Choosing Your Spring Pitch: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for spring pitch

In an increasingly competitive global market, sourcing the right spring pitch can pose a significant challenge for B2B buyers, particularly those in diverse regions such as Africa, South America, the Middle East, and Europe, including Germany and Nigeria. Understanding the nuances of spring pitch is crucial, as it directly influences the performance, load-bearing capacity, and overall efficiency of helical compression springs used in various applications—from automotive suspensions to industrial machinery. This comprehensive guide delves into the intricacies of spring pitch, covering essential topics such as types of springs, their applications, supplier vetting processes, and cost considerations.

By providing actionable insights and practical knowledge, this guide equips international buyers with the tools needed to make informed purchasing decisions. Whether you are looking to optimize your supply chain or enhance product performance, understanding the critical role of spring pitch will empower you to select the right components for your specific needs. With a focus on maximizing value and minimizing risk, this resource aims to bridge the knowledge gap and facilitate successful sourcing strategies in the global marketplace. Embrace the opportunity to refine your approach to spring procurement and elevate your business’s operational capabilities.

Understanding spring pitch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Closed and Ground Ends | Coils are tightly wound and ground flat at both ends. | Automotive suspensions, industrial machinery | Pros: Enhanced stability, good load capacity; Cons: Higher manufacturing complexity. |

| Closed and Squared Ends | Coils end in a square shape, providing stability. | Aerospace, heavy equipment | Pros: Improved load distribution; Cons: Limited flexibility in design. |

| Open Ends | Coils are free at both ends, allowing for easier installation. | General machinery, consumer products | Pros: Easier to manufacture; Cons: Less stability under load. |

| Double Closed Ends | Two inactive coils at each end, maximizing load capacity. | Heavy-duty applications, construction | Pros: High load capacity, stable under pressure; Cons: Increased weight and size. |

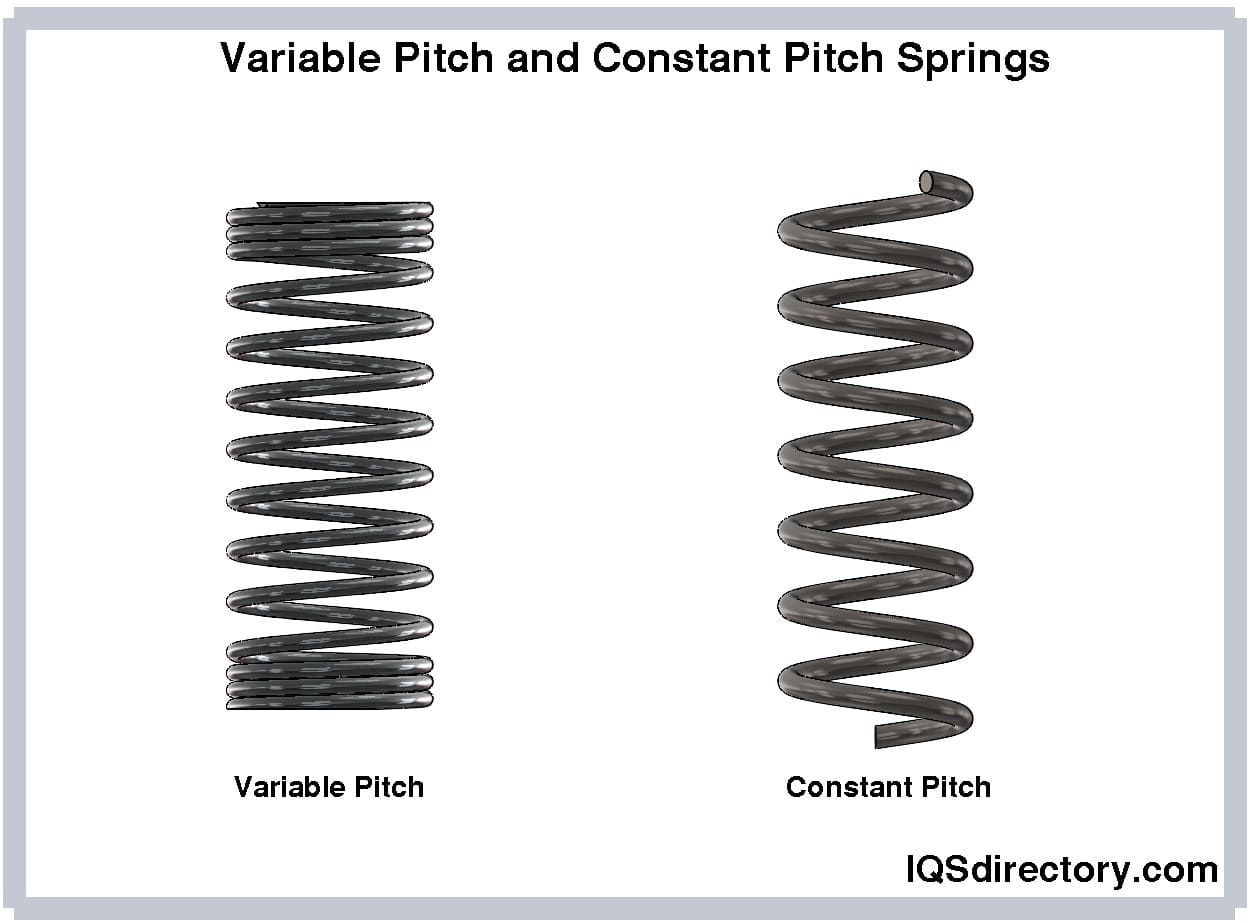

| Variable Pitch | Coils have varying distances between them, optimizing performance. | Specialized machinery, automotive | Pros: Tailored performance for specific applications; Cons: More complex design and manufacturing. |

What Are the Characteristics of Closed and Ground End Springs?

Closed and ground end springs feature coils that are tightly wound and have flat ends, ensuring a secure fit when installed. This type is particularly suitable for applications in automotive suspensions and industrial machinery where stability and load-bearing capacity are critical. Buyers should consider the higher manufacturing complexity and potential cost, but the enhanced performance in demanding environments often justifies the investment.

Why Choose Closed and Squared End Springs?

Closed and squared end springs have a square shape at the ends, which aids in load distribution and stability. They are commonly used in aerospace and heavy equipment applications where reliability and safety are paramount. While they provide excellent performance, the design limits flexibility, making it essential for buyers to evaluate whether the benefits align with their specific application needs.

What Are the Advantages of Open End Springs?

Open end springs are characterized by their free ends, making them easier to install and remove. They are widely used in general machinery and consumer products due to their straightforward manufacturing process. However, this simplicity comes at the cost of reduced stability under load. Buyers should weigh the ease of installation against the potential need for additional support in high-load scenarios.

