Choosing Your Roller Threading Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for roller threading machine

In the fast-evolving landscape of global manufacturing, sourcing a reliable roller threading machine is a pivotal challenge that many B2B buyers face. As industries across Africa, South America, the Middle East, and Europe continue to expand, the demand for efficient, high-quality thread rolling solutions has surged. This guide is designed to equip international buyers with the knowledge necessary to navigate the complexities of selecting the right roller threading machines.

From understanding the different types of machines available—such as two-die and three-die models—to exploring their applications in diverse sectors like automotive and aerospace, this comprehensive resource delves into every facet of the roller threading machine market. We will also cover critical aspects like supplier vetting processes, cost considerations, and the latest technological advancements that can influence your purchasing decision.

By the end of this guide, B2B buyers will be empowered to make informed decisions that not only meet their operational needs but also enhance their competitive edge in the global market. Whether you’re operating in Nigeria, Vietnam, or anywhere in between, understanding the nuances of roller threading machines will position you for success in your sourcing endeavors.

Understanding roller threading machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 2-Die Thread Rolling Machine | Utilizes two dies for thread formation, suitable for medium-sized parts. | Automotive, Aerospace, Manufacturing | Pros: Cost-effective, versatile for various thread sizes. Cons: Limited to medium production volumes. |

| 3-Die Thread Rolling Machine | Employs three dies for enhanced precision and strength in threads. | Heavy Machinery, Industrial Fasteners | Pros: Higher quality threads, better for larger components. Cons: Higher initial investment. |

| One-Slide Thread Rolling Machine | Features a single slide mechanism, optimizing for quick changeovers. | Mass Production, Fastener Manufacturing | Pros: Fast production rates, easy to operate. Cons: Less flexibility for complex thread profiles. |

| CNC Thread Rolling Machine | Integrates CNC technology for precise control and automation. | Aerospace, Medical Devices, High-Precision Applications | Pros: High precision, programmable for complex designs. Cons: Higher maintenance costs, steep learning curve. |

| Profile Rolling Machine | Capable of rolling complex shapes and profiles beyond standard threads. | Custom Manufacturing, Specialized Fasteners | Pros: Versatile for unique designs, high efficiency. Cons: Requires skilled operators, often more expensive. |

What Are the Key Characteristics of 2-Die Thread Rolling Machines?

The 2-Die Thread Rolling Machine is primarily designed for producing standard threads on medium-sized components. Its dual-die configuration allows for efficient thread formation, making it suitable for industries such as automotive and general manufacturing. When considering this machine, buyers should evaluate production volume needs and the types of materials they intend to work with. While cost-effective and versatile, it may not be ideal for high-volume production settings.

How Do 3-Die Thread Rolling Machines Enhance Thread Quality?

3-Die Thread Rolling Machines incorporate an additional die, resulting in superior thread strength and precision. This makes them particularly advantageous for heavy machinery and industrial fasteners, where durability is paramount. Companies should consider the initial investment and ongoing maintenance costs when opting for this machine type. The enhanced quality and reliability justify the expense for businesses focused on high-performance applications.

What Advantages Do One-Slide Thread Rolling Machines Offer for Mass Production?

One-Slide Thread Rolling Machines are designed for rapid production, featuring a single slide mechanism that allows for quick die changes and streamlined operations. This machine type is particularly effective in mass production environments, such as fastener manufacturing. Buyers should weigh the benefits of speed and ease of use against the limitations in producing complex thread profiles. This machine is ideal for high-volume operations where efficiency is critical.

Why Choose CNC Thread Rolling Machines for Precision Applications?

CNC Thread Rolling Machines leverage advanced computer numerical control technology, allowing for precise thread formation and automation. They are especially suitable for industries requiring high precision, such as aerospace and medical device manufacturing. While the upfront costs and maintenance may be higher, the benefits of programmability and accuracy make these machines a valuable investment for businesses focused on intricate designs and high-quality standards.

What Makes Profile Rolling Machines Unique in Thread and Shape Production?

Profile Rolling Machines stand out by their ability to produce not just threads but also complex shapes and profiles. This versatility is particularly beneficial for custom manufacturing and specialized fasteners. Buyers should consider the skill level of their operators, as these machines often require more expertise to operate effectively. While they may come at a higher price point, their efficiency in producing unique designs can provide significant long-term value for businesses looking to innovate.

Key Industrial Applications of roller threading machine

| Industry/Sector | Specific Application of roller threading machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of bolts, screws, and fasteners | Enhanced production efficiency and strength | Consider the machine’s throughput, compatibility with materials, and after-sales support. |

| Aerospace Engineering | Manufacturing precision threaded components | High reliability and safety standards | Look for machines capable of handling specific aerospace materials and achieving tight tolerances. |

| Construction | Fabrication of structural fasteners | Durability and cost-effectiveness | Assess the machine’s ability to produce various thread profiles and its ease of integration into existing systems. |

| Oil and Gas | Creation of threaded pipes and fittings | Improved resistance to harsh environments | Evaluate the machine’s capacity for larger dimensions and corrosion-resistant materials. |

| Electronics | Threading for enclosures and connectors | Increased production speed and precision | Prioritize machines that allow for automation and precise control over thread specifications. |

How Is the Roller Threading Machine Used in Automotive Manufacturing?

