Choosing Your Sonotube Installation: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for sonotube installation

In the rapidly evolving global construction landscape, sourcing effective solutions for sonotube installation can pose significant challenges for international B2B buyers. As the demand for durable and efficient foundation systems grows, understanding the various types of sonotubes, their applications, and the best practices for installation becomes essential. This comprehensive guide addresses these critical factors, providing insights into different sonotube materials, their specific use cases, and the nuances of supplier vetting tailored for international markets.

Throughout this guide, we will explore the intricacies of sonotube installation, including cost considerations, regional best practices, and quality assurance measures. Buyers from diverse regions—such as Africa, South America, the Middle East, and Europe—will benefit from actionable insights that empower informed purchasing decisions. Whether you are a contractor in Saudi Arabia seeking reliable suppliers or a developer in Nigeria looking to optimize project timelines, this resource is designed to equip you with the knowledge necessary to navigate the complexities of sonotube installation effectively.

By delving into the specifics of sourcing, installation techniques, and market trends, this guide aims to enhance your decision-making process, ensuring that you select the most suitable products and partners for your construction projects.

Understanding sonotube installation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Sonotube Installation | Utilizes standard cardboard tubes for concrete piers. | Residential foundations, deck supports | Pros: Cost-effective, widely available. Cons: Limited durability in wet conditions. |

| Reinforced Sonotube Installation | Incorporates steel rebar for added strength and stability. | Commercial buildings, heavy structures | Pros: Enhanced load-bearing capacity. Cons: Higher material costs. |

| Sonotube with Footing | Combines sonotube installation with a concrete footing base. | Larger structures, elevated decks | Pros: Improved stability and frost resistance. Cons: More complex installation process. |

| Precast Sonotube Variants | Uses precast concrete forms instead of cardboard tubes. | Industrial applications, high-rise buildings | Pros: Superior durability and longevity. Cons: Higher upfront investment. |

| Specialty Sonotube Solutions | Custom sizes and materials for specific project requirements. | Specialized construction projects, unique designs | Pros: Tailored solutions to meet specific needs. Cons: Potentially longer lead times and costs. |

What are the Key Characteristics of Standard Sonotube Installation?

Standard sonotube installation involves the use of traditional cardboard tubes that are ideal for forming concrete piers. This method is particularly suited for residential applications such as deck supports and light foundations. Buyers should consider the cost-effectiveness and availability of these tubes, but they should also be aware that their durability may be compromised in wet conditions, potentially leading to structural issues.

How Does Reinforced Sonotube Installation Enhance Stability?

Reinforced sonotube installation introduces steel rebar into the mix, significantly boosting the structural integrity of the concrete piers. This method is commonly used in commercial buildings and heavy structures where additional load-bearing capacity is essential. While the initial costs are higher due to materials and labor, the long-term benefits of increased strength and stability make this a compelling choice for B2B buyers focused on durability.

What Advantages Does Sonotube with Footing Provide?

The sonotube with footing variant combines the tube installation with a concrete base, enhancing stability and frost resistance. This method is particularly effective for larger structures and elevated decks, as it mitigates the risk of settling and shifting. Buyers should weigh the improved stability against the more complex installation process, which may require skilled labor and additional materials.

Why Choose Precast Sonotube Variants for Industrial Applications?

Precast sonotube variants are designed for durability and longevity, making them suitable for industrial applications and high-rise buildings. Unlike traditional cardboard tubes, precast forms can withstand harsher environmental conditions. While the upfront investment is higher, the long-term savings on maintenance and replacement make this option attractive for B2B buyers looking for reliable, long-lasting solutions.

What are Specialty Sonotube Solutions and When Should They Be Considered?

Specialty sonotube solutions offer custom sizes and materials tailored to specific project requirements. These solutions are ideal for unique construction projects where standard options may not suffice. Buyers should consider these solutions for specialized needs, but they must also account for potential longer lead times and increased costs associated with customization.

Key Industrial Applications of sonotube installation

| Industry/Sector | Specific Application of sonotube installation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Foundation Piers for Residential and Commercial Buildings | Provides stable and durable foundations, reducing long-term maintenance costs. | Ensure compliance with local building codes and environmental regulations. |

| Infrastructure | Utility Poles and Light Standards | Quick installation and reliable support for utilities, enhancing operational efficiency. | Evaluate local material availability and transport logistics for sonotubes. |

| Renewable Energy | Wind Turbine Foundations | Supports heavy structures, ensuring safety and longevity in harsh environments. | Consider weather-resistant materials and local geological conditions. |

| Agriculture | Support Structures for Greenhouses | Facilitates quick setup and stability for agricultural frameworks, improving productivity. | Assess compatibility with local soil types and climate conditions. |

| Landscaping | Tree Planting Supports | Provides a stable environment for young trees, promoting healthy growth. | Source environmentally friendly materials that align with sustainability goals. |

How is Sonotube Installation Used in Construction Foundations?

