Choosing Your Plastic Computer Keyboard Covers: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for plastic computer keyboard covers

In the rapidly evolving landscape of technology, sourcing durable plastic computer keyboard covers has become a vital consideration for businesses seeking to enhance equipment longevity and maintain hygiene standards. As organizations worldwide grapple with the challenge of protecting their assets from dust, spills, and microbial contamination, the demand for high-quality keyboard covers has surged. This guide serves as a comprehensive resource, addressing various types of keyboard covers, their diverse applications across industries, and essential supplier vetting strategies.

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Germany—will find valuable insights tailored to their unique procurement needs. The guide delves into critical factors such as cost analysis, material specifications, and compliance with regional standards, empowering decision-makers to make informed purchases. By understanding the nuances of the global market for plastic computer keyboard covers, businesses can effectively mitigate risks associated with equipment maintenance and employee health.

Whether your focus is on enhancing workplace safety or maximizing the lifespan of your technology, this guide will equip you with actionable insights and strategies to navigate the complexities of sourcing plastic keyboard covers in a competitive environment.

Understanding plastic computer keyboard covers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom-Fit Keyboard Covers | Tailored to specific keyboard models, durable polyurethane material | Hospitals, Dental offices, Manufacturing | Pros: Excellent fit, long-lasting protection. Cons: Higher initial cost. |

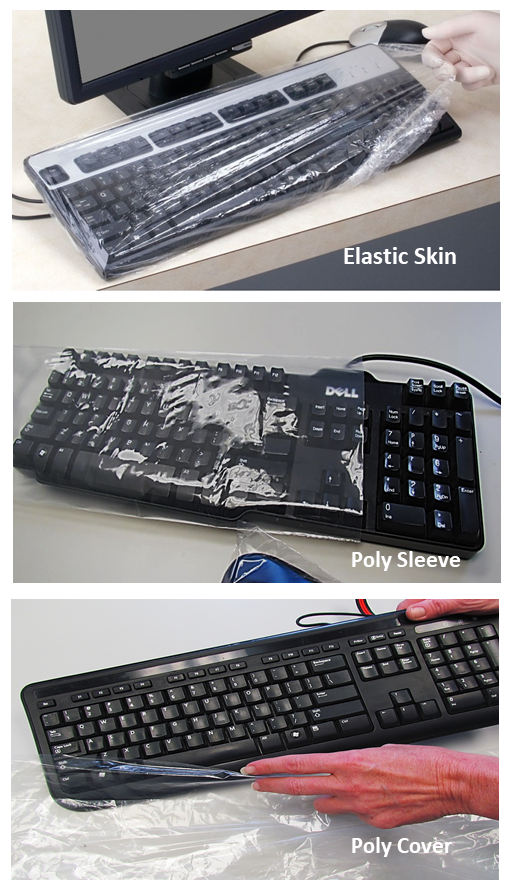

| Disposable Keyboard Covers | Single-use, clear plastic, easy to apply and remove | Healthcare, Food service, Offices | Pros: Prevents cross-contamination, convenient. Cons: Ongoing cost, not environmentally friendly. |

| Transparent Keyboard Skins | Flexible, lightweight, maintains visibility and typing feel | Office environments, Educational institutions | Pros: Easy to clean, preserves original keyboard aesthetics. Cons: May shift during use, less durable. |

| Full-Size Keyboard Covers | Covers entire keyboard, including function keys | IT departments, Call centers | Pros: Comprehensive protection, prevents dust and spills. Cons: Can be cumbersome, may affect typing speed. |

| Key-Specific Covers | Designed for individual keys, offers targeted protection | Gaming, Specialized workstations | Pros: Precise protection, customizable for specific needs. Cons: Limited scope of protection, requires more inventory management. |

What Are Custom-Fit Keyboard Covers and When Should You Use Them?

Custom-fit keyboard covers are specifically designed to match the dimensions and layout of individual keyboard models. Made from durable polyurethane, they provide robust protection against dust, spills, and wear, making them ideal for environments like hospitals and manufacturing facilities. When purchasing, consider the specific keyboard models in use within your organization to ensure compatibility and maximize the protective benefits.

How Do Disposable Keyboard Covers Offer Infection Control?

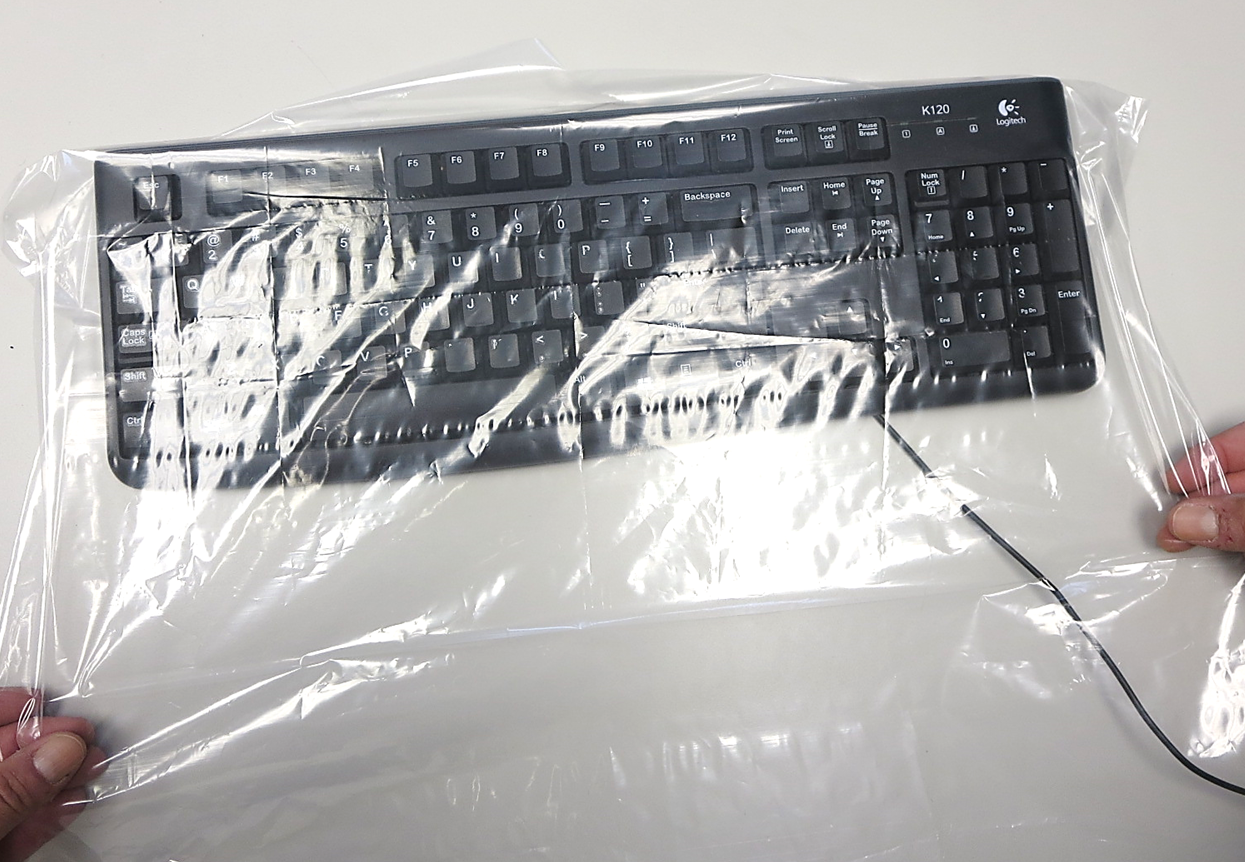

Disposable keyboard covers are a practical solution for preventing cross-contamination in environments where hygiene is paramount, such as healthcare and food service. These covers are made from clear plastic, allowing visibility and functionality while providing a barrier against germs. Buyers should evaluate the frequency of use and the potential for ongoing costs associated with single-use products when considering this option.

