Choosing Your Switch Air Pressure: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for switch air pressure

The global market for switch air pressure systems presents a unique challenge for B2B buyers seeking reliable and efficient solutions. With diverse applications ranging from industrial machinery to automotive systems, sourcing the right air pressure switch can significantly impact operational efficiency and cost-effectiveness. This guide serves as a comprehensive resource, exploring the various types of air pressure switches available, their specific applications, and critical considerations for supplier vetting.

International buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—will find actionable insights tailored to their unique needs. In addition to understanding product specifications, this guide delves into cost factors, market trends, and best practices for ensuring quality and reliability in procurement.

By providing detailed information on the functionality of different pressure switches, their compatibility with various systems, and tips on identifying reputable suppliers, this guide empowers businesses to make informed purchasing decisions. Whether you are looking to enhance the performance of pneumatic systems or ensure safety and compliance in operational settings, understanding the intricacies of switch air pressure will be pivotal in navigating the complexities of the global marketplace. This knowledge not only facilitates smarter investments but also fosters long-term partnerships that drive business success.

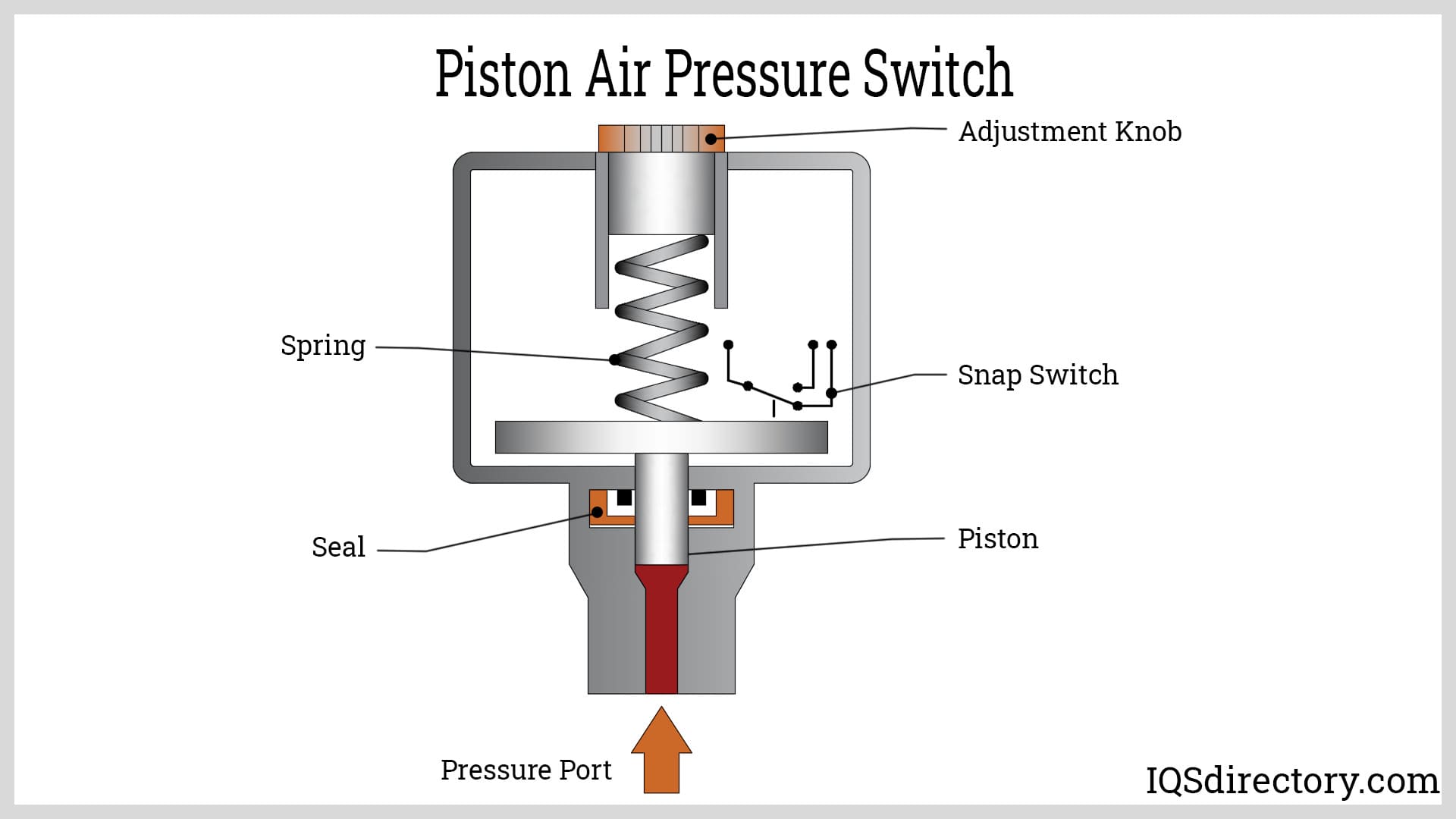

Understanding switch air pressure Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Sealed Pressure Switch | Weather-resistant, designed for harsh environments | Automotive, industrial machinery, HVAC systems | Pros: Long-lasting, reliable in tough conditions. Cons: Higher initial cost. |

| Unsealed Pressure Switch | Simple design, suitable for clean environments | Indoor applications, light machinery | Pros: Cost-effective, easy to install. Cons: Less durable in adverse conditions. |

| Adjustable Pressure Switch | User-defined pressure settings, flexible operation | Air suspension systems, compressors | Pros: Customizable for specific needs. Cons: Complexity may require technical knowledge. |

| Dual Pressure Switch | Monitors two different pressure levels simultaneously | Pneumatic systems, HVAC applications | Pros: Versatile, enhances system monitoring. Cons: Can be more expensive and complex. |

| Relay-Equipped Pressure Switch | Built-in relay for high-current applications | Heavy-duty compressors, industrial equipment | Pros: Handles high loads efficiently. Cons: Requires careful wiring and setup. |

What are Sealed Pressure Switches and Their Advantages?

Sealed pressure switches are engineered to withstand harsh environments, making them ideal for applications in automotive and industrial machinery. Their weather-resistant design protects internal components from moisture and debris, ensuring longevity and reliability. When considering a sealed pressure switch, B2B buyers should evaluate the operating environment and potential exposure to elements, as this will influence the switch’s durability and performance.

How Do Unsealed Pressure Switches Compare?

Unsealed pressure switches are simpler and more cost-effective options suitable for clean indoor environments. They are commonly used in light machinery where exposure to dirt and moisture is minimal. Buyers should consider the operational context when selecting unsealed switches, as their lower cost comes at the expense of durability in challenging conditions.

What Makes Adjustable Pressure Switches Unique?

Adjustable pressure switches allow users to define their operational pressure settings, providing flexibility for various applications such as air suspension systems and compressors. This customization enables businesses to optimize performance based on specific requirements. However, the complexity of these switches may necessitate technical expertise for proper setup and adjustment, making them a consideration for businesses with specialized needs.