How Do Double Closed End Springs Perform?

Double closed end springs feature two inactive coils at each end, maximizing their load capacity. This design is ideal for heavy-duty applications such as construction and industrial machinery, where high strength and stability are necessary. While these springs provide significant advantages, buyers must consider the increased weight and size, which may affect the overall design of their machinery.

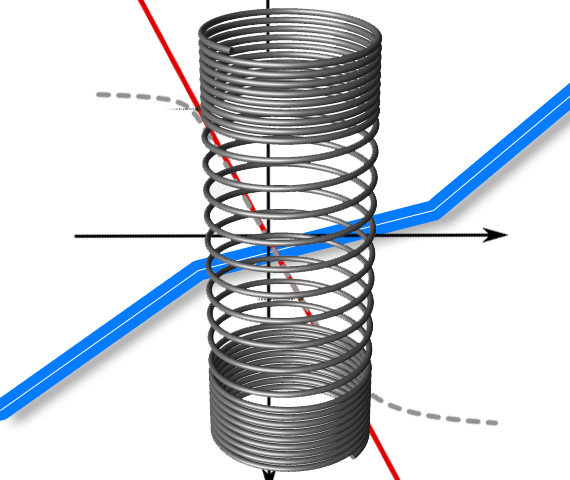

Illustrative image related to spring pitch

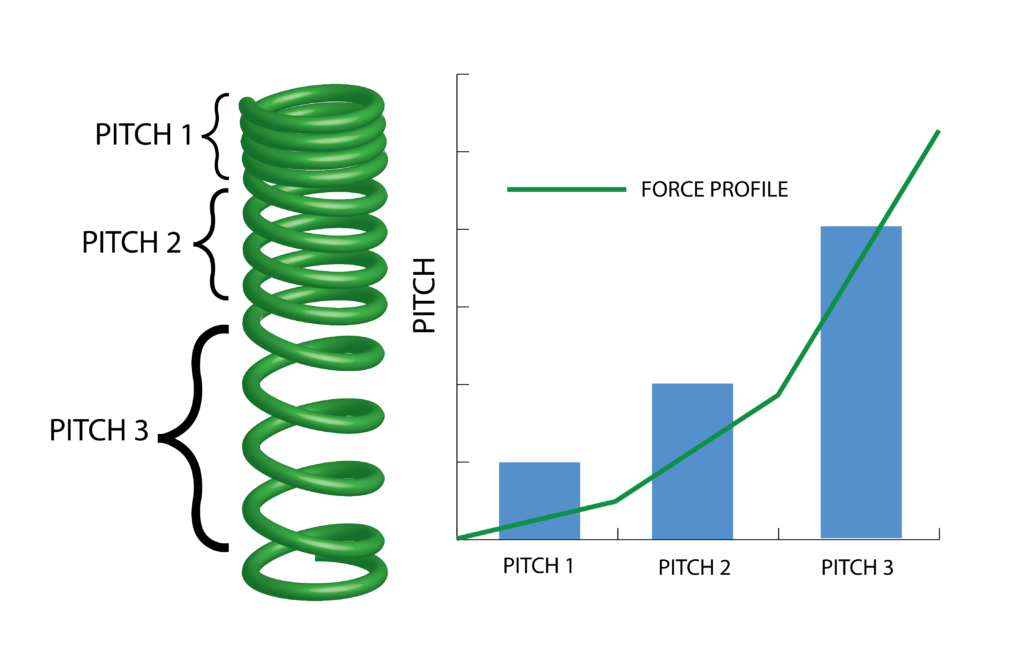

When Should You Consider Variable Pitch Springs?

Variable pitch springs have coils with varying distances between them, allowing for tailored performance characteristics. They are particularly useful in specialized machinery and automotive applications, where specific load and deflection responses are required. However, the complexity in design and manufacturing means that buyers should ensure they have a clear understanding of their performance needs to justify the investment in these custom solutions.

Key Industrial Applications of spring pitch

| Industry/Sector | Specific Application of spring pitch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems | Enhanced vehicle stability and comfort during dynamic loads | Need for precise spring specifications to match vehicle design |

| Manufacturing | Machinery and equipment | Improved energy efficiency and load-bearing capacity | Customization options for varying load requirements |

| Aerospace | Landing gear systems | Reliable performance under high-stress conditions | Compliance with strict safety and performance standards |

| Construction | Heavy machinery and lifting equipment | Increased durability and shock absorption | Sourcing from manufacturers with robust quality control processes |

| Consumer Electronics | Electronics housing and support structures | Space optimization and improved product longevity | Need for lightweight yet durable materials for compact designs |

How is Spring Pitch Utilized in the Automotive Sector?

In the automotive industry, spring pitch plays a crucial role in the design of suspension systems. A well-calibrated spring pitch ensures that the vehicle maintains stability and comfort, especially under dynamic loads such as cornering or rough terrain. For international buyers, particularly in markets like Germany and Nigeria, sourcing springs that meet specific load and deflection requirements is essential. Buyers must ensure that the springs are manufactured to precise tolerances to enhance vehicle performance and safety.

What are the Applications of Spring Pitch in Manufacturing?

Manufacturing sectors utilize spring pitch in various machinery and equipment applications. The correct pitch enhances energy efficiency and load-bearing capacity, allowing machines to operate smoothly under heavy loads. For B2B buyers, especially in South America, it is vital to consider customization options that cater to specific operational loads and environmental conditions. This ensures that the springs can withstand the rigors of continuous use while optimizing production efficiency.

Why is Spring Pitch Important in Aerospace Applications?

In aerospace, spring pitch is critical for landing gear systems, where reliability under high-stress conditions is paramount. A well-designed spring pitch contributes to the overall safety and performance of the aircraft during takeoff and landing. International buyers in this sector, particularly from the Middle East, must prioritize sourcing springs that comply with stringent safety and performance standards. This includes verifying the manufacturer’s certifications and quality assurance processes to ensure reliability.

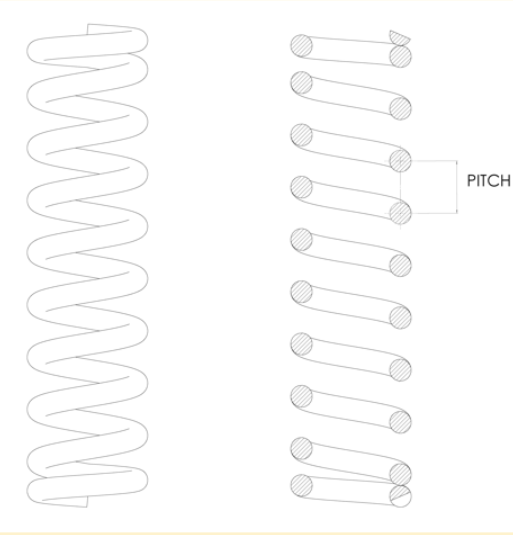

Illustrative image related to spring pitch

How Does Spring Pitch Benefit Construction Equipment?

