Choosing Your Pod House: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for pod house

In an ever-evolving global market, sourcing innovative housing solutions like pod houses presents both opportunities and challenges for international B2B buyers. With the growing demand for affordable, eco-friendly, and efficient living spaces, understanding the nuances of pod house options is essential. This guide delves into the diverse types of pod houses, their applications in residential and commercial sectors, and the advantages they offer over traditional housing models.

International buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Vietnam—will find valuable insights into supplier vetting processes, cost considerations, and market trends. By addressing key factors such as construction speed, sustainability, and customization options, this comprehensive resource empowers businesses to make informed purchasing decisions that align with their strategic goals.

Whether you’re looking to enhance your property portfolio, invest in sustainable living solutions, or explore modular construction trends, this guide serves as a crucial tool in navigating the global market for pod houses. Prepare to unlock the potential of modern housing solutions that promise not only cost-effectiveness but also a commitment to environmental stewardship and innovative design.

Understanding pod house Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Pod Homes | Prefabricated sections, quick assembly, customizable layouts | Residential, vacation rentals | Pros: Fast construction, cost-effective. Cons: Limited customization compared to traditional homes. |

| Mobile Pods | Lightweight, portable, designed for easy relocation | Temporary housing, event spaces | Pros: Flexibility in location, quick setup. Cons: Smaller living space, may lack permanent amenities. |

| Eco-Friendly Pods | Built with sustainable materials, energy-efficient designs | Eco-tourism, off-grid living | Pros: Low environmental impact, reduced energy costs. Cons: Higher initial investment for sustainable materials. |

| ADUs (Accessory Dwelling Units) | Compact, often used for rental income or extended family living | Real estate investment, affordable housing | Pros: Adds property value, generates rental income. Cons: Zoning regulations can limit placement. |

| Commercial Pods | Designed for business use, often with office or studio configurations | Startups, small businesses | Pros: Flexible workspace solutions, quick setup. Cons: May require additional permits for commercial use. |

What Are Modular Pod Homes and Their Suitability for B2B Buyers?

Modular pod homes are constructed from prefabricated sections, allowing for rapid assembly and customization. These homes appeal to B2B buyers looking for efficient residential solutions, such as developers and real estate investors. The ability to scale production and reduce construction time makes them particularly attractive in markets with high housing demand. Buyers should consider local regulations and potential for future expansion when investing in modular options.

How Do Mobile Pods Provide Flexibility in Business Applications?

Mobile pods are lightweight and designed for easy relocation, making them ideal for temporary housing or event spaces. This type of pod is particularly suited for businesses that require flexibility, such as event organizers or companies needing temporary staff accommodations. The quick setup and mobility allow businesses to adapt to changing demands. However, potential buyers should weigh the limitations of smaller spaces and the absence of permanent amenities.

What Makes Eco-Friendly Pods a Smart Investment for Sustainable Projects?

Eco-friendly pods are constructed from sustainable materials and designed to be energy-efficient. They cater to B2B buyers focused on eco-tourism or off-grid living solutions. The initial investment may be higher due to the materials used, but the long-term energy savings and reduced environmental impact can make these pods a worthwhile investment. Buyers should evaluate the lifecycle costs and potential market appeal of sustainable living options.

How Can ADUs Enhance Property Value and Generate Income?

Accessory Dwelling Units (ADUs) are compact living spaces often used for rental income or accommodating extended family. They present an excellent opportunity for real estate investors looking to increase property value and generate passive income. Buyers should consider local zoning regulations, as these can impact the feasibility of placing ADUs on existing properties. The potential for rental income can offset initial costs, making ADUs a strategic investment.

What Are the Advantages of Commercial Pods for Startups?

Commercial pods are specifically designed for business use, often featuring office or studio configurations. They offer startups and small businesses flexible workspace solutions that can be set up quickly. This adaptability is crucial for companies needing to respond to rapid growth or changing market conditions. However, buyers must be aware of zoning regulations and the need for permits when utilizing pods for commercial purposes.

Key Industrial Applications of pod house

| Industry/Sector | Specific Application of Pod House | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Eco-friendly guest accommodations | Attracts eco-conscious travelers, enhancing brand image | Sustainable materials, modular design for quick setup |

| Construction | Temporary site offices and worker accommodations | Reduces construction delays and improves worker welfare | Mobility, ease of installation, compliance with local regulations |

| Real Estate Development | Affordable housing solutions for urban areas | Addresses housing shortages, increases property value | Cost-effectiveness, energy efficiency, customization options |

| Education | Portable classrooms and learning spaces | Expands educational capacity quickly and efficiently | Durability, adaptability to different climates, safety standards |

| Disaster Relief | Emergency shelters and rapid response housing | Provides immediate housing solutions in crisis situations | Transportability, ease of assembly, local sourcing capabilities |

How Can Pod Houses Enhance the Hospitality Industry?

In the hospitality sector, pod houses serve as eco-friendly guest accommodations, appealing to a growing demographic of environmentally conscious travelers. These modular units can be quickly set up in scenic locations, providing unique lodging experiences that promote sustainability. For international buyers, particularly from regions like Africa and South America, sourcing pod houses that utilize sustainable materials and can be rapidly deployed can significantly enhance their brand image while meeting the rising demand for green tourism.