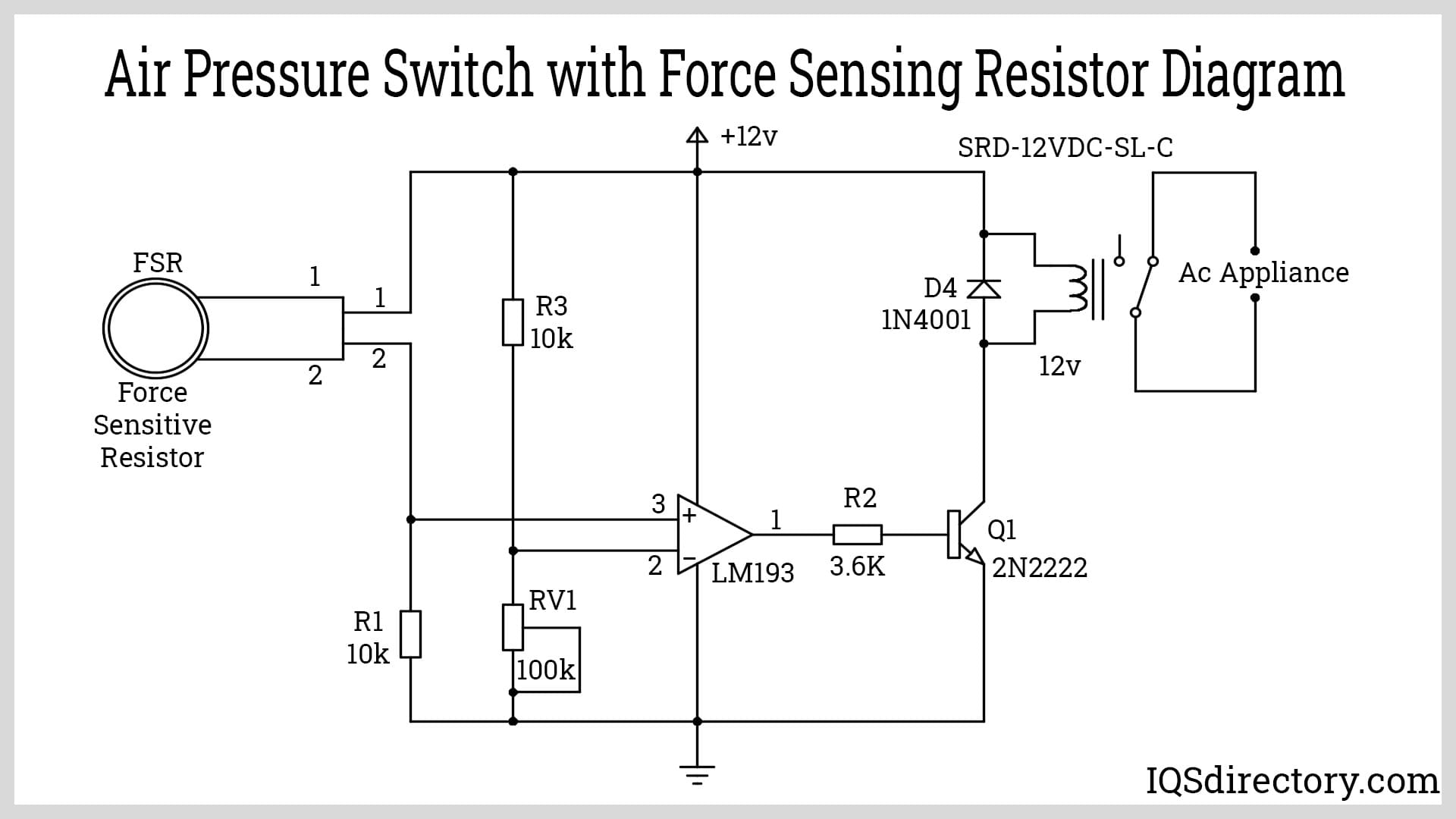

Illustrative image related to switch air pressure

Why Choose Dual Pressure Switches for Monitoring?

Dual pressure switches are designed to monitor two different pressure levels, enhancing the versatility of pneumatic systems and HVAC applications. They enable comprehensive system monitoring, which can improve efficiency and safety. However, the increased complexity and potential higher cost may require buyers to assess their specific needs and budget constraints carefully.

What are the Benefits of Relay-Equipped Pressure Switches?

Relay-equipped pressure switches are essential for heavy-duty applications, as they are capable of handling high current loads without overheating. They are commonly used in industrial equipment and heavy-duty compressors. When selecting this type of switch, buyers should ensure proper wiring and installation to maximize performance and safety. The investment in a relay-equipped switch can lead to improved operational reliability in demanding environments.

Key Industrial Applications of switch air pressure

| Industry/Sector | Specific Application of switch air pressure | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Air suspension systems | Enhances ride quality and vehicle stability | Compatibility with existing systems and pressure ratings |

| Manufacturing | Pneumatic control systems | Improves automation efficiency and safety | Durability and resistance to environmental factors |

| HVAC | Air conditioning and refrigeration systems | Ensures optimal performance and energy efficiency | Sealing and weatherproofing for diverse climates |

| Food & Beverage | Packaging and bottling processes | Maintains product quality and reduces waste | Compliance with food safety standards and reliability |

| Oil & Gas | Pressure monitoring in drilling and extraction operations | Enhances safety and operational reliability | High-pressure ratings and resistance to harsh conditions |

How Is ‘Switch Air Pressure’ Used in the Automotive Sector?

In the automotive sector, air pressure switches are crucial for air suspension systems. These systems rely on precise pressure management to maintain optimal ride height and comfort. By automatically activating or deactivating the compressor based on pressure readings, these switches prevent over-inflation and ensure consistent performance. Buyers need to consider compatibility with various vehicle models and the specific pressure ratings required for different applications, especially in regions like Saudi Arabia, where vehicle demands may vary due to terrain.

What Role Does ‘Switch Air Pressure’ Play in Manufacturing?

In manufacturing, air pressure switches are integral to pneumatic control systems that drive automation. They enable machines to operate at predetermined pressure levels, enhancing safety and efficiency. By preventing system failures and ensuring that machinery runs smoothly, these switches help reduce downtime and maintenance costs. International buyers must prioritize sourcing switches that can withstand industrial environments, particularly in regions like Nigeria, where equipment may face dust and moisture challenges.

