Choosing Your Tapestry Jacket: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for tapestry jacket

The global market for tapestry jackets presents both exciting opportunities and significant challenges for international B2B buyers. As fashion trends continue to evolve, sourcing high-quality tapestry jackets that resonate with diverse cultural aesthetics can be a daunting task. This guide aims to equip buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Germany and Nigeria—with the insights necessary to navigate this dynamic marketplace effectively.

In this comprehensive resource, we will explore the various types of tapestry jackets available, their applications across different demographics, and essential factors to consider when vetting suppliers. Additionally, we will delve into cost structures, highlighting how to balance quality with budget constraints. Understanding these aspects will empower buyers to make informed purchasing decisions, ensuring that they select products that not only meet market demands but also align with their brand identity.

Furthermore, we will provide actionable strategies to enhance sourcing efficiency and reduce risks associated with international transactions. By leveraging this guide, B2B buyers can confidently engage with suppliers, fostering partnerships that lead to successful outcomes in the tapestry jacket market. Prepare to unlock the potential of this unique apparel segment and elevate your business offerings.

Understanding tapestry jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Jacquard Tapestry Jacket | Custom designs, quilted satin lining, relaxed fit | Fashion retail, promotional merchandise | Pros: Unique designs, appealing aesthetics. Cons: Higher price point, may require specific care. |

| Tapestry Twill Jacket | Lightweight cotton twill, vintage feel, printed patterns | Casual wear, seasonal collections | Pros: Versatile for all seasons, comfortable. Cons: Limited durability compared to heavier fabrics. |

| Woven Tapestry Jacket | Unique, handcrafted designs, often inspired by pop culture | Niche markets, specialty boutiques | Pros: Exclusive pieces, strong cultural appeal. Cons: Higher production costs, potentially longer lead times. |

| Zipper Tapestry Jacket | Front zipper closure, jacquard woven material | Streetwear, casual fashion lines | Pros: Easy to wear, practical design. Cons: Limited stretch, which may affect fit. |

| Unisex Tapestry Jacket | Gender-neutral design, relaxed fit, available in various sizes | Inclusive fashion lines, promotional giveaways | Pros: Broad market appeal, versatile sizing. Cons: May not cater to specific style preferences. |

What Are the Key Characteristics of a Jacquard Tapestry Jacket?

The Jacquard Tapestry Jacket features intricate designs woven directly into the fabric, often showcasing artistic collaborations or thematic elements. This type typically includes a quilted satin lining for added comfort and style. B2B buyers in the fashion retail sector may find this type appealing for promotional merchandise due to its unique aesthetic, although the higher price point and specific care requirements could be considerations for inventory management.

How Does the Tapestry Twill Jacket Differ From Other Styles?

The Tapestry Twill Jacket is made from lightweight cotton twill, providing a vintage, aged look through special washing techniques. Its boxy, cropped fit makes it suitable for various casual settings and seasonal collections. B2B buyers looking to stock versatile items for all-year wear may prefer this jacket; however, it may not be as durable as heavier fabric options, which could affect its longevity in a retail environment.

Illustrative image related to tapestry jacket

What Makes the Woven Tapestry Jacket Unique?

Woven Tapestry Jackets are often handcrafted, featuring unique designs that draw inspiration from pop culture and art. These pieces cater to niche markets and specialty boutiques, making them ideal for businesses focused on exclusivity. While the craftsmanship adds to their appeal, the higher production costs and potential for longer lead times could pose challenges for B2B buyers aiming for quick turnover.

Why Choose a Zipper Tapestry Jacket for Your Collection?

Zipper Tapestry Jackets are characterized by their practical front zipper closures and jacquard woven materials. They are particularly popular in streetwear and casual fashion lines, appealing to a younger demographic. While their ease of wear is a significant advantage, buyers should be aware that the lack of stretch in the material may limit fit options, which could impact customer satisfaction.

How Do Unisex Tapestry Jackets Cater to Diverse Markets?

Unisex Tapestry Jackets are designed to appeal to a broad audience, featuring a relaxed fit and a range of sizes. This inclusivity makes them ideal for promotional giveaways and fashion lines that aim to reach a wider market. While their versatility is a strong selling point, B2B buyers should consider that they may not cater to specific style preferences, which could limit appeal in certain demographics.

Key Industrial Applications of tapestry jacket

| Industry/Sector | Specific Application of tapestry jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom fashion lines featuring tapestry jackets | Unique product offerings that attract niche markets | Quality of fabric, design customization options |

| Hospitality & Tourism | Uniforms for boutique hotels and resorts | Enhances brand identity and guest experience | Durability, comfort, and aesthetic appeal |

| Art & Culture | Merchandise for galleries and cultural institutions | Supports local artists and cultural heritage | Collaboration with local artists, ethical sourcing |

| Sports & Entertainment | Promotional apparel for events and conventions | Increases brand visibility and engagement | Compliance with event branding guidelines, size range |

| Retail & E-commerce | Online sales of tapestry jackets | Expands product range and attracts diverse customers | Shipping logistics, inventory management, pricing strategy |

How is the Tapestry Jacket Used in the Fashion & Apparel Industry?