In the construction industry, sonotubes are widely utilized for creating foundation piers for both residential and commercial buildings. These tubes provide a mold for pouring concrete, ensuring that piers are uniform and structurally sound. The use of sonotubes addresses common issues such as soil instability and frost heave, which can compromise a structure’s integrity. For international buyers, particularly in regions with diverse soil conditions like Africa and South America, sourcing high-quality sonotubes is crucial to meet local building codes and withstand environmental challenges.

What Role Do Sonotubes Play in Infrastructure Projects?

Sonotubes are instrumental in the installation of utility poles and light standards, where rapid and reliable support is essential. The installation process is streamlined, allowing for quick deployment while ensuring that the poles remain stable under various environmental conditions. For businesses in the Middle East and Europe, considerations such as local supply chains and the availability of durable materials are vital to ensure successful implementation and long-term performance.

How Are Sonotubes Beneficial for Renewable Energy Installations?

In the renewable energy sector, particularly for wind turbine installations, sonotubes serve as robust foundations that can withstand significant loads and harsh weather conditions. The installation of sonotubes simplifies the foundation process, which is critical given the scale and weight of wind turbines. Buyers in regions like Saudi Arabia and Nigeria should prioritize sourcing sonotubes made from weather-resistant materials to ensure durability and compliance with local regulations regarding renewable energy projects.

In What Ways Do Sonotubes Support Agricultural Structures?

Sonotubes are also used in agriculture for creating support structures for greenhouses. This application allows for quick and efficient installation, which is essential for maximizing agricultural productivity. The stability provided by sonotubes helps mitigate risks associated with shifting soil and extreme weather. Buyers from agricultural sectors in Africa and South America should evaluate the compatibility of sonotubes with local soil types and climate conditions to optimize their use in farming operations.

How Do Sonotubes Enhance Landscaping Efforts?

In landscaping, sonotubes are employed to create stable planting environments for trees. They help secure young trees, providing the necessary support for healthy growth while minimizing the risk of damage from wind or erosion. For landscaping businesses, particularly in Europe, sourcing eco-friendly sonotubes can align with sustainability goals and enhance the appeal of landscaping projects to environmentally conscious clients.

3 Common User Pain Points for ‘sonotube installation’ & Their Solutions

Scenario 1: Inconsistent Ground Conditions Leading to Installation Delays

The Problem:

B2B buyers often encounter varied soil conditions that complicate sonotube installation. For instance, in regions with unpredictable geological characteristics, such as Nigeria or parts of the Middle East, a project may begin with a firm understanding of the site, but upon excavation, the team discovers areas of unstable soil or unexpected bedrock. These conditions can delay installation timelines, increase labor costs, and require additional materials, putting pressure on budgets and client expectations.

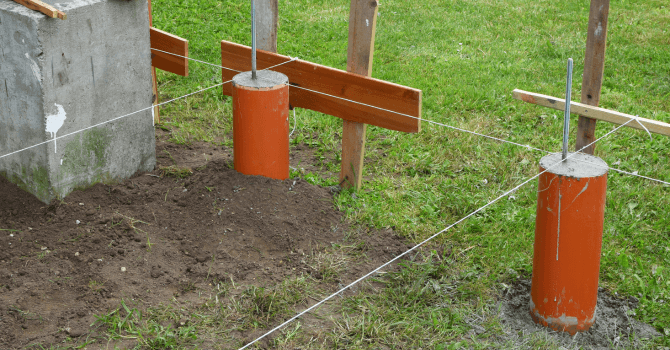

Illustrative image related to sonotube installation

The Solution:

To mitigate these challenges, thorough site assessments should be conducted prior to installation. Engaging a local geotechnical engineer can provide insights into the soil composition and strength. This upfront investment allows for the selection of appropriate sonotube sizes and materials that accommodate the specific conditions of the site. For example, if soft soil is identified, consider using larger diameter tubes or reinforcing them with additional concrete and rebar. Furthermore, having contingency plans in place, such as options for alternative footing systems, can reduce downtime and costs associated with unexpected site conditions. Always ensure that the installation team is well-trained in adapting to these variables to maintain project momentum.

Scenario 2: Difficulty in Ensuring Proper Tube Alignment

The Problem:

Maintaining proper alignment and elevation during sonotube installation can be a significant headache, especially in larger projects where multiple tubes are required. In countries like Brazil or Saudi Arabia, where climate and environmental conditions can vary widely, ensuring that each tube remains plumb and level throughout the pouring process can be challenging. Misalignment can lead to structural issues down the line, resulting in costly repairs and safety concerns.

