Choosing Your Nike Warehouse China: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for nike warehouse china

In today’s global marketplace, sourcing high-quality athletic apparel and footwear from Nike’s warehouses in China presents a significant challenge for international B2B buyers. With a complex supply chain and varying standards across regions, understanding how to navigate this landscape is crucial for businesses looking to enhance their product offerings. This guide aims to demystify the intricacies of the Nike warehouse in China, providing essential insights into types of products available, their applications in diverse markets, and effective supplier vetting processes.

By delving into the nuances of sourcing from Nike’s extensive operations in China, this comprehensive resource equips B2B buyers from Africa, South America, the Middle East, and Europe—specifically Germany and Nigeria—with actionable knowledge to make informed purchasing decisions. We will explore cost factors, logistical considerations, and the importance of building strong supplier relationships, all of which are vital in ensuring a successful procurement strategy.

As you navigate this guide, you will gain a clearer understanding of how to leverage Nike’s global presence to your advantage, ensuring that your business remains competitive in the ever-evolving sportswear industry. With the right information at your fingertips, you can confidently approach the complexities of sourcing from Nike’s warehouses in China, ultimately leading to enhanced product quality and customer satisfaction.

Understanding nike warehouse china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nike Distribution Centers | Large facilities focused on efficient inventory management. | Bulk purchasing, regional distribution. | Pros: High volume capacity, quick turnaround. Cons: Limited customization options. |

| Nike Retail Outlets | Stores that offer discounted prices on overstock or past seasons. | Direct sales to consumers, clearance. | Pros: Cost-effective for retailers. Cons: Limited stock availability. |

| Nike E-commerce Warehouses | Facilities designed to support online order fulfillment. | E-commerce, dropshipping. | Pros: Fast shipping, extensive product range. Cons: Higher logistics costs. |

| Nike Customization Centers | Locations focused on personalized products and custom orders. | Corporate gifts, promotional items. | Pros: Unique offerings, branding opportunities. Cons: Longer lead times. |

| Nike Regional Hubs | Smaller warehouses serving specific geographic markets. | Local distribution, targeted marketing. | Pros: Reduced shipping times, localized stock. Cons: Limited inventory variety. |

What are the Characteristics of Nike Distribution Centers?

Nike Distribution Centers are large-scale facilities designed for optimal inventory management and logistics efficiency. These centers are strategically located to facilitate bulk purchasing and regional distribution, making them ideal for B2B buyers seeking to stock large quantities of Nike products. They typically offer advanced inventory tracking systems and streamlined shipping processes, which can significantly reduce lead times. However, buyers should be aware that customization options may be limited, as these centers focus primarily on high-volume sales.

How do Nike Retail Outlets Function for B2B Buyers?

Nike Retail Outlets provide a unique opportunity for B2B buyers to purchase overstock or past season products at discounted prices. These outlets cater to retailers looking for cost-effective inventory solutions and can be an excellent source for clearance items. While they offer significant savings, buyers should note that stock availability can be inconsistent, and the variety may be limited to older models or sizes. Retailers can benefit from these outlets by capitalizing on lower prices, but they must act quickly to secure desirable items.

What are the Benefits of Nike E-commerce Warehouses?

Nike E-commerce Warehouses are specifically designed to support online sales and order fulfillment, catering to the growing demand for digital retail. These facilities enable quick shipping and offer a wide range of products, making them suitable for B2B buyers engaged in e-commerce or dropshipping. While the logistics costs may be higher due to the nature of online fulfillment, the advantages of fast shipping and access to a comprehensive product catalog can outweigh these drawbacks, especially for businesses focused on customer satisfaction and rapid delivery.

Why Choose Nike Customization Centers for Corporate Needs?