In the automotive sector, roller threading machines are crucial for producing high-strength bolts, screws, and fasteners essential for vehicle assembly. These machines utilize a cold-forming process that enhances the structural integrity of components, reducing the risk of failure during operation. For international buyers, especially from regions like Africa and South America, sourcing machines with high throughput and adaptability to various materials is essential. Additionally, after-sales support and availability of spare parts should be a priority to ensure continuous production.

What Role Does the Roller Threading Machine Play in Aerospace Engineering?

Aerospace engineering demands precision and reliability, making roller threading machines indispensable for manufacturing threaded components used in aircraft and spacecraft. These machines produce threads that meet stringent safety and quality standards, essential for high-stress applications. Buyers in the Middle East and Europe should focus on sourcing machines that can handle specialized aerospace materials and achieve tight tolerances, ensuring compliance with regulatory requirements while maintaining efficiency in production.

How Are Roller Threading Machines Utilized in Construction?

In the construction industry, roller threading machines are employed to fabricate structural fasteners that provide the necessary strength and durability for building projects. The cold-forming process utilized by these machines results in components that are not only cost-effective but also capable of withstanding significant loads. Buyers from developing markets must consider the machine’s versatility in producing various thread profiles and its ease of integration into existing manufacturing processes to optimize their operations.

What Is the Importance of Roller Threading Machines in Oil and Gas?

The oil and gas industry relies on roller threading machines to create threaded pipes and fittings that must endure harsh environmental conditions. These machines enhance the performance of components by ensuring they are robust and resistant to wear and corrosion. For international buyers, especially in regions rich in natural resources, evaluating the machine’s capacity for larger dimensions and compatibility with corrosion-resistant materials is vital to ensure reliability and longevity in their operations.

How Do Electronics Manufacturers Benefit from Roller Threading Machines?

In the electronics sector, roller threading machines are used for threading enclosures and connectors that require high precision and speed. The efficiency of these machines allows manufacturers to streamline production processes while ensuring the quality of threaded components. Buyers should prioritize machines that support automation and offer precise control over thread specifications, which is critical for meeting the fast-paced demands of the electronics market, especially in competitive regions like Europe and Asia.

3 Common User Pain Points for ‘roller threading machine’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Thread Quality

The Problem: B2B buyers in industries such as automotive and aerospace often face challenges with maintaining consistent thread quality during production. Variability in the threading process can lead to defects that result in costly reworks, wasted materials, and potential safety issues. Buyers may struggle with understanding how to set up the roller threading machine correctly or may not have adequate training for their operators, which exacerbates the inconsistency in thread formation.

The Solution: To ensure high-quality threads, it is crucial to invest in roller threading machines that offer precise control over the threading process. Buyers should prioritize equipment that includes advanced features such as programmable CNC controls and automated monitoring systems. Additionally, conducting regular maintenance and calibration of the machines can significantly improve performance. Training sessions for operators should be implemented to familiarize them with the machine’s capabilities and adjustments. Collaboration with suppliers for initial setup guidance and ongoing support can also help in achieving consistent quality across production runs.

Scenario 2: High Operational Costs Due to Inefficient Processes

The Problem: Many companies find that their existing roller threading machines are not optimized for efficiency, leading to high operational costs. This is especially prevalent in regions where labor costs are rising, and manufacturers are pressured to maintain profitability while delivering high-quality products. Inefficient machines may require excessive downtime for maintenance or have slow cycle times, which can adversely affect overall productivity.

The Solution: To combat high operational costs, buyers should consider investing in modern roller threading machines that are designed for efficiency. Machines with the ability to integrate automation, such as robotic part loading systems and advanced die change technologies, can significantly reduce cycle times and labor costs. Analyzing the total cost of ownership, including maintenance and energy consumption, will help buyers make informed decisions. Furthermore, engaging in regular performance evaluations and working closely with machine suppliers for updates and upgrades can ensure that the threading operations remain competitive and cost-effective.

Scenario 3: Limited Flexibility in Production Capabilities

The Problem: B2B buyers often encounter issues when their roller threading machines lack the flexibility to accommodate diverse product lines. This limitation can hinder the ability to respond to market demands, particularly in industries like fasteners and custom parts manufacturing. As customer requirements evolve, the inability to adapt quickly can lead to lost opportunities and reduced market share.

The Solution: To enhance production flexibility, companies should opt for roller threading machines that offer multi-die setups and adjustable rolling parameters. Machines that support a wide range of materials and thread sizes can enable manufacturers to pivot quickly between different production requirements. Additionally, investing in modular equipment or systems that can be easily upgraded as new technologies emerge can future-proof operations. Building a strong relationship with machine suppliers for customization options and technical support can also enhance a company’s capability to adapt to changing market demands efficiently.

Strategic Material Selection Guide for roller threading machine

What Are the Key Materials Used in Roller Threading Machines?

When selecting materials for roller threading machines, various factors such as performance, durability, and cost must be considered. Here, we analyze four common materials used in these machines: carbon steel, stainless steel, aluminum, and tool steel. Each material has unique properties that can significantly impact the performance and suitability of the machines in various applications.

How Does Carbon Steel Perform in Roller Threading Machines?

