required for subsequent processes. Advanced software systems are utilized to track material batches, enabling precise inventory management and traceability.

-

Forming: In this stage, raw materials are shaped into required components. Techniques such as precision machining, stamping, and molding are commonly employed. TEMCo utilizes state-of-the-art machinery, which allows for high precision and repeatability, minimizing waste and reducing production time.

-

Assembly: During assembly, components are meticulously put together to form the final product. This process often includes both automated and manual labor to ensure the highest quality. Skilled technicians conduct assembly under strict supervision, utilizing best practices to mitigate errors.

-

Finishing: The finishing stage involves surface treatments, coatings, or other enhancements that improve the product’s durability and aesthetic appeal. Techniques such as powder coating, anodizing, or plating may be applied, depending on the product specifications. This stage is critical as it directly impacts the product’s lifespan and performance in various environments.

How Does TEMCo Ensure Quality Control in Manufacturing?

Quality control (QC) at TEMCo is integrated into every stage of the manufacturing process. By adhering to international standards such as ISO 9001, TEMCo demonstrates its commitment to quality management systems that enhance customer satisfaction through effective processes.

-

International and Industry-Specific Standards: TEMCo complies with various international standards, including ISO 9001 for quality management and CE marking for products sold in Europe. Additionally, industry-specific standards such as API for oil and gas components ensure that products meet rigorous performance and safety criteria.

-

Quality Control Checkpoints: The QC process is structured around several key checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet the necessary specifications.

– In-Process Quality Control (IPQC): During manufacturing, continuous inspections are performed to catch defects early. This proactive approach reduces rework and ensures that any deviations from standards are addressed immediately.

– Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that they meet all quality and regulatory requirements. -

Common Testing Methods: TEMCo employs various testing methods to validate product quality, including tensile testing, pressure testing, and electrical testing. These tests ensure that each product performs reliably under expected operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

Illustrative image related to temco fremont

-

Supplier Audits: Conducting regular audits of suppliers can provide deep insights into their manufacturing and QC processes. These audits can assess compliance with international standards and evaluate the effectiveness of their quality management systems.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the QC processes in place. These reports should outline inspection results, testing methods used, and any corrective actions taken to resolve identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing capabilities and quality control. This approach is particularly beneficial for buyers unfamiliar with local suppliers or those entering new markets.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various challenges related to quality control when sourcing products from manufacturers like TEMCo Fremont. Understanding these nuances can help mitigate risks and ensure successful procurement.

-

Regulatory Compliance: Different regions have varying regulatory requirements that products must meet. For instance, CE marking is essential for products sold within the European Union, while other regions may have different certifications. Buyers should ensure that suppliers provide the necessary documentation to demonstrate compliance.

-

Cultural Differences in Quality Standards: Quality perceptions can vary significantly across cultures. Buyers should familiarize themselves with the quality expectations in their specific markets to communicate effectively with suppliers about their needs.

-

Logistical Considerations: The geographical distance between buyers and suppliers can impact quality assurance processes. Buyers should consider how shipping times and customs clearance may affect product quality and integrity during transit. Establishing clear communication channels with suppliers can help address these concerns proactively.

Conclusion

Understanding the manufacturing processes and quality assurance measures at TEMCo Fremont is crucial for international B2B buyers seeking reliable industrial tools and equipment. By focusing on detailed manufacturing stages, stringent quality control measures, and effective verification strategies, buyers can make informed decisions that align with their operational needs and regional compliance standards. This comprehensive approach not only enhances product reliability but also fosters long-term supplier relationships built on trust and accountability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘temco fremont’

In the competitive landscape of industrial tools and equipment procurement, especially from suppliers like TEMCo in Fremont, CA, it is vital for international B2B buyers to follow a structured approach. This guide provides a practical checklist to streamline your sourcing process, ensuring you make informed decisions that align with your operational needs and standards.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the tools and equipment you intend to purchase. This includes dimensions, materials, performance standards, and specific functionalities. A well-defined specification helps prevent miscommunication with suppliers and ensures that the products meet your operational standards.

