Choosing Your Sheets Of Fibreglass: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for sheets of fibreglass

Navigating the complex landscape of sourcing sheets of fiberglass can present significant challenges for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With applications ranging from aerospace to automotive and industrial sectors, the demand for high-quality fiberglass sheets has surged. However, buyers often grapple with selecting the right type, understanding material specifications, and ensuring compliance with regional standards.

This comprehensive guide is designed to empower your purchasing decisions by providing in-depth insights into the various types of fiberglass sheets available, their specific applications, and the critical factors to consider when vetting suppliers. From evaluating product specifications, such as tensile strength and thermal resistance, to understanding the cost implications and logistics of international shipping, this resource serves as a one-stop solution for informed procurement.

By leveraging the knowledge contained within this guide, B2B buyers can confidently navigate the global market for fiberglass sheets, ensuring they select the right products to meet their operational needs while optimizing costs. Whether you are sourcing for construction projects, manufacturing components, or specialized applications, this guide will equip you with the essential tools to make strategic purchasing decisions that drive business success.

Understanding sheets of fibreglass Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| G-10/FR4 | High strength, flame retardant, epoxy resin reinforced | Electronics, aerospace, industrial applications | Pros: Excellent electrical insulation, high mechanical strength. Cons: Limited aesthetic options. |

| Aluminized Glass | Reflective surface, lightweight, corrosion-resistant | Marine, automotive, thermal insulation applications | Pros: Lightweight, good thermal properties. Cons: May not withstand extreme mechanical stress. |

| S-Glass | Higher tensile strength, better impact resistance | Aerospace, high-performance applications | Pros: Superior strength-to-weight ratio. Cons: Higher cost compared to standard E-glass. |

| E-Glass | Cost-effective, good mechanical properties | General construction, automotive, and marine uses | Pros: Affordable, versatile. Cons: Lower strength compared to S-glass. |

| Natural Fiberglass | Unpigmented, smooth finish, autoclave cured | Surface sheeting, templates, industrial components | Pros: Excellent dimensional stability, customizable. Cons: May have surface blemishes. |

What are the Characteristics of G-10/FR4 Fiberglass Sheets?

G-10/FR4 fiberglass sheets are known for their exceptional mechanical strength and flame retardant properties, making them suitable for a range of applications, particularly in electronics and aerospace. These sheets are made from fiberglass prepreg reinforced with high-strength epoxy resin, ensuring a rigid structure that is not reshaped once cured. Buyers should consider their specific needs for electrical insulation and mechanical strength when selecting G-10/FR4, as it excels in environments requiring durability and fire resistance.

How Do Aluminized Glass Fiberglass Sheets Stand Out?

Aluminized glass sheets are distinguished by their reflective surface, which enhances thermal insulation properties. These sheets are lightweight and corrosion-resistant, making them ideal for marine and automotive applications where weight savings are crucial. When purchasing, B2B buyers should weigh the benefits of thermal efficiency against potential limitations in mechanical strength, especially in high-stress environments.

What Makes S-Glass an Ideal Choice for Aerospace Applications?

S-glass fiberglass sheets offer a higher tensile strength and better impact resistance compared to standard E-glass. These features make S-glass particularly suited for aerospace and other high-performance applications where strength is critical. While the cost of S-glass is higher than that of E-glass, the investment may be justified for projects demanding superior material properties.

Why Choose E-Glass Fiberglass Sheets for General Use?

E-glass fiberglass sheets are widely recognized for their cost-effectiveness and versatility. They provide good mechanical properties and are suitable for various applications, including construction and automotive. Buyers should consider E-glass for projects with budget constraints, but also be mindful that it may not offer the same level of strength as S-glass or G-10/FR4.

What Are the Benefits of Natural Fiberglass Sheets?

Natural fiberglass sheets are characterized by their unpigmented finish and smooth surface, which is achieved through autoclave curing. These sheets are commonly used for surface sheeting and templates in industrial settings. B2B buyers should note that while natural fiberglass offers excellent dimensional stability and customization options, it may exhibit surface blemishes that do not affect performance but could be a concern for aesthetic applications.

Key Industrial Applications of sheets of fibreglass

| Industry/Sector | Specific Application of sheets of fibreglass | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft interior components | Lightweight, flame-retardant materials enhance safety and reduce weight | Compliance with stringent safety regulations; specific grades like FST for interiors |

| Marine | Boat hulls and components | High strength and corrosion resistance improve durability and longevity | Need for marine-grade materials; custom sizes and thicknesses to fit various designs |

| Automotive | Electrical insulation and structural parts | Excellent dielectric properties and mechanical strength contribute to vehicle safety | Requirement for high-performance grades like G10; attention to weight and thermal properties |

| Electrical & Electronics | Circuit boards and enclosures | Provides electrical insulation and mechanical stability, essential for product reliability | Sourcing of FR4 grade materials; customization options for specific dimensions and finishes |

| Construction | Structural panels and insulation | High strength-to-weight ratio and moisture resistance enhance building integrity | Consideration for local climate conditions; need for fire resistance and compliance with building codes |

How Are Sheets of Fibreglass Used in Aerospace Applications?