What Role Do Pod Houses Play in Construction?

Pod houses are increasingly used as temporary site offices and worker accommodations in the construction industry. Their modular design allows for rapid deployment, which helps reduce project delays and enhances worker welfare by providing comfortable living spaces on-site. For B2B buyers in the Middle East and Europe, key considerations include ensuring compliance with local building regulations and selecting units that are easily transportable and can withstand various weather conditions.

Why Are Pod Houses Ideal for Real Estate Development?

In real estate development, pod houses offer affordable housing solutions that can be particularly beneficial in urban areas facing housing shortages. These units are cost-effective to produce and can be customized to meet specific community needs, thereby increasing property values. International developers from regions like Europe and the Middle East must focus on the cost-effectiveness and energy efficiency of these units to attract investment and meet regulatory standards.

How Can Educational Institutions Utilize Pod Houses?

Educational institutions can leverage pod houses as portable classrooms or learning spaces, allowing for the rapid expansion of educational facilities. This adaptability is crucial in regions experiencing population growth or where traditional infrastructure is lacking. For B2B buyers in Africa and South America, sourcing durable units that can be easily modified to suit educational requirements while adhering to safety standards is essential for maximizing their investment.

What Benefits Do Pod Houses Provide in Disaster Relief Efforts?

Pod houses are increasingly recognized as effective solutions for disaster relief, providing emergency shelters that can be deployed quickly in crisis situations. Their transportability and ease of assembly make them ideal for organizations responding to natural disasters. For international buyers involved in humanitarian efforts, considerations such as local sourcing capabilities and the ability to withstand harsh environments are critical for ensuring these units meet immediate needs.

3 Common User Pain Points for ‘pod house’ & Their Solutions

Scenario 1: Navigating Cost-Effectiveness in Pod House Purchases

The Problem: For B2B buyers, particularly those involved in real estate development or hospitality, the cost of construction is a critical factor. Many are drawn to pod houses due to their lower price point compared to traditional homes. However, buyers often face challenges in accurately assessing the total cost of ownership, including installation, maintenance, and potential customization needs. Unexpected expenses can arise from shipping logistics, local regulations, and site preparation, which may turn the initially attractive price into a budgetary concern.

The Solution: To effectively navigate these cost concerns, buyers should conduct a comprehensive cost analysis before making a purchase. Start by obtaining detailed quotes from multiple pod house manufacturers and ensure these quotes include installation and transportation costs. It’s crucial to engage with local experts who understand regional building codes and can provide insights into additional expenses that may arise. Furthermore, consider the long-term savings associated with pod houses, such as energy efficiency and reduced maintenance costs. Explore financing options or partnerships with manufacturers that may offer incentives for bulk purchases, which can significantly enhance the cost-effectiveness of the investment.

Scenario 2: Overcoming Zoning and Permitting Challenges

The Problem: As pod houses gain popularity, B2B buyers often encounter zoning regulations and permitting challenges that can delay project timelines. Different regions may have varying restrictions on the placement and use of pod houses, which can complicate the development process. Buyers may feel overwhelmed by the bureaucracy involved in securing the necessary approvals, risking project delays and additional costs.

The Solution: To mitigate zoning and permitting issues, proactive research is essential. Buyers should engage local zoning boards early in the planning process to understand the specific regulations that apply to pod houses in their desired locations. Collaborating with a legal expert who specializes in real estate can provide clarity on navigating these regulations. Additionally, consider partnering with manufacturers who have experience in your area and can provide insights into successful past projects. This collaboration can streamline the permitting process and ensure compliance, ultimately minimizing project delays and associated costs.

Scenario 3: Addressing Sustainability Concerns in Pod House Selection

The Problem: With an increasing focus on sustainability, B2B buyers are often concerned about the environmental impact of their housing choices. While pod houses are generally marketed as eco-friendly options, there can be discrepancies in the materials used, energy efficiency, and overall sustainability practices among manufacturers. Buyers may struggle to identify truly sustainable options that align with their corporate responsibility goals.

The Solution: To ensure the selection of genuinely sustainable pod houses, buyers should prioritize manufacturers who provide transparency regarding their materials and construction processes. Request certifications or documentation that outline the use of eco-friendly materials, such as recycled steel or energy-efficient insulation. Additionally, assess the energy performance ratings of the pod houses and inquire about the integration of renewable energy sources, like solar panels. Conducting site visits or reviewing case studies of existing installations can also provide valuable insights into a manufacturer’s commitment to sustainability. By taking these steps, buyers can make informed decisions that align with their sustainability objectives and enhance their brand reputation.

Strategic Material Selection Guide for pod house

What Are the Best Materials for Building Pod Houses?

When selecting materials for pod houses, it is crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: steel, wood, composite materials, and insulated panels. Each material offers unique benefits and challenges, making them suitable for different applications and markets.

How Does Steel Perform in Pod House Construction?

Steel is a popular choice for pod house construction due to its strength and durability. It boasts high temperature and pressure ratings, making it suitable for various climates. Steel is also resistant to pests and rot, which enhances its longevity. However, it can be prone to corrosion if not adequately treated, particularly in humid environments.