- Consider Industry Standards: Research relevant industry benchmarks to ensure your specifications align with best practices.

- Anticipate Future Needs: Think about scalability and additional features you might require as your business evolves.

Step 2: Research Potential Suppliers Thoroughly

Investigate various suppliers that meet your specifications, focusing on their reputation and track record. Look for companies like TEMCo that specialize in high-quality industrial tools and have a solid history of customer satisfaction.

- Check Reviews and Testimonials: Seek feedback from previous customers to gauge reliability and service quality.

- Evaluate Product Range: Ensure the supplier offers a comprehensive selection of products that can meet current and future needs.

Step 3: Verify Supplier Certifications and Compliance

Ensure that your potential suppliers possess the necessary certifications and comply with relevant industry standards. This is critical in guaranteeing product safety, quality, and reliability.

- Request Documentation: Ask for copies of certifications, quality control processes, and compliance with international standards.

- Assess Warranty and Support: Understand the warranty terms and post-purchase support to ensure long-term satisfaction.

Step 4: Evaluate Pricing Structures and Payment Terms

Analyze the pricing models offered by suppliers, including bulk discounts and payment terms. Understanding the total cost of ownership, including shipping and potential tariffs, is essential for accurate budgeting.

- Compare Multiple Quotes: Obtain and compare quotes from different suppliers to ensure competitive pricing.

- Negotiate Terms: Don’t hesitate to negotiate terms that could enhance your cash flow, such as extended payment periods or discounts for early payments.

Step 5: Assess Logistics and Delivery Capabilities

Evaluate the logistics capabilities of your chosen supplier, including shipping times, methods, and costs. TEMCo is known for reliable delivery, which can significantly affect your operational efficiency.

- Inquire About Lead Times: Confirm expected delivery times to avoid disruptions in your supply chain.

- Understand Return Policies: Familiarize yourself with the supplier’s return and exchange policies in case of defects or issues.

Step 6: Establish Communication Channels

Ensure that there are clear communication channels in place with your supplier. Effective communication can prevent misunderstandings and facilitate smoother transactions.

- Designate a Point of Contact: Establish a primary contact person for all transactions and inquiries to streamline communication.

- Set Up Regular Updates: Arrange for periodic updates regarding order status and delivery schedules.

Step 7: Conduct a Final Review Before Purchase

Before finalizing your order, conduct a comprehensive review of all gathered information and ensure everything aligns with your initial specifications and expectations.

Illustrative image related to temco fremont

- Double-check Documentation: Verify that all agreements, specifications, and terms are documented accurately.

- Confirm Payment and Delivery Arrangements: Ensure that payment methods and delivery details are mutually agreed upon to avoid any last-minute issues.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for industrial tools and equipment from TEMCo in Fremont, ensuring that they secure the best products for their needs.

Comprehensive Cost and Pricing Analysis for temco fremont Sourcing

What Are the Key Cost Components for TEMCo Fremont Sourcing?

When engaging in sourcing from TEMCo Industrial LLC in Fremont, it is essential to understand the various components that contribute to the overall cost structure. Key cost components include:

-

Materials: The quality of materials used significantly impacts pricing. TEMCo is known for high-quality industrial tools and equipment, which often comes at a premium compared to lower-quality alternatives. Buyers should consider the long-term value of investing in durable materials that can withstand rigorous use.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process and the expertise required. TEMCo’s commitment to quality implies skilled labor, which can be reflected in the pricing structure.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and administrative expenses associated with production. TEMCo’s focus on quality and efficiency may result in higher overhead costs, which are passed on to the buyer.

-

Tooling: Custom tooling for specialized products can drive up initial costs but may provide better efficiency and precision in the long run. For buyers requiring tailored solutions, understanding these costs is crucial.

-

Quality Control (QC): TEMCo’s emphasis on quality assurance ensures that products meet stringent standards. The costs associated with QC processes are integral to maintaining high product quality, which can justify a higher price point.

