Choosing Your Nylon Bristle Brush: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for nylon bristle brush

In today’s competitive landscape, sourcing the right nylon bristle brush can pose significant challenges for international B2B buyers. The diverse applications of these brushes—from industrial cleaning to specialized tasks in automotive and food service sectors—demand a comprehensive understanding of product specifications, supplier reliability, and cost-effectiveness. This guide offers a thorough exploration of the nylon bristle brush market, covering various types, their applications, and key considerations for supplier vetting. It also addresses crucial aspects such as pricing strategies and quality standards to help buyers navigate their sourcing decisions effectively.

This resource is designed to empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Vietnam and Germany. By delving into the nuances of nylon bristle brush procurement, buyers can make informed decisions that align with their operational needs and budget constraints. Additionally, the guide emphasizes best practices in supplier engagement and highlights potential challenges in logistics and compliance, ensuring that you not only find the right products but also build sustainable relationships with your suppliers. With this information at your fingertips, you will be better equipped to streamline your purchasing processes and enhance your operational efficiency.

Understanding nylon bristle brush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard Bristle Brush | Stiff nylon bristles for tough scrubbing | Industrial cleaning, heavy-duty applications | Pros: Effective for tough grime; durable. Cons: Can scratch delicate surfaces. |

| Soft Bristle Brush | Flexible nylon bristles for gentle cleaning | Janitorial services, delicate surfaces | Pros: Safe for sensitive surfaces; versatile. Cons: May not handle tough stains effectively. |

| Bottle Brush | Long, narrow design for cleaning bottles and tubes | Food and beverage industry, laboratory use | Pros: Reaches narrow spaces; thorough cleaning. Cons: Limited use outside narrow applications. |

| Tile and Grout Brush | Angled bristles for effective grout cleaning | Construction, facility maintenance | Pros: Specialized for tile surfaces; efficient. Cons: Not suitable for all surfaces. |

| Specialty Brushes | Custom shapes and bristle configurations | Automotive, aerospace, and industrial sectors | Pros: Tailored for specific tasks; high efficiency. Cons: Higher cost; may require custom orders. |

What Are the Characteristics of Hard Bristle Brushes?

Hard bristle brushes feature stiff nylon bristles designed for rigorous scrubbing tasks. These brushes excel in industrial cleaning environments where tough grime and stubborn stains are common. B2B buyers in sectors such as manufacturing and construction find these brushes invaluable for maintaining equipment and surfaces. When purchasing, consider the brush’s durability and bristle stiffness to match the specific cleaning demands of your facility.

How Do Soft Bristle Brushes Differ in Use?

Soft bristle brushes utilize flexible nylon bristles, making them ideal for gentle cleaning tasks. They are particularly well-suited for janitorial services and environments where delicate surfaces are present, such as in healthcare or hospitality. Buyers should evaluate the brush’s bristle softness to ensure it meets their cleaning needs without risking damage to surfaces. While effective for routine cleaning, they may not tackle tougher stains as efficiently as their hard-bristled counterparts.

What Makes Bottle Brushes Essential in Certain Industries?

Bottle brushes are uniquely designed with long, narrow bristles to clean bottles, tubes, and other hard-to-reach areas. They are particularly useful in the food and beverage industry, as well as in laboratories where cleanliness is paramount. B2B buyers should consider the brush length and bristle density to ensure thorough cleaning. While they excel in specific applications, their utility may be limited outside of narrow spaces, which is an important factor to keep in mind.

Why Are Tile and Grout Brushes Specialized Tools?

Tile and grout brushes feature angled bristles that are specifically designed for cleaning tile surfaces and grout lines. These brushes are commonly used in construction and facility maintenance to ensure cleanliness in high-traffic areas. When selecting a tile and grout brush, B2B buyers should look for features such as bristle stiffness and brush shape to optimize cleaning effectiveness. However, these brushes may not be suitable for all surfaces, necessitating careful consideration of the intended application.

How Do Specialty Brushes Benefit Specific Industries?

Specialty brushes are crafted with unique shapes and bristle configurations tailored for specific tasks in industries such as automotive, aerospace, and manufacturing. These brushes can significantly enhance cleaning efficiency and precision. B2B buyers should assess the customizability and intended use of these brushes, as they may come at a higher cost and often require special orders. Their effectiveness in specialized applications can justify the investment for businesses that require high-performance cleaning tools.

Key Industrial Applications of nylon bristle brush

| Industry/Sector | Specific Application of nylon bristle brush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cleaning food processing equipment and surfaces | Ensures hygiene compliance and reduces contamination risks | Food-grade materials, resistance to harsh cleaning chemicals |

| Automotive Manufacturing | Surface preparation and cleaning of automotive parts | Enhances product quality and prevents defects | Durability, bristle stiffness, compatibility with various surfaces |

| Janitorial Services | General cleaning of floors, tiles, and surfaces | Increases efficiency in cleaning operations | Ergonomic design, size options, ease of use |

| Pharmaceutical Industry | Cleaning and sterilizing manufacturing equipment | Maintains product integrity and regulatory compliance | FDA compliance, non-scratch options, ease of sterilization |

| Aerospace and Defense | Precision cleaning of components and assemblies | Ensures safety and reliability of critical systems | Anti-static properties, customized sizes, and shapes |

How is a Nylon Bristle Brush Utilized in Food Processing?

