Choosing Your Plastic Cap: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for plastic cap

In today’s competitive landscape, sourcing high-quality plastic caps poses significant challenges for international B2B buyers. With various materials, designs, and sizes available, the process can be overwhelming, especially for companies in regions such as Africa, South America, the Middle East, and Europe. This comprehensive guide aims to demystify the global market for plastic caps, providing insights into types, applications, supplier vetting, and cost considerations.

Buyers will discover the importance of selecting the right materials, such as LDPE and TPE, which not only affect product performance but also influence cost and sustainability. Furthermore, understanding the specific applications of different cap types—whether for threaded or non-threaded tubing—ensures that businesses can make informed decisions tailored to their operational needs.

This guide empowers B2B buyers by offering actionable strategies for evaluating suppliers, ensuring compliance with regional regulations, and optimizing procurement processes. By equipping decision-makers with the knowledge necessary to navigate the complexities of the plastic cap market, we aim to facilitate smarter purchasing choices that align with their business objectives. Whether you’re sourcing for a manufacturing facility in Nigeria or a distribution center in Vietnam, this guide is your essential resource for achieving success in your procurement endeavors.

Understanding plastic cap Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Round Plastic Caps | Available in various sizes, snug fit for tubing | Packaging, transportation, manufacturing | Pros: Versatile, cost-effective. Cons: Limited customization options. |

| Knurled Top Plastic Caps | Textured surface for easy grip | Industrial applications, assembly lines | Pros: Enhanced handling, secure fit. Cons: Slightly higher cost. |

| Tapered Plastic Caps | Conical shape for a tight seal | Bottling, medical devices, food packaging | Pros: Excellent sealing properties. Cons: May require specific sizing. |

| Colored Plastic Caps | Available in various colors for easy identification | Branding, inventory management | Pros: Improves product visibility. Cons: Color options may be limited. |

| Threaded Plastic Caps | Designed for screw-on applications | Automotive, plumbing, and electrical sectors | Pros: Secure connection, reusable. Cons: Requires precise threading. |

What Are the Characteristics of Straight Round Plastic Caps?

Straight round plastic caps are among the most versatile options available. They are designed to fit snugly over threaded and non-threaded tubing, making them suitable for a variety of applications such as packaging, transportation, and manufacturing. Their availability in multiple sizes ensures that businesses can find a suitable fit for different tubing dimensions. When purchasing, buyers should consider the material, typically low-density polyethylene (LDPE), which offers a good balance between durability and cost-effectiveness.

How Do Knurled Top Plastic Caps Enhance Usability?

Knurled top plastic caps feature a textured surface that provides enhanced grip, making them ideal for industrial applications and assembly lines where ease of handling is crucial. These caps can be used in settings where frequent removal and replacement are necessary, such as in machinery or equipment maintenance. Buyers should evaluate the specific environments in which these caps will be used to ensure they meet handling requirements and consider the slightly higher cost compared to plain caps.

Why Choose Tapered Plastic Caps for Sealing?

Tapered plastic caps are designed with a conical shape that provides a tight seal, making them particularly effective in applications such as bottling, medical devices, and food packaging. Their sealing properties help prevent contamination and ensure product integrity during transportation and storage. When considering tapered caps, businesses should focus on the specific size requirements and the compatibility of the cap material with the product being sealed.

What Are the Benefits of Using Colored Plastic Caps?

Colored plastic caps serve a dual purpose: they enhance product visibility and assist in inventory management. By utilizing different colors, companies can easily identify various products or batches, streamlining operations. This feature is particularly beneficial in large warehouses or production facilities. However, buyers should be aware that color options may be limited, and they should confirm the availability of their desired colors before purchasing.

How Do Threaded Plastic Caps Provide Secure Connections?

Threaded plastic caps are specifically designed for screw-on applications, making them essential in sectors such as automotive, plumbing, and electrical. Their threaded design ensures a secure connection, allowing for reuse in applications where disassembly is required. Buyers should ensure that the threads are compatible with the corresponding fittings and consider the durability of the material to withstand repeated use.

Key Industrial Applications of plastic cap

| Industry/Sector | Specific Application of Plastic Cap | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Sealing Bottles and Containers | Prevents contamination and preserves product integrity | Material compatibility, size precision, and sealing effectiveness |

| Automotive | Protective Caps for Engine Components | Safeguards against dust and moisture during transport | Resistance to heat, vibration stability, and durability |

| Pharmaceuticals | Closure for Medication Bottles | Ensures product safety and compliance with regulations | Tamper-evidence features, material safety, and customization options |

| Construction | Caps for Pipe Ends and Tubing | Protects against damage and contamination during storage | UV resistance, fit for various pipe sizes, and material strength |

| Electronics | End Caps for Wires and Connectors | Prevents dust ingress and short circuits | Electrical insulation properties, size accuracy, and heat resistance |

How are Plastic Caps Used in Packaging and What Problems Do They Solve?

In the packaging industry, plastic caps are essential for sealing bottles and containers, ensuring that products remain uncontaminated and maintain their integrity during storage and transport. These caps are designed to fit various bottle sizes and shapes, providing a snug seal that prevents leakage. For international buyers, sourcing caps that are compatible with local packaging standards and regulations is crucial. Additionally, businesses should consider the materials used to ensure they meet safety standards for food and beverage applications.

What Role Do Plastic Caps Play in the Automotive Sector?

In the automotive industry, plastic caps are widely used to protect engine components from dust and moisture during transport and storage. These caps act as barriers, preventing contaminants from entering sensitive parts, which could lead to performance issues or damage. Buyers in this sector should prioritize sourcing caps that offer heat resistance and durability, as automotive environments can be harsh. Ensuring the right fit for various engine components is also essential to avoid any gaps that could compromise protection.

How are Plastic Caps Critical in Pharmaceuticals?

In the pharmaceutical sector, plastic caps serve as closures for medication bottles, providing critical tamper-evidence and ensuring compliance with health regulations. These caps help maintain the safety and efficacy of medications by preventing contamination and leakage. International buyers must pay close attention to the materials used in these caps, as they should be compliant with safety standards and regulations in their respective markets. Customization options, such as child-resistant features, can also be a significant consideration for buyers.

