Choosing Your Push Button Electric: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for push button electric

In today’s rapidly evolving industrial landscape, sourcing push button electric solutions that meet diverse operational needs can be a daunting challenge for international B2B buyers. The global market is teeming with various push button types, each designed for specific applications, from momentary switches in manufacturing to robust emergency stop buttons in safety systems. This comprehensive guide aims to demystify the complexities surrounding push button electric products, offering insights into their types, applications, and the critical factors that influence purchasing decisions.

As businesses across Africa, South America, the Middle East, and Europe seek to enhance their operational efficiency, understanding the nuances of push button electric components becomes essential. This guide provides actionable strategies for vetting suppliers, assessing product quality, and navigating cost considerations, ensuring that buyers can make informed choices tailored to their unique requirements. By focusing on the specific needs of different regions, including emerging markets like Vietnam and established economies such as Germany, we empower B2B buyers to select reliable, high-performance push button solutions that align with their operational goals.

In essence, this guide serves as a vital resource for international buyers, equipping them with the knowledge needed to confidently navigate the global market and optimize their procurement processes. With the right information at hand, businesses can enhance their productivity, safety, and overall operational success.

Understanding push button electric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Momentary Push Button | Activates only when pressed; returns to default position | Industrial machinery control, automation | Pros: Simple operation, versatile; Cons: Not suitable for continuous operation. |

| Maintained Push Button | Stays in the activated position until pressed again | Lighting control, machinery start/stop | Pros: Ideal for continuous operation; Cons: Can be unintentionally activated. |

| Emergency Stop Push Button | Brightly colored, easily accessible; designed for safety | Emergency shutdowns in manufacturing | Pros: Enhances safety; Cons: Requires clear labeling and training. |

| Illuminated Push Button | Features built-in lighting for visibility | Control panels, dark environments | Pros: Easy to locate in low light; Cons: Higher cost due to additional components. |

| Selector Switch Push Button | Allows selection between multiple options | Complex machinery operations | Pros: Flexible control; Cons: More complex installation and use. |

What Are the Characteristics of Momentary Push Buttons?

Momentary push buttons are designed to engage an action only while being pressed. Once released, they revert to their original position, making them ideal for applications requiring temporary control, such as starting or stopping machinery. These buttons are commonly used in industrial automation systems where quick, momentary actions are necessary. When purchasing, consider the button’s amperage rating and voltage compatibility to ensure it meets the operational demands of your equipment.

How Do Maintained Push Buttons Differ in Usage?

Maintained push buttons remain in the ‘on’ position until pressed again, allowing for continuous operation without the need for constant pressure. They are often used in applications like lighting control or to start and stop machinery. For B2B buyers, it is crucial to evaluate the button’s durability and resistance to environmental factors, especially in industrial settings where wear and tear can impact performance over time.

Why Choose Emergency Stop Push Buttons for Safety?

Emergency stop push buttons are critical for ensuring safety in industrial environments. They are designed for quick access and often feature a red color to signify urgency. These buttons are typically integrated into machinery control systems to allow immediate shutdown in case of an emergency. When sourcing these buttons, buyers should prioritize compliance with safety standards and ensure that they are adequately labeled and easily accessible to all personnel.

What Advantages Do Illuminated Push Buttons Offer?

Illuminated push buttons are equipped with built-in lighting, making them easy to identify, especially in low-light conditions. They are particularly beneficial in control panels or environments where visibility is compromised. Buyers should consider the power consumption of these buttons and the type of illumination (e.g., LED) to ensure they align with energy efficiency goals while meeting visibility requirements.

How Do Selector Switch Push Buttons Function in Complex Systems?

Selector switch push buttons allow operators to choose between multiple settings or functions, providing a flexible control mechanism for complex machinery. These buttons are particularly useful in environments where machines perform various tasks and require operator input to switch modes. When evaluating these switches, B2B buyers should assess the ease of use and the potential need for training staff to ensure efficient operation across different settings.

Key Industrial Applications of push button electric

| Industry/Sector | Specific Application of Push Button Electric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Control Panels for Machinery | Enhances operational efficiency and safety | Compliance with international standards (IEC, UL) |

| Oil & Gas | Emergency Shut-off Systems | Provides rapid response to hazardous situations | Durability in extreme conditions and certifications |

| Construction & Building | Lighting Control Systems | Reduces energy consumption and improves safety | Compatibility with local electrical standards |

| Transportation | Signal Control in Rail Systems | Improves safety and communication in transit systems | Robust design for outdoor use and weather resistance |

| Agriculture | Automated Irrigation Systems | Optimizes water usage and increases crop yield | Adaptability to various environmental conditions |

How is Push Button Electric Used in Manufacturing Control Panels?