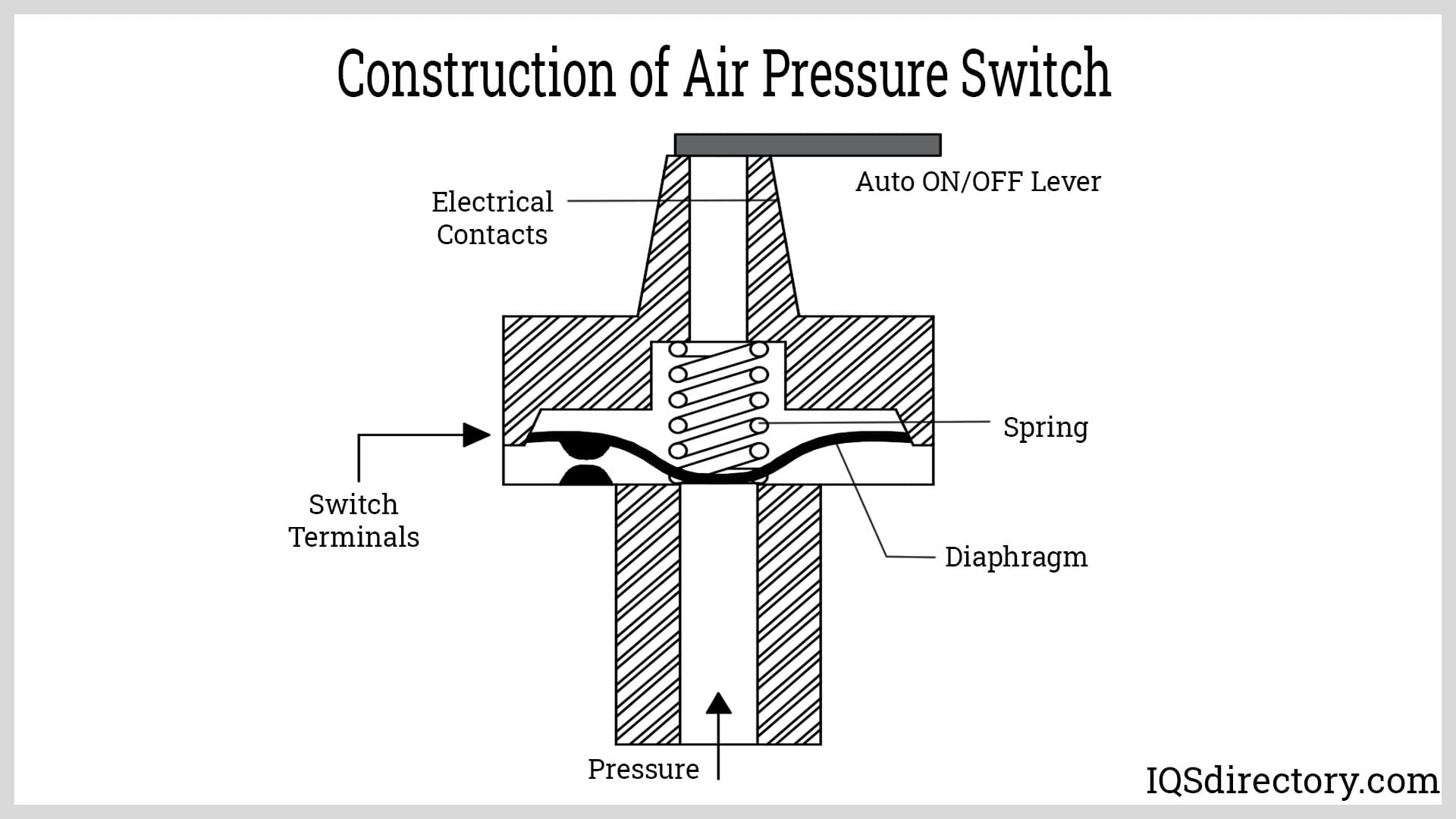

Illustrative image related to switch air pressure

How Does ‘Switch Air Pressure’ Contribute to HVAC Systems?

In HVAC applications, air pressure switches are vital for monitoring and controlling air conditioning and refrigeration systems. They ensure that systems operate within optimal pressure ranges, preventing failures that can lead to energy inefficiency and costly repairs. For businesses in the Middle East, where extreme temperatures are common, selecting weatherproof switches is essential to ensure long-term reliability and performance.

Why Is ‘Switch Air Pressure’ Important in Food & Beverage Processing?

In the food and beverage industry, pressure switches are used in packaging and bottling processes to maintain product quality. They help regulate the pressure within packaging machines, ensuring that products are sealed correctly and preventing spoilage. Buyers in this sector must ensure that the switches meet food safety standards and are reliable under high-frequency operation, particularly in fast-paced production environments across South America.

How Is ‘Switch Air Pressure’ Utilized in the Oil & Gas Industry?

Within the oil and gas industry, air pressure switches are used for monitoring pressure during drilling and extraction operations. These switches act as safety mechanisms, automatically shutting down systems when pressure levels exceed safe thresholds. This capability enhances operational reliability and reduces the risk of accidents. For buyers in this sector, sourcing switches with high-pressure ratings and durability against harsh conditions is crucial, particularly for operations in remote locations in Africa.

3 Common User Pain Points for ‘switch air pressure’ & Their Solutions

Scenario 1: Inconsistent Pressure Regulation Leading to Equipment Failure

The Problem: Many B2B buyers encounter the challenge of inconsistent pressure regulation in their pneumatic systems, which can lead to equipment failures and costly downtimes. This issue often arises from using pressure switches that do not match the specific needs of their applications. For example, if a pressure switch is not calibrated correctly for the system’s operational pressure range, it may cause the compressor to cycle too frequently or not activate at all. This inconsistency can result in equipment damage, safety hazards, and significant operational inefficiencies.

The Solution: To mitigate this issue, buyers should conduct a thorough assessment of their air system’s requirements before sourcing pressure switches. It is crucial to specify the exact pressure range needed for optimal operation, such as 85-105 PSI for standard applications or higher ranges for specialized systems. Additionally, consider using pressure switches with built-in relays for high-draw applications to prevent overloads. It’s also advisable to consult with manufacturers to ensure that the selected switch can handle the environmental conditions it will face, such as moisture or dust. Regular maintenance checks should be established to ensure the pressure switches are functioning correctly and calibrated as needed.

Scenario 2: Difficulty in Identifying Faulty Pressure Switches

The Problem: Another common pain point is the difficulty in diagnosing faulty pressure switches. B2B buyers often face uncertainty regarding whether a malfunctioning compressor is due to a faulty switch or another component in the system. Symptoms like the compressor not turning on or off at the correct pressures, or rapid cycling, can indicate issues with the pressure switch, but they can also be caused by other mechanical failures. This ambiguity leads to wasted time and resources in troubleshooting.

The Solution: Implement a systematic approach to diagnosing pressure switches. Start by checking the voltage and continuity across the switch terminals using a multimeter, which can help confirm if the switch is operational. Additionally, documenting the pressure settings and operational patterns can aid in identifying inconsistencies. Buyers should also invest in pressure switches that offer clear diagnostic features or indicators for easy troubleshooting. Training staff on how to use testing tools effectively can further enhance the ability to pinpoint issues quickly, ensuring minimal downtime in operations.

Scenario 3: Selecting the Wrong Type of Pressure Switch

The Problem: Selecting the incorrect type of pressure switch for a specific application can result in suboptimal performance and increased maintenance costs. For example, using an unsealed pressure switch in an environment exposed to moisture and debris can lead to premature failure, while a sealed switch may be unnecessary in a clean indoor setting, leading to unnecessary expenses. This scenario is particularly relevant for international buyers who may face different environmental conditions in their operations across regions such as Africa, South America, and the Middle East.

The Solution: Buyers must carefully evaluate the operational environment and application requirements before purchasing pressure switches. This includes determining whether a sealed or unsealed switch is necessary based on exposure to environmental factors. It is also beneficial to engage with suppliers who can provide insights into the best practices for their specific industry and location. Buyers should consider using adjustable pressure switches that can be fine-tuned to their specific needs, ensuring flexibility and efficiency. Furthermore, maintaining an ongoing relationship with suppliers can provide access to the latest technology and innovations in pressure switch design, allowing businesses to stay competitive and efficient.

Strategic Material Selection Guide for switch air pressure

What Are the Common Materials Used in Air Pressure Switches?

When selecting materials for air pressure switches, it’s essential to consider their properties, performance, and suitability for specific applications. Below, we analyze four common materials used in the construction of air pressure switches, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Brass

Key Properties:

Brass is known for its excellent corrosion resistance and good thermal conductivity. It typically withstands temperatures up to 150°C and pressures around 200 PSI, making it suitable for various applications.

