Choosing Your Output Dc: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for output dc

In an increasingly interconnected world, sourcing reliable output DC solutions can pose significant challenges for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The demand for efficient direct current (DC) power systems is rising, driven by applications ranging from renewable energy installations to advanced electronic devices. This guide aims to demystify the complexities surrounding output DC by providing a comprehensive overview of the various types of output DC converters, their applications, and the best practices for supplier vetting.

From understanding the nuances of voltage specifications to evaluating the cost-effectiveness of different converter options, this resource empowers decision-makers to make informed purchasing choices that align with their operational needs. By delving into critical factors such as performance metrics, regulatory compliance, and regional market trends, buyers can navigate the global landscape with confidence. The insights provided will not only enhance their procurement strategies but also ensure that they are equipped to tackle the unique challenges presented by their respective markets, ultimately driving business growth and technological advancement.

Understanding output dc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

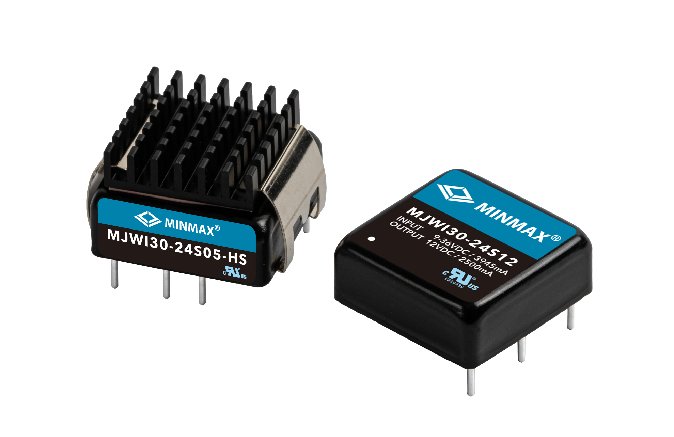

| Single Output DC Converter | Provides one output voltage; compact and cost-effective. | Consumer electronics, LED lighting. | Pros: Simple installation; Cons: Limited versatility. |

| Dual Output DC Converter | Offers two distinct output voltages; versatile design. | Telecommunications, industrial equipment. | Pros: Flexible voltage options; Cons: Slightly higher cost. |

| Adjustable DC Converter | Output voltage can be modified; suitable for varied loads. | Research and development, testing equipment. | Pros: Customizable; Cons: Requires user knowledge. |

| Isolated DC Converter | Provides electrical isolation between input and output. | Medical devices, sensitive electronics. | Pros: Enhanced safety; Cons: Higher complexity and cost. |

| High-Power DC Converter | Designed for high wattage applications; robust design. | Renewable energy systems, electric vehicles. | Pros: Handles heavy loads; Cons: Bulkier and pricier. |

What Are the Characteristics of Single Output DC Converters?

Single output DC converters are known for their simplicity and cost-effectiveness, making them ideal for applications that require only one voltage level. They are typically compact, allowing for easy integration into consumer electronics and LED lighting systems. When purchasing, buyers should consider the output voltage and current ratings to ensure compatibility with their devices. While these converters are easy to install and use, their limited versatility may not meet the needs of more complex systems.

How Do Dual Output DC Converters Differ from Other Types?

Dual output DC converters provide two distinct output voltages from a single input source, offering greater versatility for applications that require multiple voltage levels. Commonly used in telecommunications and industrial equipment, these converters can simplify wiring and reduce the need for multiple power supplies. Buyers should evaluate the specific voltage requirements and the potential for reduced installation costs. However, the slightly higher price point compared to single output options may be a consideration for budget-conscious organizations.

Why Choose an Adjustable DC Converter?

Adjustable DC converters allow users to modify the output voltage to meet varying load requirements, making them particularly useful in research and development settings or for testing equipment. These converters are favored for their flexibility and adaptability, which can lead to increased efficiency in powering diverse devices. However, buyers should ensure that their team has the technical knowledge to adjust and maintain these converters effectively, as misuse can lead to equipment damage.

What Are the Advantages of Isolated DC Converters?

Isolated DC converters offer electrical isolation between the input and output, enhancing safety and reliability, particularly in sensitive applications like medical devices and critical electronics. This feature protects against electrical shocks and interference, making them a preferred choice for high-stakes environments. Buyers should weigh the benefits of enhanced safety against the increased complexity and cost associated with these converters, ensuring they align with their operational needs.

When to Consider High-Power DC Converters?

High-power DC converters are designed to handle substantial wattage, making them essential for applications in renewable energy systems and electric vehicles. Their robust design can support heavy loads, which is crucial for industrial and commercial operations. While they are capable of delivering high performance, buyers should consider the physical size and cost, as these converters tend to be bulkier and more expensive than lower-power options.

Key Industrial Applications of output dc

| Industry/Sector | Specific Application of output dc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Solar Power Systems | Enhances energy efficiency and reduces costs | Compatibility with solar panels; voltage regulation |

| Telecommunications | Base Station Power Supplies | Ensures uninterrupted service and reliability | Input voltage range; thermal management |

| Automotive | Electric Vehicle Charging Stations | Supports growing EV market and sustainability goals | Charging speed; safety certifications |

| Industrial Automation | Robotics and Control Systems | Increases operational efficiency and precision | Load requirements; environmental resilience |

| Medical Equipment | Diagnostic and Imaging Equipment | Ensures accuracy and reliability in critical care | Compliance with medical standards; power stability |

How is output dc utilized in renewable energy systems?

In the renewable energy sector, output DC is crucial for solar power systems, where it converts solar energy into usable electrical power. This output is typically used to charge batteries or feed into the grid. For international buyers, especially in regions like Africa and South America where solar energy adoption is growing, sourcing reliable DC-DC converters is essential. They must consider compatibility with various solar panel outputs and ensure that the converters can handle the voltage and current requirements while maintaining efficiency to maximize energy output.

