Choosing Your Small Vending Machines: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for small vending machines

In an increasingly competitive landscape, sourcing small vending machines presents unique challenges for international B2B buyers. With the growing demand for automated retail solutions across diverse markets—especially in regions like Africa, South America, the Middle East, and Europe—businesses must navigate a complex web of options, regulations, and supplier capabilities. This guide serves as a comprehensive resource for understanding the myriad types of small vending machines available, including snack dispensers, beverage coolers, and specialized units for personal care products.

By exploring various applications, from corporate offices to educational institutions, this guide highlights how these machines can enhance convenience and accessibility for consumers. Additionally, we provide insights into effective supplier vetting processes, enabling buyers to identify reputable manufacturers and distributors who can meet their specific needs. Cost considerations are also addressed, offering a clear framework for budgeting that aligns with market expectations.

Ultimately, this guide empowers B2B buyers to make informed purchasing decisions, equipping them with the knowledge necessary to select the right small vending machines for their operational requirements. By understanding the landscape, potential challenges, and available solutions, businesses can leverage vending technology to boost sales, streamline operations, and enhance customer satisfaction.

Understanding small vending machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Snack Vending Machines | Multiple shelves for various snacks; compact design | Offices, schools, gyms | Pros: High demand for snacks; easy to stock. Cons: Limited to snack items only. |

| Personal Care Product Machines | Dispenses hygiene products; usually found in restrooms | Airports, malls, public restrooms | Pros: Meets urgent consumer needs; low maintenance. Cons: Niche market; limited product range. |

| Electronic Device Vending Machines | Specialized for tech gadgets; often touchscreen-enabled | Airports, tech hubs, universities | Pros: High-value items; attracts tech-savvy consumers. Cons: Higher initial investment; theft risk. |

| Toy Vending Machines | Dispenses small toys; often colorful and appealing | Arcades, amusement parks, family venues | Pros: Captivates children; low operational cost. Cons: Seasonal demand; limited adult market. |

| Healthy Food Vending Machines | Focus on nutritious snacks and beverages; promotes wellness | Offices, schools, gyms | Pros: Growing health trend; appeals to health-conscious consumers. Cons: Higher costs for healthy options. |

What are the Key Characteristics of Snack Vending Machines?

Snack vending machines are designed to accommodate a variety of packaged snacks, making them ideal for high-traffic areas such as offices, schools, and gyms. They typically feature multiple shelves that allow for easy stocking and a wide selection of items. B2B buyers should consider the machine’s capacity, payment options, and energy efficiency. The high demand for quick snacks ensures a steady revenue stream, but buyers should be aware of the potential for limited product variety.

How Do Personal Care Product Machines Serve Businesses?

Personal care product vending machines are strategically placed in locations like airports and public restrooms to provide convenience for consumers in need of hygiene products. These machines typically require minimal maintenance and can be stocked with essential items such as hand sanitizers, deodorants, and feminine hygiene products. Businesses can benefit from the low operational costs and high demand, although the market is more niche, which may limit sales volume compared to traditional snack machines.

What Makes Electronic Device Vending Machines Unique?

Electronic device vending machines cater to tech enthusiasts and travelers by dispensing gadgets such as headphones, chargers, and other accessories. These machines often feature advanced technology, including touchscreen interfaces and secure payment systems. While they can generate significant revenue due to the high value of the products, B2B buyers must consider the higher initial investment and potential theft risks associated with valuable items.

Why Choose Toy Vending Machines for Family-Oriented Venues?

Toy vending machines are a popular choice in family-oriented venues like arcades and amusement parks. They typically dispense small, colorful toys that appeal to children, making them a fun attraction. While these machines have low operational costs and require minimal maintenance, their revenue potential can be seasonal, depending on the foot traffic and the time of year. B2B buyers should evaluate the target audience and location to ensure consistent demand.

How are Healthy Food Vending Machines Meeting Market Trends?

Healthy food vending machines focus on providing nutritious snacks and beverages, catering to the growing trend of health-conscious consumers. These machines can be strategically placed in offices, schools, and gyms where there is an increasing demand for healthier options. While they may have higher stocking costs due to premium products, they also attract a dedicated consumer base willing to pay for quality. B2B buyers should assess the local market’s health trends and consumer preferences before investing.

Key Industrial Applications of small vending machines

| Industry/Sector | Specific Application of small vending machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Dispensing personal care products in hospitals | Increases patient satisfaction and convenience | Ensure machines comply with health regulations; consider antimicrobial materials. |

| Education | Providing snacks and beverages in schools | Enhances student engagement and satisfaction | Focus on healthy options; consider payment flexibility (cashless systems). |

| Corporate Offices | Offering coffee, snacks, and drinks | Boosts employee morale and productivity | Look for machines with variety and ease of refilling; assess energy efficiency. |

| Hospitality | Mini bars in hotels and resorts | Adds convenience for guests, enhancing their stay | Select machines with secure payment options; consider space constraints. |

| Retail and Convenience Stores | Supplementing product offerings with vending machines | Increases sales without additional staff costs | Evaluate machine capacity and adaptability to different product types; consider local demand. |

How Are Small Vending Machines Transforming Healthcare Settings?