In the aerospace industry, sheets of fibreglass are primarily used to manufacture aircraft interior components, such as panels and insulation. These materials are chosen for their lightweight and flame-retardant properties, which are crucial for safety compliance. Buyers must ensure that the products meet specific standards, such as Flame Smoke Toxicity (FST) ratings, which are essential for aircraft interiors. International buyers should also consider the logistical aspects of sourcing these materials, including certifications and traceability.

What Role Do Sheets of Fibreglass Play in Marine Applications?

For marine applications, fibreglass sheets are utilized in constructing boat hulls and various components that require high strength and resistance to harsh marine environments. The corrosion resistance of fibreglass ensures durability, making it a preferred choice for boat manufacturers. Buyers should focus on sourcing marine-grade materials that can withstand exposure to saltwater and UV radiation. Custom sizes and thicknesses are often necessary to accommodate diverse boat designs, making supplier flexibility a crucial consideration.

How Are Fibreglass Sheets Beneficial in the Automotive Sector?

In the automotive sector, sheets of fibreglass serve multiple functions, including electrical insulation and structural reinforcement for various vehicle components. Their excellent dielectric properties help ensure safety and reliability in electrical systems. When sourcing these materials, buyers should prioritize high-performance grades like G10, which offer enhanced mechanical strength and thermal stability. Additionally, understanding the weight implications of fibreglass components can significantly influence vehicle design and performance.

Why Are Sheets of Fibreglass Critical for Electrical and Electronics Industries?

In the electrical and electronics sectors, fibreglass sheets are commonly used for manufacturing circuit boards and protective enclosures. Their mechanical stability and electrical insulating properties are vital for maintaining product reliability in diverse applications. Buyers should focus on sourcing FR4 grade materials, which are specifically designed for electrical applications. Customization options, including specific dimensions and finishes, may also be essential to meet unique project requirements.

How Do Sheets of Fibreglass Enhance Construction Projects?

In construction, fibreglass sheets are used for structural panels and insulation, offering a high strength-to-weight ratio along with moisture resistance. These properties contribute to the overall integrity and durability of buildings, particularly in challenging climates. Buyers must consider local building codes and fire resistance standards when sourcing these materials. Furthermore, understanding the environmental conditions of the project site can influence the selection of the appropriate fibreglass grades.

3 Common User Pain Points for ‘sheets of fibreglass’ & Their Solutions

Scenario 1: Inconsistent Quality and Specifications Across Suppliers

The Problem: B2B buyers often encounter significant frustration when sourcing sheets of fiberglass due to inconsistencies in product quality and specifications from different suppliers. This inconsistency can lead to project delays and increased costs, as teams may need to rework or replace materials that do not meet the specified requirements. For instance, a company may order fiberglass sheets claiming to have a certain tensile strength, only to find that the delivered product fails to meet those standards during testing, jeopardizing safety and compliance in applications like aerospace or automotive manufacturing.

The Solution: To mitigate this challenge, buyers should establish a robust supplier qualification process that includes detailed specifications for each order. Request certifications for tensile strength, fire retardancy, and other relevant properties before placing an order. Engaging with suppliers that offer traceability for their products can help ensure that the materials meet the specified standards. Furthermore, considering a standardized testing protocol upon receipt of materials can help identify discrepancies early on, allowing for corrective actions before the materials are integrated into production.

Scenario 2: Difficulty in Customization and Sizing

The Problem: Many businesses face obstacles when trying to customize the size or thickness of fiberglass sheets to fit specific project requirements. Standard sizes may not meet the unique needs of a particular application, leading to increased waste and additional costs for re-fabrication. For instance, a construction company may need large, custom-sized sheets for a unique structural application, yet the standard offerings from suppliers do not accommodate their specifications.

The Solution: Buyers should seek out manufacturers that provide customization options for fiberglass sheets, including various thicknesses, sizes, and finishes. When discussing requirements with suppliers, it’s essential to clearly communicate the specific dimensions and any performance characteristics needed. Engaging with manufacturers who have CNC machining capabilities can ensure that the sheets are cut precisely to the required dimensions, reducing waste and improving overall project efficiency. Establishing a collaborative relationship with the supplier can also lead to quicker turnaround times and more tailored solutions.

Scenario 3: Limited Understanding of Material Properties

The Problem: Many B2B buyers lack a comprehensive understanding of the various properties of fiberglass sheets, such as electrical insulation, chemical resistance, and thermal stability. This knowledge gap can lead to incorrect material selection for specific applications, resulting in failures that could have been avoided. For instance, a company in the electronics sector may choose a fiberglass sheet that does not provide adequate insulation, leading to equipment malfunction and safety hazards.

Illustrative image related to sheets of fibreglass

The Solution: To overcome this knowledge barrier, buyers should invest time in understanding the specific properties and applications of different types of fiberglass sheets, such as G10/FR4 or S-glass. Engaging with suppliers who offer technical support and educational resources can provide valuable insights. Additionally, buyers can request samples to evaluate material performance in their specific applications before making bulk purchases. Attending industry seminars or workshops can also enhance understanding of material properties and help in making informed decisions that align with project requirements.

Strategic Material Selection Guide for sheets of fibreglass

What are the Key Properties of Common Fiberglass Sheet Materials?

