Choosing Your Rv One Way Valve: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for rv one way valve

In today’s global marketplace, sourcing high-quality RV one way valves presents a significant challenge for B2B buyers. These vital components not only prevent backflow but also ensure the integrity and efficiency of water systems in recreational vehicles. As international buyers from regions like Africa, South America, the Middle East, and Europe navigate this complex landscape, they face the daunting task of identifying reliable suppliers, understanding product specifications, and evaluating cost-effectiveness.

This comprehensive guide is designed to empower you with the insights needed to make informed purchasing decisions. It covers a wide array of topics, including the different types of RV one way valves available, their various applications in RV systems, and essential criteria for vetting suppliers. Additionally, we will delve into the cost factors involved, helping you to align quality with budget constraints.

By equipping B2B buyers with actionable knowledge and expert recommendations, this guide aims to simplify the procurement process. Whether you are seeking to enhance your inventory, improve customer satisfaction, or ensure compliance with international standards, understanding the nuances of RV one way valves will position you for success in a competitive market.

Understanding rv one way valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brass Check Valve | Durable, rust-resistant, lead-free construction | RV plumbing systems, hot water applications | Pros: Long-lasting, safe for potable water; Cons: Can be more expensive than plastic options. |

| Plastic Check Valve | Lightweight, cost-effective, corrosion-resistant | Low-pressure applications, temporary setups | Pros: Affordable, easy to install; Cons: Less durable under high pressure. |

| Spring-Loaded Check Valve | Mechanism with a spring to ensure immediate closure | High-pressure systems, industrial applications | Pros: Reliable performance under varying conditions; Cons: More complex and may require maintenance. |

| Silent Check Valve | Designed to minimize noise during operation | Residential and commercial plumbing | Pros: Reduces noise pollution; Cons: Generally pricier and may not be necessary for all applications. |

| Dual-Function Check Valve | Combines backflow prevention and pressure regulation | Water supply systems, irrigation systems | Pros: Versatile, saves space; Cons: More complicated installation and higher cost. |

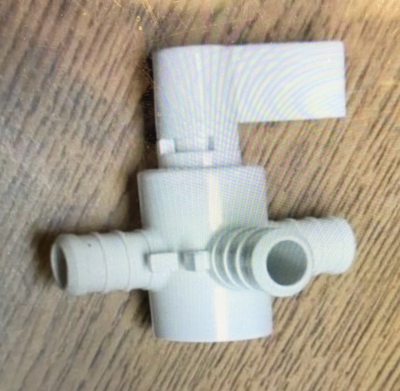

What Are the Characteristics of Brass Check Valves?

Brass check valves are known for their robust construction and longevity, making them ideal for applications where durability is crucial. They are often used in RV plumbing systems and hot water applications due to their lead-free nature, which ensures safety for potable water use. B2B buyers should consider the initial investment against the long-term benefits of reduced maintenance and replacement costs, particularly in environments with fluctuating temperatures or pressures.

Illustrative image related to rv one way valve

How Do Plastic Check Valves Compare?

Plastic check valves are a lightweight and economical option, making them suitable for low-pressure applications and temporary setups. Their corrosion-resistant properties are beneficial in environments where metal components may degrade. However, buyers should be cautious about using them in high-pressure situations, as their durability may not match that of brass alternatives. Cost-effectiveness is a major selling point, especially for large-scale projects with budget constraints.

What Makes Spring-Loaded Check Valves Unique?

Spring-loaded check valves are designed to offer immediate closure, enhancing reliability in high-pressure systems. They are commonly used in industrial applications where backflow prevention is critical. While they provide excellent performance under varying conditions, the complexity of their design may necessitate more frequent maintenance, which is an important consideration for B2B buyers looking for long-term solutions.

Why Choose Silent Check Valves?

Silent check valves are engineered to minimize noise during operation, making them an excellent choice for residential and commercial plumbing applications. While they tend to be pricier than standard options, the reduction in noise pollution can significantly enhance user experience in sensitive environments. Buyers should weigh the importance of noise reduction against budget constraints when considering these valves.

What Are the Benefits of Dual-Function Check Valves?

Dual-function check valves provide both backflow prevention and pressure regulation, making them versatile for water supply and irrigation systems. Their multifunctionality can save space and reduce the number of components needed in a system. However, the complexity of installation and potentially higher costs should be considered by B2B buyers, particularly those looking for streamlined solutions in their plumbing systems.