In the fashion sector, tapestry jackets are increasingly being incorporated into custom clothing lines, appealing to consumers who value unique and artistic designs. Brands can leverage the intricate patterns and textures of tapestry fabric to differentiate their offerings in a crowded marketplace. For B2B buyers, sourcing high-quality fabric that allows for customization is critical to meet the evolving demands of fashion consumers.

Illustrative image related to tapestry jacket

What Role Do Tapestry Jackets Play in Hospitality & Tourism?

Tapestry jackets serve as distinctive uniforms for boutique hotels and resorts, enhancing the overall guest experience while reinforcing brand identity. By incorporating these jackets into their staff uniforms, businesses can create a cohesive and visually appealing aesthetic that resonates with their clientele. Buyers in this sector should prioritize durability and comfort to ensure that uniforms withstand the rigors of daily use while maintaining their visual appeal.

How Can Art & Culture Institutions Benefit from Tapestry Jackets?

Art galleries and cultural institutions utilize tapestry jackets as merchandise to promote local artists and cultural heritage. This not only provides an additional revenue stream but also enriches the visitor experience by offering unique, locally-inspired products. When sourcing these jackets, institutions should focus on collaborations with local artists to enhance authenticity and support the community.

How Are Tapestry Jackets Used in Sports & Entertainment?

In the sports and entertainment industry, tapestry jackets are often used as promotional apparel for events and conventions. These jackets can feature branding and designs that resonate with specific audiences, enhancing brand visibility and engagement. Buyers need to consider compliance with event branding guidelines and ensure a range of sizes to cater to diverse attendees.

What is the Importance of Tapestry Jackets in Retail & E-commerce?

Retailers and e-commerce platforms are increasingly offering tapestry jackets as part of their product range, capitalizing on the growing demand for unique fashion items. By including these jackets, businesses can attract a wider audience and differentiate themselves from competitors. Key considerations for sourcing include effective shipping logistics, inventory management, and establishing a competitive pricing strategy to maximize sales opportunities.

Illustrative image related to tapestry jacket

3 Common User Pain Points for ‘tapestry jacket’ & Their Solutions

Scenario 1: Sizing and Fit Issues in Tapestry Jackets

The Problem: Sizing and fit discrepancies often pose significant challenges for B2B buyers when sourcing tapestry jackets. Many manufacturers provide size charts, but variances in measurements and the unisex nature of many designs can lead to confusion. Buyers may experience dissatisfaction if the jackets do not fit their target demographics correctly, resulting in increased return rates and unhappy customers. This issue is particularly acute in regions with diverse body types, such as Africa and South America, where standard sizing may not be as applicable.

The Solution: To mitigate sizing and fit issues, B2B buyers should request comprehensive size guides that include detailed measurements for each size, such as shoulder width, chest circumference, and sleeve length. Additionally, buyers can ask for sample pieces to evaluate fit and comfort before placing bulk orders. Implementing a fit-testing phase, where select customers or employees wear the jackets, can provide valuable feedback on sizing and overall satisfaction. Lastly, offering a flexible return policy for mismatched sizes can enhance customer confidence in purchasing, ensuring a more seamless shopping experience.

Scenario 2: Quality Control and Fabric Durability Concerns

The Problem: Buyers often face challenges regarding the quality of tapestry jackets, particularly concerning fabric durability and craftsmanship. Tapestry jackets may feature intricate designs that can be susceptible to wear and tear, fading, or even fraying over time. This is especially critical for international buyers who need assurance that products will withstand varying climates and usage conditions, particularly in regions with extreme weather conditions like the Middle East.

The Solution: Establishing clear quality control measures is essential for ensuring that tapestry jackets meet buyer standards. Before finalizing an order, buyers should request samples from manufacturers to assess fabric quality and durability firsthand. Conducting thorough inspections of materials, such as checking for colorfastness and stitch integrity, can prevent future issues. Additionally, creating a detailed specification sheet that outlines material requirements and performance expectations can help manufacturers deliver products that align with buyers’ quality standards. Ongoing communication with manufacturers about quality expectations and potential adjustments can also foster a collaborative approach to quality assurance.

Scenario 3: Cultural Relevance and Design Authenticity

The Problem: For international B2B buyers, particularly those sourcing for regions like Africa and South America, cultural relevance and design authenticity in tapestry jackets can present a challenge. Buyers may struggle to find designs that resonate with local audiences or reflect the cultural narratives important to their customer base. This disconnect can lead to poor sales and brand misalignment, ultimately affecting the buyer’s reputation in their respective markets.

Illustrative image related to tapestry jacket

The Solution: To address this concern, buyers should prioritize sourcing from manufacturers who have a deep understanding of cultural aesthetics and narratives relevant to their target markets. Engaging in discussions with local designers or cultural consultants can provide insights into preferred patterns, colors, and motifs that resonate with customers. Additionally, collaborating with manufacturers to develop exclusive designs or limited-edition collections that reflect regional influences can strengthen brand identity and appeal. Conducting market research to identify trends and preferences in specific regions will further enable buyers to make informed decisions and foster a strong connection with their customer base.

