Choosing Your Parts Of A Steam Boiler: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for parts of a steam boiler

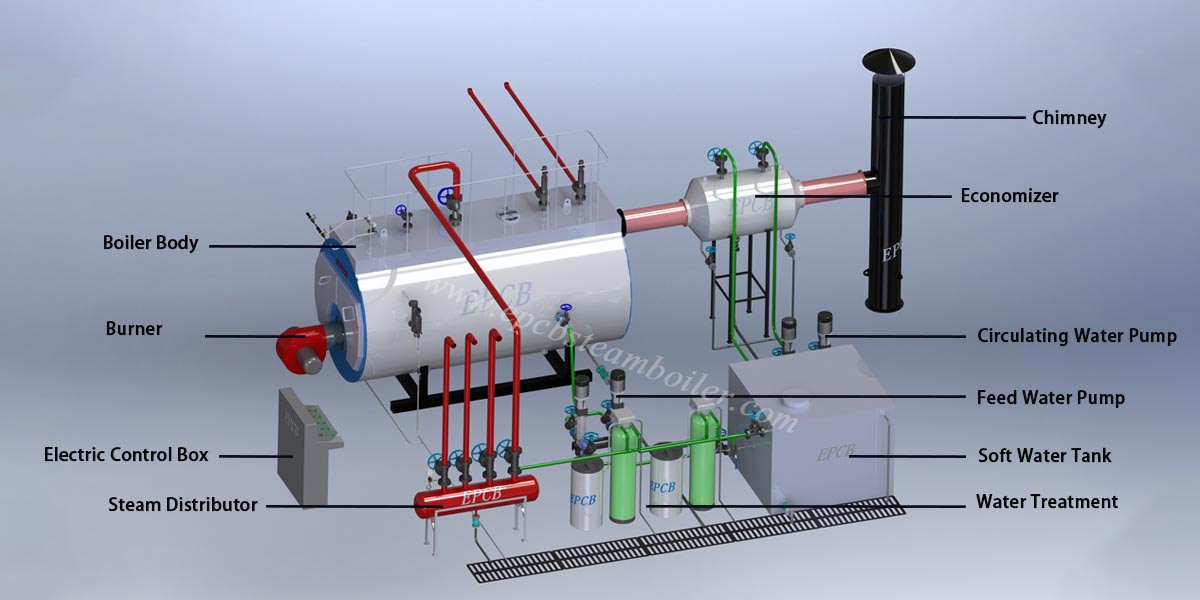

In the complex landscape of industrial operations, sourcing the right parts for a steam boiler is a critical challenge that can significantly impact efficiency and cost-effectiveness. As businesses strive to optimize their thermal systems, understanding the various components—such as burners, heat exchangers, and economizers—becomes essential. This comprehensive guide delves into the intricate world of steam boiler parts, offering insights into their functions, applications across diverse industries, and the nuances of supplier vetting.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in sourcing these critical components. Fluctuating market conditions, regulatory differences, and varying quality standards can complicate procurement efforts. This guide empowers decision-makers by providing in-depth knowledge on the types of steam boiler parts available, their respective costs, and best practices for evaluating suppliers. With actionable insights and expert recommendations, buyers will be equipped to make informed purchasing decisions that align with their operational needs and budgetary constraints.

By navigating this guide, businesses can not only streamline their procurement processes but also enhance their operational reliability and sustainability. Whether you are in Brazil, Saudi Arabia, or beyond, understanding the global market for steam boiler parts is crucial for maintaining a competitive edge in today’s dynamic business environment.

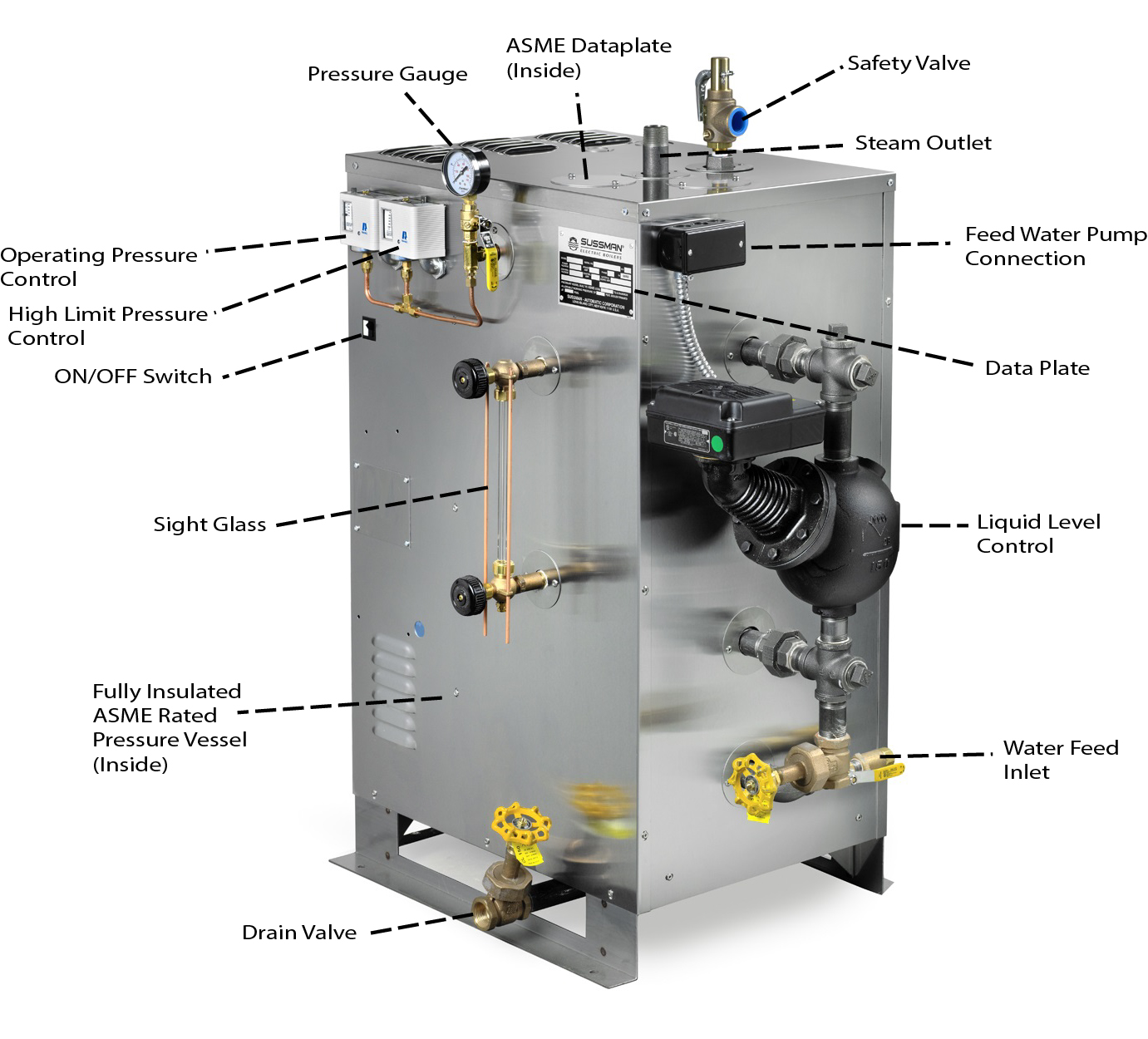

Understanding parts of a steam boiler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fire-Tube Boiler | Hot gases pass through tubes surrounded by water. | Manufacturing, food processing | Pros: Lower initial cost, compact design. Cons: Limited steam capacity, slower response time. |

| Water-Tube Boiler | Water circulates through tubes heated by combustion. | Power generation, chemical plants | Pros: High efficiency, quick steam generation. Cons: Higher upfront costs, complex maintenance. |

| Electric Boiler | Uses electric current to heat water directly. | Small-scale operations, laboratories | Pros: Low emissions, easy installation. Cons: Higher operational costs, limited output capacity. |

| Biomass Boiler | Burns organic materials for steam generation. | Agriculture, waste management | Pros: Renewable energy source, lower emissions. Cons: Variable fuel quality, larger footprint. |

| Condensing Boiler | Recovers heat from exhaust gases for increased efficiency. | Commercial heating, district heating | Pros: High efficiency, reduced fuel costs. Cons: Higher initial investment, requires specific venting. |