What Advantages Do Transparent Keyboard Skins Provide?

Transparent keyboard skins are flexible and lightweight, designed to preserve the original aesthetics of the keyboard while providing a layer of protection. They are easy to clean and maintain, making them suitable for office environments and educational institutions. Buyers should assess the balance between aesthetics and protection, as these skins may shift during use and are generally less durable than custom-fit options.

Why Choose Full-Size Keyboard Covers for Comprehensive Protection?

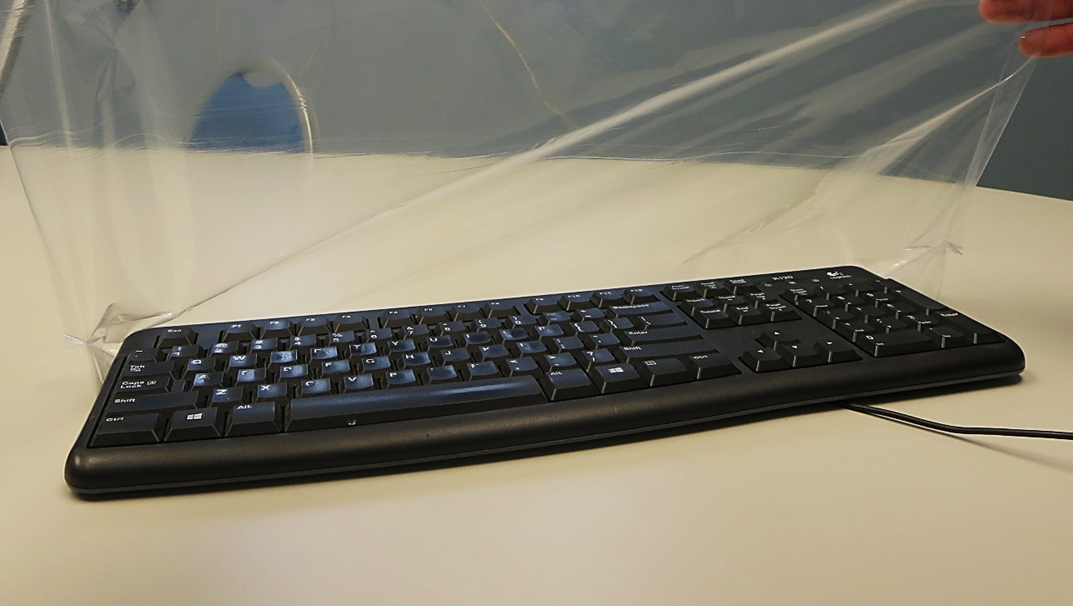

Full-size keyboard covers offer extensive protection by enveloping the entire keyboard, including function keys. They are particularly beneficial in IT departments and call centers where keyboards are exposed to frequent spills and dust. While they provide excellent coverage, buyers should consider the potential inconvenience of added bulk and how it may affect typing efficiency.

How Do Key-Specific Covers Cater to Specialized Needs?

Key-specific covers are tailored for individual keys, providing targeted protection for specialized applications such as gaming or unique workstation setups. These covers allow for customization based on specific user requirements. However, they may require more inventory management and may not offer comprehensive protection compared to other types. Buyers should weigh the benefits of customization against the limitations in scope.

Key Industrial Applications of plastic computer keyboard covers

| Industry/Sector | Specific Application of plastic computer keyboard covers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Use in hospitals and clinics to prevent cross-contamination | Reduces infection risk, ensuring patient safety | Compliance with healthcare regulations and standards |

| Food Service | Covers for keyboards in restaurants and kitchens | Maintains hygiene standards, preventing foodborne illnesses | Durability against spills and easy cleaning capabilities |

| Education | Keyboard covers in schools and universities | Protects equipment, prolongs lifespan, and enhances hygiene | Customization options for different keyboard models |

| Manufacturing | Protective covers for keyboards in industrial settings | Shields against dust and contaminants, enhancing equipment longevity | Resistance to harsh chemicals and environmental factors |

| IT Services | Use in tech support and repair shops | Ensures cleanliness and functionality of equipment | Compatibility with a variety of keyboard types |

How Are Plastic Computer Keyboard Covers Utilized in Healthcare Settings?

In healthcare environments, plastic computer keyboard covers are essential for minimizing cross-contamination. Hospitals and clinics often deal with high volumes of patients, and the risk of spreading infections through commonly used equipment is significant. These covers act as a barrier against pathogens, ensuring that keyboards remain clean and hygienic. International buyers in this sector should consider sourcing covers that meet health regulations and are made from materials that can withstand frequent disinfection without degrading.

Why Are Plastic Keyboard Covers Crucial in Food Service Industries?

In the food service sector, maintaining strict hygiene standards is paramount. Plastic keyboard covers are used in restaurants, cafes, and food processing facilities to protect keyboards from spills, crumbs, and contaminants that could lead to foodborne illnesses. The covers are easy to clean and can be disposed of after use, ensuring that food safety protocols are upheld. Buyers should prioritize covers that are durable, easy to install, and resistant to moisture and grease to suit the demanding kitchen environment.

What Role Do Keyboard Covers Play in Educational Institutions?

Educational institutions utilize plastic keyboard covers to protect equipment in computer labs and classrooms. These covers help maintain cleanliness, reducing the spread of germs among students who frequently use shared devices. They also extend the lifespan of keyboards by shielding them from dust and debris. When sourcing for schools, it’s important to consider covers that can accommodate various keyboard types and are available in bulk for cost-efficiency.