In the food processing industry, nylon bristle brushes are essential for cleaning machinery and surfaces that come into contact with food. They effectively remove residues and contaminants, ensuring compliance with hygiene regulations. These brushes can withstand harsh cleaning agents, making them ideal for rigorous sanitation protocols. International buyers must consider food-grade materials and bristle types that resist degradation from chemicals to ensure safety and efficiency in their operations.

What Role Do Nylon Bristle Brushes Play in Automotive Manufacturing?

Automotive manufacturers use nylon bristle brushes for surface preparation and cleaning of parts before assembly or painting. These brushes help eliminate dust, grease, and other contaminants that could affect product quality. By ensuring a clean surface, manufacturers can prevent defects and enhance the durability of their products. Buyers should focus on the durability and stiffness of the bristles, as well as compatibility with various automotive materials, to meet specific cleaning requirements.

Why Are Nylon Bristle Brushes Important for Janitorial Services?

Janitorial services rely on nylon bristle brushes for a wide range of cleaning tasks, from scrubbing floors to detailing surfaces. The versatility of these brushes allows for efficient cleaning across different environments, including offices, schools, and hospitals. Their ergonomic designs and various sizes cater to diverse cleaning needs, improving the overall effectiveness of cleaning crews. Sourcing considerations should include the brush’s ease of use and maintenance, ensuring longevity and efficiency in cleaning operations.

How Do Nylon Bristle Brushes Support the Pharmaceutical Industry?

In the pharmaceutical industry, maintaining a sterile environment is crucial. Nylon bristle brushes are used to clean and sterilize equipment, ensuring that no contaminants affect product quality. These brushes must meet strict regulatory standards, including FDA compliance, to ensure safety. Buyers should look for brushes that are easy to sterilize, non-scratch, and effective in cleaning complex equipment to uphold the integrity of their pharmaceutical products.

What Benefits Do Nylon Bristle Brushes Offer in Aerospace and Defense?

Nylon bristle brushes are vital in the aerospace and defense sectors for the precision cleaning of components and assemblies. These brushes help ensure that parts are free from debris, which is critical for safety and reliability in high-stakes environments. Buyers in this sector should prioritize brushes with anti-static properties and customizable sizes to meet specific cleaning challenges posed by intricate aerospace components.

3 Common User Pain Points for ‘nylon bristle brush’ & Their Solutions

Scenario 1: Ensuring Quality and Consistency in Supply

The Problem: B2B buyers often face challenges in sourcing nylon bristle brushes that meet their specific quality standards. In industries such as automotive, food service, and pharmaceuticals, where hygiene and durability are paramount, inconsistent quality can lead to operational disruptions. For example, a cleaning service provider may receive brushes that shed bristles or do not effectively remove contaminants, resulting in wasted time and increased costs for replacements.

The Solution: To ensure a consistent supply of high-quality nylon bristle brushes, buyers should establish relationships with reputable manufacturers that provide detailed product specifications, including bristle density, material sourcing, and manufacturing processes. Requesting samples prior to bulk orders can help verify quality. Additionally, implementing a vendor management system to track supplier performance over time can ensure that only those who meet quality standards are retained. Buyers should also consider suppliers that offer custom solutions tailored to their specific applications, ensuring they have the right brushes for their unique cleaning needs.

Scenario 2: Addressing Environmental Concerns with Brush Disposal

The Problem: The environmental impact of disposable cleaning tools, including nylon bristle brushes, is a growing concern for many businesses. B2B buyers in sectors like hospitality and healthcare are increasingly pressured to adopt sustainable practices. The challenge lies in managing the disposal of worn-out brushes responsibly while maintaining effective cleaning protocols.

The Solution: Buyers should seek out nylon bristle brushes designed for longevity and reusability. Selecting brushes with replaceable bristle heads can significantly reduce waste. Additionally, partnering with suppliers who offer recycling programs for used brushes can help businesses manage their environmental footprint effectively. Implementing a systematic approach to brush lifecycle management, including training staff on proper cleaning and storage practices to extend the brushes’ usability, can also contribute to sustainability goals. Finally, considering brushes made from recycled or biodegradable materials can further enhance a company’s commitment to eco-friendly practices.

Scenario 3: Finding the Right Brush for Diverse Applications

The Problem: Many B2B buyers struggle to find nylon bristle brushes that are versatile enough to handle various applications, from industrial cleaning to delicate tasks. For instance, a facility manager may require brushes that can effectively clean both heavy machinery and sensitive electronic components, which demands different bristle stiffness and configurations. The lack of suitable options can lead to inefficiencies and increased costs due to the need for multiple specialized brushes.