Pros: Steel is highly durable, cost-effective in large quantities, and allows for quick assembly. Its structural integrity supports larger spans and designs, making it versatile for various pod configurations.

Cons: The initial cost can be higher than other materials, and it requires specialized skills for fabrication and welding. Additionally, thermal conductivity can lead to heat loss unless properly insulated.

For international buyers, especially in regions like the Middle East and Africa, compliance with local building codes and standards (such as ASTM) is essential. Buyers should also consider the availability of treated steel to prevent corrosion in coastal areas.

What Role Does Wood Play in Pod House Construction?

Wood is often favored for its aesthetic appeal and natural insulation properties. It offers a warm, inviting atmosphere, making it suitable for residential applications. Wood has good thermal performance, which is beneficial in both hot and cold climates.

Pros: Wood is generally easier to work with and can be sourced locally, reducing transportation costs. Its lightweight nature allows for easier handling and installation.

Cons: Wood is susceptible to pests, rot, and fire, which can limit its lifespan if not properly treated. It may also require regular maintenance to preserve its appearance and structural integrity.

International buyers should ensure that the wood sourced complies with sustainability certifications like FSC (Forest Stewardship Council). In regions like South America, where tropical hardwoods are prevalent, ensuring legality and sustainability is crucial.

How Do Composite Materials Enhance Pod House Design?

Composite materials, such as fiberglass and engineered wood products, combine the advantages of various materials to enhance performance. They are designed to resist weathering, UV damage, and pests, making them suitable for diverse climates.

Pros: Composites are lightweight, durable, and often require less maintenance than traditional materials. They can be molded into various shapes, allowing for creative designs.

Cons: The cost can be higher than traditional materials, and some composites may have environmental concerns regarding their production and disposal.

For buyers in Europe and North America, compliance with standards like EN (European Norms) is essential. In regions like Africa and the Middle East, understanding local preferences for eco-friendly materials can influence the choice of composites.

Why Are Insulated Panels Ideal for Pod Houses?

Insulated panels are increasingly popular in pod house construction due to their energy efficiency and quick installation. These panels typically consist of a core material sandwiched between two outer layers, providing excellent thermal insulation.

Pros: They significantly reduce energy consumption and can be installed rapidly, minimizing labor costs. Insulated panels also offer design flexibility and can be customized for various applications.

Cons: The initial investment can be high, and sourcing quality panels may be challenging in some regions. Additionally, improper installation can lead to thermal bridging.

International buyers should consider compliance with energy efficiency standards, such as LEED (Leadership in Energy and Environmental Design) in North America and Europe. Understanding local market preferences for energy-efficient solutions is also crucial.

Summary Table of Material Selection for Pod Houses

| Material | Typical Use Case for pod house | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural framework and cladding | High durability and strength | Prone to corrosion without treatment | Medium |

| Wood | Interior finishes and framing | Aesthetic appeal and natural insulation | Susceptible to pests and rot | Medium |

| Composite Materials | Exterior cladding and structural elements | Lightweight and weather-resistant | Higher cost and potential environmental concerns | High |

| Insulated Panels | Walls and roofs for energy efficiency | Excellent thermal insulation and quick installation | High initial investment and sourcing challenges | High |

This guide provides a comprehensive overview of materials suitable for pod house construction, enabling international B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for pod house

What Are the Main Stages of the Manufacturing Process for Pod Houses?

The manufacturing process of pod houses involves several critical stages, ensuring efficiency and quality in the final product. Understanding these stages is essential for B2B buyers, as they can significantly influence the cost and delivery time.

-

Material Preparation

The first step in manufacturing pod houses is material preparation. Key materials typically include sustainable and durable options such as Q235 steel, aluminum alloys, and eco-friendly composites. These materials are chosen for their strength, lightweight properties, and recyclability. In this stage, suppliers often conduct material inspections to ensure compliance with international standards, which is crucial for maintaining quality throughout the production process. -

Forming

Once materials are prepared, the next step is forming. This involves cutting and shaping materials into the desired pod structure. Advanced technologies like CNC (Computer Numerical Control) machining and laser cutting are commonly employed to ensure precision. This stage also includes the creation of modular components, which allows for quick assembly and reduces construction time on-site. -

Assembly

The assembly phase is where the individual components come together to form the complete pod house. This process is often streamlined in a factory setting, allowing for rapid construction. Skilled workers or automated systems are used to ensure that each pod meets design specifications. Modular assembly techniques not only speed up the process but also enhance quality control, as components can be tested for fit and function before final assembly. -

Finishing

The finishing stage involves applying aesthetic and protective coatings to the pod house. This can include painting, sealing, and installing fixtures. In addition to enhancing the visual appeal, these finishes are essential for durability, especially in varying climates. Quality checks during this stage focus on the integrity of the finishes and their resistance to environmental factors.

How Is Quality Assurance Managed in Pod House Manufacturing?

Quality assurance is a critical aspect of pod house manufacturing, ensuring that products meet both international standards and customer expectations. For B2B buyers, understanding these processes can help mitigate risks associated with procurement.

