Choosing Your Sonotubes Near Me: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for sonotubes near me

In the dynamic world of construction and infrastructure development, sourcing reliable sonotubes near me presents a significant challenge for international B2B buyers. With varying quality standards, shipping logistics, and local supplier reliability, making informed purchasing decisions can be daunting, especially in diverse markets across Africa, South America, the Middle East, and Europe, including countries like Brazil and Saudi Arabia. This guide aims to simplify the procurement process by offering a comprehensive overview of sonotubes, detailing their various types, applications, and the critical factors to consider when selecting suppliers.

Throughout this guide, we will explore the diverse applications of sonotubes, from residential and commercial building columns to specialized projects such as theatrical props and signage. We will also delve into essential aspects of supplier vetting, ensuring that you partner with reputable manufacturers who meet your quality and delivery requirements. Additionally, we will provide insights on pricing structures, helping you navigate the financial aspects of your purchase.

By empowering B2B buyers with actionable insights and strategies, this guide serves as a vital resource for those looking to make well-informed decisions in the global market for sonotubes. Whether you are a contractor, architect, or project manager, you will find the information necessary to streamline your sourcing process and enhance project outcomes.

Understanding sonotubes near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Sonotube | Available in various diameters and heights; made of cardboard | Residential and commercial columns, footings | Pros: Cost-effective, easy to use. Cons: Less durable in wet conditions. |

| Heavy Wall Sonotube | Thicker walls for enhanced strength; suitable for larger projects | Large commercial buildings, bridges | Pros: High strength, withstands heavy loads. Cons: Higher cost, heavier to handle. |

| Rainguard Sonotube | Rain-resistant technology; lighter than standard versions | Projects in wet climates, outdoor structures | Pros: Reduces risk of water damage, easier to transport. Cons: May be less sturdy than heavy wall options. |

| Foam Column Forms | Made of foam for lightweight applications; reusable | Decorative structures, temporary installations | Pros: Lightweight, reusable. Cons: Not suitable for permanent structures. |

| Recycled Paper Sonotube | Eco-friendly option; made from recycled materials | Sustainable building projects | Pros: Environmentally friendly, cost-effective. Cons: May lack strength compared to traditional options. |

What are the Characteristics of Standard Sonotubes and Their Suitability for B2B Buyers?

Standard sonotubes are the most commonly used concrete forming tubes, available in a variety of diameters and heights to accommodate different project requirements. They are primarily made from cardboard, making them cost-effective for various applications, including residential and commercial columns and footings. B2B buyers should consider their ease of use and affordability, particularly for projects with budget constraints. However, they may not perform well in wet conditions, which could lead to structural issues.

How Do Heavy Wall Sonotubes Differ and When Should They Be Used?

Heavy wall sonotubes are designed with thicker walls, providing enhanced strength and durability. These tubes are ideal for large-scale projects, such as commercial buildings and bridges, where structural integrity is paramount. B2B buyers should weigh the benefits of their high load-bearing capacity against the increased cost and handling challenges. While they provide superior strength, the heavier weight can complicate transportation and installation.

What Advantages Do Rainguard Sonotubes Offer for Construction in Wet Conditions?

Rainguard sonotubes feature innovative rain-resistant technology, making them suitable for projects that may encounter wet weather. They are lighter than standard sonotubes, which aids in transportation and handling. B2B buyers operating in regions with unpredictable weather should consider these tubes to minimize the risk of water damage to their concrete forms. However, it is important to note that while they are easier to work with, they may not be as durable as heavy wall options.

In What Scenarios are Foam Column Forms the Best Choice for B2B Buyers?

Foam column forms are a lightweight alternative to traditional sonotubes, often used for temporary installations or decorative structures. They are reusable, making them an attractive option for companies focused on reducing waste. B2B buyers looking for flexibility and ease of handling may find foam forms advantageous. However, these forms are not suitable for permanent structures, limiting their application scope.

Why Should B2B Buyers Consider Recycled Paper Sonotubes for Sustainable Projects?

Recycled paper sonotubes are an eco-friendly option, crafted from sustainable materials. They are particularly appealing to businesses committed to green building practices. These tubes are cost-effective and suitable for various applications, but buyers should be aware that they may lack the strength of traditional sonotubes. This could limit their use in projects requiring significant structural support, making it essential for buyers to assess their specific needs when selecting this option.

Key Industrial Applications of sonotubes near me

| Industry/Sector | Specific Application of sonotubes near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Column forms for residential and commercial buildings | Provides quick and efficient concrete pouring solutions, reducing labor costs and time | Ensure compliance with local building codes and standards; consider delivery timelines to project sites. |

| Infrastructure | Foundation footings for bridges and highways | Enhances structural integrity while minimizing material waste | Assess load-bearing capacities; evaluate environmental conditions during installation. |

| Event Management | Temporary structures for festivals and events | Enables rapid setup and teardown, ensuring flexibility in planning | Consider weather-resistant options; ensure availability in various sizes for different applications. |

| Landscaping | Decorative garden columns and posts | Adds aesthetic value while supporting plant structures | Source lightweight options for easy handling; consider local aesthetics and design preferences. |

| Film and Theater Production | Props and set designs | Offers versatility in creating custom shapes and designs | Evaluate the need for specific finishes; ensure timely delivery for production schedules. |

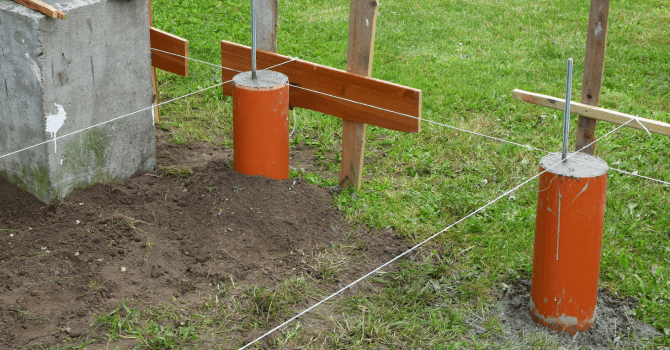

How Are Sonotubes Used in Construction Projects?