Key Properties: Carbon steel is known for its high strength and hardness, making it suitable for high-pressure applications. It has a good temperature tolerance and can withstand significant mechanical stress.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. However, it is prone to corrosion, which can limit its lifespan in humid or corrosive environments. The manufacturing complexity is moderate, as it can be easily machined and welded.

Impact on Application: Carbon steel is ideal for applications requiring high strength, such as automotive and heavy machinery components. However, its susceptibility to rust means that protective coatings or treatments may be necessary for specific environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM A36 for structural steel. Additionally, understanding the local climate’s impact on material selection is crucial.

What Advantages Does Stainless Steel Offer for Roller Threading Machines?

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It is also non-reactive, making it suitable for various media.

Pros & Cons: The key advantage of stainless steel is its longevity and low maintenance requirements. However, it is more expensive than carbon steel and can be more challenging to machine due to its toughness.

Impact on Application: Stainless steel is particularly well-suited for applications in the food processing and pharmaceutical industries, where hygiene is paramount. Its corrosion resistance ensures that it maintains integrity in wet or corrosive environments.

Considerations for International Buyers: Buyers in Europe and the Middle East often prefer stainless steel due to stringent hygiene standards. Compliance with standards like ASTM A240 is essential for ensuring quality.

How Does Aluminum Compare for Use in Roller Threading Machines?

Key Properties: Aluminum is lightweight and has good corrosion resistance. It also has excellent thermal and electrical conductivity, making it useful in specific applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which can enhance machine efficiency and reduce operational costs. However, it has lower strength compared to steel, which may limit its use in high-stress applications.

Impact on Application: Aluminum is ideal for lightweight components in industries such as aerospace and automotive. Its corrosion resistance makes it suitable for outdoor applications, but its lower strength limits its use in heavy-duty machinery.

Considerations for International Buyers: In regions like Africa and Vietnam, the availability of aluminum may vary. Buyers should ensure that the material meets local standards, such as JIS H 4040 for aluminum alloys.

Illustrative image related to roller threading machine

What Role Does Tool Steel Play in Roller Threading Machines?

Key Properties: Tool steel is designed for high wear resistance and durability, making it ideal for cutting and shaping tools. It can withstand high temperatures and has excellent hardness.

Pros & Cons: The main advantage of tool steel is its ability to maintain sharp edges and resist deformation. However, it is more expensive and can be challenging to machine, requiring specialized tools.

Impact on Application: Tool steel is commonly used in the manufacturing of dies and tools for thread rolling due to its durability and precision. Its high wear resistance ensures longevity in high-volume production environments.

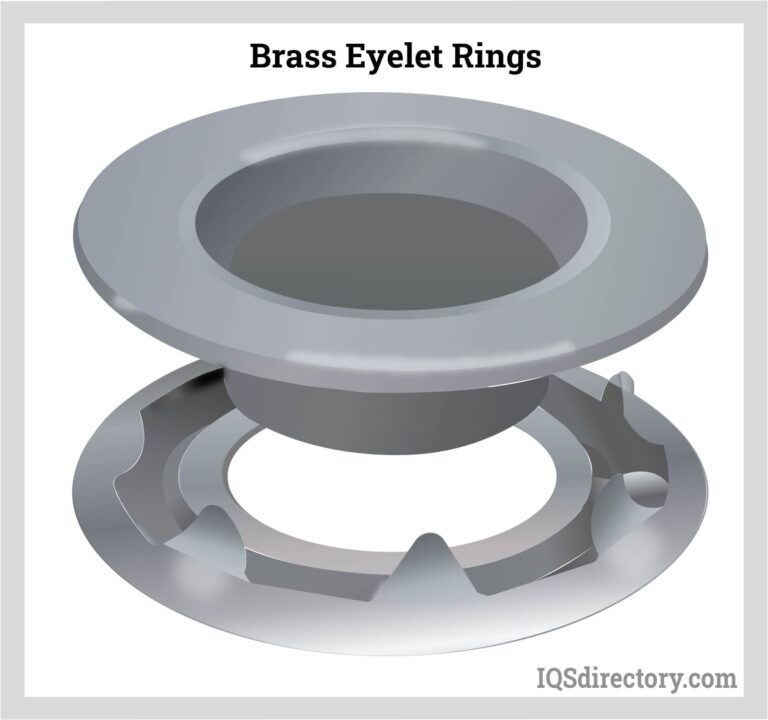

Illustrative image related to roller threading machine

Considerations for International Buyers: Buyers must ensure that tool steel complies with standards such as ASTM A681. Its higher cost may be a consideration for budget-sensitive projects, particularly in developing regions.

Summary Table of Material Selection for Roller Threading Machines

| Material | Typical Use Case for roller threading machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy machinery components | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Food processing and pharmaceutical industries | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace and automotive lightweight parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Med |

| Tool Steel | Manufacturing dies and tools | High wear resistance and durability | Expensive and difficult to machine | High |

This analysis provides a comprehensive overview of the materials used in roller threading machines, helping international B2B buyers make informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for roller threading machine

What Are the Main Stages of Manufacturing a Roller Threading Machine?

The manufacturing process of roller threading machines is intricate and involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical in ensuring the machine’s performance and durability.

Material Preparation: What Materials Are Used?