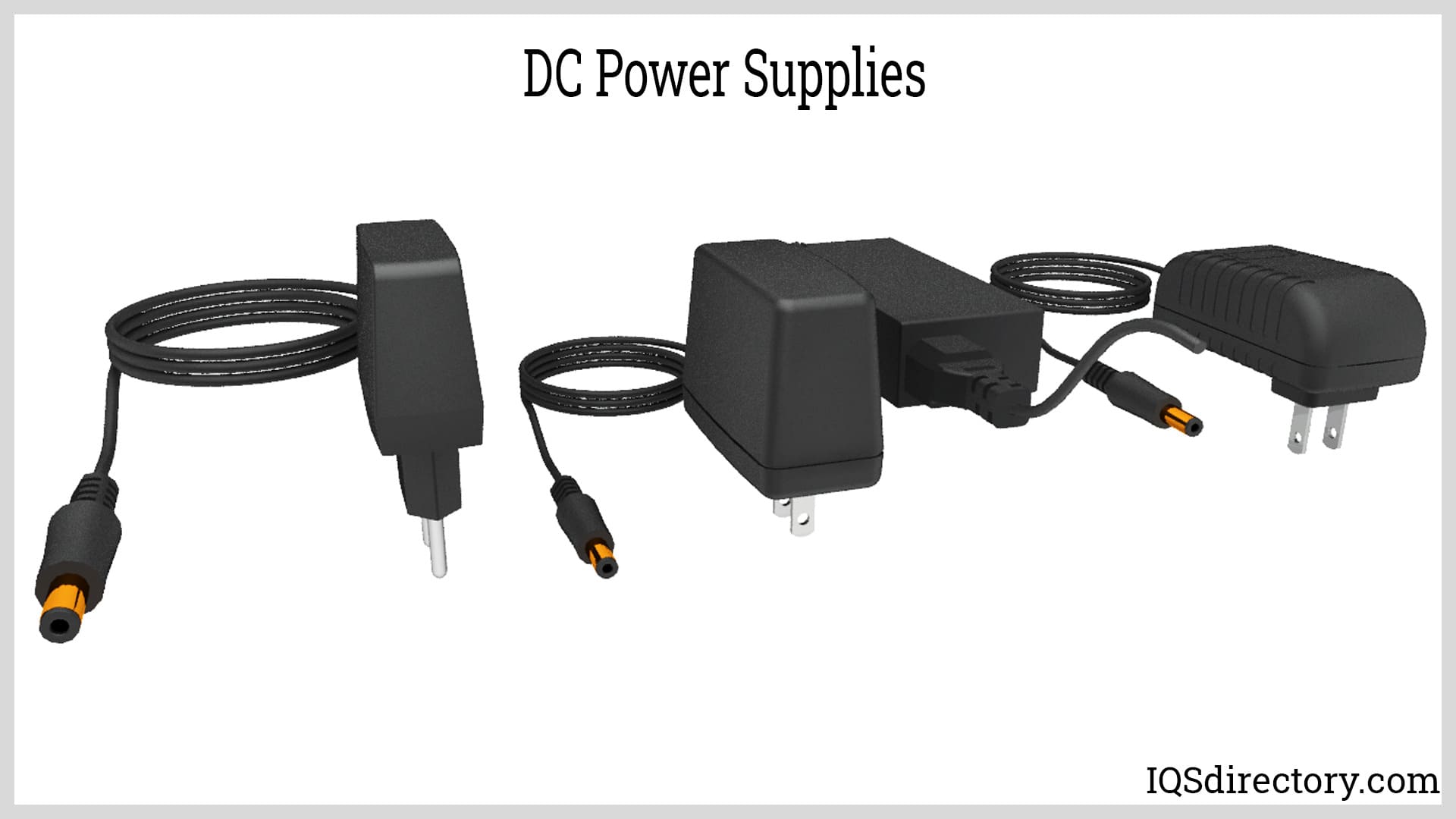

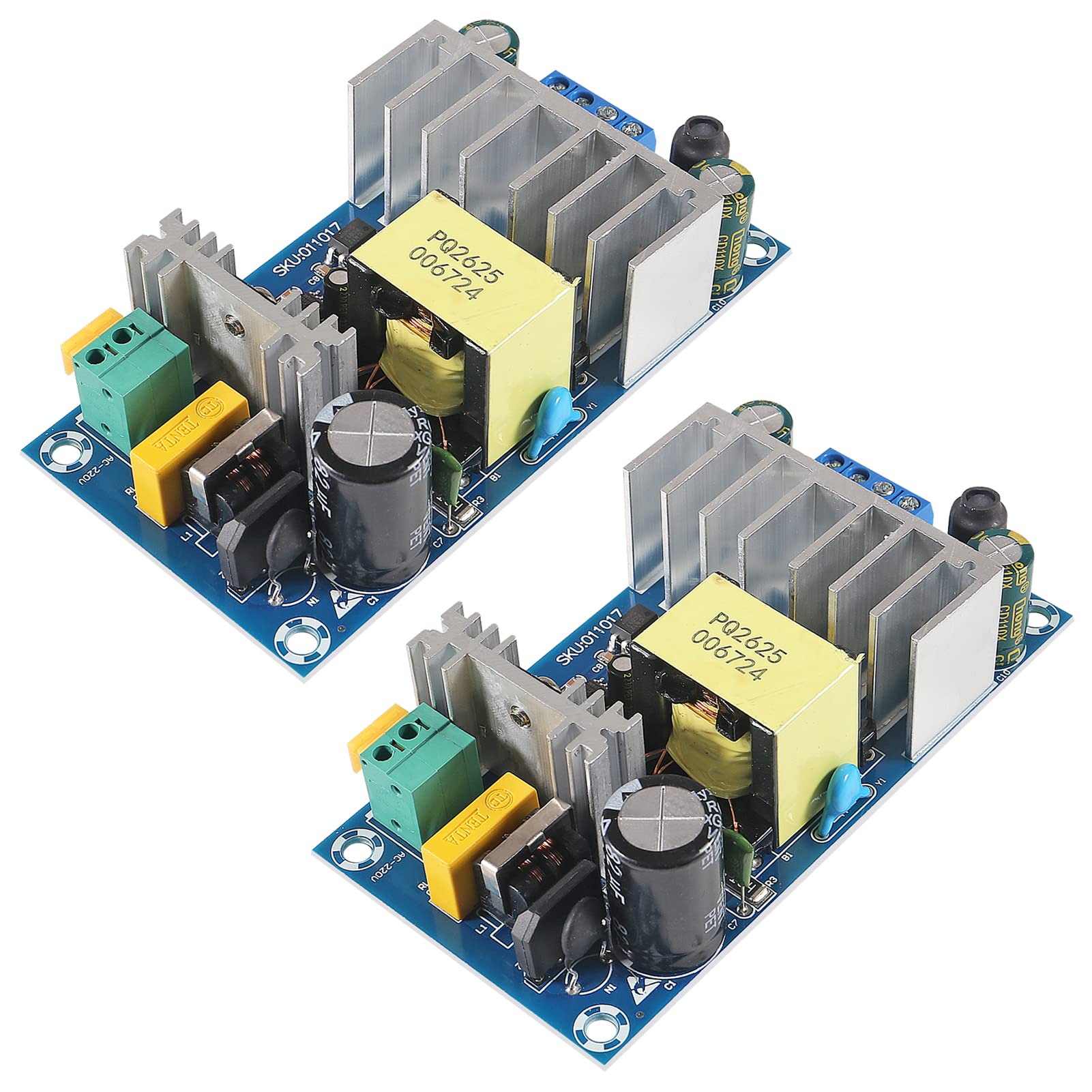

Illustrative image related to output dc

What role does output dc play in telecommunications?