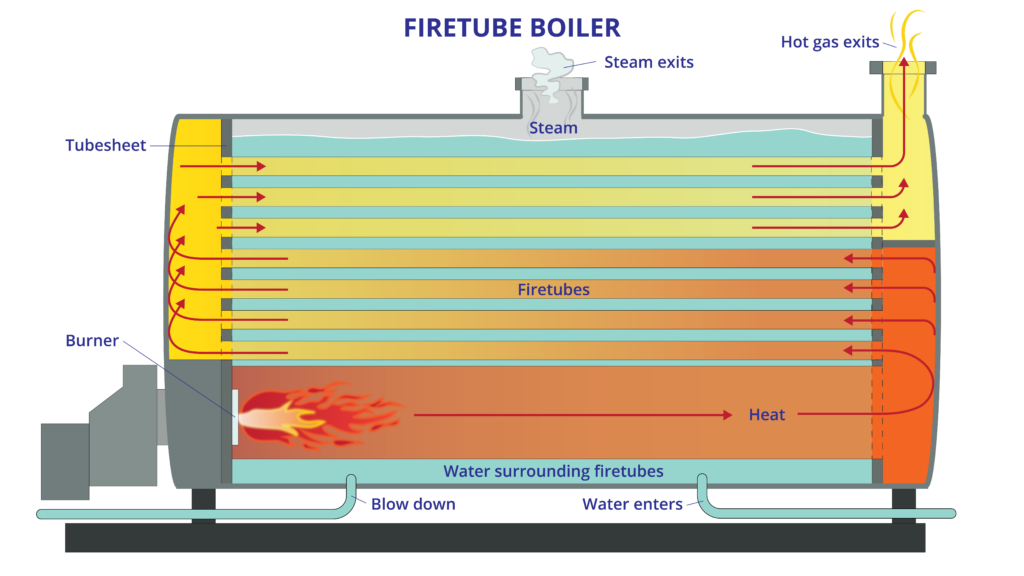

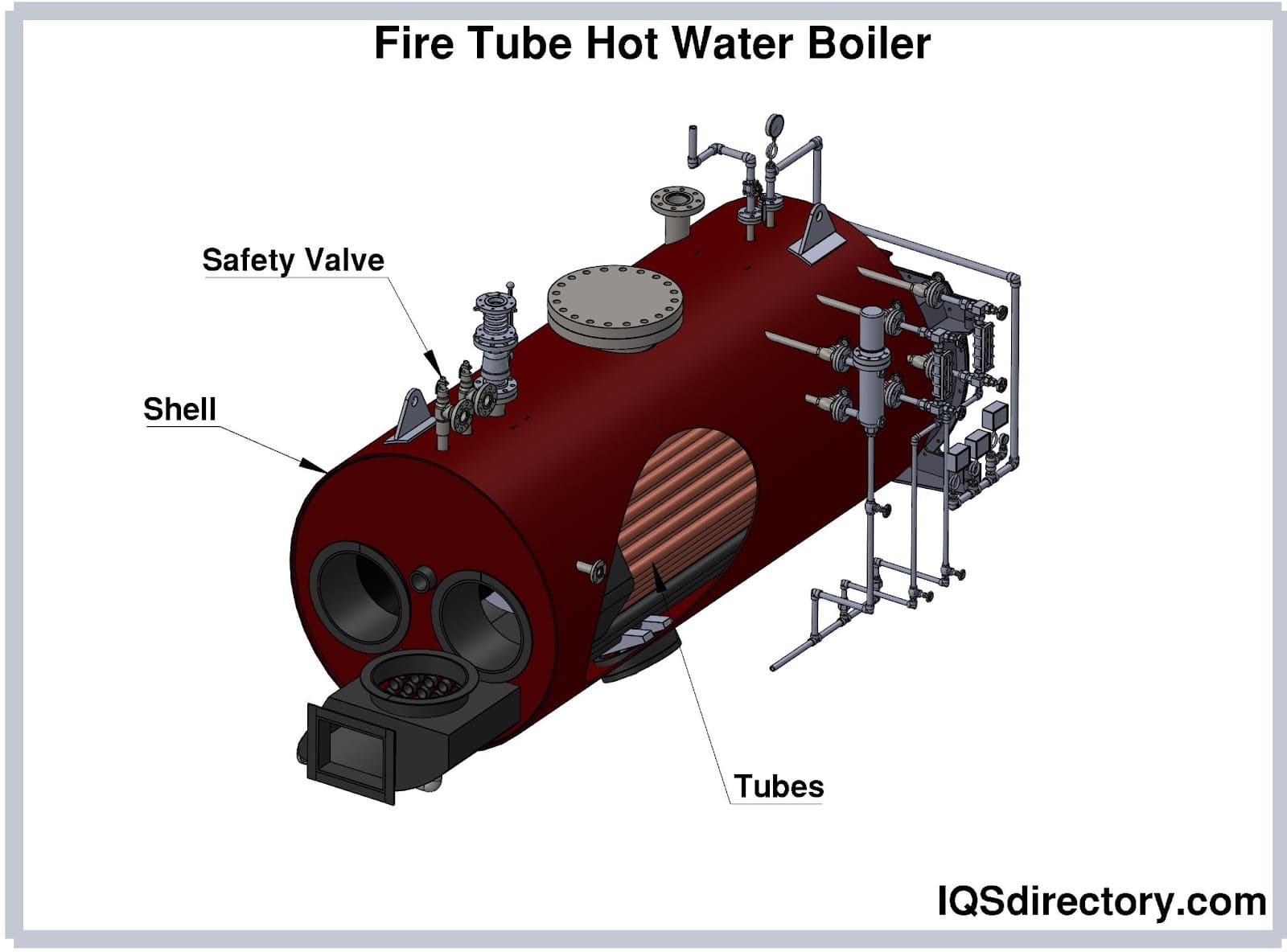

What are the characteristics of Fire-Tube Boilers and their suitability for B2B applications?

Fire-tube boilers are characterized by their design, where hot gases produced from combustion pass through tubes that are immersed in water. This type of boiler is typically more compact and has a lower initial purchase cost, making it suitable for smaller manufacturing and food processing facilities. However, they may not be ideal for operations requiring high steam capacity or rapid pressure changes, as their response time can be slower compared to other types.

How do Water-Tube Boilers differ and what B2B sectors benefit from them?

Water-tube boilers feature a design where water circulates through tubes that are heated externally by combustion gases. This arrangement allows them to achieve higher efficiency and steam generation rates, making them suitable for power generation and large chemical plants. While they come with higher initial costs and complex maintenance requirements, their ability to handle high pressures and rapid steam demand makes them a preferred choice for larger industrial applications.

What advantages do Electric Boilers offer and in which scenarios are they most effective?

Electric boilers utilize electric currents to heat water directly, providing a clean and efficient steam generation method. They are particularly effective in small-scale operations, laboratories, and locations where emissions regulations are stringent. Their installation is straightforward, and they require minimal maintenance. However, the operational costs can be higher compared to traditional fuel-based boilers, and their output capacity is limited, which may not suit larger industrial needs.

Why should B2B buyers consider Biomass Boilers?

Biomass boilers utilize organic materials, such as wood chips or agricultural residues, as fuel to generate steam. They represent a renewable energy source, aligning with sustainability initiatives in sectors like agriculture and waste management. While they contribute to lower emissions, buyers should be aware of the variable quality of biomass fuel and the larger physical footprint required for installation and operation. This can impact overall efficiency and operational planning.

What makes Condensing Boilers a valuable choice for commercial heating?

Condensing boilers are designed to recover heat from exhaust gases, significantly increasing their efficiency. This feature makes them an excellent choice for commercial heating applications, including district heating systems. While they typically require a higher initial investment and specific venting solutions, the long-term savings on fuel costs and reduced emissions can make them a financially viable option for businesses looking to improve their energy efficiency and sustainability profile.

Key Industrial Applications of parts of a steam boiler

| Industry/Sector | Specific Application of parts of a steam boiler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Steam generation for cooking and sterilization processes | Ensures food safety and quality, increases efficiency | Compliance with health standards, energy efficiency ratings |

| Chemical Manufacturing | Heat supply for chemical reactions and distillation processes | Enhances production rates and product quality | Material compatibility, pressure ratings, safety features |

| Power Generation | Steam production for turbines in power plants | Maximizes energy output and operational reliability | Scale of production, regulatory compliance, maintenance support |

| Textile Industry | Steam for dyeing and finishing fabrics | Improves product quality and reduces processing time | Temperature control, energy efficiency, sourcing from reliable suppliers |

| Pharmaceuticals | Steam for sterilization and process heating | Guarantees product safety and compliance with regulations | Quality certifications, reliability of supply, customization options |

How Are Parts of a Steam Boiler Utilized in the Food and Beverage Industry?