The process begins with the selection of high-quality materials. Common materials used include hardened steel for dies and robust cast iron for the machine frame, ensuring durability and strength. Advanced material testing, such as tensile strength and hardness assessments, is often conducted to verify that the materials meet the necessary specifications before fabrication begins.

How Is the Forming Process Conducted?

Once the materials are prepared, the forming stage commences. This phase primarily involves machining operations, where raw materials are shaped into components using CNC (Computer Numerical Control) machines. The precision of this step is critical, as it lays the groundwork for the assembly of various parts, such as the frames, slides, and rolling dies.

What Techniques Are Employed in the Assembly Process?

The assembly stage is where the individual components come together to form the complete machine. This process typically follows a systematic approach, often guided by detailed assembly instructions. Skilled technicians meticulously align and fit parts, ensuring that all mechanical connections are secure and functional. Attention to detail during assembly is vital, as even minor misalignments can lead to performance issues.

What Finishing Techniques Are Commonly Used?

After assembly, the finishing stage is crucial for enhancing the machine’s performance and aesthetics. This can include surface treatments such as powder coating, which protects against corrosion, and grinding processes that ensure smooth operation of moving parts. Quality checks are performed at this stage to confirm that the finishing meets industry standards.

What International Standards Guide Quality Assurance in Manufacturing?

Quality assurance in the manufacturing of roller threading machines is governed by several international standards, most notably ISO 9001. This standard ensures that the manufacturing process adheres to a quality management system that promotes consistent quality and continuous improvement. Compliance with ISO 9001 is often a prerequisite for B2B buyers, as it guarantees that suppliers maintain high-quality production practices.

Illustrative image related to roller threading machine

Which Industry-Specific Standards Are Relevant?

In addition to ISO 9001, various industry-specific standards may apply. For example, CE marking is important for compliance within the European market, indicating that the machine meets EU safety, health, and environmental protection requirements. For industries like oil and gas, adherence to API (American Petroleum Institute) standards can be critical, especially for machines used in harsh environments.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is an integral part of the manufacturing process, typically involving several checkpoints, including:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival. Ensuring that they meet specified standards is essential to prevent defects down the line.

-

In-Process Quality Control (IPQC): During manufacturing, various checks are conducted at different stages to monitor the process and identify any deviations from established standards. This includes regular measurements and tests of critical dimensions.

-

Final Quality Control (FQC): Once the machine is fully assembled, a comprehensive inspection is performed. This includes functional testing to ensure all components operate correctly under specified conditions.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to ensure the quality and reliability of roller threading machines:

-

Functional Testing: This involves running the machine under operational conditions to verify performance, including speed, accuracy, and durability.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection may be used to detect internal flaws in components without damaging them.

-

Performance Testing: Machines may undergo stress tests to evaluate their performance under extreme conditions, ensuring they can withstand operational demands.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality assurance measures. Look for certifications and adherence to international standards.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports that outline their QC processes, testing methods, and results from previous production runs.

-

Engage Third-Party Inspectors: Consider hiring independent third-party inspection agencies to evaluate the manufacturing facilities and processes. These experts can offer unbiased assessments of the supplier’s capabilities.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate certain nuances when it comes to quality control. For instance, language barriers may complicate communication about quality standards and expectations. Additionally, varying regulations across countries can impact compliance requirements. It’s essential for buyers to thoroughly understand the specific standards applicable to their market and ensure that suppliers are well-informed and compliant.

Conclusion: Ensuring Quality in Roller Threading Machine Manufacturing

The manufacturing processes and quality assurance practices for roller threading machines are complex and require careful consideration. By understanding the stages involved in manufacturing, the relevant international and industry-specific standards, and the key quality control checkpoints, B2B buyers can make informed decisions when selecting suppliers. Thorough verification of a supplier’s quality practices, including audits and quality reports, is essential in ensuring that the machines meet the necessary performance and durability standards required for various industrial applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roller threading machine’

Introduction

Sourcing a roller threading machine is a critical investment for manufacturers seeking to enhance their production capabilities. This guide provides a practical checklist that will help international B2B buyers navigate the procurement process effectively, ensuring they select the right equipment to meet their operational needs.

Step 1: Define Your Technical Specifications

Before beginning the sourcing process, it’s essential to outline your technical requirements. Consider factors such as the types of materials you will be threading, the thread sizes, and the production volume you expect.

– Material Compatibility: Ensure the machine can handle the materials you use, such as steel or aluminum.

– Thread Type: Identify whether you need machines for external or internal threads.

Step 2: Research Supplier Options

Conduct thorough research on potential suppliers in the market. Look for manufacturers with a proven track record in producing reliable roller threading machines.

– Industry Reputation: Check for reviews and testimonials from other customers.

– Product Range: Ensure they offer a variety of models that suit your specifications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Supplier History: Look for suppliers with significant experience in the threading machine market.

– Customer Support: Assess the level of post-purchase support they provide, including maintenance and training.

Step 4: Verify Certifications and Standards

Ensure that the suppliers meet industry standards and have the necessary certifications. This step is vital for ensuring quality and compliance with regulations.

– ISO Certification: Check if the supplier has ISO certification, which indicates adherence to international quality management standards.

– Local Compliance: Verify that the machines comply with local safety and operational regulations in your country.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. A comprehensive quote should outline the costs involved, including machine price, shipping, and installation fees.