In healthcare facilities, small vending machines can dispense personal care products, such as hygiene items and snacks, directly to patients and visitors. This convenience significantly enhances patient satisfaction by providing immediate access to essential items without the need to visit a pharmacy or store. For international buyers, compliance with health regulations is crucial, so sourcing machines made from antimicrobial materials can provide added value and safety assurance.

What Role Do Small Vending Machines Play in Educational Institutions?

In educational settings, small vending machines serve as a valuable source for snacks and beverages, thereby enhancing student engagement and satisfaction. These machines can be strategically placed in hallways or cafeterias, allowing students to access nutritious options quickly. Buyers in Africa, South America, and Europe should prioritize healthy offerings and flexibility in payment methods, including cashless systems, to meet diverse student needs and preferences.

How Can Small Vending Machines Enhance Employee Experience in Corporate Offices?

Corporate offices are increasingly utilizing small vending machines to provide coffee, snacks, and drinks, which can boost employee morale and productivity. By offering a variety of options, companies can cater to different tastes and dietary requirements, creating a more enjoyable workplace environment. For B2B buyers, it’s essential to consider machines that are easy to refill and maintain, as well as those that are energy-efficient to align with sustainability goals.

Why Are Small Vending Machines Essential for the Hospitality Sector?

In the hospitality industry, mini bars equipped with small vending machines can enhance guest experiences by providing convenient access to snacks and drinks. This not only adds value to the guest’s stay but also allows hotels and resorts to increase their revenue without additional staffing. Buyers should focus on machines with secure payment options and those that fit within limited space constraints to maximize efficiency and guest satisfaction.

How Do Small Vending Machines Benefit Retail and Convenience Stores?

Retailers and convenience stores can supplement their product offerings with small vending machines, which can drive sales without the need for additional staff. These machines can be stocked with popular items, ensuring constant availability and convenience for customers. When sourcing these machines, it is important to evaluate their capacity and adaptability to various product types, as well as local consumer demand to optimize inventory and sales strategies.

3 Common User Pain Points for ‘small vending machines’ & Their Solutions

Scenario 1: Limited Product Variety Leading to Low Sales

The Problem: Many businesses investing in small vending machines face the challenge of offering a limited product selection. This restriction often results in customer dissatisfaction and reduced sales, especially in diverse markets like Africa and South America, where consumer preferences vary widely. For instance, a vending machine stocked primarily with snacks may not attract health-conscious consumers seeking nutritious options. As a result, businesses miss out on potential revenue streams and struggle to maintain consistent foot traffic.

The Solution: To overcome this issue, B2B buyers should consider a modular vending machine design that allows for easy product rotation and diversification. When sourcing machines, opt for models with adjustable shelving and multiple product slots to accommodate a wide array of items, such as healthy snacks, beverages, and personal care products. Collaborate with local suppliers to identify trending products that resonate with the target demographic. Regularly updating the machine’s inventory based on seasonal trends and consumer feedback will help keep offerings fresh and appealing, ultimately driving sales and customer loyalty.

Scenario 2: Inadequate Payment Options Hindering Transactions

The Problem: In today’s cashless economy, many small vending machines are outdated, relying solely on coin and cash transactions. This limitation can frustrate customers who prefer the convenience of card or mobile payments. For international buyers in regions like the Middle East and Europe, where digital payment methods are increasingly common, the absence of diverse payment options can lead to lost sales opportunities and decreased customer satisfaction.

The Solution: B2B buyers should prioritize vending machines equipped with modern payment systems, including card readers and mobile payment options like QR codes or NFC technology. When negotiating with suppliers, inquire about machines that support multiple payment methods, ensuring they are adaptable to various currencies and payment platforms. Additionally, consider partnering with payment service providers to integrate seamless transaction processes. Offering multiple payment options not only enhances customer experience but also increases the likelihood of impulse purchases, thus boosting overall profitability.

Scenario 3: Maintenance and Technical Issues Affecting Reliability

The Problem: Small vending machines can encounter technical malfunctions that disrupt service, leading to frustrated customers and potential revenue loss. Common issues include product jams, temperature control problems, and software glitches. For businesses operating in high-traffic environments, such as schools or offices, machine downtime can significantly impact service reliability and customer trust.

The Solution: To address maintenance challenges, B2B buyers should invest in vending machines with robust technical support and warranty options. When selecting a vendor, assess their reputation for customer service and the availability of remote monitoring features. Machines equipped with IoT technology can provide real-time data on inventory levels and operational status, allowing businesses to proactively address issues before they escalate. Establishing a routine maintenance schedule and training staff on basic troubleshooting can also enhance machine reliability. By ensuring consistent operation and swift response to technical issues, businesses can maintain high customer satisfaction and loyalty.

Strategic Material Selection Guide for small vending machines

When selecting materials for small vending machines, several factors come into play, including durability, cost-effectiveness, and compliance with international standards. Here, we analyze four common materials used in the construction of small vending machines: stainless steel, glass, plastic, and aluminum. Each material has unique properties and implications for performance, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Stainless Steel for Small Vending Machines?

Stainless steel is widely recognized for its excellent corrosion resistance and durability, making it an ideal choice for vending machines that may be exposed to various environmental conditions. It can withstand high temperatures and pressures, which is particularly beneficial for machines dispensing heated or cold products. The material is also easy to clean, ensuring hygiene standards are maintained.

