Choosing Your Ricoma Embroidery Machine: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for ricoma embroidery machine

In the competitive landscape of textile production, international B2B buyers face the significant challenge of sourcing high-quality Ricoma embroidery machines that meet their diverse business needs. As companies strive to enhance their offerings with customized apparel and intricate designs, understanding the features and capabilities of these machines becomes essential. This guide provides a comprehensive overview of Ricoma embroidery machines, covering various types—from single-needle to multi-head models—along with their applications across industries such as fashion, sportswear, and promotional merchandise.

Buyers will benefit from detailed insights on supplier vetting, ensuring they select reputable distributors who provide robust support and training. Additionally, this guide delves into pricing structures, maintenance considerations, and the potential return on investment (ROI) for businesses looking to expand their embroidery capabilities. By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Nigeria—with actionable knowledge, this resource aims to empower informed purchasing decisions. Ultimately, understanding the landscape of Ricoma embroidery machines not only enhances operational efficiency but also positions businesses to thrive in a global market increasingly driven by customization and quality.

Understanding ricoma embroidery machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| EM-1010 Multi-Needle | User-friendly interface, ideal for startups, multi-needle capability | Small businesses, startups in custom apparel | Pros: Affordable entry point, versatile. Cons: Limited to smaller production volumes. |

| MT-1501-7S Single-Head | High-speed operation, large embroidery area, 15 needles | High-volume embroidery services, custom merchandise | Pros: Efficient for detailed designs, great for scaling. Cons: Single-head limits simultaneous jobs. |

| MT-2001-8S Commercial | 8 needles, optimized for larger projects, robust construction | Medium to large businesses focused on bulk orders | Pros: Versatile for various fabric types. Cons: Higher price point, may require more training. |

| Marquee 20-Needle | Advanced touchscreen panel, 20 needles, suitable for complex designs | Professional embroidery shops, high-end customization | Pros: High productivity, capable of intricate designs. Cons: Higher upfront investment, maintenance costs. |

| CHT2 Series Multi-Head | Multi-head design, customizable configurations, high output | Large-scale production, promotional items | Pros: Maximize output, ideal for bulk orders. Cons: Space requirements, higher initial costs. |

What Are the Key Characteristics of the EM-1010 Multi-Needle Machine?

The EM-1010 Multi-Needle machine is designed with user-friendliness in mind, making it an ideal choice for startups and smaller businesses venturing into custom embroidery. Its multi-needle capability allows users to work on a variety of projects, from hats to shirts, without frequent thread changes. This model is particularly suited for businesses looking to enter the custom apparel market without a significant upfront investment. Buyers should consider the machine’s capacity for smaller production volumes, which is a vital aspect for those just starting.

How Does the MT-1501-7S Single-Head Machine Stand Out?

The MT-1501-7S Single-Head machine is tailored for businesses ready to scale their operations with high-speed embroidery capabilities and a generous embroidery area. It features 15 needles, allowing for efficient processing of detailed designs and larger projects. This model is particularly effective for high-volume embroidery services, making it a popular choice among companies that require precision and speed. When considering this machine, buyers should evaluate their production needs against the limitations of a single-head setup, which restricts simultaneous job handling.

Why Is the MT-2001-8S Ideal for Medium to Large Businesses?

The MT-2001-8S Commercial machine is built with robust construction and optimized for larger projects, featuring eight needles for versatile fabric applications. This machine is perfect for medium to large businesses that focus on bulk orders, offering a balance of performance and reliability. Buyers should take into account the potential for higher efficiency in production, but also be prepared for a steeper learning curve and higher initial investment compared to entry-level models.

What Makes the Marquee 20-Needle Machine a Professional Choice?

The Marquee 20-Needle machine is equipped with an advanced touchscreen panel and is capable of handling complex designs with ease. It is particularly suited for professional embroidery shops that require high productivity and the ability to execute intricate designs. Businesses should weigh the benefits of its high output against the initial investment and ongoing maintenance costs, making it a choice for those committed to high-quality, large-scale production.

How Does the CHT2 Series Multi-Head Machine Enhance Production?

The CHT2 Series Multi-Head machine is designed for large-scale production, featuring customizable configurations that allow businesses to maximize output. This machine is ideal for companies focusing on promotional items or bulk orders, as it can handle multiple projects simultaneously. However, buyers should consider the space requirements and higher initial costs associated with multi-head machines, ensuring they align with their operational capabilities and production goals.

Key Industrial Applications of ricoma embroidery machine

| Industry/Sector | Specific Application of Ricoma Embroidery Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel Manufacturing | Custom garment decoration for brands | Enhances brand visibility and customer personalization | Reliability, speed, and ease of use; support services |

| Promotional Products | Embroidered promotional items (hats, bags, etc.) | Increases brand recognition and marketing effectiveness | Versatility in design and color; cost-effectiveness |

| Hospitality & Uniforms | Employee uniforms and custom linens | Boosts professional image and employee morale | Durability and quality of stitching; volume capacity |

| Sportswear | Custom team jerseys and sports apparel | Fosters team spirit and enhances merchandise sales | Ability to handle diverse fabric types; scalability |

| Home Décor | Personalized home textiles (cushions, towels) | Meets consumer demand for unique, custom products | Range of embroidery designs; compatibility with home textiles |

How is the Ricoma Embroidery Machine Used in Apparel Manufacturing?

