Choosing Your Substation Transformer Parts: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for substation transformer parts

In the complex landscape of electrical infrastructure, sourcing reliable substation transformer parts presents a significant challenge for international B2B buyers. Understanding the nuances of these critical components is essential for ensuring optimal performance and longevity of electrical systems. This guide is designed to provide a comprehensive overview of substation transformer parts, including their types, applications, and the intricacies of supplier vetting. Additionally, it delves into cost considerations and best practices for maintenance, equipping buyers with the knowledge needed to make informed purchasing decisions.

As businesses in regions such as Africa, South America, the Middle East, and Europe (including key markets like Nigeria and Germany) navigate the global marketplace, the importance of sourcing high-quality transformer parts cannot be overstated. This guide empowers stakeholders to identify reputable suppliers, understand product specifications, and evaluate pricing structures, ultimately leading to enhanced operational efficiency and reduced downtime. By leveraging this resource, B2B buyers will be well-prepared to tackle the challenges of sourcing and maintaining essential transformer components, ensuring that their electrical systems operate seamlessly in an ever-evolving energy landscape.

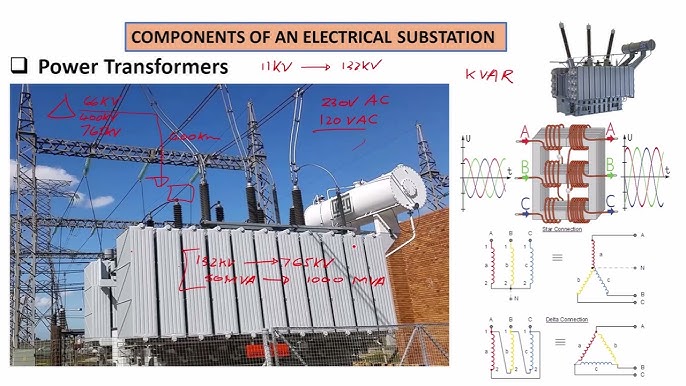

Understanding substation transformer parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laminated Core | Made of stacked sheets of steel or iron; reduces eddy currents | Electrical distribution and transmission | Pros: Efficient magnetic properties; Cons: Heavier than alternatives. |

| Transformer Oil | Hydro-carbon mineral oil; provides insulation and cooling | Oil-immersed transformers | Pros: Excellent thermal management; Cons: Requires regular monitoring and replacement. |

| Tap Changer | Adjusts voltage output; available in on-load and off-load types | Voltage regulation in substations | Pros: Flexibility in voltage control; Cons: Mechanical wear over time. |

| Cooling Tubes/Radiators | Facilitates oil circulation; can be forced or natural | High-capacity transformers | Pros: Enhances cooling efficiency; Cons: May require additional maintenance. |

| Control Box | Manages voltage/current; integrates protective devices | Grid management and fault protection | Pros: Enhances safety and reliability; Cons: Complex installation may be needed. |

What Are the Key Characteristics of Laminated Cores in Substation Transformers?

Laminated cores are integral to substation transformers, designed to optimize electromagnetic efficiency by minimizing energy losses. Constructed from thin sheets of steel or iron, they reduce eddy currents and hysteresis losses, ensuring effective magnetic flux transmission. These cores are suitable for various transformer types, from isolation to distribution transformers. B2B buyers should consider the core’s material and design, which directly affect performance and efficiency, particularly in high-demand applications.

How Does Transformer Oil Contribute to Transformer Efficiency?

Transformer oil serves dual purposes: insulation and cooling. It effectively separates electrical components while dissipating heat generated during operation. This oil is typically paraffin- or naphtha-based, allowing for optimal thermal management. For buyers, selecting high-quality transformer oil is crucial, as it directly influences operational reliability and longevity. Regular monitoring and timely replacement are essential to prevent performance degradation and ensure the transformer operates within safe parameters.

What Is the Role of Tap Changers in Voltage Regulation?

Tap changers are vital for adjusting the voltage output of transformers, with options for on-load and off-load adjustments. On-load tap changers allow voltage changes without disconnecting the transformer, ensuring continuous power supply. This adaptability is particularly beneficial in fluctuating load conditions. When purchasing, B2B buyers should evaluate the type of tap changer based on operational needs and maintenance capabilities, as mechanical wear can impact long-term performance.

Why Are Cooling Tubes and Radiators Essential for Transformer Operation?

Cooling tubes or radiators play a critical role in maintaining optimal operating temperatures within transformers. They facilitate the circulation of transformer oil, either through forced pumps or natural convection, ensuring efficient heat dissipation. For high-capacity transformers, these components are indispensable for preventing overheating and enhancing overall efficiency. Buyers should assess the cooling system’s design and capacity to ensure it meets the demands of their specific applications, as inadequate cooling can lead to transformer failure.

How Do Control Boxes Enhance Transformer Safety and Performance?

Control boxes are essential for managing voltage and current flow within transformers, integrating protective devices like fuses and circuit breakers. They play a significant role in safeguarding the electrical grid from faults and overloads. For B2B buyers, investing in advanced control box technology can improve transformer reliability and operational efficiency. However, the complexity of installation and integration should be considered, as it may require specialized expertise and additional costs.

Key Industrial Applications of substation transformer parts

| Industry/Sector | Specific Application of substation transformer parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Energy & Utilities | Power distribution in grid systems using transformers | Ensures reliable energy supply and minimizes downtime | Quality of materials, compliance with international standards |

| Mining & Metals | Voltage regulation for heavy machinery using tap changers | Enhances operational efficiency and equipment lifespan | Availability of specialized components for high-demand environments |

| Manufacturing & Industry | Power supply stabilization through cooling systems and control boxes | Reduces production interruptions and improves safety | Compatibility with existing systems and maintenance support |

| Renewable Energy | Integration of solar and wind energy through transformer windings | Supports sustainable energy solutions and grid reliability | Adaptability to varying voltage levels and environmental conditions |

| Transportation & Logistics | Power supply for electric rail systems using transformer oil and insulation | Ensures consistent power delivery and safety in operations | Sourcing from reputable suppliers with proven reliability |

How Are Substation Transformer Parts Used in the Energy & Utilities Sector?