Pros: The primary advantages of stainless steel include its longevity, aesthetic appeal, and resistance to rust and staining. It is a robust material that can endure the wear and tear of frequent use.

Cons: On the downside, stainless steel can be more expensive than other materials, which may impact the overall cost of the vending machine. Additionally, manufacturing processes can be complex, requiring specialized equipment and expertise.

Impact on Application: Stainless steel is suitable for a wide range of products, including beverages and snacks, as it does not react with food items. However, international buyers should ensure compliance with food safety standards in their respective regions.

How Does Glass Enhance the Functionality of Small Vending Machines?

Glass, particularly tempered glass, is often used for the doors of vending machines. Its transparency allows customers to see the products inside, which can enhance sales through visual appeal. Tempered glass is known for its strength and safety, as it shatters into small, blunt pieces rather than sharp shards.

Pros: The key advantage of using glass is its ability to provide a clear view of the products, which can significantly improve customer engagement. It also offers a modern aesthetic that can attract more buyers.

Cons: However, glass is more fragile than metals and can be prone to breakage. This can lead to increased maintenance costs and potential safety hazards.

Impact on Application: Glass is compatible with a wide range of products, but its use requires careful consideration of the machine’s location to minimize the risk of damage. Buyers should also ensure that glass components meet safety standards relevant to their region.

What Role Does Plastic Play in the Design of Small Vending Machines?

Plastic is often used for internal components and housing of vending machines due to its lightweight nature and versatility. It can be molded into various shapes, allowing for innovative designs that can accommodate a variety of products.

Pros: The main advantages of plastic include its low cost and ease of manufacturing. It is also resistant to corrosion, making it suitable for machines that dispense snacks and beverages.

Cons: However, plastic may not be as durable as metals, particularly in high-traffic areas. It can also be susceptible to UV degradation if exposed to sunlight for extended periods.

Impact on Application: While plastic is suitable for many applications, it is essential for international buyers to consider local regulations regarding plastic use, especially in food-related applications.

Why Is Aluminum a Popular Choice for Small Vending Machines?

Aluminum is another common material used in vending machines, known for its lightweight and strength. It is resistant to corrosion and can be easily recycled, making it an environmentally friendly option.

Pros: The key advantages of aluminum include its lightweight nature, which makes transportation easier, and its resistance to rust. It is also generally less expensive than stainless steel.

Cons: However, aluminum may not offer the same level of durability as stainless steel, particularly in terms of structural integrity under heavy use.

Impact on Application: Aluminum is suitable for a variety of products but should be evaluated for compliance with international standards, especially in regions with strict regulations regarding materials used in food and beverage dispensing.

Summary of Material Selection for Small Vending Machines

| Material | Typical Use Case for small vending machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | External casing, product compartments | Excellent durability and hygiene | Higher cost and manufacturing complexity | High |

| Glass | Display doors | Enhances product visibility | Fragile and prone to breakage | Medium |

| Plastic | Internal components, housing | Low cost and easy to mold | Less durable and UV sensitive | Low |

| Aluminum | Structural components, frames | Lightweight and corrosion-resistant | Lower durability compared to steel | Medium |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for small vending machines

What Are the Key Stages in the Manufacturing Process of Small Vending Machines?

The manufacturing of small vending machines involves several critical stages that ensure the final product meets both functional and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in the manufacturing process involves sourcing high-quality materials. Common materials include stainless steel for the body and tempered glass for the front display. Suppliers must ensure that these materials meet international standards for durability and safety. Before fabrication, materials undergo inspections to confirm compliance with specifications.

-

Forming: This stage involves shaping the materials into the desired components. Techniques such as laser cutting and CNC machining are employed to achieve precise dimensions. The forming process must account for the functionality of the machine, ensuring that slots for products, payment systems, and cooling units are accurately designed.

-

Assembly: Once components are formed, they are assembled into the final product. This includes integrating the refrigeration system, payment systems (cash and card readers), and electronic controls. Each assembly line should adhere to strict protocols to minimize errors. For instance, automated assembly tools may be used for consistency, followed by manual checks for complex components.

-

Finishing: The final stage involves applying protective coatings and conducting aesthetic enhancements. This may include powder coating for durability and visual appeal, as well as the installation of user interfaces like touch screens. Quality checks at this stage ensure that all components work harmoniously and meet design specifications.

How Is Quality Assurance Implemented in Small Vending Machine Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that small vending machines are safe, reliable, and compliant with international standards. Various QA processes are implemented, including adherence to ISO standards and industry-specific certifications.

-

International Standards Compliance: Many manufacturers pursue ISO 9001 certification, which outlines requirements for a quality management system. This ensures that processes are standardized and continuously improved. Additionally, compliance with CE marking (European Conformity) and API (American Petroleum Institute) standards may be necessary, depending on the machine’s intended market.

-

Quality Control Checkpoints: Manufacturers typically establish multiple checkpoints throughout the production process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet required specifications.

– In-Process Quality Control (IPQC): Continuous monitoring is conducted during the manufacturing stages to detect and rectify defects early.