The Solution: To address this challenge, buyers should conduct a thorough analysis of their cleaning requirements and identify brushes that offer versatility. Suppliers that provide a range of nylon bristle brushes with varying stiffness, sizes, and shapes should be prioritized. Consideration should be given to brushes that feature interchangeable heads or adjustable designs for different tasks. It’s also beneficial to engage in discussions with suppliers about their product lines to gain insights into innovative brush designs that can serve multiple purposes. Investing in training for staff on how to select and use the right brush for each task can further optimize cleaning processes and reduce the need for excessive inventory.

Strategic Material Selection Guide for nylon bristle brush

What Are the Key Materials Used in Nylon Bristle Brushes?

When selecting nylon bristle brushes for various applications, understanding the materials involved is crucial. Here, we analyze four common materials used in the construction of nylon bristle brushes: nylon, wood, polypropylene, and stainless steel. Each material has unique properties, advantages, and limitations that can significantly impact product performance and suitability for specific applications.

How Does Nylon Impact the Performance of Bristle Brushes?

Nylon is a synthetic polymer known for its resilience and versatility. It exhibits excellent abrasion resistance, making it suitable for scrubbing and cleaning tasks. Nylon bristles can withstand temperatures up to 80°C (176°F), which is beneficial for applications involving hot water or steam.

Pros: Nylon bristles are durable, flexible, and resistant to chemicals, making them ideal for a variety of cleaning tasks. They are also relatively cost-effective compared to natural bristle options.

Cons: While nylon is durable, it can become brittle over time, especially when exposed to UV light or extreme temperatures. This can affect the longevity of the brush in outdoor applications.

International Considerations: Buyers in regions like Europe and South America should ensure compliance with REACH regulations regarding chemical safety and environmental impact.

What Role Does Wood Play in Brush Construction?

Wood is often used as the block material for nylon bristle brushes. It provides a sturdy base that can withstand rigorous cleaning tasks. Wood blocks can be treated to enhance their resistance to moisture and chemicals.

Pros: Wood offers a classic aesthetic and is biodegradable, appealing to environmentally conscious buyers. It also has a natural grip, making it comfortable to handle.

Cons: Wood can absorb moisture, leading to warping or deterioration over time, especially in humid environments. Additionally, wood blocks may require more maintenance than synthetic alternatives.

International Considerations: Buyers from Africa and the Middle East should consider the availability of sustainably sourced wood to meet local environmental standards.

How Does Polypropylene Enhance Brush Functionality?

Polypropylene is another synthetic material used in nylon bristle brushes, particularly for the handle or block. It is lightweight, resistant to moisture, and can withstand temperatures up to 90°C (194°F).

Pros: Polypropylene is highly resistant to chemicals and does not absorb water, making it suitable for wet environments. Its lightweight nature makes it easy to handle.

Cons: While durable, polypropylene may not provide the same level of stiffness as nylon, which could affect scrubbing efficiency in certain applications.

International Considerations: Compliance with ASTM standards is essential for buyers in North America and Europe to ensure product quality and safety.

What Advantages Does Stainless Steel Offer in Brush Design?

Stainless steel is often used for the brush’s handle or as a reinforcement material. It provides excellent strength and durability, particularly in industrial applications.

Pros: Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it ideal for heavy-duty cleaning tasks. It also offers a modern look and feel.

Cons: The primary drawback is cost; stainless steel brushes are generally more expensive than their nylon or polypropylene counterparts. Additionally, they can be heavier, which may not be suitable for all users.

International Considerations: Buyers in Europe, particularly Germany, should ensure that stainless steel products comply with DIN standards for material quality.

Summary Table of Material Selection for Nylon Bristle Brushes

| Material | Typical Use Case for nylon bristle brush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | General cleaning and scrubbing | Excellent abrasion resistance | Can become brittle over time | Low |

| Wood | Handheld scrub brushes | Biodegradable and comfortable grip | Absorbs moisture, may warp | Medium |

| Polypropylene | Lightweight cleaning tools | Resistant to moisture and chemicals | May lack stiffness compared to nylon | Low |

| Stainless Steel | Heavy-duty industrial applications | Highly durable and corrosion-resistant | Higher cost and weight | High |

This guide aims to assist international B2B buyers in making informed decisions regarding material selection for nylon bristle brushes, considering factors such as application suitability, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for nylon bristle brush

What Are the Key Manufacturing Processes for Nylon Bristle Brushes?

The manufacturing of nylon bristle brushes involves several critical stages, each playing a vital role in ensuring the final product meets the quality standards expected by B2B buyers. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Nylon Bristle Brushes?

The process begins with sourcing high-quality nylon, which is a synthetic polymer known for its durability and resistance to wear. Suppliers often conduct initial inspections of the raw materials to ensure they meet specified standards. The nylon is then processed into bristles through extrusion, where the polymer is melted and forced through a die to create continuous strands. This step is crucial, as the diameter and consistency of the bristles will affect the brush’s performance.

What Techniques Are Used in Forming Nylon Bristle Brushes?