In the energy and utilities sector, substation transformer parts are critical for power distribution in grid systems. Components such as the laminated core and windings facilitate the efficient transfer of electricity at various voltage levels. This ensures a reliable energy supply, crucial for minimizing outages and maintaining grid stability. International buyers, particularly from regions like Africa and South America, must prioritize sourcing high-quality materials that comply with local and international standards to ensure durability and performance.

What Role Do Transformer Parts Play in Mining & Metals Operations?

The mining and metals industry heavily relies on transformers for voltage regulation of heavy machinery. Tap changers are particularly valuable as they allow for adjustments in voltage levels without interrupting operations. This capability enhances operational efficiency and extends the lifespan of mining equipment. Buyers from regions with extreme operational demands must consider the availability of specialized components that can withstand harsh conditions and high energy requirements.

How Do Substation Transformer Parts Support Manufacturing & Industry?

In manufacturing, transformer parts such as cooling systems and control boxes are essential for stabilizing power supply. These components help mitigate production interruptions by ensuring consistent voltage delivery, thereby enhancing safety and operational efficiency. For international buyers, especially in Europe, sourcing considerations should include compatibility with existing systems and the availability of maintenance support to ensure seamless integration and operation.

In What Ways Are Transformer Parts Integral to Renewable Energy Solutions?

Substation transformer parts are vital for integrating renewable energy sources like solar and wind into the power grid. Windings in transformers facilitate the conversion of energy generated from these sources into usable electricity at stable voltage levels. This capability supports sustainable energy initiatives and enhances grid reliability. Buyers in the Middle East and Africa should focus on sourcing adaptable transformer components that can operate efficiently under varying environmental conditions.

How Do Transformer Parts Enhance Power Supply in Transportation & Logistics?

In the transportation and logistics sector, transformer parts are crucial for providing reliable power supply to electric rail systems. The use of transformer oil and insulation materials ensures the safe and efficient operation of these systems. This consistency is vital for maintaining operational safety and efficiency. Buyers must prioritize sourcing from reputable suppliers known for their reliability and quality to minimize risks associated with power delivery in critical transportation infrastructure.

3 Common User Pain Points for ‘substation transformer parts’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Transformer Components

The Problem: B2B buyers often face challenges in sourcing high-quality substation transformer parts, especially when dealing with international suppliers. Inconsistent quality, long lead times, and varying standards can lead to significant operational disruptions. For instance, a buyer in Nigeria may struggle to find reliable suppliers who can guarantee that the insulating materials or transformer oil meet international standards. Such issues can result in equipment failures, increased downtime, and financial losses.

The Solution: To mitigate these risks, buyers should develop a robust supplier evaluation process that focuses on quality assurance and compliance with international standards. This involves conducting thorough research on potential suppliers, including checking certifications, customer reviews, and past project success. Engaging with suppliers who have a proven track record in the region can also ensure better quality control. Furthermore, establishing long-term relationships with manufacturers can facilitate better communication and quicker resolutions to issues. Implementing a quality management system (QMS) can help monitor incoming parts and ensure they meet the necessary specifications before integration into the larger system.

Scenario 2: Managing Maintenance and Replacement of Transformer Parts

The Problem: Many businesses experience unexpected failures in transformer components due to insufficient maintenance and lack of awareness about the lifespan of parts like the tap changer or cooling tubes. For example, a utility company in South America might find that their transformer has overheated due to a malfunctioning cooling system, leading to costly emergency repairs and service disruptions. This lack of foresight can severely impact service reliability and customer satisfaction.

The Solution: To address this challenge, B2B buyers should implement a proactive maintenance schedule that includes regular inspections and predictive analytics. Leveraging IoT technology can enhance monitoring capabilities, allowing for real-time assessments of transformer health. By integrating condition-based monitoring systems, companies can track critical parameters such as temperature and pressure, enabling timely interventions before failures occur. Additionally, training personnel on the importance of maintaining specific parts, like the cooling system and oil levels, can foster a culture of proactive maintenance. This approach not only extends the life of transformer parts but also reduces unexpected operational costs.

Scenario 3: Navigating Regulatory Compliance for Transformer Parts

The Problem: International buyers often encounter challenges related to regulatory compliance when importing substation transformer parts. Regulations may vary significantly across regions, and failure to adhere to them can lead to fines, project delays, and even the rejection of shipments. For instance, a buyer in Germany may find that specific insulating materials do not meet the stringent EU environmental regulations, resulting in costly rework or delays in project timelines.

The Solution: To navigate these complexities, buyers should invest in understanding the regulatory landscape of their target market. Engaging a compliance consultant familiar with local regulations can provide invaluable insights. It’s also beneficial to create a checklist that outlines all necessary certifications and compliance documentation required for each part. Regular training sessions for procurement teams on regulatory updates can ensure that all personnel are informed and compliant. Establishing a network of local partners can also help facilitate smoother import processes and provide guidance on the regulatory requirements specific to transformer parts in their region.

Strategic Material Selection Guide for substation transformer parts

When selecting materials for substation transformer parts, it is crucial to consider their properties, advantages, limitations, and the specific needs of international markets. Below is an analysis of four common materials used in transformer components, focusing on their performance characteristics and implications for B2B buyers in regions such as Africa, South America, the Middle East, and Europe.

What are the Key Properties of Laminated Steel in Transformer Cores?

Laminated steel is widely used for transformer cores due to its excellent magnetic properties. The key properties include high permeability, low hysteresis loss, and good thermal conductivity. Laminated steel is designed to minimize eddy current losses through its layered structure, which reduces energy loss during operation.