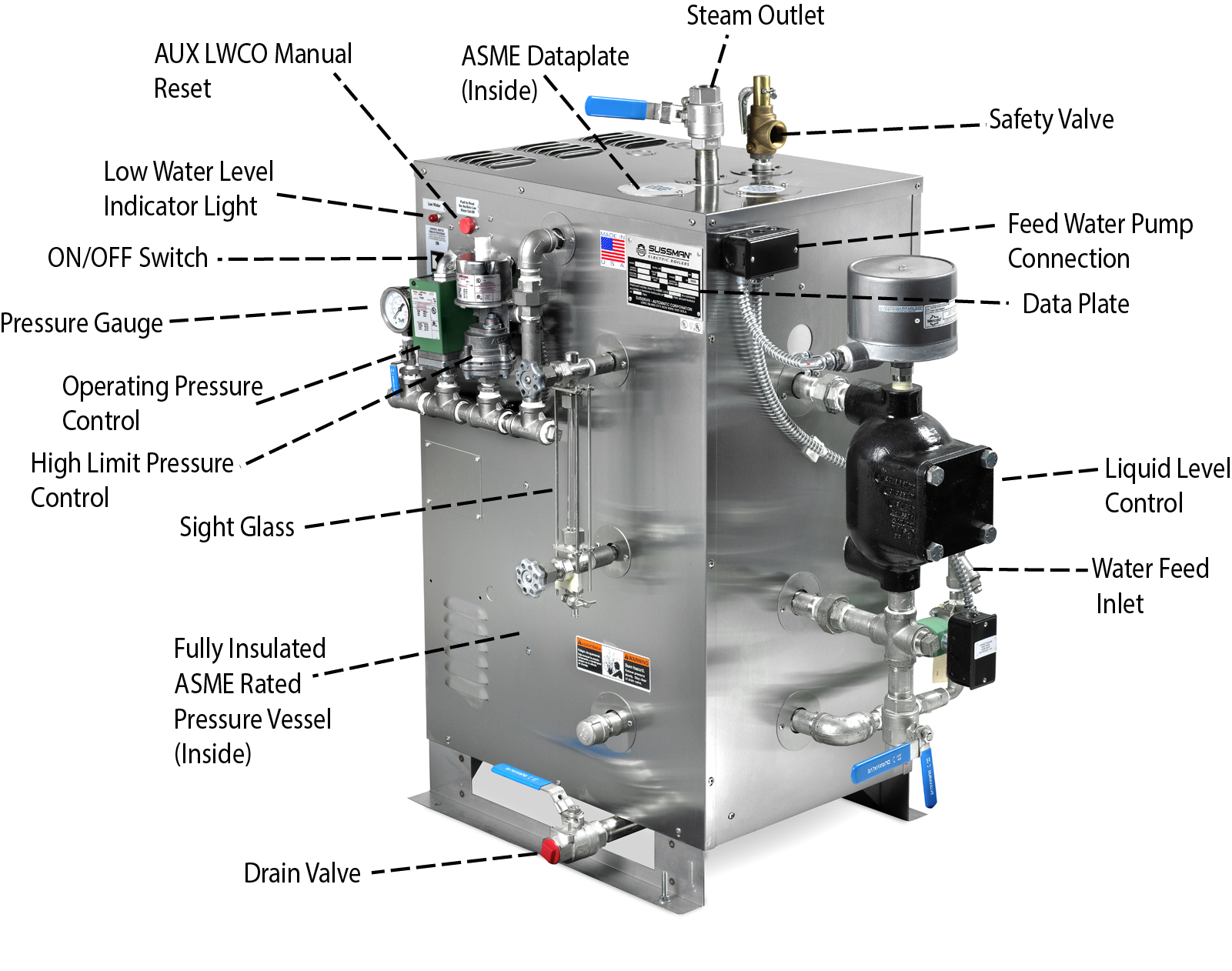

In the food and beverage sector, steam boilers are crucial for cooking, sterilization, and pasteurization processes. The burner and heat exchanger components ensure that steam is generated efficiently, maintaining the required temperatures for food safety. Buyers in this industry must prioritize compliance with health and safety standards, as well as energy efficiency ratings to reduce operational costs. The reliability of sourcing parts that meet these criteria is essential for maintaining consistent production quality.

What Role Do Steam Boiler Parts Play in Chemical Manufacturing?

In chemical manufacturing, steam boilers provide the necessary heat for various processes, including chemical reactions and distillation. The combustion chamber and heat exchanger are vital for maintaining precise temperature controls, which enhance production rates and ensure product quality. For international buyers, sourcing materials that are compatible with specific chemicals and meeting pressure ratings is crucial. Additionally, safety features must be considered to prevent hazardous incidents in this high-stakes environment.

How Is Steam Boiler Technology Applied in Power Generation?

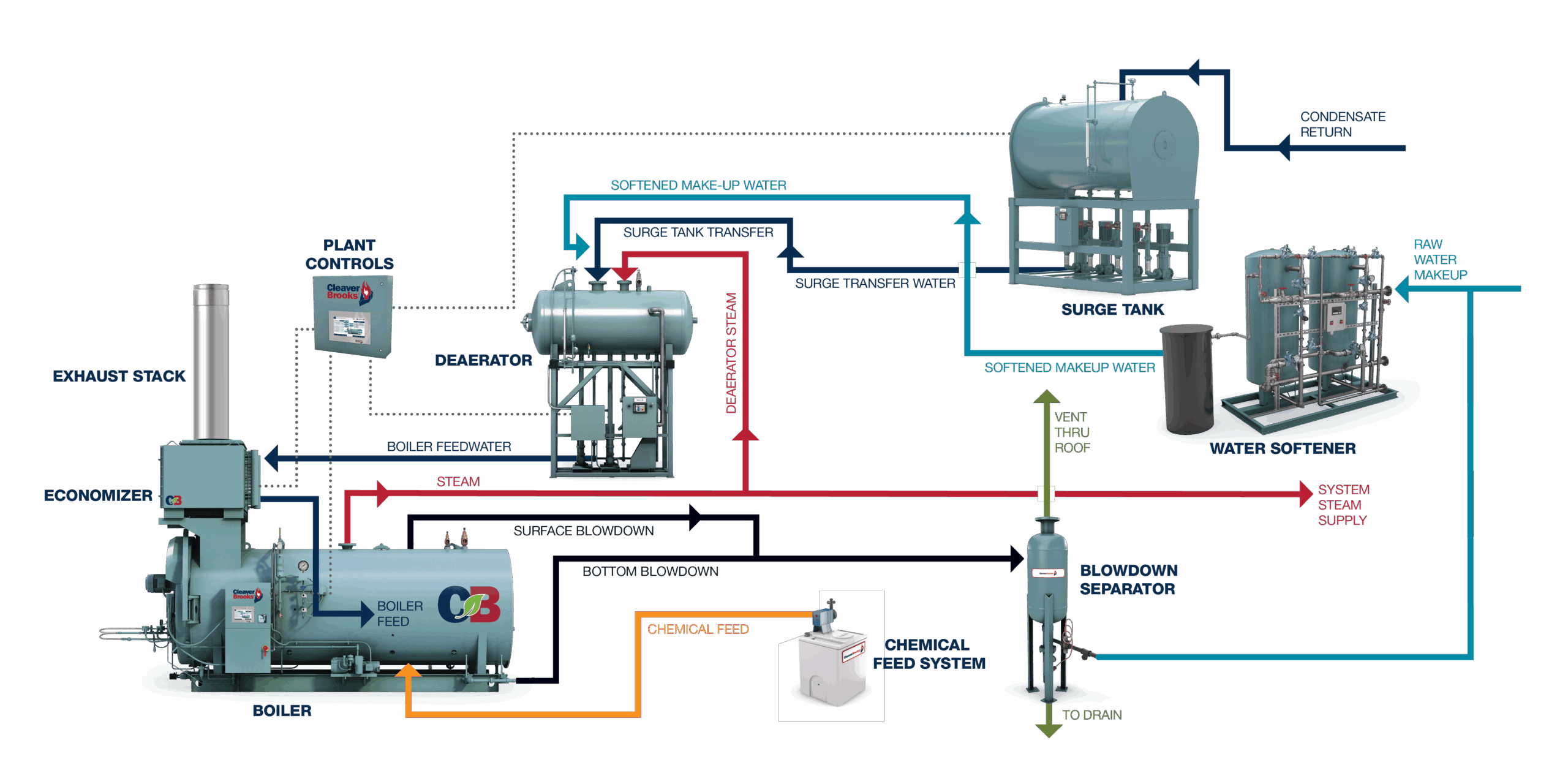

Steam boilers are integral to power generation, where they produce steam that drives turbines. The superheater and economizer components optimize steam temperature and efficiency, maximizing energy output. Buyers should consider the scale of production and regulatory compliance when sourcing boiler parts, as these factors directly impact operational reliability. Maintenance support is also a critical consideration, as consistent performance is necessary to meet energy demands.

What Importance Do Steam Boilers Have in the Textile Industry?

In the textile industry, steam is essential for dyeing and finishing processes, where precise temperature control is necessary. The circulator pumps and heat exchangers play a significant role in distributing steam efficiently throughout the production line. Buyers should focus on energy efficiency and reliable sourcing of components to minimize downtime and improve product quality. The ability to customize solutions to meet specific processing needs is also a valuable consideration.

How Are Parts of a Steam Boiler Critical in Pharmaceutical Manufacturing?

In pharmaceuticals, steam is used for sterilization and heating processes, ensuring product safety and compliance with stringent regulations. The deaerators and condensers are particularly important for maintaining water quality and preventing contamination. Buyers in this sector must prioritize quality certifications and the reliability of suppliers, as any failure in the boiler system can lead to significant compliance issues and financial losses. Customization options may also be necessary to meet specific operational requirements.

3 Common User Pain Points for ‘parts of a steam boiler’ & Their Solutions

Scenario 1: Inconsistent Heat Output Leading to Operational Inefficiencies

The Problem: Many industrial facilities face the challenge of inconsistent heat output from their steam boilers, which can lead to significant operational inefficiencies. For instance, a manufacturing plant in Brazil may experience fluctuations in steam pressure, causing interruptions in production schedules and impacting overall productivity. This inconsistency often stems from issues with key components such as the burner or heat exchanger, which may not be functioning optimally due to age, improper maintenance, or incorrect specifications.

The Solution: To address this issue, buyers should prioritize regular maintenance and consider retrofitting or upgrading existing components. First, implement a comprehensive maintenance schedule that includes periodic inspections of the burner and heat exchanger. This will help identify wear and tear or any buildup that could obstruct efficiency. Additionally, when sourcing replacement parts, ensure they meet the specific requirements of your boiler system. Collaborating with reputable suppliers who understand your operational needs can help you select components that enhance reliability. For example, investing in high-efficiency burners can significantly improve heat output consistency, translating to smoother operations and reduced energy costs.

Scenario 2: Unexpected Boiler Downtime Due to Component Failures

The Problem: Unexpected downtime caused by component failures is a common pain point for businesses operating steam boilers. A facility in Saudi Arabia, for example, might face sudden shutdowns due to a malfunctioning circulator pump, leading to lost revenue and increased operational costs. Such failures can occur due to lack of predictive maintenance or the use of substandard parts, resulting in a domino effect on production schedules and customer deliveries.

The Solution: To mitigate the risk of unexpected failures, businesses should adopt a proactive approach to maintenance and sourcing. Implementing a predictive maintenance program that utilizes IoT sensors can provide real-time data on component performance and alert management to potential issues before they escalate. Moreover, when purchasing parts, prioritize quality over cost; investing in OEM (Original Equipment Manufacturer) parts can significantly reduce the risk of failures. Establishing long-term relationships with trusted suppliers can also ensure you have access to high-quality components and technical support, facilitating quicker repairs and minimizing downtime.