Strategic Material Selection Guide for tapestry jacket

What Are the Key Materials for Tapestry Jackets and Their Properties?

When selecting materials for tapestry jackets, several options stand out based on their unique properties, performance characteristics, and suitability for various applications. This analysis focuses on four common materials: cotton, polyester, jacquard, and a cotton-polyester blend. Each material offers distinct advantages and disadvantages that can influence purchasing decisions for international B2B buyers.

How Does Cotton Perform in Tapestry Jackets?

Cotton is a natural fiber known for its breathability and comfort, making it a popular choice for tapestry jackets. It has good moisture absorption properties, which helps regulate body temperature in various climates. However, cotton is less durable than synthetic fibers and may not withstand heavy use or harsh environmental conditions.

Pros: Cotton is soft, hypoallergenic, and biodegradable, making it an environmentally friendly option. It is also relatively inexpensive, which can be appealing for bulk purchases.

Cons: The main drawbacks include lower durability and potential shrinkage when washed improperly. Cotton jackets may require more care to maintain their appearance and longevity.

Illustrative image related to tapestry jacket

What Role Does Polyester Play in Tapestry Jackets?

Polyester is a synthetic fiber that offers excellent durability and resistance to wear and tear. It is also resistant to shrinking, stretching, and wrinkling, which makes it suitable for everyday use. Polyester can wick moisture away from the body, enhancing comfort during physical activities.

Pros: The key advantages of polyester include its strength, lightweight nature, and quick-drying properties. It is also available at a relatively low cost, making it a cost-effective option for manufacturers.

Cons: On the downside, polyester is less breathable than natural fibers, which may lead to discomfort in hot climates. Additionally, it is not biodegradable, raising concerns about environmental sustainability.

Why Choose Jacquard Fabric for Tapestry Jackets?

Jacquard fabric is characterized by its intricate patterns and textures, often created using complex weaving techniques. This material can be made from various fibers, including cotton and polyester, offering versatility in design and functionality.

Pros: Jacquard fabric provides a unique aesthetic appeal, making jackets visually striking. The fabric’s density adds durability, ensuring that the jacket can withstand regular wear.

Cons: The manufacturing complexity of jacquard fabrics can lead to higher production costs. Additionally, the weight of the fabric may limit its suitability for warmer climates.

What Are the Benefits of Cotton-Polyester Blends?

Cotton-polyester blends combine the best properties of both fibers, offering a balance of comfort and durability. This blend is often used to create tapestry jackets that are both stylish and practical.

Pros: The blend retains the softness and breathability of cotton while benefiting from the durability and wrinkle resistance of polyester. This makes it suitable for a wide range of climates and activities.

Illustrative image related to tapestry jacket

Cons: While the blend improves overall performance, it may not be as environmentally friendly as pure cotton options. Additionally, the presence of synthetic fibers can affect the jacket’s breathability.

What Should International B2B Buyers Consider?

When sourcing tapestry jackets, international buyers from regions such as Africa, South America, the Middle East, and Europe should consider local climate conditions, cultural preferences, and compliance with international standards. Understanding regulations, such as ASTM or DIN standards, can help ensure product quality and safety. Additionally, buyers should assess the overall cost-effectiveness of materials, factoring in shipping and import duties.

| Material | Typical Use Case for tapestry jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cotton | Casual wear, everyday use | Soft, breathable, and hypoallergenic | Less durable, potential shrinkage | Low |

| Polyester | Active wear, outdoor use | Strong, lightweight, and quick-drying | Less breathable, not biodegradable | Low |

| Jacquard | Fashion-forward, statement pieces | Unique aesthetic, durable fabric | Higher production costs, heavier | Med |

| Cotton-Polyester Blend | Versatile, all-season jackets | Balanced comfort and durability | Less environmentally friendly | Med |

This strategic material selection guide provides valuable insights for B2B buyers looking to make informed decisions when sourcing tapestry jackets, ensuring they choose materials that align with their specific needs and market demands.

Illustrative image related to tapestry jacket

In-depth Look: Manufacturing Processes and Quality Assurance for tapestry jacket

What Are the Key Stages in the Manufacturing Process of Tapestry Jackets?

The manufacturing of tapestry jackets involves several critical stages, each contributing to the quality and durability of the final product. Understanding these stages helps B2B buyers appreciate the craftsmanship involved, ensuring they make informed purchasing decisions.

Material Preparation: How Are Fabrics Selected and Processed?

The process begins with the careful selection of fabrics, typically cotton or polyester blends, that can hold intricate tapestry designs. Manufacturers often source these materials from reputable suppliers, ensuring they meet specific quality standards. The fabric undergoes pre-treatment processes like washing and dyeing to achieve the desired color and texture. This step is crucial as it ensures that the fabrics are not only visually appealing but also durable and resistant to wear.

What Techniques Are Used in Forming Tapestry Jackets?