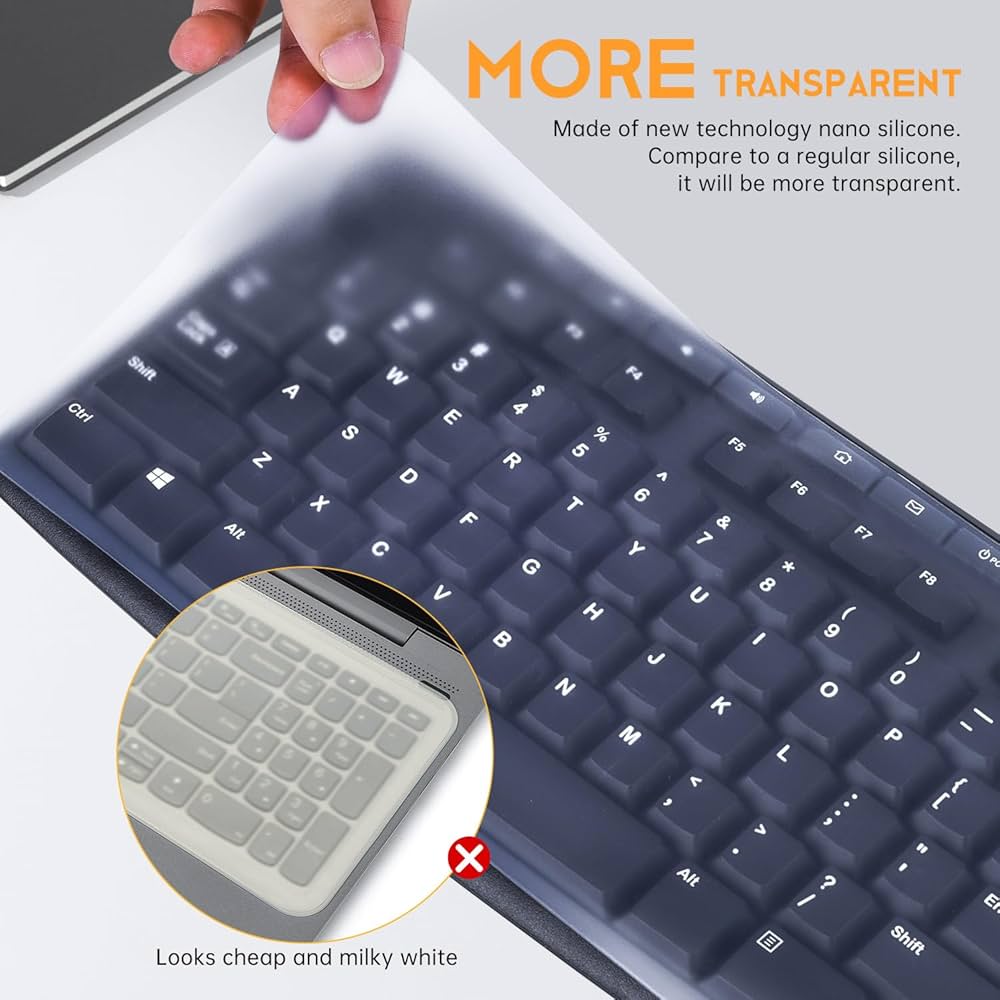

Illustrative image related to plastic computer keyboard covers

How Do Keyboard Covers Benefit Manufacturing Facilities?

In manufacturing settings, keyboard covers are vital for protecting equipment from dust, dirt, and exposure to harsh chemicals. These covers help maintain the functionality of keyboards in environments where spills and contaminants are common. By implementing protective measures, businesses can reduce maintenance costs and prolong the life of their equipment. Buyers in this sector should look for covers that are specifically designed to withstand industrial conditions and offer robust protection against environmental factors.

Why Are Plastic Keyboard Covers Important for IT Services?

For IT service providers and repair shops, plastic keyboard covers are crucial for ensuring that keyboards remain clean and operational. These covers prevent dust accumulation and protect against accidental spills, which can damage sensitive electronics. Additionally, they can enhance the overall professionalism of the service environment. Sourcing considerations should include compatibility with a wide range of keyboard models, ensuring that the covers provide a snug fit without hindering usability.

3 Common User Pain Points for ‘plastic computer keyboard covers’ & Their Solutions

Scenario 1: Ensuring Hygiene in Shared Workspaces

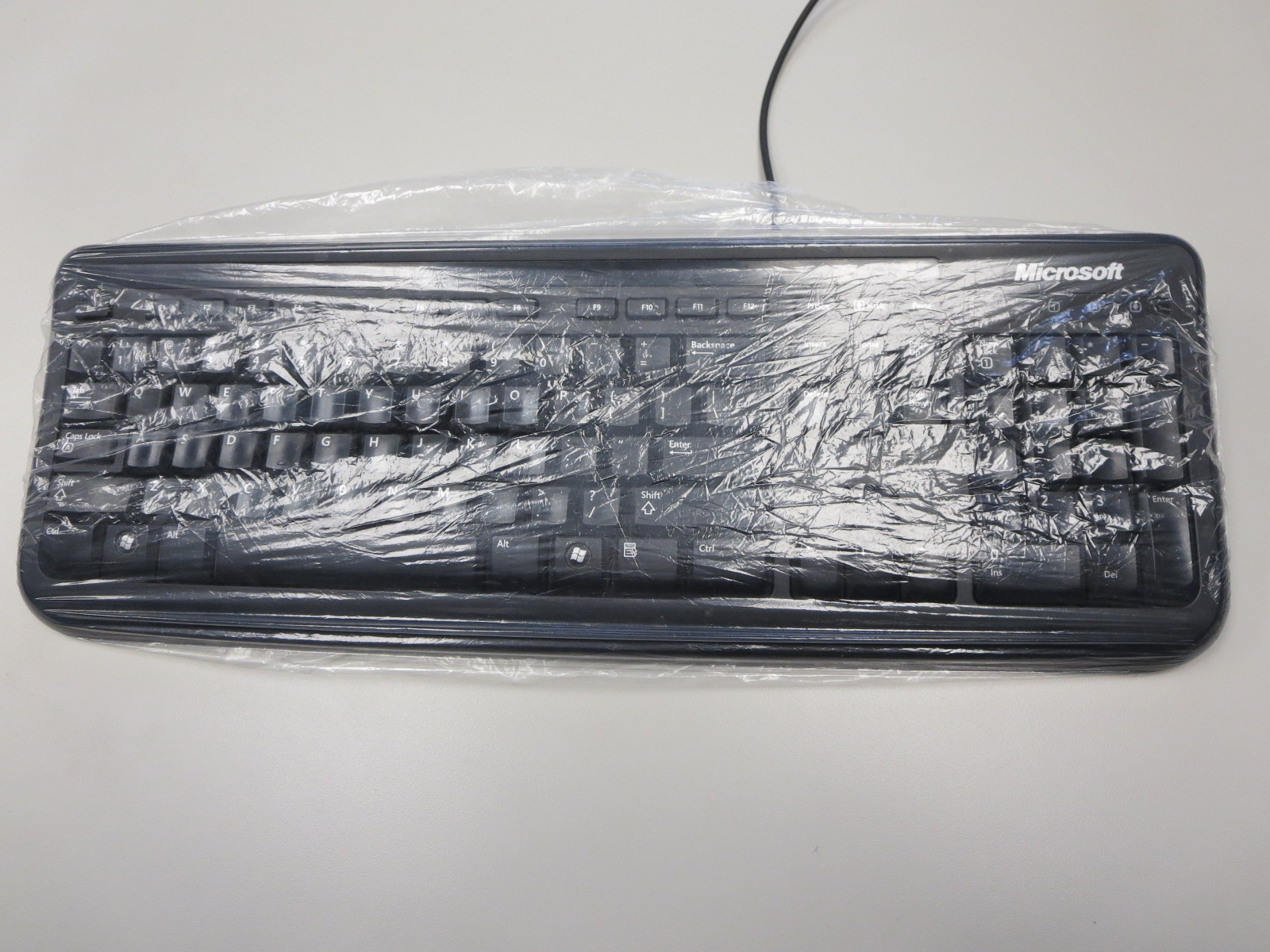

The Problem: In environments such as hospitals, schools, and coworking spaces, keyboards are frequently shared among multiple users. This raises significant hygiene concerns, as studies indicate that keyboards can harbor bacteria levels far exceeding those found on toilet seats. B2B buyers in these sectors face the challenge of maintaining a clean and safe workspace while ensuring that equipment remains functional and accessible. The fear of cross-contamination can lead to reluctance among employees and clients to use shared resources, impacting productivity and morale.