-

International Standards and Certifications

Compliance with international quality standards such as ISO 9001 is essential for manufacturers. This standard outlines requirements for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications like CE marking for products sold in Europe or API standards for specific materials can be crucial for international buyers. -

Quality Control Checkpoints

Effective quality control involves several key checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before production begins. Suppliers should have documented procedures for inspecting materials against specifications.

– In-Process Quality Control (IPQC): During assembly, IPQC measures are taken to ensure that each component is correctly manufactured and assembled. This stage often includes visual inspections and functional tests.

– Final Quality Control (FQC): Once the pod house is complete, FQC involves a thorough inspection of the entire unit, ensuring it meets all design and performance specifications before shipping. -

Common Testing Methods

Various testing methods are employed to ensure the quality and durability of pod houses. These include:

– Structural Integrity Tests: Assessing the strength of materials and the overall stability of the structure.

– Environmental Testing: Evaluating how the pod holds up under various weather conditions, including moisture resistance and thermal performance.

– Safety Compliance Tests: Ensuring that the pod meets safety regulations, including fire safety and electrical standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is paramount to ensuring product reliability. Here are several strategies to effectively assess supplier quality:

-

Supplier Audits

Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing practices and quality control measures. During these audits, buyers can evaluate the production process, material handling, and adherence to safety and quality standards. -

Quality Assurance Reports

Requesting detailed quality assurance reports from suppliers can help buyers understand their quality control processes. These reports should outline the methods used for quality assessment, results of previous inspections, and any corrective actions taken for non-compliance. -

Third-Party Inspections

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent evaluations of the manufacturing process and final products, ensuring that they meet agreed-upon standards and specifications.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must be aware of the nuances in quality control and certification that can vary by region. Here are some considerations:

-

Regional Regulations

Different regions may have specific regulations that affect the manufacturing and certification of pod houses. For instance, products entering the European market must comply with CE marking, while other regions may have their own certification requirements. Buyers should familiarize themselves with these regulations to avoid compliance issues. -

Cultural Considerations

Understanding the cultural context of the supplier’s location can impact quality expectations and communication. For instance, some cultures may emphasize relationship-building and trust, which can influence the reliability of quality assurances. -

Logistical Challenges

Logistics play a significant role in the quality assurance process, particularly when shipping products internationally. Buyers should consider the potential for damage during transit and inquire about the supplier’s packaging and handling procedures to ensure that products arrive in optimal condition.

By understanding the manufacturing processes and quality assurance practices associated with pod houses, B2B buyers can make informed decisions, ensuring they select reliable suppliers that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pod house’

Introduction

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing pod houses. As the demand for alternative housing solutions rises globally, especially in regions like Africa, South America, the Middle East, and Europe, understanding the procurement process is essential. This checklist will help you navigate the complexities of sourcing pod houses, ensuring that you make informed decisions.

Step 1: Define Your Project Requirements

Before engaging suppliers, clarify your project requirements, including the intended use of the pod house—whether for residential, commercial, or mixed purposes. Understanding your needs will help you communicate effectively with potential suppliers and select a pod house that meets your specifications, such as size, layout, and energy efficiency.

Step 2: Research Market Trends and Regulations

Stay informed about the latest trends in pod housing and any regulations specific to your target market. Researching local building codes and zoning laws is crucial, as these can impact your project. This step will help you avoid potential legal issues and ensure that your pod house complies with regional standards.

Step 3: Identify and Evaluate Potential Suppliers

Conduct thorough research to identify reputable suppliers of pod houses. Look for companies with a proven track record in the industry and positive customer reviews. Request detailed company profiles, including case studies and references, to gauge their reliability and quality of work. It’s also beneficial to explore their experience in your specific region, as local knowledge can significantly impact the project’s success.

Step 4: Assess Product Quality and Sustainability

Evaluate the quality and sustainability of the materials used in the pod houses. Ensure that the suppliers offer eco-friendly options that align with modern construction standards. Look for certifications that indicate compliance with sustainability practices, such as the use of recycled materials or energy-efficient technologies. This assessment is vital for ensuring long-term durability and environmental responsibility.

Step 5: Request and Compare Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline costs, delivery times, and payment terms. Comparing multiple quotes will give you a clearer understanding of the market rates and help you identify any hidden costs. Pay attention to the specifics of what each quote includes, such as installation services, warranty, and after-sales support.

Step 6: Verify Supplier Certifications and Compliance

Ensure that the suppliers possess all necessary certifications and comply with international standards for construction and safety. This verification process is crucial to mitigate risks associated with quality and legal compliance. Look for evidence of industry certifications, such as ISO standards, which can provide additional assurance of the supplier’s credibility.

Step 7: Finalize Contracts and Payment Terms

After selecting a supplier, carefully review and finalize the contract. Ensure that all terms regarding delivery, installation, warranty, and after-sales support are clearly stated. Agree on payment terms that are favorable and protect your interests. A well-drafted contract will help prevent misunderstandings and ensure a smooth procurement process.

By following this checklist, B2B buyers can streamline the sourcing process for pod houses, making informed decisions that align with their project goals and regional requirements.

Comprehensive Cost and Pricing Analysis for pod house Sourcing

What Are the Key Cost Components in Pod House Sourcing?