Illustrative image related to rv one way valve

Key Industrial Applications of rv one way valve

| Industry/Sector | Specific Application of rv one way valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Used in filtration systems to prevent backflow | Ensures system integrity and prevents contamination | Compliance with local regulations for potable water safety |

| Agriculture | Installed in irrigation systems to maintain water pressure | Enhances efficiency and conserves water resources | Durability against environmental factors and chemical exposure |

| HVAC Systems | Utilized in heating systems to manage fluid flow | Improves system performance and energy efficiency | Compatibility with existing systems and pressure ratings |

| Automotive | Incorporated in fuel lines to prevent siphoning | Protects fuel systems and improves safety | Material resistance to fuel types and temperature conditions |

| Oil & Gas | Used in pipeline systems to prevent reverse flow | Protects equipment and maintains operational efficiency | Compliance with industry standards and certifications |

How is the RV One Way Valve Used in Water Treatment Systems?

In water treatment facilities, RV one way valves are critical in filtration systems, where they prevent backflow and ensure that treated water remains uncontaminated. This application is crucial, especially in regions with limited access to clean water, such as parts of Africa and South America. Buyers in this sector must prioritize valves that comply with local health regulations regarding potable water, ensuring safety and reliability.

What Role Does the RV One Way Valve Play in Agriculture?

In agricultural irrigation systems, RV one way valves help maintain consistent water pressure and prevent backflow into the water supply. This application is vital for optimizing water usage, particularly in areas facing water scarcity. B2B buyers should consider valves that are durable against environmental factors and resistant to chemicals commonly used in farming, ensuring long-term performance.

How Do RV One Way Valves Enhance HVAC Systems?

Within HVAC systems, RV one way valves are installed to regulate fluid flow, preventing reverse flow that can disrupt heating and cooling processes. This enhances system efficiency and reduces energy costs, which is particularly beneficial in commercial buildings across Europe and the Middle East. Buyers should focus on valves that are compatible with their existing systems and meet specific pressure ratings to avoid operational issues.

In What Ways Are RV One Way Valves Essential for Automotive Applications?

RV one way valves are commonly found in automotive fuel lines to prevent siphoning, which can lead to fuel loss and safety hazards. This application is crucial for maintaining fuel system integrity, especially in regions with stringent safety regulations, such as Germany and Saudi Arabia. Sourcing considerations should include material compatibility with various fuel types and the ability to withstand varying temperature conditions.

Illustrative image related to rv one way valve

Why Are RV One Way Valves Important in Oil & Gas Pipeline Systems?

In the oil and gas industry, RV one way valves are vital for preventing backflow in pipeline systems, protecting equipment from damage and ensuring efficient operation. This application is critical in maintaining safety and compliance with industry standards. International buyers must ensure that the valves meet specific certifications and standards relevant to their operational regions, guaranteeing reliability and safety in high-pressure environments.

3 Common User Pain Points for ‘rv one way valve’ & Their Solutions

Scenario 1: Inconsistent Water Flow Causing Operational Delays

The Problem: Many B2B buyers in the RV and marine industries encounter issues with inconsistent water flow due to backflow in their systems. This can lead to delays in operations, particularly in hospitality services where water quality is crucial for customer satisfaction. For example, a campsite relying on RVs with faulty check valves might find that guests experience unexpected hot water in cold taps, leading to complaints and a potential loss of business. This not only affects guest comfort but can also damage the reputation of service providers.

The Solution: To effectively mitigate this issue, B2B buyers should prioritize sourcing high-quality one-way valves specifically designed for RV applications. When selecting a valve, look for those made from durable materials such as lead-free brass to ensure longevity and safety. It’s essential to consider the valve’s specifications, such as flow rate and pressure rating, to match the specific needs of the RV plumbing system. Installing the valve upstream of the water heater or pump can prevent any unwanted backflow, thus maintaining consistent water quality and temperature. Additionally, regular maintenance checks should be implemented to ensure that the valves are free of debris and functioning correctly, which can help prevent operational delays.

Scenario 2: Risk of Contaminated Water Supply

The Problem: A significant concern for B2B buyers is the risk of contamination in water systems due to backflow. In regions where water quality regulations are stringent, having a reliable backflow prevention system is not just an operational need but a legal requirement. For example, RV parks in areas with stringent health codes may face fines or legal actions if their water supply is found to be contaminated, especially if backflow occurs from wastewater systems.

The Solution: To address this pain point, it is crucial for B2B buyers to invest in high-performance RV one-way valves that meet local and international health regulations. Buyers should conduct thorough research on suppliers to ensure that the products comply with safety standards for potable water use. Installing a check valve with a clear flow direction indication will help eliminate any confusion during installation, ensuring it is placed correctly. Additionally, regular training for maintenance staff on the importance of monitoring these valves can significantly reduce the risk of contamination and improve compliance with health regulations.

Illustrative image related to rv one way valve

Scenario 3: High Replacement and Maintenance Costs

The Problem: Many companies face high replacement and maintenance costs associated with low-quality one-way valves. Frequent failures can lead to costly repairs and operational downtime. For instance, an RV rental company may find itself repeatedly replacing valves that corrode or fail under pressure, which not only increases operational costs but also affects the availability of rental units.