In the apparel manufacturing sector, Ricoma embroidery machines are essential for customizing garments, allowing brands to showcase logos and intricate designs. This capability not only enhances product appeal but also fosters customer loyalty through personalization. International buyers, particularly in Africa and South America, should consider the machine’s reliability and speed to meet growing demand. Additionally, training and support services are crucial to ensure optimal operation from the outset.

What Role Does the Ricoma Embroidery Machine Play in Promotional Products?

Ricoma machines are widely used to create embroidered promotional items such as hats, bags, and other merchandise. This application significantly boosts brand recognition by providing high-quality, visually appealing products that can be used in marketing campaigns. For businesses in the Middle East and Europe, sourcing machines with versatility in design and color options is key to producing a wide array of promotional items efficiently and cost-effectively.

How Does the Ricoma Embroidery Machine Benefit the Hospitality Industry?

In the hospitality industry, Ricoma embroidery machines enable the production of custom uniforms and linens, enhancing the professional image of establishments. By offering embroidered staff uniforms and personalized table linens, businesses can elevate their branding and guest experience. Buyers in Europe and the Middle East should prioritize machines that deliver durability and high-quality stitching to withstand frequent use in a demanding environment.

Why is the Ricoma Embroidery Machine Important for Sportswear?

The sportswear industry leverages Ricoma embroidery machines to produce custom team jerseys and apparel, which fosters a sense of community and team spirit. These machines can handle diverse fabric types, allowing for the creation of high-quality sports merchandise. B2B buyers, particularly in regions like Africa, should focus on machines that can scale production to meet the needs of local sports teams and clubs while ensuring design flexibility and quality.

How Can the Ricoma Embroidery Machine Enhance Home Décor Products?

Ricoma embroidery machines are increasingly used in the home décor sector to create personalized textiles such as cushions, towels, and wall hangings. This customization meets the rising consumer demand for unique home products, allowing businesses to differentiate themselves in a competitive market. Buyers in South America and Africa should consider the range of embroidery designs available and the machine’s compatibility with various home textile materials to maximize their offerings.

3 Common User Pain Points for ‘ricoma embroidery machine’ & Their Solutions

Scenario 1: Navigating Complex Embroidery Designs with Limited Knowledge

The Problem: Many B2B buyers, particularly those new to the embroidery business, struggle with the complexity of creating intricate designs for their products. This challenge can lead to frustration, wasted materials, and ultimately, financial losses. Buyers often feel overwhelmed by the technical aspects of digitizing designs, which can deter them from utilizing the full capabilities of their Ricoma embroidery machines. For instance, a startup apparel company might have excellent product ideas but lack the expertise to turn those ideas into marketable embroidered designs.

The Solution: Ricoma offers comprehensive training resources that can bridge the knowledge gap for new users. Buyers should take advantage of the free live training sessions and the extensive video library available through the MyRicoma portal. These resources provide step-by-step guidance on using the Chroma digitizing software, which is included with each machine. Additionally, investing time in learning about file formats, such as DST, and practicing with the software will enable users to create detailed designs confidently. Collaborating with experienced digitizers for complex projects can also provide insights into optimizing designs for embroidery, ensuring high-quality results with minimal material waste.

Scenario 2: Managing Machine Downtime and Maintenance

The Problem: A common pain point for B2B buyers is the unexpected downtime of embroidery machines due to maintenance issues. For companies that rely on Ricoma machines for fulfilling customer orders, such downtime can lead to missed deadlines and dissatisfied clients. For example, a small business in Nigeria might face significant operational disruptions if their MT-1501-7S machine breaks down unexpectedly, affecting their ability to meet increasing demand during peak seasons.

The Solution: To mitigate this risk, buyers should establish a proactive maintenance schedule that includes regular cleaning, lubrication, and inspection of the machine’s components. Ricoma provides a detailed maintenance guide that outlines best practices for keeping the machine in optimal condition. Additionally, taking advantage of the lifetime technical support offered by Ricoma can be invaluable. Buyers should not hesitate to contact support for troubleshooting any issues before they escalate. Engaging in regular training sessions can also help users identify potential problems early, ensuring that the machine operates smoothly and efficiently, ultimately reducing downtime.

Scenario 3: Sourcing Quality Materials and Supplies

The Problem: Another significant challenge for B2B buyers using Ricoma embroidery machines is sourcing high-quality materials, such as threads and fabrics, that are compatible with their machines. Poor-quality materials can lead to subpar embroidery results, such as thread breakage and uneven stitching, which can harm a brand’s reputation. A business in South America, for instance, may find it challenging to locate suppliers that offer reliable and durable embroidery threads that work seamlessly with their Ricoma machines.