In the construction industry, sonotubes serve as essential column forms for both residential and commercial buildings. They streamline the concrete pouring process, allowing contractors to achieve uniform shapes and sizes quickly. This efficiency not only reduces labor costs but also accelerates project timelines, which is particularly beneficial in fast-paced markets. For international buyers, it is crucial to verify that these products meet local building codes and standards, as well as to consider the logistics of delivering these materials to often remote or challenging locations.

Illustrative image related to sonotubes near me

What Role Do Sonotubes Play in Infrastructure Development?

Sonotubes are increasingly utilized in infrastructure projects, particularly for creating foundation footings for bridges and highways. Their ability to provide a robust base for heavy structures ensures long-lasting durability and stability. This is especially important in regions with challenging weather conditions or soil types. Buyers should pay close attention to the load-bearing capacities of sonotubes, as well as the environmental factors that may affect installation, such as moisture levels and soil composition.

How Are Sonotubes Beneficial for Event Management?

In the realm of event management, sonotubes offer a practical solution for constructing temporary structures, such as stages and exhibition booths. They allow for rapid setup and teardown, which is vital for events that require flexibility in planning and execution. International buyers should consider weather-resistant options to ensure that these structures can withstand various environmental conditions. Additionally, sourcing sonotubes in a range of sizes can accommodate diverse event layouts and designs.

What Advantages Do Sonotubes Provide in Landscaping?

In landscaping, sonotubes are often used to create decorative columns and posts that enhance the aesthetic appeal of gardens and outdoor spaces. They support plant structures while adding a touch of elegance. For landscaping businesses, sourcing lightweight options can facilitate easier handling and installation. It is also beneficial to align the product’s design with local aesthetic preferences to ensure customer satisfaction and project success.

How Are Sonotubes Used in Film and Theater Production?

In film and theater production, sonotubes are leveraged to create props and set designs that require custom shapes and sizes. Their versatility allows for creative expression while maintaining structural integrity. Timely delivery is essential in this fast-paced industry, so buyers should ensure that suppliers can meet production schedules. Additionally, evaluating the need for specific finishes can enhance the visual appeal of the final product, aligning it with the overall artistic vision of the production.

3 Common User Pain Points for ‘sonotubes near me’ & Their Solutions

Scenario 1: Sourcing Quality Sonotubes for Diverse Applications

The Problem:

B2B buyers often struggle to find high-quality sonotubes that are suitable for various applications, such as commercial buildings, parking garages, or decorative installations. This issue is exacerbated in regions like Africa and South America, where product availability can be inconsistent. Buyers may encounter low-quality products that compromise the structural integrity of their projects, leading to costly delays and reputational damage. Additionally, varying specifications and standards across different suppliers can confuse buyers, making it challenging to ensure that the sonotubes meet local building codes and project requirements.

The Solution:

To effectively source quality sonotubes, buyers should start by identifying reputable local suppliers who specialize in construction materials. Leveraging online platforms that aggregate supplier information can help buyers compare product offerings, specifications, and prices. When evaluating potential suppliers, prioritize those who provide detailed product information, including material specifications, load-bearing capacities, and compliance with local building codes.

Furthermore, consider requesting samples or visiting production facilities if feasible, as this allows buyers to assess the quality firsthand. Engaging in discussions with suppliers about their sourcing practices and certifications can also provide insights into the reliability of the products. Finally, establishing a long-term relationship with a trusted supplier can lead to better pricing and more consistent availability of high-quality sonotubes tailored to specific applications.

Scenario 2: Managing Costs in a Competitive Market

The Problem:

In a competitive construction market, cost management is crucial for B2B buyers. Fluctuating prices of sonotubes can disrupt budgeting and lead to unexpected expenses. Buyers may find themselves faced with limited options or higher prices due to a lack of negotiating power, especially when sourcing from international suppliers. This situation can be particularly challenging for projects with tight deadlines and fixed budgets, leading to stress and potential project delays.

The Solution:

To manage costs effectively, buyers should conduct thorough market research to understand price trends and seasonal fluctuations in sonotube pricing. Establishing relationships with multiple suppliers can enhance negotiating power and provide leverage for bulk purchasing discounts. Buyers might also explore alternative materials or sizes that meet their project specifications without compromising quality.

Additionally, considering the logistics and shipping costs when sourcing internationally is crucial. Buyers should inquire about local distribution centers or suppliers that can reduce transportation costs and delivery times. Implementing a just-in-time inventory system can also help maintain cash flow while ensuring that materials are available when needed, ultimately contributing to more efficient project management.

Scenario 3: Overcoming Delivery Delays and Supply Chain Issues

The Problem:

Delivery delays are a common pain point for B2B buyers sourcing sonotubes, particularly in regions with less developed logistics infrastructure. Delays can result from various factors, including inadequate transportation networks, customs clearance issues, or supplier mismanagement. Such delays can severely impact project timelines, leading to costly repercussions for contractors and their clients.

The Solution:

To mitigate delivery delays, buyers should incorporate contingency planning into their procurement strategies. This includes setting realistic lead times and maintaining open communication with suppliers about their delivery capabilities. Establishing clear timelines and expectations upfront can help suppliers prioritize orders appropriately.

Additionally, utilizing technology to track shipments can provide buyers with real-time updates, allowing them to proactively address potential delays. Collaborating with suppliers who have established logistics networks can also enhance delivery reliability. Lastly, consider diversifying the supply chain by identifying alternative suppliers or local manufacturers who can provide sonotubes on shorter notice, thus reducing dependency on a single source and improving overall supply chain resilience.

Strategic Material Selection Guide for sonotubes near me

What Are the Key Materials Used in Sonotubes?