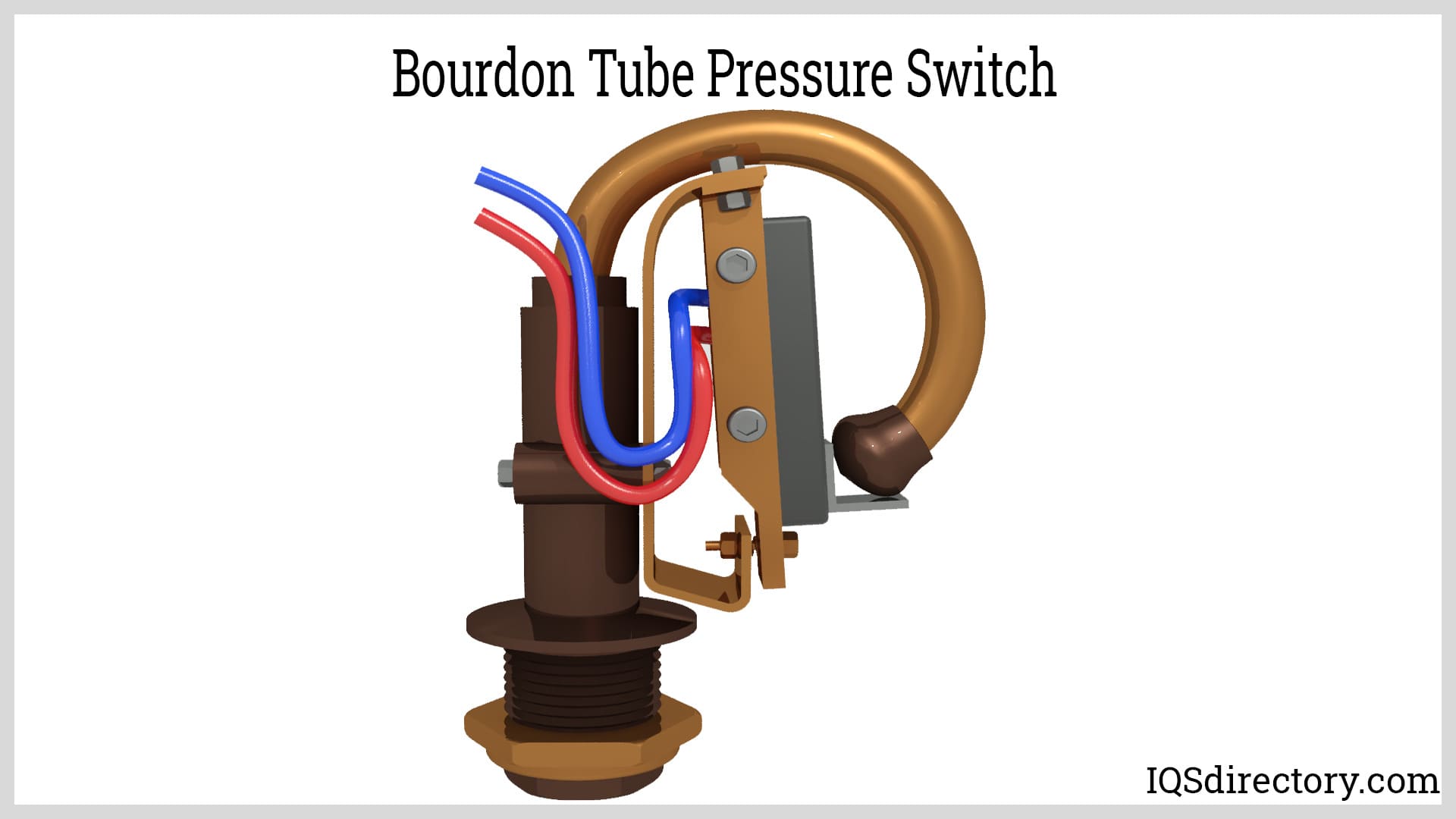

Illustrative image related to switch air pressure

Pros & Cons:

Brass is durable and has a relatively low cost, which makes it a popular choice. However, it can be susceptible to dezincification in certain environments, leading to structural weakness over time. Additionally, manufacturing complexity can increase if intricate designs are required.

Impact on Application:

Brass is compatible with air and non-corrosive gases, making it ideal for general-purpose applications. However, it may not be suitable for environments with high humidity or corrosive substances.

Considerations for International Buyers:

Brass components should comply with standards such as ASTM B36 and JIS H3250. Buyers in regions like Africa and the Middle East should ensure that local regulations regarding metal use are met.

2. Stainless Steel

Key Properties:

Stainless steel offers exceptional corrosion resistance and can handle high temperatures (up to 300°C) and pressures (up to 500 PSI), making it suitable for demanding environments.

Illustrative image related to switch air pressure

Pros & Cons:

The durability of stainless steel is a significant advantage, as it can withstand harsh conditions without degrading. However, the higher cost and manufacturing complexity may deter some buyers. Additionally, it can be heavier than other materials, which may impact installation.

Impact on Application:

Stainless steel is compatible with a wide range of gases and liquids, including corrosive media. This makes it ideal for applications in industries such as automotive and chemical processing.

Considerations for International Buyers:

Compliance with international standards like ASTM A276 and DIN 17440 is crucial. Buyers in Europe and South America should be aware of specific certification requirements for stainless steel components.

3. Plastic (Polymer)

Key Properties:

Plastics, particularly high-performance polymers, offer good chemical resistance and can operate within a temperature range of -40°C to 85°C. They are lightweight and can be molded into complex shapes.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing. However, plastics generally have lower pressure ratings (up to 150 PSI) and may degrade under UV exposure or extreme temperatures.

Impact on Application:

Plastic switches are best suited for light-duty applications and environments where corrosion is a concern. They are not recommended for high-pressure or high-temperature applications.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM D638 and ISO 527. In regions like Africa, where temperature fluctuations are common, understanding the polymer’s thermal stability is critical.

Illustrative image related to switch air pressure

4. Aluminum

Key Properties:

Aluminum is lightweight and offers good corrosion resistance, with a temperature rating of up to 200°C and pressure ratings around 250 PSI.

Pros & Cons:

Aluminum is relatively inexpensive and easy to machine, making it a favorable option for many applications. However, it may not be as durable as stainless steel and can be prone to wear in abrasive environments.

Impact on Application:

Aluminum is suitable for applications where weight is a concern, such as in automotive or aerospace industries. However, it may not be ideal for environments with high humidity or corrosive substances.

Considerations for International Buyers:

Compliance with standards such as ASTM B221 and EN 573 is essential. Buyers from the Middle East and South America should consider the local availability of aluminum and its recycling potential.

Summary Table of Material Selection for Air Pressure Switches

| Material | Typical Use Case for switch air pressure | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General-purpose air systems | Good corrosion resistance | Susceptible to dezincification | Low |

| Stainless Steel | Harsh environments, chemical processing | Exceptional durability | Higher cost and complexity | High |

| Plastic | Light-duty applications | Low cost and easy to manufacture | Lower pressure ratings | Low |

| Aluminum | Automotive, aerospace applications | Lightweight and cost-effective | Less durable in abrasive environments | Medium |

This strategic material selection guide provides B2B buyers with actionable insights into the materials used for air pressure switches, enabling informed decisions based on application requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for switch air pressure

What Are the Main Stages of Manufacturing Air Pressure Switches?

Manufacturing air pressure switches involves several critical stages, each designed to ensure precision and reliability. Understanding these stages helps B2B buyers identify reputable suppliers and assess product quality.

Material Preparation: What Materials Are Used in Air Pressure Switch Manufacturing?

The first step in manufacturing air pressure switches is material preparation. Common materials include:

- Metals: Brass, stainless steel, and aluminum are favored for their durability and resistance to corrosion. These materials are often used for the switch housing and internal components.

- Plastics: High-quality plastics are used for insulation and to create lightweight designs. They can also provide protection against moisture.

- Sealing Materials: Rubber and silicone gaskets are essential for creating a weatherproof seal, particularly in sealed pressure switches.

Once the materials are sourced, they undergo quality checks to ensure they meet industry specifications.