In telecommunications, output DC is utilized in powering base stations that facilitate mobile communications. These systems require stable and reliable DC output to ensure uninterrupted service, particularly in remote areas. For buyers in the Middle East and Africa, sourcing power supplies that can handle variable input voltages and operate under high temperatures is critical. Additionally, ensuring that these power supplies meet regional safety and performance standards can help avoid service disruptions and enhance operational reliability.

How is output dc transforming the automotive industry?

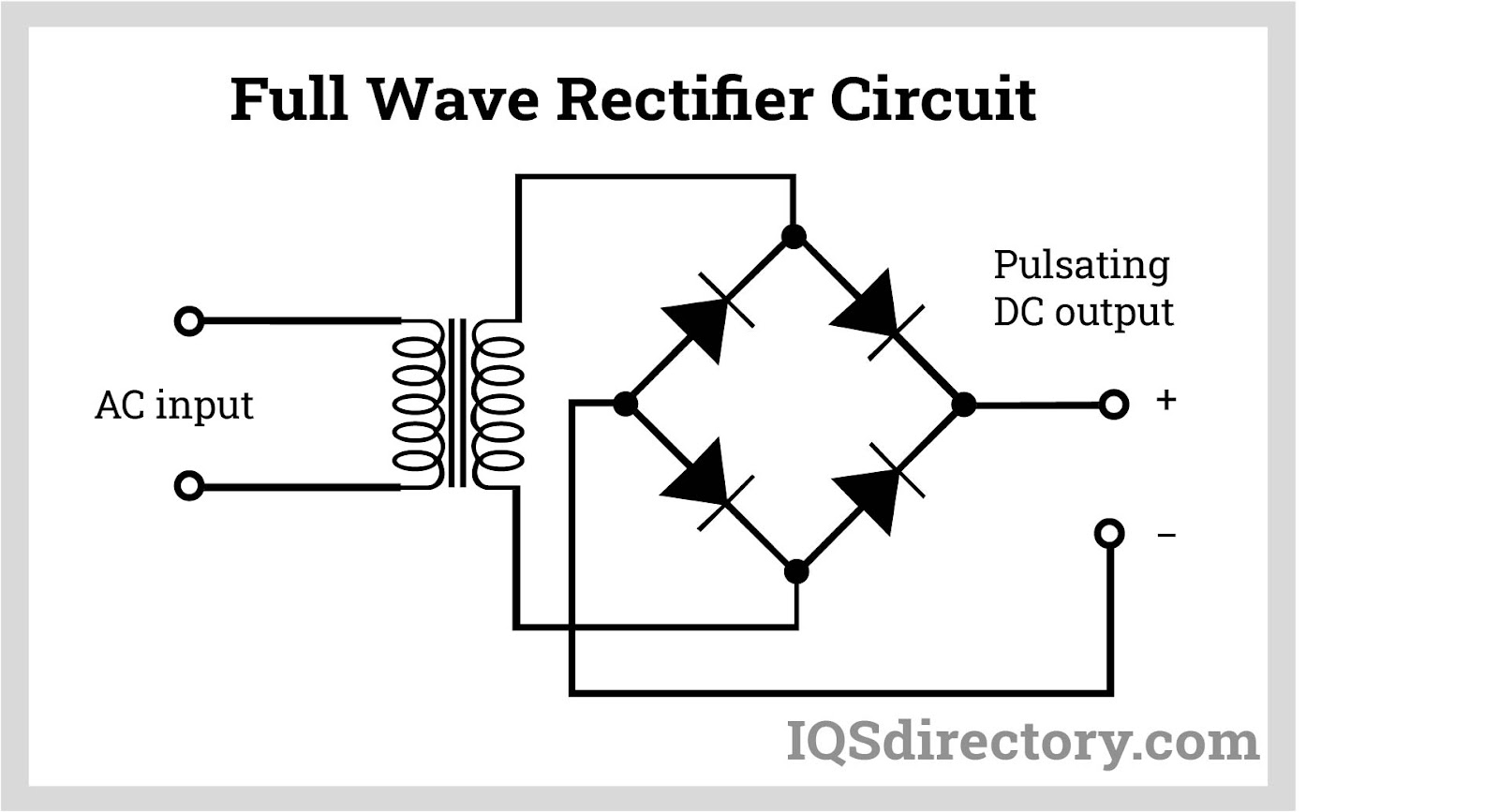

The automotive industry is increasingly relying on output DC for electric vehicle (EV) charging stations. These stations convert AC from the grid into DC for rapid charging of EV batteries. As the demand for electric vehicles rises, particularly in Europe and South America, businesses must focus on sourcing high-quality, fast-charging solutions that comply with international safety and efficiency standards. Buyers should also consider the scalability of these systems to accommodate future growth in EV adoption.

In what ways does output dc improve industrial automation?

In industrial automation, output DC is essential for powering robotics and control systems, which enhance efficiency and precision in manufacturing processes. Reliable DC power supplies ensure that these systems operate smoothly, reducing downtime and maintenance costs. For international buyers, especially those in developing regions, it is vital to source converters that can withstand challenging environments and meet specific load requirements. Additionally, understanding the efficiency ratings and thermal management capabilities of these systems is crucial for optimal performance.

Illustrative image related to output dc

How is output dc critical for medical equipment?

Output DC is vital in medical equipment, such as diagnostic and imaging devices, where precision and reliability are paramount. These devices often operate on specific voltage levels to ensure accurate readings and safe operation. For B2B buyers in the healthcare sector, particularly in Europe, sourcing DC power supplies that comply with stringent medical standards is essential. They should also evaluate the stability and reliability of the output to ensure patient safety and equipment efficacy, as any fluctuation could compromise critical medical assessments.

3 Common User Pain Points for ‘output dc’ & Their Solutions

Scenario 1: Overcoming Voltage Compatibility Issues in Diverse Applications

The Problem: One of the common challenges faced by B2B buyers, particularly those operating in regions with varying power standards, is ensuring voltage compatibility. For instance, a company in Nigeria sourcing DC output devices might need to integrate equipment that operates on different voltage levels (e.g., 12V, 24V, or 48V). This can lead to operational inefficiencies or even damage to sensitive equipment if the wrong voltage is supplied. Buyers often find themselves overwhelmed by the myriad of specifications and standards, leading to costly mistakes and project delays.

The Solution: To navigate these voltage compatibility issues, buyers should conduct a thorough assessment of their existing equipment and the specific voltage requirements of new devices. It’s advisable to engage with suppliers who offer customizable DC-DC converters that can adapt to various input voltages and provide the necessary output. For instance, sourcing a converter that accepts a wide input range (like 36V to 72V) and outputs multiple voltages can significantly simplify integration across devices. Additionally, leveraging supplier expertise during the selection process can ensure that the chosen equipment aligns with both current and future operational needs.