When selecting sonotubes for various applications, the choice of material significantly influences performance, durability, and cost-effectiveness. Below, we analyze four common materials used in sonotube manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to sonotubes near me

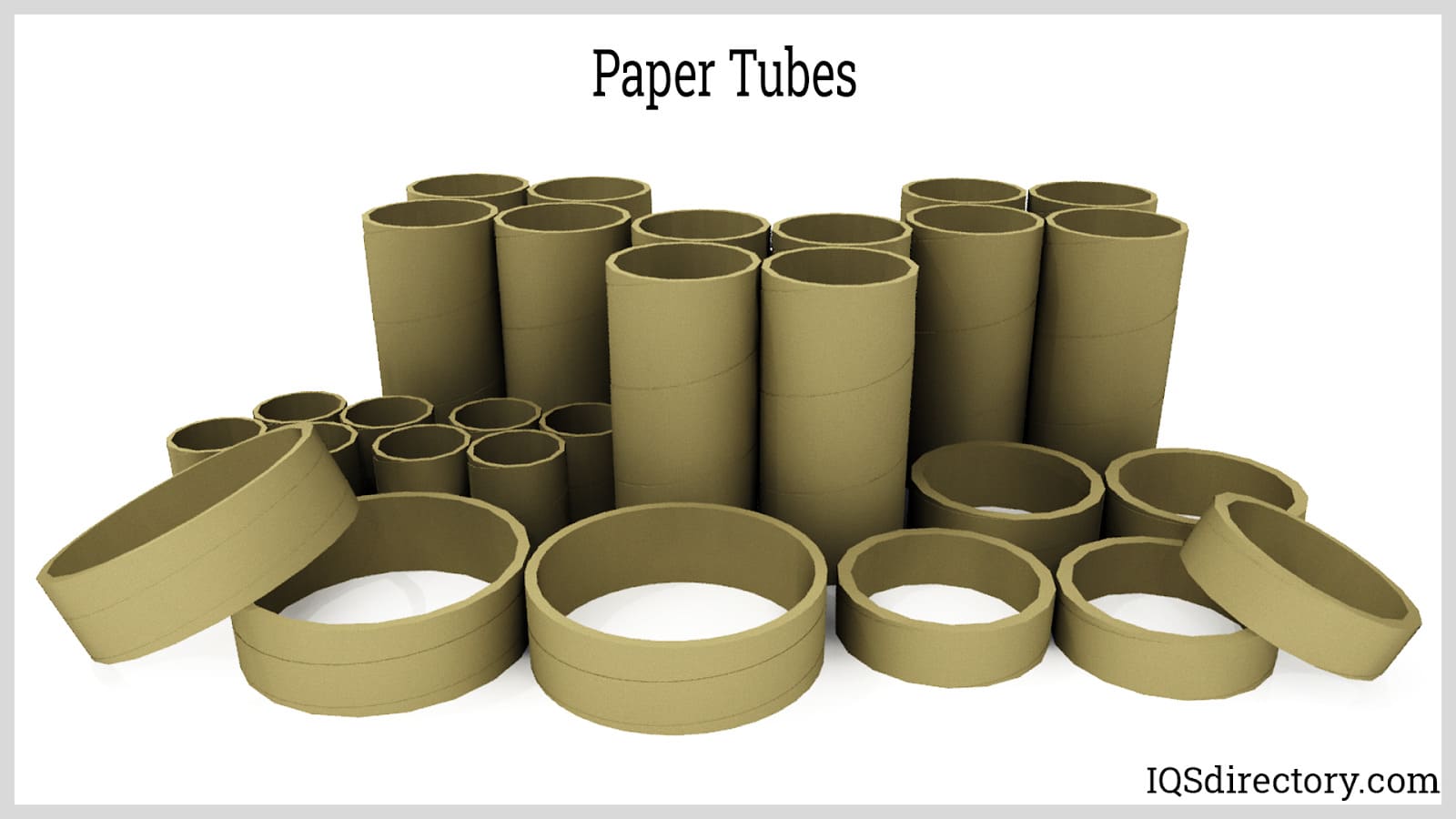

How Do Paper-Based Sonotubes Perform?

Key Properties: Paper-based sonotubes are primarily made from recycled paper and are designed to withstand concrete’s weight and pressure during curing. They typically have a temperature rating suitable for standard concrete applications, but may not perform well under extreme weather conditions without additional protective coatings.

Pros & Cons: These tubes are lightweight and easy to handle, making them ideal for smaller projects. However, they can be less durable than other materials, particularly in wet conditions, which may lead to premature degradation. Their cost is generally low, making them an attractive option for budget-conscious projects.

Impact on Application: Paper sonotubes are suitable for residential and light commercial applications, particularly where the concrete is not exposed to excessive moisture. However, they may not be the best choice for heavy-duty structural applications.

Illustrative image related to sonotubes near me

Considerations for International Buyers: Compliance with local building codes and standards such as ASTM or DIN is crucial. In regions with high humidity, such as parts of Africa and South America, buyers should consider the potential for moisture-related issues.

What Are the Benefits of Plastic Sonotubes?

Key Properties: Plastic sonotubes, often made from high-density polyethylene (HDPE), offer excellent corrosion resistance and can handle a wide range of temperatures. They are also impervious to moisture, which enhances their durability.

Pros & Cons: The primary advantage of plastic sonotubes is their longevity and resistance to environmental factors. However, they can be more expensive than paper alternatives and may require specialized equipment for cutting and handling.

Impact on Application: These tubes are ideal for applications in coastal or humid environments where moisture is a concern. They are also suitable for heavy-duty construction, including commercial buildings and infrastructure projects.

Considerations for International Buyers: Buyers should ensure that the plastic materials meet local environmental regulations, especially in regions like Europe where sustainability is a priority. Compliance with standards such as JIS may also be necessary.

How Do Composite Sonotubes Compare?

Key Properties: Composite sonotubes often combine materials like fiberglass and resin, providing high strength and resistance to both temperature and chemicals. They can withstand significant pressure, making them suitable for demanding applications.

Pros & Cons: The main advantage of composite sonotubes is their exceptional durability and strength. However, they tend to be more costly and may require specialized handling and installation techniques.

Impact on Application: These tubes are perfect for industrial applications or environments where chemical exposure is a concern. They can also be utilized in high-stress structural applications.

Considerations for International Buyers: Compliance with international standards and certifications is essential, especially in regions with stringent regulations like the Middle East. Buyers should also consider the availability of skilled labor for installation.

What Makes Steel Sonotubes a Viable Option?

Key Properties: Steel sonotubes are robust and can withstand high pressures and temperatures. They are resistant to corrosion when properly treated and are suitable for various environmental conditions.

Pros & Cons: The durability and strength of steel make it an excellent choice for heavy-duty applications. However, the cost is typically higher than other materials, and they can be heavy and cumbersome to work with.