What Applications Exist for Plastic Caps in Construction?

In construction, plastic caps are utilized to protect the ends of pipes and tubing from damage and contamination. These caps can prevent debris from entering open pipe ends, which is crucial for maintaining the integrity of the plumbing systems being installed. Buyers should consider the UV resistance and material strength of these caps, especially for outdoor applications. Sourcing caps that fit various pipe sizes accurately is also important to ensure effective protection during storage and transit.

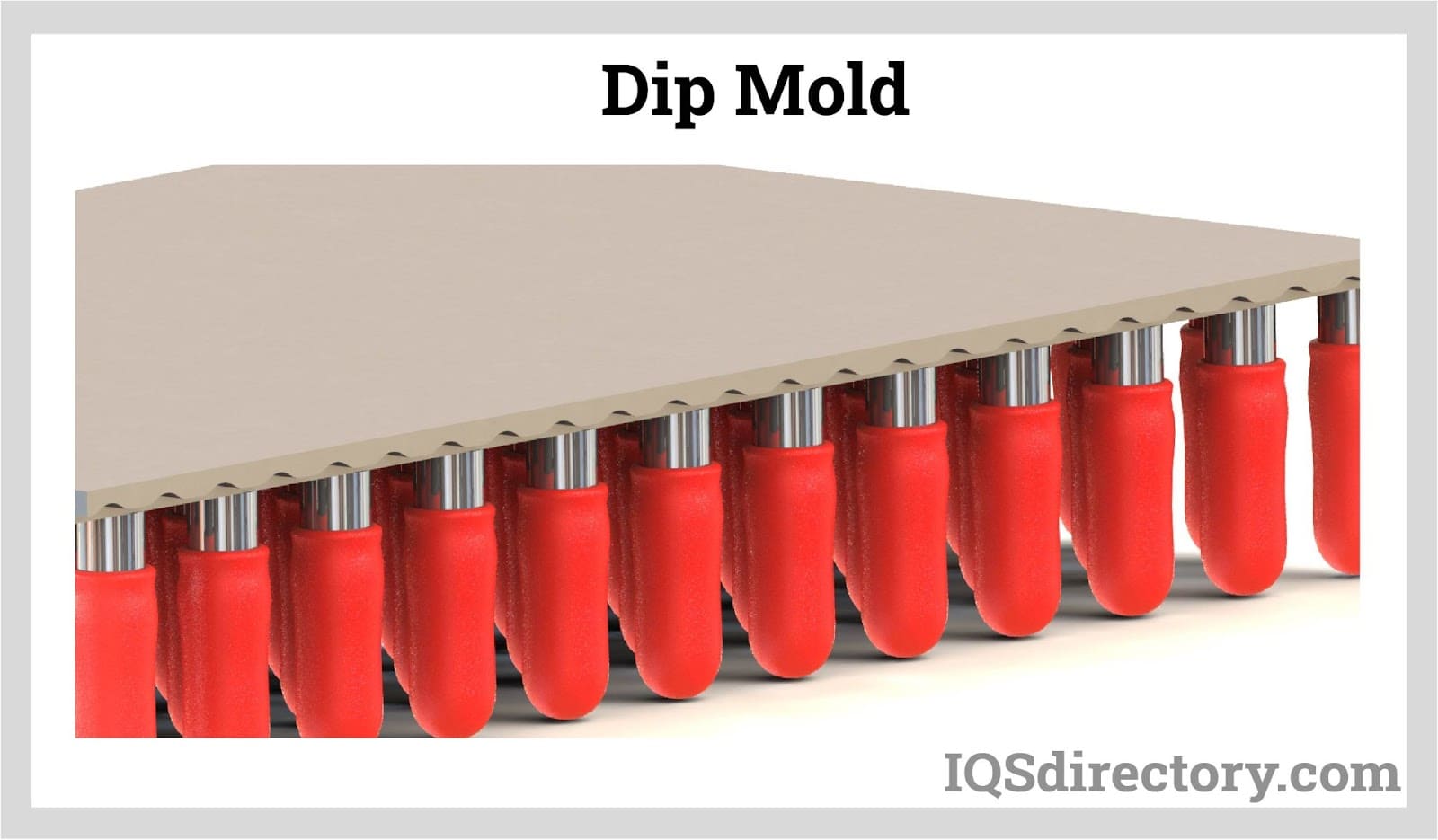

Illustrative image related to plastic cap

How Do Plastic Caps Benefit the Electronics Industry?

In the electronics sector, plastic caps are used as end caps for wires and connectors, serving to prevent dust ingress and short circuits. These caps are vital for maintaining the functionality and longevity of electronic components. Buyers in this industry should focus on sourcing caps with excellent electrical insulation properties and heat resistance to withstand operational conditions. Precision in size is also critical to ensure a secure fit that offers optimal protection.

3 Common User Pain Points for ‘plastic cap’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Fit for Tubing and Rods

The Problem: Many B2B buyers encounter challenges in sourcing plastic caps that perfectly fit their specific tubing or rod sizes. This is particularly relevant for industries like manufacturing, pharmaceuticals, and food and beverage, where the integrity of the product is paramount. An incorrect fit can lead to product contamination, loss of material, or increased operational downtime due to the need for replacements. Buyers often struggle with inconsistent sizing information and variations in manufacturing standards across suppliers, which exacerbates the issue.

The Solution: To ensure you find the right fit, it is essential to start with precise measurements of your tubing or rods. Utilize a caliper to measure the outside diameter and length accurately. Once you have these specifications, consult a reputable supplier with a comprehensive size chart for plastic caps, such as those that offer a wide range of options in materials like Low-Density Polyethylene (LDPE) and Thermoplastic Elastomer (TPE). It’s advisable to request samples before making a bulk purchase to verify the fit. Additionally, consider working with suppliers that provide custom solutions or have a robust inventory system to ensure you can quickly find the right caps for your needs.