In the manufacturing sector, push button electric switches are integral to control panels that manage machinery operations. These buttons allow operators to start, stop, or reset equipment quickly, enhancing operational efficiency and ensuring safety. For international buyers, particularly in emerging markets, sourcing switches that comply with global standards such as IEC and UL is crucial for ensuring reliability and safety in their operations. Additionally, features such as anti-vibration and weatherproof designs are important considerations for durability in various manufacturing environments.

What Role Do Push Button Electric Switches Play in Oil & Gas Emergency Systems?

In the oil and gas industry, push button electric switches are vital for emergency shut-off systems that can mitigate potential hazards. These systems enable rapid shutdown of operations in response to emergencies, minimizing risks to personnel and equipment. Buyers in this sector must prioritize sourcing switches that can withstand extreme temperatures and harsh conditions, ensuring reliability in critical situations. Certifications for explosive environments are also essential to comply with safety regulations in this highly regulated industry.

How Are Push Button Electric Devices Used in Construction Lighting Control?

Push button electric switches are commonly utilized in construction sites for lighting control systems. They provide an efficient way to manage energy consumption by allowing workers to turn lights on and off as needed, thus enhancing safety and reducing costs. For B2B buyers in construction, it is important to source switches that are compatible with local electrical standards and can withstand the rigors of outdoor use. Additionally, illuminated push buttons can offer visual feedback, improving usability in low-light conditions.

In What Ways Do Push Button Electric Switches Enhance Transportation Safety?

In the transportation sector, push button electric switches are employed in signaling systems for rail and road applications. These switches facilitate communication between vehicles and control centers, improving safety and operational efficiency. International buyers must consider the robustness of these switches, particularly those used in outdoor settings, ensuring they are weather-resistant and designed for heavy use. Compliance with transportation safety standards is also a critical factor when sourcing these components.

How Are Push Button Electric Systems Beneficial for Agricultural Automation?

In agriculture, push button electric switches are essential for automated irrigation systems, enabling farmers to manage water distribution effectively. This automation optimizes water usage, leading to increased crop yields and reduced labor costs. Buyers in the agricultural sector should focus on sourcing switches that are adaptable to various environmental conditions, including moisture and dust resistance. Furthermore, energy-efficient designs can contribute to overall sustainability in agricultural practices, aligning with the growing emphasis on eco-friendly solutions.

3 Common User Pain Points for ‘push button electric’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Push Button Electric Components

The Problem: B2B buyers often face challenges when trying to source high-quality push button electric components that meet specific operational requirements. This can be particularly problematic in regions where suppliers are limited, leading to concerns over product quality, reliability, and compliance with local regulations. Buyers may experience delays in production due to sourcing issues, which can further strain relationships with clients and affect overall business performance.

The Solution: To effectively address sourcing difficulties, B2B buyers should establish relationships with reputable suppliers that specialize in push button electric components. Start by conducting thorough research to identify manufacturers with a proven track record in quality and compliance. Attend industry trade shows or leverage online platforms to connect with suppliers from different regions, including Europe and Asia, known for their advanced manufacturing capabilities. Additionally, buyers should request product samples and certifications that demonstrate compliance with international standards (e.g., IEC60947-5-1). This proactive approach will not only ensure the procurement of reliable components but also foster long-term partnerships that can enhance supply chain resilience.

Scenario 2: Integration Challenges with Existing Systems

The Problem: Many businesses encounter significant hurdles when integrating new push button electric switches with their existing machinery or control systems. This is especially prevalent in industries like manufacturing, where outdated equipment may not be compatible with modern push button technologies. Buyers often find themselves in situations where they must choose between costly upgrades or the risk of operational inefficiencies due to improper integration.

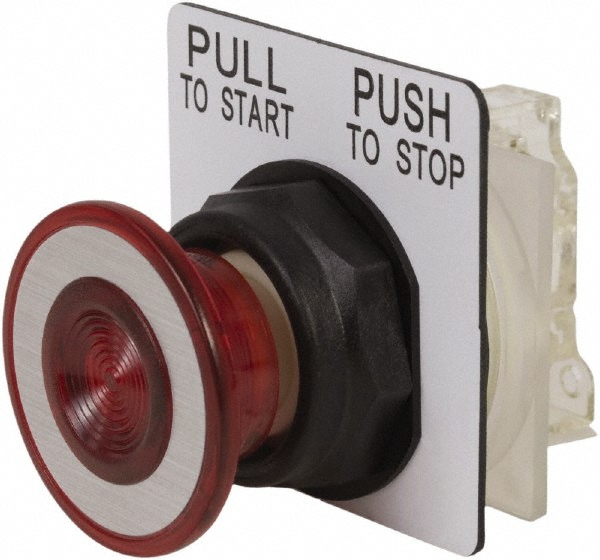

Illustrative image related to push button electric

The Solution: To mitigate integration challenges, B2B buyers should conduct a comprehensive assessment of their current systems before purchasing new push button electric components. Collaborate with technical teams to identify compatibility requirements and specifications. When selecting new components, look for modular push button systems that offer flexible configurations, allowing for easy adaptation to existing setups. Furthermore, consider working with suppliers who provide technical support and installation services, as they can guide you through the integration process, ensuring that the new components function seamlessly within your operational framework.