When selecting fiberglass sheets for various applications, understanding the material properties is crucial for ensuring optimal performance. Here, we analyze four common materials used in fiberglass sheets: G10, FR-4, S-Glass, and E-Glass. Each material has distinct properties, advantages, and limitations that can significantly impact their suitability for specific applications.

G10 Fiberglass Sheets: What Makes Them Stand Out?

G10 is a high-pressure fiberglass laminate made from woven fiberglass cloth and epoxy resin. It boasts excellent electrical insulation properties and high mechanical strength, making it suitable for applications in electrical enclosures and circuit boards.

Key Properties: G10 sheets can withstand temperatures up to 130°C (266°F) and offer good corrosion resistance. They are lightweight yet durable, with a tensile strength of approximately 40,000 psi.

Pros & Cons: The advantages of G10 include its high strength-to-weight ratio and excellent dielectric properties. However, it can be more expensive than other fiberglass options, and its brittleness may limit its use in high-impact applications.

Impact on Application: G10 is ideal for environments where electrical insulation is paramount, such as in aerospace and automotive industries. It is also compliant with various international standards, including ASTM D-635 for flame resistance.

FR-4 Fiberglass Sheets: Why Are They Preferred for Electronics?

FR-4 is another popular fiberglass laminate, often used in printed circuit boards (PCBs). It consists of woven glass fabric and epoxy resin, providing excellent electrical insulation and thermal stability.

Key Properties: FR-4 sheets can operate at temperatures up to 130°C (266°F) and exhibit minimal moisture absorption, making them suitable for humid environments.

Pros & Cons: The primary advantage of FR-4 is its excellent electrical insulating properties and flame retardance (class 94V-0). However, it may lack the mechanical strength of G10, making it less suitable for structural applications.

Impact on Application: FR-4 is widely used in the electronics industry, particularly for PCBs. Buyers should ensure compliance with international standards like IPC-4101, which governs the quality of materials used in electronics.

S-Glass Fiberglass Sheets: When to Choose Them for High-Performance Needs?

S-Glass is a high-strength fiberglass material known for its superior tensile strength and impact resistance. It is often used in applications requiring enhanced mechanical properties, such as aerospace and military applications.

Key Properties: S-Glass sheets can withstand temperatures up to 200°C (392°F) and have a tensile strength exceeding 60,000 psi.

Pros & Cons: The key advantage of S-Glass is its exceptional strength and durability. However, it is more expensive than E-Glass and may require specialized processing techniques, increasing manufacturing complexity.

Impact on Application: S-Glass is suitable for high-performance applications where mechanical integrity is critical. Buyers must consider compliance with military and aerospace standards, such as MIL-PRF-85582.

E-Glass Fiberglass Sheets: What Are Their General Applications?

E-Glass is the most commonly used fiberglass material, known for its versatility and cost-effectiveness. It is widely used in construction, automotive, and marine applications.

Key Properties: E-Glass sheets can operate at temperatures up to 130°C (266°F) and offer good chemical resistance.

Pros & Cons: E-Glass is relatively inexpensive and easy to manufacture, making it a popular choice for various applications. However, it has lower tensile strength compared to G10 and S-Glass, which may limit its use in high-stress environments.

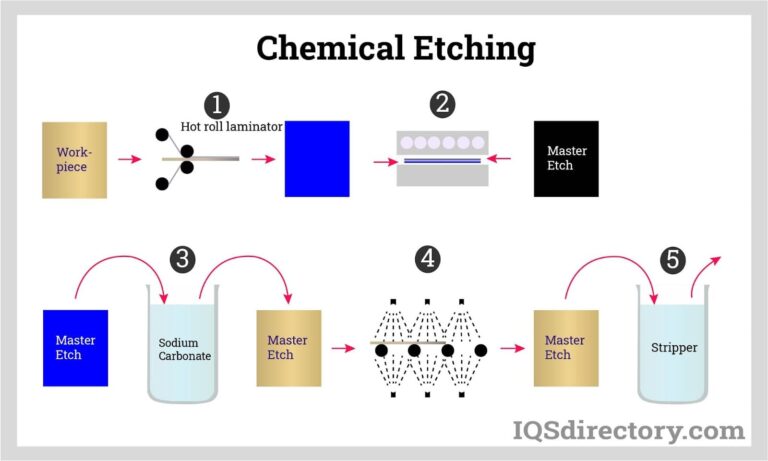

Illustrative image related to sheets of fibreglass

Impact on Application: E-Glass is suitable for general-purpose applications, but buyers should ensure that the material meets relevant standards like ASTM D578 for fiberglass reinforcement.

Summary Table of Fiberglass Sheet Materials

| Material | Typical Use Case for sheets of fibreglass | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| G10 | Electrical enclosures, circuit boards | High strength-to-weight ratio | Brittleness limits high-impact use | Medium |

| FR-4 | Printed circuit boards (PCBs) | Excellent electrical insulation | Lower mechanical strength than G10 | Medium |

| S-Glass | Aerospace, military applications | Exceptional strength and durability | Higher cost and manufacturing complexity | High |

| E-Glass | Construction, automotive, marine | Cost-effective and versatile | Lower tensile strength compared to G10/S-Glass | Low |

This guide provides international B2B buyers with actionable insights into selecting the right fiberglass sheet materials based on their specific application needs and compliance requirements. Understanding the properties, advantages, and limitations of each material will facilitate informed purchasing decisions, ensuring optimal performance in diverse environments.