Illustrative image related to output dc

Scenario 2: Managing Power Efficiency and Heat Dissipation

The Problem: Another prevalent concern for B2B buyers is the efficiency of DC output systems, particularly regarding energy waste and heat generation. This is especially critical in industries such as manufacturing and telecommunications, where excessive heat can lead to equipment failure or require costly cooling solutions. Buyers may struggle to balance performance and power consumption, resulting in increased operational costs and reduced system reliability.

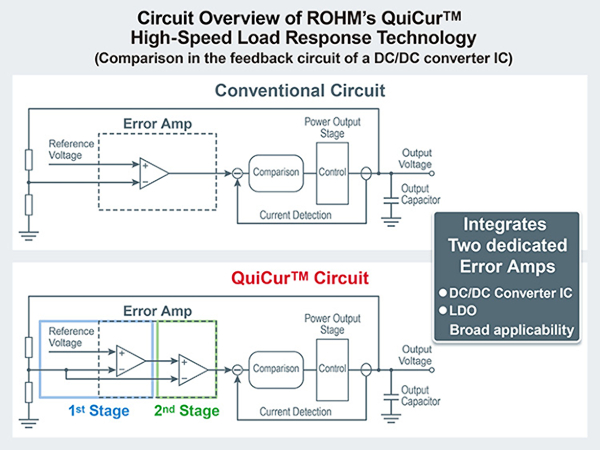

The Solution: To mitigate these issues, it is essential for buyers to prioritize energy-efficient DC-DC converters that are designed for optimal performance. Look for products that boast high efficiency ratings (above 90%) and have built-in thermal management features. This could include heat sinks or thermal cutoff mechanisms that prevent overheating. Buyers should also consider implementing monitoring solutions that track power usage and temperature, allowing for proactive adjustments to maintain efficiency. Additionally, consulting with manufacturers on best practices for installation and operation can further enhance system reliability and longevity.

Scenario 3: Ensuring Regulatory Compliance and Safety Standards

The Problem: For international B2B buyers, especially those in regions like Europe and the Middle East, navigating the complex landscape of regulatory compliance and safety standards for electrical components can be daunting. Non-compliance can lead to legal ramifications, financial penalties, and damaged reputations. Buyers may find themselves questioning whether the DC output products they are considering meet local and international safety regulations, which can stall procurement processes.

The Solution: Buyers should invest time in understanding the relevant compliance standards applicable to their industry and region, such as CE marking in Europe or IEC standards globally. Partnering with reputable suppliers who provide detailed documentation and certification for their products is crucial. Additionally, engaging in regular training and updates on compliance requirements can empower buyers to make informed decisions. It’s also beneficial to conduct due diligence on suppliers, ensuring they adhere to quality assurance processes and have a track record of successful compliance with industry standards. By proactively addressing regulatory concerns, buyers can streamline procurement and focus on their core business operations.

Strategic Material Selection Guide for output dc

What Are the Key Materials for Output DC Applications?

When selecting materials for output DC applications, it is crucial to consider their properties, advantages, and limitations. This section analyzes four common materials used in the manufacturing of output DC components, focusing on their performance characteristics and implications for international B2B buyers.

How Do Conductive Metals Perform in Output DC Applications?

Copper is the most widely used conductive metal in output DC applications due to its excellent electrical conductivity and thermal properties. It typically has a temperature rating of up to 200°C and can withstand high-pressure environments.

Pros: Copper is highly durable, resistant to corrosion, and provides low resistance, which enhances efficiency in power transmission.

Cons: The main drawbacks include its relatively high cost and susceptibility to oxidation if not properly coated. Additionally, copper’s weight can be a concern in applications where weight reduction is critical.

Impact on Application: Copper is suitable for applications requiring high conductivity, such as in power distribution systems. However, it may not be ideal for environments with high humidity or corrosive elements unless adequately protected.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with international standards such as ASTM B170 for copper wire. Understanding local availability and pricing fluctuations is also essential.

What Role Does Aluminum Play in Output DC Applications?

Aluminum is another popular choice, especially in applications where weight is a concern. It has a lower conductivity than copper but is lighter and generally less expensive.

Illustrative image related to output dc

Pros: Aluminum’s resistance to corrosion makes it suitable for outdoor applications. It is also easier to manufacture into complex shapes, which can reduce production costs.

Cons: However, aluminum has a higher electrical resistance, which can lead to energy losses. Additionally, its mechanical strength is lower than that of copper, which may limit its use in high-load applications.

Impact on Application: Aluminum is often used in overhead power lines and structures where weight savings are critical. Its compatibility with various media makes it versatile, but its limitations in high-stress environments should be considered.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B231 for aluminum conductors. In regions like the Middle East, where high temperatures are common, ensuring the material can withstand thermal expansion is vital.

How Does Polycarbonate Enhance Output DC Applications?

Polycarbonate is a thermoplastic material often used for enclosures and insulation in output DC applications. It has a temperature rating of up to 125°C and excellent impact resistance.

Illustrative image related to output dc

Pros: The primary advantage of polycarbonate is its lightweight nature combined with high durability. It is also transparent, allowing for visual monitoring of internal components.

Cons: On the downside, polycarbonate can be sensitive to UV light, which may lead to degradation over time if exposed. Its cost can also be higher than other plastics.

Impact on Application: Polycarbonate is ideal for protective casings in electronic devices, providing insulation and protection from environmental factors. However, its UV sensitivity may limit its use in outdoor applications unless treated.

Considerations for International Buyers: Compliance with safety standards such as UL 94 for flammability is crucial. Buyers in Europe should also consider REACH regulations regarding chemical safety.

What Are the Benefits of Using Thermoplastics in Output DC Applications?

Thermoplastics, such as PVC and nylon, are commonly used in insulation and housing for output DC components. They offer versatility and can be tailored for specific applications.

Pros: These materials are generally cost-effective and can be easily molded into complex shapes. They also provide good electrical insulation properties.

Cons: However, thermoplastics may have lower thermal resistance compared to metals and can degrade under high temperatures. Their mechanical properties may also vary significantly based on the formulation.

Impact on Application: Thermoplastics are suitable for applications requiring lightweight and flexible components. However, their limitations in high-temperature environments should be assessed.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM D638 for tensile properties. Understanding regional preferences for material durability and environmental impact is also essential.

Summary Table of Material Selection for Output DC Applications

| Material | Typical Use Case for output dc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Power distribution systems | Excellent conductivity and durability | High cost and oxidation susceptibility | High |

| Aluminum | Overhead power lines | Lightweight and corrosion-resistant | Higher electrical resistance | Medium |

| Polycarbonate | Protective casings for electronics | High impact resistance and lightweight | UV sensitivity and higher cost | Medium |

| Thermoplastics | Insulation and housing for components | Cost-effective and versatile | Lower thermal resistance | Low |

This guide serves as a strategic reference for international B2B buyers, helping them make informed decisions regarding material selection for output DC applications.