Heavy machinery used in construction relies on spring pitch for durability and effective shock absorption. Properly engineered springs enhance the performance of lifting equipment, enabling them to handle significant weight without failure. For buyers in Africa, where construction projects can be demanding, sourcing springs from manufacturers with robust quality control processes is crucial. This ensures that the springs can withstand the harsh operating conditions typical in construction environments.

In What Ways Does Spring Pitch Enhance Consumer Electronics?

In consumer electronics, spring pitch is utilized in housing and support structures to optimize space while ensuring product longevity. A well-calibrated spring pitch allows for compact designs without compromising strength or durability. For international buyers, particularly in Europe, sourcing lightweight yet durable materials is essential to meet market demands for high-performance electronics. This requires careful consideration of the spring specifications to align with product design and functionality.

3 Common User Pain Points for ‘spring pitch’ & Their Solutions

Scenario 1: Misunderstanding Spring Pitch Specifications

The Problem: B2B buyers often face challenges when trying to understand the intricacies of spring pitch and how it relates to their specific applications. This misunderstanding can lead to the selection of springs that do not meet their load requirements or space constraints, resulting in operational inefficiencies or equipment failures. For example, a buyer sourcing compression springs for an automotive suspension system may mistakenly choose springs with an incorrect pitch, leading to inadequate load capacity or excessive stiffness, which could compromise vehicle performance and safety.

The Solution: To address this issue, B2B buyers should prioritize education on the fundamental properties of spring pitch and its implications for performance. Engage with reputable suppliers who offer detailed specifications and educational resources about spring properties. Before finalizing any purchase, buyers should calculate the required spring pitch based on their application’s load requirements and available space. Utilizing tools or software provided by manufacturers to simulate different spring configurations can also help visualize how adjustments in pitch will affect the spring’s performance. Collaborating closely with suppliers to validate these calculations ensures that the selected springs will function optimally within the intended application.

Illustrative image related to spring pitch

Scenario 2: Inconsistent Quality in Spring Manufacturing

The Problem: A common pain point for B2B buyers is the inconsistency in the quality of springs due to variations in manufacturing processes. This inconsistency can lead to significant discrepancies in spring performance, such as unreliable load-bearing capacity and unpredictable stiffness. For instance, a buyer sourcing springs for heavy machinery may encounter springs that fail to meet the specified pitch requirements due to poor manufacturing practices, resulting in equipment malfunctions and increased downtime.

The Solution: To mitigate quality issues, buyers should establish relationships with manufacturers that utilize advanced technology and rigorous quality control measures. Request to see certifications and quality assurance processes that demonstrate the manufacturer’s commitment to precision, such as ISO certifications. Additionally, buyers should consider sourcing from suppliers that offer custom spring manufacturing capabilities, allowing them to specify exact pitch dimensions and other critical parameters. Implementing a pilot testing phase before mass production can help identify any potential issues early in the process, ensuring the final products meet the required standards.

Scenario 3: Challenges with Dynamic Loading Applications

The Problem: In applications involving dynamic loading, such as automotive suspensions or industrial machinery, B2B buyers often struggle to select springs that can adequately withstand repeated stress without failing. The spring pitch plays a crucial role in determining how a spring reacts to dynamic loads. If the pitch is too large, the spring may not absorb shocks effectively, leading to premature wear or failure, while a pitch that is too small can result in excessive stiffness, making it difficult for the spring to return to its original shape.

The Solution: To optimize spring performance under dynamic conditions, buyers should conduct a thorough analysis of their application’s loading requirements. Collaborate with engineers to determine the ideal spring pitch that balances stiffness and flexibility. Utilizing simulation software can help predict how different pitch angles will affect the spring’s performance under various loading scenarios. Furthermore, consider sourcing springs designed specifically for dynamic applications, as these will often come with tailored specifications that take pitch into account. Engaging in discussions with suppliers about your specific dynamic loading requirements can lead to valuable insights and recommendations, ensuring that the springs chosen will perform reliably in high-stress environments.

Strategic Material Selection Guide for spring pitch

What Are the Key Materials for Spring Pitch and Their Properties?

When selecting materials for spring pitch applications, it is crucial to consider the unique properties of each material and how they align with your specific requirements. The following analysis covers four common materials used in spring manufacturing, focusing on their performance characteristics, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform in Spring Pitch Applications?

Key Properties: Steel, particularly high-carbon steel, is renowned for its excellent tensile strength and fatigue resistance. It typically operates effectively in a wide temperature range and can withstand significant mechanical stress.

Pros & Cons: Steel springs are durable and cost-effective, making them a popular choice. However, they are susceptible to corrosion, which can limit their suitability in harsh environments unless treated with coatings or finishes. Manufacturing complexity can vary based on the specific steel grade and required spring geometry.

Impact on Application: Steel springs are ideal for applications requiring high load-bearing capacity, such as automotive suspensions or industrial machinery. However, their performance may degrade in corrosive environments, necessitating consideration of protective measures.

Illustrative image related to spring pitch

Considerations for International Buyers: Compliance with standards such as ASTM A228 (for music wire) or DIN 17223 is essential. Buyers from regions like Germany or Nigeria should ensure that the steel meets local regulations and quality certifications.

What Role Does Stainless Steel Play in Spring Pitch?

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and good fatigue properties, making it suitable for various applications, especially in moist or corrosive environments.

Pros & Cons: The primary advantage of stainless steel springs is their longevity and reduced maintenance needs due to their resistance to rust and corrosion. However, they tend to be more expensive than carbon steel and can be more challenging to manufacture due to their hardness.

Illustrative image related to spring pitch

Impact on Application: Stainless steel springs are particularly well-suited for applications in the food and pharmaceutical industries, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM A313 or JIS G3560. Understanding local market preferences for stainless steel grades is crucial, especially in regions with stringent quality requirements.

How Do Alloys Enhance Spring Pitch Performance?

Key Properties: Alloy steels, which combine various elements like chromium, nickel, and molybdenum, offer enhanced mechanical properties, including improved toughness and fatigue resistance compared to standard carbon steels.

Pros & Cons: The use of alloys can significantly improve performance in high-stress applications, making them suitable for aerospace and automotive sectors. However, they can be more costly and may require specialized manufacturing techniques.

Impact on Application: Alloys are particularly beneficial in applications involving dynamic loads or extreme conditions, such as high-temperature environments.

Considerations for International Buyers: Buyers should verify that alloy compositions meet international standards like ASTM or DIN. The complexity of manufacturing processes may also necessitate sourcing from specialized suppliers.