Impact on Application: Steel sonotubes are ideal for large-scale commercial projects, bridges, and other infrastructure where structural integrity is paramount.

Considerations for International Buyers: Buyers must ensure that the steel used complies with local standards and regulations. In regions like Brazil and Saudi Arabia, understanding the local supply chain for steel products is crucial for timely delivery.

Illustrative image related to sonotubes near me

Summary Table of Material Properties

| Material | Typical Use Case for sonotubes near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paper | Residential and light commercial | Lightweight and cost-effective | Less durable in wet conditions | Low |

| Plastic | Coastal and humid environments | Excellent moisture resistance | Higher cost and handling complexity | Medium |

| Composite | Industrial and chemical exposure | Exceptional durability and strength | Higher cost and installation needs | High |

| Steel | Large-scale commercial projects | High strength and pressure resistance | Heavy and more expensive | High |

This strategic material selection guide provides essential insights for B2B buyers in diverse international markets, facilitating informed decisions that align with project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for sonotubes near me

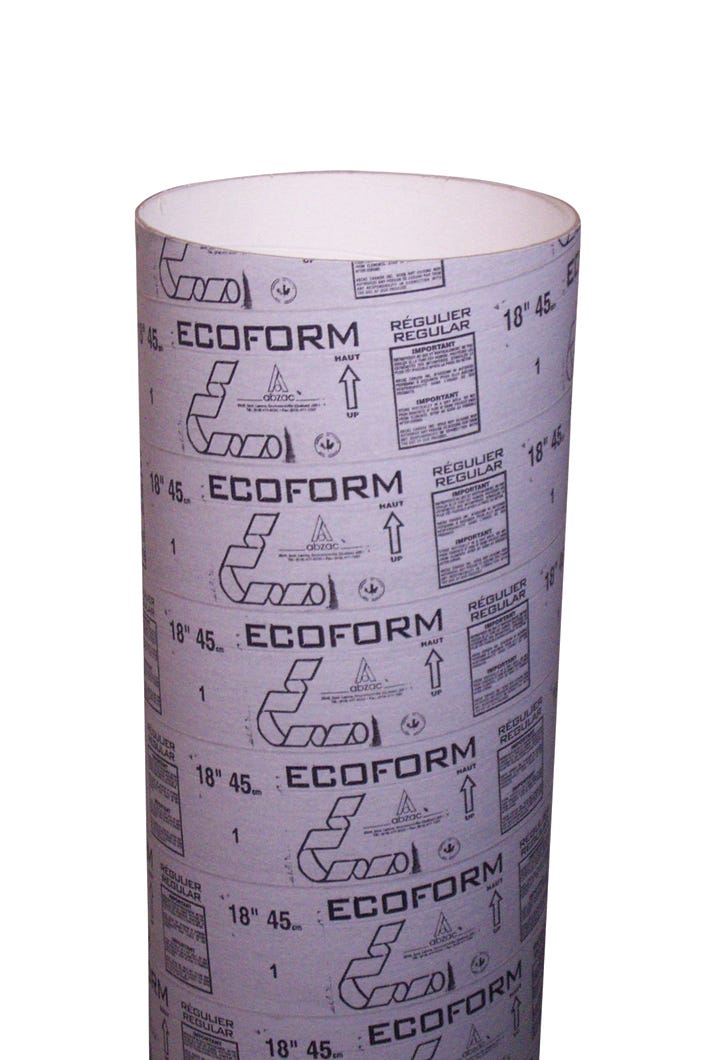

In the competitive world of construction materials, understanding the manufacturing processes and quality assurance practices for sonotubes is crucial for international B2B buyers. This guide outlines the typical stages of sonotube production and the quality control measures that ensure these products meet industry standards and customer expectations.

What Are the Main Stages of Sonotube Manufacturing?

Material Preparation

The first step in manufacturing sonotubes involves the preparation of raw materials. Most sonotubes are constructed from high-quality cardboard or fiberboard, which is sourced from sustainable forestry practices. Manufacturers often use recycled materials to enhance sustainability and reduce costs. The materials undergo rigorous inspections to ensure they meet specific strength and durability criteria.

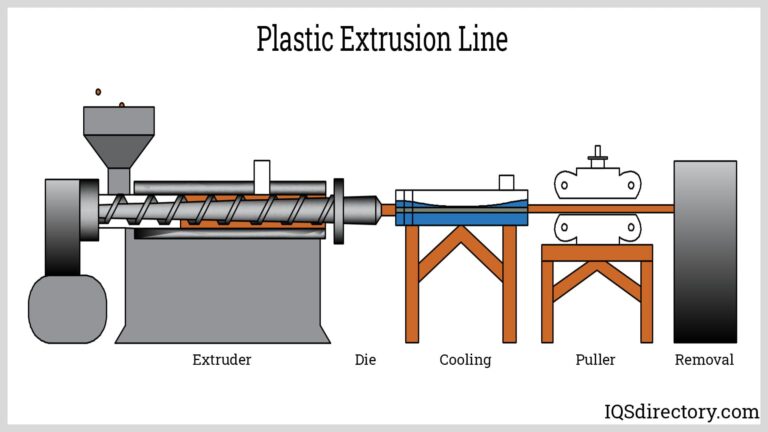

Forming Process

Once the materials are prepared, the forming process begins. The raw material is rolled into cylindrical shapes using specialized machinery that applies heat and pressure. This process not only shapes the tubes but also ensures uniform thickness and strength. Advanced techniques such as spiral winding or flat sheet lamination may be employed to enhance the structural integrity of the tubes.

Assembly

After the tubes are formed, they are cut to specified lengths and assembled with any additional features, such as Rainguard technology. This technology provides water resistance, allowing the tubes to withstand adverse weather conditions during construction. The assembly stage may also involve adding labels and other branding elements that help in product identification and traceability.

Illustrative image related to sonotubes near me

Finishing

The finishing stage includes surface treatments to improve the aesthetic and functional properties of the sonotubes. This may involve coating the tubes with protective materials or applying finishes that enhance durability. The finished products are then packaged for distribution, ensuring that they are protected during transportation.

How Is Quality Assurance Implemented in Sonotube Production?

What International Standards Are Relevant for Sonotube Quality Control?