The Solution: To minimize replacement and maintenance costs, B2B buyers should consider investing in premium quality one-way valves that are designed for durability and resistance to corrosion. When sourcing these valves, it’s advisable to review the manufacturer’s warranty and customer reviews to gauge reliability. Additionally, buyers should implement a proactive maintenance schedule that includes regular inspections and timely replacement of worn-out parts. This approach not only extends the lifespan of the valves but also ensures consistent performance, reducing the frequency of costly repairs and downtime. Investing in a reliable supplier who can provide ongoing support and parts availability can also enhance the overall efficiency of the plumbing systems in RVs.

Strategic Material Selection Guide for rv one way valve

What Are the Common Materials Used in RV One Way Valves?

When selecting materials for RV one way valves, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. This analysis will focus on four common materials: brass, plastic, stainless steel, and bronze. Each material has unique characteristics that can significantly influence the performance and longevity of the valve in various environments.

How Does Brass Perform in RV One Way Valves?

Brass is a popular choice for RV one way valves due to its excellent corrosion resistance and durability. It typically operates effectively at temperatures up to 200°C (392°F) and pressures around 150 psi. The key advantage of brass is its ability to withstand harsh conditions while maintaining structural integrity. However, it can be more expensive compared to plastic alternatives and may not be suitable for applications involving highly corrosive media.

For international buyers, particularly in regions like Europe and the Middle East, compliance with standards such as EN 12165 and ASTM B283 is essential. Brass valves must also be lead-free to meet health regulations, especially in potable water applications.

Illustrative image related to rv one way valve

What Are the Benefits of Using Plastic in RV One Way Valves?

Plastic materials, such as PVC or CPVC, are lightweight and resistant to corrosion, making them an economical choice for RV one way valves. They can handle temperatures up to 60°C (140°F) and pressures around 100 psi. The primary advantage of plastic valves is their low cost and ease of manufacturing, which can reduce overall production expenses.

However, plastic may not be suitable for high-temperature applications or where mechanical strength is a concern. International buyers should ensure that the selected plastic meets relevant standards such as ASTM D1784 and is compatible with the specific media being transported, especially in regions with varying climate conditions.

Why Choose Stainless Steel for RV One Way Valves?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it ideal for demanding environments. It can withstand temperatures up to 300°C (572°F) and pressures exceeding 200 psi. The key advantage of stainless steel is its longevity and reliability, particularly in applications involving aggressive chemicals or high-pressure systems.

However, stainless steel valves are typically more expensive and may require more complex manufacturing processes. Buyers in Africa and South America should consider the availability of stainless steel grades that comply with international standards, such as ASTM A312 and DIN EN 10088-1, to ensure product quality and safety.

Illustrative image related to rv one way valve

What Role Does Bronze Play in RV One Way Valves?

Bronze, an alloy of copper and tin, offers excellent corrosion resistance and is commonly used in marine applications. It can handle temperatures up to 150°C (302°F) and pressures around 150 psi. The primary advantage of bronze is its ability to resist corrosion from seawater and other harsh environments, making it suitable for RVs used in coastal regions.

On the downside, bronze valves can be more costly than plastic and may not be as readily available in certain markets. Buyers should verify compliance with standards such as ASTM B584 and consider the specific environmental conditions in their region, particularly in areas with high humidity or salinity.

Summary Table of Material Properties for RV One Way Valves

| Material | Typical Use Case for rv one way valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Potable water systems, general plumbing | Excellent durability and corrosion resistance | Higher cost compared to plastic | Medium |

| Plastic | Low-pressure water systems, non-potable applications | Low cost and lightweight | Limited temperature and pressure ratings | Low |

| Stainless Steel | High-pressure systems, aggressive chemical applications | Exceptional strength and longevity | Higher manufacturing complexity and cost | High |

| Bronze | Marine applications, corrosive environments | Superior corrosion resistance | Higher cost and limited availability | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions when sourcing RV one way valves that meet specific operational requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rv one way valve

What Are the Key Stages in the Manufacturing Process of RV One Way Valves?

The manufacturing process of RV one way valves involves several critical stages, each designed to ensure the final product meets the necessary performance and safety standards.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage involves selecting high-quality materials, typically brass or lead-free alloys, known for their corrosion resistance and durability. The materials undergo rigorous inspection to ensure they meet industry standards. Once approved, they are cut into required shapes and sizes, often using precision machining techniques to guarantee accuracy.

Forming: How Are the Valve Components Shaped?

The forming stage is crucial in creating the distinct components of the valve. Techniques such as stamping, forging, or CNC machining are commonly employed. For instance, brass components may be stamped into shape before being subjected to heat treatment, which enhances their strength and durability. Proper forming ensures that each component fits perfectly during assembly, reducing the risk of leaks or failures.