What Are the Benefits of Using Plastic Materials for Spring Pitch?

Key Properties: Plastics, such as nylon or polycarbonate, provide lightweight solutions with good chemical resistance and flexibility. They can operate effectively at lower temperatures and are often non-conductive.

Pros & Cons: The primary advantage of plastic springs is their resistance to corrosion and lower weight, which can be beneficial in applications where weight savings are critical. However, they generally have lower load-bearing capacities compared to metal springs and can be less durable under high-stress conditions.

Illustrative image related to spring pitch

Impact on Application: Plastic springs are ideal for applications in electronics or household appliances, where corrosion resistance and weight are more critical than load capacity.

Considerations for International Buyers: Compliance with material safety standards is essential, especially for applications in sensitive industries. Buyers should also consider the availability of specific plastic grades in their local markets.

Summary Table of Material Selection for Spring Pitch

| Material | Typical Use Case for spring pitch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive suspensions, industrial machinery | High load-bearing capacity | Susceptible to corrosion | Low |

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Alloy Steel | Aerospace, automotive applications | Enhanced toughness and fatigue resistance | More expensive and specialized manufacturing | Medium |

| Plastic | Electronics, household appliances | Lightweight and corrosion-resistant | Lower load-bearing capacity | Low |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for spring pitch applications, ensuring informed decisions that align with performance requirements and regional standards.

Illustrative image related to spring pitch

In-depth Look: Manufacturing Processes and Quality Assurance for spring pitch

What Are the Main Stages of Manufacturing Spring Pitch?

Manufacturing helical compression springs involves several critical stages to ensure that the spring pitch and pitch angle meet precise specifications. This process typically includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for Spring Manufacturing?

The first step in the manufacturing process is the careful selection and preparation of raw materials. Spring manufacturers often use high-carbon steel, stainless steel, or specialty alloys depending on the application. The material is first drawn to the required wire diameter, which is crucial since the wire diameter directly influences the spring’s load capacity and stiffness.

Quality control begins at this stage, with inspections to verify that the material meets required standards. Checks may include tensile strength tests and dimensional inspections to ensure uniformity. Suppliers should provide mill certificates that document the material properties and compliance with international standards such as ISO 9001.

What Techniques Are Used in Forming Springs?

Once the material is prepared, the next stage is forming the spring. This can be done through various techniques, including mechanical coiling and CNC (Computer Numerical Control) coiling. Mechanical coiling machines are often used for high-volume production, while CNC machines allow for more intricate designs and tighter tolerances.

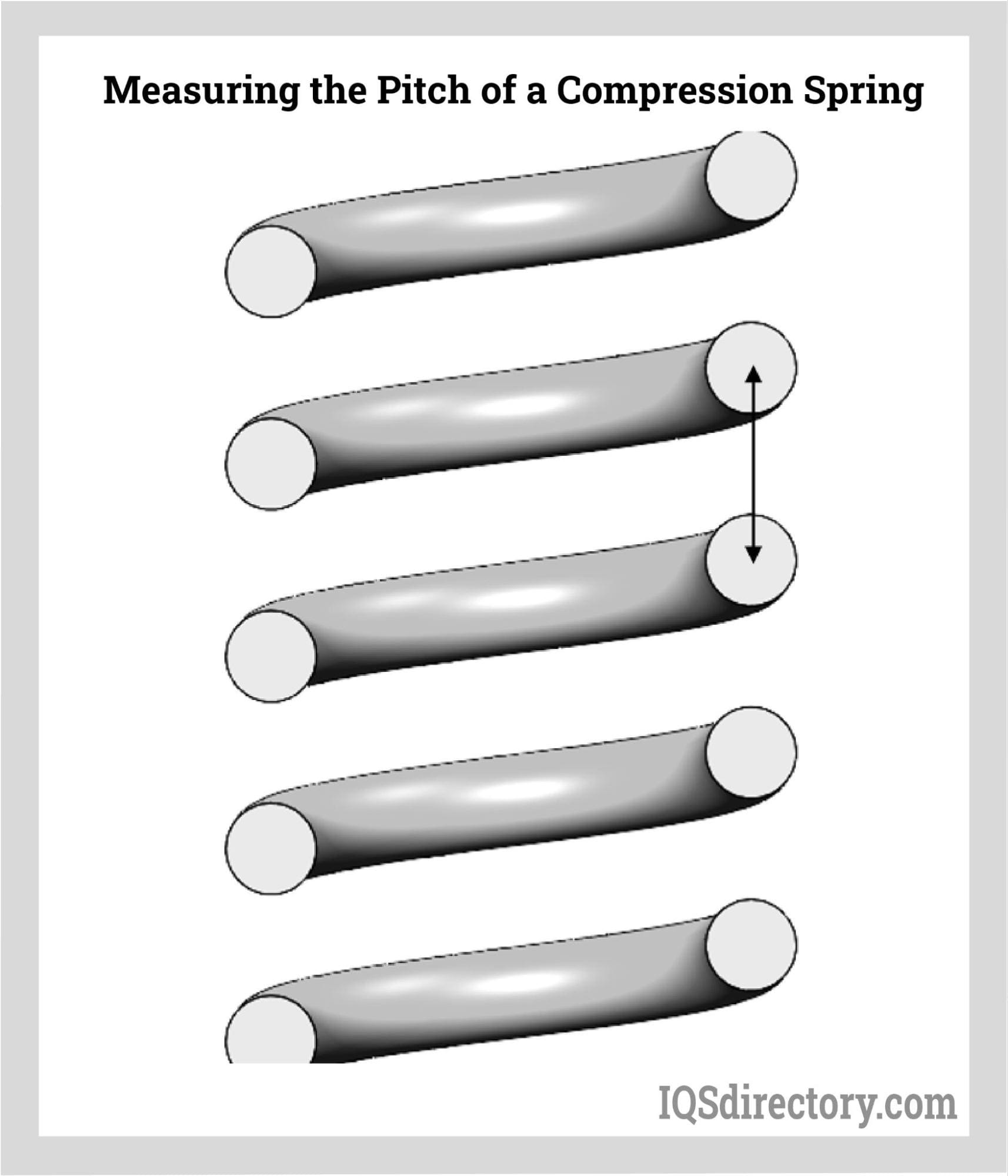

During the forming process, manufacturers must control the spring pitch and pitch angle precisely. This is typically achieved through the programming of CNC machines, which can produce complex geometries with high accuracy. Key parameters, such as the number of active and inactive coils, are programmed into the machine to ensure the finished product meets design specifications.

How Is the Assembly Process Conducted for Springs?

