Choosing Your Rf Blocking: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for rf blocking

In today’s interconnected world, the challenge of sourcing effective RF blocking solutions has never been more critical. As businesses expand their operations across Africa, South America, the Middle East, and Europe, the need to protect sensitive electronic equipment from radio frequency interference (RFI) becomes paramount. RF shielding is not just a technical requirement; it is a strategic imperative that ensures the reliability and performance of devices in sectors ranging from telecommunications to medical equipment.

This comprehensive guide delves into the multifaceted landscape of RF blocking, exploring various shielding techniques, materials, and applications tailored to meet the diverse needs of international B2B buyers. From understanding the differences between solid enclosures and vent shields to evaluating the effectiveness of different materials such as copper and aluminum, this resource equips you with the knowledge necessary to make informed purchasing decisions. Furthermore, we provide insights into supplier vetting processes, cost considerations, and best practices for integrating RF shielding into your operations.

By harnessing the information in this guide, businesses can confidently navigate the global market for RF blocking solutions. This ensures not only compliance with industry standards but also the long-term protection of their valuable assets against the detrimental effects of electromagnetic interference. Whether you are based in Nigeria, Saudi Arabia, or elsewhere, our guide will empower you to secure the most effective RF shielding options for your organization’s unique needs.

Understanding rf blocking Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| RF Shielding Gaskets | Made from elastomeric materials with conductive fillers | Aerospace, Telecommunications | Pros: Cost-effective, versatile; Cons: May require precise installation for effectiveness. |

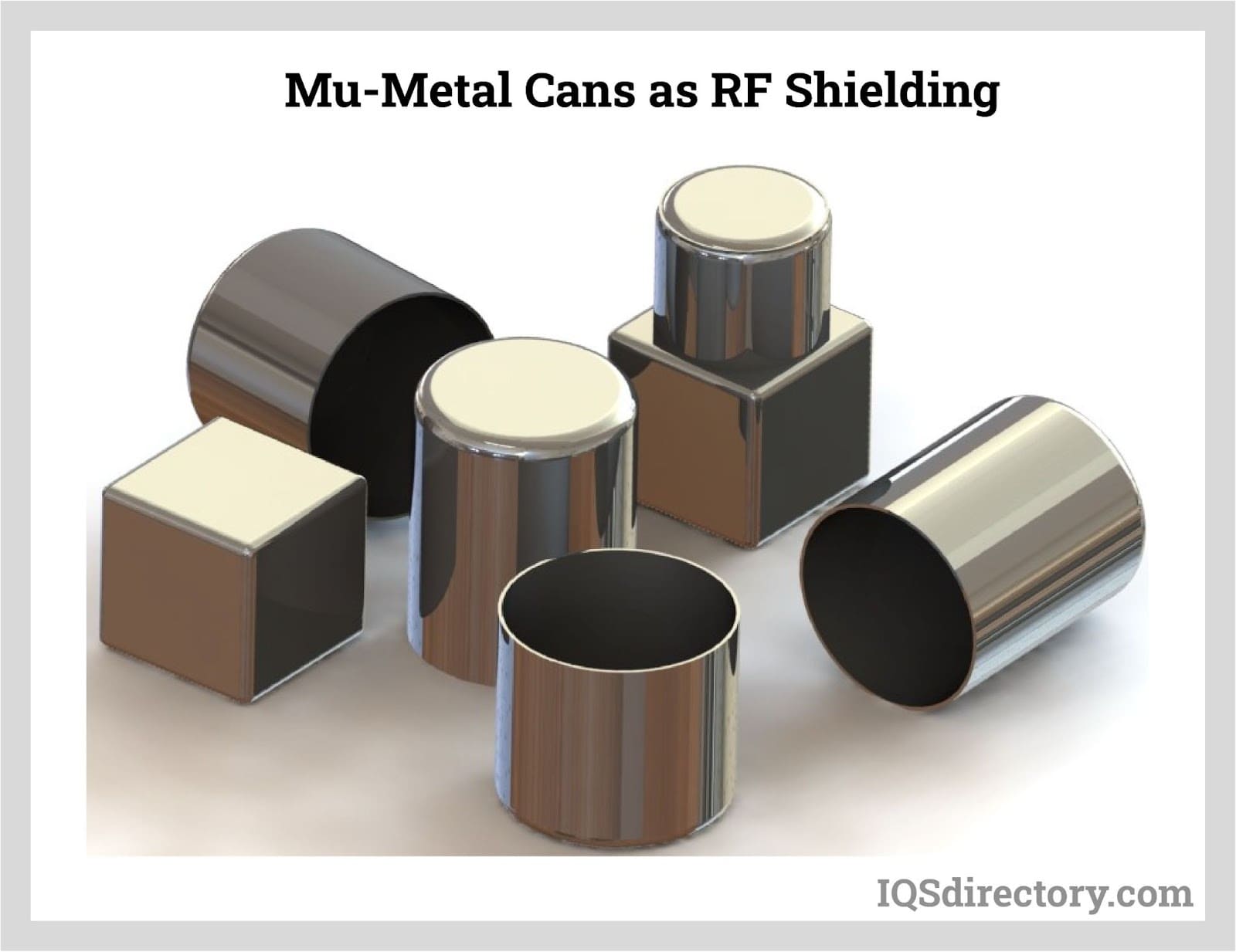

| Solid RF Shielding Enclosures | Completely encases sensitive components | Medical Devices, Defense | Pros: High level of protection; Cons: Bulkier, more expensive to manufacture. |