Scenario 3: Safety Concerns in Industrial Applications

The Problem: Safety is a paramount concern in industrial environments, and B2B buyers often struggle to find push button electric solutions that adhere to stringent safety standards. The risks associated with electrical components, such as accidental activation or failure, can lead to severe workplace accidents, legal liabilities, and costly downtime. Buyers must ensure that the products they choose not only meet their operational needs but also prioritize user safety.

The Solution: To address safety concerns, it is crucial for B2B buyers to prioritize the selection of push button electric components that are designed with safety features. Look for products equipped with emergency stop buttons, which provide immediate control in critical situations. Additionally, ensure that the components comply with relevant safety standards and certifications, such as UL or CE marking. Implement regular safety audits and training sessions for employees to educate them on the proper use and maintenance of these components. By fostering a culture of safety and investing in high-quality, compliant products, businesses can significantly reduce the risk of accidents and enhance overall operational safety.

Strategic Material Selection Guide for push button electric

What Are the Key Materials Used in Push Button Electric Devices?

When selecting materials for push button electric devices, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: plastic, metal, rubber, and glass. Each material presents unique characteristics that can significantly impact the performance and suitability of push button switches in various applications.

How Does Plastic Perform in Push Button Electric Applications?

Plastic is a widely used material for push button switches due to its lightweight nature and versatility. Common types include polycarbonate and ABS (Acrylonitrile Butadiene Styrene). Key properties include good electrical insulation, resistance to impact, and a temperature rating typically between -40°C to 85°C.

Illustrative image related to push button electric

Pros: Plastic is cost-effective and can be molded into complex shapes, making it ideal for custom designs. It also offers good resistance to corrosion and chemicals, which is beneficial in various environments.

Cons: While durable, plastics can degrade under UV exposure and may not withstand extreme temperatures over prolonged periods. Additionally, some plastics may not be suitable for high-pressure applications.

Impact on Application: Plastic push buttons are often used in consumer electronics and industrial equipment where weight and cost are critical. However, they may not be suitable for applications involving harsh chemicals or extreme temperatures.

What Advantages Do Metal Push Buttons Offer?

Metal push buttons, typically made from stainless steel or aluminum, are favored for their durability and aesthetic appeal. They often have a higher temperature rating, ranging from -40°C to 120°C, and exhibit excellent corrosion resistance.

Illustrative image related to push button electric

Pros: The robustness of metal ensures longevity and reliability, making it ideal for heavy-duty applications. Metal buttons also provide a tactile feedback that can enhance user experience.

Cons: The manufacturing process for metal components can be more complex and costly. Additionally, metal is heavier than plastic, which may be a consideration in portable applications.

Impact on Application: Metal push buttons are commonly used in industrial settings, such as manufacturing and automation, where durability is paramount. They are also preferred in environments that require a high level of hygiene, such as food processing.

Why Choose Rubber for Push Button Electric Devices?

Rubber is often used in push button applications that require a soft touch or a weather-resistant feature. Silicone rubber, in particular, is known for its flexibility and resilience, with a temperature range from -60°C to 200°C.

Pros: Rubber provides excellent sealing properties, making it suitable for outdoor or wet environments. Its softness can also reduce the risk of injury in high-traffic areas.

Cons: Rubber can wear down over time, especially in high-friction applications. Additionally, it may not be as aesthetically pleasing as metal or plastic options.

Impact on Application: Rubber push buttons are ideal for outdoor equipment and consumer products that require weatherproofing. They are also used in applications where user comfort is a priority.

What Role Does Glass Play in Push Button Electric Devices?

Glass is less common but can be used in high-end applications where aesthetics are crucial. Tempered glass can withstand high temperatures and is often combined with metal or plastic components.

Pros: Glass offers a sleek and modern look, is easy to clean, and provides good resistance to chemicals.

Cons: It is more fragile than other materials, making it less suitable for heavy-duty applications. The cost of glass components can also be significantly higher.

Impact on Application: Glass push buttons are typically found in luxury appliances, control panels, and environments where design is as important as functionality.

Illustrative image related to push button electric

Summary of Material Selection for Push Button Electric Devices

| Material | Typical Use Case for push button electric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Consumer electronics, light industrial applications | Lightweight and cost-effective | Degrades under UV exposure | Low |

| Metal | Industrial automation, heavy-duty applications | Durable and reliable | Higher manufacturing cost | High |

| Rubber | Outdoor equipment, consumer products | Excellent sealing and comfort | Wears down over time | Medium |

| Glass | Luxury appliances, modern control panels | Aesthetic appeal and easy to clean | Fragile and costly | High |

This guide provides valuable insights for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, where material compliance and performance standards are critical for successful applications. Understanding the properties and implications of each material will aid in making informed purchasing decisions that align with both operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for push button electric

What Are the Key Manufacturing Processes for Push Button Electric Devices?