-

Logistics: Shipping costs, including freight and handling fees, can vary based on destination and order volume. Buyers should consider potential delays and additional fees when calculating logistics expenses.

-

Margin: TEMCo’s pricing will also include a profit margin, which reflects their brand positioning and market competitiveness. Understanding their pricing strategy can help buyers gauge value against competitors.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing in the B2B landscape. Notable price influencers for TEMCo include:

Illustrative image related to temco fremont

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically qualify for discounts, making it essential for buyers to assess their needs against MOQ requirements. Bulk purchasing can lead to significant cost savings.

-

Specifications and Customization: Custom products can incur additional charges due to the need for unique tooling or materials. Buyers should clarify specifications upfront to avoid unexpected costs.

-

Quality and Certifications: Products with certifications (e.g., ISO, CE) may be priced higher due to the assurance of quality and compliance. International buyers should evaluate the importance of these certifications based on their regulatory requirements.

-

Supplier Factors: The reliability and reputation of the supplier can also affect pricing. TEMCo’s established reputation for customer service and product quality may justify a premium price.

-

Incoterms: Understanding the terms of shipping and delivery can significantly impact overall costs. Different Incoterms dictate who bears responsibility for shipping costs, insurance, and customs clearance, which can alter final pricing.

What Buyer Tips Can Help Optimize Costs in International Sourcing?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions about pricing, especially for bulk orders or long-term contracts. Establishing a good relationship with the supplier can lead to favorable terms and discounts.

-

Consider Total Cost of Ownership (TCO): Assess not just the purchase price but also maintenance, operational costs, and potential downtime. Investing in higher-quality tools may lead to lower TCO over time.

-

Research Pricing Nuances: Understand regional pricing trends and currency fluctuations, especially when purchasing from international suppliers. Being informed can aid in negotiating better rates.

-

Review Shipping Options: Evaluate different shipping methods and suppliers to find the most cost-effective solution. Consider lead times and reliability alongside pricing.

-

Stay Updated on Market Trends: Keeping abreast of changes in raw material costs and market dynamics can provide leverage in negotiations and purchasing decisions.

Disclaimer on Indicative Prices

Pricing can vary widely based on the factors discussed, and the prices quoted by TEMCo may not reflect the final costs incurred by buyers. It is advisable to request formal quotes and consider all variables involved in the sourcing process to achieve the best possible outcome.

Alternatives Analysis: Comparing temco fremont With Other Solutions

Understanding Alternatives for Temco Fremont Solutions

In the competitive landscape of industrial tools and equipment, it is crucial for B2B buyers to evaluate various options available in the market. This comparison will focus on Temco Fremont’s offerings against other viable solutions. By analyzing these alternatives, businesses can make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Temco Fremont | Alternative 1: Nidec Corp | Alternative 2: Kollmorgen Corp |

|---|---|---|---|

| Performance | High-quality tools; durable and reliable for industrial use | Innovative motors with high performance; suitable for diverse applications | Precision motion control; known for reliability and efficiency |

| Cost | Competitive pricing; offers discounts for direct purchases | Higher price point due to advanced technology | Mid-range pricing; reflects engineering excellence |

| Ease of Implementation | User-friendly products; straightforward installation | Requires technical knowledge for setup | Moderate complexity; may need specialized training |

| Maintenance | Low maintenance; excellent warranty support | Regular maintenance needed; complex systems | Requires skilled personnel for upkeep |

| Best Use Case | General industrial applications and small to medium enterprises | Automotive and consumer electronics industries | Aerospace, defense, and automation sectors |

In-Depth Look at Alternatives

Nidec Corp: Known for its high-performance motors and precision components, Nidec caters to a wide range of industries, including automotive and consumer electronics. The main advantage of Nidec products is their innovative technology, which leads to enhanced efficiency and performance. However, the higher price point may deter budget-conscious buyers, and the complexity of their systems often requires specialized technical knowledge for installation and maintenance.