In-depth Look: Manufacturing Processes and Quality Assurance for output dc

What Are the Main Stages of Manufacturing Processes for Output DC Devices?

The manufacturing of output DC devices, such as DC-DC converters, involves several critical stages that ensure efficiency, reliability, and performance. Understanding these stages is essential for B2B buyers who are sourcing from international suppliers.

Material Preparation: What Materials Are Used in Output DC Manufacturing?

The first step in the manufacturing process is material preparation. This includes sourcing high-quality components such as semiconductors, capacitors, inductors, and resistors. The choice of materials directly impacts the efficiency and longevity of the product. Suppliers often leverage materials that meet international standards for safety and durability, such as RoHS (Restriction of Hazardous Substances) compliance.

How Are Output DC Devices Formed?

Once materials are prepared, the next stage is forming. This typically involves techniques such as PCB (Printed Circuit Board) fabrication, where the electronic components are mounted onto a board. Advanced methods like surface-mount technology (SMT) allow for compact designs and better electrical performance. Moreover, forming processes may include automated soldering techniques to ensure consistent quality and reduce production time.

What Assembly Techniques Are Common in Output DC Manufacturing?

The assembly stage is crucial for integrating all components into a functional unit. Techniques such as automated assembly lines are commonly employed to enhance productivity. Quality assurance begins here, as proper alignment and connections are necessary to prevent failures.

During assembly, devices may undergo initial functionality tests to ensure they meet design specifications. This stage may also involve the installation of protective casings or heat sinks, which are vital for maintaining performance under various operating conditions.

What Finishing Processes Are Involved in Output DC Devices?

Finishing processes finalize the manufacturing stage. This includes applying coatings for protection against environmental factors and aesthetic enhancements. For output DC devices, thermal and electrical insulation coatings are essential. Additionally, labeling and packaging are performed to prepare the products for shipment, ensuring they are identifiable and compliant with international shipping standards.

What Quality Assurance Measures Are in Place for Output DC Devices?

Quality assurance is a vital component of the manufacturing process, ensuring that the final products meet required specifications and standards.

Which International Standards Are Relevant to Output DC Quality Assurance?

International standards like ISO 9001 provide a framework for quality management systems, focusing on continuous improvement and customer satisfaction. Compliance with these standards is crucial for suppliers aiming to operate in global markets. Industry-specific standards, such as CE marking for the European market or UL certification for North America, also play a significant role in ensuring safety and reliability.

What Are the Key Quality Control Checkpoints in Output DC Manufacturing?

Quality control checkpoints are strategically placed throughout the manufacturing process. These typically include:

Illustrative image related to output dc

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During the assembly and forming stages, IPQC checks are conducted to monitor processes and ensure compliance with production specifications.

-

Final Quality Control (FQC): After assembly, FQC involves comprehensive testing of the finished product to confirm functionality, reliability, and safety.

What Common Testing Methods Are Used to Ensure Output DC Quality?

Several testing methods are employed to ensure the quality of output DC devices. These include:

-

Electrical Testing: Verifying voltage, current, and power output to ensure compliance with specifications.

-

Thermal Testing: Assessing the device’s performance under different temperature conditions to ensure it operates within safe limits.

-

Load Testing: Subjecting the device to its maximum rated load to evaluate performance and reliability.

-

Environmental Testing: Simulating real-world conditions such as humidity, vibration, and shock to ensure durability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take steps to ensure the quality of their suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. Audits should assess compliance with international standards and internal quality metrics.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the testing methods employed and the results obtained. This transparency is crucial for building trust.

-

Third-party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment, ensuring that the products meet the buyer’s specifications.

What Are the QC Certification Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances regarding quality control certifications.

-

Regional Compliance: Different regions have varying compliance requirements. For instance, CE marking is essential for products sold in Europe, while products exported to the Middle East may require specific local certifications.

-

Documentation: Buyers should request comprehensive documentation of certifications and compliance tests from suppliers. This documentation is vital for customs clearance and regulatory compliance in the buyer’s country.

-

Cultural Differences: Understanding cultural nuances in business practices can facilitate smoother communication and ensure that quality expectations are clearly defined and met.

By being informed about the manufacturing processes and quality assurance measures, B2B buyers can make educated decisions when sourcing output DC devices, ensuring that they obtain products that are not only reliable but also compliant with international standards.

Illustrative image related to output dc

Practical Sourcing Guide: A Step-by-Step Checklist for ‘output dc’

Introduction

This sourcing guide is designed to assist international B2B buyers in procuring DC output converters effectively. By following this checklist, you will ensure that you make informed decisions that meet your specific technical requirements while optimizing supplier relationships and costs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements for the DC output converters. This includes voltage, current capacity, and specific application needs. Defining these specifications helps you narrow down suitable products and ensures compatibility with your existing systems.

- Voltage Requirements: Determine the necessary input and output voltage levels.

- Current Ratings: Specify the required output current to match your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in DC output converters. Look for manufacturers with a proven track record and positive customer feedback. This will lay the groundwork for a successful procurement process.

- Online Reviews: Check industry forums and platforms for supplier ratings.

- Industry Experience: Prioritize suppliers with experience in your specific market or region.

Step 3: Evaluate Product Quality and Compliance

Assess the quality of the products offered by suppliers. Ensure that their DC output converters meet international standards and certifications such as CE or FCC. This step is crucial to prevent issues related to performance and safety.

Illustrative image related to output dc

- Quality Certifications: Request documentation of compliance with relevant standards.

- Testing Procedures: Inquire about their quality assurance processes and product testing.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers possess the necessary certifications and licenses to operate in your region. This step protects you from legal and compliance issues that could arise from sourcing products from unverified vendors.

- Legal Compliance: Confirm that suppliers adhere to local regulations.

- Certifications: Look for ISO certifications or similar quality management standards.

Step 5: Request Samples for Testing

Before finalizing your order, request samples of the DC output converters to test in your application. This allows you to evaluate product performance and compatibility firsthand, reducing the risk of costly mistakes.

- Testing Criteria: Establish parameters for testing, such as efficiency and thermal performance.

- Feedback Loop: Use the sample testing phase to communicate with suppliers about any necessary adjustments.

Step 6: Negotiate Terms and Pricing

Once you have selected your preferred supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to better pricing and favorable terms that benefit your procurement process.

- Volume Discounts: Inquire about discounts for bulk orders.

- Payment Flexibility: Discuss payment options that suit your financial planning.

Step 7: Establish a Long-term Relationship

After successful procurement, consider establishing a long-term relationship with your supplier. This can lead to better service, more favorable pricing, and collaboration on future projects.

Illustrative image related to output dc

- Regular Communication: Maintain open lines of communication for future needs.