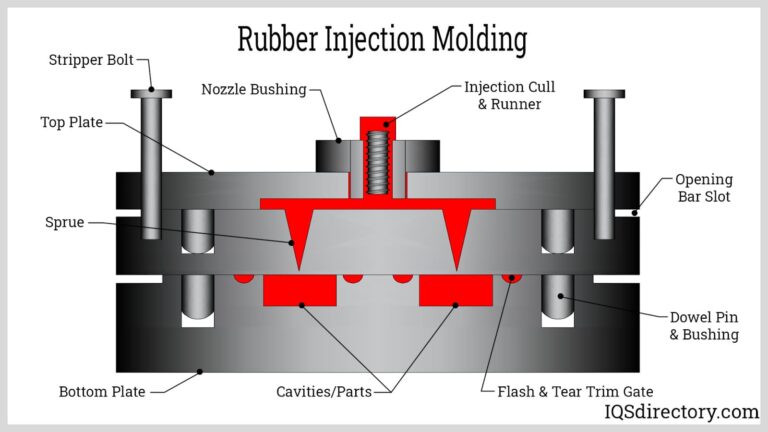

Once the nylon strands are prepared, they undergo a forming process. The bristles are cut to specific lengths and then inserted into brush blocks, typically made of wood or plastic. Various techniques, such as staple setting or injection molding, are employed to secure the bristles in place. This step may include arranging the bristles in specific patterns to enhance cleaning efficacy, particularly for specialized brushes like those used in industrial cleaning applications.

How Is Assembly Conducted for Nylon Bristle Brushes?

Assembly involves attaching handles to the brush heads, which can vary in length and material depending on the intended use. Handles are often designed ergonomically to provide comfort during extended use. Quality checks at this stage ensure that all components fit correctly and function as intended. For example, brushes designed for heavy-duty applications may feature reinforced handles to withstand rigorous cleaning tasks.

What Finishing Processes Are Involved in Nylon Bristle Brush Manufacturing?

The final stage, finishing, includes several operations such as cleaning, packaging, and labeling. Brushes are cleaned to remove any manufacturing residues and are then packaged in a way that protects them during transport. Labels often contain important information such as specifications, usage instructions, and compliance markings, which are essential for international markets.

What Quality Assurance Measures Are Implemented in Nylon Bristle Brush Production?

Quality assurance (QA) is critical in maintaining the integrity of nylon bristle brushes, especially for B2B buyers who rely on consistent performance. Manufacturers typically adhere to international standards, such as ISO 9001, which outlines best practices in quality management systems.

Which International Standards Are Relevant for Quality Assurance in Nylon Bristle Brushes?

ISO 9001 certification indicates that a manufacturer has established and maintains a quality management system. Other relevant standards may include CE marking for products sold in Europe, which ensures compliance with health, safety, and environmental protection standards. For specific industries, certifications like API (American Petroleum Institute) may also be required, particularly for brushes used in oil and gas applications.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are crucial at various stages of the manufacturing process. These checkpoints typically include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Regular inspections occur during the manufacturing stages, including the forming and assembly processes, to catch any defects early.

-

Final Quality Control (FQC): Finished products undergo comprehensive testing to ensure they meet all quality specifications before packaging.

Common testing methods include tensile strength tests for bristles, visual inspections for defects, and functionality tests to assess cleaning effectiveness.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should actively engage in verifying the quality control processes of their suppliers. This can include several strategies:

-

Conducting Audits: Regular audits of suppliers can help confirm adherence to quality standards. Buyers should consider both scheduled and surprise audits to get an accurate picture of a supplier’s operations.

-

Requesting QC Reports: Suppliers should provide documentation of their QC processes, including inspection reports and compliance certifications. This transparency is vital for building trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality assurance measures. This is particularly important for international transactions where buyers may not have direct oversight.

What Are the QC/Cert Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of regional compliance requirements. For example, the EU has stringent regulations regarding product safety and environmental impact, which may not be as rigorous in other regions. Buyers should ensure that their suppliers understand and comply with the regulations relevant to their target markets.

Additionally, cultural differences may affect communication and expectations regarding quality. It is essential for buyers to establish clear quality benchmarks and maintain open lines of communication with suppliers to ensure that products meet their specifications.

Conclusion

Understanding the manufacturing processes and quality assurance measures for nylon bristle brushes is crucial for B2B buyers seeking reliable suppliers. By focusing on the key stages of production, relevant international standards, and effective verification methods, buyers can make informed decisions that ensure the quality and performance of their cleaning tools. With a strategic approach to supplier selection and quality management, businesses can enhance their operational efficiency and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon bristle brush’

Introduction

Navigating the procurement process for nylon bristle brushes can be complex, especially for international B2B buyers. This practical sourcing guide provides a step-by-step checklist designed to streamline your purchasing journey, ensuring you select the right products and suppliers to meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for nylon bristle brushes. Consider factors such as bristle stiffness (hard, medium, or soft), dimensions, and application suitability. This step is crucial as it aligns your procurement strategy with your specific cleaning and maintenance needs, reducing the risk of purchasing unsuitable products.