The assembly stage may involve additional processes, particularly for springs that require specific end configurations, such as closed or ground ends. This may include processes like end grinding or flattening to ensure that the spring can be effectively integrated into its intended application.

Quality control continues during assembly. Manufacturers often perform inspections to verify that the coil configurations and pitches are consistent with design specifications. This may involve visual inspections, as well as measurements taken with specialized tools like calipers and micrometers.

What Finishing Techniques Are Common in Spring Manufacturing?

The finishing stage is essential for enhancing the durability and performance of the springs. Common finishing techniques include shot peening, surface hardening, and coating. Shot peening is particularly beneficial for increasing fatigue resistance, while coatings can improve corrosion resistance, an important factor for applications in harsh environments.

After finishing, springs undergo final inspections, ensuring they meet all specifications for spring pitch and angle, as well as any surface treatment requirements. This final quality control checkpoint is critical, as it validates the entire manufacturing process.

What International Quality Standards Are Relevant for Spring Manufacturing?

For international B2B buyers, understanding the quality standards that suppliers adhere to is crucial. Many manufacturers comply with ISO 9001, which outlines quality management principles aimed at improving processes and customer satisfaction. Compliance with this standard indicates a commitment to maintaining quality throughout the manufacturing process.

In addition to ISO standards, industry-specific certifications may be relevant. For example, the CE marking signifies compliance with European health, safety, and environmental protection standards. If the springs are to be used in the oil and gas industry, certifications from the American Petroleum Institute (API) may be necessary.

How Are Quality Control Checkpoints Structured in Spring Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure that each spring meets design specifications and quality standards. Common checkpoints include:

Illustrative image related to spring pitch

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During the manufacturing process, inspections are performed to monitor the critical dimensions of spring pitch and angle. This helps identify any deviations early on.

- Final Quality Control (FQC): This final inspection checks the finished springs against the specifications, including spring pitch and angle, to ensure they are ready for delivery.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to verify the performance and integrity of the springs. Common testing methods include:

- Tensile Testing: To measure the strength and elasticity of the spring material.

- Fatigue Testing: To assess how the spring performs under cyclic loading conditions.

- Dimensional Testing: To ensure that the spring pitch and angle are within specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control measures:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the quality control processes and adherence to standards.

- Request Quality Reports: Suppliers should be able to provide documentation regarding their quality control processes, including any certifications and inspection reports.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of various nuances in quality control. Language barriers and differences in local regulations can complicate quality assurance processes. Buyers should ensure that they clearly communicate their quality requirements and expectations, including any specific certifications or standards relevant to their region.

Additionally, understanding the logistical challenges associated with international shipping can help mitigate issues related to product quality. Ensuring that quality control measures are maintained throughout the shipping process is essential for delivering products that meet specifications.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for spring pitch is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control checkpoints and international standards, buyers can ensure they select reliable suppliers who meet their specifications and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘spring pitch’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring springs with the appropriate pitch specifications. Understanding spring pitch is crucial as it directly affects the performance, stiffness, and load capacity of compression springs. Following this checklist will ensure that you make informed decisions when sourcing springs that meet your application requirements.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications needed for your spring application. This includes determining the desired spring pitch, load requirements, and environmental conditions.

– Consider factors such as the maximum load capacity and the expected frequency of use, as these will influence the spring’s design and performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in spring manufacturing. Look for companies with a proven track record in producing high-quality springs tailored to your specifications.

– Check online reviews, industry certifications, and case studies to gauge their expertise and reliability.

Step 3: Evaluate Supplier Capabilities

Assess the manufacturing capabilities of potential suppliers to ensure they can meet your technical requirements. This includes examining their machinery, technology, and production processes.

– Inquire about their ability to customize spring pitch and pitch angles, as well as their experience with materials that suit your application.

Step 4: Request Samples

Always request samples of the springs that meet your specifications before making a bulk purchase. Testing samples allows you to evaluate the spring’s performance and ensure it aligns with your expectations.

– Look for consistency in dimensions, load-bearing capacity, and overall quality during your evaluation.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers have the necessary certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management practices.

– Verify their adherence to industry standards relevant to your application, especially if you’re in sectors with stringent requirements, such as automotive or aerospace.

Illustrative image related to spring pitch

Step 6: Discuss Lead Times and Delivery Options

Communicate with suppliers about their lead times and delivery options to ensure they can meet your project deadlines. Understanding their production schedules and logistics capabilities is critical.

– Ask about their ability to handle urgent orders or fluctuations in demand, which can impact your supply chain.

Step 7: Negotiate Terms and Pricing

Finally, negotiate terms and pricing to secure a favorable deal. Be clear about your budget constraints while also considering the value of quality and reliability.

– Discuss payment terms, warranty, and after-sales support to ensure a smooth procurement process and long-term partnership.

By following this checklist, B2B buyers can effectively navigate the sourcing process for springs with the right pitch, ensuring they select the best suppliers for their specific needs.

Comprehensive Cost and Pricing Analysis for spring pitch Sourcing

Understanding the cost structure and pricing dynamics associated with spring pitch sourcing is essential for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This section provides a detailed analysis of the cost components, price influencers, and strategic buyer tips.

What Are the Key Cost Components in Spring Pitch Sourcing?

The cost structure for sourcing spring pitch can be broken down into several critical components:

-

Materials: The primary material used in spring manufacturing is typically high-carbon steel, stainless steel, or specialized alloys. The choice of material significantly affects the overall cost. Higher-grade materials provide better performance but come at a premium.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor is necessary for precision engineering, particularly in custom spring designs.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Advanced manufacturing techniques, such as CNC machining, can increase overhead costs but yield higher precision and efficiency.

-

Tooling: Tooling costs involve the creation and maintenance of molds and dies used in the production process. For customized springs, this can be a significant initial investment, but it is amortized over larger production runs.

-

Quality Control (QC): Ensuring that each spring meets specified standards incurs additional costs. Rigorous testing and inspection processes are vital for maintaining quality, especially in industries with strict compliance requirements.

-

Logistics: Transportation costs depend on the distance from the supplier to the buyer, the shipping method, and any tariffs or customs duties. Efficient logistics planning can mitigate these costs.

-

Margin: Suppliers typically add a markup to cover risks and ensure profitability. Understanding the industry standard margins can aid in negotiations.

What Influences Prices in Spring Pitch Sourcing?

Several factors can influence the pricing of spring pitch:

-

Volume/MOQ: Suppliers often provide better pricing for larger order quantities. Minimum Order Quantities (MOQs) can vary significantly between suppliers, impacting the cost per unit.

-

Specifications and Customization: Custom specifications lead to variations in price. Unique designs or materials may require more extensive tooling and setup, thus increasing costs.

-

Materials: The choice of material directly influences price. Specialty materials or those with certifications (like ISO or ASTM) will generally cost more.