– Final Quality Control (FQC): A thorough inspection of the completed machines is performed before they are packaged for shipment. This may involve functional testing, safety checks, and verification of features such as payment processing and product dispensing. -

Common Testing Methods: Various testing methods are employed to ensure product reliability. These include:

– Electrical Testing: Checks for proper function of electrical components and safety features.

– Durability Testing: Simulates real-world usage to assess wear and tear over time.

– Temperature Control Testing: Ensures that refrigeration units maintain the required temperatures for perishable items.

What Should B2B Buyers Look for When Verifying Supplier Quality Control?

When sourcing small vending machines, B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. This not only ensures product reliability but also minimizes risks associated with international procurement.

-

Supplier Audits: Conducting supplier audits is a vital step in assessing quality control practices. Buyers should request detailed reports on the supplier’s quality management system, including any certifications obtained, such as ISO 9001. On-site audits can provide deeper insights into the manufacturing process and adherence to quality standards.

-

Quality Control Reports: Suppliers should provide regular QC reports that outline testing results, defect rates, and corrective actions taken. These documents can help buyers gauge the supplier’s commitment to quality and identify any recurring issues.

-

Third-Party Inspections: Engaging independent third-party inspection services can offer an unbiased assessment of the manufacturing process. These inspections can cover various aspects, including compliance with international safety standards, functional performance, and aesthetic quality.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial.

-

Understanding Local Regulations: Different regions may have specific regulations regarding product safety and compliance. Buyers should familiarize themselves with these regulations to ensure that the machines they procure meet local market requirements.

-

Cultural Considerations: Cultural differences can influence business practices and expectations. Building strong relationships with suppliers and maintaining open lines of communication can facilitate better understanding and adherence to quality standards.

-

Logistics and Supply Chain Management: Quality control does not end with manufacturing. Buyers must also consider logistics and supply chain management to ensure that products are handled appropriately during transport. This includes ensuring that machines are adequately packaged to prevent damage and that they are stored in suitable conditions before reaching the final destination.

By following these guidelines and understanding the manufacturing and quality assurance processes for small vending machines, B2B buyers can make informed decisions that enhance their procurement strategies and ensure successful market entry.

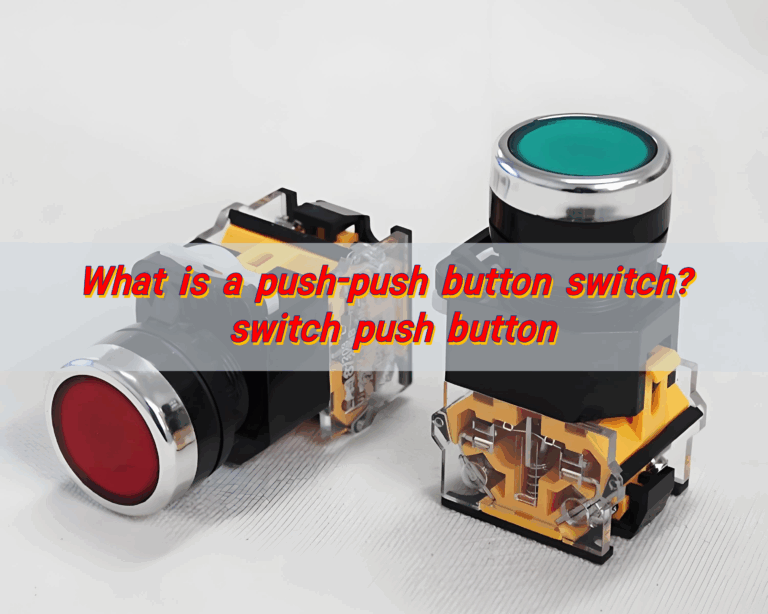

Illustrative image related to small vending machines

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small vending machines’

Introduction

Sourcing small vending machines for your business requires careful planning and consideration. This guide provides a practical checklist to help B2B buyers streamline the procurement process, ensuring you select the right machines that meet your specific needs and operational requirements.

1. Identify Your Target Market

Understanding your target market is essential for selecting the appropriate vending machine type. Consider the demographics, preferences, and purchasing habits of your intended audience. For instance, if you are targeting schools, snack and beverage machines may be ideal, while corporate offices might prefer healthier options.

2. Define Your Technical Specifications

Establish clear technical specifications based on your operational needs. This includes:

– Size and Capacity: Determine how much space you have and the volume of products you want to dispense.

– Power Requirements: Check the voltage and energy consumption to ensure compatibility with your location.

– Product Types: Decide on the range of items your machine will offer, such as snacks, drinks, or personal care products.

3. Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct thorough evaluations. Look for suppliers with a proven track record in the vending machine market. Request the following:

– Company Profiles: Understand their history, market presence, and expertise.

– References: Seek testimonials from clients in similar industries or regions to assess reliability and service quality.

4. Assess Machine Features and Technology

Modern vending machines come equipped with advanced features that can enhance user experience and operational efficiency. Key aspects to evaluate include:

– Payment Options: Ensure the machine supports multiple payment methods, including cash, credit cards, and mobile payments.

– Data Management: Opt for machines with built-in data tracking systems to monitor sales and inventory levels easily.

5. Check for Compliance and Certifications

Ensure that the machines comply with local regulations and industry standards. This is particularly important for food safety and electrical safety. Look for:

– Certifications: Verify that the machines meet standards such as CE, UL, or ISO.