Nike Customization Centers focus on creating personalized products tailored to specific buyer needs, such as corporate gifts or promotional items. These centers allow businesses to enhance their branding through unique offerings, making them a valuable resource for companies looking to differentiate themselves in the market. However, buyers should consider that customization often leads to longer lead times, which may not be suitable for last-minute orders. Understanding the balance between uniqueness and delivery timelines is crucial for B2B buyers in this segment.

How Do Nike Regional Hubs Enhance Local Distribution?

Nike Regional Hubs are smaller warehouses that serve specific geographic markets, providing localized distribution solutions. They reduce shipping times and allow for targeted marketing efforts, making them an attractive option for businesses looking to optimize their supply chain. While these hubs offer the advantage of quicker access to inventory, buyers should be aware that the variety of products may be limited compared to larger distribution centers. This localized approach can greatly benefit businesses aiming for efficiency and responsiveness in their operations.

Key Industrial Applications of nike warehouse china

| Industry/Sector | Specific Application of nike warehouse china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Direct-to-Consumer Fulfillment | Faster delivery times and improved customer satisfaction | Reliability of logistics and shipping processes |

| Sports Equipment Retail | Inventory Management and Distribution | Streamlined operations and reduced overhead costs | Scalability and flexibility in warehouse operations |

| E-commerce | Omnichannel Sales Integration | Enhanced customer experience and increased sales | Technology integration for inventory tracking |

| Apparel Manufacturing | Bulk Sourcing of Raw Materials and Finished Goods | Cost efficiency and access to quality products | Supplier reliability and compliance with standards |

| Logistics and Transportation | Centralized Hub for Global Distribution | Improved supply chain efficiency and reduced lead times | Customs regulations and international shipping options |

How Can Retailers Leverage Nike Warehouse China for Direct-to-Consumer Fulfillment?

Nike Warehouse China serves as a pivotal hub for retailers aiming to enhance their direct-to-consumer fulfillment strategies. By utilizing this facility, businesses can benefit from faster delivery times, which significantly boosts customer satisfaction. This warehouse’s strategic location allows for efficient shipping within the region, making it an ideal choice for B2B buyers in Africa, South America, and Europe. Key considerations for these buyers include ensuring the reliability of logistics and the ability to handle seasonal demand fluctuations.

What Advantages Does Nike Warehouse China Offer for Sports Equipment Retail?

For sports equipment retailers, Nike Warehouse China provides advanced inventory management and distribution capabilities. This facility enables businesses to streamline their operations, reducing overhead costs associated with warehousing and logistics. By sourcing directly from Nike’s warehouse, retailers can maintain a diverse product lineup and quickly respond to market trends. Buyers should consider scalability and flexibility in warehouse operations to accommodate fluctuating demand, especially in emerging markets.

How Does Nike Warehouse China Enhance E-commerce Operations?

E-commerce businesses can greatly benefit from the omnichannel sales integration offered by Nike Warehouse China. This facility supports a seamless shopping experience by enabling efficient order fulfillment across multiple channels. Enhanced customer experience leads to increased sales and brand loyalty. International B2B buyers should prioritize technology integration for inventory tracking to ensure real-time data access, which is crucial for managing stock levels and fulfilling orders promptly.

Why is Bulk Sourcing from Nike Warehouse China Essential for Apparel Manufacturers?

Nike Warehouse China is an advantageous resource for apparel manufacturers looking to source raw materials and finished goods in bulk. This facility allows for cost-efficient procurement and access to high-quality products that meet international standards. For manufacturers, the ability to reduce lead times and maintain consistent product quality is vital. Buyers should focus on supplier reliability and compliance with industry standards when sourcing from this warehouse to mitigate risks in the supply chain.

How Can Logistics Companies Optimize Operations Using Nike Warehouse China?

Logistics and transportation companies can utilize Nike Warehouse China as a centralized hub for global distribution. This strategic location enhances supply chain efficiency and reduces lead times, crucial for maintaining a competitive edge in the logistics sector. International B2B buyers must consider customs regulations and international shipping options to ensure smooth operations when partnering with this warehouse. By optimizing these aspects, logistics companies can significantly improve their service offerings and reduce operational costs.