- Bristle Material: Ensure you specify nylon as the preferred material for durability and effectiveness.

- Application Requirements: Identify if the brushes will be used for industrial, janitorial, or specialized cleaning tasks.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in nylon bristle brushes. Utilize online directories, trade shows, and industry forums to compile a list of potential vendors. This step is vital to find reliable suppliers who can meet your quality standards and delivery timelines.

- Supplier Reviews: Look for feedback from other B2B buyers to gauge their reputation.

- Industry Experience: Prioritize suppliers with experience in your specific industry for tailored solutions.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications, such as ISO 9001, to ensure they adhere to quality management standards. This verification is essential for maintaining product quality and compliance with international regulations, especially when sourcing from different regions.

- Quality Assurance: Certifications can indicate a commitment to high-quality production processes.

- Regulatory Compliance: Ensure the supplier meets local and international safety standards relevant to your industry.

Step 4: Request Samples for Testing

Before finalizing any orders, request samples of the nylon bristle brushes from shortlisted suppliers. Testing samples allows you to evaluate the product’s performance and suitability for your specific applications. This step helps mitigate risks associated with bulk purchases of inadequate products.

- Performance Evaluation: Assess the brushes in real-world conditions to ensure they meet your cleaning effectiveness expectations.

- Durability Testing: Check for wear and tear to ensure longevity under your operational conditions.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a preferred supplier based on samples and evaluations, enter negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to cost savings and more favorable contract terms, which are critical for maintaining your budget.

- Volume Discounts: Discuss pricing for bulk orders to maximize savings.

- Lead Times: Confirm expected delivery times to align with your inventory management needs.

Step 6: Establish a Quality Control Process

Implement a quality control system to monitor the incoming shipments of nylon bristle brushes. This process ensures that the products received meet your predefined specifications and quality standards, minimizing the risk of operational disruptions.

- Inspection Protocols: Develop a checklist for inspecting the brushes upon arrival.

- Supplier Feedback Loop: Maintain open communication with suppliers regarding quality issues for continuous improvement.

Step 7: Review and Optimize Your Procurement Strategy

After your initial procurement, take time to review the entire sourcing process. Gather insights on supplier performance, product effectiveness, and overall satisfaction. This reflection will help you optimize your procurement strategy for future orders, ensuring a more efficient and effective sourcing process.

- Performance Metrics: Establish KPIs to evaluate supplier and product performance.

- Continuous Improvement: Use feedback to refine your specifications and sourcing practices.

By following this checklist, international B2B buyers can navigate the sourcing process for nylon bristle brushes with confidence, ensuring that they acquire high-quality products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for nylon bristle brush Sourcing

What Are the Key Cost Components in Sourcing Nylon Bristle Brushes?

When evaluating the sourcing of nylon bristle brushes, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of nylon bristles varies based on quality and sourcing. High-grade nylon offers durability and resistance to wear, affecting the overall price. Additionally, the choice between different bristle stiffness levels can influence material costs.

-

Labor: Labor costs will differ based on the manufacturing location. Regions with lower labor costs, such as parts of Asia, may provide more competitive pricing, whereas European or North American manufacturers might incur higher labor expenses, which can be reflected in the final price.

-

Manufacturing Overhead and Tooling: This includes costs related to factory maintenance, utilities, and equipment depreciation. Tooling costs, particularly for custom brushes, can also add to the initial outlay. Buyers should consider these elements when evaluating suppliers.

-

Quality Control (QC): Ensuring product quality is non-negotiable, especially for industrial applications. QC processes, which may involve testing and compliance certifications, add to the cost but ultimately protect against long-term expenses related to defective products.

-

Logistics: Shipping and handling costs can significantly impact the total cost, especially for international shipments. Factors such as distance, shipping method, and customs duties should be taken into account.

-

Margin: Suppliers will factor in their profit margins, which can vary widely based on market conditions, competition, and perceived value of the product.

How Do Price Influencers Affect Nylon Bristle Brush Costs?

Several factors can influence the pricing of nylon bristle brushes, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Bulk orders typically yield better pricing. Suppliers often set MOQs, which can affect the overall cost if the buyer cannot meet these minimums.

-

Specifications and Customization: Custom brushes tailored to specific needs can significantly increase costs. Buyers should weigh the necessity of customization against the potential for savings with standard products.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., ISO, FDA compliance) can raise prices. Buyers should assess the importance of these certifications in their purchasing decisions.

-

Supplier Factors: The supplier’s reputation, reliability, and financial stability can influence pricing. Established suppliers might command higher prices due to perceived reliability, while new entrants may offer lower rates to gain market share.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is vital, as they dictate who bears the costs and risks at various stages of shipping, impacting the overall price.

What Buyer Tips Can Help Optimize Costs and Pricing in International Sourcing?