The manufacturing of push button electric devices involves several critical stages that ensure the production of reliable and high-quality products. Understanding these processes is essential for B2B buyers looking to source components that meet specific operational standards and requirements.

How Are Raw Materials Prepared for Push Button Manufacturing?

The first step in the manufacturing process is the preparation of raw materials, which typically includes metals, plastics, and electronic components. Suppliers often source high-grade materials to ensure durability and compliance with international standards. For example, polycarbonate or nylon may be used for button housings due to their excellent insulating properties and resistance to chemicals.

During this stage, manufacturers conduct material inspections to verify that all inputs meet required specifications. This initial quality check helps prevent issues in later stages of production.

What Techniques Are Used in the Forming Stage?

Following material preparation, the forming stage involves shaping the components of the push button. This can be achieved through various techniques such as injection molding for plastic parts and stamping for metal components.

Injection molding allows for complex shapes and designs, enabling manufacturers to create intricate button designs that may include features like illumination or tactile feedback. Stamping processes, on the other hand, are ideal for creating metal contacts that require precision and strength.

Manufacturers often employ advanced CAD software to design these components, ensuring that they fit seamlessly together during assembly.

How Is Assembly Conducted for Push Button Electric Devices?

Assembly is a crucial phase where all the components come together to form the final product. This process usually involves several steps, including:

- Component Integration: Individual parts such as buttons, housings, and circuitry are assembled either manually or through automated machinery.

- Soldering: Electrical connections are established through soldering, ensuring that the device functions correctly when activated.

- Final Assembly: The assembled components are housed in protective casings to ensure durability and safety.

Quality control is integrated at this stage, with manufacturers often employing techniques like visual inspection and automated testing to verify that each unit meets quality standards.

What Quality Assurance Measures Are Essential for Push Button Electric Devices?

To ensure the reliability and safety of push button electric devices, manufacturers must adhere to stringent quality assurance measures. These measures not only comply with international standards but also cater to the unique requirements of various markets.

Illustrative image related to push button electric

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a pivotal role in establishing quality management systems within manufacturing processes. ISO 9001 focuses on customer satisfaction, process improvement, and compliance with regulatory requirements.

In addition to ISO certifications, industry-specific standards are crucial. For instance, CE marking is necessary for products sold in the European Union, indicating compliance with health, safety, and environmental protection standards. Similarly, API standards may apply in specific industrial applications, ensuring that push button devices can withstand demanding conditions.

How Are Quality Control Checkpoints Structured?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure product reliability:

Illustrative image related to push button electric

- Incoming Quality Control (IQC): This initial checkpoint involves testing raw materials and components upon arrival to verify they meet specifications.

- In-Process Quality Control (IPQC): During assembly, continuous monitoring is conducted to catch defects early in the process. This may include random sampling and functional testing of units.

- Final Quality Control (FQC): After assembly, each push button device undergoes thorough testing, including electrical testing, operational testing, and safety checks to confirm that it meets all necessary standards.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to ensure that push button devices perform reliably:

- Electrical Testing: This includes continuity tests to ensure proper electrical flow and insulation resistance tests to verify safety.

- Environmental Testing: Push buttons may undergo tests for temperature extremes, humidity exposure, and vibration to ensure they can withstand various operational environments.

- Durability Testing: Mechanical endurance tests assess how well the buttons can handle repeated use, which is vital for products used in high-traffic areas.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, it is essential to verify a supplier’s quality control processes to ensure product reliability and compliance with local standards.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a critical method for assessing quality control practices. Buyers should consider the following:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe processes firsthand, evaluate cleanliness, and review documentation related to quality control.

- Requesting Certification Documents: Suppliers should provide copies of relevant certifications (e.g., ISO 9001, CE) as proof of compliance with international standards.

- Third-Party Inspections: Engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality practices and product reliability.

What Are the Nuances of Quality Certification for International Buyers?

Navigating quality certification can be complex for international buyers. Each region may have specific regulations that must be met, and it is vital for buyers to understand these nuances. For instance, while CE marking is essential for products sold in Europe, UL certification may be more relevant for the North American market.

Buyers should work closely with suppliers to ensure that all necessary certifications are obtained, as this can significantly impact market access and product acceptance.