– Cost Breakdown: Look for transparency in pricing to avoid hidden costs.

– Warranty and Maintenance: Ensure the quotation includes information on warranties and available maintenance packages.

Step 6: Assess Delivery and Installation Timelines

Understand the lead times for delivery and installation, as these can significantly impact your production schedule.

– Delivery Timeframes: Inquire about the estimated shipping time to your location.

– Installation Support: Confirm whether the supplier offers installation services and training for your team.

Step 7: Finalize Terms and Conditions

Before making a purchase, carefully review the terms and conditions. Ensure you are clear on payment terms, return policies, and after-sales support.

– Payment Terms: Negotiate favorable payment terms that align with your budget.

– Return Policy: Understand the process for returning or exchanging machinery if it does not meet your expectations.

By following this checklist, international B2B buyers can effectively navigate the complexities of sourcing roller threading machines, ensuring they make informed decisions that align with their manufacturing goals.

Comprehensive Cost and Pricing Analysis for roller threading machine Sourcing

When sourcing roller threading machines, understanding the comprehensive cost structure and pricing dynamics is crucial for making informed purchasing decisions. This analysis will outline the key cost components, influential pricing factors, and actionable tips for buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Roller Threading Machines?

-

Materials: The primary materials used in manufacturing roller threading machines include high-grade steel and alloys for durability and precision. The choice of materials directly affects the machine’s longevity and performance, impacting the initial purchase cost and maintenance expenses.

-

Labor: Skilled labor is essential for both the manufacturing process and the assembly of roller threading machines. Labor costs can vary significantly based on geographic location, with developed regions typically commanding higher wages than emerging markets. This can influence the overall cost of the machine.

-

Manufacturing Overhead: Overhead costs include utilities, facility maintenance, and administrative expenses that are indirectly related to production. Efficient manufacturing processes can help minimize these costs, potentially lowering the final price for buyers.

-

Tooling: Tooling costs encompass the expenses associated with creating the dies and molds necessary for thread rolling. Custom tooling for specific applications can significantly increase initial costs but may lead to better long-term performance and efficiency.

-

Quality Control (QC): Implementing robust quality control measures ensures that machines meet industry standards and specifications. This adds to the cost but is essential for minimizing defects and ensuring customer satisfaction.

-

Logistics: The cost of transporting machines from manufacturers to buyers can vary based on distance, shipping methods, and import duties. Buyers should factor in these logistics costs when considering total expenses.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary widely based on market conditions, competition, and the perceived value of their products.

How Do Price Influencers Affect the Sourcing of Roller Threading Machines?

Several factors influence the pricing of roller threading machines:

-

Volume/MOQ: Purchasing in bulk often leads to significant discounts. Buyers should inquire about minimum order quantities (MOQ) to optimize their cost.

-

Specifications and Customization: Custom features or specific technical requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Machines made from premium materials or those with certifications (e.g., ISO) may command higher prices but often offer better performance and reliability.

-

Supplier Factors: The reputation and location of the supplier can influence pricing. Established suppliers with a proven track record may charge more due to their reliability and service.

-

Incoterms: Understanding Incoterms is vital for international transactions. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can affect total landed costs, impacting overall pricing.

What Are the Best Tips for Buyers to Optimize Cost-Efficiency?

-

Negotiate Strategically: Engage suppliers in discussions about pricing, especially when placing larger orders. Leverage competitive quotes to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also maintenance, operational costs, and potential downtime when assessing machine value.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import taxes, and tariffs that can affect the final cost of machines when sourcing from abroad.

-

Conduct Market Research: Analyze various suppliers and their offerings. Understanding market trends and pricing can provide leverage in negotiations and help identify the best deals.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and service, as suppliers may prioritize loyal customers.

Conclusion

Sourcing roller threading machines involves a complex interplay of costs and pricing factors. By understanding the various components and leveraging strategic negotiation tactics, international buyers can optimize their purchasing decisions to ensure they receive high-quality machines at competitive prices. Remember that while initial costs are crucial, evaluating the long-term value through TCO considerations can lead to more beneficial investments in the long run.

Alternatives Analysis: Comparing roller threading machine With Other Solutions

Understanding Alternative Solutions for Threading Needs

In the realm of manufacturing, particularly when it comes to forming threads on fasteners, choosing the right technology is critical. While roller threading machines are a popular choice due to their efficiency and strength, several alternative methods exist that may better suit specific operational requirements. This section explores these alternatives, providing a comprehensive comparison to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Roller Threading Machine | Cold Heading Machine | Tapping Machine |

|---|---|---|---|

| Performance | High throughput; precision threading; strong threads | Excellent for bulk production; forms threads in one step | Lower speed; suitable for detailed work; can create internal threads |

| Cost | Moderate initial investment; lower long-term operating costs | Higher initial cost; cost-effective for high volumes | Low to moderate initial cost; varying operating costs based on complexity |

| Ease of Implementation | Requires skilled operators; moderate setup time | Complex setup; skilled labor needed for operation | Easy to implement; often requires less training |

| Maintenance | Regular maintenance needed for dies; durable | Higher maintenance due to complexity; requires specialized knowledge | Low maintenance; simpler machinery |

| Best Use Case | Ideal for high-volume production of strong fasteners | Best for mass production of parts with specific shapes | Suitable for applications needing precise internal threading |

In-Depth Analysis of Alternatives

What is a Cold Heading Machine and How Does It Compare?