The Solution: To address this issue, B2B buyers should consider sourcing high-quality disposable plastic keyboard covers. These covers provide a protective barrier against germs while being transparent enough to allow visibility and functionality. When selecting these covers, it’s crucial to choose products that fit securely over various keyboard sizes and types, ensuring they stay in place during use. Establish a routine for replacing the covers regularly, particularly in high-traffic areas, and educate users on the importance of hygiene. Pairing the use of disposable covers with regular disinfecting practices can significantly reduce the risk of infection, fostering a safer environment for all.

Scenario 2: Protecting Equipment in Harsh Environments

The Problem: Industries such as manufacturing, automotive, and healthcare often expose equipment to dust, spills, and harsh chemicals. B2B buyers responsible for maintaining office equipment in these settings may struggle with the challenge of prolonging the lifespan of keyboards while ensuring they remain operational under tough conditions. Dust and liquid intrusion can lead to malfunctioning keys and expensive repairs or replacements, which strain budgets and disrupt workflows.

Illustrative image related to plastic computer keyboard covers

The Solution: Investing in durable, custom-fit plastic keyboard covers designed for harsh environments is essential. These covers should be crafted from high-quality materials like polyurethane, which can withstand chemicals and resist wear and tear. When sourcing these covers, buyers should specify their exact keyboard models to ensure a perfect fit, as this prevents slippage and maximizes protection. Additionally, implementing a maintenance schedule that includes periodic checks of the covers for any wear can help in identifying potential issues before they escalate. By prioritizing durability and fit, companies can protect their investments and maintain operational efficiency.

Scenario 3: Enhancing User Comfort and Experience

The Problem: Many B2B buyers overlook the impact that keyboard covers can have on user experience. Some plastic covers may feel uncomfortable or hinder typing efficiency, leading to frustration among employees. This discomfort can result in decreased productivity, particularly in industries where typing speed and accuracy are critical. Buyers need to ensure that while keyboards are protected, the typing experience remains optimal.

The Solution: To enhance user comfort, buyers should look for keyboard covers that are specifically designed to maintain a natural typing feel. Features such as a soft-touch surface or ergonomic design can significantly improve the typing experience. When sourcing these products, it’s beneficial to request samples to test how the covers feel during use before making a bulk purchase. Additionally, consider involving employees in the selection process to gather feedback on their preferences regarding texture and responsiveness. This collaborative approach not only ensures that the final choice meets user needs but also fosters a culture of inclusivity, leading to greater satisfaction and productivity in the workplace.

Strategic Material Selection Guide for plastic computer keyboard covers

What Are the Key Materials Used in Plastic Computer Keyboard Covers?

When selecting materials for plastic computer keyboard covers, it’s essential to consider various factors that affect performance, durability, and compliance with international standards. Below, we analyze four common materials used in the manufacturing of these covers, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Polyurethane Perform as a Material for Keyboard Covers?

Polyurethane is a popular choice for keyboard covers due to its excellent elasticity and durability. It can withstand a wide range of temperatures and is resistant to chemicals, making it suitable for environments such as hospitals and manufacturing facilities. The material’s flexibility allows for a snug fit over different keyboard shapes, ensuring effective protection against dust and spills.

Illustrative image related to plastic computer keyboard covers

Pros: Polyurethane offers high durability and resistance to abrasion, making it ideal for high-traffic areas. It also maintains a comfortable typing feel, which is crucial for user satisfaction.

Cons: The manufacturing process can be more complex than other materials, potentially leading to higher costs. Additionally, polyurethane may not be as biodegradable as other options, raising environmental concerns.

Impact on Application: This material is particularly compatible with keyboards used in medical and industrial settings, where hygiene and durability are paramount.

Illustrative image related to plastic computer keyboard covers

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially in regions like Europe and the Middle East, where regulations regarding material safety and environmental impact are stringent.

What Are the Benefits of Silicone in Keyboard Cover Manufacturing?

Silicone is another widely used material for keyboard covers, known for its excellent resistance to extreme temperatures and chemicals. It is inherently flexible and provides a soft touch, which enhances the typing experience.

Pros: Silicone covers are easy to clean and maintain, making them ideal for environments requiring high levels of hygiene. They are also resistant to UV light, preventing yellowing over time.

Illustrative image related to plastic computer keyboard covers

Cons: The cost of silicone can be higher than that of other materials, which may deter budget-conscious buyers. Additionally, silicone may not provide the same level of abrasion resistance as polyurethane.

Impact on Application: Silicone is particularly effective in settings where keyboards are exposed to harsh chemicals or extreme temperatures, such as laboratories.

Considerations for International Buyers: Buyers should ensure that silicone products meet relevant international standards, such as JIS in Japan and DIN in Germany, to guarantee quality and safety.

How Does PVC Compare as a Material for Keyboard Covers?

Polyvinyl chloride (PVC) is a cost-effective option for keyboard covers, offering decent durability and flexibility. It is resistant to moisture and can be manufactured in various thicknesses, allowing for customization based on specific needs.

Pros: PVC is generally less expensive than polyurethane and silicone, making it an attractive option for bulk purchasing. It is also widely available and easy to mold into different shapes.

Illustrative image related to plastic computer keyboard covers

Cons: While PVC is durable, it may not withstand extreme temperatures as effectively as silicone or polyurethane. Additionally, concerns regarding its environmental impact due to its non-biodegradable nature are growing.

Impact on Application: PVC covers are suitable for everyday office use and environments where exposure to harsh conditions is minimal.

Considerations for International Buyers: Compliance with local regulations regarding PVC use, especially in regions concerned about environmental impact, is essential for maintaining a positive brand image.

Why Choose Thermoplastic Elastomers (TPE) for Keyboard Covers?

Thermoplastic elastomers (TPE) combine the properties of rubber and plastic, offering excellent flexibility, durability, and resistance to various environmental factors. TPE is particularly favored for its ability to be recycled, making it a more sustainable option.

Illustrative image related to plastic computer keyboard covers

Pros: TPE provides a comfortable typing experience and is easy to clean, making it suitable for a variety of applications. Its recyclability aligns with growing environmental concerns.

Cons: The cost of TPE can be higher than PVC, which may be a consideration for budget-sensitive projects. Additionally, its performance can vary based on the specific formulation used.

Impact on Application: TPE is suitable for both consumer and industrial keyboards, especially in settings where sustainability is a priority.

Considerations for International Buyers: Buyers should look for TPE products that comply with ASTM or ISO standards to ensure quality and safety across different markets.

Summary Table of Material Options for Keyboard Covers

| Material | Typical Use Case for plastic computer keyboard covers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Medical and industrial environments | High durability and chemical resistance | Higher manufacturing complexity | Medium |

| Silicone | Laboratories and high-hygiene areas | Easy to clean and UV resistant | Higher cost than other materials | High |

| Polyvinyl Chloride (PVC) | Everyday office use | Cost-effective and widely available | Limited temperature resistance | Low |

| Thermoplastic Elastomers (TPE) | Consumer and industrial keyboards | Comfortable and recyclable | Higher cost than PVC | Medium |

This guide provides a comprehensive overview of the key materials available for plastic computer keyboard covers, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic computer keyboard covers

What Are the Main Stages in the Manufacturing Process of Plastic Computer Keyboard Covers?