Pros and Cons: Laminated steel is durable and cost-effective, making it a popular choice. However, it can be heavy, which may complicate transportation and installation. Additionally, the manufacturing process can be complex, requiring precision to ensure optimal performance.

Impact on Application: Laminated steel cores are compatible with various transformer designs, enhancing efficiency. Buyers should consider the impact of local environmental conditions on steel, particularly corrosion, which can be a concern in humid or coastal regions.

How Do Insulating Materials Affect Transformer Performance?

Insulating materials, such as paper, cardboard, and synthetic polymers, play a critical role in transformer reliability. These materials must have high dielectric strength, thermal stability, and resistance to moisture and chemicals.

Pros and Cons: High-quality insulating materials provide excellent performance and longevity, reducing maintenance costs. However, they can be relatively expensive, and sourcing them may pose challenges in certain regions. Additionally, the complexity of manufacturing these materials can lead to longer lead times.

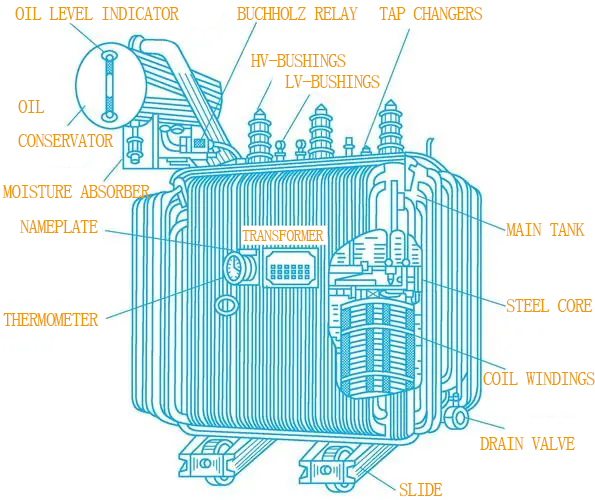

Illustrative image related to substation transformer parts

Impact on Application: The choice of insulating material directly affects the transformer’s operational safety and efficiency. B2B buyers should ensure compliance with international standards such as ASTM or IEC, particularly when sourcing materials from different countries.

What Are the Advantages of Using Copper for Windings?

Copper is the preferred material for transformer windings due to its superior electrical conductivity, which is approximately 60% better than aluminum. This high conductivity allows for reduced energy losses and improved efficiency.

Pros and Cons: Copper windings are durable and have excellent thermal properties, contributing to overall transformer performance. However, copper is more expensive than aluminum, which can impact the overall cost of the transformer. Additionally, the weight of copper can complicate logistics and installation.

Impact on Application: The use of copper windings is essential for high-performance transformers, especially in regions with high load demands. Buyers should be aware of local market conditions, as fluctuations in copper prices can significantly affect project budgets.

Why is Transformer Oil Critical for Cooling and Insulation?

Transformer oil serves dual purposes: it acts as an insulator and a coolant. The oil must have high dielectric strength and thermal stability to efficiently manage heat generated during operation.

Pros and Cons: The primary advantage of transformer oil is its ability to enhance the transformer’s operational lifespan by preventing overheating. However, sourcing high-quality oil can be costly, and there are environmental regulations that must be adhered to regarding its disposal.

Impact on Application: Buyers need to consider local regulations regarding transformer oil, especially in regions with strict environmental laws. Compliance with standards such as DIN or ISO can be crucial for international projects.

Summary Table of Material Selection for Substation Transformer Parts

| Material | Typical Use Case for substation transformer parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Laminated Steel | Transformer cores | High magnetic efficiency | Heavy and complex manufacturing | Medium |

| Insulating Materials | Winding insulation | Excellent dielectric properties | Higher cost and potential sourcing challenges | High |

| Copper | Windings | Superior electrical conductivity | Expensive and heavier than alternatives | High |

| Transformer Oil | Cooling and insulation | Enhances lifespan and operational reliability | Costly and subject to environmental regulations | Medium |

This guide provides international B2B buyers with essential insights into material selection for substation transformer parts, ensuring informed decisions that align with performance requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for substation transformer parts

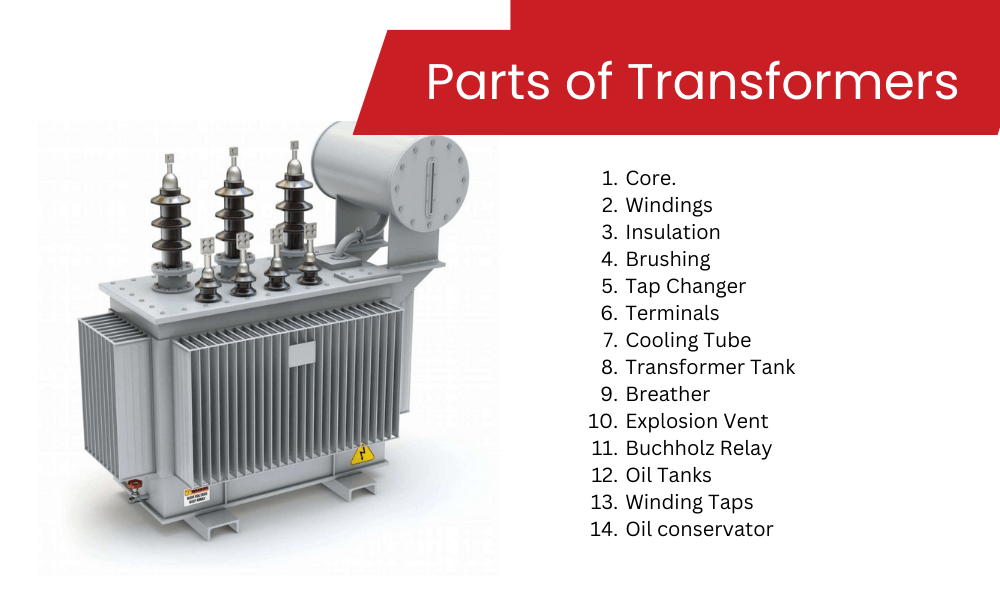

What Are the Key Stages in the Manufacturing Process of Substation Transformer Parts?