Cold heading machines are designed to produce fasteners and other components by forming metal at room temperature. They offer a significant advantage in terms of production speed and efficiency, particularly for high-volume applications. However, the initial investment is higher compared to roller threading machines, making them less appealing for smaller operations. The cold heading process is particularly beneficial for creating complex shapes and forms, but it requires specialized training and maintenance, which can increase operational costs.

Illustrative image related to roller threading machine

How Does a Tapping Machine Function as an Alternative?

Tapping machines utilize a different approach by cutting internal threads into a pre-drilled hole. They are generally easier to implement due to their straightforward operation and lower initial costs. However, tapping machines are not suited for high-volume production compared to roller threading machines, as they operate at lower speeds and are limited to internal threading. They are most effective in applications where precision is paramount, but they may not deliver the same strength and durability in threads as those produced by roller threading.

Conclusion: Choosing the Right Threading Solution for Your Business

When selecting the most appropriate threading solution, B2B buyers must consider their specific operational needs, including production volume, the complexity of components, and budget constraints. Roller threading machines are ideal for high-speed and high-strength applications, while cold heading machines excel in mass production with complex shapes. Conversely, tapping machines may be the right choice for precision work requiring internal threads. By carefully evaluating these alternatives against their production goals, buyers can ensure they invest in the right technology that aligns with their strategic objectives and operational capabilities.

Essential Technical Properties and Trade Terminology for roller threading machine

What Are the Key Technical Properties of Roller Threading Machines?

Understanding the technical specifications of roller threading machines is crucial for B2B buyers looking to invest in this equipment. Here are several key properties to consider:

-

Rolling Force Capacity

This specification indicates the maximum force the machine can exert during the rolling process, typically measured in kilonewtons (kN). A higher rolling force capacity allows for the processing of tougher materials and larger diameters, making it essential for manufacturers in industries such as automotive and aerospace. Knowing the rolling force capacity helps buyers assess whether the machine can meet their production requirements. -

Material Grade of Construction

The material from which the machine is constructed significantly affects its durability and operational efficiency. Common materials include high-grade cast iron and steel, which offer excellent rigidity and longevity. A robust construction material ensures that the machine can withstand the stresses of continuous operation, thereby reducing maintenance costs and downtime. -

Die Configuration

Roller threading machines can feature various die configurations, including flat dies and cylindrical dies. The choice of die impacts the quality and precision of the threads produced. Understanding the die configuration is vital for buyers, as it directly influences the types of threads that can be manufactured and the overall production efficiency. -

Production Rate (Pieces Per Minute)

This metric indicates the number of components that can be processed in one minute. A higher production rate is often essential for manufacturers aiming to meet high demand and optimize output. Buyers should evaluate their production needs against the machine’s capabilities to ensure alignment with their operational goals. -

Tolerance Levels

Tolerance refers to the permissible limit or limits of variation in a physical dimension, which is critical for ensuring the functionality and interoperability of threaded components. Tighter tolerances may be required for high-precision applications, making it essential for buyers to understand the tolerance levels offered by different machines. -

Automation Compatibility

Many modern roller threading machines are designed to integrate seamlessly with automated handling systems. This compatibility can enhance efficiency and reduce labor costs. Buyers should assess whether the machines they are considering can be easily integrated into their existing production lines.

What Are the Common Trade Terms Used in the Roller Threading Industry?

Navigating the terminology associated with roller threading machines is essential for effective communication in B2B transactions. Here are several important terms to be familiar with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of roller threading machines, buyers may work directly with OEMs for custom machinery solutions or parts, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge the scale of their investment and the feasibility of purchasing equipment or components in bulk. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other relevant information for specific products or services. Submitting an RFQ helps buyers gather competitive offers from multiple suppliers, allowing for informed decision-making. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms is essential for negotiating shipping costs, delivery timelines, and risk management in transactions involving roller threading machines. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is fulfilled. Understanding lead times is vital for manufacturers to plan their production schedules and manage inventory effectively. -

Die Regrinding

This process involves sharpening or restoring the dies used in roller threading machines to maintain precision and quality. Knowledge of die regrinding is important for buyers as it can affect ongoing operational costs and the lifespan of the threading machinery.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions and enhance their procurement strategies for roller threading machines.

Navigating Market Dynamics and Sourcing Trends in the roller threading machine Sector

What Are the Key Trends Shaping the Roller Threading Machine Market?

The roller threading machine market is experiencing a significant transformation driven by several global factors. Technological advancements in automation and artificial intelligence are reshaping production processes, enhancing efficiency, and reducing operational costs. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly adopting smart manufacturing practices that integrate IoT-enabled machines for real-time monitoring and predictive maintenance. This shift is aimed at improving production quality and minimizing downtime, which is critical in competitive markets.

Sourcing trends also reflect a growing emphasis on customization and flexibility. Manufacturers are developing machines that can easily adapt to various thread profiles and materials, catering to the unique demands of diverse industries such as automotive, aerospace, and construction. Additionally, the rise of e-commerce platforms has simplified procurement, allowing buyers from emerging markets to access a broader range of suppliers and products. Consequently, international buyers must focus on evaluating the capabilities of machine manufacturers to deliver tailored solutions that meet specific operational needs.