Quality assurance for sonotubes typically adheres to several international standards, including ISO 9001 for quality management systems. Compliance with these standards ensures that manufacturers maintain consistent quality in their products and processes. In addition, specific industry standards such as CE marking for products sold in Europe or API specifications for construction materials may also apply.

What Are the Key Quality Control Checkpoints?

Quality control in sonotube manufacturing is a multi-stage process that includes:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before production begins. Suppliers are often required to provide certification of their materials, and random sampling is conducted to verify compliance with specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are performed to monitor critical parameters, such as wall thickness, dimensional accuracy, and structural integrity. This helps identify any deviations from the desired quality early in the process.

-

Final Quality Control (FQC): After the sonotubes are finished, they undergo final inspections to ensure they meet all relevant specifications. This includes testing for strength, durability, and compliance with safety standards. Documentation of these tests is crucial for maintaining quality assurance.

What Common Testing Methods Are Used for Sonotubes?

Manufacturers employ various testing methods to ensure the quality and performance of sonotubes:

-

Compression Testing: This test evaluates the load-bearing capacity of the tubes, ensuring they can withstand the pressures encountered during construction.

-

Moisture Resistance Testing: For products with Rainguard technology, testing for moisture absorption is critical to confirm that the tubes will perform adequately in wet conditions.

-

Dimensional Inspection: Ensuring that the tubes meet specified dimensions is essential for compatibility with other construction components. This is typically done using calipers and other precision measuring tools.

How Can B2B Buyers Verify Supplier Quality Control Processes?

What Should Buyers Look for in Supplier Audits and Reports?

International B2B buyers should conduct thorough due diligence when selecting suppliers for sonotubes. This includes requesting quality assurance reports, compliance certifications, and audit results. A reputable supplier will be transparent about their quality control processes and willing to share documentation.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct audits and product inspections to verify that suppliers adhere to international standards and internal quality guidelines. This is particularly important for buyers from regions such as Africa, South America, the Middle East, and Europe, where regulatory compliance may vary.

Are There Specific Quality Control Nuances for International Buyers?

What Should Buyers Be Aware of Regarding Certification Nuances?

Different regions may have varying requirements for product certification. For example, while a CE mark is essential for products sold within the European Union, other regions may prioritize local certifications. Buyers should familiarize themselves with the certification requirements specific to their market to ensure compliance and avoid potential legal issues.

How Can Buyers Address Quality Concerns with International Suppliers?

Communication is key when dealing with international suppliers. Buyers should establish clear quality expectations and maintain ongoing dialogue to address any concerns that arise. Developing a robust partnership with suppliers can lead to improved product quality and reliability over time.

Conclusion

Understanding the manufacturing processes and quality assurance practices for sonotubes is essential for international B2B buyers. By familiarizing themselves with the stages of production, relevant standards, and quality control measures, buyers can make informed decisions and ensure they source high-quality products that meet their specific needs. Through diligence in supplier selection and ongoing verification of quality practices, businesses can mitigate risks and enhance their construction projects’ success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sonotubes near me’

Introduction

This practical sourcing guide is designed to assist B2B buyers in efficiently procuring sonotubes in their local markets. Whether you’re in construction, landscaping, or any sector requiring concrete forming solutions, understanding how to navigate the procurement process can save time and resources. This checklist provides a structured approach to ensure you find reliable suppliers and quality products that meet your project specifications.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline the specific requirements for your sonotubes. Consider factors such as the diameter, length, and type (e.g., heavy wall, rain guard). This clarity will help you communicate effectively with suppliers and ensure that you receive the correct products for your projects.

- Diameter and Length: Specify the sizes needed based on your project requirements.

- Type of Sonotubes: Different applications may require specific features, such as moisture resistance.

Step 2: Research Local Suppliers

Conduct thorough research to identify potential suppliers of sonotubes in your area. Utilize online directories, industry forums, and local business listings to compile a list of suppliers. This step is crucial to finding vendors who can provide competitive pricing and timely delivery.

- Online Platforms: Websites like Yellow Pages or industry-specific directories can offer insights into local suppliers.

- Referrals: Reach out to industry contacts for recommendations to trustworthy suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; engage directly with their sales representatives to gauge their responsiveness and expertise.

- Certifications and Compliance: Check if the supplier meets local and international standards.

- Experience in Your Industry: Ensure they have a track record of supplying to businesses similar to yours.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of the sonotubes you intend to purchase. This allows you to assess the quality and suitability of the product for your specific applications.

Illustrative image related to sonotubes near me

- Material Quality: Examine the strength and durability of the samples.

- Compliance with Specifications: Ensure the samples meet your defined technical specifications.

Step 5: Compare Pricing and Terms

After evaluating samples, compare the pricing and terms offered by each supplier. Look beyond just the unit cost; consider shipping fees, payment terms, and bulk order discounts. This step is critical for maintaining budget compliance while ensuring quality.

- Total Cost of Ownership: Factor in shipping and handling when calculating the overall cost.

- Payment Flexibility: Evaluate terms that suit your cash flow requirements.

Step 6: Negotiate Contracts

Engage in negotiations to finalize your order with the selected supplier. This is your opportunity to clarify any remaining questions and secure the best possible terms.

- Clear Terms and Conditions: Ensure that delivery timelines, return policies, and warranty agreements are well-defined.

- Communication Protocols: Establish points of contact for any future inquiries or issues.

Step 7: Plan for Logistics and Delivery

Finally, coordinate logistics to ensure timely delivery of your sonotubes. Confirm shipping details and prepare for the arrival of your order to avoid project delays.

- Delivery Schedule: Align delivery dates with your project timelines.

- Handling and Storage: Prepare your site for receiving and storing the sonotubes to maintain their integrity.

By following this step-by-step checklist, B2B buyers can streamline the procurement of sonotubes, ensuring they meet project demands effectively and efficiently.

Comprehensive Cost and Pricing Analysis for sonotubes near me Sourcing

What Are the Key Cost Components for Sourcing Sonotubes?

When sourcing sonotubes, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The predominant material for sonotubes is paper, often recycled, which can affect pricing based on market demand and availability. High-quality, weather-resistant options like those with RainGuard technology may incur higher material costs due to advanced manufacturing processes.