The Solution: Buyers should establish relationships with trusted suppliers who specialize in embroidery materials. Ricoma’s network includes recommendations for reputable vendors, and buyers can also explore local trade shows to discover new suppliers. Before making bulk purchases, it’s advisable to request samples to test compatibility with their specific Ricoma machine. Furthermore, joining industry forums or local embroidery associations can provide insights into material sourcing and supplier reliability. By focusing on high-quality materials, buyers will enhance the durability and visual appeal of their embroidered products, ultimately leading to higher customer satisfaction and loyalty.

Strategic Material Selection Guide for ricoma embroidery machine

What Are the Key Materials Used in Ricoma Embroidery Machines?

When selecting materials for use with Ricoma embroidery machines, it’s essential to consider their properties, benefits, and limitations. This analysis focuses on four common materials: polyester, cotton, nylon, and twill. Each material has distinct characteristics that can significantly impact the performance and quality of embroidered products.

How Does Polyester Perform in Embroidery Applications?

Polyester is a synthetic fabric known for its durability and resistance to shrinking and stretching. It has a high-temperature rating, making it suitable for various embroidery techniques. The fabric’s smooth texture allows for clean stitching, which is crucial for intricate designs.

Pros: Polyester is highly durable, resistant to fading, and generally less expensive than natural fibers. It is also easy to care for, making it a popular choice for commercial applications.

Cons: While polyester is versatile, it may not be as breathable as natural fibers, which could affect comfort in certain applications. Additionally, some lower-quality polyester fabrics may not hold up well under high-stress conditions.

Impact on Application: Polyester is compatible with most embroidery machines, including Ricoma models, and works well for items like sportswear, uniforms, and promotional products.

Considerations for International Buyers: Buyers in regions such as Africa and the Middle East should ensure that the polyester used meets local quality standards, as well as international standards like ASTM or ISO.

What Benefits Does Cotton Offer for Embroidery?

Cotton is a natural fiber that is soft, breathable, and highly absorbent. It is often preferred for apparel and home textiles due to its comfort and versatility.

Pros: Cotton is easy to embroider on due to its softness, and it provides a high-quality finish. It is also biodegradable, appealing to environmentally conscious consumers.

Cons: Cotton can shrink when washed and is less durable than synthetic options. It may also fade over time, particularly when exposed to sunlight.

Impact on Application: Cotton is ideal for items such as t-shirts, baby clothes, and home textiles like towels and tablecloths. However, it may require special care in terms of washing and maintenance.

Considerations for International Buyers: In markets like South America and Europe, there is a growing preference for organic cotton. Buyers should verify that suppliers can provide certifications for organic or sustainably sourced cotton.

How Does Nylon Compare in Embroidery?

Nylon is another synthetic fabric known for its strength and elasticity. It is often used in applications requiring high durability and resistance to wear and tear.

Pros: Nylon is lightweight, resistant to mildew, and can withstand various environmental conditions. It is ideal for outdoor applications like jackets and bags.

Cons: The fabric can be more expensive than polyester and may require specific embroidery techniques to avoid puckering.

Impact on Application: Nylon is suitable for items that undergo frequent use, such as sports gear and outdoor apparel. Its resilience makes it a preferred choice for high-performance applications.

Considerations for International Buyers: Buyers in regions with extreme weather conditions, such as the Middle East, should consider nylon’s performance in high temperatures and humidity. Compliance with local textile regulations is also crucial.

What Role Does Twill Fabric Play in Embroidery?

Twill is a type of weave that creates a diagonal pattern, giving it a unique texture and durability. It is commonly used in workwear and uniforms.

Pros: Twill is strong and resistant to creasing, making it suitable for heavy-duty applications. Its texture provides a distinctive look that enhances embroidered designs.

Cons: Twill can be more challenging to embroider on due to its thickness, which may require adjustments in machine settings.

Impact on Application: Twill is ideal for uniforms, jackets, and bags, where durability and aesthetics are essential.

Considerations for International Buyers: Buyers should ensure that twill fabrics comply with local standards for workwear, especially in regions like Africa and Europe, where safety regulations may apply.

Summary of Material Properties for Ricoma Embroidery Machines

| Material | Typical Use Case for Ricoma Embroidery Machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Sportswear, uniforms, promotional products | High durability and resistance to fading | Less breathable than natural fibers | Medium |

| Cotton | T-shirts, baby clothes, home textiles | Soft, breathable, high-quality finish | Shrinks and fades over time | Low |

| Nylon | Outdoor apparel, sports gear | Lightweight and resistant to wear | More expensive, may pucker | High |

| Twill | Workwear, uniforms, jackets | Strong and resistant to creasing | Challenging to embroider on | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their embroidery processes with Ricoma machines. By understanding the properties and applications of each material, businesses can make informed decisions that enhance their product offerings and meet market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for ricoma embroidery machine

What Are the Main Stages of Manufacturing Ricoma Embroidery Machines?