When sourcing pod houses, understanding the cost structure is essential for making informed purchasing decisions. Key cost components include:

-

Materials: The primary materials used in pod house construction typically involve prefabricated elements, such as steel, aluminum alloys, and sustainable materials. The choice of materials directly influences the overall cost, with eco-friendly options generally being more expensive but offering long-term savings through energy efficiency.

-

Labor: Labor costs can vary significantly based on geographical location and the complexity of the pod design. Modular construction often requires less labor time compared to traditional homes, which can lead to cost savings.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities and factory maintenance. Efficient manufacturing processes can reduce overhead costs, ultimately affecting the pricing of the final product.

-

Tooling: Initial tooling costs for custom designs can be substantial. However, for standard designs, these costs are amortized over larger production runs, resulting in lower prices per unit.

-

Quality Control (QC): Ensuring the quality of pod houses through rigorous QC processes can add to costs. However, investing in quality control can lead to fewer defects and lower warranty claims, which is a crucial consideration for long-term buyers.

-

Logistics: The cost of transporting pod houses from the manufacturing site to the end-user is a significant factor. This can vary based on distance, transportation mode, and the weight of the units.

-

Margin: Finally, manufacturers typically include a profit margin in their pricing. This can vary widely based on market competition and the perceived value of the product.

What Influences Pricing in Pod House Sourcing?

Several factors can influence the pricing of pod houses, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate MOQs to achieve more favorable pricing.

-

Specifications and Customization: Custom designs and specifications can increase costs significantly. Standard models are generally more cost-effective, so buyers should evaluate whether customization is necessary for their needs.

-

Materials and Quality Certifications: The choice of materials and whether they meet specific certifications (e.g., energy efficiency) can impact pricing. Buyers should assess the long-term benefits of higher-quality materials versus initial costs.

-

Supplier Factors: Supplier reputation, reliability, and location can influence pricing. It’s beneficial to establish relationships with reputable suppliers to ensure consistent quality and pricing.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) can affect total costs. Buyers should clarify responsibilities for shipping and insurance to avoid unexpected expenses.

How Can Buyers Optimize Costs in Pod House Sourcing?

To optimize costs, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate Effectively: Leverage volume purchasing and establish long-term relationships with suppliers to secure better pricing and payment terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, energy efficiency, and potential resale value. A higher initial cost may yield lower TCO over time.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, import tariffs, and local regulations that may affect overall costs. Working with experienced logistics partners can mitigate these risks.

Disclaimer on Pricing

It is important to note that prices for pod houses can vary widely based on the factors outlined above. Prices provided by suppliers may be indicative and should be confirmed through direct communication with manufacturers. Always seek detailed quotations to understand the full scope of costs involved in sourcing pod houses for your specific needs.

Alternatives Analysis: Comparing pod house With Other Solutions

Introduction: Exploring Alternative Housing Solutions

As the demand for affordable, sustainable housing solutions rises, particularly in emerging markets, various alternatives to traditional homes are becoming increasingly popular. Among these, pod houses stand out due to their modular design and eco-friendly features. However, B2B buyers should also consider other viable options, such as container homes and tiny houses, which offer unique benefits and cater to different needs. This analysis will provide a comparative overview of these housing solutions, helping buyers make informed decisions.

Comparison Table

| Comparison Aspect | Pod House | Container Homes | Tiny Houses |

|---|---|---|---|

| Performance | High energy efficiency, durable | Strong structural integrity | Compact, efficient living space |

| Cost | Generally lower upfront costs | Moderate costs, variable by design | Affordable, but customization can increase costs |

| Ease of Implementation | Quick to install, prefabricated | Requires modifications for comfort | DIY options available, but can be labor-intensive |

| Maintenance | Low maintenance due to materials | Moderate, depends on insulation | Generally low, but size limits storage for tools |

| Best Use Case | Permanent homes, eco-friendly spaces | Commercial and residential uses | Minimalist living, vacation homes |

Detailed Breakdown of Alternatives

Container Homes

Container homes utilize repurposed shipping containers to create durable and innovative living spaces. They are known for their strong structural integrity, making them suitable for various climates and conditions. However, the initial cost can vary significantly based on design and modifications needed for comfort. While they are generally easy to maintain, the insulation and ventilation require careful planning to ensure a comfortable living environment. Container homes are ideal for commercial applications or unique residential setups, offering flexibility in design but necessitating a good understanding of construction.

Tiny Houses

Tiny houses focus on minimalist living, typically ranging from 100 to 400 square feet. They are affordable and can be built quickly, especially with DIY methods. However, the small size means limited storage and living space, which may not be suitable for larger families or those with extensive belongings. Tiny houses can be mobile, allowing for flexibility in location, but this can also limit the amenities available. They cater well to individuals seeking a simpler lifestyle or vacation homes, but potential buyers must weigh the trade-offs of compact living against their needs.