The manufacturing of substation transformer parts involves several critical stages, each designed to ensure high-quality production and performance reliability. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Is Involved?

The first step in manufacturing transformer parts is material preparation. This stage involves sourcing high-quality raw materials that meet specific performance standards. For instance, the core is typically made from laminated silicon steel, while windings can be crafted from copper or aluminum. Each material is subjected to rigorous testing to confirm its mechanical and electrical properties. Suppliers often provide material certificates, which document the quality and characteristics of the materials used.

Illustrative image related to substation transformer parts

Forming: How Are Parts Shaped?

Once materials are prepared, the next step is forming. This involves shaping the materials into the desired components through various techniques such as stamping, machining, and casting. For example, the laminated core is created by stacking and bonding sheets of silicon steel, while windings are produced by winding copper or aluminum wires around a core. Precision in this phase is critical, as even minor deviations can lead to performance issues in the final product.

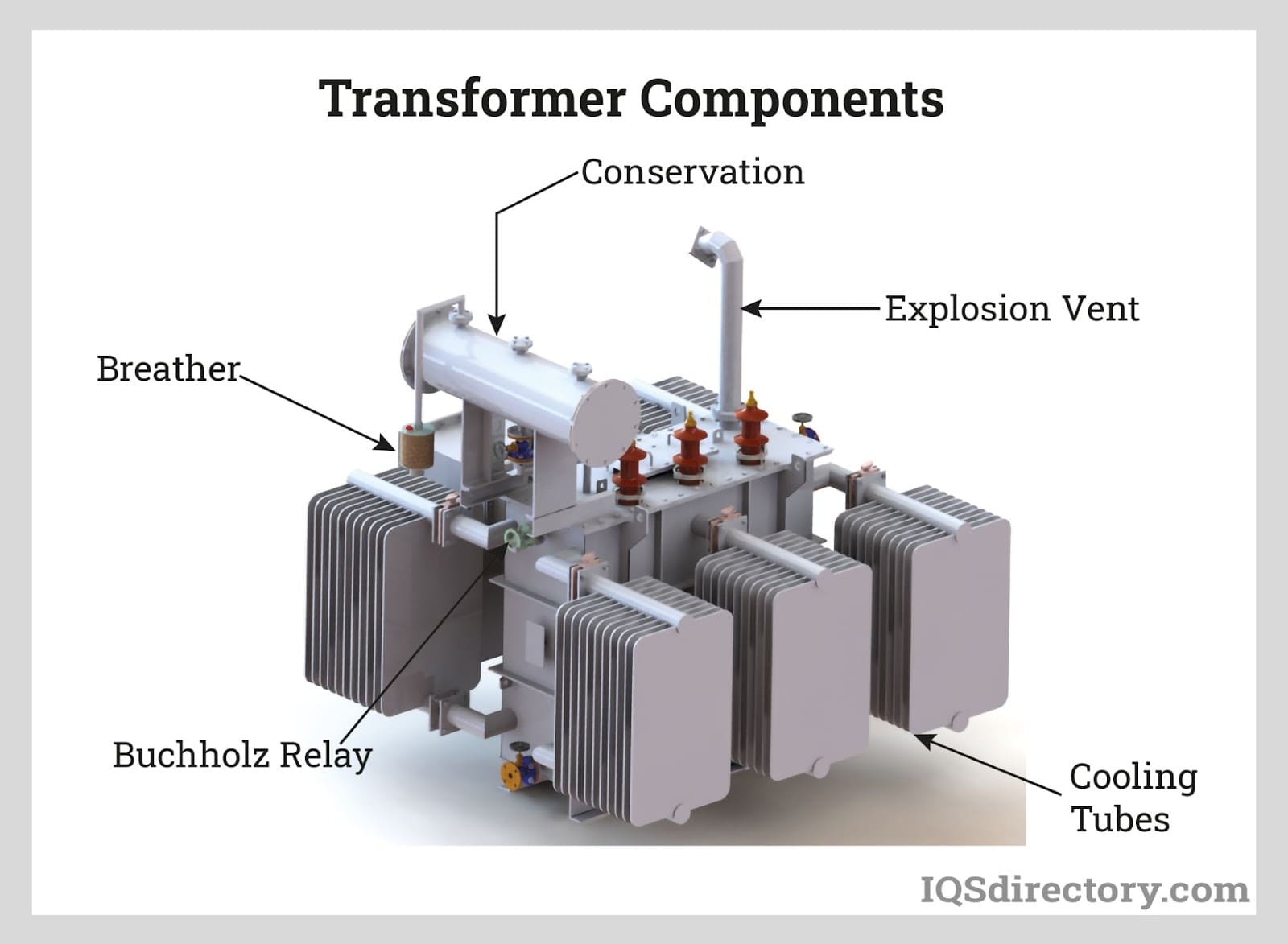

Assembly: How Are Components Joined Together?

Following the forming process, the components are assembled. This stage is crucial for ensuring that all parts fit together properly and function as intended. The assembly of transformer parts typically includes the integration of the core, windings, insulating materials, and tanks. Advanced techniques such as automated welding and precision fitting are often employed to enhance the integrity of the assembly. Quality control checks are also performed during this stage to identify any potential issues before moving to the finishing phase.

Finishing: What Is Done for Final Touches?