Assembly: How Are the Components Joined Together?

During the assembly stage, various components—including the valve body, seat, and spring—are meticulously joined. This may involve soldering or using specialized adhesives that can withstand high pressures and temperatures. Skilled technicians often oversee this process to ensure that all parts are correctly aligned and securely fastened, as any misalignment can compromise the valve’s functionality.

Finishing: What Surface Treatments Are Applied?

The finishing stage involves applying surface treatments that enhance the valve’s resistance to corrosion and wear. Techniques such as electroplating or powder coating may be used to create a protective layer. Additionally, final inspections are performed to check for surface defects, ensuring that the product meets aesthetic and functional standards.

What Quality Control Measures Are Essential for RV One Way Valves?

Quality control (QC) is critical in the manufacturing of RV one way valves, ensuring that each unit performs reliably under various conditions. International and industry-specific standards guide these QC measures.

Illustrative image related to rv one way valve

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 play a significant role in the quality assurance of manufactured goods. ISO 9001 focuses on maintaining a quality management system that emphasizes customer satisfaction and continuous improvement. Additionally, specific certifications like CE (European Conformity) and API (American Petroleum Institute) are vital for valves used in different applications, indicating compliance with safety and performance standards.

What Are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter production. Any substandard materials are rejected at this stage.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to ensure that the processes are being followed correctly and that the components meet specifications.

-

Final Quality Control (FQC): Once the valves are assembled, they undergo final inspections and testing. This includes pressure testing and functional testing to ensure they perform as expected.

What Common Testing Methods Are Used for RV One Way Valves?

Several testing methods are employed to validate the performance and safety of RV one way valves:

-

Pressure Testing: Valves are subjected to high-pressure conditions to ensure they can withstand operational stresses without leaking.

-

Flow Testing: This assesses the valve’s ability to allow fluid to flow in one direction while preventing backflow.

-

Durability Testing: Valves are tested for wear and tear under simulated operational conditions to determine their lifespan.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount. Here are several actionable steps:

What Auditing Processes Should Be Implemented?

Conducting supplier audits is an effective way to assess their quality control measures. This includes reviewing their manufacturing processes, QC checkpoints, and compliance with international standards. B2B buyers should request documentation of past audits and certifications to ensure transparency.

How Can Buyers Request Quality Reports?

Buyers can ask suppliers for detailed quality reports that outline the results of various tests conducted on the valves. This documentation should include specifications, test results, and any corrective actions taken for non-conforming products.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing and quality control processes. These inspections can validate compliance with international standards and identify any potential issues before the product reaches the buyer.

What Are the Specific QC and Certification Nuances for International Buyers?

International buyers must navigate various regulatory landscapes when sourcing RV one way valves. For example, the CE mark is mandatory for products sold in the European market, indicating compliance with EU safety and environmental requirements. Buyers should familiarize themselves with the specific regulations in their region, such as the need for lead-free materials in certain markets, to ensure compliance and avoid legal complications.

Furthermore, understanding the differences in quality expectations across regions can help buyers make informed decisions. For instance, European buyers may have stricter standards for material safety compared to buyers in other regions, necessitating a more thorough vetting process for suppliers.

Conclusion: How to Ensure Quality in Your RV One Way Valve Sourcing

By understanding the manufacturing processes and quality assurance measures for RV one way valves, B2B buyers can make informed decisions when sourcing these critical components. Ensuring compliance with international standards, implementing thorough QC checkpoints, and engaging in rigorous supplier assessments are essential steps in securing high-quality products that meet specific operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rv one way valve’

In the competitive landscape of B2B procurement, sourcing the right components is critical to maintaining operational efficiency and product integrity. This guide provides a comprehensive checklist for international buyers looking to procure RV one-way valves, ensuring a streamlined sourcing process.

-

Define Your Technical Specifications

Clearly outline the technical requirements for the RV one-way valve you need. Consider factors such as size (e.g., 1/2” or 3/4”), material (brass, lead-free, etc.), and the specific application (e.g., plumbing systems or water heaters). Defining these specifications upfront will help narrow your search and ensure compatibility with your existing systems. -

✅ Research Regulatory Compliance

Ensure the valves comply with international standards relevant to your market. Depending on your location, this may include NSF/ANSI standards for potable water systems, CE marking for European markets, or other local certifications. Compliance not only guarantees safety but also enhances product reliability and market acceptance. -

Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request company profiles, product catalogs, and references from other businesses in your industry. Look for suppliers that have a proven track record in manufacturing RV one-way valves, as their experience can significantly impact quality and reliability. -

✅ Compare Pricing and Terms

Collect quotes from multiple suppliers to compare pricing structures. Be mindful of additional costs such as shipping, taxes, or customs duties, especially for international transactions. Understanding payment terms, lead times, and minimum order quantities is crucial for effective budget management and inventory planning. -