Conclusion: Choosing the Right Housing Solution for Your Needs

When selecting the ideal housing solution, B2B buyers should consider their specific requirements, such as budget constraints, desired lifestyle, and intended use. Pod houses offer a compelling blend of affordability and efficiency, especially for those prioritizing sustainability. Container homes provide robustness and versatility, suitable for various applications, while tiny houses appeal to minimalist lifestyles. By evaluating the pros and cons of each alternative, buyers can make strategic decisions that align with their long-term goals, ensuring a sound investment in innovative housing solutions.

Essential Technical Properties and Trade Terminology for pod house

What Are the Essential Technical Properties of a Pod House?

When considering the procurement of pod houses, it is crucial to understand the technical properties that define their quality and performance. Here are several critical specifications to consider:

-

Material Grade

Pod houses are often constructed from high-grade materials such as Q235 steel or eco-friendly composites. The material grade impacts durability, resistance to environmental factors, and overall lifespan. For B2B buyers, understanding material grade ensures compliance with safety regulations and longevity of investment. -

Thermal Insulation Value (R-Value)

The R-Value measures thermal resistance. Higher values indicate better insulation properties, which is vital for energy efficiency. For businesses operating in regions with extreme temperatures, selecting a pod house with superior insulation can significantly reduce heating and cooling costs, enhancing overall sustainability. -

Structural Tolerance

This refers to the ability of the pod house to withstand various loads and stresses, including wind, snow, and seismic activity. A well-defined structural tolerance ensures that the pod house can meet local building codes and withstand environmental conditions, minimizing risk for investors. -

Modularity and Expandability

Pod houses are typically modular, allowing for easy expansion or modification. This feature is particularly advantageous for businesses anticipating growth or changes in spatial requirements. Understanding modularity can aid in planning for future scalability without the need for extensive renovations. -

Energy Consumption Efficiency

Many modern pod houses incorporate energy-efficient technologies, such as solar panels and high-efficiency heating and cooling systems. B2B buyers should evaluate the expected energy consumption metrics to assess long-term operational costs and sustainability goals. -

Quick Assembly Time

The construction speed of pod houses can often be significantly quicker than traditional homes, sometimes completed in a matter of days. This rapid assembly can be a major advantage for businesses needing immediate space solutions, reducing downtime and associated costs.

What Are Common Trade Terms in the Pod House Industry?

Familiarity with industry terminology is essential for effective communication and negotiation in the pod house market. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pod houses, understanding OEM relationships can help buyers evaluate the quality and reliability of components used in construction. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can assist in budgeting and inventory management, particularly when considering bulk purchases of pod houses or components. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to bid on providing specific products or services. For businesses looking to procure pod houses, issuing an RFQ allows them to compare prices and terms from different manufacturers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to navigate shipping, insurance, and delivery responsibilities effectively. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. In the pod house industry, knowing lead times can help businesses plan construction schedules and manage project timelines effectively. -

Sustainability Certification

This term encompasses various certifications that indicate a product meets specific environmental standards. For B2B buyers focused on eco-friendly solutions, understanding sustainability certifications can provide assurance regarding the environmental impact of their investment in pod houses.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their investments in pod houses align with their operational and sustainability goals.

Navigating Market Dynamics and Sourcing Trends in the pod house Sector

What Are the Key Trends Shaping the Global Pod House Market?

The pod house market is experiencing significant growth driven by various global trends. The rising demand for affordable housing solutions, particularly in urban areas, is pushing buyers toward innovative alternatives like pod homes. This trend is particularly pronounced in developing regions of Africa and South America, where traditional housing options are often financially unfeasible. Additionally, the growing popularity of minimalist lifestyles and eco-friendly living is shifting consumer preferences towards compact, sustainable housing solutions.

Emerging technologies such as advanced manufacturing processes and smart home integrations are also influencing sourcing trends in the pod house sector. Modular construction techniques reduce construction time and costs, appealing to B2B buyers looking for efficient solutions. Furthermore, the adoption of digital platforms for sourcing and purchasing pod homes is becoming increasingly common, allowing international buyers to compare options, access designs, and engage with manufacturers directly.

Market dynamics are further shaped by regional factors. In the Middle East, for instance, the push for sustainable development aligns with government initiatives promoting eco-friendly housing. In Europe, stricter regulations around energy efficiency and building codes are pushing the market towards innovative solutions that meet these standards. Buyers from diverse regions must stay informed about these trends to make informed purchasing decisions.

How Is Sustainability Impacting Sourcing in the Pod House Sector?

Sustainability is at the forefront of the pod house market, influencing both product design and sourcing practices. The environmental impact of construction is a growing concern, leading to a demand for eco-friendly materials and energy-efficient designs. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability, such as using recycled materials, energy-efficient manufacturing processes, and low-impact construction techniques.

The importance of ethical supply chains cannot be overstated. Buyers must ensure that their sourcing partners adhere to sustainable practices, from material extraction to production and delivery. Certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) are becoming essential for validating the sustainability claims of pod house manufacturers. Such certifications not only enhance brand reputation but also align with the values of increasingly environmentally conscious consumers.

As buyers seek to mitigate their environmental footprints, the demand for sustainable pod houses is likely to grow. Suppliers who can showcase their commitment to green practices and provide transparent sourcing information will be better positioned to meet the needs of this evolving market.

What Is the Evolution of the Pod House Concept?