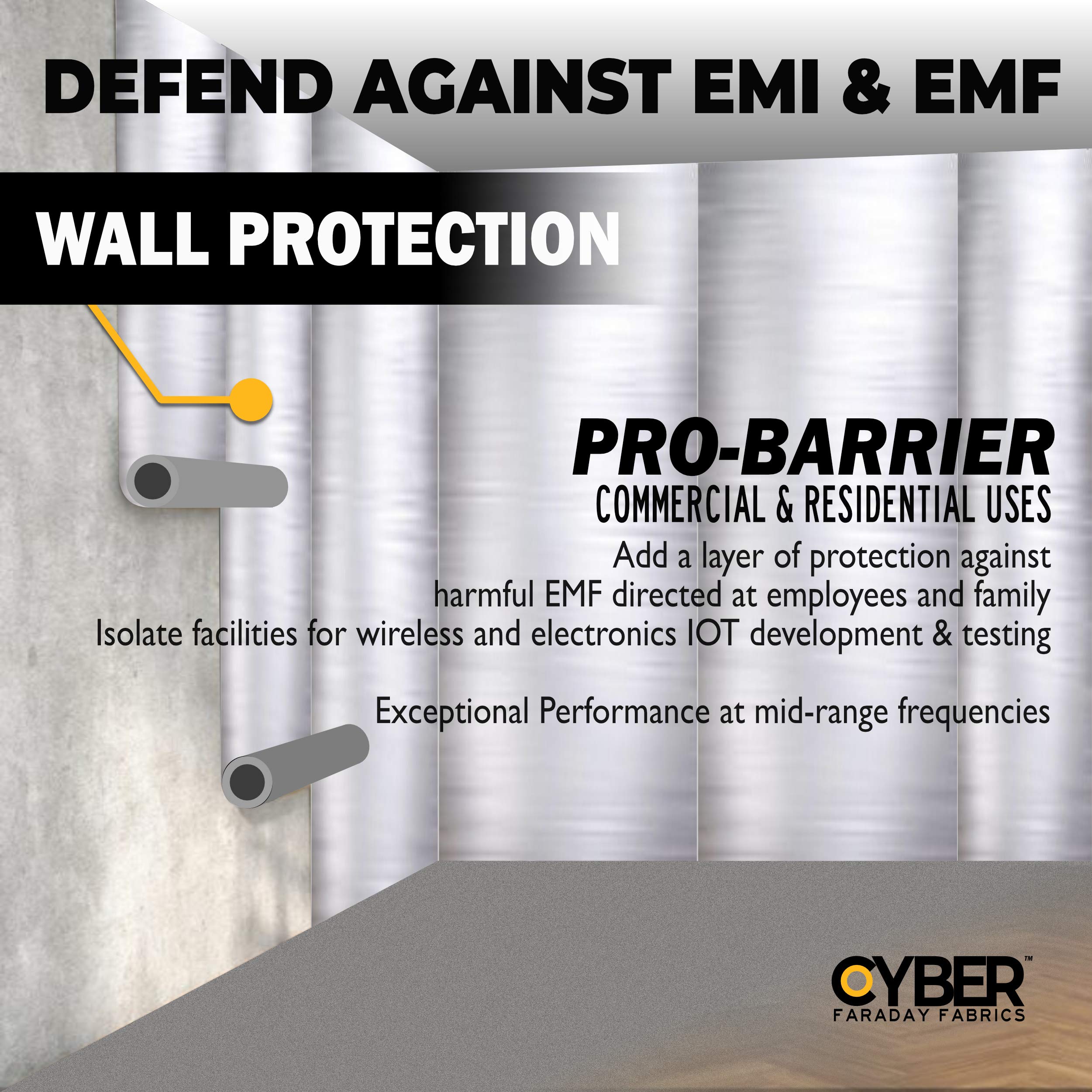

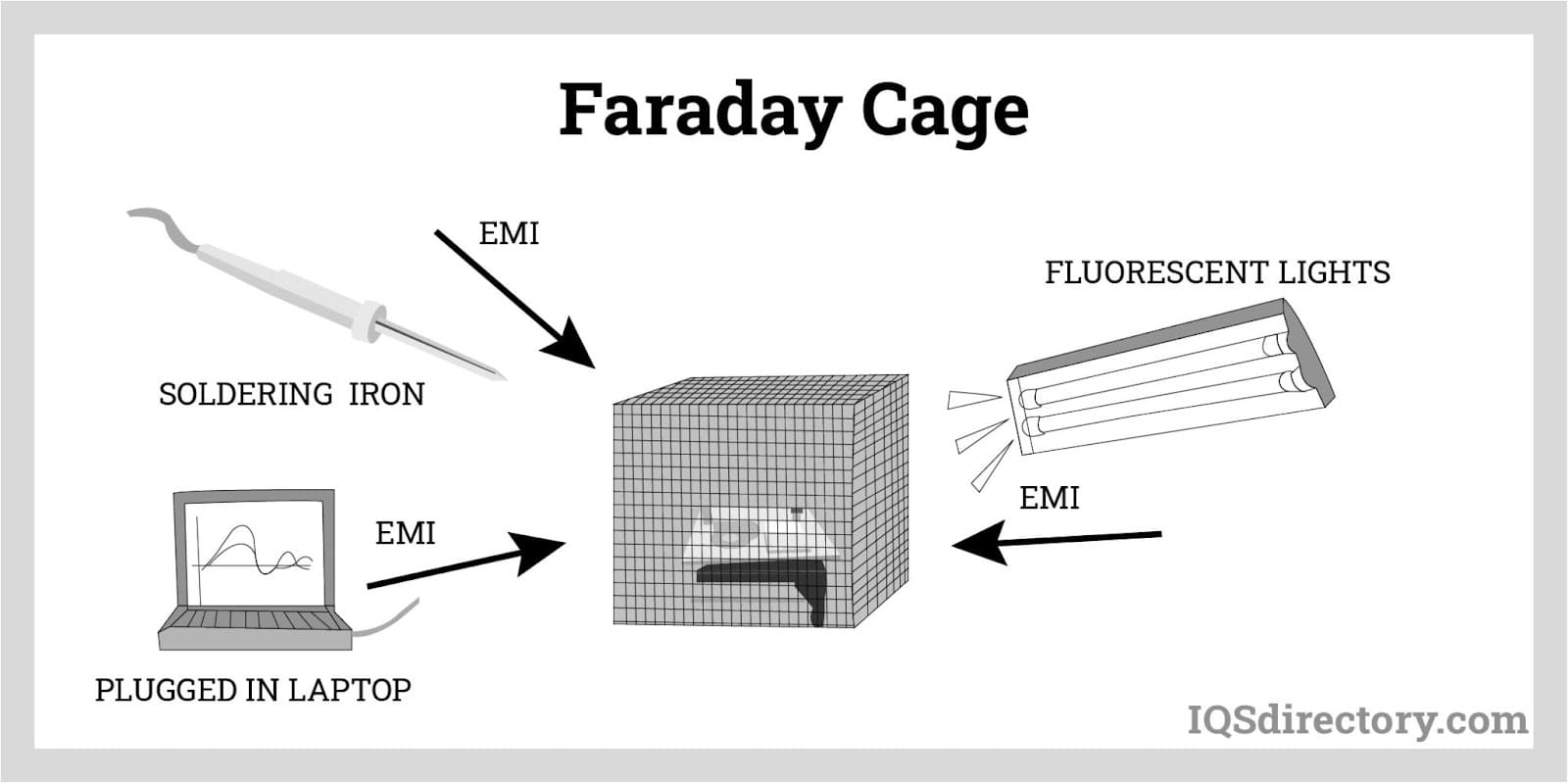

| Faraday Cages | Wire mesh structure that redistributes signals | Research Facilities, Electronics | Pros: Effective for large applications; Cons: Limited to specific shapes and sizes. |

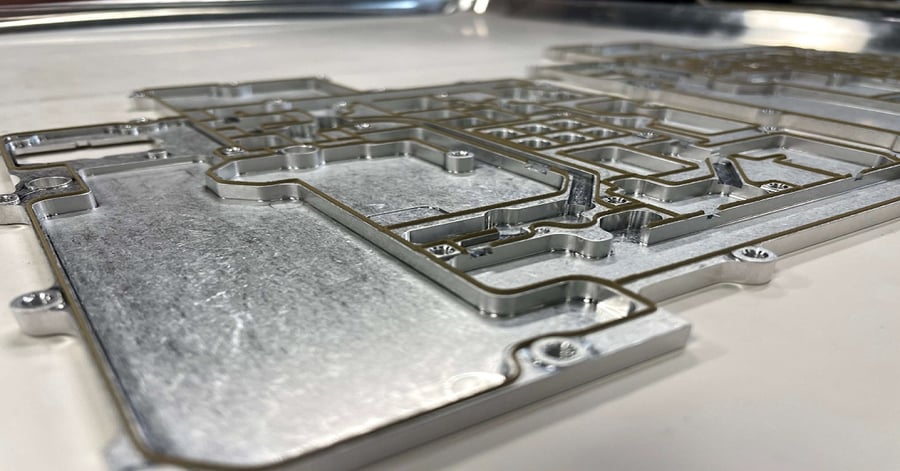

| Board RF Shields | Small, precise shields for circuit boards | Consumer Electronics, Telecommunications | Pros: Space-efficient, tailored protection; Cons: Requires precise manufacturing. |

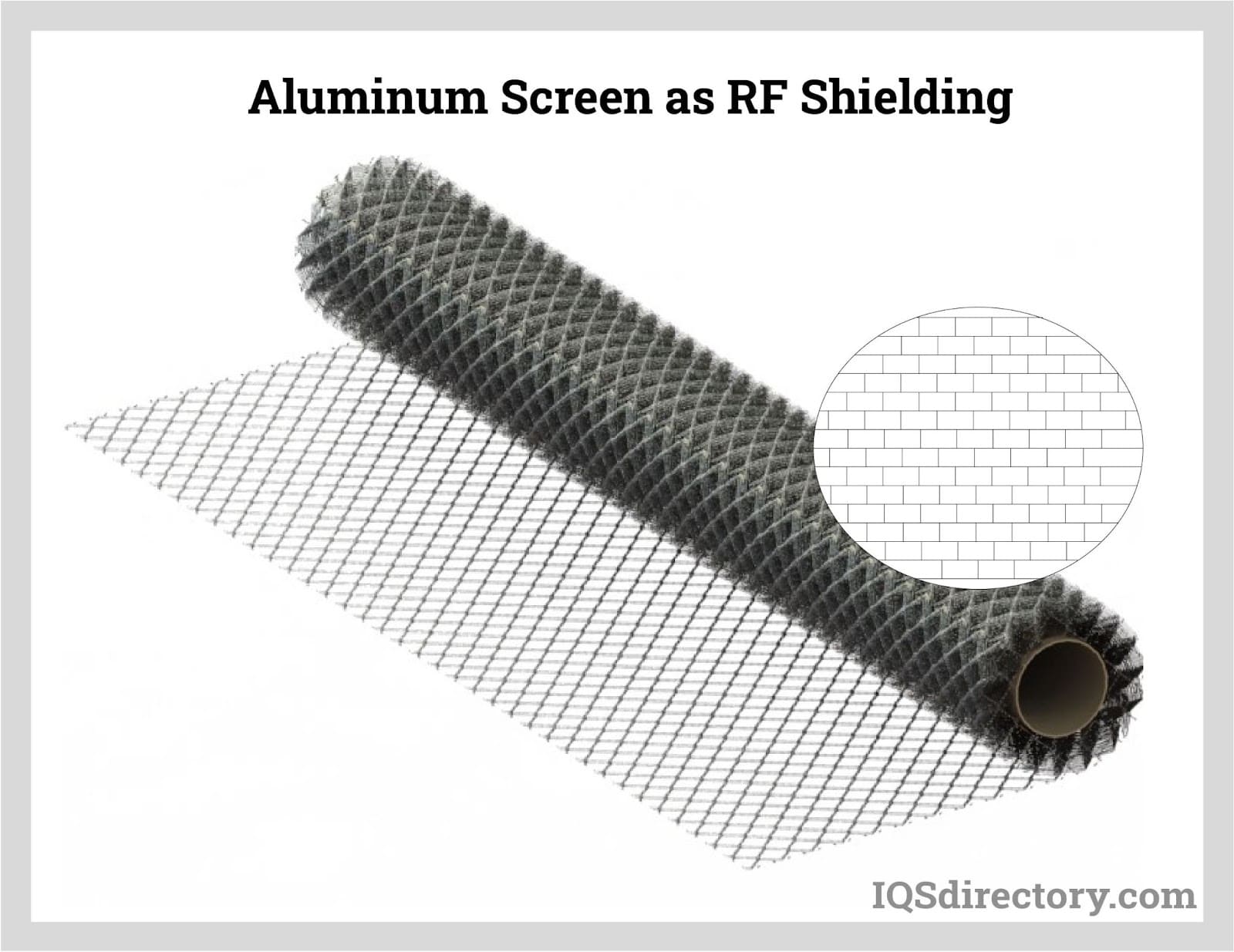

| Cable RF Shields | Shields designed specifically for cables | Industrial Equipment, Automotive | Pros: Protects against interference and signal loss; Cons: Can be costly based on material. |

What are RF Shielding Gaskets and Their Applications?