Once the materials are prepared, the next stage is forming. This involves cutting the fabric into the required patterns and shapes for the jacket design. Advanced techniques such as computer-aided design (CAD) software are often employed to ensure precision in cutting. This stage also includes the creation of tapestry panels that feature unique designs, often inspired by cultural motifs or artistic themes. The accuracy of this process is vital, as it lays the foundation for the jacket’s fit and aesthetic appeal.

Illustrative image related to tapestry jacket

How Is the Assembly of Tapestry Jackets Carried Out?

After cutting, the assembly process begins. This typically involves sewing the tapestry panels together with high-quality stitching techniques to enhance durability. Manufacturers may use reinforced stitching at stress points, such as seams and pockets, to prevent tearing. Additionally, assembly includes attaching zippers, buttons, and other hardware, which are selected based on their functionality and aesthetic compatibility with the design.

What Finishing Touches Are Applied to Tapestry Jackets?

The final stage of manufacturing is finishing, which ensures that each tapestry jacket is ready for market. This includes quality checks for sewing accuracy, aesthetic details, and overall garment integrity. Finishing processes may also involve pressing the jackets to eliminate wrinkles and improve presentation. Some manufacturers apply protective treatments to enhance the fabric’s resistance to stains or water, ensuring the jackets remain in excellent condition even after repeated use.

How Is Quality Assurance Implemented in Tapestry Jacket Production?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, ensuring that each tapestry jacket meets industry standards and customer expectations. For B2B buyers, understanding these QA protocols is essential for establishing trust in their suppliers.

What International Standards Are Relevant for Tapestry Jacket Production?

Many manufacturers adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard demonstrates a commitment to quality and continuous improvement. Additionally, specific industry standards, such as CE marking for safety and compliance in the European market, may also apply depending on the jacket’s intended use.

Illustrative image related to tapestry jacket

What Are the Key Quality Control Checkpoints in Tapestry Jacket Manufacturing?

Quality control (QC) is generally divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Buyers can request IQC reports to verify material quality.

-

In-Process Quality Control (IPQC): Throughout the assembly process, manufacturers conduct periodic checks to identify defects early. This proactive approach reduces waste and enhances overall quality.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing. This includes checking for defects, measuring dimensions, and ensuring all design elements are correctly executed.

What Testing Methods Are Commonly Used in Tapestry Jacket Quality Assurance?

Various testing methods are employed to ensure that tapestry jackets meet quality standards. These may include:

- Physical Testing: Assessing the durability of fabrics and seams through stress and strain tests.

- Colorfastness Testing: Evaluating how well the fabric retains its color when subjected to washing, light exposure, and other environmental factors.

- Comfort Testing: Ensuring that the jacket fits well and is comfortable for the wearer, which may involve wear trials with samples.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of their suppliers. Here are some actionable strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Buyers may consider scheduling both announced and unannounced audits for a comprehensive overview.

-

Request Quality Reports: Suppliers should be able to provide detailed QC reports, including IQC, IPQC, and FQC findings. These documents can help buyers assess the reliability of the manufacturing process.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased evaluation of the production quality. These inspectors can conduct tests and provide certification that meets international standards.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital. Different markets may have varying compliance requirements. For instance, European buyers may require CE marking, while others may focus on sustainability certifications, such as OEKO-TEX® for textile safety.

Illustrative image related to tapestry jacket

Engaging with suppliers who have experience in exporting to these markets can facilitate smoother transactions and compliance with local regulations. Additionally, buyers should be aware of potential tariffs, duties, and trade agreements that may affect the cost and availability of tapestry jackets.

Conclusion

In summary, the manufacturing processes and quality assurance for tapestry jackets are multifaceted, involving careful material selection, precision in assembly, and rigorous quality control. B2B buyers can enhance their procurement strategies by understanding these processes and actively engaging with suppliers to ensure compliance with international standards. By doing so, they can secure high-quality products that meet the expectations of their target markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tapestry jacket’

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing tapestry jackets. Understanding the nuances of the market and ensuring that the procurement process aligns with business needs will lead to successful partnerships and quality products.

Step 1: Define Your Technical Specifications

Clearly outlining your requirements for tapestry jackets is crucial to ensure that suppliers can meet your expectations. Consider factors such as fabric composition (e.g., cotton, polyester), fit (e.g., relaxed, boxy), and design elements (e.g., custom tapestry patterns). Additionally, include specifics about sizing options and any unique features like pockets or closures.

Step 2: Research Market Trends and Demands

Understanding current market trends will inform your purchasing decisions and help you align with consumer preferences. Investigate popular designs, colors, and patterns that resonate with target demographics in your region. For instance, South American buyers may prefer vibrant and culturally inspired motifs, while European buyers might lean towards minimalist aesthetics.