The manufacturing of plastic computer keyboard covers involves a series of well-defined stages that ensure the final product meets quality standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Keyboard Covers?

The process begins with selecting high-quality raw materials, typically polyurethane or silicone, known for their durability and flexibility. These materials are sourced from reliable suppliers to ensure consistency in quality. Once received, the materials undergo thorough inspection for defects or impurities, which is critical to maintaining product integrity. The raw materials are then prepped through processes such as drying and cutting to specific dimensions that fit various keyboard models.

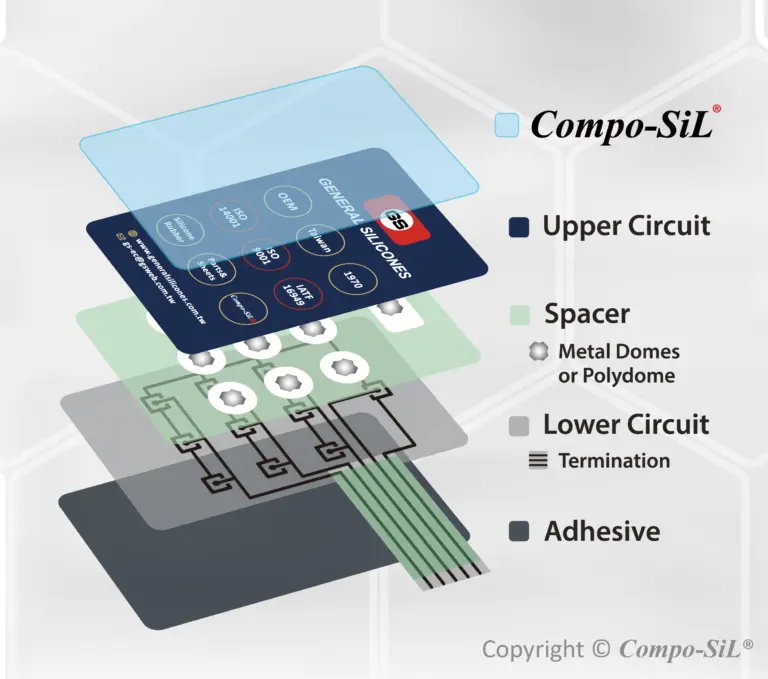

What Techniques Are Used to Form Plastic Keyboard Covers?

After material preparation, the forming stage commences. This is usually done through techniques such as injection molding or thermoforming. In injection molding, heated plastic is injected into a mold that shapes it into the desired form of the keyboard cover. This method is favored for its precision and ability to produce large volumes quickly. Thermoforming involves heating a plastic sheet until pliable and then forming it over a mold. While this method is less precise than injection molding, it allows for more complex designs and is often used for custom covers.

How Are Keyboard Covers Assembled and Finished?

The assembly process for keyboard covers may involve several steps, depending on the design complexity. For covers with additional features, such as adhesive linings or integrated touchpads, these components are attached during this stage. The finishing process includes trimming excess material, applying surface treatments for better grip, and quality checks to ensure that each cover meets the set specifications. Finally, the products are packaged carefully to avoid damage during transit, ready for distribution to clients.

What Quality Assurance Standards Are Relevant for Keyboard Covers?

Quality assurance (QA) in the manufacturing of plastic keyboard covers is paramount, particularly for B2B buyers. The most recognized international standard is ISO 9001, which outlines criteria for a quality management system. Compliance with ISO 9001 ensures that suppliers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking (indicating conformity with health, safety, and environmental protection standards) and API (American Petroleum Institute) standards for specialized applications can also be relevant, especially in sectors like healthcare and industrial manufacturing.

What Are Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential to maintaining high standards throughout the manufacturing process. These typically include:

Illustrative image related to plastic computer keyboard covers

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken for inspection. This ensures that any defects are caught early, reducing waste and rework.

- Final Quality Control (FQC): Once production is complete, a final inspection is conducted to verify that the finished products meet all specifications and quality standards before shipment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers can take several steps to verify the quality control processes of suppliers. Conducting audits is a key method; this involves reviewing the supplier’s QA processes, documentation, and compliance with international standards. Buyers can request quality reports, which should detail testing methods, results, and any corrective actions taken for non-conformance issues.

Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality practices. These inspections can take place at various stages—during raw material sourcing, in-process inspections, and final product evaluations—ensuring that the products meet agreed-upon specifications.

What Testing Methods Are Commonly Used for Quality Assurance?

Several testing methods are commonly employed to ensure the quality of plastic keyboard covers. These may include:

- Mechanical Testing: Assessing the durability and flexibility of the material through tensile strength and elongation tests.

- Chemical Resistance Testing: Evaluating how the covers react to various substances, especially important for applications in healthcare or industrial environments where exposure to chemicals is likely.

- Dimensional Inspection: Using precision instruments to ensure that the covers fit the designated keyboard models accurately.

- Environmental Testing: Simulating conditions such as extreme temperatures or humidity to evaluate how the covers perform under stress.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control when sourcing keyboard covers. Different regions may have varying compliance requirements and standards. For instance, buyers in Europe may prioritize CE marking for health and safety compliance, while buyers in the Middle East may require adherence to local standards.

Additionally, understanding tariffs, shipping logistics, and potential delays in customs clearance is crucial for ensuring timely delivery. Buyers should also consider the supplier’s ability to adapt to local regulations and the quality of customer support provided, as these factors can significantly impact the overall purchasing experience.

Illustrative image related to plastic computer keyboard covers

By comprehensively understanding the manufacturing processes and quality assurance protocols in place, B2B buyers can make informed decisions and establish long-term partnerships with reliable suppliers of plastic computer keyboard covers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic computer keyboard covers’

Introduction

Sourcing plastic computer keyboard covers requires a strategic approach to ensure you select the right products that meet your operational needs. This guide provides a step-by-step checklist for B2B buyers to facilitate informed purchasing decisions, focusing on quality, supplier reliability, and compliance with regional standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the keyboard covers meet your specific requirements. Consider factors such as material quality, dimensions, and compatibility with various keyboard models. Identify whether you need custom designs or standard sizes to streamline your procurement process.

- Material Quality: Look for high-quality materials like polyurethane that offer durability and comfort.

- Dimensions: Ensure that the covers fit the keyboards used in your organization.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in keyboard covers. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors. It’s essential to assess their market presence and customer reviews to gauge reliability.

Illustrative image related to plastic computer keyboard covers

- Industry Directories: Use platforms such as Alibaba or ThomasNet for supplier listings.

- Customer Reviews: Check for testimonials and ratings from other businesses to evaluate supplier credibility.

Step 3: Evaluate Supplier Certifications

Before finalizing any supplier, verify their certifications and compliance with international standards. Certifications can indicate quality assurance and adherence to safety regulations, which is particularly important in industries such as healthcare and manufacturing.

- ISO Certifications: Look for suppliers with ISO 9001 or similar certifications that demonstrate their commitment to quality.

- Compliance with Local Regulations: Ensure the products meet any regional compliance standards, especially if you are sourcing from international suppliers.

Step 4: Request Samples for Testing

Requesting samples from shortlisted suppliers is a vital step in the sourcing process. This allows you to assess the quality and fit of the keyboard covers before making a bulk purchase. Pay attention to the tactile feel and durability of the materials used.