- Feedback Mechanism: Provide feedback to help suppliers improve their products and services.

By following this checklist, B2B buyers can make informed decisions, ensuring a smooth procurement process for DC output converters tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for output dc Sourcing

When sourcing output DC products, a comprehensive understanding of the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will cover the key components of cost, the various influencers on pricing, and strategic tips for negotiation and sourcing efficiency.

What Are the Key Cost Components for Output DC Products?

The cost structure for output DC products typically includes several components:

-

Materials: The quality and type of materials used in manufacturing output DC converters can significantly impact costs. Higher-grade materials usually lead to better performance and longevity, which may justify a higher price.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for manufacturing. In some regions, lower labor costs may offset higher material expenses, leading to competitive pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, particularly for custom output DC products. These costs are often amortized over the production run, making them a critical factor for larger orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards, which can add to the overall cost but are essential for minimizing returns and enhancing brand reputation.

-

Logistics: Transportation and handling fees, especially for international shipping, are vital components of the cost structure. Incoterms will determine who bears these costs, impacting the overall pricing strategy.

-

Margin: Suppliers will typically apply a markup to cover their operational costs and desired profit margins. This can vary widely based on market competition and supplier positioning.

How Do Volume and Specifications Influence Pricing?

Pricing for output DC products is influenced by several key factors:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better terms and reduce per-unit costs.

-

Specifications and Customization: Custom specifications or unique features may lead to higher prices due to additional development and production costs. Buyers should carefully assess the necessity of custom features against budget constraints.

-

Materials and Quality Certifications: The presence of quality certifications (e.g., CE, FCC) can influence pricing. Buyers should weigh the benefits of certified products against potential cost increases.

-

Supplier Factors: Supplier reliability, reputation, and the overall relationship can affect pricing. Long-term partnerships may lead to more favorable pricing due to established trust and volume-based negotiations.

-

Incoterms: The agreed-upon Incoterms will affect logistics costs and responsibilities. Buyers should be aware of these terms to avoid unexpected expenses.

What Negotiation Tips Can Enhance Cost Efficiency for International Buyers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Understand Total Cost of Ownership (TCO): When evaluating pricing, consider not just the purchase price but also factors like maintenance, energy consumption, and lifespan. A lower upfront cost may lead to higher long-term expenses.

-

Leverage Competition: Engaging multiple suppliers can drive competitive pricing. Requesting quotes from different manufacturers can provide leverage during negotiations.

-

Negotiate Payment Terms: Flexible payment terms can help manage cash flow and allow for better budgeting, especially for large purchases.

-

Focus on Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and enhanced support.

-

Be Aware of Pricing Nuances: Currency fluctuations and trade tariffs can impact international sourcing costs. Staying informed about these factors can help in making timely purchasing decisions.

Conclusion: How to Approach Pricing in Output DC Sourcing?

While indicative prices for output DC products can vary widely, understanding the underlying cost structure and pricing influencers allows buyers to make informed decisions. By employing strategic negotiation techniques and considering the total cost of ownership, international buyers can optimize their sourcing strategies, ensuring they receive the best value for their investment.

Alternatives Analysis: Comparing output dc With Other Solutions

Understanding Alternatives in DC Output Solutions

In the landscape of electrical systems, particularly in industrial and commercial applications, choosing the right power conversion solution is crucial. While ‘output DC’ systems have their advantages, it’s essential to consider alternative solutions that may provide better performance, cost-efficiency, or ease of implementation. This analysis will compare ‘output DC’ with two viable alternatives: AC-DC converters and battery-powered systems.

Comparison Table

| Comparison Aspect | Output DC | AC-DC Converter | Battery-Powered Systems |

|---|---|---|---|

| Performance | High efficiency, stable output | Good for variable loads, less efficient | Dependent on battery type, can vary |

| Cost | Moderate initial investment | Generally lower cost, but requires AC source | Higher long-term costs due to replacements |

| Ease of Implementation | Requires integration with existing systems | Simple installation in AC environments | Setup complexity varies by application |

| Maintenance | Low maintenance with proper use | Moderate, requires periodic checks | High, regular battery replacement needed |

| Best Use Case | Industrial applications needing stable DC power | Residential and commercial power supply | Remote applications without grid access |

Detailed Breakdown of Alternatives

What Are the Advantages and Disadvantages of AC-DC Converters?