3 Common User Pain Points for ‘nike warehouse china’ & Their Solutions

Scenario 1: Navigating Import Regulations and Compliance Challenges

The Problem: B2B buyers often face significant hurdles when importing goods from Nike’s warehouse in China. The complexity of international trade regulations, varying compliance requirements, and potential tariffs can lead to delays, increased costs, and even legal issues. For buyers, especially those from regions like Africa or South America, understanding the local regulations in conjunction with Chinese export laws can be overwhelming, causing frustration and uncertainty.

Illustrative image related to nike warehouse china

The Solution: To mitigate these challenges, it’s crucial to engage with a freight forwarder who specializes in international shipping and understands both Chinese export regulations and the specific import laws of the buyer’s country. This expert can guide you through the necessary documentation, including customs declarations and certificates of origin, ensuring that all aspects of the import process comply with legal requirements. Additionally, consider investing in a compliance management software tool that can track changes in regulations and automate documentation. This proactive approach not only streamlines the import process but also minimizes the risk of costly delays and penalties.

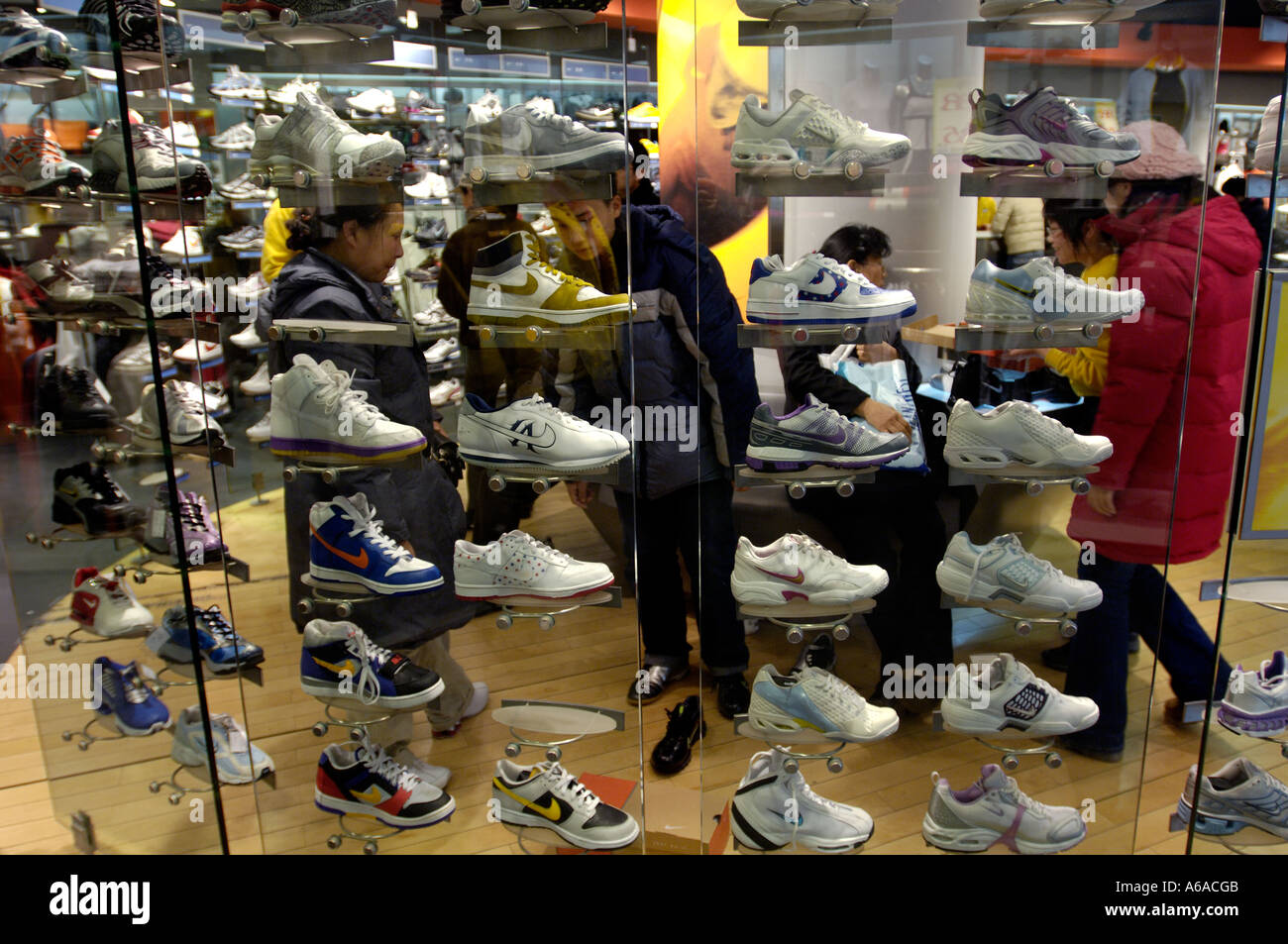

Scenario 2: Ensuring Product Quality and Authenticity

The Problem: One of the major concerns for B2B buyers sourcing from Nike’s warehouse in China is the potential risk of receiving counterfeit products or goods that do not meet the expected quality standards. With the prevalence of counterfeit athletic gear in the market, buyers are often apprehensive about the authenticity of the products, which can damage their reputation and customer trust.

The Solution: To ensure product quality and authenticity, buyers should establish a robust vetting process for suppliers. Begin by requesting detailed product specifications, certifications, and samples before placing bulk orders. Conduct factory audits to assess production capabilities and quality control measures. Additionally, consider collaborating with Nike’s official distribution channels or authorized wholesalers in China, as they typically adhere to strict quality standards and provide guarantees on the authenticity of their products. Utilizing blockchain technology for supply chain transparency can also enhance trust, as it provides a verifiable record of product provenance.