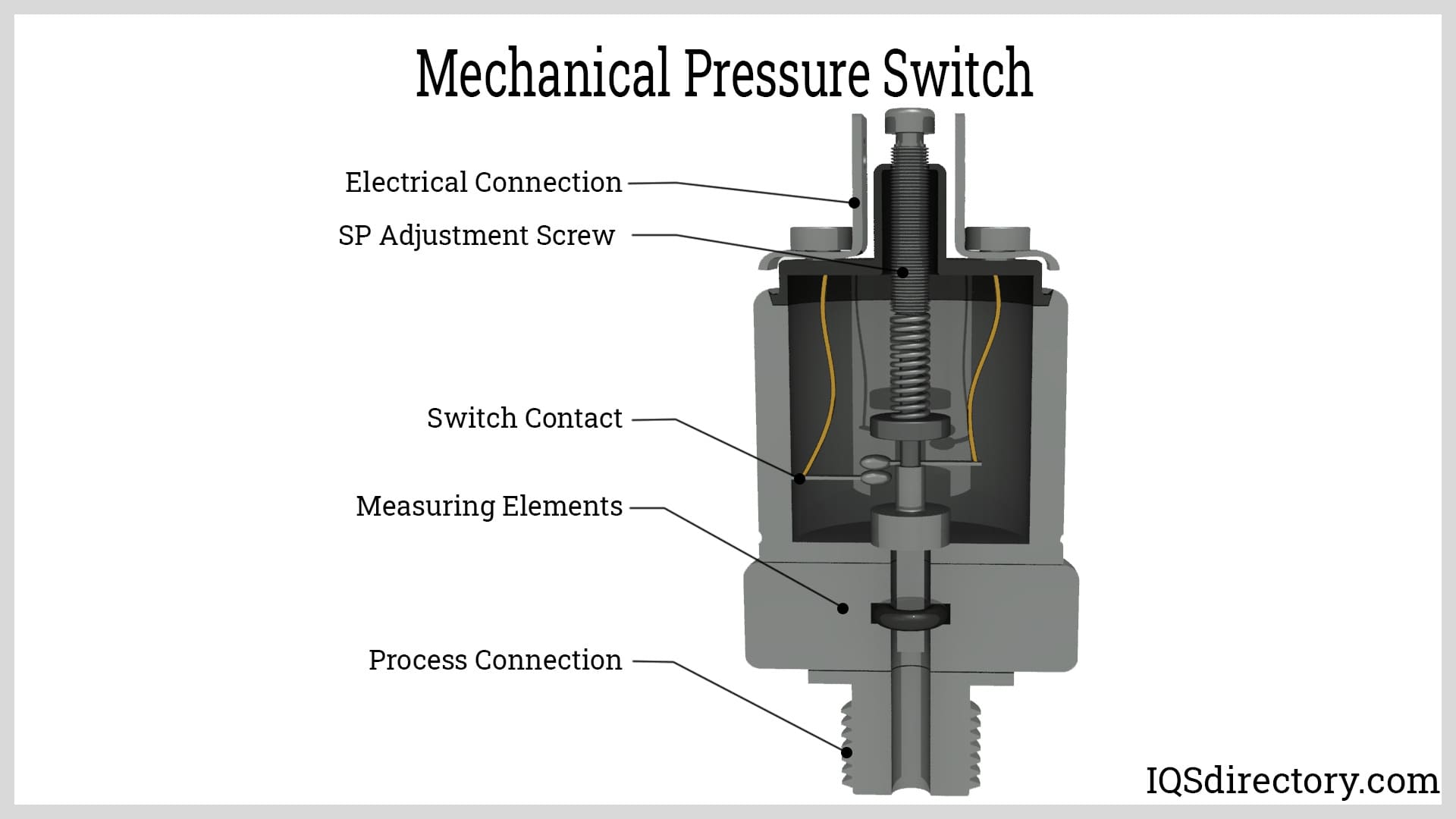

How Are Air Pressure Switches Formed and Assembled?

The forming and assembly processes are crucial for ensuring that air pressure switches operate correctly under various conditions.

-

Forming Techniques: Techniques such as stamping, machining, and injection molding are employed. Stamping is used for metal components, while injection molding is ideal for plastic parts. Each component is created with precision to meet specific pressure and operational standards.

-

Assembly: After forming, components are assembled. This can be done manually or through automated processes. Key components include diaphragms, electrical contacts, and housings. Each switch must be assembled in a way that maintains its integrity and functionality.

What Finishing Processes Are Applied to Air Pressure Switches?

Finishing processes enhance the performance and aesthetics of air pressure switches. These may include:

- Coating: Protective coatings are applied to prevent corrosion and enhance durability. Common coatings include powder coating and anodizing for metal parts.

- Quality Control Checks: After finishing, switches undergo rigorous quality control to ensure they meet the required specifications. This includes testing for leaks and verifying the accuracy of the pressure settings.

What Quality Assurance Standards Are Relevant for Air Pressure Switches?

For B2B buyers, understanding the quality assurance (QA) standards that govern the manufacturing of air pressure switches is critical. International standards such as ISO 9001 ensure that manufacturers adhere to quality management principles.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and ensure compliance with standards. Key checkpoints include:

- Incoming Quality Control (IQC): At this stage, raw materials and components are inspected for compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from standards are caught and corrected in real time.

- Final Quality Control (FQC): Once assembly is complete, final inspections are conducted. This includes functional testing of the switches to confirm that they operate within specified pressure ranges and that all safety mechanisms are functioning correctly.

What Common Testing Methods Are Used for Air Pressure Switches?

Several testing methods are employed to ensure the reliability and performance of air pressure switches:

- Functional Testing: This tests the switch’s response to pressure changes to ensure it activates and deactivates correctly.

- Leak Testing: Ensures that the switch is sealed properly to prevent air leakage, which can compromise performance.

- Endurance Testing: Simulates long-term usage to verify that the switch can withstand repeated cycles without failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, ensuring that suppliers maintain high-quality standards is paramount. Here are effective methods to verify supplier quality control:

What Are the Best Practices for Conducting Supplier Audits?

-

On-Site Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control systems firsthand. This includes reviewing documentation, equipment, and employee training programs.

-

Requesting Quality Reports: Suppliers should provide detailed quality reports that outline their quality control processes, test results, and compliance with international standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality practices. These agencies can conduct independent audits and testing, ensuring that the products meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate various certification requirements depending on their region. For example:

- CE Marking: In Europe, products must comply with EU standards and obtain CE marking, indicating conformity with health, safety, and environmental protection standards.

- API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards is crucial for pressure switches used in hazardous environments.

Understanding these nuances helps buyers select suppliers that meet their specific regulatory requirements and operational needs.

Conclusion: Why Is Quality Assurance Essential for Air Pressure Switches?

Quality assurance in the manufacturing of air pressure switches is not just about compliance; it directly impacts the reliability and safety of the final product. For B2B buyers, being diligent in evaluating manufacturing processes and quality control practices ensures they procure switches that will perform effectively in their applications. By focusing on suppliers with robust quality assurance systems and certifications, buyers can mitigate risks and enhance the operational efficiency of their systems.

Illustrative image related to switch air pressure

Practical Sourcing Guide: A Step-by-Step Checklist for ‘switch air pressure’

To assist B2B buyers in efficiently procuring air pressure switches, this guide offers a structured checklist designed to streamline the sourcing process. By following these steps, international buyers can ensure they choose the right products that meet their specific operational needs.

Step 1: Define Your Technical Specifications

Before initiating any procurement process, it is essential to clarify your technical requirements. Identify the pressure range, electrical specifications (such as voltage and amperage), and the type of application (e.g., automotive, industrial, or HVAC). This step is crucial as it narrows down the options and ensures compatibility with your existing systems.

- Pressure Range: Determine whether you need a switch that operates at low (e.g., 85-105 PSI) or high pressure (e.g., 165-200 PSI).

- Connection Type: Decide on the necessary NPT (National Pipe Thread) size for seamless integration.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in air pressure switches. Look for companies with a solid reputation in the market and positive customer feedback. Supplier reliability is vital as it impacts the performance and lifespan of the switches.

Illustrative image related to switch air pressure

- Supplier Background: Investigate the supplier’s history, product range, and areas of expertise.

- Customer Reviews: Read testimonials and case studies to gauge customer satisfaction and product performance.

Step 3: Evaluate Product Quality and Certifications

Assess the quality of the products offered by potential suppliers. Check for industry certifications and compliance with international standards, which indicate reliability and safety. Quality assurance is crucial for preventing operational disruptions and ensuring long-term functionality.

- Certifications: Look for certifications such as ISO, CE, or UL that validate the product’s safety and quality.

- Material Durability: Inquire about the materials used (e.g., stainless steel or brass) to ensure they can withstand the environmental conditions of your application.

Step 4: Request Technical Documentation

Once you have shortlisted suppliers, request detailed technical documentation for the air pressure switches. This should include installation guides, operational manuals, and specifications sheets. Having access to this information is important for troubleshooting and ensuring proper installation.

- Installation Guides: These documents will help your technical team understand installation processes and requirements.