To optimize costs and navigate pricing nuances effectively, B2B buyers should consider the following strategies:

-

Negotiation: Engage in negotiations with suppliers to seek better terms, especially for larger orders. Leveraging competitive quotes can provide leverage.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential replacement costs. This perspective can help identify the best value rather than the lowest price.

-

Pricing Nuances for International Buyers: Be aware of regional market conditions and economic factors that may influence pricing. For example, fluctuations in currency exchange rates can affect the final cost when sourcing from overseas suppliers.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including reviews and past performance, to ensure quality and reliability. This can help avoid costly errors down the line.

-

Understand Local Regulations: Different regions may have unique regulations regarding materials and safety. Ensure compliance to avoid unexpected costs related to fines or product recalls.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, order size, and supplier negotiations. Always seek updated quotes and proposals from multiple suppliers to ensure the best pricing strategy for your specific needs.

Alternatives Analysis: Comparing nylon bristle brush With Other Solutions

Exploring Alternatives to Nylon Bristle Brushes for Industrial Cleaning

In the industrial cleaning sector, choosing the right tool is critical for ensuring efficiency, cost-effectiveness, and the desired cleanliness level. While nylon bristle brushes are popular for their durability and versatility, there are alternative solutions worth considering. This analysis will compare nylon bristle brushes against two viable alternatives: polypropylene bristle brushes and steel wire brushes.

Comparison Table

| Comparison Aspect | Nylon Bristle Brush | Polypropylene Bristle Brush | Steel Wire Brush |

|---|---|---|---|

| Performance | Good for general cleaning and scrubbing; resistant to chemicals. | Similar to nylon; effective on softer surfaces; less abrasive. | Highly effective for heavy-duty cleaning; aggressive scrubbing power. |

| Cost | Moderate initial investment; long lifespan reduces long-term costs. | Generally lower cost; may need replacement more frequently. | Higher upfront cost; longer lifespan if maintained properly. |

| Ease of Implementation | Simple to use across various surfaces; no special training required. | User-friendly; ideal for softer applications. | Requires caution; training may be necessary for safe handling. |

| Maintenance | Low maintenance; can be cleaned and reused. | Moderate; may require frequent replacements depending on usage. | High maintenance; bristles can wear quickly if not used appropriately. |

| Best Use Case | Versatile; suitable for a range of applications, from light to medium cleaning tasks. | Best for non-abrasive tasks on delicate surfaces like plastics or painted surfaces. | Ideal for heavy-duty applications, such as removing rust or paint from metal surfaces. |

Detailed Breakdown of Alternatives

Polypropylene Bristle Brushes

Polypropylene bristle brushes are a cost-effective alternative to nylon. They offer good performance on softer surfaces and are resistant to moisture and chemicals. However, their bristles may not be as durable as nylon, leading to more frequent replacements. They are ideal for applications where gentle cleaning is required, such as on plastics or painted surfaces. While they are user-friendly, their longevity can be a concern in high-demand environments.

Steel Wire Brushes

Steel wire brushes excel in heavy-duty cleaning tasks, providing aggressive scrubbing power that can tackle tough substances like rust, paint, and grime on metal surfaces. Their performance is unmatched in industrial applications that demand rigorous cleaning. However, they come with higher upfront costs and require careful handling to prevent damage to the surface being cleaned. Users may need specific training to operate them safely, which can add to the implementation time and complexity. Proper maintenance is crucial to extend their lifespan, making them less convenient than nylon or polypropylene brushes.

Making the Right Choice for Your Needs

When selecting a cleaning solution, B2B buyers should consider the specific requirements of their applications. Factors such as the type of surfaces being cleaned, the nature of the contaminants, and budget constraints will heavily influence the decision. Nylon bristle brushes offer a balanced solution for various tasks, while polypropylene brushes are better suited for more delicate surfaces. In contrast, steel wire brushes should be reserved for the most demanding applications where their aggressive cleaning capabilities are necessary. Understanding these differences will help buyers choose the right tool to enhance their operational efficiency and meet their cleaning standards effectively.

Essential Technical Properties and Trade Terminology for nylon bristle brush

What Are the Key Technical Properties of Nylon Bristle Brushes?

Understanding the essential technical properties of nylon bristle brushes is crucial for international B2B buyers. Here are some of the critical specifications to consider:

-

Material Composition

Nylon is the primary fill material for these brushes due to its durability, resistance to chemicals, and flexibility. It can withstand high temperatures and is less likely to break down compared to natural bristle materials. For businesses, this translates to longer-lasting products that can handle rigorous cleaning tasks, reducing the frequency of replacements and maintenance costs. -

Bristle Stiffness

Nylon brushes come in various stiffness levels: hard, medium, and soft. Hard bristles are ideal for heavy-duty scrubbing, while soft bristles are better suited for delicate surfaces. Selecting the appropriate stiffness ensures that the brush performs effectively without damaging the surface being cleaned, which is vital for maintaining quality and minimizing liability in industrial applications. -