Scenario 3: Managing Inventory and Supply Chain Efficiency

The Problem: B2B buyers often struggle with inventory management when sourcing from Nike’s warehouse in China due to unpredictable lead times and fluctuating demand. This can lead to either overstock situations or stockouts, both of which can have serious financial implications and affect customer satisfaction.

Illustrative image related to nike warehouse china

The Solution: Implementing an integrated inventory management system can significantly enhance supply chain efficiency. Such systems allow for real-time tracking of inventory levels, sales forecasts, and reorder points. Collaborate closely with Nike’s warehouse team to establish a clear communication channel that allows for timely updates on production schedules and inventory availability. Additionally, consider using just-in-time (JIT) inventory practices to reduce holding costs and increase flexibility in response to market demand. Establishing safety stock levels based on historical sales data can also provide a buffer against unexpected spikes in demand, ensuring you maintain optimal inventory levels without overcommitting resources.

Strategic Material Selection Guide for nike warehouse china

What Are the Key Materials Used in Nike Warehouse Operations in China?

In the context of Nike’s warehouse operations in China, selecting the right materials is essential for ensuring efficiency, durability, and compliance with international standards. Below, we analyze several common materials used in warehouse settings, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

Which Plastics Are Commonly Used in Nike Warehouses?

Polyethylene (PE) is widely used in the construction of storage bins, pallets, and packaging materials. Its key properties include excellent chemical resistance and a temperature rating that can withstand a wide range of conditions.

- Pros: PE is lightweight, durable, and resistant to moisture, making it ideal for various storage applications. It is also cost-effective, which is a significant advantage for large-scale operations.

- Cons: However, it has a lower temperature tolerance compared to other materials, which may limit its use in extreme conditions. Additionally, it can be less durable under high-stress applications.