The concept of pod houses has evolved significantly over the last century. Initially influenced by modernist architectural movements, the design focused on functionality and simplicity, leading to the minimalist aesthetics we see today. The post-war era saw a rise in innovative housing solutions, paving the way for prefabricated and modular designs that are synonymous with pod homes.

In the 21st century, the pod house has gained traction as a sustainable living option, with advancements in eco-friendly materials and energy-efficient technologies. This evolution reflects a broader societal shift towards sustainability and minimalism, making pod houses not only an alternative to traditional housing but also a viable solution for those seeking to reduce their environmental impact. As the market continues to grow, understanding this historical context will aid B2B buyers in recognizing the value and potential of pod houses in today’s economy.

Frequently Asked Questions (FAQs) for B2B Buyers of pod house

-

How do I determine the suitability of a pod house for my business needs?

To assess the suitability of a pod house for your business, consider your specific requirements, such as size, functionality, and intended use (e.g., office space, accommodation). Evaluate the pod’s design features, such as energy efficiency, modularity, and adaptability for your operational needs. Additionally, consider local regulations and zoning laws that may affect installation and use. Engaging with a supplier to discuss customization options can help ensure that the pod meets your unique specifications. -

What are the key benefits of choosing a pod house over traditional construction?

Pod houses offer several advantages, including reduced construction time and cost, sustainability, and energy efficiency. Their prefabricated nature allows for quick assembly, often completed in days rather than months. They are typically built using eco-friendly materials and can incorporate energy-saving technologies, making them a cost-effective and environmentally responsible choice. Furthermore, their compact design encourages minimalism, appealing to buyers looking to reduce their environmental footprint. -

How do I vet suppliers for pod houses in international markets?

When vetting suppliers for pod houses, consider their experience and reputation in the industry. Request references from previous clients and assess their portfolio of completed projects. Verify their compliance with international standards and regulations regarding construction and safety. It’s also crucial to inquire about their production capacity, lead times, and after-sales support. Conducting site visits or utilizing third-party inspections can provide further assurance of their credibility and reliability. -

What customization options are available for pod houses?

Customization options for pod houses can vary significantly by supplier, but many offer a range of features including layout adjustments, exterior finishes, and interior design elements. You can typically choose materials, colors, and appliances that align with your brand and functional needs. Some manufacturers may also provide smart home technology integration, energy-efficient systems, and sustainable building materials. Discussing your specific requirements with the supplier will help you understand what customization options are available. -

What are the minimum order quantities (MOQ) when sourcing pod houses?

Minimum order quantities for pod houses can vary by supplier and region. Some manufacturers may have flexible MOQs, allowing for single unit purchases, especially for customized models. However, larger orders often result in better pricing and more favorable terms. It is advisable to communicate your needs directly with potential suppliers to understand their MOQ policies and explore options that fit your purchasing strategy. -

What payment terms should I expect when purchasing pod houses internationally?

Payment terms for international purchases of pod houses can differ widely among suppliers. Common arrangements include upfront payments, deposits, or installment plans based on project milestones. It’s essential to discuss and negotiate these terms before finalizing any agreement. Additionally, consider using secure payment methods that offer buyer protection, such as letters of credit or escrow services, especially for significant investments. -

How do I ensure quality assurance (QA) during the manufacturing of pod houses?

To ensure quality assurance during the manufacturing process of pod houses, request detailed information about the supplier’s QA protocols. This may include inspections at various stages of production, materials testing, and compliance with international building standards. You can also consider third-party quality audits or certifications that demonstrate the supplier’s commitment to quality. Establishing clear communication channels for regular updates throughout the production process is also beneficial. -

What logistics considerations should I keep in mind when importing pod houses?

When importing pod houses, logistics considerations include shipping methods, customs regulations, and delivery timelines. Ensure that your supplier can provide detailed shipping options and handle necessary documentation for customs clearance. Consider the size and weight of the pods, as this can affect transportation costs and methods. Additionally, plan for potential delays at ports and ensure that you have a reliable logistics partner to facilitate the movement of goods to your final destination.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Pod House Manufacturers & Suppliers List