Scenario 2: Concerns About Material Compatibility and Safety

The Problem: B2B buyers often face uncertainty regarding the compatibility of plastic cap materials with the substances they are sealing. For example, in the food and beverage industry, using a cap made from non-food-grade plastic can lead to health risks and regulatory issues. Similarly, in the pharmaceutical sector, the wrong material can compromise product integrity. This concern is heightened when sourcing from international suppliers, where standards may differ significantly.

Illustrative image related to plastic cap

The Solution: To mitigate these risks, prioritize suppliers that offer detailed information on the materials used in their plastic caps, including compliance with international safety standards such as FDA regulations for food-grade materials or ISO certifications for pharmaceuticals. Implement a rigorous vetting process for suppliers that includes checking their material safety data sheets (MSDS) and certifications. If you are dealing with highly specialized applications, don’t hesitate to engage in discussions with suppliers about your specific needs. Many companies are willing to conduct tests or provide additional documentation to reassure buyers of the safety and compatibility of their products.

Scenario 3: Supply Chain Disruptions Leading to Delayed Production

The Problem: Global supply chain disruptions can lead to significant delays in receiving plastic caps, impacting production schedules and customer satisfaction. Buyers may find themselves facing unexpected lead times, particularly when relying on single-source suppliers. This situation can create a domino effect, slowing down operations and increasing costs due to last-minute sourcing or emergency orders.

The Solution: To safeguard against supply chain disruptions, it is crucial to diversify your supplier base. Establish relationships with multiple suppliers across different regions to mitigate the risk of shortages. Additionally, implementing a just-in-time inventory system can help manage stock levels effectively, ensuring you have enough caps on hand without overcommitting capital. Consider engaging in long-term contracts with suppliers for critical components, which may provide better pricing and guaranteed availability. Regularly reviewing your supply chain strategy and staying informed about market trends can also help you anticipate potential disruptions and adapt accordingly.

Strategic Material Selection Guide for plastic cap

What Are the Key Properties of Common Materials Used for Plastic Caps?

When selecting materials for plastic caps, understanding the properties of each option is crucial for ensuring optimal performance in various applications. Here, we analyze four common materials: Low-Density Polyethylene (LDPE), Thermoplastic Elastomer (TPE), Polypropylene (PP), and Polyvinyl Chloride (PVC).

Low-Density Polyethylene (LDPE)

LDPE is widely used for plastic caps due to its flexibility and chemical resistance. It can withstand temperatures up to 80°C and offers excellent impact resistance, making it suitable for various environments.

Pros: LDPE is cost-effective, easy to manufacture, and provides a snug fit for both threaded and non-threaded applications. Its lightweight nature also contributes to reduced shipping costs.

Cons: While LDPE is durable, it may not perform well under high-temperature conditions beyond its rating. Additionally, it is less rigid than other materials, which might limit its use in applications requiring structural integrity.

Impact on Application: LDPE is compatible with a range of media, including oils and some chemicals, making it ideal for industries such as food and beverage, cosmetics, and pharmaceuticals.

Considerations for International Buyers: Compliance with international standards such as ASTM and FDA regulations is essential, especially in regions like Africa and Europe where food safety is paramount.

Thermoplastic Elastomer (TPE)

TPE combines the properties of rubber and plastic, providing excellent elasticity and flexibility. It can handle temperatures ranging from -50°C to 120°C, making it suitable for diverse applications.

Pros: TPE offers superior sealing capabilities and is resistant to UV light and ozone, enhancing its longevity. It is also recyclable, aligning with sustainability goals.

Cons: TPE can be more expensive than traditional plastics, which may affect budget-sensitive projects. Its manufacturing process can also be more complex, requiring specialized equipment.

Impact on Application: TPE is particularly effective in applications involving dynamic seals, such as in automotive or electronic components, where flexibility and durability are critical.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations, especially in regions with stringent recycling laws, such as Europe.

Polypropylene (PP)

Polypropylene is known for its high chemical resistance and ability to withstand temperatures up to 100°C. It is lightweight yet strong, making it a popular choice for various industrial applications.

Pros: PP is highly durable, resistant to fatigue, and offers excellent moisture barrier properties. Its low cost and ease of processing make it an attractive option for mass production.

Cons: While PP is robust, it can become brittle at lower temperatures, which may limit its use in colder climates. Additionally, it may not be suitable for applications involving prolonged exposure to certain solvents.

Illustrative image related to plastic cap

Impact on Application: PP is commonly used in packaging, automotive components, and medical devices, where its chemical resistance is a significant advantage.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility of PP with the intended media, as well as any relevant industry standards.

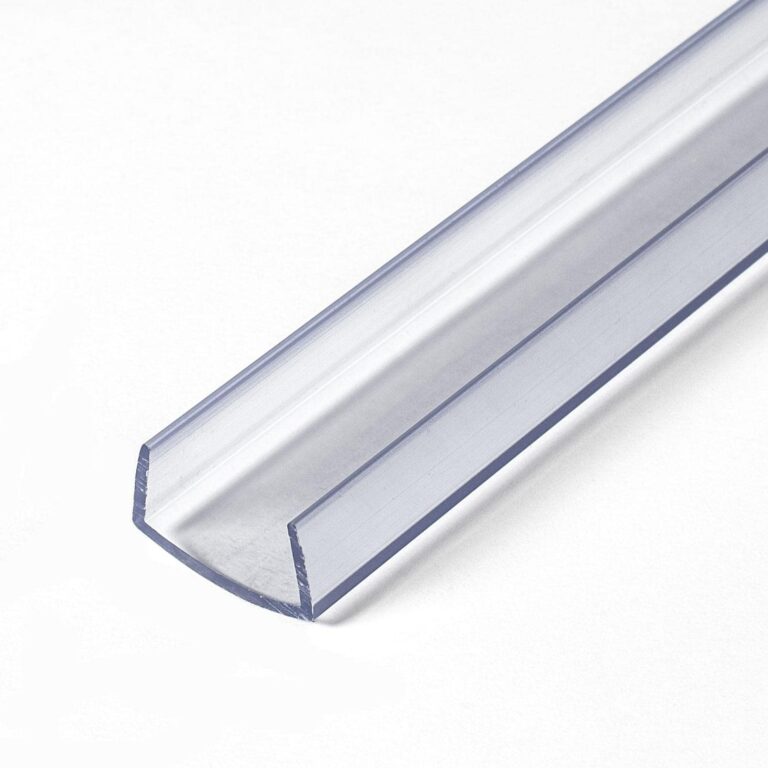

Polyvinyl Chloride (PVC)

PVC is a versatile material known for its rigidity and strength, often used in construction and plumbing applications. It can handle temperatures up to 60°C.