- Specifications Sheets: Review these sheets to confirm that the products meet your defined technical specifications.

Step 5: Confirm Warranty and Support Policies

Before finalizing your purchase, verify the warranty and post-sale support offered by the supplier. A solid warranty and responsive customer support can significantly reduce potential risks associated with product failure.

Illustrative image related to switch air pressure

- Warranty Terms: Ensure you understand the coverage period and conditions under which the warranty applies.

- Support Availability: Check if the supplier provides ongoing support, such as troubleshooting assistance and replacement parts.

Step 6: Compare Pricing and Terms of Sale

Gather quotes from your shortlisted suppliers to compare pricing. While cost is an important factor, consider the overall value, including product quality and service. Analyze payment terms, shipping costs, and delivery timelines to make an informed decision.

- Total Cost of Ownership: Evaluate not just the initial purchase price, but also the anticipated maintenance and operational costs.

- Negotiation Opportunities: Don’t hesitate to negotiate terms or ask about bulk purchase discounts.

Step 7: Finalize Purchase and Monitor Performance

After selecting a supplier and finalizing the purchase, monitor the performance of the air pressure switches in your operations. Collect feedback from your technical team regarding installation and functionality to ensure they meet your expectations.

- Performance Metrics: Track key performance indicators to evaluate efficiency and reliability.

- Supplier Feedback: Maintain communication with the supplier for ongoing support and to address any issues that may arise.

By following this checklist, B2B buyers can navigate the procurement process for air pressure switches efficiently and effectively, ensuring they select products that align with their operational needs and standards.

Comprehensive Cost and Pricing Analysis for switch air pressure Sourcing

What Are the Key Cost Components of Air Pressure Switches?

Understanding the cost structure of air pressure switches is vital for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts pricing. High-quality materials such as stainless steel or specialized plastics for weather resistance will raise costs but also enhance durability and performance. For example, sealed pressure switches designed for harsh environments may incur higher material costs.

-

Labor: Labor costs vary by region and manufacturing process. In countries with lower labor costs, such as those in parts of Africa or South America, you may find more competitive pricing. However, labor-intensive processes, such as custom fabrication, can increase overall costs.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, factory utilities, and other indirect costs. Efficient production processes can help minimize these costs, which is an essential consideration for bulk orders.

-

Tooling: Custom tooling for specialized switches can be a significant upfront investment, often amortized over large production runs. If your application requires customized specifications, expect these costs to be reflected in the unit price.

-

Quality Control: Rigorous QC measures ensure reliability and performance, especially for critical applications in industries like automotive or healthcare. Suppliers may charge a premium for comprehensive testing and certification processes.

-

Logistics: Shipping costs can vary widely based on the Incoterms agreed upon. Factors such as freight mode (air vs. sea), destination, and packaging requirements will influence the total logistics cost.

-

Margin: Supplier profit margins can vary based on market demand and competition. Understanding the typical margin in your region can help in negotiations.

How Do Price Influencers Affect Air Pressure Switch Costs?

Several factors can influence the pricing of air pressure switches, particularly for international buyers:

-

Volume/MOQ: Many suppliers have minimum order quantities (MOQs). Larger orders often result in lower per-unit costs, making it advantageous for buyers looking to stock inventory.

-

Specifications and Customization: Customized specifications can increase costs. Standard switches may be more readily available and less expensive than those tailored for specific applications.

-

Materials and Quality Certifications: Higher-grade materials and certifications (like ISO or UL) will drive up prices. However, these can also lead to lower Total Cost of Ownership (TCO) through enhanced reliability and reduced failure rates.

-

Supplier Factors: The reputation and reliability of a supplier can impact pricing. Established suppliers with proven track records may charge more, but they often provide better support and quality assurance.

-

Incoterms: Understanding Incoterms is crucial for budgeting. Terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can shift cost responsibilities and affect pricing negotiations.

What Are the Best Negotiation Tips for International B2B Buyers?

-

Understand Total Cost of Ownership: Look beyond the initial purchase price. Consider factors like maintenance, operational costs, and reliability, which can significantly affect the TCO.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs and negotiate better pricing. Suppliers are often willing to offer discounts for larger commitments.

-

Be Clear About Specifications: Clearly define your requirements to avoid misunderstandings that could lead to additional costs. This can also help in receiving accurate quotes.

-

Research Local Suppliers: For buyers in regions like Africa or South America, local suppliers may offer competitive pricing due to lower shipping costs and customs duties.

-

Evaluate Payment Terms: Flexible payment terms can improve cash flow. Discuss options such as net payment terms or installment plans.

-

Stay Informed on Market Trends: Understanding market dynamics can give you leverage in negotiations. For instance, if demand for air pressure switches is low, suppliers may be more willing to negotiate on price.

Disclaimer on Pricing

Prices for air pressure switches can fluctuate based on market conditions, supplier changes, and raw material costs. The information provided here serves as a guideline and may not reflect current market prices. Always consult suppliers directly for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing switch air pressure With Other Solutions

Understanding the Importance of Alternative Solutions to Switch Air Pressure

In the ever-evolving landscape of industrial applications, choosing the right technology for pressure management is crucial. While switch air pressure systems are widely adopted due to their reliability and simplicity, it is essential to explore viable alternatives that may offer distinct advantages depending on specific operational needs. This section compares switch air pressure with two alternative technologies: Pressure Sensors and Flow Switches. Each solution has unique features, costs, and implementation processes that can influence a B2B buyer’s decision.

Comparison Table

| Comparison Aspect | Switch Air Pressure | Pressure Sensors | Flow Switches |

|---|---|---|---|

| Performance | Reliable for on/off control based on pressure levels | High accuracy in continuous pressure monitoring | Detects fluid movement, not pressure; used for flow regulation |

| Cost | Moderate initial cost; maintenance can add to lifetime expense | Higher upfront cost; long-term savings through efficiency | Generally lower cost; less maintenance required |

| Ease of Implementation | Straightforward installation; requires basic electrical knowledge | Requires calibration and setup; may need specialized installation | Easy to install with simple wiring; no calibration necessary |

| Maintenance | Regular checks needed to ensure functionality | Minimal maintenance; occasional recalibration may be required | Low maintenance; infrequent checks required |

| Best Use Case | Ideal for systems needing clear on/off control | Best for applications requiring precise pressure readings | Suitable for systems where fluid movement monitoring is critical |