- Impact on Application: PE is suitable for storing a variety of products, including textiles and footwear, but may not be ideal for heavy machinery or equipment.

- Considerations for Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic use, while European buyers may prefer materials that meet strict environmental standards.

How Does Steel Factor into Warehouse Construction?

Steel is another critical material used in the structural framework of warehouses. It offers high strength and durability, making it suitable for heavy-duty applications.

- Pros: Steel’s corrosion resistance, especially when treated, ensures longevity in various environmental conditions. It is also recyclable, aligning with sustainability goals.

- Cons: The initial cost of steel can be high, and its manufacturing process can be complex, requiring specialized skills and equipment.

- Impact on Application: Steel is ideal for racking systems and structural supports, providing the necessary strength for heavy loads.

- Considerations for Buyers: International buyers must consider compliance with standards such as ASTM or DIN, particularly in regions like Germany, where quality assurance is paramount.

What Role Does Wood Play in Warehouse Operations?

Plywood is frequently used in the construction of pallets, crates, and shelving units. Its properties include good load-bearing capabilities and ease of handling.

- Pros: Plywood is relatively inexpensive and can be sourced sustainably, appealing to environmentally conscious buyers. It is also versatile and can be easily customized.

- Cons: However, plywood is susceptible to moisture and may warp or degrade over time if not treated properly. This limits its use in humid environments.

- Impact on Application: Plywood is suitable for lightweight storage solutions but may not be ideal for heavy or moisture-sensitive products.

- Considerations for Buyers: Buyers in humid regions like parts of Africa and South America should prioritize treated plywood to enhance durability.

Why Is Rubber Important in Warehouse Operations?

Rubber is commonly used for flooring and cushioning materials in warehouses. Its key properties include excellent shock absorption and slip resistance.

- Pros: Rubber flooring provides a safe working environment, reducing the risk of accidents. It is also durable and easy to maintain.

- Cons: The cost of high-quality rubber can be significant, and it may require specialized installation techniques.

- Impact on Application: Rubber is ideal for areas with high foot traffic or where heavy machinery operates, ensuring safety and comfort.

- Considerations for Buyers: Buyers should look for compliance with international safety standards, particularly in regions like Europe and the Middle East, where regulations may be stringent.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for Nike Warehouse China | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Storage bins, pallets, packaging | Lightweight and moisture-resistant | Lower temperature tolerance | Low |

| Steel | Structural framework, racking systems | High strength and durability | High initial cost and complex mfg | High |

| Plywood | Pallets, crates, shelving units | Cost-effective and customizable | Susceptible to moisture | Med |

| Rubber | Flooring and cushioning materials | Excellent shock absorption | High quality can be costly | Med |

This guide provides a comprehensive overview of the materials commonly used in Nike’s warehouse operations in China, offering valuable insights for international B2B buyers. Understanding these materials will assist in making informed purchasing decisions that align with operational needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for nike warehouse china

What Are the Main Stages of Manufacturing at Nike’s Warehouse in China?

Nike’s manufacturing processes in China are characterized by precision, efficiency, and a commitment to quality. The production cycle typically involves several critical stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality materials, such as advanced textiles and synthetic compounds. Nike places a strong emphasis on sustainability, often utilizing recycled materials and eco-friendly practices in sourcing. This step ensures that the raw materials meet rigorous quality standards before moving to production.

-

Forming: During this phase, materials are cut and shaped into components. Cutting-edge technologies, such as computer-aided design (CAD) and automated cutting machines, are employed to enhance precision. This not only minimizes waste but also ensures that the parts fit seamlessly together in later stages.

-

Assembly: The assembly process is where components are brought together to create the final product. Nike leverages both manual and automated assembly techniques. Skilled labor is essential here, as workers ensure that each piece is aligned correctly and meets quality benchmarks. Automated stitching and bonding techniques are also used to enhance durability and performance.