Kollmorgen Corp: This company excels in precision motion control solutions, offering a broad range of products designed for demanding applications. Kollmorgen’s strength lies in its commitment to engineering excellence and innovation, making it a preferred choice for industries like aerospace and defense. While their products are reliable and efficient, the need for skilled personnel for maintenance can be a drawback for companies with limited technical resources. Additionally, the moderate complexity of their systems might necessitate additional training.

Making the Right Choice for Your Business

When evaluating solutions like Temco Fremont against alternatives, B2B buyers should consider their specific needs, including performance requirements, budget constraints, and the technical capabilities of their team. Temco Fremont stands out for its high-quality products and exceptional customer service, making it an excellent choice for businesses seeking reliability without extensive technical expertise. On the other hand, if cutting-edge technology and precision are paramount, Nidec or Kollmorgen might be more suitable, albeit with higher costs and a steeper learning curve. Ultimately, the decision should align with both immediate operational needs and long-term business goals.

Essential Technical Properties and Trade Terminology for temco fremont

What Are the Key Technical Properties for TEMCo Fremont Products?

When considering industrial tools and equipment from TEMCo Fremont, understanding critical technical properties is essential for making informed purchasing decisions. Here are several key specifications:

-

Material Grade

The material grade refers to the quality and type of materials used in manufacturing products, such as steel, aluminum, or high-grade plastics. For example, a crimping tool made from high-carbon steel offers enhanced durability and resistance to wear. B2B buyers should assess material grades to ensure they meet the operational demands of their applications. -

Tolerance

Tolerance defines the allowable deviation from a specified dimension, crucial for components that must fit together with precision. For instance, hydraulic jacks require strict tolerances to ensure safety and functionality. Understanding tolerances helps buyers select products that will perform reliably in their specific settings, minimizing the risk of equipment failure. -

Load Capacity

Load capacity indicates the maximum weight a tool or equipment can handle safely. For example, industrial jacks have defined load capacities that determine their suitability for lifting heavy machinery. B2B buyers must consider load capacity to ensure they choose equipment that meets their operational needs without compromising safety. -

Power Rating

The power rating of electrical tools, such as motors and transformers, defines their efficiency and performance under load. A higher power rating typically means better performance but can also lead to increased energy costs. Buyers should evaluate power ratings against their operational requirements to optimize performance and energy consumption. -

Warranty Terms

Warranty terms detail the coverage period and conditions under which products can be repaired or replaced. TEMCo’s commitment to standing by its warranties is a significant advantage, providing buyers with confidence in their investment. Understanding warranty terms is vital for B2B buyers to protect themselves against defects and ensure long-term reliability.

What Common Trade Terms Should B2B Buyers Know When Dealing with TEMCo Fremont?

In the world of industrial equipment procurement, familiarity with trade terminology can streamline communication and enhance negotiations. Here are some essential terms:

Illustrative image related to temco fremont

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers when sourcing components that need to integrate seamlessly into existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for international buyers who need to manage inventory levels and costs. Knowing the MOQ helps businesses plan their purchases effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. This process is essential for B2B buyers looking to compare pricing and terms from multiple vendors, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery obligations, facilitating smoother transactions across borders. -

Lead Time

Lead time is the time taken from placing an order to receiving it. This is particularly relevant for businesses that depend on timely deliveries for their operations. Understanding lead times allows buyers to plan their production schedules and inventory management efficiently. -

Return Policy

A return policy outlines the conditions under which products can be returned or exchanged. A clear and fair return policy is vital for B2B buyers, as it provides assurance that they can address any issues with their orders without incurring significant losses.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies when sourcing from TEMCo Fremont, ensuring they make well-informed decisions that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the temco fremont Sector

What Are the Key Market Dynamics and Trends Impacting the TEMCo Fremont Sector?

The TEMCo Fremont sector is influenced by several global drivers that shape the landscape for international B2B buyers, particularly those from emerging markets in Africa, South America, the Middle East, and Europe. A significant trend is the increasing demand for high-quality industrial tools and equipment, driven by the growth of various sectors, including manufacturing, construction, and renewable energy. This demand is further supported by the rapid technological advancements in automation and smart manufacturing, which require reliable tools that can enhance operational efficiency.