– Warranty and Service Agreements: Confirm the terms of warranty and availability of technical support in case of malfunctions.

6. Negotiate Pricing and Terms

Once you have identified potential suppliers and evaluated their offerings, it’s time to negotiate pricing and contract terms. Consider:

– Bulk Purchase Discounts: Inquire about discounts for larger orders to optimize your budget.

– Payment Terms: Discuss flexible payment options that align with your cash flow needs.

7. Plan for Installation and Maintenance

Finally, ensure you have a plan for the installation and ongoing maintenance of the vending machines. This includes:

– Installation Services: Confirm if the supplier provides installation support and training for your staff.

– Maintenance Contracts: Consider establishing a maintenance agreement to ensure the machines remain operational and in good condition.

By following this checklist, B2B buyers can make informed decisions when procuring small vending machines, ensuring they select the right products for their business needs.

Comprehensive Cost and Pricing Analysis for small vending machines Sourcing

What Are the Key Cost Components for Sourcing Small Vending Machines?

When sourcing small vending machines, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

-

Materials: The quality and type of materials used, such as stainless steel for the cabinet and tempered glass for the display, significantly impact costs. Machines with advanced features like refrigeration systems and digital payment options will have higher material costs.

-

Labor: Labor costs encompass assembly, quality control, and installation. In regions with higher labor costs, such as Western Europe, this can elevate the overall price of the machines.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities and depreciation of equipment. Efficient manufacturing processes can help reduce these costs.

-

Tooling: If customized designs are required, tooling costs can increase. This involves creating specific molds or dies for unique machine features.

-

Quality Control (QC): Robust QC processes ensure machines meet safety and performance standards, which can add to the cost but are essential for international compliance.

-

Logistics: Shipping and handling costs vary by region. International buyers should account for customs duties and taxes, which can significantly affect the final cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. Understanding this can help in negotiations.

How Do Price Influencers Affect Small Vending Machine Costs?

Several factors influence the pricing of small vending machines, particularly in the international market:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Buyers should consider minimum order quantities (MOQs) to negotiate better pricing.

-

Specifications/Customization: Customized machines with specific features will generally cost more. Buyers should evaluate whether they require high-end features or if standard models suffice.

-

Materials: Higher quality materials will increase costs. Buyers should balance quality with budget constraints, especially in price-sensitive markets.

-

Quality and Certifications: Machines that meet international safety and quality standards often carry a premium price. Buyers in regions with strict regulations should prioritize certified suppliers.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their experience and service quality.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) will influence shipping costs and risk management. Buyers must clearly understand their responsibilities and potential additional costs.

What Are the Best Buyer Tips for Sourcing Small Vending Machines Internationally?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, consider the following tips:

-

Negotiate Effectively: Leverage volume purchases to negotiate better pricing. Don’t hesitate to ask for discounts, especially for first-time orders or bulk purchases.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, energy consumption, and potential downtime costs when evaluating suppliers.

-

Understand Pricing Nuances: Prices can vary significantly based on geographic location, currency fluctuations, and local market conditions. Buyers should conduct thorough market research to avoid overpaying.

-

Evaluate Shipping and Logistics: Factor in the costs of shipping, including potential delays and tariffs. Working with suppliers who understand the logistics of your region can help streamline this process.

-

Consider Local Support: Sourcing from suppliers with local representation can provide better service and support, reducing costs associated with repairs and maintenance.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier agreements, and specific machine configurations. Always seek quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing small vending machines With Other Solutions

Exploring Viable Alternatives to Small Vending Machines

In today’s fast-paced commercial environment, businesses are constantly seeking innovative solutions for providing products to customers efficiently. While small vending machines offer convenience and accessibility, there are several alternative solutions that can fulfill similar needs. This section compares small vending machines with two viable alternatives: automated retail kiosks and on-demand delivery services. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions that align with their operational goals.

| Comparison Aspect | Small Vending Machines | Automated Retail Kiosks | On-Demand Delivery Services |

|---|---|---|---|

| Performance | Quick product dispensing, minimal wait time | Interactive interface, customizable product selection | Fast delivery, but dependent on third-party logistics |

| Cost | Generally low initial investment; ongoing maintenance costs | Higher initial setup costs; potential for higher ROI | Variable costs based on delivery fees and service charges |

| Ease of Implementation | Simple setup, minimal infrastructure required | Requires more extensive setup, including technology integration | Easy to implement but relies on existing infrastructure |

| Maintenance | Regular restocking and servicing needed | Requires software updates and hardware maintenance | Minimal maintenance; relies on service providers |

| Best Use Case | High foot traffic areas like offices and schools | Retail environments needing product diversity and customer interaction | Areas with high demand for convenience and instant access to products |

What Are the Advantages and Disadvantages of Automated Retail Kiosks?

Automated retail kiosks provide a more interactive experience compared to small vending machines. These kiosks often include touchscreen interfaces that allow customers to browse a wider range of products, customize orders, and even make payments electronically. However, the initial setup costs can be significant, and businesses may need to invest in ongoing software maintenance and updates. While they can offer a higher return on investment through increased sales, the complexity of their operation may pose challenges for smaller businesses without robust IT support.

How Do On-Demand Delivery Services Compare to Small Vending Machines?