Illustrative image related to tapestry jacket

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, perform a thorough evaluation to ensure reliability and quality. Request company profiles, previous work examples, and references from other B2B clients. Pay attention to their manufacturing capabilities, lead times, and whether they can accommodate custom orders, which can be crucial for unique tapestry designs.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers adhere to international quality standards and ethical manufacturing practices. Check for certifications such as ISO 9001 for quality management or GOTS for organic textiles if applicable. This not only guarantees product quality but also aligns with increasing consumer demand for sustainability and ethical sourcing.

Step 5: Request Samples and Conduct Quality Testing

Before placing a bulk order, request samples of the tapestry jackets to assess quality firsthand. Examine the craftsmanship, fabric durability, and overall aesthetic appeal. Testing for colorfastness and fabric feel will help ensure that the final product meets your standards and is suitable for your target market.

Step 6: Understand Pricing Structures and Payment Terms

Engage in discussions with suppliers about their pricing models and payment terms. Transparency regarding costs, including shipping and potential tariffs, is essential to avoid unexpected expenses. Consider negotiating terms that allow for flexibility, especially if you are placing a large order or establishing a long-term relationship.

Illustrative image related to tapestry jacket

Step 7: Establish Clear Communication Channels

Maintaining open lines of communication with your suppliers is vital throughout the sourcing process. Set expectations regarding response times, updates on order status, and handling of any issues that may arise. Strong communication fosters a collaborative relationship and can lead to better outcomes in quality and delivery.

By following these steps, B2B buyers can effectively source tapestry jackets that meet their needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for tapestry jacket Sourcing

What Are the Key Cost Components for Sourcing Tapestry Jackets?

Understanding the cost structure of tapestry jackets is essential for B2B buyers looking to source these products effectively. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of fabric significantly influences costs. Tapestry jackets often utilize premium materials like jacquard, cotton twill, or blended fabrics, which can raise material costs. Custom designs, such as licensed artwork or unique patterns, may further increase expenses.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Countries with lower labor costs, such as those in parts of Asia, can offer competitive pricing, but this must be weighed against potential quality trade-offs.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and equipment maintenance. These costs can fluctuate based on the efficiency of the manufacturing facility.

-

Tooling: Custom designs may require specific tooling, which adds to initial costs. Buyers should consider whether the tooling costs can be amortized over large orders to minimize the impact on per-unit pricing.

-

Quality Control: Ensuring product quality through rigorous QC processes is crucial, especially for international buyers. This may involve additional costs for testing and inspections, particularly for certifications required in certain markets.

-

Logistics: Shipping costs are influenced by the volume of the order, shipping methods, and destinations. Buyers should factor in duties and tariffs when calculating total logistics expenses.

-

Margin: Suppliers will apply a profit margin, which can vary widely based on the brand, exclusivity, and market demand.

How Do Pricing Influencers Impact Tapestry Jacket Costs?

Several factors can influence the final pricing of tapestry jackets:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders typically yield lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their inventory needs.

-

Specifications and Customization: Custom designs or specific material requirements can raise costs. Buyers should clearly communicate their needs to avoid unexpected charges.

-

Quality and Certifications: Products that meet specific quality standards or certifications may incur higher costs due to the additional processes involved. Buyers in markets like Europe may need to ensure compliance with EU regulations, adding to expenses.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their experience and quality assurances.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate responsibility for shipping costs, insurance, and customs duties, which can significantly affect the total cost.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Tapestry Jackets?

B2B buyers can adopt several strategies to enhance cost-efficiency:

-

Negotiate Pricing: Engage suppliers in discussions about pricing structures. Highlighting long-term relationships or potential for repeat orders can provide leverage for better rates.

-

Consider Total Cost of Ownership (TCO): Evaluate the complete costs associated with sourcing tapestry jackets, including logistics, duties, and potential returns. A lower upfront cost may not always equate to the best overall value.

-

Understand Pricing Nuances in Different Markets: Pricing can vary significantly based on the region. For instance, buyers from Africa may face different import duties compared to those in Europe or South America. It’s crucial to do market research to understand local pricing structures.

-

Leverage Technology: Utilize digital platforms to compare suppliers and prices efficiently. Tools like procurement software can streamline sourcing processes and reveal hidden costs.

Disclaimer on Indicative Prices

Prices for tapestry jackets can vary widely based on factors such as design complexity, material choice, and supplier location. The figures provided in this analysis are indicative and should be verified with suppliers for accuracy before making purchasing decisions. Always conduct thorough due diligence to ensure the best sourcing outcomes.

Alternatives Analysis: Comparing tapestry jacket With Other Solutions

Exploring Alternatives to Tapestry Jackets for B2B Buyers

In the fashion industry, particularly within the realm of unique outerwear, the tapestry jacket stands out for its artistic designs and cultural significance. However, B2B buyers should consider alternative solutions that may offer similar aesthetic appeal or functional benefits. Below, we compare the tapestry jacket against two notable alternatives: the traditional denim jacket and the bomber jacket.