- Testing for Comfort: Ensure that the cover does not hinder typing efficiency.

- Durability Assessment: Check for resistance to spills, dust, and wear over time.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier based on your evaluations, it’s time to negotiate pricing and purchase terms. Discuss bulk order discounts, payment terms, and shipping options to optimize your costs.

- Bulk Discounts: Inquire about volume pricing to reduce overall expenditure.

- Shipping Terms: Clarify shipping responsibilities and costs, especially for international transactions.

Step 6: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of the keyboard covers upon delivery. This step is crucial to ensure that the received products meet your specifications and standards.

- Inspection Checklist: Create a checklist to evaluate the quality of the delivered products.

- Feedback Loop: Establish a communication channel with the supplier for addressing any quality concerns promptly.

Step 7: Plan for Future Orders

Consider your long-term needs and establish a relationship with your chosen supplier for future orders. Discuss potential contracts or agreements that can secure favorable terms for subsequent purchases.

Illustrative image related to plastic computer keyboard covers

- Supply Chain Stability: A solid relationship can ensure consistent supply and better negotiation power.

- Adaptability: Ensure the supplier can accommodate future changes in your requirements or product specifications.

By following this structured checklist, B2B buyers can efficiently source high-quality plastic computer keyboard covers tailored to their specific needs while mitigating risks associated with procurement.

Comprehensive Cost and Pricing Analysis for plastic computer keyboard covers Sourcing

What Are the Key Cost Components in Sourcing Plastic Computer Keyboard Covers?

When sourcing plastic computer keyboard covers, understanding the cost structure is crucial for B2B buyers. The primary cost components typically include:

-

Materials: The choice of materials significantly impacts costs. High-quality polyurethane and other durable plastics may raise initial costs but can lead to longer-lasting products, thereby reducing the Total Cost of Ownership (TCO).

-

Labor: Labor costs can vary widely depending on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but be cautious of potential compromises in quality and craftsmanship.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, including utilities, rent, and administrative costs. Efficient production processes can help minimize these overheads.

-

Tooling: The initial investment in molds and tooling for custom designs can be substantial. This cost is often amortized over larger production runs, making it essential to consider Minimum Order Quantities (MOQs) when negotiating prices.

-

Quality Control (QC): Implementing stringent QC measures is vital for ensuring product reliability, especially in markets with strict compliance regulations. While this may add to costs, it helps prevent costly returns and enhances brand reputation.

-

Logistics: Transportation and shipping costs can vary depending on the chosen Incoterms and the shipping method. Consideration of local tariffs and international shipping regulations is essential to avoid unexpected expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and earn a profit. Understanding the typical margin range in your target market can aid in negotiation.

How Do Price Influencers Affect Sourcing Decisions for Keyboard Covers?

Several factors can influence the pricing of plastic keyboard covers:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating favorable terms based on anticipated demand can yield significant savings.

-

Specifications and Customization: Custom designs or specific features can increase costs. Buyers should balance the need for customization with budget constraints, ensuring that essential functionalities are prioritized.

-

Materials and Quality Certifications: The presence of certifications (e.g., ISO, CE) can add credibility and may affect pricing. Buyers should consider whether such certifications are necessary for their market.

-

Supplier Factors: The reliability and reputation of suppliers can significantly impact pricing. Established suppliers may charge a premium for their experience and quality assurance processes.

-

Incoterms: Understanding shipping terms is crucial. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence overall costs and risks associated with shipping.

What Are Effective Buyer Tips for Negotiating Keyboard Cover Prices?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, strategic negotiation can lead to better pricing and terms:

-

Conduct Market Research: Understanding prevailing market prices and trends can empower buyers during negotiations. Utilize industry reports and supplier comparisons to inform decisions.

-

Build Relationships with Suppliers: Establishing long-term relationships can often lead to better pricing, especially if suppliers see potential for repeat business. Trust and reliability are key.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with the product, including maintenance, replacement, and potential downtime.

-

Be Aware of Pricing Nuances for International Transactions: Currency fluctuations, import duties, and local market conditions can significantly affect pricing. Buyers should factor these into their budgeting and negotiations.

-

Request Samples and Bulk Discounts: Before finalizing orders, ask for samples to assess quality. Additionally, inquire about discounts for bulk purchases to maximize savings.

Conclusion

Sourcing plastic computer keyboard covers requires a detailed understanding of cost components and price influencers. By leveraging effective negotiation strategies and considering the Total Cost of Ownership, international B2B buyers can make informed decisions that align with their budget and quality requirements. Always remember that indicative prices can fluctuate due to market conditions, so ongoing vigilance is essential.

Alternatives Analysis: Comparing plastic computer keyboard covers With Other Solutions

Introduction to Alternative Solutions for Keyboard Protection

When considering keyboard protection, plastic computer keyboard covers are a popular choice due to their durability and effectiveness. However, businesses often explore various alternatives that might better align with their operational needs, budget constraints, or specific use cases. This analysis compares plastic keyboard covers with disposable keyboard covers and keyboard cleaning solutions to provide a comprehensive overview for B2B buyers.

Comparison Table

| Comparison Aspect | Plastic Computer Keyboard Covers | Disposable Keyboard Covers | Keyboard Cleaning Solutions |

|---|---|---|---|

| Performance | Excellent dust and spill protection; maintains typing feel | Good for hygiene; prevents cross-contamination | Effective in sanitizing and removing debris |

| Cost | Moderate initial investment, reusable | Lower cost per unit, single-use | Varies by product, generally low to moderate |

| Ease of Implementation | Simple to apply; tailored to specific keyboards | Quick to place; requires frequent replacement | Requires training for proper use |

| Maintenance | Minimal; can be washed | High; must be replaced after each use | Regular cleaning needed, but can be quick |

| Best Use Case | Ideal for long-term use in various environments | Best for high-traffic areas like hospitals or public offices | Suitable for environments where regular cleaning is feasible |

Detailed Breakdown of Alternatives

Disposable Keyboard Covers

Disposable keyboard covers are a practical alternative for environments where hygiene is paramount, such as healthcare facilities or shared workspaces. These covers are designed for single use, providing a barrier against germs and contaminants. The key advantages include lower upfront costs and ease of use; however, they require frequent replacements, which can lead to higher long-term costs and waste. For B2B buyers in sectors that prioritize cleanliness, disposable options are a strong contender, though they may not be as environmentally friendly.

Keyboard Cleaning Solutions

Keyboard cleaning solutions encompass a variety of products, including disinfectant sprays, wipes, and air dusters. These options are geared towards maintaining the cleanliness of keyboards without the need for physical barriers. The effectiveness of cleaning solutions can vary, but they typically excel in sanitizing surfaces and removing debris. While they may be cost-effective and easy to implement, they require regular application and may necessitate staff training to ensure proper usage. This method is best suited for environments where keyboards can be regularly maintained, such as office spaces with dedicated cleaning schedules.

Conclusion: How to Choose the Right Keyboard Protection Solution

Selecting the right keyboard protection solution depends on various factors, including the specific needs of your business, budget considerations, and the environment in which the keyboards are used. Plastic computer keyboard covers offer durability and long-term protection, making them suitable for a wide range of applications. In contrast, disposable covers excel in high-hygiene settings, while cleaning solutions are ideal for businesses that can commit to regular maintenance. By assessing these alternatives against your operational requirements, you can make an informed decision that enhances workplace hygiene and efficiency.