Pros: PVC is cost-effective and offers excellent resistance to corrosion and abrasion, making it suitable for harsh environments. Its availability in various grades allows for tailored applications.

Cons: PVC can be less flexible than other materials, which may limit its use in applications requiring bending or stretching. Additionally, it may release harmful chemicals during production and disposal.

Impact on Application: PVC is ideal for applications in construction, electrical insulation, and plumbing, where strength and durability are essential.

Considerations for International Buyers: Compliance with local regulations regarding the use of PVC, especially in food-related applications, is crucial for buyers in regions like Africa and the Middle East.

Summary Table of Material Selection for Plastic Caps

| Material | Typical Use Case for Plastic Cap | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Food and beverage, cosmetics | Cost-effective and flexible | Limited high-temperature performance | Low |

| Thermoplastic Elastomer (TPE) | Automotive, electronics | Excellent elasticity and UV resistance | Higher cost and complex manufacturing | High |

| Polypropylene (PP) | Packaging, automotive, medical devices | Durable and moisture-resistant | Brittle in low temperatures | Med |

| Polyvinyl Chloride (PVC) | Construction, plumbing | Cost-effective and corrosion-resistant | Less flexible and potential toxicity | Low |

This guide provides a comprehensive overview of material options for plastic caps, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic cap

What Are the Key Stages in the Manufacturing Process of Plastic Caps?

The manufacturing process of plastic caps typically consists of several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing plastic caps involves selecting the appropriate materials. Commonly used materials include Low-Density Polyethylene (LDPE) and Thermoplastic Elastomer (TPE), which provide flexibility and durability. The material is sourced in bulk and is often subjected to quality checks to ensure it meets the necessary specifications. This step may also involve granulating or pelletizing the raw materials to prepare them for processing.

How Are Plastic Caps Formed?

The forming stage utilizes various techniques depending on the complexity and design of the caps. The most prevalent methods include injection molding and blow molding:

-

Injection Molding: This technique is often used for producing high volumes of caps with intricate designs. The raw material is heated until molten and injected into a mold, where it cools and solidifies into the desired shape. This method is efficient and provides consistent quality.

-

Blow Molding: Primarily used for hollow caps, blow molding involves inflating a heated plastic tube inside a mold to create the cap’s shape. This method is beneficial for producing caps that require a lightweight structure.

What Does the Assembly Stage Involve?

After forming, the caps may require assembly, especially if they consist of multiple components or features (e.g., seals or closures). Automated assembly lines are often employed to enhance efficiency, but manual assembly may be necessary for specialized designs or quality control.

How Is the Finishing Process Conducted?

Finishing processes include trimming, surface treatment, and printing. Trimming removes any excess material from the molding process, while surface treatments may involve applying coatings or treatments to enhance durability or appearance. Additionally, printing techniques are often employed to add branding or labeling to the caps, which is essential for market differentiation.

What Quality Assurance Measures Are Essential in Plastic Cap Manufacturing?

Quality assurance (QA) is a pivotal aspect of plastic cap production, ensuring that the final products meet international standards and customer expectations.

Which International Standards Should B2B Buyers Look For?

For B2B buyers, understanding the relevant international standards is crucial. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system (QMS). It is essential for suppliers to adhere to this standard to demonstrate their commitment to quality and customer satisfaction. Additionally, specific industries may require compliance with standards like CE marking for safety or API specifications for caps used in oil and gas applications.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint evaluates the quality of raw materials before they enter production. It ensures that materials meet predefined specifications and standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC monitors various parameters, including temperature, pressure, and cycle times, to ensure consistency and quality in production.

-

Final Quality Control (FQC): After the caps are produced, FQC involves comprehensive testing and inspection of the final products to ensure they meet quality standards and specifications before shipment.

What Common Testing Methods Are Used to Ensure Quality?

Various testing methods are employed to verify the quality and functionality of plastic caps:

-

Dimensional Inspection: This process checks the physical dimensions of the caps against specified tolerances.

-

Material Testing: Tests such as tensile strength, impact resistance, and thermal stability are conducted to ensure the caps can withstand the intended use.

-

Leak Testing: For caps designed to seal containers, leak testing is vital to ensure they meet performance criteria.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive measures to verify the quality control practices of potential suppliers. Here are some effective strategies:

Illustrative image related to plastic cap

-

Conduct Audits: Regular audits of supplier facilities can provide insight into their manufacturing processes and quality control measures. Buyers should look for documented procedures and adherence to standards.

-

Request Quality Reports: Suppliers should be willing to provide documentation, including quality control reports and testing results, to demonstrate their commitment to quality.

-

Engage Third-party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Specific QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding certification nuances is essential. Different regions may have specific regulatory requirements or certifications that suppliers must comply with. For example, buyers in the European Union may require CE marking, while those in the Middle East might need to ensure compliance with local standards.

Furthermore, buyers should be aware of the implications of tariffs, trade agreements, and import regulations that could affect the procurement process. Engaging with suppliers who have experience in navigating these complexities can facilitate smoother transactions and mitigate risks.

Conclusion

In summary, the manufacturing processes and quality assurance measures for plastic caps are multifaceted and critical for ensuring product quality and compliance with international standards. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately enhancing their supply chain and product reliability. Establishing clear communication and verification strategies with suppliers will further ensure that the products meet their specific requirements and industry standards.