Scenario 3: Compliance Challenges with Environmental Regulations

The Problem: As environmental regulations become increasingly stringent, businesses must ensure their steam boiler systems comply with local and international standards. A company in Europe, for example, may struggle with emissions regulations that require specific boiler components to reduce pollutants. Failure to comply can result in hefty fines and reputational damage, creating a pressing need for updated parts that meet these regulations.

The Solution: To effectively navigate compliance challenges, businesses should stay informed about relevant regulations and invest in modern, compliant parts. Collaborate with suppliers who specialize in environmentally friendly boiler technologies, such as low-NOx burners and economizers that improve fuel efficiency while reducing emissions. Conducting a thorough audit of your current boiler system can help identify components that require upgrades or replacements. Additionally, consider engaging with industry experts or consultants who can provide insights into the latest technologies and compliance requirements, ensuring your operations not only meet regulations but also enhance sustainability efforts. By taking these proactive steps, businesses can reduce compliance risks while promoting a greener operational footprint.

Strategic Material Selection Guide for parts of a steam boiler

When selecting materials for parts of a steam boiler, it is crucial to consider properties such as temperature and pressure ratings, corrosion resistance, and overall durability. The right material choice not only affects the performance of the boiler but also its longevity and maintenance costs. Below, we analyze four common materials used in steam boiler components, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Carbon Steel in Steam Boilers?

Carbon steel is widely used in the construction of steam boilers, particularly for pressure vessels and piping. Its primary properties include high tensile strength and good ductility, making it suitable for high-pressure applications. Carbon steel can withstand temperatures up to approximately 400°C (752°F) under pressure, which is often sufficient for many boiler applications.

Pros and Cons:

The advantages of carbon steel include its cost-effectiveness and ease of fabrication. It is readily available and can be welded and machined with relative ease. However, carbon steel has a lower corrosion resistance compared to other materials, which can lead to premature failure in harsh environments.

Impact on Application:

Carbon steel is compatible with water and steam but may require protective coatings or treatments in corrosive environments.

International Considerations:

For buyers in regions like Africa and South America, understanding local standards such as ASTM A106 for carbon steel pipes is essential. Compliance with these standards ensures safety and reliability in boiler operations.