The manufacturing process for Ricoma embroidery machines is meticulously designed to ensure quality, efficiency, and precision. The typical stages of production include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step involves sourcing high-quality materials that meet international standards. Components such as the machine frame, electronic parts, and sewing mechanisms are procured from reputable suppliers. Rigorous inspections are conducted on incoming materials to ensure compliance with specifications, which is crucial for maintaining the integrity of the final product. -

Forming

In this stage, the raw materials undergo various processes to create the necessary parts. Techniques such as CNC machining and laser cutting are employed to shape metal components with high precision. This ensures that every part fits perfectly during the assembly stage, which is vital for the machine’s operational efficiency. -

Assembly

The assembly process is where individual components come together. Ricoma utilizes both manual and automated assembly techniques to ensure consistency and quality. Skilled technicians work alongside automated systems to integrate electronic circuits, sewing mechanisms, and user interfaces, such as the high-definition touchscreen panels. Each machine is built according to strict specifications to ensure optimal performance. -

Finishing

The finishing stage includes thorough cleaning, painting, and applying protective coatings to enhance durability. This process not only improves the machine’s aesthetic appeal but also protects it from wear and corrosion. Finally, a series of tests are conducted to verify that each machine meets performance standards before it is packaged for shipping.

How Is Quality Assurance Implemented in Ricoma Embroidery Machines?

Quality assurance (QA) is a fundamental aspect of Ricoma’s manufacturing process. The company adheres to several international standards and industry-specific regulations to ensure that every machine meets the highest quality benchmarks.

-

What International Standards Are Followed?

Ricoma complies with ISO 9001, an internationally recognized standard for quality management systems. This certification signifies that Ricoma’s processes are consistently monitored and improved, ensuring that customers receive high-quality products. Additionally, compliance with CE marking and other relevant certifications assures buyers in regions like Europe and the Middle East that the machines meet safety and environmental regulations. -

What Are the QC Checkpoints During Production?

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined quality standards.

– In-Process Quality Control (IPQC): Throughout the assembly process, various inspections and tests are conducted to identify any defects early.

– Final Quality Control (FQC): Before shipment, each machine undergoes a comprehensive final inspection to verify its functionality and performance. This includes testing for stitch quality, speed, and user interface responsiveness. -

What Common Testing Methods Are Used?

Testing methods include functional tests, stress tests, and performance evaluations. Each machine is subjected to operational simulations to ensure that it can handle the demands of commercial embroidery. Additionally, electronic components are tested for reliability and longevity, ensuring that the machines can withstand high-volume production environments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in diverse international markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial for ensuring product reliability.

-

What Audits and Reports Should Buyers Request?

Buyers should request access to the supplier’s quality management system documentation, including ISO certifications, internal audit reports, and quality control procedures. Regular audits conducted by third-party organizations can provide additional assurance regarding the supplier’s adherence to quality standards. -

How Can Third-Party Inspections Be Conducted?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and product quality. These services can conduct on-site inspections during various production stages, ensuring compliance with quality standards and specifications. -

What Are the QC and Certification Nuances for International Buyers?

International buyers must be aware of regional regulations and standards that may affect product compliance. For instance, machines sold in the European market must meet CE standards, while buyers in Africa or South America may require different certifications. Understanding these nuances can help buyers make informed decisions and mitigate risks associated with non-compliance.

Conclusion: Ensuring Quality and Reliability in Ricoma Embroidery Machines

In summary, the manufacturing processes and quality assurance practices employed by Ricoma ensure that their embroidery machines are built to last and perform reliably under demanding conditions. By understanding the stages of production and the various quality control measures in place, B2B buyers can confidently invest in Ricoma machines, knowing they are acquiring a product that meets rigorous international standards. For buyers from regions like Africa, South America, the Middle East, and Europe, thorough verification of supplier quality control processes is essential for achieving successful long-term partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ricoma embroidery machine’

Introduction

Sourcing an embroidery machine, specifically a Ricoma model, is a significant investment for any business looking to enhance its production capabilities. This guide serves as a practical checklist to help international B2B buyers navigate the procurement process efficiently and effectively. By following these steps, you can ensure you make a well-informed decision that aligns with your operational needs and business goals.

1. Define Your Technical Specifications

Start by clearly outlining your technical requirements. Consider factors such as the type of projects you plan to undertake, the volume of production, and the specific features needed, such as the number of needles or embroidery area size. This clarity will help you narrow down your options and select a model that fits your operational demands.

2. Research Available Models

Familiarize yourself with the various Ricoma embroidery machine models available. Each model offers different capabilities, such as the MT-1501-7S, which is ideal for high-volume tasks with its 15 needles and large embroidery field. Evaluate specifications such as speed, versatility, and ease of use to determine which models align best with your needs.

3. Evaluate Potential Suppliers

Before finalizing a purchase, it’s essential to vet suppliers thoroughly. Request company profiles, case studies, and references from other buyers in similar industries or regions. Assess their reputation for quality, customer service, and support, as these factors will significantly influence your experience post-purchase.

- Check for Direct Factory Support: Ricoma offers factory-direct sales which often means better pricing and direct access to support.

- Look for Warranty and Service Agreements: Ensure that the supplier provides a comprehensive warranty and service options, as this can save you costs in the long run.