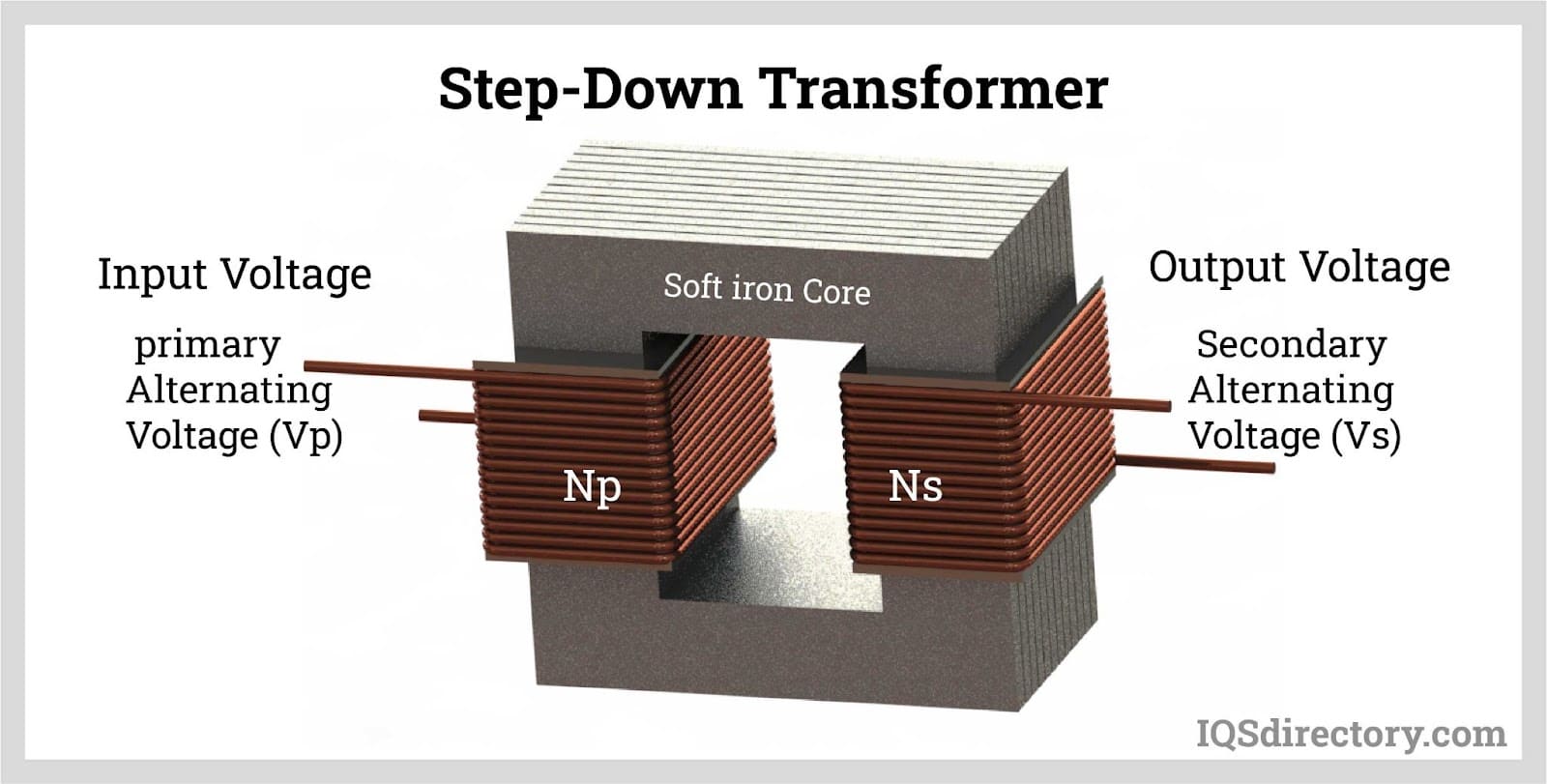

AC-DC converters are widely used in various applications due to their ability to convert alternating current (AC) from the grid into direct current (DC) for use in electronic devices. Their primary advantage is cost-effectiveness, especially in setups where AC power is readily available. They tend to be simpler to install and maintain compared to ‘output DC’ systems since they leverage existing AC infrastructure. However, they may not achieve the same level of efficiency as dedicated ‘output DC’ systems, especially under variable loads. Thus, they might result in higher operational costs in the long run.

How Do Battery-Powered Systems Compare to Output DC Solutions?

Battery-powered systems are an excellent alternative, particularly in environments where grid access is limited or non-existent. These systems provide the flexibility of mobile power solutions and are ideal for remote applications. However, the performance of battery systems can be inconsistent, as it heavily relies on the type and condition of the batteries used. The initial investment can be lower, but ongoing costs associated with battery replacements can accumulate over time, making this option potentially more expensive in the long term. Maintenance is also more frequent and involved, requiring regular checks and replacements.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate power solution requires careful consideration of your specific operational needs. If your application demands a stable and efficient power source, ‘output DC’ systems may be the best choice, particularly in industrial settings. On the other hand, if budget constraints are a priority and your installation is primarily in an area with existing AC infrastructure, an AC-DC converter might be more suitable. Conversely, for remote operations where grid access is not feasible, battery-powered systems offer invaluable flexibility despite their higher maintenance requirements. By weighing these factors, B2B buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for output dc

What Are the Key Technical Properties of Output DC?

When considering output DC systems, several critical specifications must be understood to ensure compatibility and performance. Here are the essential properties:

1. Voltage Rating

The voltage rating specifies the maximum voltage that the output DC can deliver. It is crucial for matching the system’s requirements, as exceeding this rating can lead to equipment damage or failure. Buyers should always verify the voltage specifications to align with their operational needs, particularly in applications involving sensitive electronic devices.

2. Current Capacity (Amperage)

Current capacity indicates the maximum amount of current that can flow through the output DC system, measured in amperes (amps). This property is vital for ensuring that the system can handle the load without overheating or causing circuit failures. For B2B buyers, understanding the current requirements of their devices helps prevent costly downtime due to inadequate power supply.

3. Efficiency Rating

Efficiency measures how effectively a DC output system converts input power to output power. High efficiency means less energy waste, which is critical for reducing operational costs, especially in large-scale applications. Buyers should seek systems with high-efficiency ratings to enhance their energy savings and reduce the carbon footprint of their operations.

4. Operating Temperature Range

The operating temperature range indicates the environmental conditions under which the output DC system can function optimally. This specification is particularly important for industries in regions with extreme temperatures, such as parts of Africa and South America. Ensuring that the equipment operates within the specified range helps maintain performance and longevity.

5. Ripple Voltage

Ripple voltage refers to the AC voltage fluctuations superimposed on the DC output. High ripple voltage can adversely affect sensitive electronic components. B2B buyers should consider ripple specifications to ensure the reliability and stability of their electronic systems, especially in critical applications.

What Are Common Trade Terms Related to Output DC?

Understanding industry jargon can significantly enhance communication and negotiation in B2B transactions. Here are some common terms you might encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of output DC, OEMs are crucial as they often set the standards for quality and compatibility. Buyers should engage with reputable OEMs to ensure they receive reliable and compliant products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is particularly important for B2B buyers as it impacts inventory management and cost-effectiveness. Understanding MOQ helps businesses plan their purchases more strategically and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This term is vital in procurement processes, allowing buyers to compare options and negotiate better deals. Crafting a comprehensive RFQ can lead to more favorable terms and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps B2B buyers understand shipping costs, risks, and delivery responsibilities, making it easier to navigate cross-border trade.

Illustrative image related to output dc

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. This term is essential for project planning and inventory management, particularly in industries with tight deadlines. B2B buyers should always inquire about lead times to ensure they can meet their operational schedules.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions regarding output DC systems, ultimately enhancing their operational efficiency and strategic purchasing capabilities.

Navigating Market Dynamics and Sourcing Trends in the output dc Sector

What Are the Key Drivers Shaping the Global Output DC Market?

The output DC sector is experiencing significant growth, driven by several global trends. The increasing demand for efficient energy solutions, particularly in renewable energy applications, has propelled the need for reliable DC output systems. As countries in Africa, South America, the Middle East, and Europe push for sustainable energy sources, the integration of DC systems in solar and wind applications is becoming critical. The rise of electric vehicles (EVs) is another key driver, as these vehicles require sophisticated DC output technologies for charging and performance.

Emerging B2B tech trends include the adoption of smart grid technology and the Internet of Things (IoT), which facilitate real-time monitoring and management of energy consumption. Companies are increasingly looking for DC-DC converters and power supplies that are not only efficient but also compact and versatile to meet diverse application needs. Moreover, as organizations seek to optimize supply chains, the focus on sourcing from manufacturers who offer customizable solutions is becoming more pronounced. This adaptability allows buyers to tailor products to fit specific operational requirements, enhancing efficiency and reducing waste.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Output DC Sector?

Sustainability is becoming an essential consideration for B2B buyers in the output DC market. The environmental impact of sourcing decisions can no longer be overlooked, as stakeholders demand transparency regarding the origins and lifecycle of products. Buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices, ensuring that materials used in output DC systems are sourced responsibly and sustainably.