The finishing process involves applying protective coatings, conducting final inspections, and performing any necessary adjustments. This phase may also include the testing of electrical insulation and thermal properties. For substation transformers, the finishing stage is vital for ensuring that the parts can withstand harsh environmental conditions and operate efficiently over their expected lifespan.

What International Standards and Quality Assurance Measures Are Relevant?

Quality assurance is a critical aspect of manufacturing transformer parts, especially for international B2B buyers. Adhering to recognized standards not only ensures product reliability but also facilitates smoother transactions across borders.

Which International Standards Should Buyers Look For?

International standards such as ISO 9001 play a significant role in the quality assurance process. This standard focuses on maintaining consistent quality in products and services, which is essential for building trust between suppliers and buyers. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for ensuring that transformer parts meet specific safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential for maintaining high standards throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they are used in production. Ensuring that materials meet specified standards prevents defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checks are conducted to monitor the quality of components as they are being formed and assembled. This allows for immediate rectification of any issues.

-

Final Quality Control (FQC): The final inspection occurs after the assembly and finishing processes. This stage includes comprehensive testing of the entire unit to ensure it meets all specifications and performance criteria.

What Testing Methods Are Commonly Used in Transformer Part Manufacturing?

Various testing methods are employed throughout the manufacturing process to guarantee the reliability and performance of transformer parts. Common testing methods include:

-

Dielectric Testing: This test evaluates the insulating properties of materials to prevent electrical failures.

-

Thermal Imaging: Thermal imaging is used to assess the heat distribution and identify potential hotspots in transformer assemblies.

-

Mechanical Testing: This includes tensile testing and hardness testing to evaluate the physical properties of materials.

-

Leak Testing: For components like the main tank and conservator tank, leak testing is essential to ensure that no oil escapes during operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential. Here are some actionable steps:

Illustrative image related to substation transformer parts

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality assurance reports from suppliers. These reports should outline their quality control processes, testing methods, and certifications. Additionally, conducting supplier audits can provide firsthand insight into the manufacturing practices and quality assurance measures in place.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing quality. These organizations typically follow international standards and can offer detailed assessments of both the manufacturing processes and the final products.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the landscape of quality control and certification can be complex for international buyers. Different regions may have varying regulations and standards. For instance, European buyers may prioritize CE certification, while buyers in the Middle East might focus on local compliance standards. Understanding these nuances is vital for successful procurement.

B2B buyers should also be aware of potential language barriers and cultural differences when communicating with suppliers. Clear communication regarding quality expectations and compliance requirements is essential to avoid misunderstandings.

Illustrative image related to substation transformer parts

Conclusion: Ensuring Quality in Substation Transformer Parts Manufacturing

The manufacturing processes and quality assurance measures for substation transformer parts are critical to ensuring the reliability and performance of these essential components. By understanding the key stages of manufacturing, relevant international standards, and effective quality control practices, B2B buyers can make informed decisions when sourcing transformer parts globally. Taking the time to verify supplier practices and certifications will ultimately lead to enhanced operational efficiency and reduced risks in electrical infrastructure projects.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘substation transformer parts’

Introduction

Sourcing parts for substation transformers is a critical task for ensuring operational efficiency and reliability in electrical systems. This guide provides a step-by-step checklist to assist international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, in making informed procurement decisions. Each step outlines essential actions to facilitate the selection of high-quality transformer components.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first crucial step in the procurement process. Determine the specifications for each component, such as voltage ratings, material types, and operational capabilities. This ensures that the parts you source will meet the specific demands of your substation.

- Key Considerations:

- Voltage levels (high vs. low)

- Material requirements (e.g., copper vs. aluminum windings)

Step 2: Research Reliable Suppliers

Conduct thorough research to identify potential suppliers who specialize in transformer parts. Look for companies with a proven track record and expertise in the electrical transformer industry. This step is vital to ensure you partner with a supplier capable of meeting your quality and delivery requirements.

- How to Research:

- Check online reviews and ratings.

- Consult industry forums and networks for recommendations.

Step 3: Verify Supplier Certifications

Before finalizing any agreements, verify the certifications and standards that your potential suppliers adhere to. Certifications such as ISO 9001 and compliance with local regulations indicate a commitment to quality and safety in manufacturing processes.

- Why It Matters:

- Ensures that the parts meet international quality standards.

- Reduces the risk of sourcing defective or subpar components.

Step 4: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage directly with their customer service for deeper insights.

- What to Look For:

- Case studies demonstrating successful projects.

- Testimonials from satisfied customers.

Step 5: Request Samples

Once you have shortlisted potential suppliers, request samples of the transformer parts. This allows you to assess the quality and compatibility of the components with your specifications. It’s an essential step to avoid costly mistakes later in the procurement process.

- Focus Areas:

- Material quality and durability.

- Fit and compatibility with existing systems.

Step 6: Analyze Pricing and Terms

Gather detailed pricing information from your shortlisted suppliers. Analyze not only the cost of the parts but also payment terms, shipping costs, and potential discounts for bulk purchases. This comprehensive analysis helps in making cost-effective decisions.

- Considerations:

- Total cost of ownership versus initial purchase price.

- Payment options and credit terms.

Step 7: Establish a Clear Communication Plan

After selecting a supplier, establish a clear communication plan to ensure smooth collaboration. Define points of contact, communication frequency, and preferred methods of communication. Effective communication is essential for managing expectations and addressing any issues that may arise during the procurement process.

- Best Practices:

- Schedule regular check-ins during the order process.

- Use project management tools to track progress and updates.

Following these steps will help you navigate the complexities of sourcing substation transformer parts efficiently and effectively. By taking a structured approach, you can ensure that you obtain high-quality components that meet your operational needs.

Comprehensive Cost and Pricing Analysis for substation transformer parts Sourcing

What Are the Key Cost Components in Sourcing Substation Transformer Parts?