Illustrative image related to tapestry jacket

| Comparison Aspect | Tapestry Jacket | Traditional Denim Jacket | Bomber Jacket |

|---|---|---|---|

| Performance | Unique designs; cultural relevance | Durable; versatile for casual wear | Warm and stylish; suitable for layering |

| Cost | $170 – $262, depending on the design | $50 – $150, generally more affordable | $60 – $200, varies by brand |

| Ease of Implementation | Requires careful handling; spot clean only | Easy care; machine washable | Moderate; typically machine washable |

| Maintenance | Low; spot cleaning recommended | Low; regular wash and wear | Low; easy to clean and maintain |

| Best Use Case | Fashion-forward events and cultural showcases | Everyday wear; casual settings | Transitional weather; casual to semi-formal |

In-Depth Analysis of Alternatives

Traditional Denim Jacket

The traditional denim jacket is a staple in casual wear, known for its durability and versatility. It can be dressed up or down, making it suitable for a variety of occasions. Its affordability is a significant advantage, appealing to budget-conscious buyers. However, it lacks the unique artistic flair that a tapestry jacket offers. Additionally, while denim is generally easy to care for, fading and wear over time can detract from its initial appeal.

Bomber Jacket

Bomber jackets provide a stylish option that combines warmth and contemporary design. They are often made from lightweight materials, making them ideal for transitional weather. The versatility of bomber jackets allows them to be paired with various outfits, from casual to semi-formal settings. However, they may not offer the same level of unique aesthetic appeal as tapestry jackets. Pricing can vary widely based on brand and material, and while they are generally easy to clean, the variety of fabrics can affect maintenance requirements.

Making an Informed Decision for Your Business

When selecting an outerwear solution for your B2B needs, it’s essential to weigh the unique features of each option against your specific requirements. If your focus is on cultural significance and unique designs, the tapestry jacket may be the best fit. However, if budget constraints or versatility are more critical, the traditional denim or bomber jackets could be more suitable. Ultimately, understanding your target audience and the context in which these jackets will be worn will guide you in making the most strategic choice.

Illustrative image related to tapestry jacket

Essential Technical Properties and Trade Terminology for tapestry jacket

What Are the Key Technical Properties of Tapestry Jackets?

When considering tapestry jackets for B2B procurement, it’s vital to understand the essential technical properties that influence quality, performance, and marketability. Here are some critical specifications:

-

Material Composition

The fabric blend plays a significant role in the jacket’s durability and comfort. Common materials include cotton, polyester, and jacquard weave. For example, a cotton-polyester blend offers both softness and resilience, making it ideal for everyday wear. Understanding material properties helps buyers assess the product’s suitability for different climates and target demographics. -

Weight and Thickness

The weight of the fabric, often described in grams per square meter (GSM), affects the jacket’s insulation and overall feel. Mid-weight fabrics are versatile for year-round wear, whereas heavier fabrics may be suited for colder climates. Buyers should evaluate the intended use of the jackets to select the appropriate weight. -

Fit and Sizing

Tapestry jackets often come in various fits, such as relaxed, boxy, or tailored. Accurate sizing is crucial for customer satisfaction and return rates. Providing clear sizing charts and fit descriptions enables B2B buyers to make informed decisions, reducing the risk of mismatched inventory. -

Construction Quality

Key construction details include stitching type, seam finishes, and hardware quality (e.g., zippers and buttons). High-quality stitching and durable hardware enhance the jacket’s longevity, which is essential for maintaining brand reputation. Buyers should ensure that the construction meets industry standards to avoid high return rates. -

Care Instructions

Specific care requirements can affect the usability of the product. For instance, jackets that require spot cleaning versus machine washing may have different appeal based on the target market’s lifestyle. Clear care instructions help buyers communicate proper handling to end consumers, influencing product longevity.

What Are Common Trade Terms Used in the Tapestry Jacket Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms relevant to tapestry jackets:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. For tapestry jackets, an OEM might produce garments based on a design provided by a retailer. Understanding OEM relationships can help buyers identify potential manufacturing partners. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for buyers as it directly impacts inventory management and cash flow. Knowing the MOQ can help businesses plan their purchasing strategy effectively, especially in emerging markets where demand can be unpredictable. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products, such as tapestry jackets. This process helps buyers compare offers and negotiate better deals. Being familiar with RFQ procedures can streamline procurement processes and ensure competitive pricing. -

Incoterms

International Commercial Terms (Incoterms) are standard trade terms that define the responsibilities of buyers and sellers in international transactions. For tapestry jackets, understanding Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential to clarify shipping responsibilities and costs, which can significantly impact the total landed cost of goods. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Lead time can vary based on manufacturing capabilities and shipping logistics. For B2B buyers, understanding lead times is crucial for inventory planning and meeting customer demand. -

Sample Approval

The process of evaluating a prototype or sample before mass production. This step is critical in the tapestry jacket industry to ensure that the final product meets quality and design specifications. Buyers should prioritize sample approval to mitigate risks associated with production errors.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they select the right tapestry jackets to meet their market needs while optimizing their supply chain operations.

Navigating Market Dynamics and Sourcing Trends in the tapestry jacket Sector

What are the Current Market Dynamics and Key Trends in the Tapestry Jacket Sector?