The Solution:

To address alignment issues, implement a multi-step approach that includes utilizing laser levels and stakes to establish clear reference points before installation begins. Employ a dedicated team member to continuously monitor tube alignment while concrete is poured. Using a leveling device that allows for real-time adjustments during the pouring process can significantly enhance accuracy. Additionally, consider incorporating a temporary bracing system to stabilize the tubes until the concrete sets. This added layer of support can prevent shifting and ensure that the foundations are secure.

Scenario 3: Cost Management and Material Sourcing Challenges

The Problem:

B2B buyers often face challenges related to the sourcing of quality materials for sonotube installation, especially in regions with limited access to reliable suppliers. In areas like parts of Africa and South America, fluctuating prices and varying quality of concrete and sonotubes can lead to budget overruns and project delays. Buyers may struggle to find suppliers who can deliver materials on time and meet the required specifications.

The Solution:

To effectively manage costs and ensure material quality, buyers should establish relationships with multiple suppliers to create a competitive environment that can lead to better pricing and availability. Conducting a thorough vetting process for suppliers, including checking references and past project performance, can help ensure that the materials meet the required standards. Moreover, consider bulk purchasing agreements or long-term contracts with trusted suppliers to lock in prices and secure a consistent supply chain. Implementing a robust logistics plan that includes buffer times for material delivery can also help mitigate delays, allowing projects to proceed smoothly without unexpected interruptions. By being proactive in sourcing and establishing reliable partnerships, buyers can better manage costs and improve project outcomes.

Strategic Material Selection Guide for sonotube installation

What Are the Key Materials for Sonotube Installation?

When it comes to sonotube installation, selecting the right material is crucial for ensuring structural integrity and performance. Here, we analyze four common materials used in sonotube applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Cardboard

Key Properties: Cardboard sonotubes are lightweight, easy to handle, and biodegradable. They typically have a temperature tolerance of up to 200°F (93°C) and are suitable for standard concrete applications.

Illustrative image related to sonotube installation

Pros & Cons: The primary advantage of cardboard is its low cost and ease of disposal. However, it is less durable than other materials, particularly in wet conditions, where it can become compromised. The manufacturing process is straightforward, but the tubes can be susceptible to moisture, which may limit their use in humid climates.

Impact on Application: Cardboard is best suited for temporary structures or applications where environmental conditions are controlled. In regions with high humidity, such as parts of Africa and South America, buyers should consider the potential for degradation.

International Considerations: Compliance with local environmental regulations is essential, especially in regions where biodegradable materials are preferred. Buyers should also check for local standards that may dictate the use of more durable materials.

2. Plastic (PVC/HDPE)

Key Properties: Plastic sonotubes, typically made from PVC or HDPE, offer excellent corrosion resistance and can withstand a wide range of temperatures, often exceeding 140°F (60°C). They are also resistant to chemicals and moisture.

Pros & Cons: The main advantage of plastic tubes is their durability and resistance to environmental factors. They are lightweight and easy to transport. However, they can be more expensive than cardboard and may require specialized manufacturing processes, which could lead to longer lead times.

Illustrative image related to sonotube installation

Impact on Application: Plastic sonotubes are ideal for applications in corrosive environments or where moisture is a concern, making them suitable for use in coastal areas and regions with heavy rainfall.

International Considerations: Buyers from the Middle East and Europe should ensure compliance with local standards such as ASTM or DIN for plastic materials. Additionally, there may be preferences for recycled materials in certain markets.

3. Steel

Key Properties: Steel sonotubes provide exceptional strength and durability, withstanding high pressures and temperatures. They are resistant to corrosion when properly treated and can last for decades.

Illustrative image related to sonotube installation

Pros & Cons: The key advantage of steel is its structural integrity, making it suitable for heavy-duty applications. However, steel sonotubes are significantly heavier and more expensive than other materials. The manufacturing process is complex, often requiring welding and treatment for corrosion resistance.

Impact on Application: Steel is ideal for permanent structures and applications requiring high load-bearing capacity. It is particularly useful in industrial settings or where heavy machinery is involved.

International Considerations: Compliance with international standards such as JIS or ASTM is critical. Buyers in regions like Saudi Arabia and Nigeria should also consider the availability of materials and local manufacturing capabilities.

4. Fiber-Reinforced Composite

Key Properties: Fiber-reinforced composites combine materials like fiberglass with resins to create lightweight, strong sonotubes. They offer high corrosion resistance and can withstand temperatures up to 300°F (149°C).

Pros & Cons: The primary advantage is their lightweight nature combined with high strength, making them easy to handle and transport. However, they can be more costly to produce and may require specialized manufacturing techniques.

Impact on Application: These composites are suitable for applications in extreme environments, including chemical plants and coastal areas, where traditional materials may fail.

International Considerations: Buyers should be aware of compliance with local standards and certifications, especially in regions focusing on sustainability and advanced materials.