In-depth Look: Manufacturing Processes and Quality Assurance for sheets of fibreglass

What Are the Main Stages in the Manufacturing Process of Fiberglass Sheets?

The manufacturing process of fiberglass sheets involves several critical stages, each designed to ensure the final product meets the required specifications for performance and durability. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate fiberglass fibers and resin systems. Fiberglass sheets typically utilize E-glass or S-glass fibers due to their excellent strength-to-weight ratios. The fibers are often pre-impregnated with epoxy resin (known as prepreg), which enhances the mechanical properties of the final product. Quality control begins here, as suppliers should ensure that raw materials meet specific standards for consistency and purity.

-

Forming: The forming stage entails laying down the fiberglass layers in molds or on flat surfaces, depending on the desired final shape and thickness. Techniques such as hand lay-up, vacuum bagging, and autoclave curing are commonly employed. Autoclave curing, in particular, is favored for its ability to produce high-strength laminates by applying heat and pressure to eliminate voids and ensure uniform resin distribution.

-

Assembly: For more complex structures, multiple layers or components may need to be assembled. This stage may involve bonding different fiberglass sheets together or integrating other materials, such as core materials for increased structural integrity. Proper alignment and adherence are critical to maintaining the mechanical properties of the assembly.

-

Finishing: The finishing stage includes cutting, sanding, and applying surface coatings to achieve the desired aesthetic and performance characteristics. This step may also involve surface treatment to enhance properties such as chemical resistance or flame retardancy. The quality of finishing plays a significant role in the product’s marketability and performance in end-use applications.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is paramount in the fiberglass sheet manufacturing process, particularly for international B2B transactions. Buyers should familiarize themselves with both international and industry-specific standards that govern quality and safety.

-

International Standards: ISO 9001 is the most recognized standard for quality management systems. It emphasizes continuous improvement and customer satisfaction, ensuring that manufacturers adhere to strict quality control processes. Certification to this standard can provide buyers with confidence in the supplier’s commitment to quality.

-

Industry-Specific Standards: Depending on the application, other certifications may be relevant. For instance, CE marking indicates compliance with European safety and environmental standards, while API (American Petroleum Institute) standards are critical for products used in the oil and gas sector. Buyers in sectors like aerospace may require compliance with AS9100, a standard specifically for aerospace quality management systems.

What Are the Key Quality Control Checkpoints in Fiberglass Sheet Manufacturing?

Quality control (QC) is integral to the production of fiberglass sheets, with several checkpoints ensuring that the final product meets specifications.

-

Incoming Quality Control (IQC): This initial checkpoint occurs upon receipt of raw materials. Inspections focus on verifying the quality and specifications of fiberglass fibers and resin systems. Documentation, such as material safety data sheets (MSDS) and certificates of compliance, should be reviewed.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is essential. This stage involves checking the consistency of the lay-up process, ensuring proper curing temperatures and pressures, and verifying dimensional tolerances. Statistical process control (SPC) techniques may be employed to track variability and identify trends.

-

Final Quality Control (FQC): After the product is completed, final inspections are conducted to assess mechanical properties, surface finish, and overall dimensions. Common testing methods include tensile strength tests, flexural strength tests, and thermal cycling tests, which help validate the performance characteristics of the fiberglass sheets.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial to ensuring product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality management systems and manufacturing practices. Buyers should look for suppliers who welcome audits and have transparent processes.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC measures in place. These reports should include data on testing results, non-conformance reports, and corrective actions taken to address any issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s manufacturing and quality assurance practices. This is particularly beneficial for buyers unfamiliar with local suppliers or those operating in regions with less stringent regulations.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When sourcing fiberglass sheets from international suppliers, B2B buyers should be aware of specific nuances related to quality control and certification.

-

Cultural Differences: Different regions may have varying interpretations of quality standards. Buyers from Africa, South America, the Middle East, and Europe should ensure that suppliers understand their specific market requirements and expectations.

-

Documentation and Compliance: International trade often requires extensive documentation. Buyers should ensure that suppliers can provide all necessary certifications and compliance documentation, including customs paperwork, to facilitate smooth transactions.

-

Local Regulations: Buyers should familiarize themselves with local regulations in their target markets. This knowledge will help ensure that imported fiberglass sheets comply with local safety and environmental standards, thus avoiding potential legal or logistical issues.

Conclusion

Understanding the manufacturing processes and quality assurance standards for fiberglass sheets is essential for B2B buyers seeking reliable products. By focusing on key manufacturing stages, adhering to international and industry-specific standards, and implementing rigorous quality control checkpoints, suppliers can deliver high-quality fiberglass sheets that meet the diverse needs of various industries. Buyers can enhance their procurement strategies by verifying supplier QC practices and staying informed about regional nuances, ultimately ensuring successful business relationships across borders.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sheets of fibreglass’

In the realm of industrial applications, sourcing high-quality fiberglass sheets is crucial for ensuring durability and performance. This guide provides a systematic approach for B2B buyers to navigate the procurement process effectively. By following these steps, you can make informed decisions and select the right materials for your projects.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your fiberglass sheets. Consider factors such as thickness, size, and material grade (e.g., G10 or FR4). Establishing these parameters early ensures that you focus on products that meet your project needs, reducing the risk of purchasing unsuitable materials.