Assess Quality Assurance Processes

Investigate the quality control measures employed by suppliers. Inquire about their testing protocols for the RV one-way valves, including any certifications that demonstrate their commitment to quality, such as ISO 9001. A robust quality assurance process is essential to minimize the risk of defects and ensure long-term performance. -

✅ Consider After-Sales Support and Warranty

Evaluate the level of after-sales support offered by the supplier, including warranty terms and customer service availability. Reliable after-sales support can be a significant asset, especially if issues arise post-purchase. A strong warranty indicates confidence in the product’s durability and can protect your investment. -

✅ Finalize Contracts with Clear Terms

Before placing an order, ensure that all terms and conditions are clearly outlined in the contract. This includes delivery timelines, payment schedules, and return policies. A well-defined contract mitigates risks and sets clear expectations for both parties, paving the way for a successful business relationship.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing RV one-way valves effectively, ensuring they select the right products and suppliers to meet their operational needs.

Comprehensive Cost and Pricing Analysis for rv one way valve Sourcing

What Are the Key Cost Components in Sourcing RV One-Way Valves?

When considering the sourcing of RV one-way valves, it is essential to understand the various cost components that contribute to the final price. These components typically include:

-

Materials: The choice of materials significantly influences the cost. Commonly used materials for RV one-way valves include lead-free brass and durable plastics, which ensure both longevity and compliance with safety standards. The price of raw materials can fluctuate based on market conditions, affecting the overall cost.

-

Labor: Labor costs vary depending on the region of production. In countries with lower wage standards, labor costs are typically reduced, which can lower the overall price of the valves. However, this may also impact quality if not managed properly.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, equipment maintenance, and factory rent. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to evaluate suppliers based on their operational efficiency.

-

Tooling: Custom tooling for specific valve designs or sizes can be a significant upfront investment. Buyers should consider the tooling costs in relation to their order volume; larger orders may justify the investment in custom tooling.

-

Quality Control (QC): Implementing robust QC measures is crucial for ensuring product reliability and compliance with international standards. While QC processes add to the cost, they ultimately save money in the long run by reducing returns and maintaining brand reputation.

-

Logistics: Transportation and shipping costs can vary widely based on the location of the supplier and the delivery destination. International buyers should factor in customs duties, tariffs, and shipping fees, which can considerably influence the total cost.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary based on market competition, brand reputation, and perceived value of the product.

How Do Price Influencers Affect the Cost of RV One-Way Valves?

Several key factors can influence the pricing of RV one-way valves:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts based on order volume. Higher volumes can lead to reduced per-unit costs, making it beneficial for buyers to consolidate orders.

-

Specifications and Customization: Custom specifications, such as unique sizes or enhanced features, can increase costs. Buyers should balance the need for customization with budget constraints.

-

Material Quality and Certifications: Premium materials and certifications (e.g., NSF for drinking water safety) may raise the price but are essential for compliance, especially in regulated markets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their brand value and proven track record.

-

Incoterms: The terms of delivery can significantly impact total costs. Understanding Incoterms (e.g., FOB, CIF) is crucial for budgeting and determining who bears the shipping costs and risks.

What Are the Best Negotiation Tips for International Buyers?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to more favorable pricing:

-

Conduct Market Research: Understand the average prices and market trends for RV one-way valves. This knowledge empowers buyers during negotiations.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms. Regular communication fosters trust and may result in exclusive deals.

-

Assess Total Cost of Ownership (TCO): Look beyond initial purchase price. Consider installation, maintenance, and potential replacement costs to gauge the true value of the product.

-

Be Transparent About Needs: Clearly communicate specifications and requirements to avoid misunderstandings that could lead to additional costs.

-

Leverage Competition: Use quotes from multiple suppliers to negotiate better terms. A competitive environment can encourage suppliers to offer better pricing.

Conclusion: Understanding Pricing Nuances in International B2B Transactions

Buyers must be aware that indicative prices can vary widely based on the factors discussed above. Engaging with multiple suppliers, assessing total costs, and considering market dynamics can help in making informed sourcing decisions for RV one-way valves. By understanding the comprehensive cost structure and pricing influencers, buyers can optimize their procurement strategies and achieve cost-efficient solutions that meet their operational needs.