Moreover, sustainability is becoming a pivotal concern in the sourcing process. As global awareness of environmental issues rises, buyers are increasingly seeking suppliers that prioritize eco-friendly practices and materials. This trend is not only about compliance but also about enhancing brand reputation and aligning with consumer values. Therefore, understanding these market dynamics and sourcing trends is essential for B2B buyers to make informed decisions in the roller threading machine sector.

How Important Is Sustainability and Ethical Sourcing in the Roller Threading Machine Sector?

Sustainability and ethical sourcing have become paramount in the roller threading machine sector, driven by both regulatory pressures and consumer expectations. The manufacturing process of threading machines can have significant environmental impacts, including energy consumption and waste generation. B2B buyers are increasingly scrutinizing suppliers for their environmental policies and practices, seeking those who implement energy-efficient technologies and sustainable materials in their production processes.

Moreover, ethical supply chains are gaining traction, with buyers emphasizing the importance of transparency and accountability. This trend is particularly relevant in regions such as Africa and South America, where social and economic disparities can influence sourcing decisions. Buyers are encouraged to partner with manufacturers that not only comply with international labor standards but also promote fair trade practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential indicators of a supplier’s commitment to sustainability and ethical practices.

Additionally, the adoption of ‘green’ materials in the production of roller threading machines is on the rise. Suppliers who utilize recyclable materials and environmentally friendly lubricants and coatings are more likely to appeal to conscious buyers. By prioritizing sustainability and ethical sourcing, businesses can not only reduce their ecological footprint but also enhance their market competitiveness and foster long-term partnerships with clients who share similar values.

How Has the Roller Threading Machine Sector Evolved Over Time?

The evolution of roller threading machines can be traced back to the late 19th century, when the need for efficient and precise thread production became paramount in the manufacturing sector. Initially, traditional cutting methods dominated the market; however, the introduction of cold forming techniques revolutionized the industry. Roller threading machines emerged as a superior alternative, offering enhanced strength and durability of threads by compressing rather than cutting materials.

Over the decades, technological advancements have significantly improved the efficiency and functionality of these machines. The integration of CNC (Computer Numerical Control) technology has allowed for greater precision and automation, enabling manufacturers to produce complex thread profiles with minimal human intervention. Furthermore, the shift towards modular designs has facilitated easier maintenance and customization, catering to the diverse needs of various industries.

As global manufacturing practices continue to evolve, the roller threading machine sector is poised for further innovation, with a focus on sustainability, automation, and smart manufacturing solutions. This historical perspective underscores the importance of adapting to market changes and leveraging technological advancements to remain competitive in the ever-evolving landscape of B2B manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of roller threading machine

-

How do I choose the right roller threading machine for my production needs?

Selecting the appropriate roller threading machine depends on various factors, including the type of material you work with, the thread specifications required, and your production volume. Evaluate your operational needs, such as maximum thread diameter and length, production speed (pieces per minute), and whether you require automation capabilities. It’s advisable to consult with manufacturers or industry experts who can provide insights into the best models suited for your specific applications, ensuring you achieve optimal efficiency and quality. -

What are the advantages of using roller threading machines over traditional threading methods?

Roller threading machines offer several advantages, including increased production speed and higher thread strength due to the cold-forming process. Unlike traditional cutting methods, which can weaken the material, rolling compresses it, resulting in more durable threads. Additionally, these machines reduce material waste and improve consistency in thread quality. For businesses focused on efficiency and product reliability, investing in roller threading technology can lead to significant long-term savings and enhanced competitiveness. -

What should I consider when vetting suppliers of roller threading machines?

When vetting suppliers, assess their reputation, experience in the industry, and customer reviews. Look for manufacturers that provide comprehensive support, including installation, training, and after-sales service. Verify their compliance with international quality standards, such as ISO certifications, to ensure product reliability. Additionally, inquire about their ability to customize machines based on your specific needs and their responsiveness to inquiries, as this can indicate their commitment to customer satisfaction. -

What are common payment terms when purchasing roller threading machines internationally?

Payment terms can vary significantly between suppliers and regions. Common arrangements include upfront payment, a deposit followed by the balance upon delivery, or letter of credit arrangements for larger orders. It’s essential to negotiate terms that protect your interests and align with your cash flow. Ensure clarity on currency exchange rates and potential additional costs, such as taxes and tariffs, which may apply to international transactions. -

Can I customize a roller threading machine to fit my specific production requirements?

Yes, many manufacturers offer customization options for roller threading machines to meet specific production requirements. This could involve modifications in size, thread specifications, or integration with automated handling systems. When approaching a supplier, clearly outline your needs and ask about their capabilities for customization. Be sure to review any additional costs or lead times associated with these modifications to ensure they align with your production schedule. -

What quality assurance measures should I expect from suppliers of roller threading machines?

Reputable suppliers should have robust quality assurance processes in place, including testing machines before shipment and providing detailed documentation of compliance with industry standards. Expect to receive performance guarantees and warranties that cover defects and operational issues. Additionally, inquire about their procedures for machine maintenance and support, as ongoing quality assurance is crucial for the longevity and performance of your investment. -

What logistics considerations should I keep in mind when importing roller threading machines?