Bristle Diameter

The diameter of the bristles, typically measured in millimeters, can influence the brush’s effectiveness. For instance, a smaller diameter bristle may reach into tight spaces, whereas a larger diameter provides more scrubbing power. Buyers need to match the bristle diameter with the specific cleaning requirements of their operations, ensuring efficiency and effectiveness. -

Trim Length

Trim length refers to the length of the bristles from the block. This specification affects the brush’s ability to clean various surfaces and reach into crevices. Understanding the trim length helps businesses choose the right brush for their cleaning needs, optimizing performance and reducing time spent on cleaning tasks. -

Block Material

The block material, often wood or plastic, impacts the brush’s durability and usability. Wooden blocks provide a classic feel and can be more robust, while plastic blocks may offer better resistance to moisture and chemicals. This choice can affect the overall lifespan of the brush and its suitability for specific environments, such as food service or industrial settings. -

Rows of Bristles

The arrangement and number of rows of bristles can affect cleaning efficiency. More rows may provide better coverage and scrubbing action. Understanding this specification helps businesses make informed choices about brush design to meet their specific cleaning requirements.

What Are Common Trade Terms Related to Nylon Bristle Brushes?

Familiarity with industry jargon can streamline the procurement process for B2B buyers. Here are several common terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, as it can impact cash flow and storage capacity. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotes from suppliers for specific products. This is a critical step in the procurement process, enabling buyers to compare prices and terms effectively before making purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for managing shipping logistics, costs, and risks associated with international trade. -

Lead Time

Lead time refers to the time taken from placing an order to receiving it. For businesses, knowing the lead time is crucial for inventory management and operational planning, ensuring that cleaning supplies are available when needed. -

Certification Standards

Certifications (e.g., ISO, FDA compliance) indicate that products meet specific safety and quality standards. Buyers should look for these certifications to ensure that the nylon bristle brushes are suitable for their intended applications, especially in regulated industries.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the nylon bristle brush Sector

What are the Current Market Dynamics and Key Trends Influencing the Nylon Bristle Brush Sector?

The nylon bristle brush market is experiencing significant growth driven by diverse factors, including increased demand in industrial cleaning, automotive, and food service sectors. The global shift towards automation and advanced cleaning technologies is pushing the adoption of specialized brushes, enhancing operational efficiency. Notably, emerging markets in Africa and South America are witnessing a surge in construction and manufacturing activities, which catalyzes the demand for durable cleaning tools.

Technological advancements, particularly in e-commerce, are reshaping sourcing trends. International buyers can now leverage online platforms to access a wider range of suppliers, compare product specifications, and negotiate prices. The integration of data analytics in supply chain management is enabling companies to optimize their inventory levels and predict market trends more accurately. Furthermore, the rise of custom-brush manufacturing allows buyers to source tailored solutions that meet specific cleaning requirements, fostering greater competitiveness.

How is Sustainability Shaping Ethical Sourcing in the Nylon Bristle Brush Industry?

Sustainability is becoming a cornerstone of the nylon bristle brush industry, influencing both production processes and sourcing strategies. Manufacturers are increasingly adopting environmentally friendly practices, such as using recycled materials and reducing water usage during production. The environmental impact of nylon production, particularly regarding its petroleum-based origins, has prompted buyers to seek alternatives that align with sustainability goals.

Ethical supply chains are now a priority for international buyers, particularly in Europe and the Middle East, where regulations are tightening around environmental standards. Certifications like ISO 14001 and the use of sustainable materials not only enhance brand reputation but also ensure compliance with global environmental standards. Buyers are encouraged to partner with suppliers who can demonstrate a commitment to sustainable practices, thus fostering a more responsible sourcing ecosystem.

What is the Historical Context of Nylon Bristle Brushes in B2B Markets?

The nylon bristle brush has evolved significantly since its inception in the mid-20th century. Initially designed for household cleaning, these brushes gained popularity in industrial applications due to their durability and resistance to chemical wear. As industries expanded, the demand for specialized brushes tailored for specific applications grew, leading to innovations in design and materials.

Over the decades, the nylon bristle brush has adapted to meet changing market needs, from food safety regulations in the food service industry to stringent hygiene standards in healthcare. This evolution reflects broader trends in industrial cleaning practices and the ongoing quest for efficiency and effectiveness in cleaning solutions. Today, the nylon bristle brush stands as a vital tool across various sectors, embodying both functionality and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of nylon bristle brush

-

How do I choose the right nylon bristle brush for my cleaning application?

Selecting the appropriate nylon bristle brush depends on the specific cleaning task and surface material. For general-purpose cleaning, a medium-bristle nylon brush is often suitable. However, for heavy-duty scrubbing, a hard bristle option may be more effective. Consider the surface to be cleaned; softer brushes are ideal for delicate surfaces, while harder bristles can tackle tough grime on concrete or tile. Always review product specifications and consult with suppliers to ensure the brush meets your requirements. -

What are the key benefits of using nylon bristle brushes compared to other materials?