4. Request Demonstrations or Virtual Demos

Whenever possible, request a demonstration of the machine to see its performance firsthand. This step is crucial to understanding how well the machine operates in real-world conditions. If in-person demonstrations are not feasible, ask for a virtual demo to evaluate the machine’s features and ease of use.

5. Understand the Total Cost of Ownership

Beyond the initial purchase price, calculate the total cost of ownership, which includes maintenance, operational costs, and any additional accessories or software needed. For example, Ricoma machines often come with included software, which can reduce overall costs. Consider these factors to ensure your investment remains sustainable over time.

6. Review Training and Support Options

Evaluate the training and support offered by the supplier. Ricoma provides extensive training resources, including video tutorials and live sessions. Access to robust support can enhance your team’s proficiency with the machine, ultimately leading to better productivity and fewer operational hiccups.

7. Finalize Your Purchase Agreement

Once you’ve gathered all the necessary information and are satisfied with your choice, proceed to finalize the purchase agreement. Ensure that all terms, including delivery timelines, payment conditions, and service agreements, are clearly outlined and understood. A well-defined agreement can prevent misunderstandings and ensure a smooth transaction process.

By following this step-by-step checklist, you can confidently source a Ricoma embroidery machine that meets your business needs, ultimately enhancing your production capabilities and supporting your growth ambitions.

Comprehensive Cost and Pricing Analysis for ricoma embroidery machine Sourcing

What Are the Key Cost Components of Ricoma Embroidery Machines?

When sourcing Ricoma embroidery machines, it is essential to understand the various cost components that contribute to the overall pricing structure. The primary cost elements include:

-

Materials: This encompasses the cost of raw materials used in manufacturing the machines, such as metal components, electronic parts, and specialized software. The quality and source of these materials can significantly impact the final price.

-

Labor: Labor costs vary based on the location of manufacturing and the skill level of the workforce. Machines produced in regions with higher labor costs will generally be priced higher.

-

Manufacturing Overhead: This includes indirect costs related to the production process, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs, thus impacting the final price.

-

Tooling: The investment in specialized tools and machinery for production can also affect pricing. High-quality tooling often results in better machine performance and longevity, justifying a higher initial cost.

-

Quality Control (QC): Rigorous QC processes ensure that each machine meets industry standards. This can add to the cost, but it is crucial for maintaining reliability and performance, especially for commercial use.

-

Logistics: Costs associated with shipping and handling, including freight charges and insurance, need to be factored in, particularly for international buyers. These costs can vary significantly based on the delivery location.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the margin can aid in negotiation and identifying competitive offers.

How Do Price Influencers Affect Ricoma Embroidery Machines?

Several factors influence the pricing of Ricoma embroidery machines:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Buyers should consider their needs and explore bulk purchasing options to optimize costs.

-

Specifications and Customization: Custom features or specifications can increase the price. Buyers should assess their requirements carefully to avoid unnecessary expenses.

-

Materials and Quality Certifications: Machines made with higher-quality materials or those that have been certified for specific industry standards may command a premium price. However, these investments can lead to lower maintenance costs and better performance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record of quality and support.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is crucial for international buyers. These terms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To maximize cost-efficiency while sourcing Ricoma embroidery machines, consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate pricing, especially if you’re making a bulk purchase. Leverage quotes from different suppliers to strengthen your position.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, repairs, and operational efficiency. A higher upfront cost may lead to lower TCO if the machine is more durable and efficient.

-

Pricing Nuances for International Buyers: Be aware of the impact of currency fluctuations, import duties, and taxes when sourcing from international suppliers. These factors can significantly alter the final cost.

-

Research Local Market Conditions: For buyers in regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics and regional pricing trends can provide leverage in negotiations and help identify the best deals.

In conclusion, careful analysis of the cost components, price influencers, and strategic negotiation can lead to better sourcing decisions for Ricoma embroidery machines. By focusing on these aspects, international B2B buyers can achieve more favorable pricing and enhance their overall purchasing strategy.

Alternatives Analysis: Comparing ricoma embroidery machine With Other Solutions

Understanding Alternatives in Embroidery Solutions

When considering the purchase of an embroidery machine, it’s essential for B2B buyers to explore various alternatives that can meet their specific needs. Different technologies and methods can provide similar outcomes, each with unique advantages and drawbacks. This section compares the Ricoma embroidery machine against alternative solutions, allowing businesses to make informed decisions based on performance, cost, and usability.