- Thickness and Size: Identify the specific dimensions and thickness needed for your application.

- Material Grade: Determine the appropriate grade based on the intended use, such as electrical insulation or structural support.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in fiberglass sheets. Look for manufacturers and distributors with a proven track record in your specific industry. Evaluating multiple suppliers helps you compare offerings and find the best fit for your requirements.

Illustrative image related to sheets of fibreglass

- Supplier Reputation: Check online reviews and testimonials from other B2B buyers.

- Product Range: Ensure the supplier offers a diverse selection of fiberglass sheets to meet varying project needs.

Step 3: Evaluate Supplier Certifications

Supplier certifications are critical indicators of quality assurance and compliance with industry standards. Verify that potential suppliers possess relevant certifications such as ISO 9001 or ASTM compliance, which can assure you of their product quality and reliability.

- Quality Management Systems: Look for certifications that demonstrate adherence to quality management practices.

- Industry Standards: Ensure the products meet necessary safety and performance standards relevant to your application.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the fiberglass sheets you are considering. Testing samples in your specific application can provide valuable insights into performance, durability, and compatibility with other materials.

- Material Testing: Conduct tests to assess mechanical properties such as tensile strength and chemical resistance.

- Fit and Finish: Evaluate the surface finish and dimensional accuracy against your project requirements.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers and tested samples, engage in negotiations regarding pricing, delivery terms, and payment options. Establishing favorable terms can significantly impact your overall project budget and timeline.

- Bulk Discounts: Inquire about discounts for larger orders to optimize your procurement costs.

- Delivery Schedule: Ensure the supplier can meet your timeline requirements without compromising on quality.

Step 6: Confirm After-Sales Support

Assess the level of after-sales support offered by the supplier. Good customer service can be invaluable for addressing any issues that arise post-purchase, such as defects or delivery discrepancies.

- Technical Support: Ensure the supplier provides assistance for any technical queries regarding the product.

- Return Policies: Understand the terms for returns or exchanges in case the materials do not meet your expectations.

By following this checklist, you can streamline your sourcing process and enhance the likelihood of acquiring high-quality fiberglass sheets that meet your specific needs.

Comprehensive Cost and Pricing Analysis for sheets of fibreglass Sourcing

When sourcing fiberglass sheets, understanding the cost structure and pricing nuances is essential for international B2B buyers. This analysis delves into the various components influencing costs, pricing factors, and valuable tips for effective negotiations, particularly for buyers from Africa, South America, the Middle East, and Europe.

What are the Key Cost Components in Fiberglass Sheet Pricing?

The pricing of fiberglass sheets is influenced by several cost components:

-

Materials: The primary cost driver is the raw materials used, such as fiberglass fabric and resin. High-quality materials, like epoxy resins or specialized fiberglass types (e.g., G10/FR-4), will increase costs but also enhance performance and durability.

-

Labor: Labor costs encompass the workforce involved in manufacturing processes, including cutting, curing, and finishing fiberglass sheets. Skilled labor is often required for precision tasks, adding to the overall cost.

-

Manufacturing Overhead: This includes expenses related to equipment maintenance, utilities, and facility operations. As production scales, these costs can be distributed over a larger output, potentially reducing the per-unit cost.

-

Tooling: Customization or specific designs may necessitate special tooling, which can significantly impact initial costs. Buyers should consider these expenses when evaluating quotes for bespoke solutions.

-

Quality Control (QC): Ensuring product quality involves additional costs, including testing and certification. Products with certifications (e.g., fire retardancy) may command higher prices due to the assurance of safety and compliance.

-

Logistics: Shipping and handling costs are particularly relevant for international buyers. Factors such as distance, shipping methods, and Incoterms can dramatically affect overall costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition, demand, and market conditions.

How Do Price Influencers Affect the Cost of Fiberglass Sheets?

Several factors influence the final price of fiberglass sheets:

-

Volume/MOQ: Larger orders often attract discounts due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs.

-

Specifications and Customization: Custom specifications, such as unique dimensions or specific material properties, can increase costs. Buyers should clearly outline their requirements to receive accurate pricing.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., UL94V-0 for flame resistance) can increase costs but provide long-term value through enhanced performance and safety.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and geographic location can affect pricing. Established suppliers with a track record of reliability may charge a premium.

-

Incoterms: Understanding shipping terms and responsibilities can help buyers negotiate better prices. For example, FOB (Free on Board) pricing may be more favorable than CIF (Cost, Insurance, and Freight) in certain situations.

What Buyer Tips Can Enhance Cost-Efficiency in Fiberglass Sheet Sourcing?

To maximize value when sourcing fiberglass sheets, consider these strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your position as a repeat buyer to secure better rates.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also long-term factors such as durability, maintenance, and potential savings from using higher-quality materials.