Illustrative image related to sonotube installation

Summary Table

| Material | Typical Use Case for sonotube installation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cardboard | Temporary structures, controlled environments | Low cost and biodegradable | Less durable in wet conditions | Low |

| Plastic (PVC/HDPE) | Corrosive environments, humid climates | Excellent corrosion resistance | Higher cost and longer lead times | Medium |

| Steel | Heavy-duty applications, permanent structures | Exceptional strength and durability | Heavy and expensive | High |

| Fiber-Reinforced Composite | Extreme environments, chemical plants | Lightweight and strong | Higher production costs | High |

Selecting the appropriate material for sonotube installation is essential for ensuring the longevity and effectiveness of the structure. Each material offers distinct advantages and limitations that must be considered in the context of specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for sonotube installation

What Are the Key Stages in the Manufacturing Process of Sonotubes?

The manufacturing of sonotubes, which are essential for concrete forming applications, involves several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The primary material used for sonotubes is cardboard, often treated to withstand moisture and provide structural integrity. Manufacturers begin by sourcing high-quality, durable paper that meets specific strength requirements. This material is then processed into sheets, which are cut to the required dimensions based on the sonotube size specifications.

-

Forming: In this stage, the cut sheets are rolled into cylindrical shapes. This is typically achieved using automated machinery that ensures consistent diameter and wall thickness. The edges of the rolled paper are glued together using a strong adhesive that can endure the pressures exerted during concrete pouring.

-

Assembly: After forming, the sonotubes are stacked and prepared for quality checks. This stage may involve the addition of features such as lifting rings or other accessories that facilitate handling and installation.

-

Finishing: The final stage includes cutting the tubes to specific lengths and applying any necessary surface treatments. Some manufacturers may add a coating to enhance moisture resistance or durability. The finished sonotubes are then packaged for shipment.

How Is Quality Assurance Maintained During Sonotube Manufacturing?

Quality assurance (QA) is crucial in the sonotube manufacturing process to ensure that the products meet international standards and customer specifications.

Illustrative image related to sonotube installation

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines the requirements for a quality management system. Compliance with ISO standards ensures that the manufacturing process is consistently monitored and improved. Additionally, specific certifications such as CE marking or API (American Petroleum Institute) standards may be necessary, depending on the intended application of the sonotubes.

-

Quality Control Checkpoints: Quality control (QC) is integrated at various checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, ongoing assessments are conducted to monitor production consistency, including dimensions and structural integrity.

– Final Quality Control (FQC): Before packaging, finished sonotubes undergo rigorous testing for strength, moisture resistance, and overall quality. -

Common Testing Methods: Various testing methods are employed, including:

– Compression Testing: To assess the load-bearing capacity of the sonotubes.

– Moisture Resistance Testing: Ensuring that the tubes can withstand exposure to wet concrete without deforming.

– Dimensional Accuracy Checks: Verifying that the tubes meet precise size specifications.

What Actions Can B2B Buyers Take to Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are actionable steps:

-

Supplier Audits: Conducting on-site audits of suppliers allows buyers to assess the manufacturing processes, quality control measures, and adherence to international standards firsthand. This practice fosters transparency and trust.

-

Requesting Quality Reports: Buyers should ask for detailed quality control reports that document the results of IQC, IPQC, and FQC. These documents should outline testing methods, results, and any corrective actions taken in the event of discrepancies.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This step is particularly valuable for buyers unfamiliar with local manufacturing practices.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing sonotubes internationally, buyers must navigate several nuances in quality control:

-

Understanding Local Standards: Different regions may have varying quality standards. It is crucial for buyers to familiarize themselves with local regulations and how they align with international standards. For instance, in the Middle East, compliance with local building codes is vital.

-

Cultural and Operational Differences: Cultural attitudes toward quality and business practices can vary significantly across regions. Buyers should consider these differences when negotiating contracts and setting quality expectations.

-

Supply Chain Considerations: Delays in shipping or customs clearance can affect the integrity of the product. Buyers should ensure that suppliers have robust logistics and supply chain management processes in place to mitigate these risks.

How Can B2B Buyers Ensure Long-Term Quality in Sonotube Suppliers?

Building long-term relationships with suppliers can lead to consistent quality and reliability. Here are strategies for maintaining these relationships:

-

Regular Communication: Establishing open lines of communication with suppliers can help address any quality concerns promptly. Regular updates on production status and quality issues can foster collaboration.

-

Performance Reviews: Implementing periodic performance reviews can help assess suppliers against established KPIs (Key Performance Indicators) related to quality, delivery times, and responsiveness.

-

Continuous Improvement Programs: Encourage suppliers to adopt continuous improvement initiatives. This can involve training programs for staff, investment in better equipment, or innovation in manufacturing processes.

By understanding the manufacturing processes and quality assurance practices associated with sonotube production, B2B buyers can make informed decisions and foster partnerships that enhance their project outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sonotube installation’

To ensure a successful sonotube installation, B2B buyers must approach procurement systematically. This checklist serves as a comprehensive guide for sourcing the necessary materials and services while ensuring quality and efficiency throughout the process.