-

Finishing: Finally, the finishing stage includes quality checks, branding applications, and packaging. This step is crucial as it involves the final inspection of the products to ensure they adhere to Nike’s high standards. Branding is applied using advanced techniques that ensure longevity and visual appeal.

How Does Nike Ensure Quality Control During Manufacturing in China?

Quality assurance at Nike’s warehouse in China is integral to its reputation for excellence. The company adheres to international quality standards, such as ISO 9001, along with industry-specific certifications like CE and API.

Illustrative image related to nike warehouse china

-

International Standards Compliance: ISO 9001 certification ensures that Nike’s manufacturing processes are consistently monitored and improved. This standard focuses on process efficiency, customer satisfaction, and continuous improvement, making it a cornerstone of Nike’s quality assurance strategy.

-

Quality Control Checkpoints: Nike employs a multi-tiered quality control system that includes:

-

Incoming Quality Control (IQC): This initial check assesses the quality of raw materials before they enter the production line. Suppliers are required to provide certificates of compliance to ensure that materials meet Nike’s standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring takes place to identify any defects or deviations from quality standards. This proactive approach allows for immediate corrective actions.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that they meet all specifications. This step includes random sampling and testing to verify the quality of the finished goods.

What Testing Methods Are Commonly Used in Nike’s Quality Assurance Processes?

Nike utilizes a variety of testing methods to ensure that its products meet high performance and safety standards. Some of the common testing methods include:

-

Physical Testing: This includes tensile strength tests, abrasion resistance tests, and water resistance tests. Such tests ensure that products can withstand the rigors of athletic use.

-

Chemical Testing: To ensure safety and compliance with regulations, materials are tested for harmful substances. This is especially important for markets with stringent safety standards.

-

Performance Testing: Products are subjected to real-world conditions to assess performance. This includes wear tests, comfort evaluations, and climate adaptability assessments.

How Can B2B Buyers Verify Supplier Quality Control in China?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing capabilities, quality control processes, and adherence to international standards. This firsthand observation is invaluable in establishing trust.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their processes and compliance levels. These reports should detail the outcomes of IQC, IPQC, and FQC checks.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and product quality. These inspections can include pre-shipment inspections to confirm that goods meet the agreed-upon specifications.

What Quality Control and Certification Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers must navigate several nuances related to quality control and certification when dealing with suppliers in China:

Illustrative image related to nike warehouse china

-

Cultural Differences: Understanding cultural differences in business practices can affect negotiations and quality expectations. Building strong relationships can enhance communication and ensure quality standards are maintained.

-

Regulatory Compliance: Different markets have varying regulatory requirements. Buyers should be aware of specific certifications required in their regions, such as CE marking in Europe, to ensure compliance and avoid potential legal issues.

-

Language Barriers: Language differences can lead to misunderstandings regarding quality expectations. It’s advisable to have a clear communication plan, possibly involving bilingual staff or translators, to facilitate smooth interactions.

By grasping these intricacies, international B2B buyers can better navigate the complexities of sourcing from Nike’s warehouse in China, ensuring they receive products that meet their quality and performance standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nike warehouse china’

This guide provides a comprehensive checklist for international B2B buyers seeking to procure from Nike’s warehouse in China. By following these steps, you can ensure a smoother sourcing process and make informed decisions that align with your business goals.

Step 1: Identify Your Sourcing Needs

Before engaging with suppliers, clearly define what products you need from Nike’s warehouse in China. Specify product categories, quantities, and any unique requirements. This clarity helps suppliers provide accurate quotes and ensures that you receive the correct items to meet your market demands.

Illustrative image related to nike warehouse china

- Detail your specifications: Include sizes, colors, and any customization options.

- Consider seasonal trends: Identify if you need products for specific seasons or events.