Moreover, the shift towards digital procurement processes is transforming sourcing strategies. International buyers are increasingly leveraging e-commerce platforms to streamline purchasing, which not only improves efficiency but also provides access to a broader range of products. This is particularly relevant for buyers in regions like Brazil and Vietnam, where digital infrastructure is rapidly developing. Additionally, the importance of strong customer service and post-purchase support is becoming a critical differentiator in this sector, as evidenced by TEMCo’s commitment to warranty support and customer satisfaction.

How Is Sustainability and Ethical Sourcing Shaping B2B Practices in the TEMCo Fremont Sector?

Sustainability is now a cornerstone of B2B operations, particularly in the TEMCo Fremont sector. The environmental impact of industrial manufacturing is under scrutiny, and companies are increasingly being held accountable for their supply chain practices. Ethical sourcing, which emphasizes transparency and responsibility, is becoming a non-negotiable expectation among international buyers. This is particularly true for those in Europe and the Middle East, where regulations around sustainability are stringent.

Buyers are looking for suppliers who prioritize ‘green’ certifications and materials, aligning with their corporate social responsibility goals. TEMCo’s focus on high-quality, durable products can be leveraged to promote a sustainable lifecycle, reducing waste and promoting long-term use. Furthermore, the adoption of eco-friendly materials in product manufacturing can enhance TEMCo’s appeal to environmentally-conscious buyers. In this context, establishing a transparent supply chain that highlights sustainability practices can provide a competitive edge.

What Is the Historical Context of the TEMCo Fremont Sector and Its Evolution?

The TEMCo Fremont sector has evolved significantly over the years, positioning itself as a reputable supplier in the industrial tools and equipment market. Founded in an era where industrialization was rapidly expanding, TEMCo recognized the need for reliable, high-quality products that could support this growth. Over time, the company has adapted to changing market dynamics by embracing technological advancements and enhancing its product offerings.

This evolution has been marked by a commitment to customer service and satisfaction, as demonstrated by the numerous testimonials from satisfied clients. The transition towards digital platforms and e-commerce has also been a pivotal development, allowing TEMCo to reach international markets more effectively. As the sector continues to evolve, the focus on sustainability and ethical sourcing will further define its trajectory, ensuring that TEMCo remains a trusted partner for B2B buyers across the globe.

Frequently Asked Questions (FAQs) for B2B Buyers of temco fremont

-

How can I effectively resolve product issues with TEMCo Industrial?

TEMCo Industrial prides itself on exceptional customer service. If you encounter a product issue, promptly reach out to their support team via email or phone. Provide your order details and any relevant photos to facilitate a swift resolution. Many customers have reported receiving replacements or solutions within days, underscoring TEMCo’s commitment to customer satisfaction and hassle-free support. -

What types of industrial tools and equipment does TEMCo offer?

TEMCo offers a diverse range of high-quality industrial tools and equipment, including cable strippers, hydraulic jacks, electrical components, and various fittings. They cater to a wide array of industries, ensuring that their products meet the unique needs of each customer. This extensive product line positions TEMCo as a reliable supplier for businesses looking for durable and efficient industrial solutions. -

What should I consider when vetting TEMCo as a supplier for my business?

When vetting TEMCo, consider their reputation for quality and customer service. Look for customer testimonials and reviews to gauge reliability and support responsiveness. Additionally, evaluate their product range to ensure it meets your specific needs. Investigate their delivery options and warranty policies, as these factors can significantly impact your purchasing decisions and overall satisfaction. -

Are customization options available for TEMCo products?

Yes, TEMCo offers customization options for certain products to meet specific customer requirements. If your project demands tailored solutions, reach out to their sales team to discuss your needs. They can provide insights into available modifications, ensuring that the products you receive align perfectly with your operational requirements. -

What are the minimum order quantities (MOQ) when ordering from TEMCo?