On-demand delivery services offer a flexible alternative to traditional vending solutions by allowing customers to order products directly to their location. This model thrives in urban areas with a high density of consumers seeking convenience. While the initial investment is lower than that of vending machines, costs can fluctuate based on delivery fees and service charges, making it less predictable for budgeting purposes. Moreover, businesses must rely on third-party logistics providers, which can introduce variability in service quality and delivery times.

Choosing the Right Solution for Your Business Needs

Selecting the right solution among small vending machines, automated retail kiosks, and on-demand delivery services depends largely on your specific business context. Consider factors such as target market, product range, budget constraints, and customer preferences. For businesses in high-traffic areas looking for a straightforward, low-maintenance option, small vending machines may be ideal. Conversely, if your market demands a more engaging shopping experience with diverse product offerings, automated retail kiosks could provide the necessary flexibility. Lastly, if your customer base values convenience and speed, particularly in urban settings, on-demand delivery services may be the most effective choice. By aligning the chosen solution with your operational strategy, you can enhance customer satisfaction and drive sales growth.

Essential Technical Properties and Trade Terminology for small vending machines

What Are the Essential Technical Properties of Small Vending Machines?

When considering the procurement of small vending machines, understanding their technical specifications is crucial for making informed purchasing decisions. Below are some key properties that B2B buyers should consider:

1. Dimensions and Weight

The dimensions (LxWxH) and weight of a vending machine significantly impact its placement and mobility. For instance, a typical mini vending machine may measure approximately 762 mm x 610 mm x 580 mm and weigh around 55 kg. These specifications are essential for determining whether the machine can fit in the desired location and whether additional transportation considerations are necessary.

2. Product Capacity and Selection Slots

The capacity of a vending machine, often indicated by the number of selection slots, directly influences its profitability. A small vending machine may have around 21 slots, accommodating up to 140 products. Higher capacity allows for a more diverse product offering, catering to various consumer preferences, which is vital for maximizing sales potential.

3. Power Supply and Consumption

Understanding the power requirements, such as voltage (e.g., 110-120 V) and power consumption (e.g., 50 W), is critical for operational planning. This specification helps buyers ensure that the machine can be adequately powered in their intended location, especially in regions with varying electrical infrastructure.

Illustrative image related to small vending machines

4. Material Quality

The choice of materials, such as stainless steel for the body and explosion-proof tempered glass for the door, affects durability and maintenance. High-quality materials not only extend the machine’s lifespan but also contribute to its aesthetic appeal, which can enhance customer engagement. Buyers should prioritize machines that offer robust construction to withstand daily use.

5. Payment Systems

The integration of various payment systems—coins, cash, and card readers—enhances customer convenience and can significantly impact sales. As consumer preferences shift towards cashless transactions, the inclusion of contactless payment options becomes increasingly important, making it a key consideration for B2B buyers.

6. Refrigeration Systems

For machines dispensing perishable items, the efficiency of the refrigeration system is vital. Options like R134a fluid for cooling and low-energy consumption compressors can affect operational costs. A reliable refrigeration system ensures product quality, which is essential for maintaining customer satisfaction and loyalty.

What Are the Common Trade Terms Related to Small Vending Machines?

Familiarity with industry jargon is crucial for effective communication and negotiation in the vending machine market. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the vending machine industry, understanding whether a machine is sourced from an OEM can impact quality assurance and after-sales support.

Illustrative image related to small vending machines

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to purchase multiple machines, as it can affect pricing and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. For vending machines, an RFQ helps buyers gather detailed pricing and specification information from different vendors, facilitating a competitive purchasing decision.

4. Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B buyers to clarify shipping, risk, and cost responsibilities.

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. In the vending machine industry, knowing the lead time helps buyers plan their inventory and sales strategies effectively.

6. Warranty and Support Terms

These terms define the conditions under which the manufacturer or seller will repair or replace the machine. Clear warranty terms are essential for B2B buyers to understand the level of support available post-purchase, impacting long-term operational decisions.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the small vending machine market more effectively, ensuring they make informed decisions that align with their business goals.

Navigating Market Dynamics and Sourcing Trends in the small vending machines Sector

What Are the Key Market Dynamics and Trends Influencing Small Vending Machines?

The small vending machine sector is witnessing significant growth driven by several global trends. Increasing urbanization, a shift towards self-service retail solutions, and the demand for convenience in consumer purchasing behaviors are key factors propelling this market. B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should take note of the rising interest in innovative vending solutions that cater to diverse consumer needs. Machines are increasingly equipped with advanced technology such as cashless payment systems, real-time inventory tracking, and smart analytics, allowing businesses to optimize operations and enhance customer experiences.

Emerging trends include the integration of contactless payment options, which have gained prominence due to the COVID-19 pandemic, and the rise of healthy vending machines that offer nutritious snack options. In Europe, for example, a growing health-conscious consumer base is driving demand for machines that provide fresh and organic products. Additionally, the introduction of customizable vending solutions that allow businesses to tailor offerings based on local preferences is becoming commonplace. As international B2B buyers navigate these market dynamics, understanding regional preferences and technological advancements will be crucial for successful sourcing and implementation.

How Can Sustainability and Ethical Sourcing Impact Your B2B Decisions in the Vending Machine Sector?