Conclusion: Ensuring Quality in Push Button Electric Device Manufacturing

Understanding the manufacturing processes and quality assurance measures for push button electric devices is vital for B2B buyers. By familiarizing themselves with the stages of production, relevant international standards, and quality control practices, buyers can make informed decisions when sourcing these essential components. This knowledge not only ensures compliance and reliability but also strengthens partnerships with suppliers across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘push button electric’

To assist B2B buyers in effectively sourcing push button electric components, this guide provides a practical checklist. This checklist is designed to streamline the procurement process, ensuring that buyers make informed decisions that align with their operational needs and compliance requirements.

Step 1: Define Your Technical Specifications

Before embarking on the sourcing journey, it’s essential to establish clear technical specifications for the push button electric components you require. This includes determining the type (momentary, maintained), voltage ratings, and environmental factors (such as IP ratings for moisture resistance). Having precise specifications will help narrow down potential suppliers who can meet your needs effectively.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing is crucial for making competitive procurement decisions. Investigate average costs for various types of push buttons across different suppliers. This research will help you identify reasonable pricing and anticipate budget needs, ensuring you are not overpaying for components.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is vital to ensure reliability and quality. Request detailed company profiles, product certifications, and customer references, particularly from businesses within your industry or region. Look for suppliers who offer warranties and have a solid reputation for customer service, as this can indicate their commitment to quality and support.

- Check for certifications: Ensure suppliers comply with relevant international standards, such as IEC60947-5-1, which governs electrical components.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the push buttons to conduct hands-on testing. This step allows you to assess the quality, durability, and functionality of the products in real-world conditions. Testing samples can help identify any potential compatibility issues with your existing systems.

Step 5: Understand Lead Times and Delivery Options

Inquire about the lead times for production and delivery from your shortlisted suppliers. Understanding these timelines is crucial for planning your project schedules and avoiding delays. Additionally, explore shipping options to ensure they align with your logistical requirements, particularly if sourcing from international suppliers.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations to finalize terms and pricing. Discuss payment options, bulk discounts, and any potential for long-term contracts. Effective negotiation can lead to better pricing and terms that benefit both parties, fostering a strong business relationship.

Step 7: Establish a Quality Assurance Process

Post-purchase, it’s important to implement a quality assurance process to monitor the performance of the push button components. Regularly review the functionality and reliability of the products, and maintain open lines of communication with your supplier for any issues or necessary adjustments.

By following this structured checklist, B2B buyers can ensure a comprehensive approach to sourcing push button electric components, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for push button electric Sourcing

What Are the Key Cost Components in Sourcing Push Button Electric Products?

When evaluating the cost structure of push button electric components, several key components come into play. Materials make up a significant portion of the total cost, with variations depending on the quality and type of materials used, such as plastic or metal. Labor costs are influenced by the complexity of the manufacturing process; more intricate designs require skilled labor, which can drive up expenses. Manufacturing overhead includes utilities, equipment depreciation, and maintenance costs, which vary by region and production scale.

Tooling costs can also be substantial, especially for custom designs or high-precision components. In addition, quality control (QC) processes are essential to ensure product reliability and safety, and these can further add to the overall cost. Finally, logistics expenses, including shipping and handling, are crucial, particularly for international transactions where tariffs and customs can impact pricing.

How Do Price Influencers Affect Push Button Electric Sourcing?

Several factors influence the pricing of push button electric products. Volume and Minimum Order Quantities (MOQs) play a critical role; larger orders typically yield better pricing due to economies of scale. Specifications and customization can also significantly affect pricing. Custom features or unique designs usually incur additional costs.

The quality of materials and certifications required for specific markets can further influence pricing. For example, compliance with international safety standards often requires additional testing and certification, which can raise costs. Supplier factors, such as their location, reputation, and production capabilities, also play a role in the final pricing structure. Furthermore, Incoterms—which define the responsibilities of buyers and sellers in international transactions—can impact logistics costs and overall pricing.

What Tips Can Help Buyers Negotiate Better Prices for Push Button Electric Products?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings. Begin by understanding the Total Cost of Ownership (TCO), which encompasses not just the purchase price but also logistics, installation, and maintenance costs. This holistic view can strengthen your position in negotiations.

Illustrative image related to push button electric

When negotiating, consider leveraging your purchasing volume as a bargaining chip. Suppliers are often willing to offer discounts for larger orders. Additionally, establishing long-term relationships with suppliers can lead to better pricing and preferential treatment in future transactions.

It’s also vital to be aware of pricing nuances in different regions. For instance, buyers from Europe may face stricter regulations compared to those in Africa or South America, which can affect pricing strategies. Understanding the local market dynamics and being flexible with specifications can open opportunities for cost-effective solutions.

Are There Any Disclaimers Buyers Should Be Aware Of Regarding Prices?

While the indicative prices for push button electric products can vary widely, it’s essential for buyers to understand that these prices are subject to change based on market conditions, supplier policies, and exchange rates. Always request a detailed quote and verify all costs before finalizing any agreements. Being informed about potential fluctuations can help in budgeting and strategic sourcing decisions, ultimately leading to more successful procurement outcomes.