Comparison Table

| Comparison Aspect | Ricoma Embroidery Machine | Brother Entrepreneur Pro PR670E | Janome MB-7 |

|---|---|---|---|

| Performance | 15 needles, up to 1200 stitches/minute | 6 needles, up to 1000 stitches/minute | 7 needles, up to 800 stitches/minute |

| Cost | Starting at $14,995 | Approximately $6,499 | Approximately $7,999 |

| Ease of Implementation | User-friendly with extensive training | Moderate learning curve; good support | User-friendly, but limited support |

| Maintenance | Lifetime support; robust warranty | Standard support; average warranty | Good support; average warranty |

| Best Use Case | High-volume commercial embroidery | Small to medium businesses; diverse applications | Small businesses, hobbyists, custom projects |

Detailed Breakdown of Alternatives

1. Brother Entrepreneur Pro PR670E

The Brother Entrepreneur Pro PR670E is a versatile embroidery machine designed for small to medium-sized businesses. Its six needles allow for quick color changes and multi-color designs. With a lower price point, it provides a cost-effective solution for companies that do not require the high volume of production that Ricoma offers. However, the performance is slightly less robust, with a maximum speed of 1000 stitches per minute. While it is user-friendly, the learning curve may be steeper for those unfamiliar with embroidery technology.

2. Janome MB-7

The Janome MB-7 is another alternative that caters to small businesses and hobbyists. With seven needles and a maximum speed of 800 stitches per minute, it offers decent performance for custom projects. The machine is known for its reliability and ease of use, making it a great option for those new to embroidery. However, it may lack some of the advanced features and extensive training support provided by Ricoma, which could be a drawback for businesses looking to scale operations quickly.

Conclusion: How to Choose the Right Embroidery Solution

Selecting the right embroidery solution hinges on understanding your business’s unique requirements. If you are a high-volume producer needing advanced features and extensive support, the Ricoma embroidery machine stands out as a premier choice. However, for smaller operations or those just starting, alternatives like the Brother Entrepreneur Pro PR670E or Janome MB-7 may provide sufficient functionality at a lower cost. It’s crucial to evaluate factors such as performance, budget, and the level of support available to determine the best fit for your business needs. By thoroughly assessing these alternatives, B2B buyers can make strategic investments that align with their operational goals.

Essential Technical Properties and Trade Terminology for ricoma embroidery machine

What Are the Essential Technical Properties of Ricoma Embroidery Machines?

When investing in Ricoma embroidery machines, understanding their technical properties is crucial for making informed B2B purchasing decisions. Here are some of the key specifications to consider:

-

Number of Needles

Ricoma machines typically feature multiple needles, with models like the MT-1501-7S offering up to 15 needles. This allows for the simultaneous stitching of various thread colors, significantly enhancing productivity and reducing setup time. For businesses focusing on diverse designs, a multi-needle system ensures versatility and efficiency in production. -

Maximum Embroidery Speed (SPM)

The speed of embroidery machines is often measured in stitches per minute (SPM). For example, the MT-1501-7S boasts a maximum speed of 1,200 SPM. A higher SPM translates to quicker turnaround times for orders, which is a critical factor for B2B buyers aiming to meet tight deadlines and increase output without compromising quality. -

Embroidery Area Size

The maximum embroidery area, such as the 19.7″ x 14.2″ field on the MT-1501-7S, determines the size of the designs that can be embroidered. A larger embroidery area is essential for businesses that require the ability to handle oversized logos or intricate designs, allowing for greater creativity and customization options in product offerings. -

Control Panel Technology

Modern Ricoma machines come equipped with high-definition touchscreen panels, enhancing user interface and control. For example, the 7″ LCD touchscreen on the MT-1501-7S facilitates easy navigation through design settings and machine operations. A user-friendly control panel is vital for reducing training time and increasing operational efficiency, especially in high-volume production environments. -

Memory Capacity

The memory capacity of Ricoma machines, which can hold up to 20 million stitches or 200 designs, is significant for businesses that frequently switch between projects. This feature allows for the storage of multiple designs directly on the machine, minimizing downtime during design changes and streamlining the production process. -

Warranty and Support

Understanding the warranty terms, such as Ricoma’s 5-year limited warranty on main drive components, is essential for B2B buyers. A robust warranty and comprehensive support system provide peace of mind and assurance of quality, allowing businesses to operate with confidence in their equipment investment.

What Common Trade Terms Should B2B Buyers Know When Purchasing Ricoma Embroidery Machines?

Familiarity with industry terminology can enhance communication and negotiation with suppliers. Here are some key trade terms relevant to Ricoma embroidery machine transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Ricoma, it indicates that the machines are made by Ricoma, ensuring quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to assess how it aligns with their purchasing needs and inventory capabilities, especially when considering large-scale operations. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific goods or services. For businesses looking to acquire Ricoma machines, submitting an RFQ can help in comparing prices and terms across different suppliers. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is important for B2B buyers to understand shipping logistics, costs, and risks associated with their purchase. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This is a critical consideration for B2B buyers as it impacts inventory management and production schedules. -

Technical Support

This term encompasses the assistance provided by manufacturers regarding the operation and troubleshooting of machines. Knowing the extent of technical support available for Ricoma machines can influence purchasing decisions, as ongoing support is vital for maintaining operational efficiency.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs, ensuring a successful investment in Ricoma embroidery machines.

Navigating Market Dynamics and Sourcing Trends in the ricoma embroidery machine Sector

What Are the Current Market Dynamics and Key Trends Impacting Ricoma Embroidery Machines?