When evaluating the cost structure for substation transformer parts, it’s essential to consider several components that contribute to the overall pricing. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. For instance, copper and aluminum are commonly used for windings, with copper being more expensive but offering higher conductivity. Insulating materials and transformer oil also contribute substantially to material costs.

-

Labor: Labor costs vary depending on geographic location and the complexity of the components being manufactured. Skilled labor is essential for tasks such as winding coils and assembling the transformer parts.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in tooling can be significant, especially for custom parts. This cost is often amortized over the production run, impacting the price per unit.

-

Quality Control (QC): Ensuring that parts meet industry standards necessitates a robust QC process. This includes testing and inspection, which can add to the overall cost but is crucial for reliability and safety.

-

Logistics: The transportation of parts from the manufacturer to the buyer can incur significant costs, particularly for international shipments. Factors such as distance, shipping method, and customs duties can influence these logistics costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary widely based on market conditions and supplier relationships.

How Do Price Influencers Affect Substation Transformer Parts?

Several factors can influence the pricing of substation transformer parts:

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should consider their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom parts or those with specific technical specifications usually come at a premium. Buyers should evaluate whether the additional cost aligns with their operational requirements.

-

Material Quality and Certifications: Parts that meet higher quality standards or have specific certifications (such as ISO or IEC) may cost more but provide greater reliability and safety.

-

Supplier Factors: The supplier’s reputation, reliability, and financial stability can influence pricing. Established suppliers with proven track records may charge more but offer better quality assurance.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers concerning shipping costs, insurance, and liability, impacting the total price.

What Are the Best Practices for Negotiating Costs in Substation Transformer Parts Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, adopting strategic negotiation practices can lead to significant cost savings:

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront cost. This includes maintenance, operational efficiency, and potential downtime. A lower initial price may not always equate to the best long-term investment.

-

Leverage Market Research: Understanding market trends and pricing benchmarks can empower buyers during negotiations. Being informed about competitor pricing can provide leverage in discussions.

-

Build Long-term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing agreements and enhanced service. Consistent business often translates to loyalty discounts.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow concerns and may allow buyers to negotiate a better price in exchange for prompt payments.

Are There Pricing Nuances for International Buyers of Substation Transformer Parts?

International buyers face unique challenges and opportunities in pricing. Fluctuations in currency exchange rates can impact costs, as can regional tariffs and trade agreements. Buyers should also consider the implications of shipping delays and associated costs, which can affect project timelines and budgets. Therefore, it’s prudent to include contingencies in budget planning.

Disclaimer

Prices for substation transformer parts can vary significantly based on the aforementioned factors. The information provided is indicative and should be verified with suppliers for accurate, current pricing tailored to specific needs and circumstances.

Alternatives Analysis: Comparing substation transformer parts With Other Solutions

Introduction

When evaluating solutions for electrical infrastructure, particularly in the context of substation transformer parts, it is essential to consider viable alternatives that can achieve similar objectives. By comparing substation transformer parts with alternative technologies or methods, B2B buyers can make informed decisions that align with their operational goals, budget constraints, and maintenance capabilities. This analysis will explore two notable alternatives: Static Frequency Converters (SFC) and Power Electronics Modules (PEM), providing a comprehensive overview of their respective advantages and disadvantages.

Comparison Table

| Comparison Aspect | Substation Transformer Parts | Static Frequency Converters (SFC) | Power Electronics Modules (PEM) |

|---|---|---|---|

| Performance | High efficiency in voltage regulation and power distribution | Excellent for frequency conversion and power quality management | Flexible operation for various applications, including renewable integration |

| Cost | Moderate to high initial investment with ongoing maintenance costs | High initial investment but lower long-term operational costs | Variable costs based on application and complexity |

| Ease of Implementation | Requires specialized installation and knowledge | Complex installation requiring skilled personnel | Easier to integrate with existing systems, but may need customization |

| Maintenance | Regular maintenance required for optimal performance | Minimal maintenance with periodic checks | Low maintenance, often self-diagnostic capabilities |

| Best Use Case | Traditional power distribution systems | Applications requiring variable frequency and high power quality | Modern grids, renewable energy systems, and electric vehicles |

Detailed Breakdown

What Are the Advantages and Disadvantages of Static Frequency Converters (SFC)?

Static Frequency Converters (SFC) are designed to convert electrical power from one frequency to another, making them invaluable in applications where power quality is crucial, such as in renewable energy integration or industrial drives. The primary advantage of SFCs lies in their ability to enhance power quality and provide precise frequency control, resulting in improved system reliability. However, the initial investment can be significant, and their installation may require specialized skills, which can complicate the implementation process.

How Do Power Electronics Modules (PEM) Compare to Substation Transformer Parts?

Power Electronics Modules (PEM) are versatile components that facilitate the conversion and control of electrical power in various applications, including energy storage systems and electric vehicles. Their primary benefit is flexibility, as they can easily adapt to different operational requirements and integrate with renewable energy sources. Additionally, PEMs typically have low maintenance needs due to their self-diagnostic capabilities. However, their costs can vary widely based on the specific application and complexity, making budget planning essential.

Illustrative image related to substation transformer parts

Conclusion

In choosing the right solution for electrical infrastructure needs, B2B buyers must assess their unique requirements, including performance expectations, budget constraints, and maintenance capabilities. While substation transformer parts provide reliable and efficient power distribution, alternatives like Static Frequency Converters and Power Electronics Modules can offer specialized benefits that may align better with modern applications, such as renewable energy integration and advanced power quality management. By thoroughly evaluating these options, buyers can ensure they select the most appropriate technology for their operational needs and strategic goals.

Essential Technical Properties and Trade Terminology for substation transformer parts

What Are the Critical Specifications for Substation Transformer Parts?