Labor: Labor costs can vary significantly based on the region where the manufacturing occurs. For instance, labor in South America might be less expensive compared to Europe, impacting the final pricing of sonotubes.

Manufacturing Overhead: This includes costs associated with running manufacturing facilities, including utilities, rent, and administrative expenses. Efficient operations can help minimize these costs.

Illustrative image related to sonotubes near me

Tooling: The initial setup for producing different sizes and specifications of sonotubes requires investment in tooling. Customization can lead to higher tooling costs, which may be passed on to the buyer.

Quality Control (QC): Ensuring the durability and performance of sonotubes through rigorous QC processes adds to the overall cost but is essential to maintaining product standards, especially for international buyers who may need certifications for compliance.

Logistics: Shipping costs can vary greatly depending on the distance from the manufacturer to the buyer, mode of transport, and freight terms. Incoterms will determine who is responsible for shipping costs and risks during transit.

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary based on competition and market conditions.

Illustrative image related to sonotubes near me

How Do Price Influencers Impact Sonotube Sourcing Decisions?

Several factors influence the pricing of sonotubes in the B2B market.

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower prices per unit due to economies of scale. Buyers should consider their project needs carefully to negotiate better rates.

Specifications and Customization: Custom sizes and features, such as additional strength or weather resistance, can increase costs. Buyers should weigh the benefits of customization against potential price increases.

Materials Quality and Certifications: Higher quality materials and certifications (e.g., ISO, ASTM) can justify higher prices but ensure product reliability, particularly for structural applications.

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge premium prices for quality assurance and timely delivery.

Incoterms: Understanding shipping terms is crucial for international buyers. Different Incoterms can shift cost responsibilities and risks, influencing the total landed cost of sonotubes.

What Are Effective Buyer Tips for Negotiating Sonotube Prices?

B2B buyers can adopt several strategies to enhance cost-efficiency when sourcing sonotubes.

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate discounts or better payment terms.

Total Cost of Ownership (TCO): Consider not only the upfront price but also the long-term costs associated with the sonotubes, including installation, maintenance, and disposal. A lower initial price may not always equate to better value.

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of local market conditions and currency fluctuations, which can affect pricing. Additionally, understanding local regulations and standards can lead to more informed purchasing decisions.

Disclaimer on Indicative Prices

Prices for sonotubes can vary significantly based on factors such as location, supplier, and market conditions. The figures provided in references may serve as a guideline but are not definitive. Always consult with suppliers for the most accurate and current pricing based on your specific sourcing requirements.

Illustrative image related to sonotubes near me

Alternatives Analysis: Comparing sonotubes near me With Other Solutions

In the construction industry, selecting the appropriate concrete forming solution is critical for project success. While ‘sonotubes near me’ are a popular choice for creating concrete columns and footings, various alternative methods and products can be considered. Understanding these alternatives helps B2B buyers make informed decisions based on performance, cost, and specific project requirements.

| Comparison Aspect | Sonotubes Near Me | Quikrete QUIK-TUBE | Plastic Concrete Forms |

|---|---|---|---|

| Performance | High strength, moisture-resistant options | Durable, suited for moderate weather | Lightweight, less durable |

| Cost | Moderate pricing, varies by size | Generally lower cost per unit | Comparable to sonotubes, often cheaper |

| Ease of Implementation | Easy to handle and install | Simple installation process | Requires additional support structures |

| Maintenance | Minimal, disposable after use | Minimal, also disposable | May require cleaning and maintenance |

| Best Use Case | Ideal for large-scale commercial projects | Suitable for residential and light commercial work | Best for DIY and small-scale applications |

What Are the Pros and Cons of Quikrete QUIK-TUBE as an Alternative to Sonotubes?

Quikrete QUIK-TUBE offers a cost-effective solution for concrete forming, particularly for smaller projects. Its lightweight design makes it easy to transport and install, making it a popular choice for residential applications. However, while it performs adequately under normal conditions, its durability may not match that of sonotubes, especially in wet weather. Therefore, it may not be the best option for larger or more demanding structures.

How Do Plastic Concrete Forms Compare to Sonotubes?

Plastic concrete forms are another viable alternative that provides a lightweight option for forming concrete structures. They are easy to handle and can be reused multiple times, making them an attractive choice for cost-conscious buyers. However, they may require additional support during installation and may not withstand extreme weather conditions as effectively as sonotubes. For projects that do not necessitate heavy-duty forms, plastic options can be a practical solution.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between sonotubes and their alternatives, B2B buyers should evaluate project specifications, budget constraints, and the environmental conditions they will face. Sonotubes are well-suited for large-scale commercial applications requiring high durability and moisture resistance. In contrast, alternatives like Quikrete QUIK-TUBE and plastic concrete forms may be more appropriate for smaller, less demanding projects. Ultimately, the best choice will depend on balancing performance needs with cost-effectiveness, ensuring that the selected solution aligns with the specific requirements of each project.

Illustrative image related to sonotubes near me

Essential Technical Properties and Trade Terminology for sonotubes near me

What Are the Key Technical Properties of Sonotubes?

Sonotubes, widely utilized in construction for forming concrete columns and footings, possess several critical specifications that directly impact their performance and suitability for various applications. Understanding these properties is essential for B2B buyers looking to make informed purchasing decisions.

1. Material Composition

Sonotubes are primarily made from high-strength paper or composite materials. The use of recycled paper is common, which not only offers a lightweight alternative but also aligns with sustainable practices. This property is significant for B2B buyers focused on environmental impact and cost-effectiveness, as lighter forms are easier to handle and transport, reducing labor costs.

2. Diameter and Length Variations

Sonotubes are available in various diameters (e.g., 10″ to 60″) and lengths (commonly 4′ to 12′). The ability to choose the appropriate size is crucial for meeting specific project requirements, such as the structural load and design specifications. B2B buyers must ensure they select the correct dimensions to avoid project delays and ensure structural integrity.

3. Wall Thickness

The wall thickness of a Sonotube is a critical specification that determines its strength and durability. Thicker walls provide added support for heavier concrete pours, making them suitable for more demanding applications. Understanding the wall thickness is vital for construction firms aiming to comply with local building codes and standards.