-

Quality and Certifications: Springs used in critical applications may require higher quality standards and certifications, affecting overall pricing.

-

Supplier Factors: The supplier’s reputation, production capacity, and geographical location can impact pricing. Suppliers with advanced technologies may offer better pricing due to efficiency.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can affect total costs. Buyers should carefully evaluate these terms to understand their responsibilities and potential additional costs.

How Can Buyers Negotiate for Better Prices on Spring Pitch?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, replacement, and downtime. Choosing a supplier that offers reliable, high-quality products can lead to lower TCO.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs. This can provide negotiating leverage for better pricing.

-

Evaluate Supplier Options: Don’t settle for the first quote. Compare prices and services from multiple suppliers to identify the best value.

-

Be Clear About Specifications: Providing detailed specifications can minimize misunderstandings and ensure that quotes reflect the true cost of your requirements.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce shipping costs and lead times, potentially resulting in better pricing.

-

Explore Long-Term Contracts: Establishing long-term relationships with suppliers can lead to favorable pricing arrangements and priority service.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

Buyers from different regions should be aware of unique pricing nuances, including:

- Currency fluctuations can impact costs when sourcing internationally.

- Import tariffs and regulations may add to the overall cost of spring pitch.

- Understanding local market dynamics and labor costs can provide insights into pricing variances.

Disclaimer on Pricing

Prices for spring pitch can vary widely based on the factors discussed above. It is advisable for buyers to obtain multiple quotes and engage in thorough discussions with suppliers to ensure they are getting the best possible pricing aligned with their specific needs.

Alternatives Analysis: Comparing spring pitch With Other Solutions

Exploring Alternatives to Spring Pitch in Compression Spring Solutions

In today’s competitive landscape, understanding the various alternatives to spring pitch is crucial for B2B buyers seeking optimal solutions for their applications. Spring pitch directly influences the performance and efficiency of helical compression springs. However, there are other technologies and methods available that can also fulfill similar roles, each with its own set of advantages and limitations. This section compares spring pitch with two viable alternatives: Air Springs and Rubber Springs.

Comparison Table

| Comparison Aspect | Spring Pitch | Air Springs | Rubber Springs |

|---|---|---|---|

| Performance | High load-bearing capacity; customizable stiffness based on pitch and angle | Excellent shock absorption; adjustable pressure for varying loads | Good damping properties; less precise load management |

| Cost | Moderate; depends on material and design complexity | Higher initial costs due to technology and installation | Generally lower; cost-effective for many applications |

| Ease of Implementation | Requires precise calculations and manufacturing | Installation requires expertise; can be complex | Simple installation; more user-friendly |

| Maintenance | Low; durable with minimal upkeep | Moderate; requires regular pressure checks | Low; generally maintenance-free |

| Best Use Case | Heavy machinery, automotive suspensions, and applications requiring precise load management | Applications needing variable load support, such as vehicles and industrial machinery | General-purpose applications where shock absorption is needed |

Detailed Breakdown of Alternatives

Air Springs

Air springs utilize air pressure to provide a cushioning effect, making them highly effective for applications requiring variable support. The ability to adjust air pressure allows for customization based on load conditions, which can be particularly beneficial in dynamic environments like automotive suspensions. However, air springs can be more expensive due to their advanced technology and installation complexity. They also require regular maintenance to ensure optimal pressure levels, which can add to operational costs.

Illustrative image related to spring pitch

Rubber Springs

Rubber springs offer a cost-effective alternative with good shock absorption properties. They are easy to install and typically require little to no maintenance, making them appealing for many applications. However, rubber springs may not provide the same level of precise load management as spring pitch, which can lead to performance inconsistencies under varying loads. They are best suited for general-purpose applications where damping is a priority rather than precise load control.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the most suitable solution for your application, consider the specific requirements of your project. If precise load management and high performance under varying conditions are critical, spring pitch might be the best choice. On the other hand, if cost-effectiveness and ease of installation are your priorities, rubber springs could be the way to go. For applications that require flexibility and adaptability, air springs offer a compelling alternative. Assessing these factors will empower B2B buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for spring pitch

What Are the Key Technical Properties of Spring Pitch That B2B Buyers Should Understand?

Understanding the essential technical properties of spring pitch is critical for B2B buyers involved in industries such as automotive, aerospace, and manufacturing. Here are some key specifications to consider:

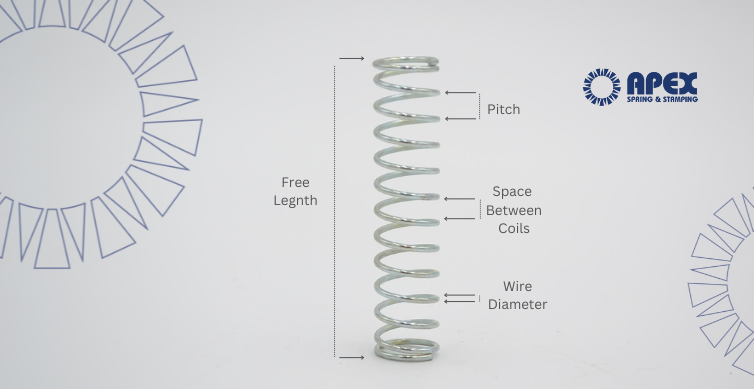

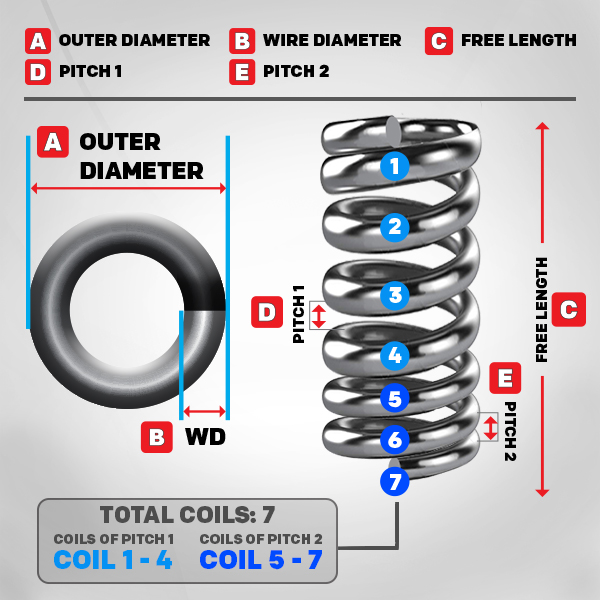

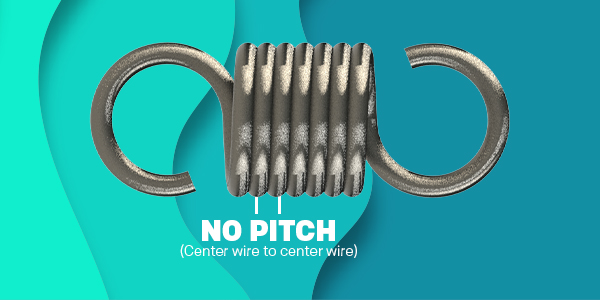

1. Spring Pitch

Spring pitch is the axial distance between the centerlines of two adjacent coils in a helical compression spring when unloaded. It directly influences the spring’s stiffness and load-bearing capacity. A larger spring pitch typically reduces stiffness, which can affect the performance of the spring in various applications. Buyers must assess the required spring pitch to ensure optimal performance for their specific needs.