Alternatives Analysis: Comparing push button electric With Other Solutions

In today’s industrial landscape, the choice of control solutions can significantly impact operational efficiency and safety. Push button electric systems are a common choice for equipment control, but there are viable alternatives that may better suit specific applications or environments. This analysis will explore how push button electric compares to alternative solutions such as toggle switches and touch-sensitive controls, providing insights into their respective advantages and limitations.

| Comparison Aspect | Push Button Electric | Toggle Switch | Touch-Sensitive Controls |

|---|---|---|---|

| Performance | Reliable for momentary or maintained actions | Good for on/off control; limited to binary states | Versatile; can offer multiple functionalities in one interface |

| Cost | Generally affordable ($3 – $10 per unit) | Typically lower cost ($1 – $5 per unit) | Higher initial investment ($50 – $200 per unit) |

| Ease of Implementation | Simple wiring; can be installed quickly | Very straightforward installation | Requires more complex integration and possibly software |

| Maintenance | Low maintenance; durable under typical use | Low maintenance; mechanical wear over time | Requires regular updates and potential recalibration |

| Best Use Case | Industrial machinery, emergency stops | General electrical applications | Modern environments, user-friendly interfaces |

What are the Pros and Cons of Toggle Switches Compared to Push Button Electric?

Toggle switches provide a straightforward on/off control mechanism that is highly reliable and cost-effective. Their mechanical design allows for a tactile feedback, which many users appreciate. However, toggle switches are limited to binary states, making them less flexible for applications that require multiple functions or controls. They may also suffer from wear over time, necessitating replacements in high-usage scenarios.

How Do Touch-Sensitive Controls Stack Up Against Push Button Electric?

Touch-sensitive controls represent a modern approach to user interface design, allowing for intuitive operation without the need for physical buttons. They can integrate multiple functions into a single interface, which can be beneficial in complex systems. However, they typically come with a higher price point and may require more intricate installation and maintenance. Additionally, they may be less reliable in environments with high dust or moisture levels, where physical buttons might perform better.

Conclusion: How to Choose the Right Control Solution for Your Needs?

When deciding between push button electric systems and their alternatives, B2B buyers should carefully consider their specific operational requirements. Push button electric systems offer a reliable and cost-effective solution for most industrial applications, particularly where durability and ease of use are critical. Toggle switches serve well for straightforward applications, while touch-sensitive controls provide advanced functionality but at a higher cost and complexity. By evaluating the performance, cost, ease of implementation, and maintenance needs, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for push button electric

What Are the Key Technical Properties of Push Button Electric Devices?

When evaluating push button electric devices, several technical properties are critical to ensure optimal performance and reliability in various industrial applications. Understanding these specifications can significantly influence purchasing decisions for B2B buyers.

1. Material Grade

The material used in push buttons can vary widely, affecting durability and suitability for specific environments. Common materials include thermoplastic, metal alloys, and silicone. For example, thermoplastics are often chosen for their resistance to corrosion and electrical insulation properties, while metal buttons may be preferred for their robustness in harsh conditions. Selecting the right material is essential for meeting industry standards and ensuring longevity in operational settings.

2. Contact Type and Configuration

Push buttons come with different contact types, such as Single Pole Single Throw (SPST) and Double Pole Double Throw (DPDT). These configurations determine how the switch interacts with electrical circuits. For instance, SPST switches are widely used for simple on/off applications, while DPDT switches can control multiple circuits simultaneously. Understanding the right contact type is crucial for buyers to match their specific application needs, enhancing operational efficiency.

3. Voltage and Current Ratings

Voltage and current ratings specify the maximum electrical load that a push button can handle. This is typically expressed in volts (V) and amperes (A). For instance, a push button rated for 10A and 250V AC can safely control devices within those limits. Selecting a push button with the appropriate ratings is vital for preventing electrical failures and ensuring safety in industrial environments.

4. IP Rating (Ingress Protection)

The IP rating indicates the level of protection a device offers against dust and water ingress. For example, an IP65 rating means the device is dust-tight and can withstand low-pressure water jets. B2B buyers must consider the operating environment; for instance, if a push button will be used outdoors or in a wet environment, a higher IP rating is necessary to ensure durability and reliability.

Illustrative image related to push button electric

5. Operating Temperature Range

This specification defines the temperature limits within which the push button can operate effectively. It is essential for applications exposed to extreme temperatures, as exceeding these limits can lead to malfunction or damage. Buyers should assess their operational environment to select a push button that can withstand the expected temperature fluctuations.

What Are Common Trade Terms Related to Push Button Electric Devices?