Detailed Breakdown of Alternatives

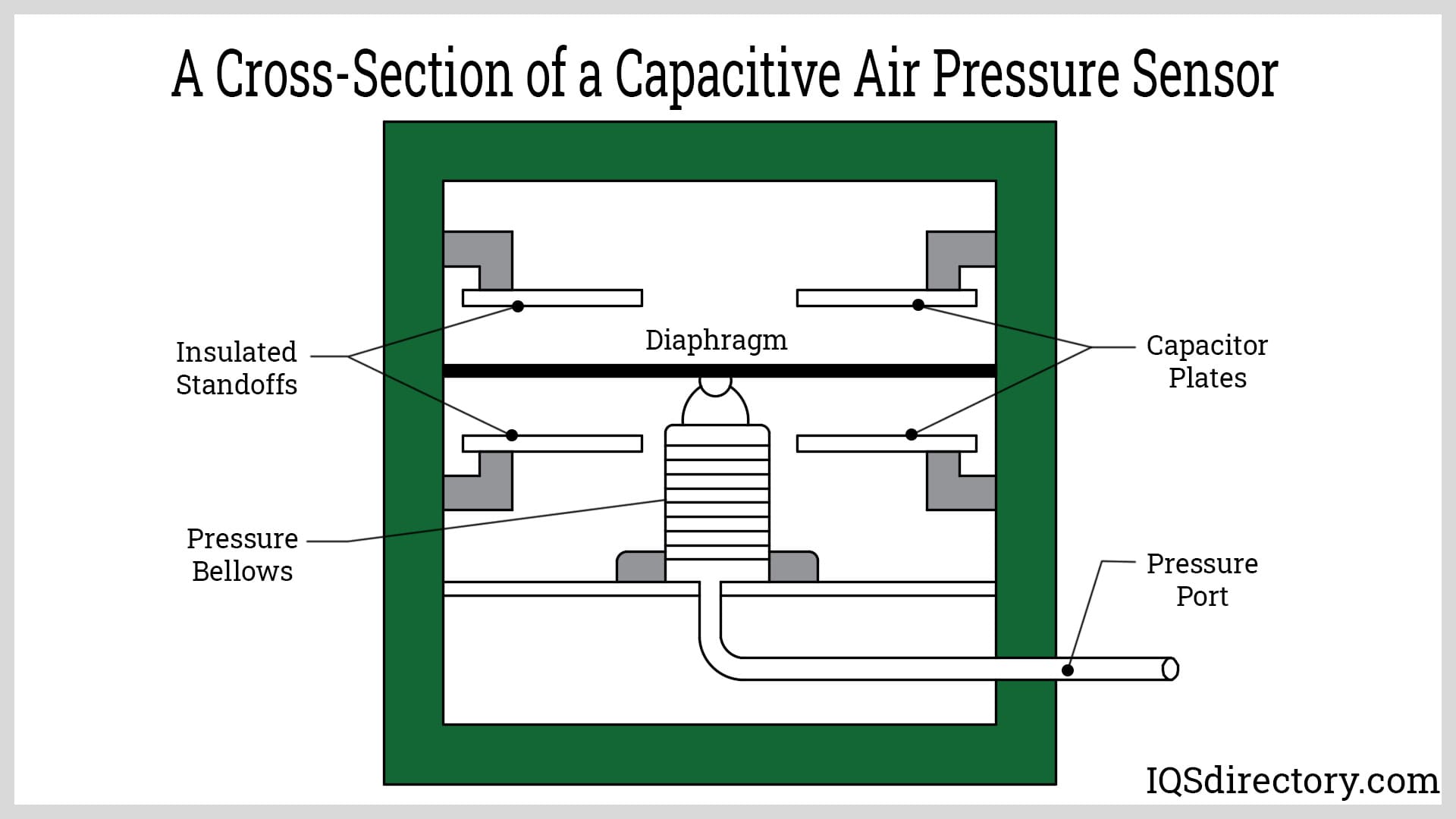

What Are the Advantages and Disadvantages of Pressure Sensors?

Pressure sensors provide continuous monitoring of pressure levels, allowing for real-time data collection and analysis. These devices can offer high accuracy and are suitable for complex systems that require precise pressure management. However, their higher initial cost and the need for calibration can be a barrier for some businesses. Moreover, pressure sensors typically require more advanced installation procedures, which might necessitate the involvement of specialized personnel, increasing overall costs.

Illustrative image related to switch air pressure

How Do Flow Switches Compare to Switch Air Pressure Systems?

Flow switches are designed to detect the movement of fluid rather than pressure levels. They are often simpler and more cost-effective than switch air pressure systems, making them an attractive option for many applications. Their ease of installation and lower maintenance needs can lead to significant operational savings. However, flow switches are not suitable for applications that require precise pressure management, as they do not provide the same level of control over air pressure as switch air pressure systems do.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When evaluating the best pressure management solution, B2B buyers must consider the specific requirements of their operations. Switch air pressure systems are ideal for applications needing straightforward on/off control based on pressure levels. In contrast, pressure sensors offer enhanced accuracy and continuous monitoring, suitable for complex systems. Flow switches serve well in scenarios where fluid movement is more critical than pressure control. By thoroughly assessing performance requirements, budget constraints, and maintenance capabilities, buyers can make informed decisions that align with their operational goals and drive efficiency.

Essential Technical Properties and Trade Terminology for switch air pressure

What Are the Critical Technical Properties of Air Pressure Switches?

Understanding the technical properties of air pressure switches is essential for B2B buyers, especially those looking to integrate these devices into industrial applications. Here are some critical specifications:

-

Pressure Range

The pressure range of a switch indicates the minimum and maximum pressure levels it can handle. Common ranges include 85-200 PSI, with specific models tailored for different applications such as automotive or pneumatic systems. Selecting the appropriate pressure range ensures optimal performance and prevents damage to the system. -

Tolerance

Tolerance refers to the allowable deviation from a set pressure point, typically expressed as a percentage. For example, a tolerance of ±5% means that if a switch is set to activate at 100 PSI, it may trigger anywhere between 95 and 105 PSI. Accurate tolerances are crucial for maintaining system reliability and efficiency, particularly in sensitive applications. -

Material Grade

The material used in the construction of the pressure switch affects its durability and resistance to environmental factors. Common materials include brass, stainless steel, and plastic. Choosing the right material is vital for applications exposed to harsh conditions, ensuring longevity and reducing maintenance costs. -

Electrical Rating

This specification indicates the maximum voltage and current the switch can handle without failure. For instance, switches may be rated for 12V or 24V systems with varying amperage ratings. Ensuring compatibility with existing electrical systems is critical to avoid operational failures. -

Connection Type

The connection type, often specified in NPT (National Pipe Thread) sizes such as 1/8″ or 1/4″, determines how the switch interfaces with the air system. Proper connection sizing is essential for leak prevention and optimal system performance. -

Sealing Type

Sealed switches are designed to protect internal components from moisture and debris, making them suitable for outdoor or industrial environments. Unsealed switches are better suited for clean, controlled environments. Understanding the sealing type aids in selecting the right switch for the intended application.

What Are Common Trade Terms Used in Air Pressure Switch Transactions?

Familiarity with industry jargon can significantly enhance communication between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air pressure switches, buyers may seek OEM products to ensure compatibility with existing systems and adherence to quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their inventory and budget, especially when considering bulk purchases or new product lines. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. It is an essential step in the procurement process, enabling buyers to compare offers and negotiate terms effectively. -

Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international trade, particularly concerning shipping, insurance, and tariffs. Familiarity with these terms helps in understanding costs and responsibilities, particularly for buyers in regions like Africa or South America. -

Lead Time

Lead time is the time taken from placing an order to delivery. Knowing the lead time is crucial for planning and inventory management, especially in industries where downtime can lead to significant financial losses. -

Warranty Period

This term refers to the duration for which a product is guaranteed to function as intended. Understanding warranty periods helps buyers assess the reliability of products and plan for potential replacements or repairs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their air pressure systems.

Navigating Market Dynamics and Sourcing Trends in the switch air pressure Sector

What Are the Key Drivers Influencing the Switch Air Pressure Market?

The global switch air pressure market is experiencing significant growth, driven by increased demand across various sectors, including automotive, manufacturing, and HVAC systems. Internationally, the expansion of industrial applications in regions such as Africa, South America, the Middle East, and Europe is creating a robust demand for reliable and efficient pressure management solutions. For B2B buyers, understanding the nuances of these regional markets is crucial.

Emerging technologies such as IoT-enabled pressure switches are gaining traction, allowing for real-time monitoring and automation. This trend aligns with the increasing push for smart manufacturing solutions, enabling businesses to enhance operational efficiency while minimizing downtime. Additionally, the integration of pressure switches with advanced control systems is becoming a standard practice, catering to the needs of modern industrial applications.

Buyers should also consider the impact of regional regulations and standards, which can vary significantly. For instance, Europe has stringent safety and environmental regulations that may necessitate sourcing compliant products. In contrast, emerging markets might prioritize cost-effectiveness, which could affect product selection and supplier relationships.

How Does Sustainability Impact Sourcing Decisions in the Switch Air Pressure Sector?

Sustainability is increasingly becoming a pivotal factor in B2B sourcing strategies. Companies are now compelled to evaluate the environmental impact of their supply chains, particularly regarding energy consumption and waste management associated with pressure switch production. Buyers are encouraged to seek suppliers who demonstrate a commitment to sustainable practices, such as using recyclable materials or implementing energy-efficient manufacturing processes.