Illustrative image related to sonotube installation

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clarify the technical requirements for your sonotube installation project. This includes determining the size, length, and material specifications of the sonotubes based on local environmental conditions and building codes.

– Consider factors such as load-bearing requirements and frost depth, which can significantly affect the installation process.

Step 2: Research Reputable Suppliers

Identify suppliers that specialize in sonotubes and related installation materials. Conduct thorough research to find companies with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe.

– Look for suppliers who have experience with international shipping and compliance with local regulations. Reading customer reviews and case studies can provide insights into their reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Ensure they can provide certifications for quality and safety standards. This step will help you avoid delays and ensure your project adheres to local building codes.

Step 4: Request Samples and Product Specifications

Once you have shortlisted potential suppliers, request samples of the sonotubes and detailed product specifications. This allows you to assess the quality of the materials firsthand.

– Verify that the samples meet your defined specifications and are suitable for your project’s environmental conditions. Pay attention to the durability and ease of handling.

Step 5: Confirm Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms with your selected suppliers. Understanding the total cost of ownership is essential for budgeting.

– Ensure that all costs, including shipping, taxes, and potential tariffs, are clearly outlined. Negotiate payment terms that align with your cash flow and project timelines.

Step 6: Assess Installation Services

If your project requires installation services, inquire about the availability of experienced contractors. Some suppliers may offer installation as part of their service package.

– Evaluate the contractor’s credentials and previous project experience. A skilled installation team can significantly impact the success of your sonotube installation.

Step 7: Plan for Logistics and Delivery

Finally, establish a logistics plan that details the delivery schedule and handling procedures for your sonotubes. Timely delivery is critical to keep your project on track.

– Confirm the supplier’s capabilities regarding shipping and handling, including any special requirements for transporting large or bulky items. Ensure that you have the necessary equipment and personnel ready for unloading and installation.

By following this step-by-step checklist, B2B buyers can effectively navigate the procurement process for sonotube installation, ensuring that they source high-quality materials and services that meet their project needs.

Comprehensive Cost and Pricing Analysis for sonotube installation Sourcing

What Are the Key Cost Components of Sonotube Installation?

When sourcing sonotube installation services, it’s crucial to understand the various cost components involved. The primary elements include:

-

Materials: The cost of sonotubes varies based on size, thickness, and material quality. Standard cardboard sonotubes tend to be less expensive than specialized versions made from reinforced materials. Additionally, concrete, rebar, and any other supporting materials are significant contributors to the overall material cost.

-

Labor: Labor costs can fluctuate widely based on local wage standards, the complexity of the installation, and the experience level of the workforce. In regions like Africa and South America, labor may be more affordable, while in Europe and the Middle East, skilled labor rates can drive costs higher.

-

Manufacturing Overhead: This encompasses the costs associated with producing sonotubes, including facility expenses, utilities, and equipment maintenance. Understanding the manufacturing overhead can provide insights into the pricing structure from suppliers.

-

Tooling: Depending on the scale of your project, specific tools may be required for installation, such as mixers, excavators, and other equipment. These costs should be factored into the total project expenditure.

-

Quality Control (QC): Ensuring the integrity and performance of sonotubes can involve additional QC measures, particularly if the installation is for critical structures. This can include testing and certification costs.

-

Logistics: Shipping and handling costs are vital, especially for international buyers. The distance from the supplier to the job site can significantly affect logistics costs, influenced by fuel prices, customs, and import duties.

-

Margin: Suppliers typically incorporate a profit margin into their pricing, which can vary based on market demand and competition. Understanding typical margins in your region can assist in negotiating fair prices.

How Do Price Influencers Affect Sonotube Installation Costs?

Several factors can influence the pricing of sonotube installation:

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually lead to reduced per-unit costs. If your project can accommodate bulk purchasing, negotiating for better rates can be advantageous.

-

Specifications and Customization: Custom sonotubes designed for specific applications will generally incur higher costs than standard models. Clearly defining your project requirements can help manage expenses.

-

Quality and Certifications: Higher quality materials and certified products often come at a premium. However, investing in quality can reduce long-term costs associated with repairs and replacements.

-

Supplier Factors: Supplier reputation, reliability, and financial stability can impact pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: The terms of sale (Incoterms) dictate who bears the cost and responsibility for logistics. Understanding these terms is crucial for budgeting and can lead to savings if negotiated effectively.

What Negotiation Tips Can Help Buyers Achieve Cost Efficiency?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings:

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial price. This includes maintenance, durability, and performance over time, which can lead to better long-term investment decisions.

-

Research Market Prices: Familiarizing yourself with current market prices can empower you during negotiations. Understanding price ranges for different specifications allows for informed discussions with suppliers.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and other benefits. Consider establishing partnerships that extend beyond single transactions.