Familiarity with industry terminology can streamline the purchasing process and enhance communication between buyers and suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products to be sold under another company’s brand. In the context of push buttons, buyers often seek OEMs for customized solutions tailored to their specific requirements, ensuring quality and compatibility with their equipment.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers as it impacts inventory management and pricing strategies. Companies should assess their needs and negotiate MOQs that align with their operational capacity.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. For push button electric devices, submitting an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive the best value for their investments.

Illustrative image related to push button electric

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international trade. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and risk during transportation. Understanding these terms helps buyers manage logistics and costs effectively.

5. Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. For push button electric devices, lead times can vary significantly based on production schedules and shipping methods. Buyers should consider lead times when planning their projects to avoid delays in operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and enhance their purchasing strategies in the push button electric market.

Navigating Market Dynamics and Sourcing Trends in the push button electric Sector

What Are the Key Trends Shaping the Global Push Button Electric Market?

The push button electric sector is experiencing a dynamic evolution influenced by several global drivers. The increasing automation in manufacturing processes is a significant factor, propelling demand for reliable control mechanisms, including push buttons. Additionally, the rise of smart technologies and IoT applications is reshaping the landscape, leading to the development of advanced push button solutions that offer connectivity and enhanced functionality. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking products that integrate with modern automation systems, which necessitates a focus on both compatibility and advanced features.

Emerging sourcing trends indicate a shift towards online procurement platforms, allowing buyers to access a broader range of suppliers and products. This trend is particularly relevant in developing markets where traditional sourcing methods may be less efficient. Furthermore, the push for quick delivery times is driving suppliers to optimize their logistics and inventory management, thereby enhancing the overall supply chain efficiency. As buyers become more discerning, they are also prioritizing suppliers who can provide comprehensive product information and support, reflecting a growing trend towards transparency and customer-centric services.

How Is Sustainability Influencing Sourcing Practices in the Push Button Electric Sector?

Sustainability has emerged as a critical consideration in the sourcing practices of international B2B buyers. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting companies to seek out suppliers who prioritize eco-friendly practices. This shift is particularly pertinent in regions like Europe, where stringent regulations and consumer expectations drive the demand for sustainable products.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly interested in the sourcing of materials used in push button electric products, favoring those that employ recycled or sustainably sourced components. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming essential for suppliers looking to enter or expand in competitive markets. By prioritizing sustainability, businesses not only meet regulatory requirements but also enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

What Is the Historical Context of Push Button Electric Technology in B2B Markets?

The evolution of push button technology dates back to the early 20th century when mechanical switches began to replace traditional control methods in electrical applications. Initially utilized in basic electrical circuits, push buttons have evolved significantly, incorporating advanced materials and technologies that enhance their durability and functionality. As industrial automation gained momentum in the latter half of the century, the demand for reliable and efficient control mechanisms surged.

In recent years, the integration of digital technologies has transformed the push button electric sector. Today’s products not only serve as simple on/off controls but also feature advanced functionalities such as momentary action, illumination, and connectivity with other smart devices. This evolution reflects broader trends in the B2B landscape, where innovation and adaptability are paramount for meeting the diverse needs of international buyers across various regions.

Frequently Asked Questions (FAQs) for B2B Buyers of push button electric

-

1. How do I choose the right push button switch for my application?

Selecting the appropriate push button switch involves understanding your specific application requirements. Consider factors such as the operating voltage, amperage rating, and whether you need momentary or maintained contact. Assess the environmental conditions, including moisture and dust levels, to determine if you require IP-rated switches for protection. Additionally, review the compatibility with existing systems and ensure that the push button meets relevant industry standards such as IEC60947-5-1. Engaging with suppliers for technical specifications and product samples can also aid in making an informed choice. -

2. What types of push button switches are available for industrial applications?

There are several types of push button switches suitable for industrial settings, including momentary, maintained, illuminated, and emergency stop buttons. Momentary switches are commonly used for temporary control, while maintained switches remain in the last position until manually changed. Illuminated switches enhance visibility in low-light conditions, and emergency stop buttons are essential for safety. Each type serves different operational needs, so it’s important to evaluate the specific requirements of your machinery or control systems when choosing the right type. -

3. What should I consider when vetting suppliers for push button switches?

When vetting suppliers, consider their industry experience, product certifications, and customer reviews. Check if they adhere to international standards and have a proven track record in quality assurance. Request samples to evaluate the product quality and ensure their capability to meet your order quantities and customization needs. Assess their responsiveness and customer service, as these are crucial for ongoing support. Additionally, inquire about their logistics capabilities to ensure timely delivery to your region. -

4. What are the typical minimum order quantities (MOQs) for push button switches?

Minimum order quantities for push button switches can vary significantly based on the supplier and product type. Some manufacturers may have MOQs as low as 100 units for standard items, while custom designs may require larger orders, often starting at 500 to 1,000 units. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your project requirements. Consider the potential for bulk discounts if you anticipate future orders. -