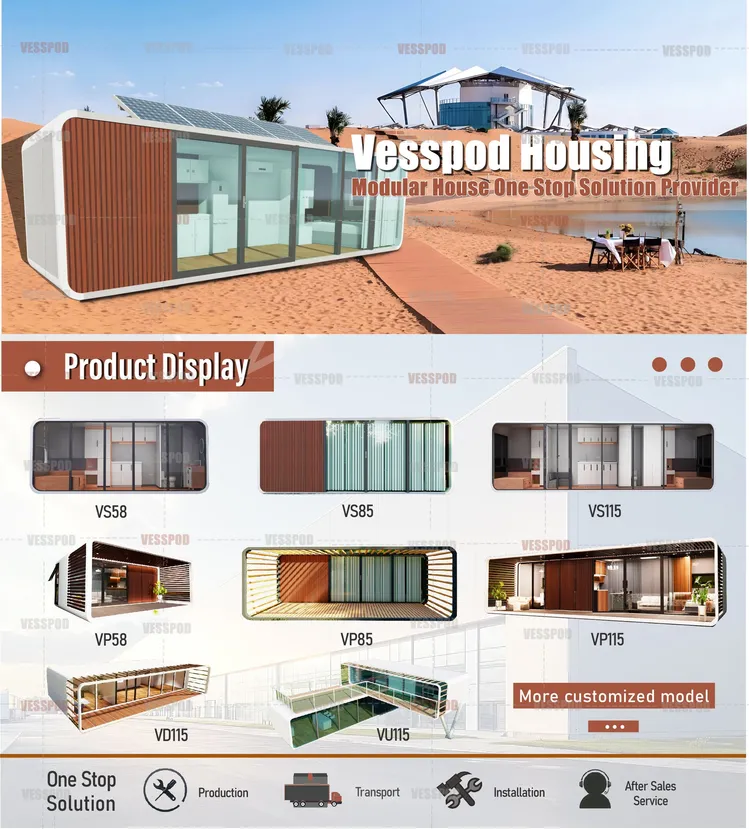

1. CHERY – Tiny House Pod Cabin

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {‘title’: ’16 ft x 7.4 ft Tiny House Pod House Cabin Prefab House Outdoor Living & Working’, ‘price’: ‘US $21,999.00 or Best Offer’, ‘condition’: ‘New’, ‘quantity_available’: 5, ‘brand’: ‘CHERY’, ‘type’: ‘Tiny House’, ‘number_of_bedrooms’: 1, ‘number_of_bathrooms’: 1, ‘manufacturer_warranty’: ‘1 Year’, ‘item_height’: ‘7.7 ft’, ‘style’: ‘Contemporary’, ‘material’: ‘Steel’, ‘item_length’: ‘7.4 ft’, …

2. LoftyPod – Modular Homes

Domain: loftypods.com

Registered: 2020 (5 years)

Introduction: LoftyPod offers a range of modular homes in Quebec, featuring optimized floor plans and smart home technology. Key models include: Antarctica Series (Antarctica 2, Antarctica Perpendicular, Antarctica Parallel, Antarctica X), Ushuaia Series (Ushuaia 2, Ushuaia 2 Large), Calafate Series (Calafate Parallel, Calafate Triple Parallel), and additional models like Hawaii Mezzanine, Finland, Denmark, Ice…

3. Glitz Camp – Modern Pod Houses

Domain: glitzcamp.com

Registered: 2016 (9 years)

Introduction: Modern pod houses are prefabricated modular homes designed for minimalist living. They are cost-effective, eco-friendly, and quick to construct, often taking less than a day to install. Key features include a streamlined exterior design with large windows, modern materials like aluminum alloys and PVC fabrics, and a compact interior that maximizes space efficiency. Many pods integrate smart techno…

4. Pinterest – Pod Homes

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Pod Homes, also known as Hivehaus Modular Tiny Hexagonal Pods, are prefabricated, eco-friendly, and modern living solutions. They feature minimalist architecture with glass panels, allowing for natural light and views of nature. The designs include options like glass cabins, container homes, and hexagon houses, suitable for various environments such as forests and beaches. These homes are part of …

5. RG Pro Builders – Modern Series ADUs

Domain: rgprobuilders.com

Registered: 2014 (11 years)

Introduction: Modern Series ADUs are designed as modern, affordable, and expandable living solutions in Washington and Oregon. They offer a combination of modern style and real-home comforts, including connected water pipes. The ADUs can be customized to fit various spaces, tastes, and budgets, with options ranging from backyard bungalows to luxury suites. Key features include:

– Modern look with minimal style …

6. Backyard Pod – Luxury Tiny Homes & ADUs

Domain: backyardpod.com

Registered: 2012 (13 years)

Introduction: Backyard Pod offers a variety of luxury tiny homes, ADUs, and backyard spaces in Austin, TX, including:

1. **Pod Essentials Collection**:

– Pod 12: 120 sqft

– Pod 16: 160 sqft

– Pod 20: 200 sqft

– Pod Twist: 190 sqft

– Pod Living: Studio, 1 & 2 Bedrooms, Bathroom

– Pod Studio: 210 sqft, 1 bathroom

– Pod One Bedroom: 340 sqft, 1 bed, 1 bathroom

– Pod Two Bedroom wit…

Strategic Sourcing Conclusion and Outlook for pod house

In the evolving landscape of global housing solutions, pod houses present a compelling alternative to traditional accommodations, especially for B2B buyers seeking cost-effective, sustainable, and innovative construction options. Their modular design facilitates rapid deployment, making them ideal for diverse markets, from urban developments in Europe to off-grid living solutions in Africa and South America.

Strategic sourcing of pod houses enables businesses to leverage lower construction costs, reduced energy consumption, and a smaller environmental footprint. As the demand for flexible living and working spaces grows, investing in pod homes not only meets contemporary housing needs but also aligns with the increasing emphasis on sustainability and minimalism.

Looking ahead, the potential for pod houses in international markets is vast. B2B buyers are encouraged to explore partnerships with manufacturers specializing in modular construction to capitalize on this trend. By adopting pod houses, businesses can enhance their real estate portfolios and respond to changing consumer preferences, paving the way for innovative housing solutions in the years to come. Engage with suppliers today to stay ahead in this transformative market.