RF shielding gaskets are critical components designed to mitigate radio frequency interference by utilizing elastomeric materials embedded with conductive fillers. These gaskets are particularly suited for applications where flexibility and adaptability are required, such as in telecommunications and aerospace. B2B buyers should consider the specific installation needs and the potential for varying effectiveness based on the gasket’s design and material quality, as improper installation can compromise performance.

How Do Solid RF Shielding Enclosures Provide Protection?

Solid RF shielding enclosures are metal casings that provide a robust barrier against RF signals. They are ideal for sensitive medical devices and defense applications where complete isolation from interference is paramount. While these enclosures offer superior protection, buyers must weigh the benefits against the increased manufacturing costs and bulkiness, which may limit design flexibility.

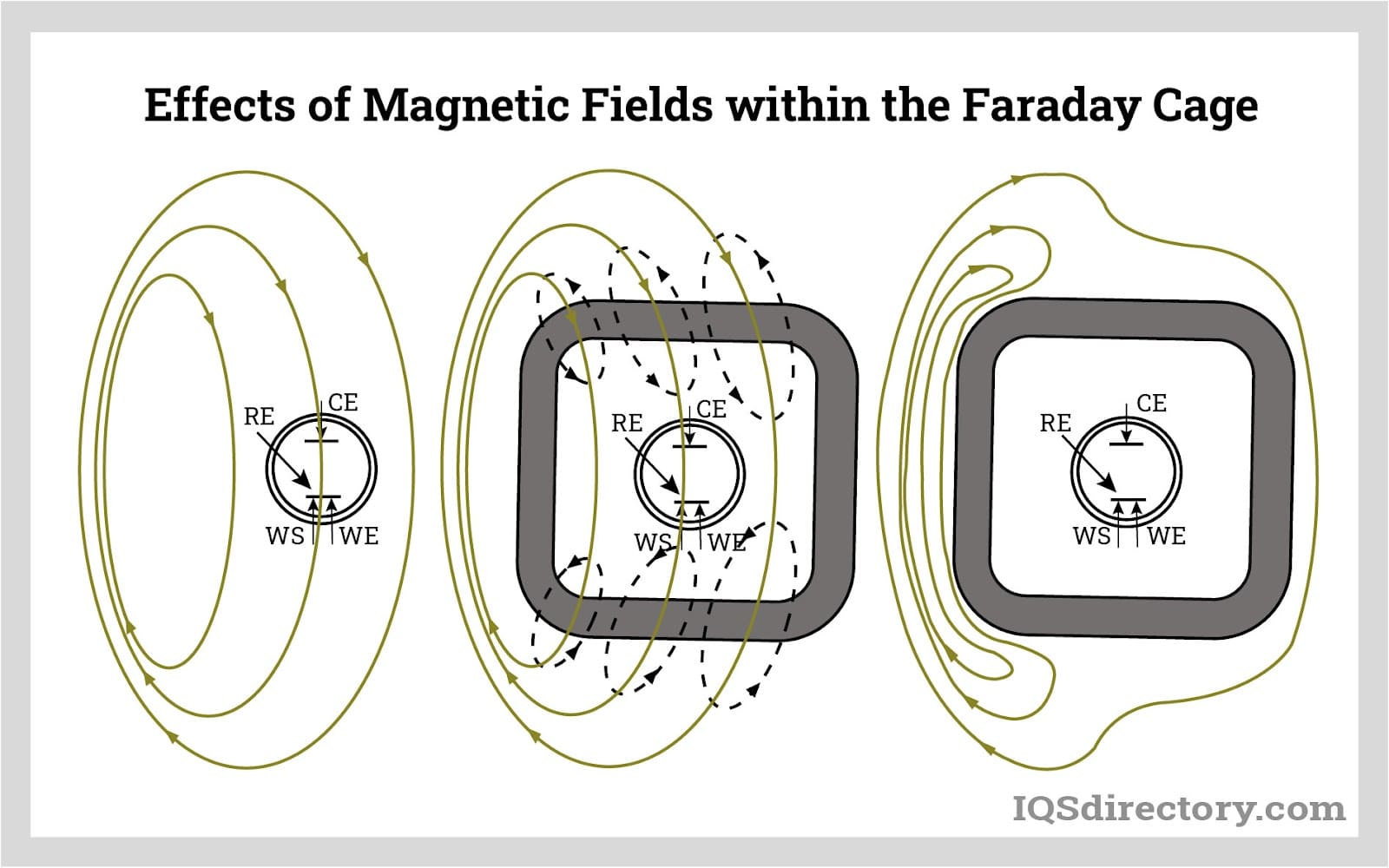

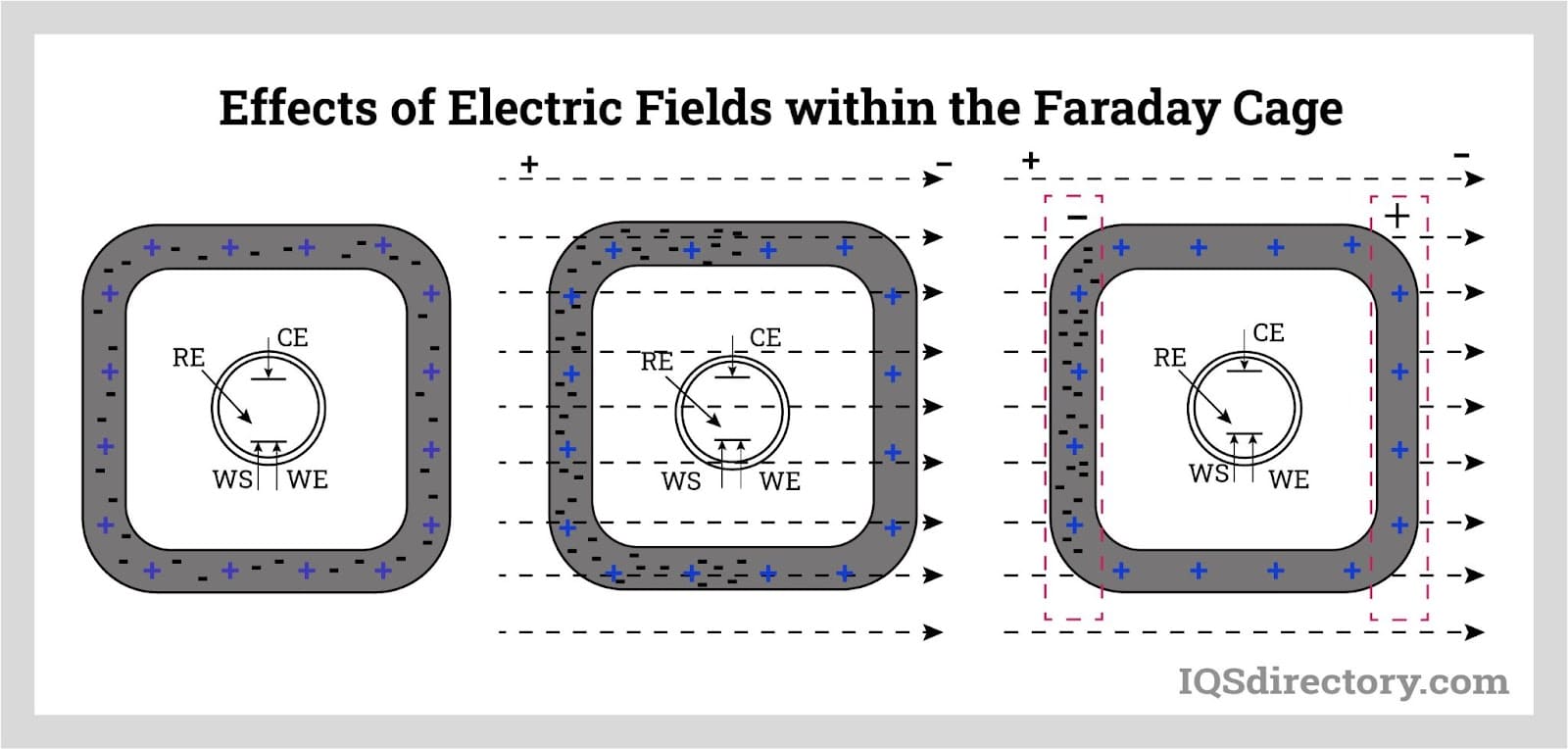

What Makes Faraday Cages Unique for RF Shielding?

Faraday cages are constructed from conductive wire mesh that effectively redistributes incoming RF signals, preventing them from reaching protected components. This type of shielding is particularly useful in research facilities and electronics labs where large equipment needs protection. B2B buyers should consider the specific dimensions and configurations required for their applications, as Faraday cages can be limited in shape and size.

Why Choose Board RF Shields for Circuit Protection?

Board RF shields are small, tailored solutions specifically designed for circuit boards. These shields are essential in consumer electronics and telecommunications, where space is at a premium. Buyers need to focus on precise manufacturing capabilities, as the effectiveness of board RF shields heavily relies on their fit and the quality of materials used.

What Are the Advantages of Cable RF Shields in Industrial Applications?