-

Understand Pricing Nuances for International Transactions: Be aware of fluctuations in currency exchange rates and how they affect pricing. Additionally, familiarize yourself with local regulations and import duties that could impact overall costs.

-

Request Samples: Before finalizing large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure the product meets your specifications.

-

Leverage Technology: Utilize online platforms and tools to compare prices and specifications from multiple suppliers, allowing for informed decision-making.

Conclusion

In conclusion, a thorough understanding of the cost components and pricing influences associated with fiberglass sheets can empower international B2B buyers to make informed purchasing decisions. By employing strategic negotiation tactics and considering the total cost of ownership, buyers can enhance their sourcing efficiency and ensure they are getting the best value for their investments.

Alternatives Analysis: Comparing sheets of fibreglass With Other Solutions

Exploring Alternatives to Fibreglass Sheets for Industrial Applications

When considering materials for industrial applications, sheets of fibreglass are often a go-to choice due to their strength, durability, and versatility. However, there are alternative solutions that may better suit specific needs based on performance, cost, and application. This section explores these alternatives, providing a comparative analysis to help B2B buyers make informed decisions.

| Comparison Aspect | Sheets of Fibreglass | Carbon Fiber Sheets | Aluminum Sheets |

|---|---|---|---|

| Performance | High tensile strength, excellent chemical resistance, good electrical insulation | Very high strength-to-weight ratio, excellent fatigue resistance | High strength, good thermal and electrical conductivity |

| Cost | Moderate ($27.99 to $843.99) | High (typically $100+ per square foot) | Low to moderate ($15 to $50 per square foot) |

| Ease of Implementation | Moderate; requires cutting and shaping | High; can be complex to work with due to brittleness | Easy; can be cut and shaped with standard tools |

| Maintenance | Low; resistant to moisture and chemicals | Low; resistant to corrosion but can be brittle | Moderate; prone to corrosion without proper treatment |

| Best Use Case | Electrical insulation, structural components in humid environments | Aerospace, high-performance automotive applications | Structural supports, heat exchangers, and enclosures |

Understanding Carbon Fiber Sheets as an Alternative

Carbon fiber sheets are renowned for their exceptional strength-to-weight ratio. They outperform fibreglass in applications where weight is a critical factor, such as in aerospace and high-performance automotive industries. However, the high cost and brittleness of carbon fiber can be drawbacks, limiting their use in environments where impact resistance is crucial. Additionally, the complexity of working with carbon fiber can increase manufacturing times and costs.

Evaluating Aluminum Sheets as a Cost-Effective Solution

Aluminum sheets present a cost-effective alternative to fibreglass, especially for structural applications. They are relatively inexpensive and easy to fabricate, making them suitable for a wide range of industrial uses, from construction to heat exchangers. However, aluminum lacks the same level of electrical insulation and chemical resistance as fibreglass, which may limit its applicability in specific sectors. Additionally, aluminum is prone to corrosion if not properly treated, which can lead to increased maintenance costs over time.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right material for your project hinges on understanding the specific requirements of your application. Sheets of fibreglass offer a balanced combination of strength, durability, and resistance to environmental factors, making them ideal for electrical insulation and structural components in moist conditions. On the other hand, if weight is a priority and budget allows, carbon fiber sheets may be the superior choice. For more general structural applications where cost is a primary concern, aluminum sheets could be the most practical solution. Ultimately, evaluating performance, cost, ease of implementation, and maintenance needs will guide B2B buyers in making the most informed decision tailored to their operational demands.

Essential Technical Properties and Trade Terminology for sheets of fibreglass

What Are the Key Technical Properties of Fiberglass Sheets That B2B Buyers Should Know?

When evaluating fiberglass sheets for industrial applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications that every buyer should consider:

-

Material Grade (G10/FR4)

Fiberglass sheets are often classified by material grade, such as G10 and FR4. G10 is a high-pressure fiberglass laminate known for its excellent electrical insulation properties and mechanical strength, making it suitable for various applications, including aerospace and electronics. FR4 is a fire-retardant version of G10, which meets specific flame resistance standards. Choosing the right material grade ensures compliance with safety regulations and performance requirements in critical applications. -

Thickness Tolerance

Thickness is a key specification that affects the performance and application of fiberglass sheets. Common thicknesses range from 0.005 inches to 1 inch, with tolerances typically specified in terms of +/- values (e.g., +/- 0.002 inches). This tolerance impacts the fit and function in assemblies, making it important for buyers to confirm that the thickness meets their design specifications to avoid costly rework. -

Tensile Strength

Tensile strength is the maximum amount of tensile (pulling) stress that a material can withstand before failure. For fiberglass sheets, tensile strengths can vary significantly, with values often exceeding 40,000 psi. This property is critical for applications where the material will be subjected to mechanical loads, ensuring durability and longevity in use. -

Flexural Strength

Flexural strength measures the ability of a material to resist deformation under load. Fiberglass sheets can have flexural strengths ranging from 45,000 psi to 55,000 psi. A higher flexural strength indicates better performance in load-bearing applications, making it essential for B2B buyers in industries such as construction and automotive to assess this property. -

Chemical Resistance

Fiberglass sheets exhibit varying degrees of chemical resistance, which is vital for applications in harsh environments. This property ensures that the material will not degrade or corrode when exposed to chemicals, moisture, or extreme temperatures. Buyers should evaluate the specific chemical resistance of the sheets based on their intended application to ensure compatibility.