4. RainGuard Technology

Some Sonotubes feature RainGuard technology, which enhances their water resistance. This property ensures that the forms maintain their integrity even in wet conditions, allowing construction to proceed uninterrupted. For B2B buyers, this technology reduces the risk of job delays due to weather, thereby enhancing project efficiency and reliability.

5. Load-Bearing Capacity

The load-bearing capacity of a Sonotube is essential for determining its suitability for various structural applications. Buyers should evaluate the maximum weight the forms can support during concrete curing to ensure safety and compliance with engineering standards. This specification is crucial for projects involving heavy-duty construction, such as commercial buildings and parking garages.

6. Ease of Use

Factors such as weight, handling, and stripping ease significantly influence the efficiency of construction projects. Lightweight forms that are easy to strip can lead to quicker project turnaround times and reduced labor costs. Buyers should consider these usability factors when selecting Sonotubes for their projects.

Illustrative image related to sonotubes near me

What Are Common Trade Terms Related to Sonotubes?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions involving Sonotubes. Here are several key terms that buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Sonotubes, understanding whether a supplier is an OEM can help buyers assess product quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, especially when budgeting for large projects or when managing inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. For buyers looking to procure Sonotubes, issuing an RFQ can facilitate competitive pricing and help identify the best suppliers.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers, particularly when sourcing Sonotubes from international suppliers, to ensure clarity on delivery responsibilities.

5. Lead Time

Lead time refers to the period from placing an order to receiving the product. Buyers should consider lead time when planning project timelines, as delays in receiving Sonotubes can impact overall construction schedules.

6. Certification Standards

Certification standards refer to the qualifications that products must meet to be considered safe and reliable. Familiarity with relevant certification standards (such as ASTM or ISO) helps buyers ensure that the Sonotubes they select comply with industry regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions regarding Sonotubes, enhancing project efficiency and ensuring compliance with industry standards.

Navigating Market Dynamics and Sourcing Trends in the sonotubes near me Sector

What Are the Key Market Dynamics and Trends in the Sonotubes Sector?

The global sonotubes market is experiencing significant growth, driven by the increasing demand for concrete forming solutions in construction projects across various sectors, including residential, commercial, and infrastructure development. Factors such as urbanization, population growth, and the need for durable construction materials are propelling market expansion, especially in developing regions like Africa and South America. Notably, countries like Brazil and Saudi Arabia are ramping up their construction activities, thereby increasing the demand for sonotubes.

Emerging B2B tech trends are reshaping sourcing strategies in this sector. Companies are increasingly adopting digital platforms for procurement, enhancing transparency and efficiency in the supply chain. E-commerce platforms and online marketplaces are becoming vital for international buyers seeking competitive pricing and product variety. Additionally, the use of advanced analytics and AI in supply chain management allows businesses to better forecast demand and optimize inventory levels, thus reducing costs.

Moreover, international buyers are becoming more discerning, favoring suppliers who can offer not just quality products but also timely deliveries and robust customer support. As competition intensifies, suppliers that can leverage technology to enhance their service offerings stand to gain a competitive edge.

How Are Sustainability and Ethical Sourcing Impacting the Sonotubes Market?

Sustainability is increasingly at the forefront of sourcing decisions for B2B buyers in the sonotubes sector. The environmental impact of construction materials is under scrutiny, prompting businesses to seek eco-friendly alternatives. Many suppliers are now offering sonotubes made from recycled paper and other sustainable materials, which not only minimize waste but also appeal to environmentally conscious clients.

Ethical sourcing practices are becoming essential in establishing trust with international buyers. The importance of maintaining an ethical supply chain cannot be overstated; companies are expected to ensure that their suppliers adhere to fair labor practices and environmental regulations. Certifications such as FSC (Forest Stewardship Council) for sustainably sourced materials and other ‘green’ labels are becoming crucial differentiators in the market.

Illustrative image related to sonotubes near me

Furthermore, suppliers who invest in sustainable practices often find that they can reduce costs in the long term. By minimizing waste and improving resource efficiency, these companies can enhance their profitability while contributing positively to the environment. Thus, B2B buyers should prioritize partnerships with suppliers committed to sustainability and ethical practices.

What Is the Historical Context of Sonotubes in Construction?

The evolution of sonotubes can be traced back to the early 20th century when the need for efficient concrete forming solutions became apparent with the boom in construction. Originally made from wood, these forms faced challenges such as weight, durability, and susceptibility to moisture. The introduction of paper-based forms revolutionized the industry, providing a lighter, more versatile, and cost-effective alternative.

Over the years, advancements in material technology have further enhanced the performance of sonotubes. Innovations such as RainGuard technology have made these forms resistant to adverse weather conditions, allowing contractors to work more effectively regardless of the environment. As the construction landscape continues to evolve, sonotubes remain an integral component, adapting to the needs of modern construction projects while maintaining their core advantages of efficiency and reliability.

This historical context underscores the importance of sonotubes in construction, highlighting their ongoing relevance and the potential for future advancements in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of sonotubes near me

-

1. How do I choose the right sonotube for my project?

Selecting the right sonotube depends on the specific requirements of your project. Consider the diameter and height needed for your concrete columns or footings, as sonotubes come in various sizes, typically ranging from 8 inches to 60 inches in diameter. Additionally, evaluate the environmental conditions, such as moisture levels, which may necessitate features like Rainguard technology for added durability. Always consult with your supplier for recommendations based on your project specifications. -

2. What are the key benefits of using sonotubes for concrete forming?

Sonotubes offer several advantages, including ease of use, cost-effectiveness, and versatility. They eliminate the need for wood forms, reducing labor and material costs. Their lightweight design allows for easy handling and installation, while their strength ensures that they can withstand the pressures of wet concrete. Additionally, sonotubes are available in various lengths and diameters, making them suitable for a wide range of applications, from residential to commercial projects. -

3. What factors should I consider when sourcing sonotubes internationally?

When sourcing sonotubes internationally, consider factors such as supplier reliability, quality certifications, and compliance with local regulations. Evaluate the supplier’s experience in the industry and their ability to meet your specific requirements. Additionally, review shipping logistics, including costs, delivery times, and customs regulations. It’s beneficial to request samples before placing a bulk order to assess the product quality firsthand. -