-

Explore Multiple Quotes: Obtaining quotes from various suppliers can provide leverage during negotiations. It also helps in understanding the competitive landscape and identifying the best value.

-

Be Flexible: If your project timeline allows, being flexible with delivery schedules can help negotiate better terms, particularly in logistics costs.

Disclaimer

The prices and insights provided in this analysis are indicative and may vary based on specific project requirements, geographic location, and market conditions. Always conduct thorough research and consult with multiple suppliers to obtain accurate and current pricing for your sonotube installation needs.

Alternatives Analysis: Comparing sonotube installation With Other Solutions

When evaluating construction methods for foundation support, it’s crucial to consider various solutions that might meet the specific needs of a project. Sonotube installation, known for its efficiency and ease of use, is just one option among several. Below, we compare sonotube installation with two viable alternatives: traditional concrete footings and helical piers.

| Comparison Aspect | Sonotube Installation | Traditional Concrete Footings | Helical Piers |

|---|---|---|---|

| Performance | Strong load-bearing capacity; reliable | High durability; good for various loads | Excellent for uneven terrains; quick installation |

| Cost | Moderate; economical for small projects | Higher due to labor and materials | Higher upfront cost but reduces time on site |

| Ease of Implementation | Simple setup; requires basic tools | More labor-intensive; requires forms and curing time | Specialized equipment needed; requires professional installation |

| Maintenance | Minimal; lasts long with proper use | Can require periodic inspections | Minimal; typically maintenance-free once installed |

| Best Use Case | Residential decks, patios, light structures | Larger buildings, commercial applications | Areas with unstable soil, deep foundations |

What are the Pros and Cons of Traditional Concrete Footings Compared to Sonotube Installation?

Traditional concrete footings are a time-tested foundation method that provides significant strength and stability, particularly for larger structures. Their main advantages include high durability and suitability for various load types, making them ideal for commercial buildings. However, they are more labor-intensive and require a longer curing time, which can delay project timelines. Additionally, the costs can escalate due to the need for labor and materials, especially in regions where skilled labor is scarce.

How Do Helical Piers Compare to Sonotube Installation in Terms of Performance and Cost?

Helical piers are an innovative solution for foundation support, particularly in areas with unstable soil conditions. They excel in terms of speed of installation and can be used in tight spaces where traditional methods may struggle. Their capacity to bear heavy loads makes them suitable for both residential and commercial projects. However, the initial costs can be higher than sonotube installation, and they require specialized equipment and trained professionals for installation. This may pose a challenge for projects in regions with limited access to such expertise.

How Can B2B Buyers Choose the Right Solution for Their Specific Needs?

When deciding between sonotube installation and its alternatives, B2B buyers should consider several factors, including project size, soil conditions, and budget constraints. For smaller residential projects, sonotubes offer a cost-effective and straightforward solution. In contrast, larger commercial projects may benefit from the durability of traditional concrete footings. If the project is located in an area with challenging soil conditions, helical piers could be the best choice despite their higher initial cost. Ultimately, understanding the specific requirements and constraints of a project will guide buyers in selecting the most appropriate foundation solution.

Essential Technical Properties and Trade Terminology for sonotube installation

What Are the Key Technical Properties of Sonotubes in Installation?

When considering sonotube installation, understanding the technical properties of the tubes is crucial for ensuring structural integrity and meeting project specifications. Here are several critical specifications to consider:

-

Material Grade

Sonotubes are typically made from high-quality cardboard or composite materials. The grade of the material affects the tube’s strength, moisture resistance, and durability. For international buyers, selecting a material grade that can withstand local climate conditions is essential to ensure longevity and performance. -

Diameter and Length Tolerance

Standard sonotubes come in various diameters, commonly ranging from 6 inches to 24 inches, with lengths varying typically between 8 to 12 feet. Tolerance refers to the permissible variation in these measurements. Precise dimensions are vital as they affect the load-bearing capacity and compatibility with concrete forms. Inaccurate dimensions can lead to structural failure, impacting project timelines and costs. -

Compressive Strength

This property indicates how much weight a sonotube can support before failing. The compressive strength is influenced by both the material used and the diameter of the tube. For B2B buyers, knowing the compressive strength helps in determining whether the sonotube is suitable for specific construction applications, especially in regions with varying soil and load conditions. -

Water Resistance

Sonotubes often feature a moisture-resistant coating that prevents the absorption of water during the concrete curing process. This property is particularly important in humid or rainy climates, as it helps to maintain the integrity of the concrete and the overall structure. Ensuring water resistance can mitigate risks associated with mold and degradation. -

Weight Capacity

The weight capacity of a sonotube must be assessed based on the anticipated load it will bear once filled with concrete. This involves not only the weight of the concrete but also any additional structural loads from above. Understanding weight capacity is crucial for project safety and compliance with building regulations.