Essential Technical Properties and Trade Terminology for plastic computer keyboard covers

What Are the Essential Technical Properties of Plastic Computer Keyboard Covers?

When sourcing plastic computer keyboard covers, understanding their critical specifications can enhance decision-making and ensure product suitability for your business needs. Here are some essential technical properties to consider:

1. Material Composition

Most keyboard covers are made from high-quality polyurethane (PU) or polyvinyl chloride (PVC). PU is preferred for its durability and flexibility, providing excellent resistance to wear and tear while maintaining a comfortable typing experience. PVC, while slightly less flexible, is often more cost-effective and offers good protection against spills and dust.

2. Thickness

The thickness of the keyboard cover is a vital specification that influences both protection and usability. Standard thickness ranges from 0.2 mm to 0.5 mm. Thicker covers provide better protection against spills and dust but may hinder the tactile feel of the keys. Understanding the balance between protection and usability is crucial for end-user satisfaction.

3. Adhesive Properties

Some keyboard covers come with adhesive linings for secure placement. This feature prevents the cover from slipping during use, ensuring consistent protection against contaminants. The adhesive should be strong enough to hold the cover in place but not so permanent that it damages the keyboard when removed.

4. Compatibility and Fit

Keyboard covers are often designed to fit specific models or layouts. Ensuring compatibility with the intended keyboard model is essential for effective protection and user experience. Many suppliers offer customizable options to fit unique keyboard designs, which can be beneficial for businesses with specific requirements.

5. Transparency and Visibility

A transparent cover allows users to see the keyboard layout while offering protection. This feature is particularly important in environments where visibility is crucial, such as healthcare settings. Buyers should assess the clarity and optical quality of the material to ensure that it does not distort visibility.

6. Chemical Resistance

In industrial settings, keyboard covers may be exposed to various chemicals. Selecting a cover with high chemical resistance is critical for protecting both the keyboard and the user. This property is particularly relevant in sectors such as healthcare, automotive, and food services, where exposure to harsh substances is common.

Which Trade Terms Are Important When Sourcing Plastic Keyboard Covers?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common trade terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of keyboard covers, an OEM may supply customized covers for a specific brand of keyboards. Understanding OEM relationships can help buyers identify quality suppliers and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it can affect inventory levels and cash flow. Knowing the MOQ can assist businesses in planning their purchases effectively.

Illustrative image related to plastic computer keyboard covers

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. Including detailed specifications in an RFQ can help ensure that the received quotes meet your business requirements, enabling better comparisons and decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping agreements. Familiarity with these terms can help businesses navigate logistics, costs, and risks associated with importing keyboard covers from overseas suppliers. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight).

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is critical for inventory management, especially when dealing with international suppliers where delays can occur due to customs or shipping issues.

6. Customization

Customization involves modifying standard products to meet specific customer requirements. For keyboard covers, this may include alterations in size, shape, or material. Knowing your customization options can provide competitive advantages in niche markets or specialized applications.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing plastic computer keyboard covers, ensuring that they meet their operational needs while maximizing value.

Navigating Market Dynamics and Sourcing Trends in the plastic computer keyboard covers Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Computer Keyboard Covers Sector?

The plastic computer keyboard covers market is experiencing significant growth, driven by an increasing focus on hygiene and equipment longevity across various sectors, including healthcare, education, and corporate environments. Global drivers such as the rise in remote work and heightened awareness of germ transmission have fueled demand for protective solutions. In regions like Africa, South America, the Middle East, and Europe, particularly in countries such as Saudi Arabia and Germany, buyers are increasingly looking for products that not only protect keyboards but also enhance user experience through custom designs and ergonomic features.

Emerging trends include the adoption of disposable keyboard covers, which offer convenience and ease of use in high-traffic areas, such as hospitals and educational institutions. B2B buyers are also gravitating towards customizable options that cater to specific keyboard models, allowing for better fit and protection. Additionally, there is a growing preference for covers that provide tactile comfort while maintaining durability against spills, dust, and wear. Buyers are increasingly utilizing e-commerce platforms to streamline their sourcing processes, seeking bulk purchasing options and competitive pricing, which can significantly impact their procurement strategies.

How Is Sustainability and Ethical Sourcing Impacting B2B Purchases of Plastic Keyboard Covers?

Sustainability is becoming a critical consideration in the sourcing of plastic computer keyboard covers. B2B buyers are increasingly aware of the environmental impact of their purchasing decisions, prompting a shift toward suppliers that prioritize eco-friendly materials and practices. The use of biodegradable plastics or recycled materials is gaining traction, aligning with global sustainability goals and consumer demand for greener products.

Illustrative image related to plastic computer keyboard covers

Moreover, ethical sourcing practices are essential for building trust and long-term relationships with suppliers. Buyers are encouraged to evaluate the supply chain transparency of their manufacturers, ensuring that they adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and other green certifications can serve as indicators of a supplier’s commitment to sustainable practices. By prioritizing these factors, international buyers can not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally conscious consumers.

What Is the Brief Evolution and History of Plastic Keyboard Covers in the B2B Sector?

The evolution of plastic keyboard covers began in the early 2000s, primarily as a response to the increasing need for protection against dust and spills in both commercial and residential settings. Initially, these covers were simple, transparent plastic sheets designed to safeguard keyboards from dirt. Over the years, advancements in material technology have led to the development of more sophisticated products that offer enhanced durability, comfort, and a better fit for various keyboard models.

With the rise of digital technology and the growing prevalence of computer usage in workplaces, the demand for protective solutions has surged. This shift has paved the way for innovations in design, including features such as antimicrobial properties and custom fitting for specific keyboard types. As the market continues to evolve, suppliers are focusing on integrating sustainability into their product offerings, reflecting the changing priorities of B2B buyers who are increasingly seeking environmentally responsible solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic computer keyboard covers

-

1. How do I choose the right plastic keyboard cover for my business needs?

When selecting a plastic keyboard cover, consider the specific keyboard models your team uses, as well as the environment in which they operate. Look for covers that offer protection against dust, spills, and wear, while ensuring they maintain a comfortable typing experience. Custom-engineered options that fit your keyboard layout precisely can enhance usability. Additionally, evaluate the material’s durability and resistance to chemicals, especially if your workplace is in a healthcare or industrial setting. -

2. What are the benefits of using disposable keyboard covers for my office?

Disposable keyboard covers offer a hygienic solution to prevent the spread of germs, especially in shared workspaces. They are particularly valuable in environments like hospitals and schools, where cleanliness is paramount. These covers can significantly reduce the bacterial load on keyboards, making them safer for users. Their convenience allows for easy replacement and maintenance, ensuring that keyboards remain clean and protected without the need for extensive cleaning protocols. -

3. What is the minimum order quantity (MOQ) for plastic keyboard covers?

MOQs for plastic keyboard covers can vary widely depending on the supplier and the specific product. Typically, MOQs range from 100 to 1,000 units. It’s advisable to communicate directly with suppliers to negotiate terms that suit your purchasing needs. If your order is large enough, you may also be able to secure better pricing or additional customization options, which can be beneficial for larger businesses or institutions. -