Which Trade Terms Are Essential for Understanding Fiberglass Sheet Transactions?

Navigating the procurement process for fiberglass sheets involves familiarizing oneself with industry jargon. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand name. Understanding the role of OEMs can help buyers identify reliable suppliers and ensure that they are sourcing high-quality materials that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it directly impacts inventory costs and cash flow. Suppliers often set MOQs to optimize production efficiency, so buyers must assess their needs against these requirements. -

RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. Including detailed specifications in the RFQ allows suppliers to provide accurate pricing and lead times, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and liability. Familiarity with these terms helps buyers understand their obligations and potential risks in the supply chain, ensuring smoother transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is vital for inventory management and project planning, as it directly affects production schedules and delivery commitments.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing fiberglass sheets, ensuring that they select the right materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the sheets of fibreglass Sector

What Are the Key Trends Driving the Fiberglass Sheets Market?

The global fiberglass sheets market is witnessing robust growth, fueled by increasing demand across diverse sectors such as automotive, marine, aerospace, and construction. Key drivers include the rise of lightweight and durable materials in manufacturing processes, which enhance fuel efficiency and reduce emissions. Technological advancements in composite materials have also led to the development of high-performance fiberglass sheets, such as G10/FR4, which offer superior mechanical and electrical properties.

Current B2B sourcing trends reflect a shift towards digital platforms, enabling international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, to access a broader range of suppliers and products. E-commerce solutions are streamlining procurement processes, allowing for better price comparisons and quicker turnaround times. Additionally, customization and flexibility in order quantities are becoming increasingly important as manufacturers seek to meet specific project requirements without incurring significant overhead costs.

Moreover, the impact of global trade dynamics, including tariffs and trade agreements, is shaping sourcing strategies. Buyers must stay informed about these factors to mitigate risks and capitalize on opportunities in the fiberglass sheets market.

How Are Sustainability and Ethical Sourcing Addressing Environmental Concerns in Fiberglass Production?

Sustainability is becoming a crucial consideration in the fiberglass sheets sector as environmental regulations tighten and consumers increasingly demand eco-friendly products. The production of fiberglass can have significant environmental impacts, including energy consumption and emissions. As a result, manufacturers are exploring sustainable practices such as using recycled materials and reducing waste during production.

The importance of ethical supply chains is gaining traction, with buyers prioritizing suppliers who can demonstrate sustainable practices. Certifications such as ISO 14001 (Environmental Management) and Green Seal are becoming essential for companies seeking to enhance their brand reputation and meet regulatory requirements.

Additionally, the availability of ‘green’ fiberglass materials, which utilize less harmful resins and additives, is on the rise. These innovations not only contribute to reducing the environmental footprint but also align with global sustainability goals. International buyers should consider these factors when sourcing fiberglass sheets to ensure compliance with environmental standards and to appeal to eco-conscious consumers.

How Has the Fiberglass Sheets Market Evolved Over Time?

The evolution of the fiberglass sheets market can be traced back to the mid-20th century when fiberglass composites began to gain popularity due to their strength-to-weight ratio and resistance to corrosion. Initially used in the aerospace and marine industries, the applications of fiberglass sheets expanded to include automotive parts, electrical insulation, and construction materials.

Over the decades, advancements in manufacturing processes, such as autoclave curing and the development of high-strength epoxy resins, have significantly improved the performance characteristics of fiberglass sheets. Today, these materials are celebrated for their versatility, dimensional stability, and excellent mechanical properties.

Illustrative image related to sheets of fibreglass

As the market continues to adapt to technological innovations and sustainability demands, the future of fiberglass sheets looks promising, with ongoing research and development paving the way for even more advanced applications across various sectors. International B2B buyers should remain vigilant to these trends to ensure they make informed sourcing decisions that align with both market demands and ethical considerations.

Frequently Asked Questions (FAQs) for B2B Buyers of sheets of fibreglass

-

How do I choose the right thickness of fiberglass sheets for my application?

Selecting the appropriate thickness of fiberglass sheets is crucial and depends on the specific application requirements. Thicker sheets provide greater strength and durability, making them suitable for high-stress environments such as aerospace or automotive applications. Conversely, thinner sheets may be sufficient for less demanding uses like insulation or decorative applications. Always consider the load-bearing capacity, the environmental conditions (e.g., humidity, temperature), and any regulatory standards relevant to your industry when making your choice. -

What is the best type of fiberglass sheet for marine applications?

For marine applications, G10 or FR4 fiberglass sheets are highly recommended due to their excellent moisture resistance and structural integrity. These sheets are designed to withstand harsh marine environments, including exposure to saltwater and UV radiation. Additionally, ensure that the fiberglass sheets have a flame-retardant rating if they are to be used in areas where fire safety is a concern. Always consult with your supplier about the specific requirements for marine-grade materials. -

How can I customize fiberglass sheets to meet my project specifications?