Step 2: Conduct Market Research on Nike Warehouse Capabilities

Understanding the operational capabilities of Nike’s warehouse in China is crucial. Investigate the types of products they handle and their distribution efficiency. This knowledge allows you to align your sourcing strategy with their strengths.

- Review logistics and shipping options: Assess how quickly they can fulfill orders and the reliability of their shipping methods.

- Explore inventory management practices: Determine how they manage stock levels and product turnover.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers associated with Nike’s warehouse operations. Request company profiles, case studies, and references from buyers in similar industries or regions. This step mitigates risks and helps establish trust.

- Check for certifications: Ensure that suppliers meet industry standards and Nike’s own requirements.

- Assess financial stability: A financially sound supplier is more likely to fulfill long-term contracts.

Step 4: Verify Compliance with Local Regulations

Ensure that the products you are sourcing comply with regulations in your target markets, especially if you are importing into regions like Africa, South America, or Europe. Non-compliance can lead to legal complications and additional costs.

- Research import tariffs and duties: Understand the financial implications of bringing goods into your country.

- Review safety standards: Confirm that products meet local safety and quality regulations.

Step 5: Request Samples for Quality Assurance

Before making a bulk order, request samples from your chosen suppliers. This allows you to assess the quality of the products firsthand and ensures they meet your specifications.

- Evaluate product quality: Check for durability, material quality, and overall craftsmanship.

- Test functionality: If applicable, ensure that the products perform as expected in real-world conditions.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear agreements help prevent misunderstandings and ensure both parties are aligned.

- Discuss payment methods: Consider options like letters of credit or escrow services for added security.

- Establish clear delivery timelines: Agree on lead times to avoid delays in your supply chain.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Develop a clear plan for regular updates and check-ins with your supplier. This proactive approach helps address any issues quickly and keeps the project on track.

- Schedule regular meetings: Use video calls or instant messaging for quick updates.

- Define points of contact: Ensure both sides have designated representatives for streamlined communication.

By following this checklist, B2B buyers can navigate the complexities of sourcing from Nike’s warehouse in China, ensuring a successful procurement process that meets their business needs.

Comprehensive Cost and Pricing Analysis for nike warehouse china Sourcing

What Are the Key Cost Components in Sourcing from Nike Warehouse in China?

When considering sourcing from Nike’s warehouse in China, understanding the cost structure is vital for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly affects the overall pricing. Nike’s commitment to sustainability often involves using high-quality, eco-friendly materials, which can be more expensive than standard options. Buyers should evaluate the material specifications in relation to their desired product quality.

-

Labor: Labor costs in China can vary widely based on the region and the skill level of the workforce. Nike’s focus on innovation and quality often requires skilled labor, which may contribute to higher costs. Buyers must consider these labor dynamics when negotiating pricing.

-

Manufacturing Overhead: This includes costs associated with utilities, maintenance, and other operational expenses of production facilities. Given Nike’s advanced manufacturing processes, overhead costs may be higher, impacting the final price.

-

Tooling: Custom tooling for specific designs can lead to significant upfront costs. However, these costs can be amortized over larger production runs. Buyers should assess their anticipated volume to determine if investing in custom tooling is financially viable.

-

Quality Control: Nike maintains stringent QC standards to ensure product excellence. The costs associated with quality inspections and compliance certifications may influence pricing. Buyers should inquire about the QC processes to understand how they affect overall costs.

-

Logistics: Transportation and warehousing costs are critical, especially for international shipments. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) play a crucial role in logistics costs. Buyers should consider these elements when calculating total expenses.

-

Margin: Nike’s pricing strategy incorporates a margin that reflects brand value, quality, and market positioning. Understanding this margin can help buyers assess the fairness of pricing in relation to the product’s perceived value.

How Do Pricing Influencers Affect Sourcing Costs?

Several key influencers can affect the pricing structure when sourcing from Nike’s warehouse in China:

Illustrative image related to nike warehouse china

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes typically result in lower per-unit costs due to economies of scale. Buyers should inquire about MOQs and how they can leverage larger orders for better pricing.