Illustrative image related to plastic cap

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic cap’

Introduction

This practical sourcing guide aims to assist international B2B buyers in effectively procuring plastic caps for various applications. Given the diverse requirements across industries and regions, understanding the critical steps in the sourcing process can ensure that you make informed decisions, minimize risks, and secure the best products for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the plastic caps meet your requirements. Consider factors such as material type (e.g., LDPE, TPE), size, shape, and application (e.g., threaded vs. non-threaded).

– Material Considerations: Different materials offer varying degrees of flexibility, durability, and resistance to environmental factors.

– Size and Shape: Ensure you have precise measurements for the outside diameter and length required for your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in plastic caps. Look for suppliers with a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe.

– Supplier Reviews: Check online reviews and testimonials to gauge the reliability and quality of potential suppliers.

– Industry Experience: Prioritize suppliers with experience in your specific industry to ensure they understand your unique needs.

Illustrative image related to plastic cap

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 or compliance with specific industry standards can indicate a supplier’s commitment to quality and consistency.

– Quality Assurance: Certifications often reflect a supplier’s adherence to rigorous quality management systems.

– Regulatory Compliance: Ensure that the products meet local regulations and standards relevant to your industry.

Step 4: Request Samples for Testing

Always request samples of the plastic caps before placing a bulk order. Testing samples can help you evaluate the quality, fit, and functionality of the caps in your specific application.

– Quality Check: Assess the samples for durability, flexibility, and overall quality.

– Fit Testing: Ensure that the caps fit properly with the intended tubes or rods to avoid operational issues later.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules.

– Volume Discounts: Inquire about discounts for bulk orders, which can significantly reduce costs.

– Payment Flexibility: Discuss payment options that align with your cash flow requirements, such as letters of credit or installment payments.

Step 6: Establish Clear Communication Channels

Effective communication is vital for a successful sourcing relationship. Ensure that there are clear channels for discussing order updates, product specifications, and any potential issues that may arise.

– Regular Updates: Set expectations for regular updates on order status and delivery timelines.

– Point of Contact: Designate a specific point of contact on both sides to streamline communication.

Illustrative image related to plastic cap

Step 7: Plan for Logistics and Delivery

Finally, consider the logistics involved in shipping the plastic caps to your location. Evaluate shipping options and timelines to ensure timely delivery.

– Shipping Methods: Compare air and sea freight options based on urgency and cost.

– Customs and Duties: Be aware of any import duties or customs regulations that may affect the delivery of your products.

By following these steps, B2B buyers can navigate the sourcing process for plastic caps with confidence, ensuring that they secure the right products from reliable suppliers.

Comprehensive Cost and Pricing Analysis for plastic cap Sourcing

What Are the Key Cost Components in Plastic Cap Manufacturing?

Understanding the cost structure of plastic cap sourcing is crucial for international B2B buyers. The primary components include:

-

Materials: The type of plastic used (e.g., LDPE, TPE) significantly influences costs. Higher-grade materials with specific certifications may increase expenses but can also enhance product durability and compliance with international standards.

-

Labor: Labor costs vary by region. Countries with lower wage rates might offer competitive pricing, but it’s essential to consider the skill level and productivity of the workforce, as these factors can impact quality and lead times.

-

Manufacturing Overhead: This includes utilities, factory maintenance, and administrative expenses. Efficient operations can lower overhead costs, which are often reflected in the pricing of the final product.

-

Tooling: Initial tooling costs can be substantial, especially for customized caps. While these costs are typically amortized over the production run, they can affect initial pricing significantly.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability but adds to costs. Buyers should evaluate the level of QC necessary for their applications to balance quality and cost.

-

Logistics: Shipping expenses can vary widely based on destination, volume, and chosen Incoterms. Understanding the logistics landscape is vital for accurate cost forecasting.

-

Margin: Suppliers will add a margin to cover their risks and profit. This can vary based on the supplier’s market position, reputation, and relationship with the buyer.

How Do Pricing Influencers Affect Plastic Cap Costs?

Several factors can influence the pricing of plastic caps, including:

-

Volume/MOQ: Larger orders often qualify for discounts. Buyers should assess their needs and negotiate minimum order quantities (MOQs) to leverage better pricing.

-

Specifications and Customization: Custom designs or specific material requirements can drive up costs. Standard products generally offer better pricing due to economies of scale.

-

Quality and Certifications: Caps meeting international quality standards or certifications (e.g., ISO, FDA) may incur higher costs but are crucial for industries like food and pharmaceuticals.

-

Supplier Factors: The supplier’s experience, reliability, and market position can impact pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: Different shipping terms can affect total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential to calculate the total landed cost effectively.

What Are Effective Buyer Tips for Sourcing Plastic Caps?

B2B buyers should consider the following strategies to optimize their sourcing process:

-

Negotiate Strategically: Building a relationship with suppliers can lead to better pricing and terms. Engage in open discussions about cost structures and explore ways to reduce expenses together.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), including purchase price, shipping, and potential quality-related costs. Sometimes, a lower initial price may lead to higher long-term expenses due to quality issues or increased logistics costs.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and trade tariffs that can influence costs.

-

Request Samples: Before placing large orders, request samples to evaluate quality. This can prevent costly mistakes and ensure the product meets specifications.

-

Leverage Technology: Utilize digital platforms for sourcing and supplier management. These tools can enhance visibility into pricing trends, supplier performance, and market conditions.