Sustainability is increasingly becoming a central focus in the vending machine industry, and B2B buyers are urged to consider the environmental impact of their sourcing decisions. The production and operation of vending machines can contribute to significant energy consumption and waste generation. Therefore, choosing suppliers that prioritize sustainable practices is essential. This includes selecting machines that utilize energy-efficient technologies, such as LED lighting and low-energy refrigeration systems, which can significantly reduce operational costs and carbon footprints.

Moreover, ethical sourcing of materials is vital for building a responsible supply chain. Buyers should look for manufacturers that use recyclable materials, possess certifications for sustainable practices, and adhere to fair labor standards. Green certifications, such as Energy Star or ISO 14001, can serve as indicators of a supplier’s commitment to sustainability. By investing in eco-friendly vending machines and supporting ethical practices, B2B buyers can enhance their brand reputation and appeal to a growing demographic of environmentally conscious consumers.

What Is the Evolution of Small Vending Machines and Its Relevance for B2B Buyers?

The small vending machine sector has evolved significantly over the decades, transforming from simple mechanical units to sophisticated, technology-driven solutions. Initially, vending machines primarily dispensed snacks and beverages in static locations. However, advancements in technology have led to the introduction of digital displays, interactive interfaces, and sophisticated payment systems that enhance user experience.

This evolution is particularly relevant for B2B buyers as it opens up new avenues for revenue generation and customer engagement. Modern vending machines are capable of offering a wide range of products, from healthy snacks to electronics, and can be customized to fit various environments such as offices, schools, and public spaces. Understanding this historical context allows buyers to appreciate the technological advancements that can influence their purchasing decisions, ensuring they select machines that align with current market demands and consumer preferences.

In summary, navigating the small vending machine sector requires an awareness of market dynamics, a commitment to sustainability, and an understanding of the evolution of vending technology. By focusing on these aspects, international B2B buyers can make informed decisions that drive profitability and align with consumer trends.

Frequently Asked Questions (FAQs) for B2B Buyers of small vending machines

-

How do I choose the right small vending machine for my business needs?

When selecting a small vending machine, consider the location and target audience. Analyze foot traffic patterns and the preferences of potential customers—whether they prefer snacks, beverages, or personal care items. Additionally, assess the machine’s capacity, selection options, and payment systems available (cash, card, or mobile payment). Finally, factor in the machine’s size and power requirements to ensure it fits your chosen space and local regulations. -

What are the common payment options available for small vending machines?

Most small vending machines offer multiple payment options to accommodate various customer preferences. Standard methods include coin and cash payments, while many modern machines also support card readers and contactless payment systems, such as mobile wallets. When sourcing machines, inquire about the payment processing fees, compatibility with local payment systems, and the ease of upgrading existing machines to include new payment technologies. -

How can I customize a small vending machine to suit my brand?

Customization options for small vending machines can include exterior branding, color schemes, and the product selection offered. Suppliers often provide the option to design the machine’s graphics, enabling you to incorporate your logo and brand colors. Additionally, you can curate the product offerings to align with your target market’s preferences, ensuring that your vending machine reflects your brand identity and meets customer needs. -

What are the minimum order quantities (MOQ) for small vending machines?

Minimum order quantities can vary significantly among manufacturers and suppliers. Some may allow single-unit purchases, while others may require bulk orders ranging from 5 to 10 machines. When negotiating with suppliers, clarify the MOQ and explore potential discounts for larger orders. This can help you optimize your investment, especially if you plan to deploy multiple machines across different locations. -

What are the payment terms I should expect when purchasing small vending machines?

Payment terms can differ based on the supplier and the size of your order. Common arrangements include upfront payment, payment upon delivery, or financing options that allow you to spread the cost over several months. Discussing payment terms upfront is crucial to avoid surprises later. Additionally, inquire about warranties and return policies, as these factors can influence your overall investment security. -

How can I ensure quality assurance (QA) for my small vending machines?

To maintain high-quality standards, request detailed specifications and certifications from the supplier regarding their manufacturing processes. Look for suppliers who adhere to international quality standards, such as ISO certifications. It’s also advisable to ask for product samples or references from previous customers. Conducting thorough research and vetting potential suppliers will help ensure that you receive reliable machines that meet your operational standards. -

What logistics considerations should I keep in mind when sourcing small vending machines internationally?

When sourcing internationally, consider shipping costs, import duties, and local regulations that may affect delivery times and expenses. Engage with logistics providers experienced in handling vending machines to ensure safe transportation and timely delivery. Additionally, verify the supplier’s ability to provide necessary documentation for customs clearance and ensure that the machines are adequately insured during transit. -

How can I vet suppliers of small vending machines to ensure reliability?

To vet suppliers effectively, start by researching their reputation through customer reviews and industry ratings. Evaluate their experience in the vending machine market, including the range of products offered and their responsiveness to inquiries. Request references from past clients and consider visiting their facilities if possible. Finally, ensure they provide adequate support services, including installation, maintenance, and warranty options, to safeguard your investment.