Ethical sourcing is another critical component. B2B buyers are increasingly aware of the social implications of their procurement decisions, driving demand for suppliers who uphold fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the use of ‘green’ materials in the production of switch air pressure devices is gaining importance. Buyers should actively seek out products that utilize environmentally friendly components, as these not only reduce the overall carbon footprint but also resonate with end-users who prioritize sustainability in their purchasing decisions.

What Is the Evolution of the Switch Air Pressure Sector?

The switch air pressure sector has evolved significantly over the past few decades. Initially, mechanical pressure switches dominated the market, relying on simple diaphragm mechanisms to detect pressure changes. However, advancements in technology have led to the development of electronic pressure switches, which offer greater accuracy and reliability.

Illustrative image related to switch air pressure

The introduction of smart pressure switches, integrated with IoT technology, marks a pivotal moment in this evolution. These devices provide real-time data analytics, allowing businesses to optimize their operations and predictive maintenance strategies. As industries continue to prioritize automation and efficiency, the demand for innovative pressure management solutions is likely to grow, shaping the future landscape of the switch air pressure market.

In summary, B2B buyers must navigate a complex market characterized by technological advancements, sustainability concerns, and regional dynamics. By focusing on these key aspects, buyers can make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of switch air pressure

-

How do I determine if my air pressure switch is malfunctioning?

To identify a malfunctioning air pressure switch, look for signs such as the compressor not activating or deactivating at the set pressures, rapid cycling, or no response at all. A practical way to test is by using a multimeter to check continuity across the terminals when the system reaches the trigger PSI. If the contacts do not open or close properly, or if the switch fails to engage at the designated pressure range, replacement is necessary. Regular maintenance and testing can prevent operational disruptions. -

What is the best pressure switch for my air compressor system?

The ideal pressure switch for your air compressor depends on several factors, including the compressor’s specifications, tank size, and application. Common pressure settings range from 85/105 PSI for general use to 165/200 PSI for more demanding applications like air suspension systems. It’s essential to select a switch that matches your compressor’s rated cutoff pressure and the specific needs of your system. Consulting with a supplier can help ensure compatibility and optimal performance. -

What factors should I consider when sourcing air pressure switches internationally?

When sourcing air pressure switches from international suppliers, consider factors such as product quality, compliance with industry standards, and supplier reputation. Evaluate the supplier’s manufacturing capabilities, certifications, and previous client testimonials. Additionally, assess the logistics of shipping, including lead times and customs regulations in your country. Establishing clear communication regarding your requirements will help ensure you receive products that meet your operational needs. -

Are there customization options available for air pressure switches?

Many manufacturers offer customization options for air pressure switches, including specific PSI settings, size, and electrical specifications. If your application requires unique features, such as sealed units for harsh environments or specific terminal configurations, it’s advisable to discuss these requirements with potential suppliers. Custom orders may involve longer lead times and higher costs, so plan accordingly to align with your project timelines. -

What is the minimum order quantity (MOQ) for purchasing air pressure switches?

Minimum order quantities (MOQs) for air pressure switches can vary significantly between suppliers, typically ranging from a few units to several hundred. Factors influencing MOQ include the manufacturer’s production capabilities, the complexity of the product, and market demand. When negotiating with suppliers, clarify the MOQ and explore options for smaller initial orders or samples to assess product quality before committing to larger purchases. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary widely among international suppliers, but common practices include advance payment, letters of credit, or payment upon delivery. Many suppliers may require a deposit (typically 30-50%) with the balance due before shipment. It’s crucial to discuss and agree on payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially for larger transactions. -

How can I ensure the quality assurance (QA) of the air pressure switches I purchase?

To ensure quality assurance for air pressure switches, request detailed product specifications, certifications, and quality control processes from your supplier. Many reputable manufacturers conduct rigorous testing and provide documentation to verify compliance with industry standards. Additionally, consider requesting samples before placing a larger order to evaluate the product’s performance and reliability firsthand. Establishing a clear return policy can also safeguard your investment. -

What logistical considerations should I keep in mind when importing air pressure switches?

When importing air pressure switches, consider factors such as shipping methods, customs duties, and delivery timelines. Choose a reliable logistics partner experienced in handling international shipments to navigate customs processes efficiently. Be aware of any import regulations specific to your country, including product compliance standards. Planning for potential delays and ensuring proper documentation will help streamline the logistics process and minimize disruptions to your supply chain.

Top 6 Switch Air Pressure Manufacturers & Suppliers List

1. HornBlasters – Air Compressor Pressure Switches

Domain: hornblasters.com

Registered: 2003 (22 years)

Introduction: This company, HornBlasters – Air Compressor Pressure Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. DIRTY AIR – Pressure Switch 12V Sealed 5 Amp

Domain: dirtyworks-kc.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “DIRTY AIR Pressure Switch – 12V Sealed 5 Amp”, “sku”: “DA-PS01”, “price”: “$29.99”, “on_off_psi_options”: [“165/200”, “140/175”], “current_shipping_lead_time”: “”, “features”: [“Sealed pressure switch”, “5 Amp”, “Custom DIRTY AIR stainless steel sealed pressure switches for 165/200”, “Custom DIRTY AIR brass sealed pressure switches for 140/175”, “Ultra reliable”], “thread_size”: …

3. Hubbell – Pressure Switches

Domain: hubbell.com

Registered: 1995 (30 years)

Introduction: This company, Hubbell – Pressure Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Cleveland – Air Pressure Switches

Domain: boilerwarehouse.com

Registered: 2011 (14 years)

Introduction: [{‘name’: ‘Cleveland Air Pressure Switch’, ‘type’: ‘Fixed’, ‘range’: ‘0.05″ W.C.’, ‘SKU’: ‘PS-306-001’, ‘price’: ‘$219.72’, ‘stock’: ’10 available’}, {‘name’: ‘Cleveland SPDT Air Pressure Switch’, ‘type’: ‘Fixed’, ‘range’: ‘0.03″ W.C.’, ‘SKU’: ‘DFS-301-112’, ‘price’: ‘$63.98’, ‘stock’: ’45 available’}, {‘name’: ‘Cleveland SPDT Air Pressure Switch’, ‘type’: ‘Adjustable’, ‘range’: ‘0.05″ – 12.0″ W.C…

5. McMaster – Adjustable Pressure Switches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Adjustable Pressure Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Compressor Pressure Switches – Electronic vs Mechanical

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around compressor pressure switches, comparing electronic and mechanical types. The user mentions reusing a 20G hot dog tank after a motor failure and expresses concerns about the mechanical switch’s design. They consider using an electronic switch but note potential limitations in adjustability. A commenter advises against the electronic switch due to safety issues, explai…

Strategic Sourcing Conclusion and Outlook for switch air pressure

In navigating the complexities of sourcing air pressure switches, international B2B buyers must prioritize strategic partnerships and product reliability. Key considerations include understanding the specific applications of pressure switches, such as their role in compressor systems and pneumatic controls. Opting for sealed models can enhance durability in harsh environments, while selecting the appropriate PSI range is crucial for optimizing system performance.

Investing in high-quality pressure switches not only ensures operational efficiency but also significantly reduces maintenance costs over time. As markets in regions such as Africa, South America, the Middle East, and Europe continue to evolve, aligning sourcing strategies with reputable manufacturers can facilitate access to cutting-edge technology and innovations.

Looking ahead, it is vital for businesses to stay informed about emerging trends and best practices in air pressure systems. Engaging with industry experts and attending relevant trade shows can provide invaluable insights and networking opportunities. By taking proactive steps in their sourcing strategies, B2B buyers can secure a competitive edge and drive sustainable growth in their operations. Embrace the future of air pressure solutions and position your business for success in a dynamic global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.