Logistics are critical when importing machinery. Consider factors such as shipping methods, lead times, and customs clearance processes in your country. It’s advisable to work with a freight forwarder experienced in handling industrial equipment to navigate international shipping regulations. Ensure that you understand the total landed cost, including shipping, duties, and insurance, to avoid unexpected expenses. Clear communication with your supplier about packaging and handling can also mitigate risks during transit. -

What is the typical minimum order quantity (MOQ) for roller threading machines?

The minimum order quantity for roller threading machines varies by supplier and the type of equipment. While some manufacturers may offer single machines, others might have higher MOQs, particularly for custom-built models. It’s essential to clarify this during your discussions with potential suppliers. If your production needs don’t meet the MOQ, consider collaborating with other businesses to aggregate orders or exploring used equipment options as a cost-effective alternative.

Top 8 Roller Threading Machine Manufacturers & Suppliers List

1. Tesker – Thread Rolling Machines

Domain: tesker.com

Registered: 1996 (29 years)

Introduction: Tesker Manufacturing Corporation offers a range of thread rolling machines and dies, including models with 2-die and 3-die configurations. Key models include:

– Tesker Model 200E 2-Die

– Tesker Model 215E 2-Die

– Tesker Model 35E 2-Die

– Tesker Model 236E 2-Die

– Tesker Model 280E 2-Die

– Tesker Model 320E 2-Die

– Tesker Model 380E 2-Die

– Tesker Model 440E 2-Die

– Tesker Model 645E 2-Die…

2. Profiroll – Thread and Profile Rolling Machines

Domain: profiroll.com

Registered: 1999 (26 years)

Introduction: Profiroll Thread and Profile Rolling Machines are designed for high-quality thread manufacturing using cold rolling technology. Key features include:

– Rolling force ranging from 50kN to 1000kN

– Statically and dynamically stiff iron cast C-frame

– Excellent accessibility for part insertion and extraction

– Options for infeed and through-feed rolling

– Custom drive and control systems tailore…

3. Surplus Record – Thread Rollers

Domain: surplusrecord.com

Registered: 1995 (30 years)

Introduction: This company, Surplus Record – Thread Rollers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. C.J. Winter – Thread Roller

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: This company, C.J. Winter – Thread Roller, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Organ Tools – Thread Rolling Machine

6. Bhavya Machine Tools – Hydraulic Thread & Form Rolling Machines

Domain: bhavyamachinetools.com

Registered: 2007 (18 years)

Introduction: Hydraulic Thread & Form Rolling Machine

Model Numbers: TR-25, TR-30, TR-40, TR-50, TR-80, TR-190, TR-120

Technical Specifications:

– Max. Pitch Can Be Rolled (in mm): 3, 25, 35, 4, 5, 6, 8

– Max. Dia can be Rolled in Feed (in mm): 25, 30, 40, 50, 80, 100, 120

– Max. Dia can be Rolled in Through Feed (in mm): 18, 20, 28, 35, 40, 50, 70

– Max. Rolling Length in Feed (in mm): 80, 100, 100, 150, 150,…

7. Yieh Chen – 3 Roll Thread Rolling Machine

Domain: yiehchen.com

Registered: 1997 (28 years)

Introduction: 3 Roll Thread Rolling Machine for Tube (Max rolling Outer Diameter 60mm or 2-1/4″) | Hydraulic operation for mass production of various thread forms on hollow sections | Applications: oil pipe connectors, electric fan shafts, automobile and motorcycle parts, jacks and props, cycle hubs, closures | Workpiece Range: Outside Diameter 15 – 60 mm (5/8″ – 2-1/4″), Thread Pitch 0.75 – 3.0P (40 – 8 TPI) |…

8. Hariton Machinery – Hand Feed Thread Rollers

Domain: haritonmachinery.com

Registered: 1996 (29 years)

Introduction: Threading Machines, Flat Die Thread Rollers, Hand Feed; Models include: Waterbury Farrel Model #40 Heavy Frame Hand Feed Thread Roller, Waterbury Farrel Model #60 Horizontal Hand Feed Thread Roller, Hartford Model 312 Hand Feed Thread Roller (5/16″), Hartford Model 10-400 High Speed Thread Roller (3/8″), Hartford Model 190 Horizontal Hand Feed Thread Roller; Various manufacturers include Hariton, …

Strategic Sourcing Conclusion and Outlook for roller threading machine

In the competitive landscape of manufacturing, the strategic sourcing of roller threading machines is paramount for businesses aiming to enhance productivity and product quality. By investing in advanced thread rolling technology, companies can benefit from improved thread consistency, reduced material waste, and increased operational efficiency. The insights from leading manufacturers underline the importance of selecting machines that not only meet current production needs but also have the capacity for automation and scalability, ensuring adaptability in a rapidly changing market.

International buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize sourcing machines that offer robust support and service options, facilitating seamless integration into their existing operations. As industries continue to evolve with technological advancements, the demand for high-quality, reliable threading solutions will only grow.

To remain competitive, businesses must be proactive in their sourcing strategies, leveraging the latest innovations in roller threading machines. Now is the time to engage with suppliers, explore diverse product offerings, and secure the machinery that will drive future success. By making informed decisions today, companies can position themselves as leaders in their respective markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to roller threading machine

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.