2. Spring Pitch Angle

The spring pitch angle is the angle between the coils and the central horizontal axis of the spring. This property is vital for determining how the spring behaves under load, including its compressed height. A well-calculated pitch angle allows for better stability and performance under dynamic loads, making it essential for applications like automotive suspensions.

3. Material Grade

The material grade of the wire used in spring manufacturing can significantly affect its performance. Common materials include carbon steel, stainless steel, and specialty alloys. Each material offers different properties, such as corrosion resistance and tensile strength. B2B buyers should consider the material grade based on environmental conditions and load requirements to ensure longevity and reliability.

4. Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of a spring. Tight tolerances are crucial for applications requiring precise performance, while looser tolerances may suffice for less demanding uses. Understanding the required tolerances helps buyers select springs that will function reliably within their operational parameters.

5. Load Capacity

Load capacity defines the maximum load a spring can handle without permanent deformation. It is influenced by the spring pitch, wire diameter, and material properties. Buyers must accurately assess the load requirements of their applications to ensure that the selected spring can withstand operational stresses without failure.

What Are Common Trade Terms Related to Spring Pitch That B2B Buyers Should Know?

Familiarity with industry jargon is essential for effective communication and procurement in the spring manufacturing sector. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring that the springs meet the necessary performance standards for specific applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers determine whether a supplier can meet their demand without over-committing resources. This is particularly important for businesses looking to maintain inventory efficiency.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. B2B buyers should prepare detailed RFQs that include all necessary specifications, such as spring pitch and angle, to receive accurate quotes.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers when negotiating contracts, as they dictate who bears the risks and costs during shipping and delivery.

5. Lead Time

Lead time refers to the time taken from placing an order until the delivery of the product. Knowing the lead time is essential for planning production schedules and inventory management, especially in industries where timely delivery is critical.

Illustrative image related to spring pitch

In summary, a solid grasp of both the technical properties and trade terminology related to spring pitch will empower B2B buyers to make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the spring pitch Sector

What Are the Current Market Dynamics and Key Trends in the Spring Pitch Sector?

The global market for spring pitch is driven by a combination of industrial growth, technological advancements, and increasing demand for customized spring solutions across various sectors such as automotive, aerospace, and machinery. Notably, regions like Africa, South America, the Middle East, and Europe are experiencing a surge in manufacturing capabilities and infrastructure development, leading to heightened demand for reliable and efficient spring solutions.

Emerging technologies, including automation and advanced manufacturing techniques such as CNC machining, are reshaping sourcing strategies. B2B buyers are increasingly prioritizing suppliers that leverage these technologies to ensure precision and consistency in spring pitch manufacturing. Moreover, the rise of e-commerce platforms is facilitating easier access to a broader range of suppliers, making it essential for buyers to evaluate options based on quality, cost, and delivery timelines.

Another key trend is the increasing emphasis on customization. Companies are seeking springs tailored to specific applications, which requires suppliers to offer flexible design and manufacturing capabilities. This trend underscores the importance of collaboration between buyers and manufacturers to achieve optimal spring performance based on precise specifications.

How Is Sustainability and Ethical Sourcing Addressed in the Spring Pitch Industry?

As the global market becomes more environmentally conscious, sustainability and ethical sourcing have emerged as critical considerations for B2B buyers in the spring pitch sector. The environmental impact of spring manufacturing, particularly concerning resource consumption and waste generation, is prompting companies to seek suppliers committed to sustainable practices.

Illustrative image related to spring pitch

Buyers should prioritize suppliers that utilize eco-friendly materials and processes, such as recycled metals and energy-efficient manufacturing techniques. Certifications like ISO 14001 for environmental management systems can serve as indicators of a supplier’s commitment to sustainability. Additionally, understanding the supply chain’s ethical implications is vital; companies are increasingly scrutinizing their suppliers for fair labor practices and responsible sourcing of raw materials.

The adoption of green certifications not only enhances a company’s reputation but also aligns with regulatory requirements and consumer expectations. By engaging with suppliers who prioritize sustainability, B2B buyers can contribute to reducing the overall environmental footprint of their operations while ensuring compliance with international standards.

What Is the Brief Evolution of Spring Pitch Manufacturing?

Historically, the spring pitch concept has evolved from basic mechanical designs to sophisticated engineering solutions. The early days of spring manufacturing involved simple coiling techniques, primarily focused on functionality. As industrial demands grew, the need for precision and reliability led to the development of advanced manufacturing technologies.

The introduction of CNC machines revolutionized the spring pitch sector, enabling manufacturers to produce highly customized springs with consistent quality. This evolution has also facilitated the integration of design software, allowing for complex geometries and configurations that meet specific application needs.

Today, the focus is not only on manufacturing efficiency but also on sustainability and ethical sourcing, reflecting a broader shift towards responsible business practices in the industrial landscape. As the market continues to evolve, B2B buyers can benefit from understanding these historical trends to make informed sourcing decisions that align with modern operational demands.

Illustrative image related to spring pitch

Frequently Asked Questions (FAQs) for B2B Buyers of spring pitch

-

How do I solve the issue of selecting the right spring pitch for my application?

Selecting the right spring pitch involves understanding your application’s load requirements and performance needs. Start by assessing the maximum load the spring will bear and the required stiffness. A smaller spring pitch typically increases stiffness, making it suitable for high-load applications. Additionally, consider the space constraints in your design; a well-calibrated pitch can help fit your spring within tighter spaces. Collaborate with your supplier to customize the spring pitch to meet your specific requirements while ensuring it aligns with your application’s operational dynamics. -

What is the best spring pitch for automotive suspension systems?

For automotive suspension systems, the ideal spring pitch should balance stiffness and shock absorption. A smaller pitch can enhance load-bearing capacity, which is essential for handling heavy loads. However, optimizing the pitch for shock absorption is crucial; larger pitches can help springs perform better under dynamic loading, such as bumps and turns. Ultimately, the best spring pitch will depend on the vehicle’s weight, intended use, and performance goals. It is advisable to work with a specialized supplier to tailor the pitch to your specific suspension design. -

How can I ensure the quality of springs sourced from international suppliers?