The global embroidery machine market is witnessing significant growth driven by the increasing demand for customized apparel and promotional products. Businesses across Africa, South America, the Middle East, and Europe are leveraging advanced embroidery technology to enhance product offerings and meet consumer preferences for personalized goods. Key trends include the rise of multi-needle machines, which allow for greater efficiency and versatility, and the integration of smart technology, enabling remote operation and real-time monitoring. Additionally, the COVID-19 pandemic has accelerated the shift towards e-commerce, prompting businesses to adopt embroidery solutions that facilitate online sales and rapid production.

International buyers should also be aware of the growing emphasis on automation and digital solutions within the embroidery sector. Advanced features such as touchscreen interfaces, USB connectivity, and embroidery software like Ricoma’s Chroma are becoming standard, allowing businesses to streamline operations and reduce labor costs. Moreover, as manufacturers like Ricoma continue to innovate, the introduction of eco-friendly machines and sustainable practices is gaining traction, appealing to environmentally conscious consumers and businesses alike.

How Does Sustainability Influence Sourcing Decisions in the Ricoma Embroidery Machine Sector?

Sustainability is a critical consideration for international B2B buyers in the Ricoma embroidery machine sector. Companies are increasingly scrutinizing the environmental impact of their supply chains, seeking to minimize carbon footprints and promote ethical sourcing. This trend is particularly pronounced in regions like Europe and North America, where regulations and consumer expectations regarding sustainability are stringent.

Ricoma is committed to reducing its environmental impact by adopting sustainable manufacturing practices and sourcing materials responsibly. Buyers should look for machines that incorporate ‘green’ certifications, such as Energy Star or ISO 14001, which indicate adherence to environmental management standards. Additionally, using recyclable materials in machine components and packaging can further enhance a company’s sustainability profile. By prioritizing ethical sourcing and sustainability, businesses not only contribute positively to the environment but also enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

How Has the Ricoma Embroidery Machine Sector Evolved Over Time?

The Ricoma embroidery machine sector has undergone a remarkable evolution since its inception. Founded in the late 1990s, Ricoma began as a small manufacturer focused on providing quality embroidery solutions. Over the years, the company has expanded its product lineup to include a diverse range of machines, from single-needle to multi-head models, catering to both small businesses and large-scale operations.

Ricoma’s commitment to innovation has positioned it as a leader in the industry, introducing groundbreaking features such as the world’s first 20-needle embroidery machine and fully responsive touchscreen interfaces. This continuous evolution not only reflects the changing demands of the market but also highlights the importance of adapting to technological advancements. For B2B buyers, understanding this historical context can provide valuable insights into the reliability and capabilities of Ricoma machines, reinforcing their decision-making in sourcing high-quality embroidery equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of ricoma embroidery machine

-

How do I choose the right Ricoma embroidery machine for my business needs?

Selecting the appropriate Ricoma embroidery machine hinges on your production volume, the types of products you intend to personalize, and your budget. For startups, the EM-1010 multi-needle machine is user-friendly and ideal for small-scale operations. For larger businesses, consider models like the MT-1501-7S or Marquee series, which offer multiple needles and larger embroidery areas for high-volume tasks. Assess your specific requirements, such as the need for cap embroidery or large designs, to make an informed choice. -

What are the key features of Ricoma embroidery machines that enhance productivity?

Ricoma machines are equipped with advanced features designed to boost productivity, including high-speed stitching (up to 1,200 SPM), large embroidery fields, and user-friendly touchscreens. The Chroma digitizing software included with your machine simplifies design creation. Additionally, many models offer multiple needle capabilities, allowing for quick color changes without stopping the machine. These features collectively enable businesses to complete orders faster and with higher precision, making them ideal for competitive markets. -

What is the minimum order quantity (MOQ) for Ricoma embroidery machines?

Typically, Ricoma embroidery machines are sold individually, allowing businesses to start with just one unit. However, for bulk purchases or special pricing, it’s advisable to contact Ricoma directly. They may offer discounts for larger orders or customized packages tailored to specific business needs. Engaging with a sales representative can provide insights into any available incentives for B2B buyers looking to scale their operations. -

What payment terms are available for purchasing Ricoma embroidery machines?

Ricoma offers various payment options, including credit card payments, bank transfers, and financing solutions. For international buyers, it’s essential to discuss payment terms with your sales representative to explore options that suit your financial strategy. Some buyers may qualify for installment plans or leasing options, which can ease the initial investment burden and help manage cash flow effectively. -

How does Ricoma ensure quality assurance for their embroidery machines?

Quality assurance at Ricoma involves rigorous testing and inspection procedures at their Miami facility before shipping. Each machine undergoes thorough quality checks to ensure it meets high standards of performance and reliability. Additionally, Ricoma provides a robust warranty that covers non-consumable parts and technical labor for a specified period, giving buyers peace of mind regarding their investment. -

What logistics support does Ricoma offer for international buyers?

Ricoma provides comprehensive logistics support for international buyers, including shipping and customs documentation assistance. Once an order is placed, machines are carefully crated and shipped within approximately 3 to 4 weeks. Buyers should discuss shipping options, estimated delivery times, and any potential customs duties with their sales representative to ensure a smooth import process. -

Can I customize my Ricoma embroidery machine?