The tapestry jacket market is experiencing notable growth, driven by a fusion of cultural heritage and contemporary fashion trends. Global demand is surging, particularly in regions like Africa, South America, the Middle East, and Europe, where consumers seek unique, expressive clothing that reflects their identities. Key trends include collaborations with popular culture brands, as seen in high-profile partnerships that leverage nostalgic themes and art-inspired designs. This not only attracts younger demographics but also resonates with consumers’ desire for authenticity in fashion.

Illustrative image related to tapestry jacket

Emerging B2B technologies are reshaping sourcing practices in the tapestry jacket sector. Digital platforms are facilitating streamlined communication between manufacturers and retailers, enhancing supply chain transparency. Innovations in fabric technology, such as eco-friendly textiles and advanced printing techniques, are also gaining traction, allowing brands to offer high-quality, sustainable products. Additionally, international B2B buyers are increasingly prioritizing suppliers who can provide rapid prototyping and customization options, catering to the growing demand for personalized fashion items.

How is Sustainability and Ethical Sourcing Impacting the Tapestry Jacket Market?

Sustainability has become a pivotal consideration for B2B buyers in the tapestry jacket sector. The environmental impact of fashion is under scrutiny, pushing brands to adopt more sustainable practices. This includes utilizing eco-friendly materials such as organic cotton, recycled fibers, and water-based inks in the production of tapestry jackets. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® are increasingly sought after by buyers who wish to ensure that their products meet stringent environmental standards.

Moreover, ethical sourcing is gaining importance as consumers demand greater transparency regarding the origins of their clothing. Brands that prioritize fair labor practices and maintain ethical supply chains not only enhance their reputations but also attract a conscientious customer base. For B2B buyers, partnering with suppliers that adhere to these principles can significantly boost brand loyalty and market competitiveness.

What is the Evolution of the Tapestry Jacket and its Relevance to B2B Buyers?

The tapestry jacket, rooted in traditional textile craftsmanship, has evolved from its historical origins to become a staple in modern fashion. Initially associated with artisanal craftsmanship and cultural significance, these garments have transcended their utilitarian roots to embody artistic expression and contemporary style. As global fashion trends shift towards inclusivity and diversity, the tapestry jacket has emerged as a symbol of cultural appreciation and fusion.

Illustrative image related to tapestry jacket

For international B2B buyers, understanding this evolution is crucial. It not only informs product sourcing strategies but also aids in marketing narratives that resonate with consumers. By positioning tapestry jackets as not just clothing but as pieces of art, brands can create compelling value propositions that appeal to a diverse global market. As the industry continues to innovate, the tapestry jacket is likely to remain a dynamic and influential player in the fashion landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of tapestry jacket

-

How do I choose the right supplier for tapestry jackets?

When selecting a supplier for tapestry jackets, consider their manufacturing capabilities, product quality, and experience in the industry. Request samples to evaluate fabric quality, stitching, and overall craftsmanship. Investigate their reputation through client testimonials and reviews. Additionally, ensure they comply with international trade regulations and ethical manufacturing practices. Communication is key; a responsive supplier will facilitate smoother transactions and address any concerns promptly. -

What customization options are available for tapestry jackets?

Many suppliers offer customization options for tapestry jackets, including fabric choice, design, color, and size specifications. Depending on the supplier, you may also have the option to incorporate your branding through labels or embroidery. It’s advisable to discuss your design requirements upfront and request digital mock-ups to visualize the final product. Be sure to confirm any additional costs and lead times associated with custom orders. -

What are the minimum order quantities (MOQs) for tapestry jackets?

Minimum order quantities can vary significantly among suppliers, typically ranging from 50 to 500 units per design. Factors influencing MOQs include the complexity of the design, fabric types, and production capacity. It’s essential to communicate your expected order volume during initial discussions to ensure alignment with the supplier’s capabilities. If your order is below the MOQ, some suppliers may offer flexibility for a higher price per unit. -

What payment terms should I expect when ordering tapestry jackets?

Payment terms for B2B orders can vary widely but commonly include options like a deposit upfront (usually 30-50%) with the balance due before shipment. Some suppliers may offer net terms, allowing you to pay within a specified period after delivery. Always clarify payment methods accepted (e.g., bank transfer, credit card) and inquire about any additional fees, such as currency conversion charges. Establishing clear payment terms is crucial to avoid misunderstandings. -

How can I ensure the quality of tapestry jackets?

To ensure the quality of tapestry jackets, establish a quality assurance process with your supplier. This may include pre-production samples, in-line inspections, and final product checks. Request certifications for materials used, such as fabric composition and sustainability standards. Additionally, consider visiting the production facility if feasible, or hiring a third-party inspection service to verify quality before shipment. -

What shipping options are available for international orders of tapestry jackets?

International shipping options typically include air freight for quicker delivery and ocean freight for cost-effective bulk shipping. Discuss shipping preferences with your supplier and ensure they can accommodate your destination and timelines. Be aware of customs duties, taxes, and import regulations that may apply upon arrival. Suppliers often provide estimated shipping times, which can range from a few days to several weeks, depending on the method chosen. -

Are there specific regulations to consider when importing tapestry jackets?