Disclaimer on Pricing

It is important to note that prices for plastic caps can vary widely based on the aforementioned factors, and the figures provided herein are indicative. Buyers should conduct thorough market research and engage directly with suppliers to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing plastic cap With Other Solutions

Exploring Alternative Solutions to Plastic Caps for Tubing and Rods

In today’s competitive B2B landscape, decision-makers must consider various alternatives when selecting products like plastic caps for tubing and rods. While plastic caps made from materials such as LDPE and TPE offer specific benefits, exploring other options can lead to enhanced performance, cost savings, and better alignment with operational needs. This analysis compares plastic caps with two viable alternatives: metal caps and cork stoppers, evaluating their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Plastic Cap | Metal Cap | Cork Stopper |

|---|---|---|---|

| Performance | Good sealing and protection | Excellent durability and sealing | Natural sealing, biodegradable |

| Cost | Low to moderate | Moderate to high | Low to moderate |

| Ease of Implementation | Easy to use, lightweight | Requires precise fitting | Simple to use, but may require sizing |

| Maintenance | Low maintenance | Low maintenance, but can rust | Requires occasional replacement |

| Best Use Case | General purpose, non-threaded applications | Heavy-duty, threaded applications | Wine bottles, food containers |

In-Depth Look at Alternatives

What are the Advantages and Disadvantages of Metal Caps?

Metal caps are renowned for their durability and ability to provide an excellent seal, making them ideal for threaded applications where pressure and temperature variations are common. They are often used in industries such as beverage and pharmaceuticals. However, the initial cost can be higher than plastic caps, and they may require specific fittings, which can complicate the implementation process. Additionally, metal caps can be prone to rust if not properly treated, which may necessitate more maintenance over time.

How Do Cork Stoppers Compare?

Cork stoppers are a natural, biodegradable alternative that offers good sealing properties, especially in applications like wine and food storage. They are cost-effective and easy to use, making them suitable for smaller-scale operations or artisanal products. However, cork stoppers may not provide the same level of consistency in sealing performance as plastic or metal options, particularly in high-pressure environments. They also have a limited lifespan and may need to be replaced more frequently than plastic caps.

How to Choose the Right Solution for Your Needs

When selecting the appropriate solution for your business, consider your specific use case and operational requirements. If you need a lightweight, cost-effective solution for general applications, plastic caps may be the ideal choice. For heavy-duty applications requiring exceptional durability, metal caps could be more suitable. Conversely, if environmental sustainability is a priority, cork stoppers may align better with your values and product goals. Evaluate the total cost of ownership, including initial costs and long-term maintenance, to make an informed decision that best meets your business needs.

Essential Technical Properties and Trade Terminology for plastic cap

What Are the Key Technical Properties of Plastic Caps for B2B Buyers?

Understanding the technical specifications of plastic caps is crucial for B2B buyers, especially when sourcing for diverse applications. Here are some essential properties to consider:

-

Material Grade

Plastic caps are commonly manufactured from materials like Low-Density Polyethylene (LDPE) and Thermoplastic Elastomer (TPE). LDPE offers flexibility and durability, making it suitable for general-purpose applications. TPE, on the other hand, combines the properties of rubber and plastic, providing excellent elasticity. Selecting the right material ensures compatibility with the intended use, which can affect product integrity and user safety. -

Tolerance

Tolerance refers to the allowable variation in dimensions during manufacturing. For example, a plastic cap designed to fit a 0.500” diameter tube must have precise measurements to ensure a snug fit. Tight tolerances are critical for applications requiring secure sealing or protection against contamination. Inadequate tolerances can lead to leaks, compromised product quality, and increased costs due to returns or rework. -

Size Variability

Plastic caps come in various sizes to accommodate different tubing and rod diameters. Providing a comprehensive size chart helps buyers find the right fit for their specific needs. This adaptability is vital in industries such as pharmaceuticals, food and beverage, and automotive, where precision and reliability are paramount. -

Color and Customization Options

The color of plastic caps, such as natural, red, or yellow, can serve functional purposes, including product identification and branding. Customization options, including printed logos or specific colors, enhance brand visibility. For international buyers, having choices in color and design can also aid in compliance with local regulations or market preferences. -

Packaging Quantity

Understanding packaging options, such as bulk quantities or smaller lots, is essential for inventory management. Minimum order quantities (MOQ) can vary by supplier, impacting cash flow and storage capabilities. Buyers must balance their immediate needs with potential cost savings from larger orders. -

Chemical Resistance

Certain applications may expose plastic caps to harsh chemicals or extreme temperatures. Knowledge of chemical resistance properties is critical for ensuring product longevity and preventing failures. Buyers should consult material safety data sheets (MSDS) for detailed compatibility information.

What Are Common Trade Terms Related to Plastic Caps?

Navigating the terminology associated with plastic caps can streamline the procurement process. Here are several key terms to understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding whether a supplier is an OEM can provide insights into product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. This term is crucial for budgeting and inventory planning. Buyers must evaluate their needs against MOQs to avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. It helps buyers compare offers and negotiate terms, ensuring they receive competitive pricing for their required plastic caps. -

Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international shipping. Familiarity with these terms helps buyers understand shipping costs, risks, and delivery timelines, which is essential for effective supply chain management. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is vital for planning production schedules and ensuring timely delivery, especially in industries where downtime can be costly. -

Certification Standards

Certifications such as ISO or FDA compliance indicate that products meet specific quality and safety standards. Buyers should prioritize suppliers with appropriate certifications to ensure that the plastic caps meet industry regulations and customer expectations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing plastic caps, ultimately enhancing their operational efficiency and product integrity.

Navigating Market Dynamics and Sourcing Trends in the plastic cap Sector

What Are the Key Trends and Dynamics in the Global Plastic Cap Market?

The global plastic cap market is witnessing significant growth driven by various factors, including the rising demand for packaged goods, advancements in manufacturing technologies, and the increasing adoption of automation in production processes. Particularly in regions like Africa, South America, the Middle East, and Europe, the demand for plastic caps is being fueled by the burgeoning beverage and food industries. B2B buyers in these regions must stay attuned to emerging trends such as customization options, which allow brands to differentiate their products, and the integration of smart technology into packaging solutions, enhancing user engagement.

In recent years, sustainability has emerged as a critical concern in sourcing practices. Buyers are increasingly inclined toward suppliers who offer biodegradable or recyclable options. Moreover, the digital transformation within the supply chain, including the use of AI for inventory management and logistics, is reshaping how businesses source plastic caps. International buyers are encouraged to engage with suppliers that leverage these technologies to improve efficiency and reduce costs, thereby enhancing overall competitiveness.