Yes, Ricoma offers customization options for their embroidery machines to cater to specific business needs. This may include adjustments to the machine configuration, additional accessories, or even special software features. Engaging with a sales representative early in the process can help outline your requirements and explore available customization options to ensure the machine aligns perfectly with your operational goals. -

What training and support does Ricoma provide after purchasing a machine?

Ricoma is committed to ensuring buyers can maximize their machine’s capabilities. After purchase, customers receive lifetime technical support, available seven days a week, and access to an extensive video training library. Additionally, Ricoma offers free live training sessions and one-on-one expert support to address any questions or challenges. This robust support system is designed to help users become proficient in operating their machines and troubleshooting any issues that may arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Ricoma Embroidery Machine Manufacturers & Suppliers List

1. Ricoma – EM-1010 Multi-Needle Embroidery Machine

Domain: ricoma.com

Registered: 2005 (20 years)

Introduction: {“products”:[{“name”:”EM-1010 Multi-Needle, Easy-to-Use Embroidery Machine for Startups”,”price”:”$8,995.00″},{“name”:”Creator Multi-Needle Embroidery Machine for Crafters”,”price”:”$10,995.00″},{“name”:”MT-1501-7S Single-Head Commercial Embroidery Machine”,”price”:”$14,995.00″},{“name”:”MT-1502-7S Two-Head Commercial Embroidery Machine”,”price”:””},{“name”:”SWD-1501-8S Commercial Embroidery Machi…

2. Ricoma – MT-1501 Single Head, CHT2 4 Head

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ricoma embroidery machines are often criticized for their longevity compared to competitors like Tajima or Barudan, which are said to last decades. Some users report positive experiences with Ricoma machines, citing models like the MT-1501 Single head, 15 needle, and the CHT2 4 head, which have performed well over several years. There are concerns about Ricoma’s claim of being an American brand, a…

3. Ricoma – Creator Single-Head 10-Needle Embroidery Machine

Domain: crafts.ricoma.com

Registered: 2005 (20 years)

Introduction: Ricoma Creator Single-Head 10-Needle Embroidery Machine

– Designed for hobbyists

– 10 needles

– Large embroidery area

– Intuitive 10.1″ built-in high-definition LCD touchscreen

– Wi-Fi capability for seamless connectivity

– Includes Chroma Embroidery Digitizing Software (free first year subscription, $799 value)

– 100 million stitch or 1,000 design memory capacity

– Automatic software updates via …

4. Ricoma – EM-1010 & MT-1501

Domain: maggieframestore.com

Registered: 2022 (3 years)

Introduction: Ricoma offers a diverse lineup of embroidery machines catering to startups and established businesses, including the single-head EM-1010 and the industrial-grade MT-1501. The MT-1501 is noted for its ability to handle demanding orders with speeds up to 600 stitches per minute and minimal thread or needle breaks. However, users report issues with thread breaks and needle problems, particularly with…

5. Ricoma – Garment Decoration Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Ricoma – Garment Decoration Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

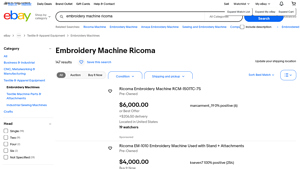

6. Ricoma – EM-1010 Embroidery Machine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Ricoma EM-1010 Embroidery Machine Used with Stand + Attachments Pre-Owned $4,000.00 Buy It Now Located in United States Free local pickup; Ricoma 10 needle single head Creator embroidery machine. new, Brand New $5,000.00 0 bids · Time left 1d 19h Buy It Now Located in United States Free local pickup; Ricoma EM-1010 Embroidery Machine Used with Stand + Attachments+Chroma Software Pre-Owned $6,500.0…

7. Maggie Frames – 15-Needle Embroidery Machine

Domain: maggieframes.com

Registered: 2022 (3 years)

Introduction: This company, Maggie Frames – 15-Needle Embroidery Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ricoma embroidery machine

Why Should International Buyers Consider Ricoma Embroidery Machines for Strategic Sourcing?

In the competitive landscape of embroidery, Ricoma machines stand out due to their innovative features, robust performance, and excellent support systems. The diverse range of models, from the user-friendly EM-1010 for startups to the high-capacity multi-head machines, caters to businesses of all sizes, ensuring scalability and versatility. For international buyers in regions like Africa, South America, the Middle East, and Europe, these machines provide not only high-quality outputs but also the reliability needed for growth.

Strategic sourcing of Ricoma embroidery machines offers several advantages, including factory-direct pricing and comprehensive training resources. With lifetime technical support and a strong warranty, businesses can invest confidently, knowing they have the backing necessary to succeed. This strategic investment can lead to enhanced productivity and the ability to meet diverse customer demands effectively.

As the embroidery market continues to evolve, leveraging advanced technology like Ricoma’s machines will be crucial for staying competitive. Explore your options today and consider how Ricoma can help propel your embroidery business forward, ensuring you remain at the forefront of this dynamic industry.