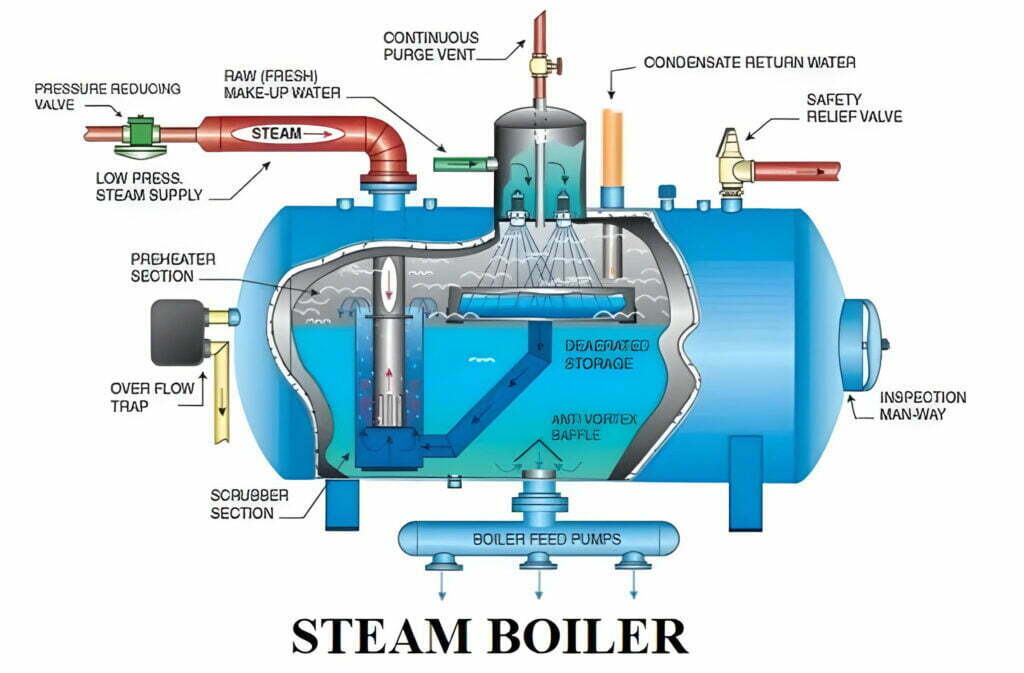

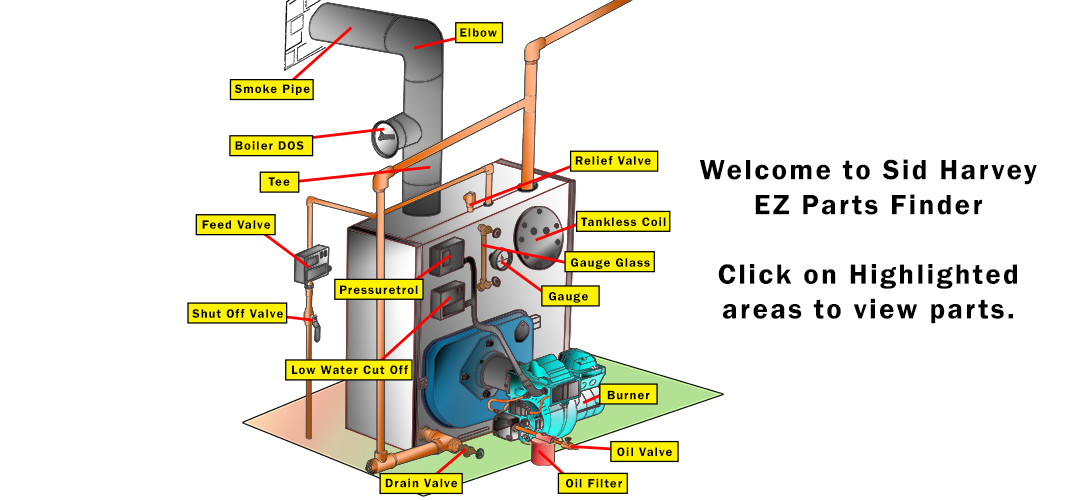

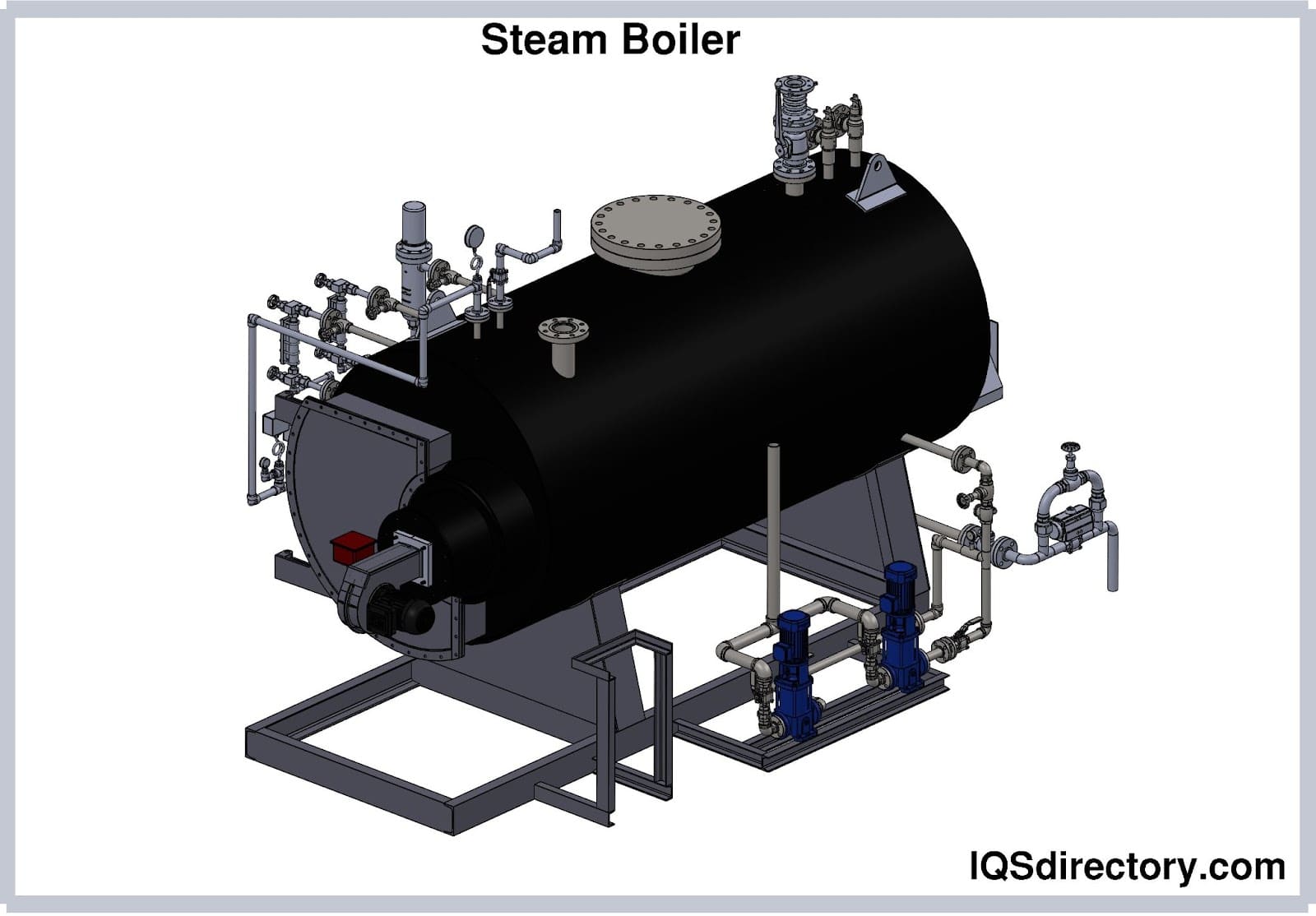

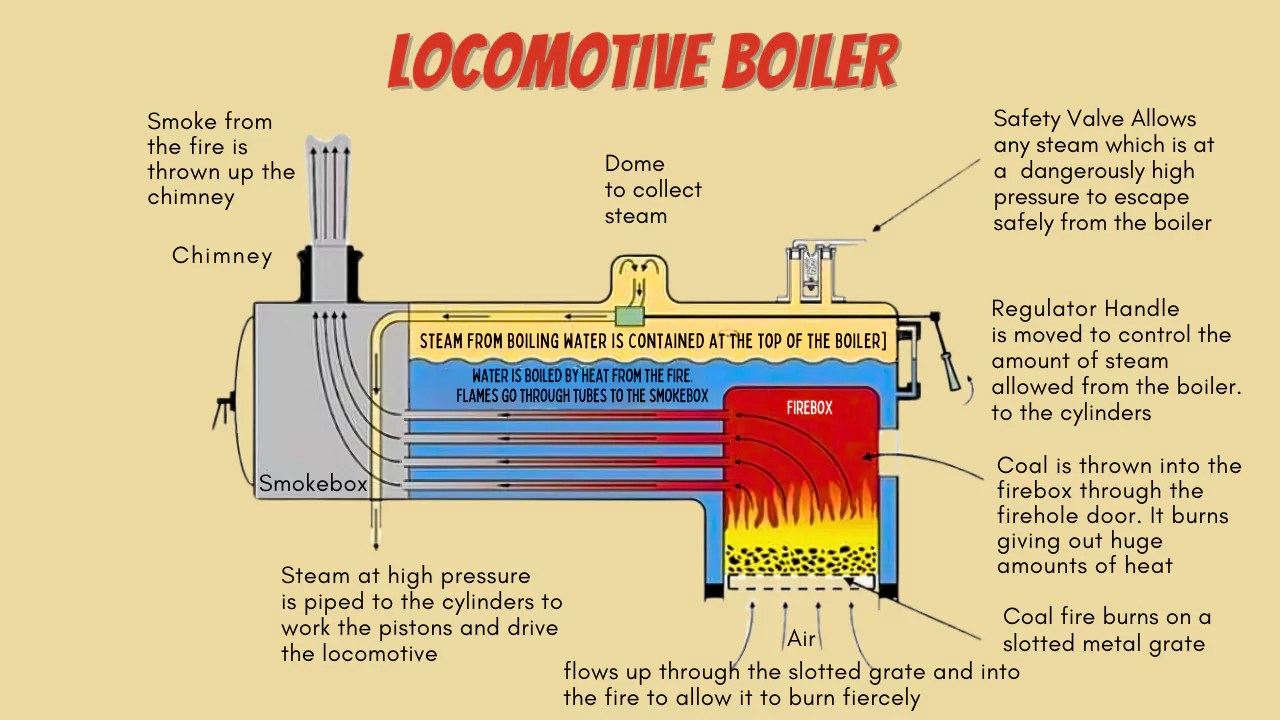

Illustrative image related to parts of a steam boiler

How Does Stainless Steel Perform in Steam Boiler Applications?

Stainless steel, particularly grades like 304 and 316, is favored for its excellent corrosion resistance and high-temperature strength. It can withstand temperatures of up to 800°C (1472°F) and is often used in areas exposed to steam and water.

Pros and Cons:

The main advantage of stainless steel is its resistance to corrosion and scaling, which extends the lifespan of boiler components. However, it is more expensive than carbon steel and can be more challenging to fabricate due to its hardness.

Impact on Application:

Stainless steel is ideal for components that come into direct contact with water and steam, such as heat exchangers and piping systems, where corrosion is a concern.

International Considerations:

Buyers in Europe and the Middle East should ensure compliance with standards like EN 10088 for stainless steel, which governs the chemical composition and mechanical properties of stainless steel products.

Illustrative image related to parts of a steam boiler

What Role Does Cast Iron Play in Steam Boiler Construction?

Cast iron is traditionally used for boiler components such as the combustion chamber and heat exchangers due to its excellent thermal conductivity and ability to withstand high temperatures and pressures.

Pros and Cons:

The advantages of cast iron include its durability and ability to retain heat, which improves energy efficiency. However, it is brittle and can crack under thermal shock or mechanical stress, which limits its application in high-pressure environments.

Impact on Application:

Cast iron is suitable for low to medium-pressure steam applications and is often used in residential and light commercial boilers.

International Considerations:

For international buyers, understanding the specifications set by standards such as ASTM A48 for cast iron is vital for ensuring quality and performance.

How Do Copper and Copper Alloys Enhance Boiler Efficiency?

Copper and its alloys are often used in steam boilers for their excellent thermal conductivity and resistance to corrosion. Copper can operate effectively at temperatures up to 200°C (392°F).

Illustrative image related to parts of a steam boiler

Pros and Cons:

The key advantage of copper is its superior heat transfer capabilities, which can enhance boiler efficiency. However, copper is more expensive than carbon steel and may not be suitable for high-pressure applications.

Impact on Application:

Copper is best suited for smaller, low-pressure steam systems and is often used in heat exchangers.

International Considerations:

Buyers should consider compliance with standards such as ASTM B280 for copper tubing, ensuring that the material meets the necessary quality and performance criteria.

Summary Table of Material Selection for Steam Boiler Parts

| Material | Typical Use Case for parts of a steam boiler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Pressure vessels, piping | Cost-effective, easy to fabricate | Lower corrosion resistance | Low |

| Stainless Steel | Heat exchangers, piping | Excellent corrosion resistance | Higher cost, more complex to fabricate | High |

| Cast Iron | Combustion chamber, heat exchangers | Durable, good heat retention | Brittle, limited high-pressure use | Medium |

| Copper | Heat exchangers | Superior thermal conductivity | Expensive, not suitable for high pressure | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

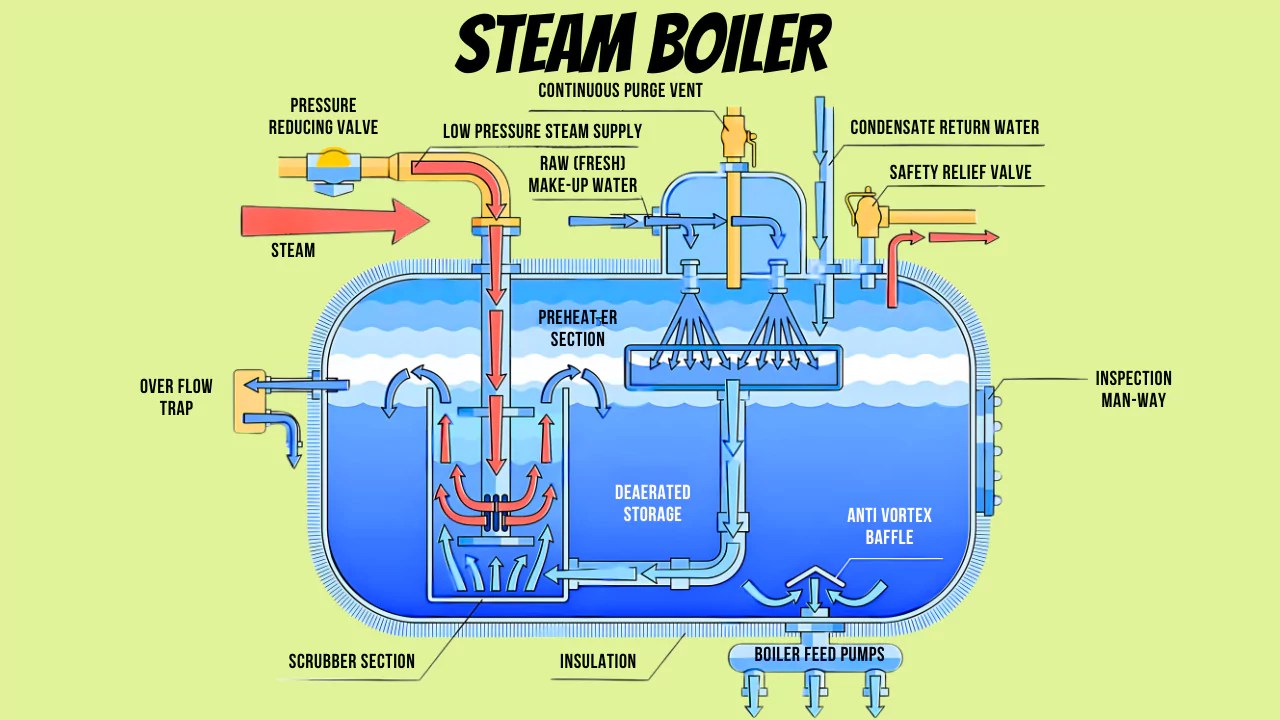

Illustrative image related to parts of a steam boiler

In-depth Look: Manufacturing Processes and Quality Assurance for parts of a steam boiler

What Are the Main Stages of Manufacturing Parts for a Steam Boiler?

The manufacturing process for steam boiler components is intricate and requires precision at every stage. The main stages include material preparation, forming, assembly, and finishing. Each stage plays a crucial role in ensuring the quality, efficiency, and reliability of the final product.

How Is Material Prepared for Boiler Components?