Many suppliers offer customization options for fiberglass sheets, including variations in thickness, size, and surface finishes. You can request specific dimensions, additional treatments for enhanced properties (like UV resistance), and even custom colors. It’s advisable to communicate your requirements clearly to the manufacturer and ask for samples or prototypes to ensure the product meets your specifications before placing a larger order. -

What are the minimum order quantities (MOQ) for fiberglass sheets?

Minimum order quantities can vary significantly between suppliers, often depending on the type of fiberglass sheets and the customization required. Typically, MOQs range from a few sheets for standard sizes to several dozen for custom orders. It is essential to discuss MOQs with potential suppliers early in the negotiation process to ensure they align with your purchasing needs and budget constraints. -

What payment terms should I expect when ordering fiberglass sheets internationally?

Payment terms can differ widely among suppliers and regions. Common practices include upfront payments, deposits followed by balance payments upon shipment, or open account terms for established relationships. For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify the terms before finalizing your order to avoid any misunderstandings. -

How do I ensure quality assurance when sourcing fiberglass sheets?

To ensure quality assurance, request detailed specifications and certifications from your supplier. Ask for test reports on mechanical properties, fire resistance, and chemical resistance to verify that the products meet industry standards. Establishing a quality control process, including random inspections and third-party testing, can further ensure the sheets meet your requirements before they are shipped. -

What logistics considerations should I take into account for shipping fiberglass sheets?

Logistics is a critical factor in international procurement. Consider the shipping methods (air vs. sea) based on cost and delivery time, and ensure that your supplier can provide the necessary documentation for customs clearance. Factor in any tariffs or duties that may apply to your shipment. Additionally, verify that the supplier has a reliable logistics partner to minimize delays and ensure safe delivery of your products. -

How can I vet potential suppliers of fiberglass sheets?

Vetting suppliers is essential for mitigating risks in international trade. Start by researching their reputation through online reviews and industry references. Request samples to assess product quality and inspect their manufacturing facilities if possible. Verify their certifications and compliance with international standards. Engaging in direct communication to understand their production capabilities, lead times, and customer service can also provide insights into their reliability and professionalism.

Top 6 Sheets Of Fibreglass Manufacturers & Suppliers List

1. Rock West Composites – Fiberglass Sheets and Custom Solutions

Domain: rockwestcomposites.com

Registered: 2009 (16 years)

Introduction: Fiberglass sheets/plates used in applications ranging from marine and automotive to aerospace and industrial. Flame Smoke Toxicity (FST) options available for aircraft interiors. Custom manufacturing options include aluminized glass sheets, S-glass sheets, and varying thicknesses of standard 7781 woven E-glass products. Available sizes include 12″ x 12″, 12″ x 24″, 24″ x 24″, 24″ x 48″, and 48″ x …

2. Smooth Fiberglass – White Sheet

Domain: us.tchweb.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Smooth Fiberglass (FRP) Sheet – White”, “MFG Item No”: “510-3700911”, “Price”: “$90.10 USD”, “Sheet Size”: “47-1/2″ x 95-1/2″”, “Total Thickness”: “1 mm / 0.040″”, “Color”: “White”, “Weight”: “9.50 lb / 4.3 kg”, “Country of Origin”: “United States”, “Shipping Information”: “Free shipping on orders over $100; $15 shipping on orders over $50 (excludes certain items)”}

3. Ridout Plastics – FRP Sheets & Fiberglass Panels

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, Ridout Plastics – FRP Sheets & Fiberglass Panels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Creative Composites Group – Fiberglass Flat Sheets

Domain: catalog.creativecompositesgroup.com

Registered: 2019 (6 years)

Introduction: This company, Creative Composites Group – Fiberglass Flat Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. McMaster – Fiberglass Sheets

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Fiberglass Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Topoloc – Flat Gelcoat FRP Sheets

Domain: topolocfrt.com

Registered: 2017 (8 years)

Introduction: Flat Gelcoat FRP Sheets for RVs, Trucks, Yachts.

**Introduction:** FRP sheet (fiberglass reinforced plastic) is a thermoset composite material formed by the composite processing of synthetic resin and fiberglass.

**Main Advantages:**

– Light Weight: Relative density is between 1.5~2.0g/cm³, only 1/4~1/5 of carbon steel.

– High Strength: Tensile strength close to or exceeds that of carbon ste…

Strategic Sourcing Conclusion and Outlook for sheets of fibreglass

In summary, effective strategic sourcing of fiberglass sheets is crucial for international B2B buyers aiming to optimize their supply chains and enhance product performance. By focusing on suppliers that offer a diverse range of fiberglass products, such as G10/FR4 sheets, buyers can ensure they meet specific industry requirements, from aerospace to automotive applications. The ability to customize materials and specifications further underscores the importance of collaborating with manufacturers who understand the nuances of their unique markets.

For businesses in Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to significant cost savings and improved product quality. Establishing strong partnerships with reliable suppliers not only fosters innovation but also ensures compliance with international standards, enhancing market competitiveness.

As we look to the future, it is imperative for B2B buyers to remain proactive in evaluating their sourcing strategies. Engage with industry leaders, explore emerging technologies, and stay informed about market trends to harness the full potential of fiberglass materials. This approach will not only drive growth but also position your business as a leader in the fiberglass sector. Take the next step in your sourcing journey and connect with trusted suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.