Cable RF shields are specialized shields that protect cables from both emitting and receiving unwanted RF signals. Commonly used in industrial equipment and automotive applications, these shields can be made from metal foil or wire mesh. Buyers should evaluate the cost-effectiveness of different materials and the specific shielding requirements of their cables to ensure optimal performance and reliability in their systems.

Key Industrial Applications of rf blocking

| Industry/Sector | Specific Application of rf blocking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | RF shielding for avionics systems | Protects sensitive electronic systems from interference, ensuring reliable operation. | High-quality materials, certification standards (e.g., AS9100), and precision manufacturing capabilities. |

| Telecommunications | RF blocking in cellular infrastructure | Enhances signal clarity and reduces interference, improving service quality for users. | Compatibility with existing infrastructure, durability, and weather resistance. |

| Medical Devices | RF shielding for MRI machines | Prevents external RF signals from affecting imaging quality, ensuring accurate diagnostics. | Compliance with medical regulations, material safety, and reliability under varying conditions. |

| Automotive | RF blocking in electric vehicle systems | Protects electronic control units from RFI, enhancing vehicle safety and performance. | Lightweight materials, thermal management properties, and integration with existing vehicle designs. |

| Consumer Electronics | RF shielding in smart devices | Ensures device functionality and user privacy by blocking unwanted signals. | Cost-effectiveness, aesthetic considerations, and ease of integration into compact designs. |

How is RF Blocking Used in Aerospace Applications?

In the aerospace sector, RF blocking is critical for avionics systems, which require protection from radio frequency interference (RFI). High levels of electromagnetic noise can disrupt navigation and communication systems, potentially jeopardizing flight safety. International B2B buyers in this field must prioritize sourcing materials that meet stringent certification standards, such as AS9100, and ensure precision manufacturing to maintain the integrity of these crucial systems.

What Role Does RF Blocking Play in Telecommunications?

Telecommunications infrastructure relies on effective RF blocking to enhance signal clarity and reduce interference. This is particularly important in densely populated areas where multiple signals can overlap. Businesses in this sector must consider sourcing solutions that are durable and weather-resistant, ensuring long-term performance in various environmental conditions. Compatibility with existing systems is also essential for seamless integration.

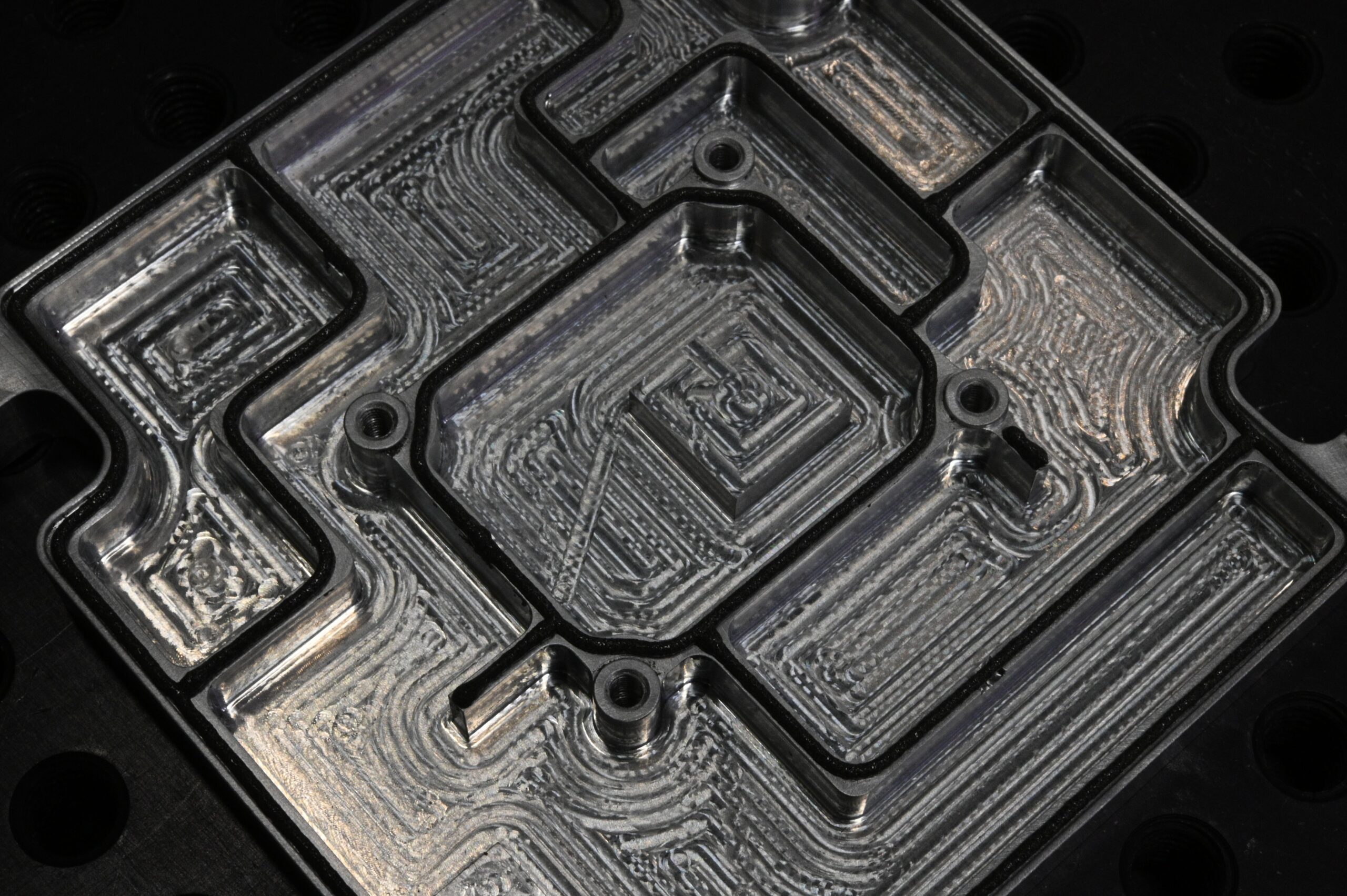

Illustrative image related to rf blocking

Why is RF Shielding Essential for Medical Devices?

In medical applications, such as MRI machines, RF shielding is vital to prevent external signals from compromising imaging quality. Accurate diagnostics depend on the clarity of the images produced, making RF blocking a crucial aspect of design. Buyers in the medical field should focus on suppliers that comply with health regulations and offer materials that ensure reliability and safety in clinical environments.

How Does RF Blocking Enhance Electric Vehicles?

RF blocking is increasingly important in the automotive industry, particularly for electric vehicles (EVs). These vehicles contain numerous electronic control units that must operate without interference to ensure safety and performance. Buyers should look for lightweight materials with thermal management properties, enabling effective RF shielding while maintaining vehicle efficiency. Integration with existing designs is another key consideration for manufacturers.

What Benefits Does RF Shielding Provide in Consumer Electronics?

In the realm of consumer electronics, RF shielding is essential for devices like smartphones and smart home products. It helps protect user privacy by blocking unwanted signals and ensures device functionality. B2B buyers should seek cost-effective solutions that also consider aesthetic factors, as these products often need to fit compact designs without sacrificing performance. Ease of integration into existing manufacturing processes is also crucial for maintaining production efficiency.

3 Common User Pain Points for ‘rf blocking’ & Their Solutions

Scenario 1: Inconsistent RF Shielding Performance in Critical Applications

The Problem: B2B buyers in sectors such as aerospace, defense, and telecommunications often face the challenge of inconsistent RF shielding performance in their devices. This inconsistency can lead to unexpected failures in critical applications, where reliable communication and device integrity are paramount. For instance, a company manufacturing medical devices might experience varying levels of radio frequency interference (RFI) protection, resulting in potential malfunctions of sensitive equipment during operations. This unpredictability can not only hinder operational efficiency but also compromise safety and regulatory compliance.

The Solution: To address this issue, it is essential to conduct a thorough analysis of the RF shielding materials and techniques employed in the manufacturing process. Buyers should prioritize working with experienced manufacturers that understand the specific RF shielding requirements of their industry. Collaborating with a partner that offers a diverse range of shielding materials—such as copper, aluminum, and specialized alloys—can help ensure consistent performance. Additionally, implementing rigorous testing protocols throughout the design and production phases can help identify weaknesses early on. Regular audits and performance evaluations of the RF shields will further enhance reliability and provide confidence that the shielding will perform effectively under varying conditions.

Illustrative image related to rf blocking

Scenario 2: Difficulty in Selecting the Right RF Shielding Material

The Problem: Many B2B buyers struggle with selecting the appropriate RF shielding material for their specific applications. With numerous options available, each with different conductive properties, thicknesses, and weights, making the right choice can be overwhelming. For example, a telecommunications company may find itself at a crossroads when deciding between a lighter aluminum shield for mobility versus a heavier copper option that provides superior shielding but adds bulk to the equipment. This indecision can lead to delays in product development and increased costs.

The Solution: To simplify the material selection process, buyers should start by clearly defining the requirements of their specific application, including factors such as frequency range, environmental conditions, and physical dimensions. Engaging with experts in RF shielding can provide valuable insights into the strengths and weaknesses of different materials. Moreover, leveraging simulation tools to model the performance of various materials in real-world scenarios can guide decision-making. Establishing a collaboration with a trusted supplier who can offer samples and prototyping services will allow buyers to evaluate performance firsthand before committing to large-scale production. This strategic approach can lead to more informed choices, ultimately saving time and resources.