Nylon bristle brushes offer several advantages, including durability, flexibility, and resistance to chemicals. Unlike natural fibers, nylon bristles do not absorb moisture, making them less prone to mold and mildew. They maintain their shape and effectiveness over time, providing consistent cleaning performance. Additionally, nylon brushes can be used on various surfaces without causing damage, making them versatile for both industrial and commercial applications. -

What is the typical minimum order quantity (MOQ) for nylon bristle brushes?

Minimum order quantities for nylon bristle brushes can vary significantly based on the supplier, product type, and customization options. Generally, MOQs range from 100 to 1,000 units for standard products. For customized brushes, suppliers may require higher MOQs to justify production costs. It’s advisable to communicate your needs clearly with potential suppliers to negotiate favorable terms that align with your purchasing strategy. -

How can I ensure the quality of nylon bristle brushes from international suppliers?

To guarantee quality, vet suppliers by checking their certifications (e.g., ISO 9001) and reviewing customer testimonials. Request samples to assess the brushes’ performance and durability firsthand. Additionally, inquire about their manufacturing processes and quality assurance protocols. Establishing clear quality standards in your purchase agreement can help mitigate risks and ensure the products meet your specifications. -

What payment terms should I expect when sourcing nylon bristle brushes internationally?

Payment terms for international transactions typically vary by supplier and can include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may request a deposit (e.g., 30-50%) upfront, with the balance due before shipment. It’s essential to discuss and agree upon payment terms upfront to avoid misunderstandings. Also, consider using secure payment methods to protect your financial interests. -

What logistics considerations should I keep in mind when importing nylon bristle brushes?

When importing nylon bristle brushes, consider shipping costs, delivery timelines, and customs regulations. Work with logistics providers who have experience in handling similar goods to ensure smooth transportation. Be aware of potential tariffs or import duties that may apply to your shipments, especially when dealing with international trade agreements. Planning ahead can help you avoid delays and additional costs. -

Can I customize nylon bristle brushes for my specific needs?

Yes, many suppliers offer customization options for nylon bristle brushes. You can typically specify bristle stiffness, brush size, and handle material based on your application requirements. Some manufacturers also allow for branding or color customization. Discuss your specific needs with suppliers to explore available options and ensure that the final product meets your operational standards. -

What industries commonly use nylon bristle brushes, and how can I identify suitable suppliers?

Nylon bristle brushes are widely used across various industries, including automotive, food service, janitorial, and healthcare. To find suitable suppliers, research industry-specific directories, attend trade shows, and leverage online B2B platforms. Networking with industry professionals can also provide valuable referrals. Ensure the suppliers you consider have experience in your specific industry to better meet your unique requirements.

Top 3 Nylon Bristle Brush Manufacturers & Suppliers List

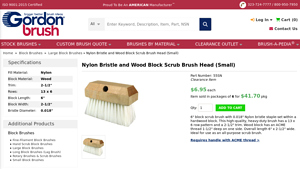

1. Gordon Brush – Nylon Bristle and Wood Block Scrub Brush Head (Small)

Domain: gordonbrush.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Nylon Bristle and Wood Block Scrub Brush Head (Small) 55SN”, “Fill Material”: “Nylon”, “Block Material”: “Wood”, “Trim”: “2-1/2\””, “Rows”: “13 x 6”, “Block Length”: “6\””, “Block Width”: “2-1/2\””, “Bristle Diameter”: “0.018\””, “Part Number”: “55SN”, “Price”: “$6.95 each”, “Package Quantity”: “sold in packages of 6 for $41.70”, “Description”: “6\” block scrub brush with 0.018\”…

2. Cleanersupply – Nylon Bristle Coat Brush 14 1/4

Domain: cleanersupply.com

Registered: 1997 (28 years)

Introduction: Nylon Bristle Coat Brush 14 1/4″

3. IKEA – Bristle Brush

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bristle brushes are recommended as the best cleaning tool for cast iron cookware. They are non-abrasive, can easily reach into the bends of pans, and have a stiff scraping edge similar to a pan scraper. A specific recommendation is made for a $.79 bristle brush from IKEA.

Strategic Sourcing Conclusion and Outlook for nylon bristle brush

As the demand for nylon bristle brushes continues to grow across various sectors, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the diverse applications of nylon bristle brushes—from industrial cleaning to food service—enables organizations to select the right products that enhance efficiency and effectiveness in their operations. By leveraging strategic sourcing practices, buyers can not only optimize their supply chains but also capitalize on cost savings and ensure the consistent quality of products.

In addition, fostering relationships with reliable suppliers can lead to long-term partnerships, facilitating better negotiation terms and access to innovative product offerings. For buyers in Africa, South America, the Middle East, and Europe, this approach is particularly valuable as it allows for tailored solutions that meet regional market needs and compliance standards.

Looking ahead, the nylon bristle brush market is poised for continued expansion, driven by sustainability trends and technological advancements. Now is the time for international B2B buyers to explore strategic sourcing opportunities that align with their business goals. Embrace this chance to enhance your operational capabilities and stay ahead of the competition by sourcing high-quality nylon bristle brushes that meet your specific requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.