The importance of certifications such as ISO 14001 (Environmental Management) and RoHS (Restriction of Hazardous Substances) cannot be understated. These certifications signal a commitment to minimizing environmental impact and promoting sustainable practices. Furthermore, the growing trend of circular economy principles encourages companies to adopt practices that reduce waste and enhance product lifecycle management. B2B buyers can leverage these sustainable sourcing strategies to enhance their brand reputation and meet regulatory requirements, while also appealing to an environmentally-conscious consumer base.

How Has the Output DC Market Evolved Over Time?

The output DC sector has undergone a remarkable evolution since its inception. Initially dominated by basic power supply units, the market has expanded to include a range of sophisticated devices such as DC-DC converters and power management systems. The shift towards renewable energy sources and electric vehicles has spurred innovation, prompting manufacturers to develop advanced technologies that enhance efficiency and reliability.

In the early 2000s, the focus was primarily on meeting basic power needs, but the landscape has shifted dramatically with the advent of smart technologies and IoT integration. Today, the market is characterized by a demand for multifunctional devices capable of adapting to various applications, from industrial machinery to consumer electronics. This evolution reflects a broader trend towards sustainability and efficiency, which will continue to shape the output DC sector for years to come.

By understanding these dynamics, B2B buyers can make informed sourcing decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of output dc

-

How do I select the right DC output converter for my application?

Selecting the right DC output converter involves assessing your specific requirements, including input voltage, output voltage, and current capacity. Consider the power needs of your devices, the environment (temperature and humidity), and any regulatory standards applicable in your region. It’s also crucial to evaluate the converter’s efficiency and safety features. Consulting with suppliers about your application can provide insights into the most suitable models, ensuring compatibility and reliability for your operations. -

What are the key specifications to consider when sourcing DC output converters?

When sourcing DC output converters, focus on specifications such as input and output voltage ranges, current ratings, efficiency levels, and thermal management capabilities. Additional factors include size and form factor, safety certifications (like CE or UL), and any required features such as short-circuit protection or overload protection. Understanding these specifications helps you choose products that align with your technical requirements and operational goals. -

What is the typical lead time for sourcing DC output converters internationally?

Lead times for international sourcing of DC output converters can vary significantly based on factors like supplier location, product availability, and shipping methods. Typically, lead times range from 2 to 12 weeks. It’s advisable to confirm with your supplier regarding their production schedules and shipping times to ensure your project timelines are met. Additionally, consider customs clearance times, which can also impact overall delivery. -

What are the minimum order quantities (MOQ) for DC output converters?

Minimum order quantities (MOQ) for DC output converters can vary depending on the manufacturer and the specific product line. Generally, MOQs may range from 10 to 100 units. It’s essential to discuss MOQs with your supplier upfront, as some may offer flexibility for first-time buyers or bulk orders. Understanding MOQs can help you better plan your inventory and budget. -

How can I ensure quality assurance (QA) for DC output converters sourced from international suppliers?

To ensure quality assurance (QA) for DC output converters, request product samples for testing before placing bulk orders. Establish clear quality standards and specifications with your supplier and inquire about their QA processes, including certifications and testing procedures. Conducting a factory audit or third-party inspection can also help verify the supplier’s capabilities. Regular communication and feedback can strengthen the partnership and enhance product quality. -

What payment terms are typically offered by suppliers for DC output converters?

Payment terms can vary widely among suppliers, but common practices include upfront payment, partial payment with the balance due upon shipment, or net 30/60 days after delivery. Some suppliers may also accept letters of credit or escrow services for larger transactions. It’s advisable to negotiate payment terms that align with your cash flow and risk management strategies while ensuring that they are secure and fair. -

What factors should I consider regarding logistics when sourcing DC output converters?

When considering logistics for sourcing DC output converters, evaluate shipping options, costs, and delivery times. Factor in the supplier’s location, your destination, and any potential customs duties or tariffs that may apply. Choose reliable freight forwarders and consider options for tracking shipments. Additionally, ensure that the packaging is suitable for protecting the converters during transit, which can minimize damage and returns. -

How can I vet suppliers for DC output converters to ensure reliability?

Vetting suppliers for DC output converters involves researching their reputation, checking customer reviews, and validating their industry certifications. Request references from previous clients and assess their production capacity and lead times. Additionally, consider visiting the supplier’s facility if possible, or use third-party auditing services to evaluate their quality control processes. Establishing clear communication and agreement on expectations can further enhance the reliability of your supplier relationship.

Top 4 Output Dc Manufacturers & Suppliers List

1. IQS Directory – DC Power Supply Essentials

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: DC Power Supply: Basics, Types and Applications; Types of DC/DC Power Supplies; Applications include server power supplies, electric vehicles, telecommunication infrastructure, IoT devices; Input types: AC, DC (5V, 12V, 24V, 48V), battery; Features include overvoltage protection, current limiting, smart charging technology; Energy harvesting from renewable sources; Block diagram illustrates regula…

2. CP Power Automation – DC-DC Converters

Domain: cppowerautomation.com

Registered: 1999 (26 years)

Introduction: DC-DC converters are essential components in power management systems, designed to convert one DC voltage level to another. They are widely used in various applications, including renewable energy systems, electric vehicles, and industrial automation. Key features include high efficiency, compact design, and the ability to handle a wide range of input voltages. These converters can provide stable …

3. Keysight – Variable DC Power Supplies

Domain: keysight.com

Registered: 2012 (13 years)

Introduction: This company, Keysight – Variable DC Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Jameco – AC-to-DC Multiple Output Power Supplies

Domain: jameco.com

Registered: 1998 (27 years)

Introduction: AC-to-DC Switching Enclosed Multiple Output Supplies available at Jameco Electronics. Products include single output power supplies, multiple output power supplies, and switching DC power supplies. All multiple output enclosed power supplies come with chassis and cover. Jameco has over 50 years of experience and offers a wide range of electronic components including over 70,000 items such as semic…

Strategic Sourcing Conclusion and Outlook for output dc

In the evolving landscape of DC output sourcing, strategic procurement stands out as a pivotal element for international B2B buyers. Emphasizing the importance of understanding specifications—such as input/output voltages and power ratings—can significantly enhance operational efficiency and product reliability. By leveraging a comprehensive approach to sourcing, organizations can not only mitigate risks associated with component failures but also capitalize on cost savings through bulk purchasing agreements and supplier partnerships.

Buyers from regions like Africa, South America, the Middle East, and Europe, including Nigeria and Brazil, should prioritize suppliers that offer robust customer support and technical expertise. This ensures that any challenges encountered can be swiftly addressed, safeguarding project timelines and budgets.

As we look to the future, staying abreast of technological advancements and market trends will be crucial. Engaging with suppliers who demonstrate innovation and adaptability will empower businesses to remain competitive in their respective markets. We encourage you to explore strategic sourcing opportunities that align with your operational goals and to forge partnerships that facilitate growth and sustainability in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.