The first step in manufacturing involves selecting the right materials, typically high-grade steel, cast iron, or alloy materials that can withstand extreme temperatures and pressures. Material preparation starts with sourcing raw materials from certified suppliers, ensuring compliance with international standards such as ASTM or EN.

Once the materials are sourced, they undergo inspection to verify their composition and properties. This includes tests for tensile strength, ductility, and corrosion resistance. Any non-conforming materials are rejected at this stage to ensure that only high-quality materials proceed to the next phase.

What Techniques Are Used in Forming Boiler Parts?

Forming processes vary based on the type of component being manufactured. Common techniques include:

- Casting: Components like the combustion chamber and heat exchanger are often cast using molds. This method allows for complex shapes and high durability.

- Machining: Parts such as valves and burners require precise machining to ensure proper fit and function. CNC (Computer Numerical Control) machines are commonly used for their accuracy.

- Welding: Various parts are welded together to form assemblies. This process demands skilled labor and adherence to welding standards (e.g., ASME Section IX).

Each forming technique is carefully monitored to ensure dimensional accuracy and adherence to specifications.

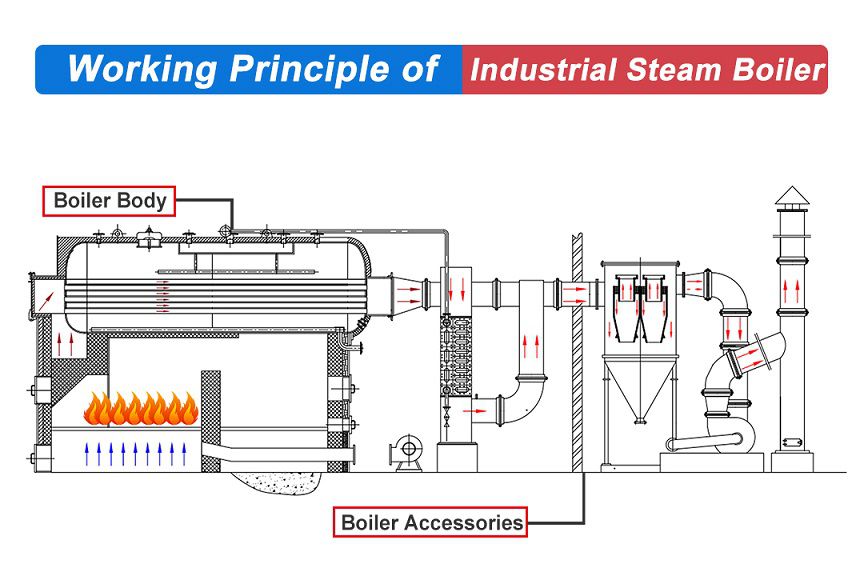

Illustrative image related to parts of a steam boiler

How Are Boiler Components Assembled?

Assembly is a critical stage where individual parts come together to form a complete unit. This process may involve:

- Fitting: Ensuring that all components, such as the burner and heat exchanger, fit together correctly.

- Welding and Fastening: Using appropriate welding techniques and fasteners to secure components. The choice of fasteners must consider thermal expansion and contraction.

Quality checks are implemented during assembly to prevent errors. For instance, the alignment of the heat exchanger and combustion chamber must be verified to ensure optimal performance.

What Finishing Processes Are Applied to Boiler Parts?

Finishing processes enhance the durability and aesthetic appeal of boiler components. Common finishing techniques include:

- Surface Treatment: Processes like sandblasting or shot peening are used to remove impurities and improve surface hardness.

- Coating: Protective coatings, such as paint or galvanization, are applied to prevent corrosion, especially for components exposed to harsh environments.

- Inspection: Final inspections are conducted to ensure that all finishing processes meet quality standards. This may include visual inspections and dimensional checks.

What Quality Assurance Standards Are Relevant for Steam Boiler Parts?

Quality assurance in the manufacturing of steam boiler components is crucial for ensuring safety and performance. International standards such as ISO 9001 provide a framework for quality management systems. Additionally, industry-specific certifications like CE marking for European markets and API (American Petroleum Institute) standards for oil and gas applications are essential.

Which Quality Control Checkpoints Are Commonly Implemented?

Quality control (QC) checkpoints are vital throughout the manufacturing process. These checkpoints typically include:

Illustrative image related to parts of a steam boiler

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet required specifications.

- In-Process Quality Control (IPQC): Monitoring manufacturing processes at various stages to detect any deviations from standards.

- Final Quality Control (FQC): Conducting comprehensive tests on finished products to verify functionality, safety, and compliance with standards.

What Testing Methods Are Commonly Used for Boiler Components?

Testing methods for boiler components can vary widely, but some of the most common include:

- Hydrostatic Testing: Used to verify the integrity of pressure vessels by filling them with water and pressurizing to check for leaks.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiographic testing, and magnetic particle testing assess the integrity of materials without causing damage.

- Performance Testing: Ensuring that components perform under expected conditions, such as temperature and pressure, is crucial for safety and efficiency.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control practices of their suppliers. Here are some strategies:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Requesting Documentation: Buyers should request certificates of compliance, test reports, and quality management system documentation to validate claims made by suppliers.

- Third-Party Inspections: Engaging independent inspection agencies can provide an objective assessment of the supplier’s quality control practices and product reliability.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate various regulations and standards that differ by region. For instance, compliance with CE marking is essential for products sold in Europe, while API certification may be necessary for operations in the oil and gas sector. Buyers should also be aware of the potential for differing quality expectations and regulations in emerging markets.

Understanding these nuances helps mitigate risks associated with sourcing and ensures that boiler components meet the necessary safety and performance standards across different markets.

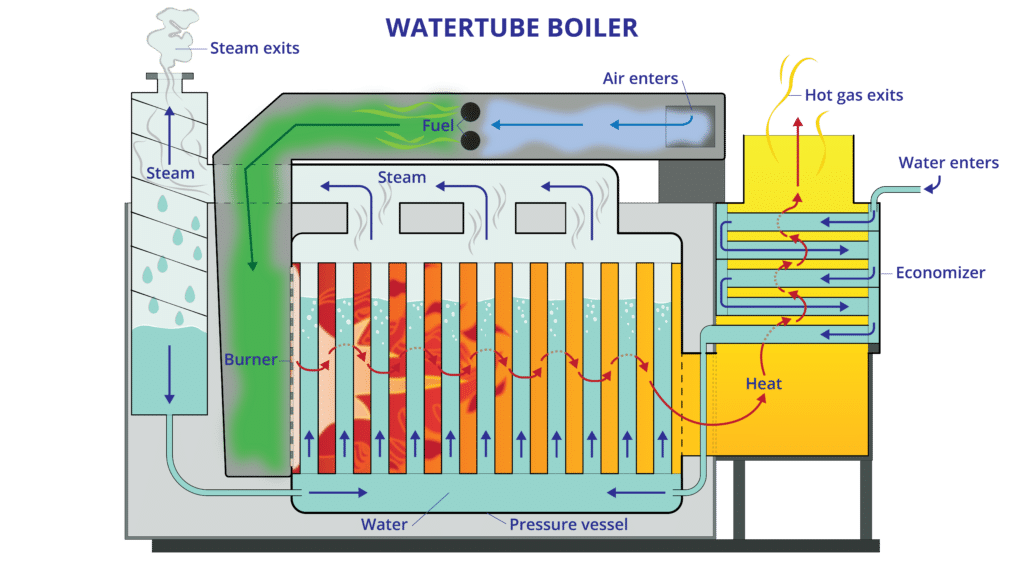

Illustrative image related to parts of a steam boiler

Conclusion

The manufacturing processes and quality assurance measures for steam boiler parts are critical to ensuring the reliability, safety, and efficiency of these essential components. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that align with their operational needs and regulatory requirements. This knowledge not only enhances procurement strategies but also fosters long-term partnerships with reliable suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parts of a steam boiler’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure parts for steam boilers. Understanding the essential components and the procurement process is crucial for ensuring operational efficiency and compliance with safety regulations. By following these steps, buyers can make informed decisions that align with their technical and business needs.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical specifications required for your steam boiler parts. This includes understanding the type of boiler system you have, the capacity needed, and the specific components that are essential for operation.

- Considerations: Identify whether you need burners, heat exchangers, or auxiliary components like deaerators.

- Importance: Accurate specifications prevent costly mistakes and ensure compatibility with existing systems.

Step 2: Research Regulatory Compliance Requirements

Investigate the regulatory standards applicable to your region and industry. This includes safety certifications and environmental regulations that the boiler parts must meet.

- Focus Areas: Look into international standards such as ASME or local certifications relevant to your country.

- Importance: Compliance is not only a legal requirement but also vital for operational safety and reliability.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from other businesses in similar industries or regions.

- Assessment Criteria: Consider their experience in supplying boiler parts, customer service reputation, and ability to meet delivery timelines.

- Importance: Selecting a reliable supplier minimizes risks associated with poor-quality components and service disruptions.

Step 4: Request Quotations and Compare Offers

Solicit detailed quotations from multiple suppliers. Ensure that each quote includes pricing, delivery timelines, and warranty information.

- Comparison Factors: Look beyond price—consider the total cost of ownership, including maintenance and support services.

- Importance: A comprehensive comparison helps identify the best overall value, not just the lowest price.

Step 5: Verify Supplier Certifications

Check the certifications and quality standards of the suppliers you are considering. This includes ISO certifications and other relevant industry standards.

- Documentation: Ask for copies of their certifications and any quality assurance processes they implement.

- Importance: Valid certifications indicate a commitment to quality and safety, which is critical in boiler operations.

Step 6: Assess After-Sales Support and Service

Inquire about the after-sales support and services offered by the supplier, such as installation assistance, maintenance contracts, and training for personnel.