Top 9 Small Vending Machines Manufacturers & Suppliers List

1. Vending.com – Affordable Vending Machines

Domain: vending.com

Registered: 1994 (31 years)

Introduction: Affordable Vending Machines for Sale including: Combo and Dual Vending Machines, Drink & Soda Vending Machines, Snack Vending Machines, Coffee and Hot Beverage Vending Machines, Frozen Food Machines, Specialized Vending Machines, Smart Coolers, Gumball and Other Candy Vending Machines, Used Vending Machines. Customization & Services available including Free Vending, Greenlite Cashless Payment, and…

2. Compact Vending Solutions – Stylish Small Machines

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a smaller-type combo vending machine that is compact and tasteful. The user is based in Orange County, CA, and is seeking recommendations for brands or models that are smaller but still functional. They want to avoid large, high-capacity machines and are open to all suggestions. The machine will be placed in a factory break room, and restocking won’t be an issue as the user works there…

3. Gumball.com – Vending Machines

Domain: gumball.com

Registered: 1996 (29 years)

Introduction: Made-in-USA Vending Machines for Sale | Gumball.com. Lowest price guarantee. Various types of vending machines available including gumball machines, candy dispensers, toy capsule machines, and claw machines. Options for tabletop, spiral, single head, double head, and triple head machines. Brands include Seaga Manufacturing, AMS, Beaver, Carousel, and Titan. Machines for snacks, drinks, and combo o…

4. Compact Vending – VT Mercato 4000 Snack Machine

Domain: compactvendingmachine.com

Registered: 2024 (1 years)

Introduction: New Vending Machines: VT Mercato 4000 Snack Machine – $4,339.00 (originally $5,339.00), Selectivend WS5000 Snack Vending Machine with Card Reader – $4,588.00 (originally $5,288.00), GPL 171 Snack Vending Machine – $1,598.00 (originally $1,795.00), Selectivend Advantage Plus Combo Snack Drink Vending Machine – $4,088.00 (originally $4,888.00), GPL 173 Snack Vending Machine – $1,599.00 (originally $…

5. Aramark – Small Office Vending Machines

Domain: aramarkrefreshments.com

Registered: 2005 (20 years)

Introduction: Best small office vending machines provide low maintenance snack options, enhance employee satisfaction and productivity, and can be integrated into breakroom spaces with RefreshSTYLE™. Key features include:

– Smaller-width vending machines for tight spaces.

– Snack and beverage combination machines to offer both food and drinks.

– Vending machines with rotating displays for an engaging experience…

6. Vending World – Economy Snack Machines

Domain: vendingworld.com

Registered: 1998 (27 years)

Introduction: Economy Snack Machines priced at $1695 or less. Key models include: 1. Automatic Products Model 112 (2 candy) Snack Machine – $1,395.00 or financing available at $34.88/mo. 2. Automatic Products Model 111 Snack Machine – $1,395.00 or financing available at $34.88/mo. 3. Automatic Products Model 7600 (1 Candy Shelf – InOne MDB Board) Snack Machine – $1,595.00 or financing available at $39.88/mo. 4….

7. Discount Vending – New & Used Vending Machines

Domain: discountvending.com

Registered: 2001 (24 years)

Introduction: New Vending Machines: $4,500-$6,500, features include remote inventory monitoring, cashless payment systems, guaranteed vend technology, one-year parts warranty, lifetime tech support. Used Vending Machines: $3,000-$4,000, fully refurbished, three-month parts warranty, lifetime tech support. Custom Vending Machines: $6,500-$13,000, fully customized, volume discounting, free storage. All machines a…

8. EPEX – Beverage Combo Vending Machine

Domain: microrealestate.leptonic.io

Registered: 2020 (5 years)

Introduction: 1. EPEX Beverage Combo Vending Machine: Compact design, sells soda cans, bottles, candy, chips, snacks; uses liquid injection foam technology; removable refrigeration system; stratified temperature control system for upper and lower trays; easy maintenance. 2. AMS Glass Front Snack Vending Machine: Supports various snacks like chips, nachos, candy; simple design; great build quality; cannot vend d…

9. eBay – Small Vending Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: small vending machine products for sale, related searches include Small Beverage Vending Machine, Mini Vending Machine, Compact Vending Machine, Free Mini Snack Vending Machine, Slim Vending Machine, Small Soda Vending Machine, Mini Vending Machine Toy, Desktop Vending Machine, Novelty Vending Machine, Vending Machine with Location. Categories include Collectible Gumball Machines, Cold Beverage & …

Strategic Sourcing Conclusion and Outlook for small vending machines

In the evolving landscape of small vending machines, strategic sourcing emerges as a pivotal element for B2B buyers aiming to capitalize on new market opportunities. Understanding the diverse range of mini vending machines—from snack dispensers to personal care products—enables businesses to cater to unique consumer demands effectively. The flexibility in payment options, such as cash, coins, and card readers, enhances customer experience, while advanced features like data export capabilities facilitate better inventory and sales management.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, the growth potential is significant. Investing in small vending machines can drive profitability by tapping into under-served markets and enhancing brand visibility in high-traffic locations. As consumer preferences shift towards convenience and accessibility, aligning procurement strategies with innovative vending solutions will be crucial.

Looking ahead, the demand for customized and technologically advanced vending machines is set to rise. B2B buyers should take proactive steps to explore partnerships with reputable suppliers, ensuring they stay ahead of market trends and consumer expectations. Embrace this opportunity to enhance your product offerings and drive business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to small vending machines

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.