What Are Common Trade Terms Related to Sonotube Installation?

Navigating the purchasing and installation process involves familiarizing oneself with specific trade terminology. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of sonotubes, knowing the OEM can help buyers ensure they are purchasing high-quality, reliable products that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, particularly in regions with limited supply, as it can affect inventory costs and lead times. It’s advisable to negotiate terms that align with project needs and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing and terms for specific products. When seeking sonotubes, issuing an RFQ allows buyers to gather competitive pricing and evaluate suppliers based on their offerings and capabilities. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to navigate shipping, insurance, and delivery responsibilities effectively. -

Lead Time

This term refers to the amount of time it takes from placing an order to the delivery of the product. In the construction industry, understanding lead times for sonotubes can significantly impact project scheduling, especially in regions where logistics might cause delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their project requirements, ensuring successful sonotube installations.

Navigating Market Dynamics and Sourcing Trends in the sonotube installation Sector

What Are the Key Market Dynamics and Trends in Sonotube Installation?

The sonotube installation sector is witnessing significant transformations driven by several global factors. As urbanization accelerates, particularly in regions like Africa, South America, and the Middle East, the demand for reliable foundation solutions is on the rise. This trend is further augmented by increased investment in infrastructure projects, including residential, commercial, and industrial developments. International buyers are now focusing on sourcing practices that not only meet structural integrity but also align with modern construction standards.

Emerging technologies are reshaping the landscape of sonotube installation. Innovations in concrete mixing and pouring techniques, along with the use of advanced materials, are enhancing efficiency and reducing labor costs. Automated processes, such as robotic concrete placement and real-time monitoring of installation conditions, are gaining traction. These technological advancements allow for precision in construction, minimizing errors and ensuring compliance with safety regulations.

Moreover, the sourcing dynamics are evolving as buyers seek partnerships with suppliers who can offer a comprehensive solution—from raw materials to installation services. For international B2B buyers, especially those in regions like Saudi Arabia and Nigeria, understanding local regulations and market conditions is essential. Collaboration with local suppliers who have insights into regional practices can lead to more successful project outcomes.

How Does Sustainability Influence Sourcing Practices in Sonotube Installation?

Sustainability has become a critical factor in the sourcing of materials for sonotube installation. The environmental impact of construction practices is under scrutiny, prompting buyers to seek eco-friendly alternatives. Sustainable sourcing involves selecting materials that are responsibly harvested and produced, reducing carbon footprints, and ensuring minimal disruption to local ecosystems.

Illustrative image related to sonotube installation

Ethical supply chains are gaining prominence as businesses recognize their responsibility toward social and environmental stewardship. Buyers are increasingly looking for suppliers who prioritize transparency and ethical practices, including fair labor conditions and community engagement. Certifications such as FSC (Forest Stewardship Council) for wood-based products and LEED (Leadership in Energy and Environmental Design) for overall sustainability are becoming prerequisites in supplier evaluation.

The adoption of “green” materials in sonotube installation, such as recycled aggregates and low-emission concrete, is also on the rise. These materials not only help in reducing environmental impact but can also improve the durability and performance of foundations. By prioritizing sustainability and ethical sourcing, international B2B buyers can enhance their brand reputation and meet the growing demand for eco-conscious construction solutions.

What Is the Historical Context of Sonotube Installation?

Sonotubes, or cardboard tube forms, have a rich history dating back to their introduction in the mid-20th century. Initially used primarily in North America for creating concrete piers and foundations, their effectiveness in simplifying the construction process quickly gained recognition. Over the years, sonotubes have evolved to accommodate various construction needs, including residential, commercial, and civil engineering projects.

As global construction practices have advanced, so too has the technology behind sonotubes. The introduction of enhanced materials and designs has improved their strength and durability, making them a staple in modern construction. Today, sonotubes are not just limited to traditional uses; they are also being adapted for innovative applications in landscaping and architectural projects. This evolution reflects the growing demand for efficient, reliable, and sustainable solutions in the construction industry, positioning sonotubes as a critical component for international B2B buyers looking to optimize their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of sonotube installation

-

How do I ensure the quality of sonotube installation for my projects?

To ensure quality sonotube installation, it is crucial to work with experienced contractors who understand the local soil conditions and frost depths. Verify their credentials and check references from previous projects. Consider implementing a quality assurance process that includes regular site inspections and adherence to industry standards. Additionally, utilizing high-quality sonotubes and materials will enhance durability and performance. Implementing a clear communication channel with your installation team can also mitigate potential issues during the process. -

What is the best type of sonotube for various soil conditions?

The best type of sonotube depends on the specific soil conditions at your site. For sandy or loose soils, larger diameter tubes may provide better stability, while narrower tubes can work well in compacted or clay-heavy soils. It is advisable to consult with a geotechnical engineer to evaluate the soil and recommend the appropriate sonotube diameter and material, such as cardboard or plastic, which can influence load-bearing capacity and resistance to moisture. -

How can I customize sonotube sizes for my project needs?