- Service Offerings: Ensure they provide adequate technical support and spare parts availability.

- Importance: Strong after-sales support can enhance the longevity and efficiency of your boiler system.

Step 7: Finalize Purchase Agreements

Once you have selected a supplier, ensure that all terms and conditions are clearly outlined in the purchase agreement. This includes payment terms, delivery schedules, and any warranties or guarantees.

- Legal Review: It may be beneficial to have legal counsel review the contract to safeguard your interests.

- Importance: A well-defined agreement protects both parties and clarifies expectations, reducing the risk of disputes later on.

By following this checklist, B2B buyers can ensure a strategic approach to sourcing steam boiler parts, ultimately leading to improved operational efficiency and safety compliance.

Comprehensive Cost and Pricing Analysis for parts of a steam boiler Sourcing

What Are the Key Cost Components in Sourcing Steam Boiler Parts?

When sourcing parts for steam boilers, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials such as stainless steel, cast iron, and various alloys are often used for durability and heat resistance. Prices can fluctuate based on market demand and availability, so it’s advisable to monitor material costs regularly.

-

Labor: Labor costs encompass both the manufacturing process and the skilled workforce required for assembly. In regions with higher wage standards, labor costs can represent a significant portion of the total price. Companies should consider the labor market in the supplier’s country when estimating costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment depreciation. Overhead can vary widely between manufacturers, affecting pricing strategies.

-

Tooling and Equipment: Custom tooling or specialized equipment for manufacturing specific boiler parts can increase initial costs but may lead to long-term savings through efficiency.

-

Quality Control (QC): Implementing robust QC processes ensures that parts meet industry standards and customer specifications. While this may increase upfront costs, it helps prevent costly failures and downtime in the future.

-

Logistics: Transportation costs can vary based on distance, mode of transport, and the shipping method used. International buyers should be aware of potential tariffs and customs duties that could affect overall logistics costs.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. Understanding the market dynamics and average margins can help buyers negotiate better deals.

How Do Price Influencers Affect the Sourcing of Steam Boiler Parts?

Several factors influence pricing beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Higher purchase volumes often lead to discounted rates, while smaller orders may incur higher per-unit costs. Buyers should negotiate MOQs that align with their operational needs.

-

Specifications and Customization: Custom parts tailored to specific boiler designs can drive up costs due to additional engineering and manufacturing processes. Clearly defining requirements can help suppliers provide accurate quotes.

-

Material Quality and Certifications: Parts that meet international certifications (e.g., ASME, ISO) or specific quality standards usually come at a premium. However, investing in certified parts can lead to enhanced reliability and safety.

-

Supplier Factors: Supplier reputation, reliability, and financial stability can impact pricing. Engaging with established suppliers may yield better service and product quality, justifying higher costs.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate shipping responsibilities and costs, which can significantly influence total pricing.

What Are the Best Practices for Negotiating Steam Boiler Parts Prices?

For international buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, adopting strategic negotiation practices can lead to substantial cost savings:

Illustrative image related to parts of a steam boiler

-

Conduct Thorough Market Research: Familiarize yourself with average pricing for the specific components you need. This knowledge empowers you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the upfront cost but also long-term expenses related to maintenance, efficiency, and potential downtime. This approach can justify a higher initial investment for superior quality parts.

-

Leverage Relationships: Building strong relationships with suppliers can lead to more favorable terms and pricing. Long-term partnerships often result in better service and potential discounts.

-

Be Aware of Pricing Nuances: Different regions may have varied pricing structures based on local economic conditions, demand fluctuations, and currency exchange rates. Understanding these nuances can help you make informed purchasing decisions.

-

Request Multiple Quotes: Soliciting bids from multiple suppliers can create competition and drive down prices. Ensure that all quotes are for comparable products to make an accurate assessment.

Conclusion

Understanding the comprehensive cost structure and pricing influencers is essential for international B2B buyers sourcing steam boiler parts. By focusing on strategic negotiation practices and total cost of ownership, businesses can optimize their procurement processes and achieve significant cost efficiencies. Always remember that indicative prices may vary, and a thorough analysis of all factors will lead to more informed purchasing decisions.

Alternatives Analysis: Comparing parts of a steam boiler With Other Solutions

Introduction to Alternative Solutions for Steam Boiler Parts

In the quest for efficient thermal energy generation, businesses often explore various technologies and methods. While traditional steam boilers have been the backbone of many industrial operations, alternative solutions have emerged that offer comparable or enhanced performance. Understanding these alternatives can help B2B buyers make informed decisions tailored to their operational requirements.

Comparison Table

| Comparison Aspect | Parts Of A Steam Boiler | Alternative 1: Electric Boiler | Alternative 2: Heat Pump Systems |

|---|---|---|---|

| Performance | High thermal efficiency, capable of producing high-pressure steam. | Good for smaller applications; limited output for larger needs. | High efficiency; effective for moderate heating needs. |

| Cost | High initial investment; ongoing fuel costs. | Lower initial cost but higher electricity costs. | Moderate initial investment; lower operating costs. |

| Ease of Implementation | Requires significant installation space and expertise. | Easier to install; less space required. | Installation can be complex, requiring professional assistance. |

| Maintenance | Regular maintenance needed to ensure safety and efficiency. | Minimal maintenance; fewer moving parts. | Moderate maintenance; requires checks for refrigerant levels. |

| Best Use Case | Ideal for heavy industrial applications with high steam demands. | Suitable for residential or light commercial use. | Best for moderate heating needs and energy efficiency goals. |

Detailed Breakdown of Alternatives

Alternative 1: Electric Boiler

Electric boilers utilize electricity to produce steam, making them a cleaner option compared to traditional gas or oil boilers. They are particularly advantageous in locations where electricity is cheaper and more reliable than fuel sources. However, electric boilers typically have lower output capacity, making them less suitable for heavy industrial applications. Their initial cost is generally lower, but electricity costs can accumulate, especially in high-demand scenarios.

Alternative 2: Heat Pump Systems

Heat pumps transfer heat from one location to another and can provide both heating and cooling. They are highly efficient, often achieving a coefficient of performance (COP) greater than 3, meaning they can produce more energy than they consume. While they are suitable for moderate heating needs, their performance can diminish in extremely cold climates. The initial installation can be complex and may require specialized knowledge, but they generally offer lower operational costs over time, making them appealing for businesses focused on energy efficiency.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate thermal energy solution requires a careful analysis of your operational requirements, budget, and long-term goals. For industries with high steam demands, traditional steam boilers remain a robust choice, offering reliability and performance. Conversely, electric boilers and heat pumps may serve well in smaller applications or where energy efficiency is a priority. Ultimately, B2B buyers should assess their specific needs, including the scale of operations and energy costs, to determine the best fit among these alternatives.

Essential Technical Properties and Trade Terminology for parts of a steam boiler

What Are the Key Technical Properties of Steam Boiler Parts?

When sourcing components for steam boilers, understanding the technical properties is essential for ensuring efficiency, safety, and longevity. Here are critical specifications that B2B buyers should consider:

-

Material Grade

The material grade of boiler components, such as carbon steel, stainless steel, or cast iron, directly affects their durability and heat resistance. Carbon steel is commonly used for pressure vessels due to its strength, while stainless steel is preferred for its corrosion resistance. Choosing the right material grade ensures that the components can withstand high temperatures and pressures, minimizing the risk of failure and reducing maintenance costs. -

Pressure Rating

The pressure rating indicates the maximum pressure that a component can safely handle, expressed in psi (pounds per square inch). This specification is crucial when selecting parts like valves and pressure gauges. Components with inadequate pressure ratings can lead to catastrophic failures, posing safety hazards and incurring costly downtime. Understanding the pressure requirements for specific applications helps in selecting appropriate components that comply with safety standards. -

Tolerance Levels

Tolerance levels define the acceptable range of variation in dimensions for manufactured parts, such as fittings and pipes. Tight tolerances ensure that components fit correctly, enhancing system efficiency and preventing leaks. For B2B buyers, specifying the right tolerances is vital to ensure compatibility with existing systems and to maintain the integrity of the steam boiler. -

Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat, which is essential for components like heat exchangers. High thermal conductivity materials, such as copper or aluminum, facilitate efficient heat transfer, improving overall boiler performance. Understanding thermal conductivity allows buyers to select parts that enhance energy efficiency and reduce operational costs. -

Corrosion Resistance

Given the high-temperature and high-pressure environments of steam boilers, components must exhibit excellent corrosion resistance. Materials treated or coated to withstand corrosive elements in steam and water can significantly extend the lifespan of boiler parts. Buyers should prioritize components with proven resistance to corrosion to minimize maintenance and replacement costs.

What Are Common Trade Terms in the Steam Boiler Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are key trade terms relevant to steam boiler parts:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in the manufacturing of a final product, such as steam boilers. Understanding OEM specifications is crucial for buyers to ensure that they are sourcing high-quality, compatible components that meet the original design criteria. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ is vital for buyers, especially when budgeting for large-scale projects. This term affects inventory management and can influence purchasing decisions based on the scale of operations. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. For buyers, submitting an RFQ allows them to compare offers and negotiate better pricing, ensuring they receive competitive quotes that align with their project budgets. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps buyers manage logistics effectively and avoid unexpected costs, especially when sourcing components from international suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. This term is critical for project planning and inventory management, as longer lead times can delay project timelines. Buyers should inquire about lead times to ensure timely delivery of essential components.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the efficiency, safety, and cost-effectiveness of their steam boiler systems.

Illustrative image related to parts of a steam boiler

Navigating Market Dynamics and Sourcing Trends in the parts of a steam boiler Sector

What Are the Global Drivers Influencing the Steam Boiler Parts Market?