Illustrative image related to rv one way valve

Alternatives Analysis: Comparing rv one way valve With Other Solutions

In the context of plumbing systems, particularly for RVs, the need for effective backflow prevention is paramount. While the RV one-way valve is a popular choice, several alternative solutions can also achieve similar objectives. This analysis will explore these alternatives, providing insights into their performance, cost, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | Rv One Way Valve | Alternative 1: Backflow Preventer Valve | Alternative 2: Check Valve with Spring Mechanism |

|---|---|---|---|

| Performance | Allows fluid flow in one direction; prevents backflow effectively. | Similar performance; prevents backflow effectively, especially in hot water systems. | High reliability; uses spring mechanism for quick response to backflow. |

| Cost | Typically ranges from $5 to $15 depending on size and material. | Priced around $10 to $15; generally offers similar functionality. | Generally more expensive, ranging from $15 to $30 due to complexity. |

| Ease of Implementation | Simple installation with standard fittings; minimal tools required. | Slightly more complex; may require additional fittings for optimal placement. | Installation can be more complicated due to the spring mechanism; may need professional assistance. |

| Maintenance | Requires periodic checks for wear; easy to clean. | Low maintenance; occasional checks needed to ensure no debris blockage. | Regular maintenance needed to ensure spring functionality; more prone to wear. |

| Best Use Case | Ideal for general RV water systems where backflow prevention is essential. | Best suited for hot water systems to avoid mixing with cold water. | Recommended for high-pressure systems or where rapid response to backflow is critical. |

What Are the Pros and Cons of Using a Backflow Preventer Valve?

The backflow preventer valve is an alternative that excels in preventing hot water from flowing back into the cold water supply, which is particularly beneficial for RV systems. Its design allows for a straightforward installation before the water heater, ensuring that hot water remains isolated from the cold supply. The primary advantage is its ability to preserve water temperature and conserve freshwater resources in RVs with limited capacity. However, it can be slightly more complex to install than a standard one-way valve, and its cost may be higher.

How Does a Check Valve with Spring Mechanism Compare?

A check valve utilizing a spring mechanism is another viable alternative. This type of valve responds quickly to changes in flow direction, providing a reliable solution for backflow prevention. Its design is suitable for high-pressure applications, making it ideal for industrial uses beyond RVs. While it generally offers superior performance, the complexity of installation can deter some users, and regular maintenance is necessary to ensure the spring remains functional. The higher cost may also be a consideration for budget-conscious buyers.

Conclusion: How to Choose the Right Backflow Prevention Solution?

When selecting the appropriate backflow prevention solution, B2B buyers must consider several factors, including the specific application, budget constraints, and maintenance capabilities. The RV one-way valve remains a solid choice for general use, while backflow preventer valves are more specialized for situations involving temperature-sensitive water systems. For high-pressure environments, a check valve with a spring mechanism may be warranted despite its higher cost and maintenance needs. Ultimately, understanding the unique requirements of your plumbing system will guide you toward the most effective and economical solution.

Illustrative image related to rv one way valve

Essential Technical Properties and Trade Terminology for rv one way valve

What Are the Key Technical Properties of an RV One Way Valve?

In the realm of RV plumbing systems, understanding the technical properties of one-way valves is crucial for ensuring the efficiency and safety of water flow. Here are some essential specifications that buyers should consider:

-

Material Composition

The material used in the construction of RV one-way valves is a primary determinant of their durability and suitability for potable water applications. Common materials include lead-free brass and PVC. Brass is favored for its corrosion resistance and longevity, while PVC is lightweight and resistant to chemical degradation. Selecting the appropriate material ensures compliance with health regulations and enhances the valve’s lifespan. -

Pressure Rating

The pressure rating indicates the maximum pressure the valve can withstand without failure. This is particularly important in RV applications where water systems can experience fluctuating pressures. A higher pressure rating (measured in PSI) allows for a wider range of applications, ensuring the valve performs effectively under varying conditions. Buyers should choose valves with ratings that exceed their system’s maximum operational pressure to prevent leaks or failures. -

Fitting Size and Type

The fitting size (e.g., 1/2″, 3/4″) and type (e.g., male NPT, female NPT) are critical for compatibility with existing plumbing systems. Proper fitting ensures a secure connection, minimizing the risk of leaks. When sourcing valves, it’s essential to match the fitting specifications with the existing pipe sizes in the RV to facilitate straightforward installation. -

Flow Direction Indicator

Many one-way valves feature a flow direction indicator, which is crucial for installation. This indicator helps ensure that the valve is installed correctly, allowing water to flow in the intended direction while preventing backflow. Understanding this feature can save time and resources during installation, as improper installation can lead to system failures. -

Lead-Free Compliance

With increasing regulations regarding lead exposure, particularly in drinking water systems, lead-free compliance is a significant factor. Valves that are certified lead-free not only meet health and safety standards but also provide peace of mind for buyers concerned about water quality. This specification is especially relevant in international markets where different countries have varying regulations regarding lead in plumbing materials.

What Common Trade Terms Should B2B Buyers Know for RV One Way Valves?