How Important Is Sustainability and Ethical Sourcing in the Plastic Cap Industry?

Sustainability and ethical sourcing are becoming imperative in the plastic cap sector, with environmental concerns at the forefront of consumer preferences. The plastic production process has significant ecological impacts, prompting businesses to seek alternatives that minimize environmental harm. B2B buyers should prioritize suppliers who utilize recycled materials or innovative bio-based plastics that reduce carbon footprints.

Additionally, ethical supply chains are crucial for fostering trust and transparency in business relationships. Certifications like ISO 14001 for environmental management and the Global Recycled Standard (GRS) can serve as benchmarks for assessing supplier commitments to sustainable practices. Buyers are advised to evaluate potential partners based on their sustainability certifications and adherence to ethical sourcing protocols, ensuring alignment with their corporate social responsibility goals.

What Is the Historical Context of the Plastic Cap Sector’s Development?

The plastic cap sector has evolved significantly over the past few decades. Initially, traditional metal and cork caps dominated the market until the introduction of plastics in the mid-20th century revolutionized packaging. This shift not only provided a cost-effective alternative but also enhanced the convenience and safety of product storage.

With the advent of innovations in polymer technology, manufacturers began to produce a wide range of plastic caps tailored for various applications, from beverages to pharmaceuticals. Today, the market continues to adapt to consumer demands for sustainability, leading to a focus on biodegradable materials and smart packaging solutions. This evolution underscores the importance of staying informed about historical trends, as they often shape current market dynamics and influence future sourcing strategies for B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic cap

-

1. How do I choose the right plastic cap for my product?

Choosing the right plastic cap involves assessing the size, material, and intended use. Consider the outside diameter and length of the tubing or rod that the cap will fit. Common materials include LDPE and TPE, each offering different levels of flexibility and durability. Additionally, evaluate whether you need a threaded or non-threaded cap and if customization is necessary for your branding or functionality. Engaging with a supplier that offers samples can help ensure you select the most suitable option for your application. -

2. What are the benefits of using plastic caps in manufacturing?

Plastic caps provide numerous benefits in manufacturing, including protection against contamination, moisture, and physical damage. They are lightweight, cost-effective, and available in various sizes and materials, making them suitable for diverse applications. Furthermore, they can be customized for branding, enhancing product appeal. Utilizing plastic caps can also streamline packaging and shipping processes, ensuring that products remain intact during transit. -

3. What is the minimum order quantity (MOQ) for plastic caps?

The MOQ for plastic caps varies by supplier and can range from a few hundred to several thousand units. Factors influencing MOQ include material costs, production capabilities, and customization options. For international buyers, it’s crucial to discuss MOQ during initial negotiations to align with your purchasing needs and budget. Many suppliers may offer flexibility on MOQs for repeat customers or larger contracts, so it’s advisable to establish a long-term relationship. -

4. How can I ensure the quality of plastic caps from a supplier?

To ensure quality, request samples before placing a bulk order. Conduct a thorough supplier audit, including their manufacturing processes, certifications, and customer reviews. Inquire about their quality assurance protocols, such as material testing and inspection processes. Establishing a clear communication channel for feedback and quality checks during production can also help maintain standards. Consider suppliers with ISO certifications or those who comply with international quality standards to minimize risks. -

5. What payment terms should I expect when sourcing plastic caps internationally?

Payment terms can vary widely based on the supplier’s policies and your negotiation. Common terms include upfront payment, partial payment upon order confirmation, and the balance before shipment. Letters of credit and escrow services may also be used for larger orders to protect both parties. It’s essential to clarify payment terms before finalizing the deal to avoid misunderstandings. Additionally, consider the currency exchange rates and transaction fees associated with international payments. -

6. How do I manage shipping and logistics for international orders of plastic caps?

Managing shipping and logistics involves selecting the right shipping method based on cost, speed, and reliability. Collaborate with your supplier to determine the best shipping option, whether by air or sea. Understand the customs regulations and duties applicable in your country to avoid delays. Working with a freight forwarder can streamline the process, ensuring compliance and efficiency. Keep track of shipment timelines and maintain open communication with the supplier for updates. -

7. Can I customize plastic caps for branding purposes?

Yes, many manufacturers offer customization options for plastic caps, including color, size, and printing logos or designs. Customization can enhance brand visibility and create a unique product presentation. Discuss your specific requirements with potential suppliers and request samples of customized caps to evaluate quality and appearance. Be aware that customization may affect lead times and pricing, so factor these into your planning. -

8. What are the common applications for plastic caps in various industries?

Plastic caps are widely used across multiple industries, including food and beverage, pharmaceuticals, and cosmetics. They serve as protective closures for bottles, tubes, and containers, ensuring product integrity. In manufacturing, they are used to cover threaded and non-threaded tubing, preventing contamination. Their versatility allows for applications in electronics, automotive, and construction as well, making them essential components in many supply chains.

Top 8 Plastic Cap Manufacturers & Suppliers List

1. MOCAP – Straight Round Polyethylene Caps

Domain: mocap.com

Registered: 1995 (30 years)

Introduction: Straight Round Polyethylene Plastic Caps for Tubing, Rods and Fittings – Manufactured by MOCAP. Material: LDPE (Low Density Polyethylene), TPE (Thermoplastic Elastomer). Stocked Material: LDPE (Natural), LDPE (Red), TPE (Yellow). General Purpose Outside Fitting Caps. Snug Fit for Threaded or Non-Threaded Tubes, Rods and Fittings. Available in varieties: Straight Plastic Caps with Plain Top, Straig…

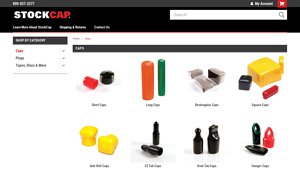

2. StockCap – Caps and Plugs

Domain: store.stockcap.com

Registered: 1996 (29 years)