The steam boiler parts market is currently experiencing significant growth, driven by several global factors. Industrial expansion, particularly in developing regions such as Africa and South America, is creating a higher demand for energy-efficient solutions. Countries like Brazil and Saudi Arabia are focusing on modernizing their infrastructure, which includes upgrading outdated boiler systems. Furthermore, the push for regulatory compliance and enhanced safety measures is prompting industries to invest in high-quality parts that meet stringent standards.

Emerging technologies are also reshaping the sourcing landscape. The adoption of smart technologies, including IoT-enabled boiler systems, is enhancing operational efficiency and predictive maintenance capabilities. This trend is particularly appealing to international buyers seeking to minimize downtime and improve overall productivity. Additionally, the rise of e-commerce platforms is facilitating easier access to a broader range of suppliers, allowing B2B buyers to compare prices and specifications efficiently.

How Are Sustainability and Ethical Sourcing Affecting B2B Decisions in the Steam Boiler Parts Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the steam boiler parts sector. Companies are increasingly aware of the environmental impact associated with boiler operations, including greenhouse gas emissions and resource depletion. As such, there is a growing emphasis on sourcing parts made from eco-friendly materials and technologies that promote energy efficiency.

Buyers are also prioritizing suppliers who demonstrate a commitment to ethical sourcing practices. This includes transparency in the supply chain, responsible labor practices, and adherence to environmental regulations. Certifications such as ISO 14001 for environmental management and Energy Star ratings for energy-efficient products are becoming essential criteria in supplier selection. By focusing on sustainability, companies not only enhance their corporate social responsibility profiles but also position themselves competitively in a market that increasingly values environmentally conscious practices.

What Is the Historical Context Behind the Steam Boiler Parts Industry?

The steam boiler parts industry has evolved significantly over the past century, influenced by technological advancements and changing market needs. Initially, steam boilers were simple devices primarily used for heating and industrial processes. As industrialization progressed, the demand for more efficient and reliable systems grew, leading to the development of sophisticated components like superheaters and economizers.

Illustrative image related to parts of a steam boiler

In recent decades, the focus has shifted towards enhancing energy efficiency and reducing emissions, reflecting broader environmental concerns. Innovations such as modular components and IoT integration have transformed the landscape, enabling real-time monitoring and maintenance. This evolution underscores the importance of adaptability in sourcing strategies, as B2B buyers must navigate a rapidly changing market characterized by both technological and regulatory shifts.

Conclusion

In conclusion, international B2B buyers in the steam boiler parts sector must stay attuned to market dynamics, sustainability trends, and historical context to make informed sourcing decisions. By understanding these elements, companies can strategically position themselves to capitalize on opportunities and address challenges in this vital industry.

Frequently Asked Questions (FAQs) for B2B Buyers of parts of a steam boiler

-

How do I solve compatibility issues with steam boiler parts?

To resolve compatibility issues with steam boiler parts, first, ensure that you have the correct specifications for your boiler model. Consult the manufacturer’s documentation or technical support for guidance on which components are suitable. When sourcing parts, work with reputable suppliers who can provide detailed product information and compatibility assurances. Additionally, consider custom solutions if standard parts do not meet your operational requirements, but verify all specifications and certifications to ensure compliance with local regulations. -

What is the best type of burner for a steam boiler?

The best type of burner for a steam boiler largely depends on the fuel type and the boiler’s operational requirements. For natural gas boilers, a low-NOx burner is often recommended to minimize emissions while maintaining efficiency. For heavy oil applications, a dual-fuel burner may be the best choice to provide flexibility. It’s crucial to assess the combustion efficiency, maintenance requirements, and safety features of the burner. Collaborating with a knowledgeable supplier can help identify the optimal burner for your specific application. -

How can I vet suppliers for steam boiler parts?

To vet suppliers for steam boiler parts, start by researching their industry reputation and experience. Look for suppliers with a proven track record in your region and check for customer reviews and references. Verify their certifications, quality assurance processes, and compliance with international standards. Engaging in direct communication can also provide insights into their responsiveness and support capabilities. Additionally, consider visiting their facilities if possible to assess their operations and inventory firsthand. -

What are common payment terms for international purchases of boiler parts?

Common payment terms for international purchases of boiler parts can vary significantly based on the supplier’s policies and the buyer’s relationship with them. Typical arrangements include payment in advance, letters of credit, or net terms (e.g., net 30 or net 60). It’s advisable to clarify payment options early in negotiations to ensure cash flow management aligns with your procurement cycle. Always confirm that payment methods are secure and that they provide adequate protection against fraud or non-delivery. -

What is the minimum order quantity (MOQ) for steam boiler parts?

Minimum order quantities (MOQ) for steam boiler parts can vary by supplier and specific part type. Generally, MOQs are influenced by manufacturing costs, inventory policies, and the nature of the component. Some suppliers may offer lower MOQs for standard parts, while custom or specialized components may require larger orders. Engaging in discussions with potential suppliers can provide flexibility, especially if you are a new customer or if you are willing to establish a long-term partnership. -

How do I ensure quality assurance for boiler parts sourced internationally?

To ensure quality assurance for internationally sourced boiler parts, request detailed product specifications, certifications, and compliance documents from suppliers. Conduct a thorough review of their quality management systems and any third-party inspection reports. It’s beneficial to establish a quality control process that includes pre-shipment inspections and quality audits. Building strong relationships with suppliers can also facilitate better communication regarding quality expectations and lead to more reliable service. -

What logistics considerations should I be aware of when importing steam boiler parts?

When importing steam boiler parts, logistics considerations include shipping methods, customs regulations, and delivery timelines. Assess the best shipping options—air freight for speed or sea freight for cost-effectiveness. Understand the customs requirements in your country, including tariffs and import documentation, to avoid delays. Collaborating with a logistics partner experienced in international trade can streamline this process and help navigate any challenges related to shipping and customs clearance. -

How can I customize steam boiler parts to meet my specific needs?

Customizing steam boiler parts begins with a clear understanding of your operational requirements and the specific modifications needed. Engage with suppliers that offer engineering services or custom manufacturing options. Provide detailed specifications and requirements to ensure that the final product meets your standards. Communication throughout the design and production process is key, and you may want to request prototypes or samples before finalizing larger orders to confirm that the custom parts will function as intended.

Top 4 Parts Of A Steam Boiler Manufacturers & Suppliers List

1. Cleaver-Brooks – Steam Boilers

Domain: cleaverbrooks.com

Registered: 1998 (27 years)

Introduction: Steam Boilers: Advanced solutions for industrial and commercial use, designed for efficiency and reliability. Types include Firetube Boilers (for commercial/small industrial), Watertube Boilers (for high pressures), Electric and Electrode Boilers (efficient, emission-free). Essential components: Pressure Vessel (ASME standards), Burner System (precision combustion), Control Systems (advanced monit…

2. GETABEC – Steam Boilers

Domain: getabecboiler.com

Registered: 1999 (26 years)

Introduction: GETABEC offers a range of steam boilers including Fire Tube Boilers, Water Tube Boilers, Hot Water Boilers, Biomass Boilers, Waste Heat Boilers (HRSG), Thermal Oil Heaters, Quick Steam Generators, and Electric Boilers. They manufacture under the license of SCHNEIDER-KESSEL Berlin and Eckrohrkessel (ERK) Berlin. Key specifications include:

– HDO 3200/13: Output 3.2 t/hr, 11 bar, Steam temperature:…

3. Savree – Watertube Boilers

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Watertube boilers convert water into steam using energy from burning fuels, primarily used in power stations. Key components include:

1. Steam Drum: Cylindrical vessel at the top that holds water and distributes steam, contains internal components like cyclone separators and scrubbers.

2. Mud Drum: Positioned at the bottom, collects sediment and impurities; may be replaced by water headers in mo…

4. Boiler Supplies – Steam Boiler & Hot Water Parts

Domain: boilersupplies.com

Registered: 2002 (23 years)

Introduction: Steam Boiler & Hot Water Supplies & Replacement Parts, Liquid Level Sight Gauges, Try Cocks, Transparent & Reflex Flat Glass Liquid Level Gauges, Boiler Trim Water Column Parts, Liquid Level Gauges, Gauge Glass Washers, Gauge Glass Accessories, Tubular Gauge Glass, Safety Sight Glass, Shell & Tube Heat Exchangers, Replacement Tube Bundles, Condensate & Boiler Feed Units, Boiler Blowdown / Blow-Off…

Strategic Sourcing Conclusion and Outlook for parts of a steam boiler

How Can Effective Strategic Sourcing Benefit Your Steam Boiler Parts Procurement?

In today’s competitive landscape, strategic sourcing of steam boiler parts is paramount for optimizing operational efficiency and reducing costs. By understanding the critical components—such as burners, heat exchangers, and economizers—international buyers can make informed decisions that enhance system performance and longevity. Establishing strong relationships with reliable suppliers not only ensures access to high-quality materials but also provides opportunities for innovation and cost savings.

Illustrative image related to parts of a steam boiler

Moreover, the global demand for steam boilers continues to rise, particularly in developing markets across Africa and South America, as well as established industries in Europe and the Middle East. This presents an ideal opportunity for businesses to leverage strategic sourcing to gain a competitive edge. By focusing on comprehensive supplier evaluations and long-term partnerships, companies can navigate market fluctuations and secure the necessary components with confidence.

As you consider your procurement strategies, take proactive steps to assess your current supply chain and identify areas for improvement. Embrace the future of sourcing by prioritizing sustainability and technological advancements. Now is the time to invest in your steam boiler parts procurement strategy—seize the opportunity to enhance your operations and drive business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to parts of a steam boiler