To ensure quality when sourcing springs internationally, start by vetting potential suppliers thoroughly. Look for manufacturers with certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to evaluate material quality and performance under load. Additionally, consider suppliers who offer transparency in their production processes and quality control measures. Establishing a clear communication channel can help address any concerns and ensure that the springs meet your specifications before placing larger orders. -

What are the typical minimum order quantities (MOQs) for custom spring pitches?

Minimum order quantities (MOQs) for custom spring pitches can vary significantly among suppliers, often depending on the complexity of the design and manufacturing processes. Typically, MOQs can range from a few hundred to several thousand units. It’s important to discuss your specific needs with potential suppliers to negotiate favorable terms. Some manufacturers may be flexible with MOQs for high-value clients or long-term partnerships, so consider establishing a relationship that allows for adjustments based on future orders. -

What payment terms are commonly offered by international spring suppliers?

Payment terms from international spring suppliers can vary widely, often influenced by the supplier’s policies and your negotiation power. Common options include full payment upfront, partial payments upon order confirmation, and payment upon delivery. Some suppliers may also offer open account terms for established clients. It’s crucial to clarify payment terms upfront to avoid misunderstandings. Consider discussing escrow services or letters of credit for larger orders to provide security for both parties involved in the transaction. -

How does spring pitch impact logistics and shipping for B2B buyers?

Spring pitch directly affects logistics, particularly in terms of packaging and shipping costs. Springs with larger pitches may require more space, leading to higher shipping fees. Furthermore, the dimensions and weight of the spring can influence how many units can fit in a shipping container, impacting overall shipping efficiency. When sourcing internationally, it’s essential to discuss logistics with your supplier to optimize packaging and minimize costs. Collaborating on the shipping method can also ensure timely delivery while reducing potential damages during transport. -

What customization options should I consider when sourcing spring pitches?

When sourcing spring pitches, consider various customization options such as wire diameter, coil count, end types, and surface treatments. Customization can enhance performance characteristics, like load capacity and fatigue resistance. Discussing your specific application requirements with the supplier will help in selecting the optimal specifications. Additionally, inquire about the ability to produce variable pitch springs if your application demands it, as this can lead to enhanced performance under dynamic loading conditions. -

How can I assess the performance of springs under dynamic loading conditions?

To assess spring performance under dynamic loading conditions, it’s essential to conduct thorough testing, including fatigue testing and load testing. Request data from your supplier regarding the spring’s response to dynamic loads, including deflection and recovery characteristics. Utilizing simulation software can also help predict how a spring will perform under real-world conditions. Collaborating with engineers who specialize in spring dynamics can provide insights into optimizing your spring design for specific applications, ensuring reliability and durability over time.

Top 7 Spring Pitch Manufacturers & Suppliers List

1. Century Spring – Helical Compression Springs

Domain: centuryspring.com

Registered: 1996 (29 years)

Introduction: Spring pitch is a property that influences a helical compression spring’s stiffness and load-bearing capacity, measuring the axial distance between the centerlines of the coils when unloaded. Spring pitch angle is the angle between the coils and the central horizontal axis of the spring. Both properties are critical in spring design and manufacturing.

2. Acxesspring – Spring Pitch Calculator

Domain: acxesspring.com

Registered: 1996 (29 years)

Introduction: Spring Pitch Calculator allows users to calculate the pitch of helical springs. Key features include:

– Input options for wire diameter, outer diameter, inner diameter, free length, total coils, and material type.

– Unit of measure can be selected as English or Metric.

– Results are approximate with a +/- 10% margin of error.

– Different formulas for calculating spring pitch based on end types…

3. Industrial Springs – Compression Spring Pitch Guide

Domain: industrial-springs.com

Registered: 2005 (20 years)

Introduction: The pitch of a compression spring is the distance measured between the centers of two coils, specifically from wire center to wire center of adjacent coils, measured parallel to the length axis. The simplest method to determine pitch is to measure the gap between coils and add the wire thickness. The pitch must not exceed the outside diameter of the compression spring to avoid production difficult…

4. Stock Springs – Compression Spring Essentials

Domain: stockspringscatalog.com

Registered: 2019 (6 years)

Introduction: This company, Stock Springs – Compression Spring Essentials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Newcomb Spring – Custom Springs & Metal Parts

Domain: newcombspring.com

Registered: 1997 (28 years)

Introduction: Newcomb Spring manufactures a variety of springs including compression springs, extension springs, torsion springs, wire forms, and stamped metal parts. They focus on high-quality parts with strict compliance to specifications, offering large runs, short runs, and fast prototypes of custom parts. The pitch of a helical spring is defined as the distance from the center of one coil to the center of …

6. CompressionSpring.com – Helical Spring Solutions

Domain: compressionspring.com

Registered: 2000 (25 years)

Introduction: Helical Spring Formulas and Equations, Spring Finder for Compression, Extension, and Torsion Springs, Search in English (inches and pounds) or Metric (millimeters and Newtons), Basic and Advanced Search Options, Parameters for Compression Springs: outer diameter, free length, spring rate, load, deflection, total coils, solid height, inner diameter, wire diameter, material type; Parameters for Exte…

7. Yost Superior – Spring Pitch Insights

Domain: yostsuperior.com

Registered: 1997 (28 years)

Introduction: Spring pitch is a critical characteristic in spring design, quantifying the distance between coils measured from the center of one coil’s wire to the center of the adjacent coil’s wire. It is important for understanding the behavior and performance of springs, particularly in compression and extension applications. The pitch can vary based on the design of the spring, including factors like regula…

Strategic Sourcing Conclusion and Outlook for spring pitch

How Can Understanding Spring Pitch Enhance Your Strategic Sourcing?

In conclusion, comprehending the intricacies of spring pitch and pitch angle is crucial for optimizing the performance of helical coil compression springs. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, must recognize that the selection of spring pitch directly influences key factors such as load capacity, stiffness, and stability under dynamic conditions. Leveraging these insights can lead to better sourcing decisions, ensuring that the springs meet specific application requirements while adhering to quality standards.

Strategic sourcing is not merely about cost; it involves aligning your procurement strategy with performance expectations and long-term operational goals. By engaging with manufacturers who utilize advanced technologies and precision engineering, you can ensure that you receive springs tailored to your unique specifications.

As we look forward, the demand for innovative spring solutions is expected to grow, driven by advancements in technology and increasing application complexities. We encourage B2B buyers to prioritize partnerships with suppliers who are committed to quality, reliability, and customization. This proactive approach will not only enhance your product offerings but also position your business for success in a competitive global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.