Scenario 3: Challenges in Implementing RF Shielding in Existing Designs

The Problem: Implementing effective RF shielding in pre-existing designs presents a significant challenge for many B2B buyers. Companies may find that their current products are not adequately shielded against RFI, resulting in performance issues that require retrofitting. For instance, a manufacturer of consumer electronics may realize that their devices are susceptible to interference from nearby wireless networks, leading to customer dissatisfaction and increased return rates. Addressing these issues in established products can be both complex and costly.

The Solution: A practical approach to overcoming this challenge involves conducting a comprehensive RF audit of existing products to identify specific vulnerabilities. Once these areas are pinpointed, buyers should explore modular RF shielding solutions that can be retrofitted without extensive redesigns. Collaborating with engineers who specialize in RF shielding can facilitate the integration of additional shielding components, such as gaskets or enclosures, into the existing design. Investing in advanced materials that offer better shielding properties without significantly altering the product’s weight or size will also enhance performance. Additionally, maintaining open communication with customers during this process can help manage expectations and demonstrate a commitment to improving product quality, ultimately leading to increased customer loyalty and satisfaction.

Illustrative image related to rf blocking

Strategic Material Selection Guide for rf blocking

What Are the Key Properties of Common Materials for RF Blocking?

When selecting materials for RF blocking, it is crucial to understand the properties that influence their performance. Below, we analyze four common materials used in RF shielding, focusing on their key properties, advantages and disadvantages, and considerations for international buyers.

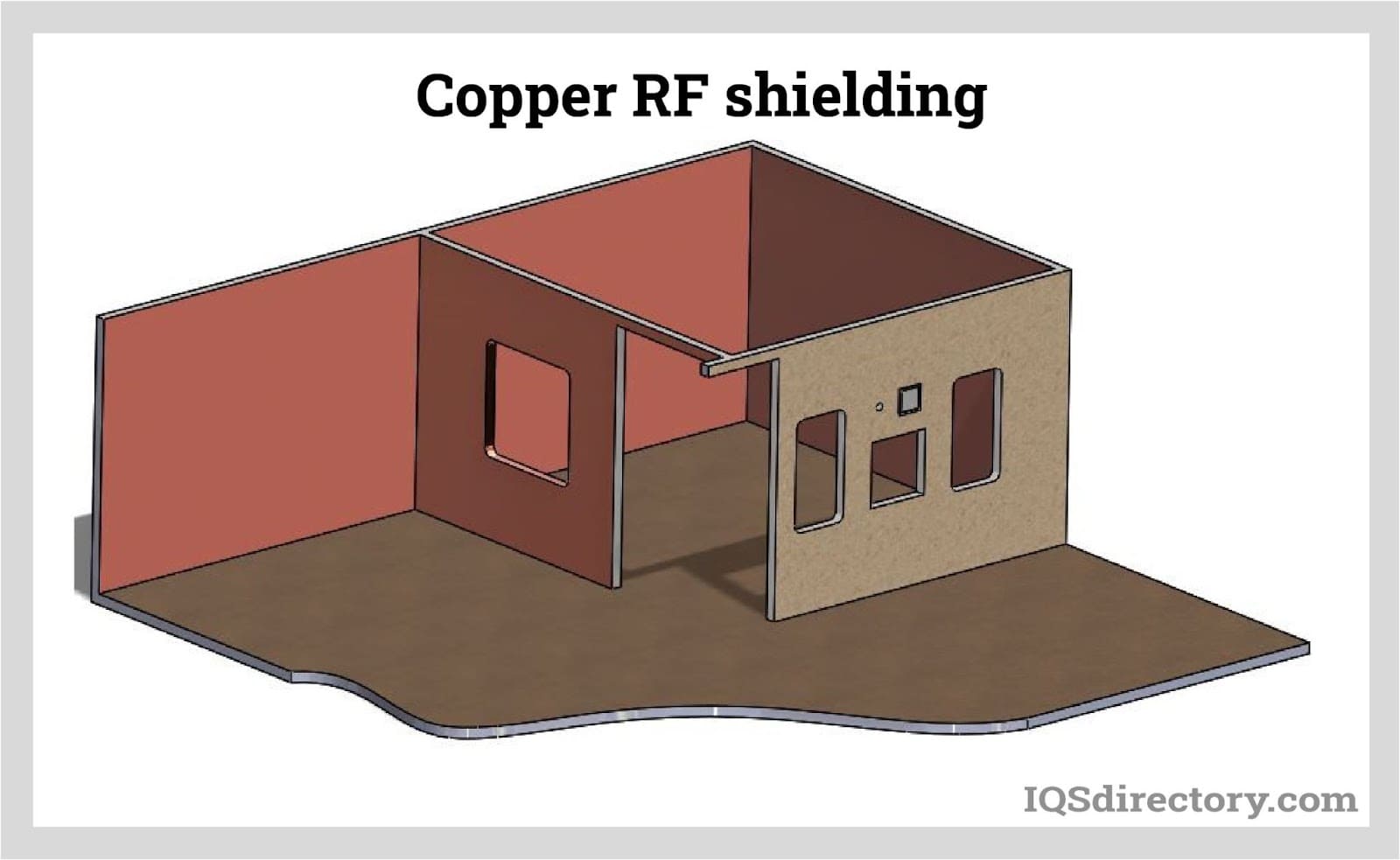

How Does Copper Perform as an RF Shielding Material?

Copper is one of the most widely used materials for RF shielding due to its excellent conductivity. It typically has a high-temperature rating, making it suitable for various applications. Copper also offers good corrosion resistance, which is vital for longevity in harsh environments.

Pros: Copper provides superior shielding effectiveness and is relatively easy to work with in manufacturing processes. Its malleability allows for complex shapes, enhancing its adaptability to different designs.

Illustrative image related to rf blocking

Cons: The primary drawback of copper is its cost, which can be higher than other materials. Additionally, it can tarnish over time, potentially affecting its performance if not properly maintained.

Impact on Application: Copper is highly effective in environments where high-frequency signals need to be blocked, such as in telecommunications and medical devices. However, its weight may be a consideration in applications where lightweight materials are preferred.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and the Middle East should also consider local sourcing options to mitigate costs.

What Role Does Aluminum Play in RF Shielding?

Aluminum is another popular choice for RF shielding due to its lightweight and good conductivity. It typically has a moderate temperature rating and is resistant to corrosion, making it suitable for outdoor applications.

Pros: Aluminum is less expensive than copper and offers a good balance between cost and performance. Its lightweight nature makes it ideal for applications where weight reduction is critical.

Illustrative image related to rf blocking

Cons: While aluminum provides decent shielding effectiveness, it is generally not as effective as copper. Additionally, it can be more challenging to work with due to its brittleness in certain forms.

Impact on Application: Aluminum is frequently used in consumer electronics and automotive applications where weight and cost are significant factors. Its corrosion resistance makes it suitable for outdoor installations.

Considerations for International Buyers: Buyers should ensure that aluminum meets local standards and regulations. In regions like South America, where environmental conditions may vary, selecting the right alloy is crucial for performance.

How Effective Are Specialized Alloys for RF Blocking?

Specialized alloys, such as brass and nickel-copper, are engineered to provide enhanced shielding effectiveness. These materials often combine the best properties of metals like copper and aluminum, offering improved performance in specific applications.

Pros: Alloys can provide excellent shielding while maintaining a balance of weight and cost. They also tend to have better resistance to corrosion and wear, extending their lifespan.

Illustrative image related to rf blocking

Cons: The complexity of manufacturing specialized alloys can lead to higher costs and longer lead times. Additionally, they may require more specialized knowledge for design and application.

Impact on Application: Alloys are ideal for high-performance applications in aerospace and defense where reliability is critical. Their tailored properties can significantly enhance device performance in challenging environments.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and their compliance with international standards. In Europe, for example, adherence to RoHS directives is essential for electronic components.

Illustrative image related to rf blocking

What Advantages Does Steel Offer for RF Shielding?

Steel, particularly stainless steel, provides a robust solution for RF shielding. It has excellent mechanical strength and can withstand harsh environmental conditions, making it suitable for industrial applications.

Pros: Steel is durable and offers good shielding effectiveness, especially in lower frequency ranges. Its strength makes it ideal for applications requiring structural integrity.

Cons: The weight of steel can be a disadvantage in applications where lightweight materials are preferred. Additionally, its cost can vary significantly based on the type of steel used.

Impact on Application: Steel is commonly used in industrial settings and for large equipment that requires robust shielding. Its durability makes it suitable for long-term installations.

Considerations for International Buyers: Buyers should consider the availability of various grades of steel and their compliance with international standards. In regions like Africa, sourcing local steel can help reduce costs and support local economies.

Summary Table of RF Blocking Materials

| Material | Typical Use Case for RF Blocking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Telecommunications, medical devices | Superior conductivity and shielding | Higher cost, potential tarnishing | High |

| Aluminum | Consumer electronics, automotive | Lightweight and cost-effective | Less effective shielding than copper | Medium |

| Specialized Alloys | Aerospace, defense | Enhanced performance and durability | Higher manufacturing complexity | High |

| Steel | Industrial equipment | Robust and durable | Heavier, variable cost | Medium |

This analysis provides B2B buyers with actionable insights into the strengths and weaknesses of common RF shielding materials, helping them make informed decisions tailored to their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for rf blocking

What Are the Key Stages in the Manufacturing Process for RF Blocking Solutions?