Customization options for sonotubes typically include adjusting diameter and length to meet specific project requirements. Many suppliers offer bespoke solutions, so it’s essential to communicate your needs clearly, including load specifications and environmental factors. When sourcing suppliers, inquire about their customization capabilities and lead times. Request samples or prototypes when possible to evaluate the material and performance before full-scale production. -

What are the minimum order quantities (MOQ) for sonotubes from suppliers?

Minimum order quantities (MOQ) can vary widely among suppliers and depend on factors such as production capacity, material type, and shipping logistics. Typically, MOQs may range from a few dozen to several hundred units. When sourcing internationally, consider the impact of shipping costs on smaller orders. It is advisable to discuss your project needs with suppliers to negotiate favorable terms, especially if you require a lower MOQ for initial projects. -

What payment terms should I expect when sourcing sonotubes internationally?

Payment terms can differ significantly among international suppliers, but common practices include advance payment, partial payment upon order confirmation, or payment upon delivery. It is essential to clarify these terms upfront and ensure they align with your budget and cash flow. Consider utilizing secure payment methods, such as letters of credit or escrow services, to protect your investment. Establishing a good relationship with your supplier may also lead to more favorable terms in future transactions. -

How do I vet suppliers for sonotube installation?

To effectively vet suppliers, start by researching their industry reputation, looking for reviews or testimonials from previous clients. Request certifications that demonstrate compliance with international quality standards, such as ISO or ASTM. Conduct interviews to assess their expertise and ask for case studies of similar projects they’ve completed. Additionally, consider visiting their facilities or requesting virtual tours to gain a better understanding of their manufacturing processes and capabilities. -

What logistics considerations should I keep in mind for international shipping of sonotubes?

When planning logistics for international shipping, consider factors such as shipping methods (air vs. sea), customs regulations, and import duties. Evaluate the supplier’s shipping capabilities and ensure they can handle packaging that protects the sonotubes during transit. It’s also important to factor in lead times, as delays can impact your project schedule. Collaborate with logistics experts or freight forwarders familiar with your destination country to streamline the process and mitigate potential issues. -

What are the common challenges in sonotube installation, and how can they be addressed?

Common challenges in sonotube installation include uneven ground, soil instability, and weather conditions. To address these, conduct thorough site assessments before installation. Ensure that the installation team is equipped with appropriate tools and knowledge to handle unexpected issues, such as using excavation equipment for uneven terrain. Implementing a contingency plan that includes alternative solutions for adverse weather or soil conditions can also help maintain project timelines and ensure successful outcomes.

Top 2 Sonotube Installation Manufacturers & Suppliers List

1. JLC Online – Cardboard Tube Forms and Concrete Solutions

Domain: jlconline.com

Registered: 1998 (27 years)

Introduction: 12-inch-diameter cardboard tube forms (usually Sonotubes), #4 rebar, sack concrete mix, Imer Rollbeta mixer (cost around $600, can handle two 80-pound bags at a time), each tube and footing requires eight bags of concrete mix.

2. The VanderVeen House – Concrete Deck Solutions

Domain: thevanderveenhouse.com

Registered: 2015 (10 years)

Introduction: Concrete deck footings and sonotubes; 2′ x 2′ frames made from 2″ x 6″ pressure treated lumber; Portland cement ordered from Morrisburg Building Centre; gravel for concrete; rebar for connecting footings to sonotubes; cardboard sonotubes; metal plates for deck posts; mini-excavator for digging holes; concrete mixer used for mixing concrete.

Strategic Sourcing Conclusion and Outlook for sonotube installation

What Are the Key Takeaways for Strategic Sourcing in Sonotube Installation?

In the realm of sonotube installation, strategic sourcing emerges as a crucial element that can significantly influence project success. By prioritizing quality materials and reliable suppliers, businesses can enhance the durability and efficiency of their construction projects. Key considerations include selecting appropriate tube sizes, ensuring compliance with local building codes, and integrating advanced techniques for installation, which collectively contribute to structural integrity.

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the value of strategic sourcing cannot be overstated. By building relationships with trusted suppliers and leveraging local knowledge, companies can optimize their procurement processes, reduce costs, and improve project timelines. This proactive approach not only safeguards investments but also fosters sustainable practices within the construction industry.

What Does the Future Hold for Sonotube Installation?

Looking ahead, the demand for efficient and cost-effective construction solutions will continue to rise. Embracing innovations in sonotube technology and installation practices will be vital. We encourage buyers to explore opportunities for collaboration and knowledge sharing within their networks. By doing so, they can position themselves at the forefront of the industry and drive their projects toward success. Engage today with suppliers who understand your unique needs and can help you navigate the complexities of sonotube installation effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to sonotube installation