Understanding the essential technical properties of substation transformer parts is crucial for ensuring operational efficiency and reliability. Here are some key specifications that B2B buyers should consider:

-

Material Grade

The material grade of transformer components, such as the core and windings, significantly impacts performance and durability. Common materials include silicone steel for the core, which offers low hysteresis loss, and copper for windings, known for its superior conductivity. Selecting high-grade materials reduces maintenance costs and enhances the lifespan of transformers, making it a critical factor in procurement decisions. -

Tolerance Levels

Tolerance levels refer to the allowable deviations in dimensions and performance specifications of transformer parts. For instance, windings must adhere to strict tolerance levels to ensure proper electrical characteristics. Tighter tolerances can lead to improved efficiency and reduced energy losses, which are paramount for operational cost management. Understanding tolerance levels helps buyers ensure that components fit seamlessly within existing systems. -

Dielectric Strength

Dielectric strength measures the ability of insulating materials to withstand electrical stress without breaking down. This property is vital for insulation materials used in transformers, as inadequate dielectric strength can lead to failures and safety hazards. B2B buyers should prioritize insulation materials with high dielectric strength to enhance safety and reliability in electrical systems. -

Thermal Conductivity

Thermal conductivity is crucial for materials used in transformer oil and cooling systems. High thermal conductivity ensures efficient heat dissipation, preventing overheating and prolonging the transformer’s lifespan. Buyers should evaluate thermal properties when selecting oil and cooling systems to maintain optimal operating temperatures and enhance overall performance. -

Voltage Rating

Voltage rating indicates the maximum voltage a transformer can handle safely. This specification is essential for ensuring that transformers operate within their design limits to avoid failures and safety issues. B2B buyers must match the voltage rating of transformers with the intended application to ensure compatibility and reliability.

What Are Common Trade Terms in Substation Transformer Procurement?

Familiarity with industry jargon is essential for effective communication and negotiation in the procurement process. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the transformer industry, buying from OEMs often ensures high-quality parts that meet specific standards, which is crucial for maintaining system integrity and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for budget planning and inventory management. Buyers must assess their needs against the MOQ to avoid excess stock or supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. Utilizing RFQs helps buyers obtain competitive pricing and ensures that all potential suppliers provide similar information for easier comparison. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand their obligations regarding shipping, insurance, and liability, facilitating smoother cross-border transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for project planning and ensuring that necessary components arrive on schedule to avoid delays in project execution. -

Warranty Period

The warranty period is the duration during which a supplier guarantees the performance and reliability of the transformer parts. Knowing the warranty terms helps buyers assess the risk associated with their investment and ensures that they are covered in case of defects or failures.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring the selection of high-quality substation transformer parts that meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the substation transformer parts Sector

What Are the Current Market Dynamics and Key Trends Affecting the Substation Transformer Parts Sector?

The global substation transformer parts market is experiencing significant transformation, driven by technological advancements and increasing demand for electricity in emerging economies. Countries in Africa, South America, the Middle East, and Europe are witnessing a surge in infrastructure investments, particularly in renewable energy and smart grid technologies. These investments are crucial for enhancing energy efficiency and reliability, with international B2B buyers increasingly focused on sourcing high-quality, durable parts that can withstand varying environmental conditions.

Illustrative image related to substation transformer parts

Among the prominent trends is the integration of IoT (Internet of Things) technologies in transformer systems, enabling real-time monitoring and predictive maintenance. This shift not only enhances operational efficiency but also reduces downtime, which is critical for businesses that rely on uninterrupted power supply. Additionally, the move towards digitalization and automation in transformer manufacturing is streamlining procurement processes, allowing for quicker and more efficient sourcing of parts.

Furthermore, the growing emphasis on energy transition and sustainability is reshaping buyer preferences. International buyers are increasingly seeking suppliers that offer innovative solutions, such as energy-efficient components that minimize losses and enhance performance. This trend is particularly relevant in regions like Nigeria and Germany, where regulatory frameworks are evolving to support cleaner energy solutions.

How Are Sustainability and Ethical Sourcing Shaping the Substation Transformer Parts Market?

Sustainability and ethical sourcing have become integral to the substation transformer parts sector, driven by both regulatory requirements and consumer expectations. The environmental impact of manufacturing processes and the lifecycle of materials used in transformer components is under scrutiny. Buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainable practices, such as using recyclable materials and reducing carbon footprints in their operations.

The importance of ethical supply chains cannot be overstated, especially in regions with diverse regulatory landscapes. International buyers are keen to partner with manufacturers who adhere to recognized standards and certifications, such as ISO 14001 for environmental management and other green certifications. These certifications not only assure buyers of the quality and sustainability of the parts but also enhance their reputation in the market.

Moreover, the adoption of green materials, such as biodegradable insulating fluids and advanced composite materials, is gaining traction. These materials not only reduce environmental impact but also enhance the performance and longevity of transformer parts. For B2B buyers, investing in sustainable products is not just a compliance measure; it is a strategic move that aligns with global trends towards decarbonization and corporate responsibility.

What Is the Brief Evolution of the Substation Transformer Parts Sector?

The substation transformer parts sector has evolved significantly over the past century. Initially, transformers were basic devices designed solely for voltage regulation. However, as electrical grids expanded and the demand for reliable power supply grew, the complexity of transformer designs increased. Innovations in materials and manufacturing processes have led to the development of advanced components that enhance performance and efficiency.

In recent decades, the focus has shifted towards integrating technology into transformers, with the introduction of digital monitoring systems and smart grid solutions. This evolution reflects the broader trends in the energy sector, where the push for sustainability and efficiency is driving innovation. As international B2B buyers continue to seek reliable and efficient transformer parts, the sector is poised for further advancements, ensuring that it meets the growing demands of a dynamic energy landscape.

Illustrative image related to substation transformer parts

Frequently Asked Questions (FAQs) for B2B Buyers of substation transformer parts

-

How do I determine the right specifications for substation transformer parts?