Introduction: StockCap offers a wide range of caps and plugs including: Short Caps, Long Caps, Rectangular Caps, Square Caps, Anti-Roll Caps, EZ Tab Caps, Grab Tab Caps, Hanger Caps, Angle Caps, Vinyl Plus Plugs, Vented Caps, T-Plugs (Tapered Plugs), End Caps, Tear Caps, Threaded Caps, Electrical Connector Caps, FC Flange Covers, SR Flange Covers, ASA Flange Covers, EPDM Caps, Silicone Caps, Hanger Tips (Flat a…

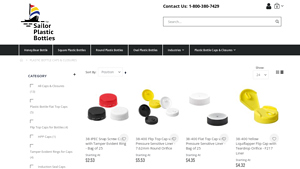

3. Sailor Plastics – 38-IPEC Snap Screw Cap

Domain: sailorplastics.com

Registered: 1999 (26 years)

Introduction: {“products”:[{“name”:”38-IPEC Snap Screw Cap with Tamper Evident Ring”,”quantity”:”Bag of 25″,”starting_price”:”$2.53″},{“name”:”38-400 Flip Top Cap with Pressure Sensitive Liner”,”orifice”:”7.62mm Round Orifice”,”starting_price”:”$5.53″},{“name”:”38-400 Flat Top Cap with Pressure Sensitive Liner”,”quantity”:”Bag of 25″,”starting_price”:”$4.35″},{“name”:”38-400 Yellow Liquiflapper Flip Cap with Te…

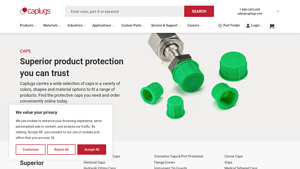

4. Caplugs – Protective Caps

Domain: caplugs.com

Registered: 1996 (29 years)

Introduction: Caplugs offers a wide selection of protective caps in various colors, shapes, and materials for product protection. Key subcategories include American Standard Caps, Connector Caps, Corner Caps, Electrical Caps, Flange Covers, and more. The caps are designed to seal out dust and moisture, protect delicate instruments during shipping and storage, and save production time with ergonomic designs. The…

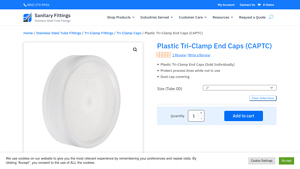

5. Sanitary Fittings – Plastic Tri-Clamp End Cap

Domain: sanitaryfittings.us

Registered: 2016 (9 years)

Introduction: Product Name: Plastic Tri-Clamp End Cap

Type: Protective Dust Cap

SKU Options: CAPTC-NATURAL.50/.75-POLYETHYLENE, CAPTC-NATURAL2-POLYETHYLENE, CAPTC-NATURAL2.5-POLYETHYLENE, CAPTC-NATURAL3-POLYETHYLENE, CAPTC-NATURAL4-POLYETHYLENE, CAPTC-NATURAL1/1.5-POLYETHYLENE

Sizes Available: 1/2″ – 3/4″, 1″ – 1 1/2″, 2″, 2 1/2″, 3″, 4″

Features: Protects process lines from dust when not in use, sold individua…

6. The Cary Company – Plastic Caps

Domain: thecarycompany.com

Registered: 1999 (26 years)

Introduction: Plastic Caps for Sale | Wholesale & Bulk Pricing. Types of plastic caps include Continuous Threaded Caps, Dome Caps, Tamper Evident Beverage Caps, Phenolic Caps, PolyCone Caps, Spice Caps, Dispensing Caps, Flapper Caps, Side Pour Caps, Disc Top Caps, Snap Top Caps, Turret Caps, Spout Caps, Spice Grinder Caps, Sifter Fitments, Child Resistant Caps, Vented Caps, Dropper Caps. Additional products inc…

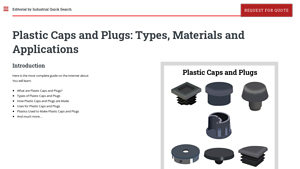

7. IQS Directory – Plastic Caps and Plugs

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Plastic caps and plugs are used for sealing the ends, tops, and openings of various tubes and containers. They come in a wide array of sizes, colors, and shapes, including custom configurations. The primary material for manufacturing these products is polyethylene, with four types commonly used for their durability and resilience. There are both threaded and non-threaded versions available, provid…

8. Roofmaster – Plastic Caps

Domain: roofmaster.com

Registered: 1996 (29 years)

Introduction: {“product_name”:”Plastic Caps”,”quantity_per_box”:2400,”product_id”:”756125″}

Strategic Sourcing Conclusion and Outlook for plastic cap

What Are the Key Takeaways for B2B Buyers in the Plastic Cap Market?

In today’s competitive landscape, strategic sourcing of plastic caps offers significant advantages for B2B buyers, especially those operating in emerging markets across Africa, South America, the Middle East, and Europe. Understanding the diverse materials, such as LDPE and TPE, and their applications allows buyers to make informed decisions that enhance product quality and operational efficiency. The variety in sizes and designs—ranging from snug-fitting caps for threaded and non-threaded tubing to specialized end caps—ensures that businesses can find solutions tailored to their specific needs.

How Can Strategic Sourcing Impact Your Business Growth?

By prioritizing strategic sourcing, companies can not only reduce costs but also improve supply chain resilience. Collaborating with reliable suppliers who understand regional market dynamics can lead to stronger partnerships and better negotiation terms. This proactive approach is essential for navigating the complexities of international trade and can ultimately drive innovation in product development.

Illustrative image related to plastic cap

What Should B2B Buyers Consider Moving Forward?

As we look ahead, the importance of sustainable sourcing practices will only grow. International B2B buyers should seek suppliers committed to environmentally friendly production processes. Engaging with manufacturers who prioritize sustainability can enhance brand reputation and meet the increasing consumer demand for responsible products. Begin your strategic sourcing journey today and unlock the full potential of your supply chain in the plastic cap market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to plastic cap

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.