5. What payment terms are commonly accepted by push button switch suppliers?

Payment terms can vary by supplier, but common practices include full payment upfront, 30% deposit with the balance before shipping, or net 30-60 days after delivery for established relationships. Some suppliers may offer credit terms based on your purchasing history. It’s important to clarify payment options and any associated fees before finalizing the order. Always ensure that payment methods are secure and that you have a clear understanding of the terms to avoid potential disputes. -

6. How can I ensure the quality of push button switches I purchase?

To ensure the quality of push button switches, request certification documents such as ISO 9001 or other relevant industry standards. Conduct factory visits or audits if feasible, or rely on third-party quality inspection services to assess products before shipment. Additionally, review warranty policies and return procedures to protect your investment. Engaging in a trial order can also help you evaluate product performance and reliability before committing to larger purchases. -

7. What logistics considerations should I keep in mind when sourcing push button switches internationally?

Logistics considerations include shipping methods, lead times, and customs regulations in your country. Determine whether you prefer air or sea freight, balancing cost and speed. Understand import duties and taxes that may apply to your order. Ensure that the supplier provides appropriate documentation for customs clearance, such as commercial invoices and packing lists. Collaborate with a reliable freight forwarder to navigate the complexities of international shipping and ensure timely delivery. -

8. Can push button switches be customized for specific applications?

Yes, many suppliers offer customization options for push button switches, including different colors, sizes, and labeling. Customization may also extend to functionality, such as adding illuminated features or integrating with specific control systems. When requesting customization, provide detailed specifications and any necessary designs to facilitate the manufacturing process. Be aware that custom orders may involve longer lead times and higher costs, so plan accordingly to meet your project timelines.

Top 5 Push Button Electric Manufacturers & Suppliers List

1. FactoryMation – Pushbuttons & Indicators

Domain: factorymation.com

Registered: 2005 (20 years)

Introduction: This company, FactoryMation – Pushbuttons & Indicators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Temco Controls Ltd. – Momentary Push Button

Domain: temcocontrols.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Momentary Push Button”, “brand”: “Temco Controls Ltd.”, “part_number”: “HPB”, “price_range”: “$3.10 – $4.00”, “weight”: “0.22 kg”, “voltage”: {“AC”: “0~380V”, “DC”: “0~220V”}, “frequency”: “50Hz or 60Hz”, “features”: [“High quality inflaming retarding materials”, “Excellent insulating performance”, “Antivibration”, “Meets IEC60947-5-1 and GB14048.5 standards”], “types”: [“Normal …

3. Superbreakers – Key Product Details

Domain: superbreakers.com

Registered: 2006 (19 years)

Introduction: Key product details extracted from the Superbreakers Push Buttons collection include:

1. **Brands Available**: Allen-Bradley, Schneider Electric, Square D, Eaton/Cutler-Hammer, General Electric, Siemens, Zinsco/Sylvania.

2. **Product Types**: Push Buttons, Pushbutton Components, Control Stations, Emergency Stop Heads, Pendant Stations.

3. **Notable Series**: 800T, 9001, 609, 10250, 3SB, Harmony.

…

4. RS Components – Pushbutton Switches

Domain: us.rs-online.com

Registered: 2001 (24 years)

Introduction: This company, RS Components – Pushbutton Switches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Classic Accents – Antique Push Button Light Switches

Domain: classicaccents.net

Registered: 1998 (27 years)

Introduction: Antique Push Button Light Switches are authentic reproductions of switches used in homes from the late 19th century to the 1950s. They comply with modern electrical codes and can be used for replacing old switches or in new constructions, adding a classic element to any room. Product offerings include: Single Pole Switch ($15.99), Single Pole Light Switch with Black Inlay and Logo ($15.99), Single…

Strategic Sourcing Conclusion and Outlook for push button electric

In today’s dynamic market, strategic sourcing of push button electric components has become essential for organizations aiming to optimize operational efficiency and reduce costs. By leveraging strong supplier relationships and conducting thorough market analysis, businesses can ensure access to high-quality products that meet their specific needs. This is particularly relevant for international buyers from Africa, South America, the Middle East, and Europe, where diverse industrial requirements and regulatory standards can pose unique challenges.

Investing in a robust sourcing strategy not only enhances supply chain resilience but also fosters innovation through collaboration with leading manufacturers. As demand for advanced electrical solutions continues to rise, understanding the nuances of push button technologies—such as momentary, maintained, and emergency stop switches—will empower businesses to make informed purchasing decisions that drive productivity.

Illustrative image related to push button electric

Looking ahead, it is vital for B2B buyers to stay abreast of emerging trends and technological advancements within the push button electric sector. Engaging with reputable suppliers and participating in industry forums can provide valuable insights and foster partnerships that propel growth. Take the next step in your sourcing journey by exploring new suppliers and technologies today to ensure your business remains competitive in this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to push button electric