Navigating the B2B landscape requires familiarity with specific trade jargon. Here are some key terms relevant to RV one-way valves:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of RV one-way valves, purchasing from OEMs can ensure compatibility and quality, as these manufacturers often produce components specifically designed for RV systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it affects purchasing decisions, especially for small businesses or those testing new products. Buyers should negotiate MOQs to align with their inventory needs without incurring excess costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products. For RV one-way valves, issuing an RFQ allows buyers to compare prices, terms, and specifications from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to understand shipping responsibilities, costs, and risk management when sourcing RV one-way valves globally. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. In the RV industry, where timely repairs and maintenance are critical, understanding lead times can help buyers plan their operations effectively. Suppliers should provide clear lead time estimates to help buyers manage their supply chain efficiently.

By grasping these technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ensuring they select the right RV one-way valves for their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the rv one way valve Sector

What Are the Key Drivers and Trends Influencing the RV One Way Valve Market?

The RV one way valve market is experiencing significant growth, driven by various global factors. The increasing popularity of recreational vehicles (RVs) across Africa, South America, the Middle East, and Europe is a primary catalyst. As consumers seek greater mobility and outdoor experiences, the demand for reliable plumbing components, such as one way valves, has surged. This trend is further amplified by the rising awareness of water conservation and the need for efficient water management systems in RVs.

Emerging technologies are also reshaping the sourcing landscape. The integration of IoT (Internet of Things) in RV manufacturing allows for real-time monitoring of plumbing systems, enhancing the functionality of one way valves. Buyers are increasingly looking for valves that not only prevent backflow but also include features like pressure regulation and automated alerts for maintenance needs. Additionally, digital sourcing platforms are becoming prevalent, enabling international buyers to access a wider range of suppliers and products, facilitating more competitive pricing and improved supply chain efficiency.

Furthermore, the regulatory landscape is evolving, particularly in regions like Europe and North America, where compliance with health and safety standards is paramount. Buyers must be aware of certifications that guarantee lead-free materials and other safety features, which are increasingly demanded by end consumers.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions for RV One Way Valves?

Sustainability is no longer a secondary consideration; it has become a cornerstone of B2B decision-making in the RV one way valve sector. The environmental impact of manufacturing processes and materials is under scrutiny, leading to a heightened demand for sustainable practices. Buyers are increasingly seeking suppliers who utilize eco-friendly materials and sustainable manufacturing methods. For instance, valves made from lead-free brass or recycled materials are gaining traction as they align with consumer preferences for health and environmental consciousness.

Ethical sourcing also plays a critical role in shaping supply chain decisions. Buyers are encouraged to partner with manufacturers who adhere to fair labor practices and transparent supply chains. This not only mitigates reputational risks but also appeals to a growing segment of environmentally and socially conscious consumers. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability.

Moreover, investing in sustainable products can provide long-term cost savings through reduced waste and increased efficiency. As water conservation becomes increasingly critical in many regions, sourcing valves that prevent backflow and ensure optimal water flow can enhance overall system performance while supporting environmental goals.

Illustrative image related to rv one way valve

What Is the Historical Context of RV One Way Valves?

The evolution of RV one way valves reflects broader advancements in plumbing technology and consumer demands. Initially designed for basic water management, these valves have evolved significantly over the decades. Early models were often made from less durable materials, leading to frequent failures and maintenance issues. However, as the RV industry expanded, the need for more reliable and efficient plumbing components became apparent.

In the late 20th century, advancements in material science introduced durable options such as brass and reinforced plastics, improving longevity and safety. The introduction of lead-free regulations in the early 2000s further transformed the market, compelling manufacturers to innovate and meet new health standards. Today, the RV one way valve is a sophisticated component that not only addresses backflow prevention but also aligns with modern sustainability practices and technological advancements, catering to the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of rv one way valve

-

How do I prevent backflow in my RV plumbing system?

To prevent backflow in your RV plumbing, installing a one-way valve, such as a check valve, is essential. These valves allow water to flow in one direction while blocking reverse flow, thus maintaining consistent water pressure and preventing contamination. When selecting a valve, ensure it’s made from durable materials like lead-free brass for safety and longevity. Regular maintenance is also crucial; inspect the valve for wear and clean it to ensure optimal performance. This will help safeguard your RV’s water system and enhance overall functionality. -

What is the best one-way valve for RV applications?

The best one-way valve for RV applications typically depends on your specific plumbing setup and requirements. A lead-free brass check valve is highly recommended due to its durability, rust resistance, and suitability for potable water. Valves with male-to-male fittings are particularly useful for easy installation in tight spaces. Consider the valve’s size and pressure rating to ensure it matches your system’s specifications. It’s advisable to consult with suppliers to find a valve that meets your particular needs for efficiency and safety. -

What should I consider when sourcing RV one-way valves internationally?