Minimum order quantities (MOQ) may vary depending on the specific product and your location. Typically, TEMCo accommodates both small and bulk orders, making them accessible for businesses of all sizes. For precise MOQ details, it is advisable to contact their sales team directly, who can provide guidance based on your specific needs and product selection. -

What payment terms does TEMCo offer for international buyers?

TEMCo generally provides flexible payment options for international buyers, including credit card transactions and bank transfers. It’s essential to discuss specific terms with their sales department, as payment options may vary based on order size and shipping location. Ensure that you clarify any potential fees associated with international transactions to avoid unexpected costs. -

How does TEMCo ensure quality assurance for their products?

TEMCo is committed to maintaining high-quality standards across its product range. They employ rigorous quality control processes during manufacturing and before shipping. Customers can expect products that meet or exceed industry standards, backed by warranties that reflect their confidence in product durability and performance. This commitment to quality makes TEMCo a trustworthy partner for industrial equipment. -

What logistics options does TEMCo provide for international shipping?

TEMCo offers a variety of logistics solutions for international shipping, including standard and expedited options. Their logistics team can assist in selecting the most cost-effective and timely shipping method based on your location and urgency. Be sure to discuss shipping terms, delivery times, and any potential customs duties or regulations that may apply to your order to ensure a smooth procurement process.

Top 4 Temco Fremont Manufacturers & Suppliers List

1. TEMCo Industrial – Industrial Tools & Equipment

Domain: temcoindustrial.com

Registered: 2012 (13 years)

Introduction: TEMCo Industrial LLC offers a variety of industrial tools and equipment including: Cable Strippers, Concrete Vibrators, Hydraulics, Flaring Pumps, Cylinders, Fittings, Jacks, Punches, Dimple Dies, Knockout Punches, Punch Dies, Stud Punches, Draw Stud Adapters, Step Drill Bits, Spare Parts, Cases, Crimpers, Wire Cutters, Wire Strippers, Ground Rod Drivers, T Post Drivers, Tube Benders, Conduit Bend…

2. TEMCo Industrial Power Supply – Electrical Equipment and Services

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: TEMCo Industrial Power Supply specializes in high-quality electrical equipment and services. Key products include transformers, power supplies, electric motors, phase converters, fuses, wire connectors, and motor starters. The company also offers custom fabrication services, on-site technical support, and comprehensive installation and maintenance services.

3. Indeed – Job Opportunities

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Indeed – Job Opportunities, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Temco Industrial – Industrial and Commercial Machinery

Domain: manta.com

Registered: 2004 (21 years)

Introduction: Temco Industrial is categorized under Machine Shops and specializes in Industrial and Commercial Machinery and Equipment, NEC. The company was established in 2018 and is located at 48621 Warm Springs Boulevard, Fremont, CA 94539. It has an estimated annual revenue of $111,377 and employs approximately 3 staff members. The Chief Executive Officer is Joshua Louis Leber.

Strategic Sourcing Conclusion and Outlook for temco fremont

As international B2B buyers increasingly seek reliable partners, TEMCo Fremont stands out with its commitment to quality and exceptional customer service. This guide highlights several key takeaways that underscore the importance of strategic sourcing. First, TEMCo’s extensive range of industrial tools and equipment ensures that buyers can find tailored solutions to meet their specific needs. Their reputation for swift issue resolution and honoring warranties reflects a dedication to customer satisfaction that is critical in today’s competitive marketplace.

Illustrative image related to temco fremont

Moreover, TEMCo’s focus on high-quality American-made products positions it as a trustworthy source for businesses across various sectors. This level of reliability fosters long-term partnerships, essential for companies looking to enhance their operational efficiency and streamline their supply chains.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should consider TEMCo Fremont not only as a supplier but as a strategic ally. By leveraging their exceptional service and quality products, businesses can improve their sourcing strategies and drive sustainable growth. Engage with TEMCo today to explore how they can support your operational needs and elevate your business to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.