The manufacturing process for RF blocking solutions consists of several critical stages that ensure the effectiveness and reliability of the final product. Each stage is designed to prepare materials, form components, assemble units, and apply finishing touches that enhance performance.

Illustrative image related to rf blocking

Material Preparation: What Materials Are Used in RF Shielding?

The foundation of effective RF shielding lies in the choice of materials. Common materials include conductive metals such as copper, aluminum, and brass, as well as specialized alloys that offer enhanced shielding properties. The preparation of these materials involves several steps:

-

Sourcing and Verification: Reliable suppliers are essential. Materials must meet specific standards for conductivity and thickness. B2B buyers should ensure that suppliers provide certificates of conformity and material data sheets.

-

Cutting and Shaping: Once sourced, materials are cut to size using precision cutting techniques such as laser cutting or CNC machining. This ensures that components meet exact specifications required for effective RF shielding.

Forming: How Are RF Shielding Components Shaped?

Forming techniques play a vital role in shaping RF shielding components. Depending on the design and application, manufacturers may employ various methods:

-

Stamping: For flat components like shields or gaskets, stamping is often used. This method allows for high-volume production with consistent quality.

-

Molding: In cases where elastomeric materials are required (such as in RF shielding gaskets), injection molding is utilized. This technique ensures that the conductive filler is evenly distributed within the elastomer.

-

Welding and Joining: For solid enclosures or multi-part assemblies, welding techniques (such as spot welding or TIG welding) are employed to create strong, conductive joints that maintain shielding integrity.

Assembly: What Are the Steps for Assembling RF Shielding Devices?

The assembly stage combines the various components into a final product. This stage is crucial for maintaining the effectiveness of RF shielding. Key steps include:

-

Component Fitting: All components are fitted together, ensuring precise alignment to prevent gaps that could compromise shielding effectiveness.

-

Sealing: Gaskets or O-rings are installed to seal joints and openings, further enhancing the shield’s performance against RF interference.

-

Final Assembly: The assembled unit undergoes a final check to ensure all parts are correctly fitted and sealed.

Finishing: How Is the RF Shielding Product Prepared for Delivery?

Finishing processes are essential for enhancing the durability and aesthetic quality of RF shielding solutions. This may include:

Illustrative image related to rf blocking

-

Surface Treatment: Techniques such as plating or anodizing are applied to enhance conductivity and protect against corrosion.

-

Quality Inspection: Before the final product is packaged, it undergoes a thorough quality inspection to ensure it meets all design specifications.

What Quality Assurance Measures Are Essential for RF Shielding Manufacturing?

Quality assurance (QA) is crucial in ensuring that RF shielding products perform as intended. Buyers should understand the QA processes that manufacturers implement to guarantee quality.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 play a pivotal role in establishing a framework for quality management systems. Compliance with ISO 9001 ensures that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications may be relevant, including:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API Standards: Particularly relevant for RF shielding solutions used in the oil and gas industry, ensuring materials and processes meet stringent quality benchmarks.

What Are the Key Quality Control Checkpoints in RF Shielding Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process. B2B buyers should be familiar with these checkpoints to assess supplier capabilities:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter the production process. It ensures that materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for the early detection of issues. This includes checking dimensional accuracy and material integrity at various stages.

-

Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing and inspection to confirm that it meets all specifications and performance criteria.

What Testing Methods Are Commonly Used to Ensure RF Shielding Effectiveness?

Several testing methods are employed to assess the performance of RF shielding products:

- Shielding Effectiveness Testing: This involves measuring the attenuation of RF signals through the shield, typically using a spectrum analyzer.

- Environmental Testing: Assessing the product’s performance under various environmental conditions ensures reliability in real-world applications.

- Mechanical Testing: Evaluating the structural integrity of components under stress or impact conditions is vital for ensuring longevity and durability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. Key strategies include:

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and QA measures in place. This allows buyers to assess compliance with international standards.

-

Reviewing Quality Reports: Requesting documentation, including QC reports and certificates of compliance, helps verify that the supplier adheres to required standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices, ensuring that products meet specifications before shipment.

What Nuances Should International B2B Buyers Consider When Sourcing RF Shielding Products?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when sourcing RF shielding products. Considerations include:

Illustrative image related to rf blocking

-

Regulatory Compliance: Different regions may have varying regulations regarding RF shielding products. Familiarity with local standards is essential to avoid compliance issues.

-

Cultural and Communication Differences: Effective communication is vital in international transactions. Understanding cultural nuances can help facilitate smoother negotiations and collaborations.

-

Logistical Challenges: Consider potential logistical challenges, including shipping times and customs regulations, which may impact delivery schedules and costs.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing RF blocking solutions, ensuring they select reliable partners that meet their stringent requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rf blocking’

Introduction

In the realm of electronic manufacturing and design, RF blocking is a critical consideration for protecting sensitive equipment from radio frequency interference (RFI). This guide provides a structured approach for B2B buyers seeking to procure effective RF blocking solutions. Following these steps will help ensure that you select the right materials and partners to meet your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in your sourcing process. Consider the frequency range you need to block, the environmental conditions your RF shields will face, and any size constraints. This foundational understanding will guide your material and supplier selection, ensuring that you meet your operational requirements.

Step 2: Identify Suitable RF Shielding Techniques

Different applications require various RF shielding techniques, so it’s vital to identify the most appropriate one for your needs. Common techniques include solid enclosures, RF shielding gaskets, and Faraday cages. Research how each technique performs under specific conditions to ensure optimal protection against RFI.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting thorough evaluations is crucial. Request detailed company profiles, case studies, and references from clients in similar industries or regions. Pay attention to their experience with the specific RF shielding techniques you require and their ability to meet your technical specifications.

Step 4: Assess Material Options for RF Shields

Selecting the right materials is essential for effective RF blocking. Materials such as copper, aluminum, and specialized alloys are commonly used due to their conductive properties. Evaluate the weight, cost, and availability of these materials, as well as their performance characteristics in your intended application.

Step 5: Verify Supplier Certifications and Quality Assurance

Ensure that your chosen suppliers have the necessary certifications, such as ISO 9001 or AS9100, which indicate adherence to quality management standards. A supplier with robust quality assurance processes will minimize the risk of defects and ensure that your RF shields perform reliably under operational conditions.

Step 6: Request Prototypes for Testing

Before placing a large order, request prototypes of the RF shielding solutions to validate their effectiveness. Conduct thorough testing to assess their performance in real-world scenarios. This step is critical to ensure that the materials and designs meet your specifications and can withstand the conditions they will encounter.

Step 7: Establish a Communication Plan

Finally, establish a clear communication plan with your chosen supplier. Regular updates on the production process, timelines, and potential challenges will foster a collaborative relationship. Effective communication is vital for addressing any issues promptly and ensuring that your RF blocking solutions are delivered on time and meet your expectations.

Illustrative image related to rf blocking

By following this checklist, B2B buyers can navigate the complexities of sourcing RF blocking solutions with confidence, ensuring the protection of their sensitive electronic devices from unwanted interference.

Comprehensive Cost and Pricing Analysis for rf blocking Sourcing

What Are the Key Cost Components in RF Blocking Sourcing?

Understanding the cost structure of RF blocking materials is crucial for B2B buyers, especially when considering the wide range of applications across industries such as telecommunications, aerospace, and medical devices. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials like copper, aluminum, and specialized alloys offer different conductive properties and price points. For example, while copper provides excellent shielding, it is generally more expensive than aluminum. Buyers must balance performance needs with budget constraints.

-

Labor: Labor costs encompass the workforce involved in manufacturing and assembling RF shields. Skilled labor is often required for precision tasks, which can drive up costs, particularly in regions where labor rates are higher.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses associated with production. Efficient operations can help mitigate these costs.

-

Tooling: Tooling costs vary based on the complexity of the RF shielding design. Custom designs often require significant upfront investment in specialized tools, impacting the overall pricing.

-

Quality Control (QC): Ensuring that RF shields meet industry standards involves rigorous quality control processes. This can add to the overall cost but is essential to avoid costly failures in sensitive applications.

-

Logistics: Transportation and handling costs are crucial, especially for international shipments. Consideration of shipping methods and associated fees can affect final pricing.

-

Margin: Suppliers typically apply a margin based on their operational costs, market demand, and competition. Understanding the margin structure can provide insights into pricing flexibility during negotiations.

How Do Price Influencers Affect RF Blocking Sourcing?

Several factors influence pricing in the RF shielding market, making it essential for buyers to be well-informed:

-

Volume/MOQ: Purchasing in bulk can lead to lower per-unit costs. Understanding Minimum Order Quantities (MOQs) can help buyers optimize their budgets.

-

Specifications/Customization: Customized solutions often come with higher costs due to the additional engineering and manufacturing efforts required. Buyers should clearly define their specifications to avoid unexpected charges.

-

Material Choices: The selection of materials directly correlates with cost. Buyers need to weigh the benefits of high-performance materials against their budgetary constraints.