When importing tapestry jackets, you must comply with local customs regulations, including tariffs, import duties, and labeling requirements. Each country may have specific textile regulations regarding fiber content, care instructions, and safety standards. It’s advisable to consult with a customs broker or trade compliance expert to ensure your shipment meets all legal requirements and avoid delays at customs. -

How do I handle returns or exchanges for tapestry jackets?

Handling returns or exchanges requires a clear return policy established with your supplier. Discuss conditions under which returns are accepted, such as defects or incorrect orders, and clarify the timeframe for returns. Ensure that your agreement includes who bears the shipping costs for returns. Documenting the return process will help maintain a positive relationship with your supplier and ensure customer satisfaction in your own market.

Top 8 Tapestry Jacket Manufacturers & Suppliers List

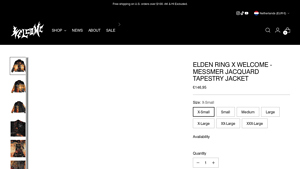

1. WELCOME – ELDEN RING X MESSMER JACQUARD TAPESTRY JACKET

Domain: welcomeskateboards.com

Registered: 2008 (17 years)

Introduction: ELDEN RING X WELCOME – Messmer Jacquard Tapestry Jacket

– Free shipping on U.S. orders over $100 (AK & HI excluded).

2. Etsy – Tapestry Jackets

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Tapestry Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. FOUND – Tapestry Twill Jacket

Domain: found.store

Registered: 2023 (2 years)

Introduction: This company, FOUND – Tapestry Twill Jacket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Pinterest – Tapestry Coats

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Tapestry coats, Tapestry outerwear, repurposed textiles, redesigned upholstery textiles, embroidered fabric, vintage textiles, couture fashion, DIY Coats, 199 Pins, Valentino Spring Summer 2017 Runway Collection Tapestry Coat Size 46 IT, Bohemian Patchwork Winter Kimono, Vintage Multicolor Long Sleeve Kimono, Patchwork Coat, Blanket Coat, American Quilt, Colorful Winter Coat, Plus Size Woven Coat,…

5. Tapestryifeel – Key Product Details

Domain: tapestryifeel.com

Registered: 2024 (1 years)

Introduction: Key Product Details:

– Brand: tapestryifeel

– Discount: 30% OFF on select items, ends in 5 days

– Shipping: 2-3 weeks for shipment

– Collections: Sporting, Anime, Rap & Pop, Trends, Halloween, Bestseller

– Product Types: Jackets, Hoodies, Shorts/Pants, Tees

– Unique Selling Proposition: Handcrafted 1OF1 unique garments using signature woven tapestry fabric inspired by pop culture and art.

-…

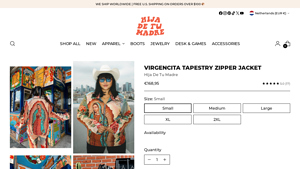

6. Hija De Tu Madre – Virgencita Tapestry Zipper Jacket

Domain: hijadetumadre.com

Registered: 2015 (10 years)

Introduction: Virgencita Tapestry Zipper Jacket | Hija De Tu Madre | WE SHIP WORLDWIDE | FREE U.S. SHIPPING ON ORDERS OVER $100

7. Tapestry – Floral Jacquard Jacket

Domain: uk.pinterest.com

Registered: 2009 (16 years)

Introduction: Tapestry jacket, lightweight layer, floral jacquard design, cropped style, suitable for bohemian and street style outfits.

8. EPTM – Tapestry Jacket

Domain: eptmusa.com

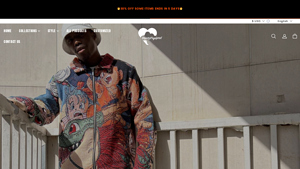

Registered: 2013 (12 years)

Introduction: This company, EPTM – Tapestry Jacket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for tapestry jacket

In summary, the tapestry jacket market presents a wealth of opportunities for international B2B buyers seeking unique and culturally inspired apparel. By leveraging strategic sourcing, businesses can tap into a diverse range of designs that resonate with local markets in Africa, South America, the Middle East, and Europe. The increasing demand for customizable and artisanal garments underscores the importance of aligning with manufacturers who prioritize quality craftsmanship and ethical production practices.

Furthermore, as global fashion trends shift towards sustainability and individuality, tapestry jackets serve as a compelling choice for retailers looking to differentiate their offerings. Buyers should focus on establishing strong relationships with suppliers who can provide flexibility in designs and sizes, as well as efficient logistics to ensure timely delivery.

Looking ahead, the tapestry jacket segment is poised for growth, driven by an expanding consumer base that values unique styles and cultural narratives. As you navigate this vibrant market, consider integrating tapestry jackets into your product lineup to meet evolving consumer demands. Take action today—explore partnerships with reputable manufacturers and capitalize on this trend to enhance your brand’s appeal and market reach.

Illustrative image related to tapestry jacket

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to tapestry jacket