When sourcing RV one-way valves internationally, consider factors such as supplier reputation, product quality, and compliance with local regulations. Check for certifications that ensure the valves are safe for potable water use. Additionally, evaluate the supplier’s experience in the RV industry and their ability to provide necessary documentation, such as material safety data sheets (MSDS). Establish communication channels for support and inquiries, and consider their logistics capabilities to ensure timely delivery to your location. -

What are the common minimum order quantities (MOQs) for RV one-way valves?

Minimum order quantities for RV one-way valves can vary significantly depending on the supplier and the valve specifications. Typically, MOQs range from 50 to 200 units, especially for customized products. However, many suppliers may offer flexible MOQs for established buyers or bulk orders. It’s essential to clarify these details before placing an order to avoid unexpected costs. Inquire about price breaks for larger orders, as this can lead to significant savings in the long run. -

What payment terms should I expect when purchasing RV one-way valves?

Payment terms for purchasing RV one-way valves can differ by supplier and region. Common practices include partial upfront payments (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, allowing you to pay within a specific period after receiving the goods. It’s crucial to negotiate clear payment terms upfront to ensure financial security for both parties. Always request a pro forma invoice detailing all costs and terms before making any payments. -

How can I ensure the quality of RV one-way valves from suppliers?

To ensure the quality of RV one-way valves, request samples before placing a bulk order. This allows you to evaluate the material, construction, and performance. Additionally, inquire about the supplier’s quality assurance processes, including testing for durability and compliance with industry standards. Check if the supplier has certifications that guarantee the valves are safe for drinking water. Regular quality audits and feedback from other customers can also provide insights into the supplier’s reliability and product consistency. -

What logistics considerations should I keep in mind when importing RV one-way valves?

When importing RV one-way valves, consider shipping methods, customs clearance, and potential tariffs. Evaluate whether air or sea freight is more cost-effective for your order size. Ensure your supplier can handle logistics and provide documentation required for customs, such as invoices and certificates of origin. Be aware of delivery timelines and possible delays, especially if sourcing from overseas. Establish a clear communication line with your logistics provider to track shipments and address any issues promptly. -

Can I customize RV one-way valves to suit my specific needs?

Yes, many suppliers offer customization options for RV one-way valves, including size, material, and fittings. Customization allows you to tailor the product to your specific plumbing system requirements. Discuss your needs with the supplier, including any unique specifications, to determine feasibility and costs. Keep in mind that custom orders may come with higher MOQs and longer lead times. It’s beneficial to establish a clear design brief and maintain regular communication throughout the customization process to ensure satisfaction with the final product.

Top 3 Rv One Way Valve Manufacturers & Suppliers List

1. RVS – 3/4 Water Check Valve

Domain: rvsurplusparts.net

Registered: 2017 (8 years)

Introduction: {“name”: “3/4″ Water Check Valve”, “price”: “$5.00”, “availability”: “In stock (568)”, “features”: [“Prevents Backflow”, “Male to Male Brass Fitting”, “Lead Free”], “description”: “The 3/4” Water Check Valve is a reliable and efficient component designed to prevent backflow and ensure the smooth and uninterrupted flow of water in your plumbing system. It features a lead-free construction, making i…

2. RecPro – RV Back Flow Preventer

Domain: recpro.com

Registered: 2005 (20 years)

Introduction: RV Back Flow Preventer, 1/2 inch, Brass Check Valve

3. Tameson – RV Water Pump Check Valve

Domain: tameson.com

Registered: 2015 (10 years)

Introduction: RV Water Pump Check Valve Replacement: Prevents backflow to avoid contamination and system malfunctions. Typically located at the water pump outlet and city water inlet. Signs of a faulty valve include leaking water, decreased water pressure, continuous pump operation, unusual noises, backflow, water contamination, and rapid cycling of the pump. Repair options include checking the RV water pump ma…

Strategic Sourcing Conclusion and Outlook for rv one way valve

The importance of strategic sourcing for RV one-way valves cannot be overstated. By focusing on high-quality materials such as lead-free brass, B2B buyers can ensure their products meet safety and durability standards, which is particularly vital in regions with stringent regulatory requirements. Moreover, understanding the specific applications—whether for hot water heaters or water pumps—enables buyers to select valves that optimize system efficiency and minimize water wastage.

As international markets expand, particularly in Africa, South America, the Middle East, and Europe, the demand for reliable plumbing solutions continues to grow. Strategic sourcing will not only enhance supply chain resilience but also improve cost-effectiveness and product availability.

Looking ahead, businesses should leverage partnerships with trusted suppliers to foster innovation and ensure access to cutting-edge technologies in valve design and manufacturing. Investing in these relationships will position companies to meet future challenges and seize opportunities in an evolving market landscape. Therefore, take action now to refine your sourcing strategies and elevate your offerings in the competitive RV plumbing sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to rv one way valve