-

Quality and Certifications: Suppliers with industry certifications (e.g., ISO 9001) and a reputation for high-quality products may charge a premium. However, investing in quality can lead to lower Total Cost of Ownership (TCO) due to reduced failure rates and enhanced performance.

-

Supplier Factors: The reputation, reliability, and location of suppliers can significantly influence pricing. Suppliers with a robust track record may command higher prices, but the assurance of quality and service can justify the cost.

-

Incoterms: Understanding the Incoterms used in contracts is vital, as they dictate responsibilities for shipping, insurance, and tariffs, which can affect overall costs.

What Are the Best Negotiation Strategies for RF Blocking Purchases?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

Illustrative image related to rf blocking

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and competitor offerings. This knowledge will empower buyers during negotiations.

-

Flexible Specifications: Being open to alternative materials or designs can help reduce costs. Suppliers may offer better pricing for standardized products.

-

Long-Term Partnerships: Establishing long-term relationships with suppliers can lead to favorable pricing and terms. Loyalty can result in better service and priority in production schedules.

-

Consider Total Cost of Ownership (TCO): Emphasize the long-term value of quality RF shielding. Sometimes a higher upfront cost can lead to lower maintenance and replacement costs, making it a more economical choice overall.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must be aware of specific pricing nuances, including currency fluctuations, local tariffs, and import regulations, which can influence the total cost of acquisition. Additionally, understanding cultural negotiation styles and business practices in different regions can facilitate smoother transactions.

Disclaimer

Pricing in the RF blocking sector can vary significantly based on multiple factors, including market conditions, supplier capabilities, and specific project requirements. It is advisable for buyers to request detailed quotations and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing rf blocking With Other Solutions

Exploring Alternatives to RF Blocking Solutions

In the realm of electronic protection, RF blocking is a critical method to mitigate interference from radio frequencies. However, several alternatives exist that can achieve similar goals, each with distinct advantages and limitations. This comparison will help B2B buyers evaluate their options based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | RF Blocking | Conductive Coatings | Active Noise Cancellation |

|---|---|---|---|

| Performance | High effectiveness in reducing RF interference | Moderate effectiveness; dependent on thickness and application | Good for specific frequencies; less effective against broad-spectrum RFI |

| Cost | Varies by materials and complexity; generally higher upfront | Lower initial costs; ongoing costs for reapplication | Higher due to technology and maintenance requirements |

| Ease of Implementation | Requires precise manufacturing; may need custom designs | Easy to apply; can be sprayed or painted | Complex installation; requires expert knowledge |

| Maintenance | Low maintenance; durable if properly installed | Requires periodic reapplication | Regular maintenance needed for system integrity |

| Best Use Case | Aerospace, medical devices, and military applications | Consumer electronics and automotive | Audio devices and specific communication systems |

What Are the Pros and Cons of Conductive Coatings as an RF Blocking Alternative?

Conductive coatings offer a versatile approach to mitigate RF interference. These coatings can be applied to various surfaces, making them suitable for a range of products, including consumer electronics and automotive parts. The primary advantage is their lower initial cost and ease of application; they can be simply sprayed or painted on. However, their effectiveness can vary significantly based on the thickness and material composition. Additionally, they may require periodic reapplication, which can lead to ongoing costs and maintenance challenges.

How Does Active Noise Cancellation Compare to RF Blocking Solutions?

Active noise cancellation (ANC) employs electronic systems to counteract unwanted noise, making it an interesting alternative for specific scenarios, particularly in audio devices and communication systems. ANC systems can be effective at neutralizing specific frequencies, but they often fall short when dealing with broad-spectrum RF interference. The installation of ANC systems can be complex and typically requires expert knowledge. Furthermore, while initial costs may be high, ongoing maintenance is necessary to ensure consistent performance, making it a less favorable option for some applications.

Illustrative image related to rf blocking

Making the Right Choice: How Should B2B Buyers Select Between RF Blocking and Alternatives?

When choosing the right solution for RF interference mitigation, B2B buyers should carefully assess their specific needs, including the nature of the application, budget constraints, and long-term maintenance capabilities. RF blocking provides robust protection and is ideal for critical applications like aerospace and medical devices. However, alternatives like conductive coatings may be more suitable for less sensitive applications where cost and ease of implementation are prioritized. Active noise cancellation, while effective in certain contexts, is best reserved for specialized scenarios where its unique capabilities can be maximized. By evaluating these factors, buyers can make informed decisions that align with their operational requirements and financial considerations.

Essential Technical Properties and Trade Terminology for rf blocking

What Are the Critical Technical Properties of RF Blocking Solutions?

When selecting RF blocking solutions, understanding the key technical properties is vital for ensuring effective performance and compliance with industry standards. Here are several critical specifications that buyers should consider:

1. Material Grade

The material grade of RF shielding components directly impacts their effectiveness. Common materials include copper, aluminum, and specialized alloys, each offering different levels of conductivity and magnetic properties. For instance, copper provides excellent conductivity and shielding effectiveness, making it suitable for high-frequency applications. Selecting the appropriate material grade ensures that the shield meets the specific requirements of the application, such as weight, strength, and corrosion resistance.

2. Shielding Effectiveness (SE)

Shielding effectiveness is a measure of an RF shield’s ability to attenuate electromagnetic interference. It is typically expressed in decibels (dB). A higher SE value indicates better performance in blocking unwanted signals. Understanding SE is crucial for B2B buyers, as it helps assess whether a particular RF shielding solution will adequately protect sensitive equipment from interference that could compromise functionality.

3. Thickness

The thickness of the shielding material plays a significant role in its performance. Thicker materials generally provide better shielding effectiveness, especially at lower frequencies. However, increased thickness can also add weight and bulk, which may not be suitable for all applications. Buyers must balance the need for effective shielding with other design considerations, such as weight constraints and space limitations.

4. Tolerance

Tolerance refers to the allowable variation in the dimensions of RF shielding components. Precise tolerances are critical for ensuring that shields fit correctly in their intended applications. Inconsistent tolerances can lead to gaps or overlaps, compromising the shield’s effectiveness. Understanding the required tolerances helps buyers select manufacturers capable of delivering high-quality, precision-engineered products.

5. Grounding Requirements

Proper grounding is essential for maximizing the effectiveness of RF shields. Grounding helps dissipate any residual electromagnetic energy, preventing it from interfering with sensitive equipment. Buyers should inquire about the grounding methods used in their RF shielding solutions to ensure that they align with the specific application requirements.

What Common Trade Terms Should B2B Buyers Know in RF Blocking?

Navigating the RF blocking market involves familiarizing oneself with industry-specific terminology. Here are key terms that can enhance understanding and communication with suppliers:

Illustrative image related to rf blocking

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of RF shielding, OEMs often provide custom solutions tailored to specific applications. Understanding OEM relationships can help buyers identify reliable partners for their RF shielding needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it affects purchasing decisions, especially for smaller companies or those testing new products. Knowing the MOQ can help buyers assess cost-effectiveness and budgetary constraints.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting a supplier to provide pricing for specific products or services. This process is essential for buyers to gather competitive pricing, understand lead times, and clarify technical specifications. A well-prepared RFQ can streamline procurement processes and foster better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who pays for shipping, insurance, and tariffs, which can significantly impact total costs. Familiarity with Incoterms helps buyers negotiate better terms and avoid unexpected expenses.

5. EMI (Electromagnetic Interference)

EMI refers to the disruption caused by electromagnetic fields from various sources, which can affect the performance of electronic devices. Understanding EMI is crucial for buyers as it informs the need for effective RF shielding solutions to protect sensitive equipment.

By grasping these essential technical properties and trade terminology, international B2B buyers can make informed decisions when sourcing RF blocking solutions, ensuring they meet their specific application requirements and business objectives.

Navigating Market Dynamics and Sourcing Trends in the rf blocking Sector

What Are the Key Market Dynamics and Trends in RF Blocking for International Buyers?

The RF blocking sector is experiencing significant growth driven by increased demand for electronic devices across various industries, including telecommunications, automotive, and healthcare. The proliferation of wireless technologies, coupled with the rise of the Internet of Things (IoT), has heightened the need for effective shielding solutions to combat radio frequency interference (RFI) and electromagnetic interference (EMI). International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are increasingly prioritizing high-quality RF shielding materials that ensure device reliability and performance.

Emerging trends include the adoption of advanced materials like graphene and specialized alloys that offer superior conductivity and lightweight properties. Moreover, the integration of automation in manufacturing processes is streamlining production and reducing lead times, making it easier for B2B buyers to source components quickly and efficiently. As buyers navigate these market dynamics, they must also consider the certifications and standards associated with RF shielding products, such as ISO 9001 and AS9100, which signify quality assurance and reliability.

Illustrative image related to rf blocking

Additionally, the shift towards customization in RF shielding solutions is notable. Manufacturers are now offering tailored designs to meet specific application requirements, enabling buyers to enhance their product performance without compromising on cost. This trend is particularly relevant for industries with stringent performance criteria, such as aerospace and defense, where every detail matters.

How Do Sustainability and Ethical Sourcing Impact RF Blocking Procurement?

Sustainability is becoming increasingly critical in the RF blocking sector, influencing how B2B buyers approach sourcing. The environmental impact of manufacturing processes and the materials used in RF shielding is under scrutiny, prompting companies to seek out eco-friendly alternatives. Buyers are now more inclined to partner with manufacturers that prioritize sustainable practices, such as utilizing recycled materials or adopting energy-efficient production methods.