4. How can I verify the quality of sonotubes before purchasing?

To ensure quality, request certifications and test reports from suppliers that demonstrate compliance with industry standards. Conduct a thorough vetting process by checking customer reviews and ratings. If possible, visit the manufacturing facility or request a factory audit. Additionally, consider ordering a small quantity for testing purposes to evaluate the performance of the sonotubes in your specific applications. -

5. What are the typical minimum order quantities (MOQs) for sonotubes?

Minimum order quantities for sonotubes can vary significantly based on the supplier and the specific product. Generally, MOQs may range from a few dozen to several hundred units, depending on the dimensions and customization options. Discuss your project needs with the supplier to negotiate MOQs that align with your procurement strategy, especially if you have specific volume requirements or are exploring bulk purchase discounts. -

6. What payment terms should I expect when ordering sonotubes internationally?

Payment terms for international orders can differ based on the supplier’s policies and your buyer-seller relationship. Common terms include advance payment, letter of credit, or payment upon delivery. It’s essential to clarify these terms upfront and ensure they are documented in the purchase agreement. Additionally, consider negotiating terms that provide protection for both parties, such as escrow services or partial payments tied to delivery milestones. -

7. How can I ensure timely delivery of sonotubes to my location?

To ensure timely delivery, maintain clear communication with your supplier regarding shipping schedules and lead times. Discuss logistics options, including freight forwarding and customs clearance processes, to avoid potential delays. It’s advisable to establish a buffer period in your project timeline to accommodate any unforeseen shipping issues. Regular follow-ups with your supplier can help keep your order on track. -

8. Are customization options available for sonotubes?

Yes, many suppliers offer customization options for sonotubes, including different lengths, diameters, and wall thicknesses. Some may also provide specific features like Rainguard technology for enhanced weather resistance or branding options for your company. When discussing your requirements with suppliers, be clear about your project specifications to explore available customization options that can meet your needs effectively.

Top 3 Sonotubes Near Me Manufacturers & Suppliers List

1. Sonoco – Sonotube Round Concrete Forming Tube

Domain: emisupply.com

Registered: 2008 (17 years)

Introduction: {‘product_name’: ‘Sonotube Round Concrete Forming Tube with Rainguard’, ‘dimensions’: ’24” x 48″‘, ‘brand’: ‘Sonoco’, ‘item_number’: ‘SON-10002795-4’, ‘manufacturer_model_number’: ‘10002795-4’, ‘price’: ‘$65.45’, ‘stock_quantity’: ’12 units’, ‘shipping_estimate’: ‘Fri. Sep 19’, ‘features’: [‘Rain-resistant’, ‘Easy to set up and brace’, ‘Superior strength-to-weight properties prevent blowouts’, ‘Ea…

2. Sonoco – Sonotube® Concrete Forms

Domain: sonoco.com

Registered: 1995 (30 years)

Introduction: Sonotube® Concrete Forms are produced by Sonoco Products Company, the world’s largest producer of tubes, cores, and fiber concrete columns, with over 75 years of experience. They are designed for architects, contractors, and DIY homeowners, providing cost savings, durability, versatility, and ease of use. Sonotube products have been used in notable projects like Carnegie 57 in New York City and th…

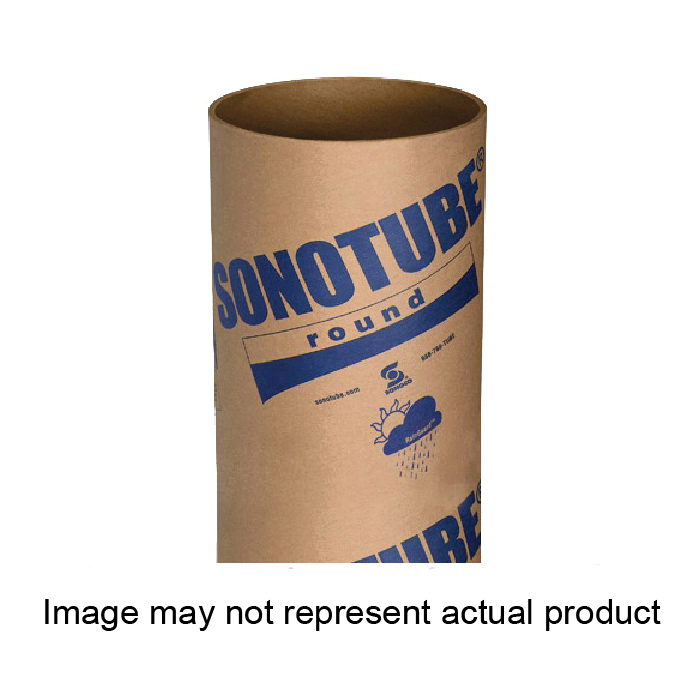

3. Sonoco – Sonotube Concrete Forms

Domain: industrialhardwarehawaii.com

Registered: 2011 (14 years)

Introduction: Product Name: Sonoco Sonotube Concrete Forms

Sizes Available: 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 24″, 26″, 28″, 30″, 36″, 42″, 48″, 60″

Advantages:

– Rain-resistant technology to protect against wet weather.

– Easier setup and bracing.

– Superior strength-to-weight properties to prevent blowouts during concrete form setting.

– More effective concrete form setting.

– Easy to cut and drill on-si…

Strategic Sourcing Conclusion and Outlook for sonotubes near me

Strategic sourcing of sonotubes presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By engaging with reliable suppliers and leveraging local distributors, businesses can ensure access to high-quality products that meet their specific construction needs. The versatility of sonotubes in applications ranging from residential buildings to commercial infrastructures underscores their value in diverse projects, reinforcing the importance of selecting the right partner for procurement.

Investing in strategic sourcing not only mitigates risks associated with supply chain disruptions but also enhances project timelines and cost efficiencies. As the demand for sustainable construction materials grows, suppliers offering innovative solutions, such as RainGuard technology, will be pivotal in maintaining competitive advantages.

Looking ahead, international buyers are encouraged to explore local sourcing options and build strong relationships with manufacturers and distributors. By doing so, they can tap into the latest advancements in concrete forming technology and secure the best pricing and delivery options. Now is the time to act—align your sourcing strategy with reliable partners to ensure successful project outcomes and drive growth in your respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.