4. How can I ensure the quality of plastic keyboard covers from international suppliers?

To ensure quality, start by vetting suppliers through online reviews, certifications, and references from previous clients. Request samples of the keyboard covers to assess their material quality and fit. Additionally, inquire about their quality assurance processes, including testing for durability and compliance with international standards. Establishing clear quality expectations in your purchase agreement can also help maintain standards throughout the transaction. -

5. What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary significantly among suppliers and regions. Common terms include payment in advance, letters of credit, or payment upon delivery. It’s crucial to discuss and agree on terms before finalizing any order to prevent misunderstandings. Be aware of any potential currency exchange risks and additional fees that might apply. Establishing a reliable relationship with your supplier can also lead to more favorable payment arrangements over time. -

6. How do I handle shipping and logistics for keyboard covers sourced internationally?

When sourcing keyboard covers internationally, consider logistics factors such as shipping methods, delivery timelines, and customs regulations. Work with suppliers who have experience in international shipping to minimize delays. It may be beneficial to partner with a freight forwarder who can manage the logistics, ensuring compliance with import/export laws and handling customs documentation. Always factor in shipping costs when calculating the total price of your order. -

7. Can I customize plastic keyboard covers with my company logo?

Yes, many suppliers offer customization options, including the ability to print your company logo on keyboard covers. This can enhance brand visibility and create a cohesive look in your workspace. Discuss your design requirements with potential suppliers, including color, size, and placement of the logo. Keep in mind that customized orders may require a higher MOQ and longer lead times, so plan accordingly. -

8. What are the common uses of plastic keyboard covers in various industries?

Plastic keyboard covers are widely used across multiple industries for their protective benefits. In healthcare settings, they help maintain hygiene and prevent cross-contamination. In manufacturing and industrial environments, they protect keyboards from dust and spills. Educational institutions use them to extend the life of shared equipment. Understanding the specific needs of your industry can help you choose the right type of cover, ensuring that it meets both functional and compliance standards.

Top 8 Plastic Computer Keyboard Covers Manufacturers & Suppliers List

1. PROTECTCOVERS® – Logitech K600 TV Keyboard Cover

Domain: protectcovers.com

Registered: 1998 (27 years)

Introduction: Product Name: PROTECTCOVERS® Logitech K600 TV Keyboard Cover with integrated touchpad, Price: $17.19, Availability: Unavailable; Product Name: PROTECTCOVERS® Microsoft Wireless 3050 Keyboard Cover, Price: $18.19, Availability: Unavailable; Product Name: PROTECTCOVERS® DELL KB525C Wired USB Keyboard Cover, Price: $18.19, Availability: Unavailable; Product Name: PROTECTCOVERS® Adesso AKB-110B Mini K…

2. MDS Associates – Clear Protection® Keyboard Covers

Domain: mdsassociates.com

Registered: 2002 (23 years)

Introduction: Product Name: Clear Protection® Disposable Computer Keyboard Covers, Tapered Edge 22in x 14in (250ct)\nProduct Code: 33-PS400\nSize: 22″W x 14″L\nPacked: 250 per box (2 box minimum order)\nFeatures: Single-use surface barriers, prevents the spread of germs, clear plastic for visibility, tapered end for secure fit.\nPrice: $17.40\nShipping: Free shipping on orders over $499; shipping costs vary bas…

3. Fentek – Keyboard and Laptop Covers

Domain: fentek-ind.com

Registered: 1997 (28 years)

Introduction: Product: Keyboard Covers and Laptop Covers

Material: Thin soft polyurethane

Features:

– Form fitted around each key

– Allows full use of keyboard without interfering with typing speed or accuracy

– Seals wrap around the edge of keyboard/laptop for additional protection

– Soft and flexible, cleans with soap and water

– Transparent for full visibility of keys

– Custom fit and universal fit options …

4. Medicus Health – Medical Keyboard Covers

Domain: medicus-health.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “Medical Keyboard Covers”, “description”: “Keyboard Covers use protective covers on keyboards to make disinfection easier. Protects your Keyboard from contamination and the spread of germs while permitting disinfection. In medical environment it is necessary to maintain strict protocols for infection prevention. Our keyboard covers offer a simple and affordable solution that helps…

5. Reddit – Mechanical Keyboard Care

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Mechanical Keyboard Care, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Techprotectus – Laptop Case with Keyboard Cover and Screen Protector

Domain: staples.com

Registered: 1995 (30 years)

Introduction: Techprotectus Laptop Case with Keyboard Cover and Screen Protector, available in various colors and models for different MacBook Pro and MacBook Air versions. Features include: hard shell cover, keyboard cover, screen protector, compatibility with specific MacBook models, lightweight plastic construction, rubberized feet for air circulation, and prices ranging from $33.19 to $40.79.

7. WetKeys – Seal Shield Clean-Wipe Medical Grade Keyboard Cover

Domain: wetkeys.com

Registered: 2007 (18 years)

Introduction: Keyboard and Laptop Covers – Disposable & Reusable Covers, Drapes, Protectors for Medical & Healthcare, Laboratory, Food Processing, Manufacturing and Industrial. Top Selling & Featured Products include: 1. Seal Shield Clean-Wipe Medical Grade “Chiclet” Keyboard Cover, Antimicrobial (Silicone Cover Only) (Clear) | MSRP: $15.99 2. Man and Machine Cool-Drape All Purpose Keyboard Covers, Laptop Drape…

8. BE Publishing – NO-PEEK Keyboard Covers

Domain: bepublishing.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “NO-PEEK Keyboard Covers”, “price”: “$25.95”, “bulk_pricing”: {“10-20”: “$25.95 ea.”, “21-40”: “$24.95 ea.”, “41-99”: “$22.95 ea.”, “100+”: “Call or email for volume pricing. $19.95 ea.”}, “description”: “NO-PEEK ™ Keyboard Covers rest easily over all standard keyboards to allow for ‘no-peek’ touch-typing. By not looking at their keys, your students will increase their typing spee…

Strategic Sourcing Conclusion and Outlook for plastic computer keyboard covers

What Are the Key Takeaways for B2B Buyers of Plastic Computer Keyboard Covers?

In summary, strategic sourcing of plastic computer keyboard covers offers significant advantages for businesses aiming to enhance workplace hygiene, extend equipment lifespan, and improve operational efficiency. By selecting high-quality, tailored keyboard covers, international buyers can effectively protect their investments from dust, spills, and wear, while also addressing critical health concerns associated with germ transmission in shared environments. The availability of disposable options further supports cleanliness in high-traffic areas, making them ideal for industries such as healthcare, education, and corporate offices.

How Can You Enhance Your Procurement Strategy?

As you consider your procurement strategy, remember that building relationships with reliable suppliers is essential. Focus on vendors who offer customizable solutions, competitive pricing, and robust customer service to ensure that your needs are met efficiently. Staying informed about market trends, such as the ongoing impact of tariffs and supply chain dynamics, will empower you to make informed decisions that align with your business goals.

Illustrative image related to plastic computer keyboard covers

What’s Next for Your Business in Sourcing Keyboard Covers?

Looking ahead, the demand for plastic keyboard covers is expected to grow, driven by heightened awareness of hygiene and the increasing reliance on technology across various sectors. Now is the time for B2B buyers in Africa, South America, the Middle East, and Europe to capitalize on these opportunities. By investing in quality keyboard protection solutions, you can safeguard your workforce and enhance productivity. Engage with suppliers today to explore innovative options tailored to your specific needs and stay ahead in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.