To determine the right specifications for substation transformer parts, start by assessing your operational requirements, including voltage ratings, current capacity, and environmental conditions. Consult with engineers or technical experts to identify compatibility with existing systems. It’s also crucial to consider the regulatory standards applicable in your region, such as IEC standards in Europe or ANSI standards in the U.S. Gathering detailed information on the specific transformer model and its components will facilitate a more informed selection of parts. -

What is the best transformer oil for my substation?

The best transformer oil depends on several factors, including the type of transformer, operational temperature, and local environmental regulations. Common options include mineral oil, which offers good dielectric properties, and ester-based oils, which provide enhanced fire safety and environmental benefits. Evaluate the thermal conductivity, viscosity, and environmental impact of the oil to ensure optimal performance and compliance. Consulting with suppliers who specialize in transformer oils can also help you make an informed choice. -

How can I verify the quality of substation transformer parts from suppliers?

To verify the quality of substation transformer parts, request certifications and compliance documents from suppliers, such as ISO 9001 or IEC standards. Conduct thorough supplier audits, including facility visits if possible, to assess their manufacturing processes and quality control measures. Additionally, seek references from other clients and review product performance data. Utilizing third-party testing services can also provide assurance regarding the quality and reliability of the parts. -

What are the common payment terms in international trade for transformer parts?

Common payment terms in international trade for transformer parts include letters of credit (LC), advance payment, and open account terms. Letters of credit provide security for both parties, ensuring that payments are made only upon meeting specific conditions. Advance payments are often required by suppliers, especially for customized parts. Open accounts may be offered to established relationships. It’s essential to negotiate terms that align with your cash flow and risk management strategies while ensuring mutual trust. -

What should I consider when sourcing transformer parts from international suppliers?

When sourcing transformer parts internationally, consider factors such as supplier reliability, lead times, compliance with local regulations, and shipping logistics. Evaluate the supplier’s history and reputation in the market, ensuring they have experience in your specific requirements. Understand the total landed cost, which includes shipping, tariffs, and taxes, to avoid unexpected expenses. Additionally, consider the implications of currency fluctuations and the potential need for after-sales support. -

What is the minimum order quantity (MOQ) for transformer parts?

The minimum order quantity (MOQ) for transformer parts varies by supplier and specific component type. Typically, MOQs can range from a few units to hundreds, depending on manufacturing processes and inventory levels. Discuss your needs with potential suppliers to see if they can accommodate smaller orders, especially for specialized parts. In some cases, combining orders with other companies or negotiating terms may help reduce MOQs. -

How do I handle logistics and shipping for transformer parts?

Handling logistics and shipping for transformer parts requires careful planning. Start by choosing a reliable freight forwarder experienced in handling heavy and bulky items, as transformer parts often require specialized transportation. Ensure that you understand the shipping regulations and customs documentation for your destination country. Additionally, consider the mode of transport (air vs. sea) based on cost, urgency, and the nature of the parts. Insurance for high-value shipments is also advisable to mitigate risks during transit. -

What are the key factors in customizing transformer parts to meet my needs?

Customizing transformer parts involves understanding your specific operational requirements, including voltage, capacity, and environmental conditions. Collaborate closely with your supplier to communicate these needs, ensuring they have the technical expertise to design parts that meet your specifications. Factors such as materials, dimensions, and performance characteristics should be discussed thoroughly. Additionally, consider the implications of customization on lead times and costs, as bespoke solutions may require more time to manufacture and test.

Top 3 Substation Transformer Parts Manufacturers & Suppliers List

1. Electrical Engineering Portal – Distribution Transformers

Domain: electrical-engineering-portal.com

Registered: 2010 (15 years)

Introduction: 1. Distribution Transformer: Main equipment of distribution substation, steps down voltage from 33kV/11kV to 415-440V. Consists of primary winding, secondary winding, and iron core. Requires external cooling (heat exchangers, radiators, fans). Power transformers rated 500 kVA or greater. Components include: transformer tank, cooling tubes, Buchholz relay, tap changer, oil outlet valve, temperature…

2. Grant Transformers – Essential Components

Domain: grant-transformers.com.au

Introduction: Core: Provides a low reluctance path for magnetic flux, ensuring efficient energy transfer. Windings: Transfers electrical energy between primary and secondary circuits. Insulation: Prevents short circuits and ensures electrical safety. Brushing: Maintains clean surfaces by removing carbon deposits. Tap changer: Adjusts turns ratio for voltage regulation. Terminals: Connection points for external …

3. UTB Transformers – Key Products

Domain: utbtransformers.com

Registered: 2020 (5 years)

Introduction: Transformer Substations are pivotal components in power distribution, ensuring efficient and safe transmission of electrical energy. Key products include: 1. **Substation Transformers** – Adjust voltage levels for transmission or distribution. 2. **Pad Mounted Transformers** – Typically used in residential areas for local distribution. 3. **Pole Mounted Transformers** – Installed on utility poles …

Strategic Sourcing Conclusion and Outlook for substation transformer parts

In the evolving landscape of energy infrastructure, strategic sourcing of substation transformer parts is crucial for ensuring operational efficiency and reliability. Understanding the integral components—such as laminated cores, windings, and insulating materials—enables buyers to make informed decisions that enhance performance and longevity. Prioritizing quality and compatibility in sourcing not only mitigates the risk of failure but also optimizes maintenance costs and minimizes downtime.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should leverage strategic partnerships with reliable suppliers. This collaboration can lead to improved procurement processes, cost efficiencies, and access to innovative technologies that enhance transformer performance.

Looking ahead, the demand for high-quality substation transformer parts will continue to grow as global energy needs escalate. By investing in strategic sourcing now, businesses can position themselves to meet future challenges head-on. Engage with trusted suppliers today to secure a competitive edge in your energy projects and ensure that your operations are equipped for the demands of tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to substation transformer parts

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.