Ethical sourcing is another vital consideration. Buyers are encouraged to evaluate their supply chains to ensure that materials are sourced responsibly, minimizing negative social and environmental impacts. Certifications such as ISO 14001 for environmental management systems can help buyers identify manufacturers committed to sustainable practices.

Moreover, the demand for ‘green’ materials is on the rise. Suppliers offering RF blocking solutions made from eco-friendly composites or recycled metals are becoming more attractive to buyers looking to enhance their corporate social responsibility (CSR) profiles. By prioritizing sustainability and ethical sourcing, businesses can not only reduce their environmental footprint but also appeal to an increasingly conscious consumer base.

What Is the Historical Context of RF Blocking Technologies in B2B?

The evolution of RF blocking technologies dates back to the early 20th century, with the advent of radio communication systems. Initially, basic shielding techniques were employed to protect sensitive equipment from RFI, primarily using metal enclosures. As technology progressed, the introduction of advanced materials and manufacturing techniques led to significant improvements in shielding effectiveness.

Illustrative image related to rf blocking

In recent decades, the rise of digital electronics and wireless communications has propelled the development of more sophisticated RF shielding solutions. The increasing complexity of electronic devices has necessitated a shift towards more specialized materials and designs, resulting in a diverse array of RF blocking products tailored for specific applications. This historical context highlights the importance of continuous innovation in the sector, as B2B buyers seek solutions that not only meet current demands but also anticipate future challenges.

By understanding these dynamics, international buyers can make informed decisions, ensuring they select the most effective RF blocking solutions for their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of rf blocking

-

How do I solve RF interference issues in my equipment?

To address RF interference, first, identify the source of the interference and assess the sensitivity of your equipment. Implementing RF shielding techniques such as using solid enclosures, gaskets, or Faraday cages can effectively block unwanted signals. Additionally, consider collaborating with a reputable manufacturer who specializes in RF shielding solutions. They can offer tailored advice on materials and design that best fit your specific application, ensuring optimal performance and reliability. -

What is the best material for RF shielding in my application?

The best material for RF shielding often depends on the specific requirements of your application. Commonly used materials include copper, aluminum, and specialized alloys, each offering different levels of conductivity and weight. For lightweight applications, aluminum is preferred, while copper provides superior conductivity for high-frequency signals. Assess factors such as thickness, environmental conditions, and cost when selecting the material to ensure it meets your operational demands. -

What customization options are available for RF shielding solutions?

Most manufacturers offer extensive customization options for RF shielding solutions, including tailored dimensions, materials, and design features. You can request modifications such as adding vent shields for cooling or specific conductive fillers for gaskets. Discussing your specific requirements with your manufacturing partner will help ensure the final product aligns with your operational needs and can enhance the performance of your devices. -

What are the minimum order quantities (MOQ) for RF shielding products?

Minimum order quantities for RF shielding products can vary significantly between manufacturers and depend on the complexity and type of shielding required. For custom solutions, MOQs may be higher due to the need for specialized materials and production setups. However, some manufacturers may offer lower MOQs for standard products. It’s essential to communicate your needs directly with potential suppliers to negotiate favorable terms. -

How can I vet suppliers for RF shielding products?

To vet suppliers, conduct thorough research into their industry experience, client testimonials, and certifications (such as ISO 9001). Request samples of previous work to evaluate quality and performance. Additionally, inquire about their engineering capabilities and customer support services. Establishing a good relationship with a supplier who understands your specific needs can lead to better collaboration and product outcomes. -

What payment terms should I expect when sourcing RF shielding products?

Payment terms for RF shielding products can vary widely based on the supplier and the nature of the transaction. Common terms include upfront deposits, net 30, or net 60 days. For international transactions, consider the implications of currency exchange rates and potential tariffs. Discussing payment terms upfront can help prevent misunderstandings and ensure a smooth procurement process. -

What quality assurance processes should be in place for RF shielding products?

Quality assurance processes are critical for ensuring the reliability of RF shielding products. Look for suppliers who implement rigorous testing protocols, such as electromagnetic compatibility (EMC) testing and material inspections. Certifications like AS9100 can indicate adherence to high-quality standards. Inquire about their quality control measures and whether they provide documentation to verify compliance with industry standards. -

How does logistics impact the sourcing of RF shielding solutions internationally?

Logistics play a vital role in sourcing RF shielding solutions internationally, affecting lead times, shipping costs, and delivery reliability. Consider suppliers with established logistics networks that can efficiently handle international shipping and customs clearance. Discuss shipping options, incoterms, and estimated delivery timelines with your supplier to ensure that you can meet your project deadlines without unexpected delays.

Top 7 Rf Blocking Manufacturers & Suppliers List

1. Signals Defense – RF Shielding Solutions

Domain: signalsdefense.com

Registered: 2006 (19 years)

Introduction: RF Shielding Products: RF/IR Shielding Films, RFoil RF Shielding Paint, RF Shielding Tapes, RF Shielding Caulk, Architectural Window Films, Decorative Window Film, Security and Safety Films, Solar Control Window Film, Cloaking Film, DAS Shield Glass and Polycarbonate Laminates, Window Treatments, Spray-Lock FRP Adhesive. Key Features: SD RF window films provide RF/IR attenuation, block ultraviolet…

2. Safe Living Technologies – RF Shielding Mesh

Domain: safelivingtechnologies.com

Registered: 2006 (19 years)

Introduction: RF Shielding Mesh is a shielding fabric designed to block electromagnetic fields (EMF) and radio frequency (RF) radiation. It is suitable for various applications including interior shielding, EMF bed canopies, and protective clothing. The mesh can be used in construction and renovation projects to enhance EMF protection in homes and workplaces. It is part of a broader range of EMF protection prod…

3. Enconnex – RF Shielded Solutions and Power Products

Domain: blog.enconnex.com

Registered: 2012 (13 years)

Introduction: RF Shielded Cabinets, RF Shielded Enclosures, Power Distribution Units (PDUs), Uninterruptible Power Supplies (UPS), Micro Data Centers, Real Device Testing Enclosures and Accessories.

4. Reddit – RF Shields for Home Electronics

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: RF shields in home electronics protect devices from electromagnetic (EM) radiation and interference. They are essential for preventing unwanted emissions of radio frequency (RF) signals, which can disrupt the operation of other devices. Electronics are tested for RF emissions to ensure they meet legal requirements, and shielding is used to minimize interference between components like processors, …

5. Less EMF – RF Wall Shield

Domain: lessemf.com

Registered: 1996 (29 years)

Introduction: RF Wall Shield: Reliable RF and EMI Shielding for Homes and Offices. Price range: $4.50 – $400.00. High-performance shielding with up to 60 dB at common cell phone frequencies and 40 dB from 100 MHz to 40 GHz. Greater than 99% shielding efficiency at common RF frequencies. Easy to cut and apply using ordinary spray adhesive. Durable and flexible, withstands temperatures from 32°F to 122°F, and is …

6. CORNET – ED88TPLUS5G2 EMF Meter

Domain: norad4u.com

Registered: 2010 (15 years)

Introduction: CORNET ED88TPLUS5G2 EMF RF/ELF-M/ELF-M Meter, ENV RD10 EMF RF/ELF-M/ELF-E Detector

7. EcoFoil – Ultra NT Radiant Barrier for SCIFs

Domain: ecofoil.com

Registered: 2007 (18 years)

Introduction: RF Shielding Foil | Ultra NT Radiant Barrier for SCIFs

– Protects against electronic surveillance in secure SCIF rooms.

– Used for government, military, corporate, and other ICD 705 compliant projects.

– Available in solid and perforated options.

– Dimensions: 4′ x 125′ (500 sq ft) and 4′ x 250′ (1,000 sq ft).

– Regular prices: Solid 4′ x 125′ – $218.00, Perforated 4′ x 125′ – $189.00 (discounted …

Strategic Sourcing Conclusion and Outlook for rf blocking

What Are the Key Takeaways for B2B Buyers in RF Blocking?

In the evolving landscape of RF blocking, strategic sourcing is paramount for ensuring the integrity and performance of sensitive electronic devices. By understanding the various RF shielding techniques and materials available—from gaskets and enclosures to specialized alloys—businesses can make informed decisions that enhance their operational reliability. Collaborating with high-quality manufacturing partners is essential; it not only streamlines production but also guarantees adherence to stringent industry standards.

Illustrative image related to rf blocking

How Can International Buyers Leverage RF Shielding Solutions?

For B2B buyers in Africa, South America, the Middle East, and Europe, investing in effective RF shielding solutions is not merely a technical necessity but a competitive advantage. As industries such as telecommunications, healthcare, and defense grow, the demand for reliable RF blocking technologies will increase. Embracing these innovations will enable your organization to mitigate risks associated with electromagnetic interference and maintain operational excellence.

What’s Next for Your RF Shielding Strategy?

As you consider your RF shielding options, prioritize partnerships with manufacturers that offer engineering expertise, vertical integration, and a commitment to quality. This strategic approach will position your business for success in an increasingly interconnected world. Take action today by assessing your RF shielding needs and exploring potential collaborations that can enhance your product offerings and market competitiveness.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to rf blocking

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.