-

Specifications and Customization: Unique specifications and customization requirements can lead to increased costs. Buyers need to clearly define their product requirements to avoid unexpected expenses.

-

Material Quality and Certifications: The level of material quality and the presence of certifications can also affect pricing. Products that meet specific industry standards may come at a premium but can enhance marketability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers like Nike often have higher costs associated with their brand value, but they also provide assurance of quality and reliability.

-

Incoterms: Understanding Incoterms is essential for international buyers. These terms define the responsibilities of buyers and sellers in the shipping process, impacting overall costs. For example, terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks.

What Are Some Negotiation Tips for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost efficiencies:

-

Understand Total Cost of Ownership (TCO): Look beyond initial pricing. Calculate the TCO, which includes logistics, duties, and potential tariffs. This perspective allows for more informed decision-making.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and service. Loyalty often results in favorable terms and priority in production schedules.

-

Leverage Market Knowledge: Being informed about market trends and competitor pricing can empower buyers during negotiations. Knowledge of regional demand and supply dynamics can provide leverage.

-

Be Clear on Specifications: Clearly outline product specifications and expectations to avoid misunderstandings that could lead to increased costs later in the process.

-

Consider Payment Terms: Negotiating favorable payment terms can significantly impact cash flow. Flexible terms may allow buyers to manage their finances more effectively while still securing competitive pricing.

Conclusion

While sourcing from Nike’s warehouse in China presents an array of cost considerations, understanding the components, influencers, and negotiation tactics can empower international B2B buyers to make informed decisions. By leveraging these insights, businesses can optimize their sourcing strategies and achieve better pricing outcomes.

Alternatives Analysis: Comparing nike warehouse china With Other Solutions

Exploring Alternative Solutions to Nike Warehouse China

In the competitive landscape of global supply chain management, businesses often seek alternatives to established solutions like Nike Warehouse China. Understanding various options allows international B2B buyers to make informed decisions that align with their logistical needs, budget constraints, and operational goals. This section provides a comparative analysis of Nike Warehouse China against two viable alternatives: Third-Party Logistics (3PL) Providers and Local Warehousing Solutions.

Illustrative image related to nike warehouse china

Comparison Table

| Comparison Aspect | Nike Warehouse China | Third-Party Logistics (3PL) | Local Warehousing Solutions |

|---|---|---|---|

| Performance | High efficiency, tailored for Nike’s specific needs | Variable, depends on the provider | Moderate, may lack scalability |

| Cost | Higher due to brand-specific features | Competitive, often volume-based pricing | Generally lower, but can vary widely |

| Ease of Implementation | Complex setup, requires alignment with Nike’s systems | Relatively straightforward, but depends on integration | Easy to set up, minimal tech requirements |

| Maintenance | Continuous support from Nike | Varies by provider, often includes customer service | Low maintenance, but limited tech support |

| Best Use Case | Brands needing extensive reach and brand alignment | Companies looking for flexible logistics solutions | Local businesses needing quick access to inventory |

Detailed Breakdown of Alternatives

Third-Party Logistics (3PL) Providers

3PL providers offer a flexible logistics solution that can adapt to the varying needs of businesses. These companies manage warehousing, transportation, and distribution, allowing businesses to focus on their core operations. The main advantage of using a 3PL is the cost-effectiveness achieved through shared resources and expertise in logistics. However, the performance can vary significantly depending on the provider, and businesses must ensure robust integration with their systems to avoid disruptions.

Local Warehousing Solutions

Local warehousing solutions cater primarily to businesses that prioritize proximity to their customer base. This approach allows for quicker delivery times and reduced shipping costs. Setting up local warehouses is typically straightforward, making it an attractive option for small to medium-sized enterprises. However, scalability can be a challenge, and these solutions may not provide the same level of advanced technology and inventory management as larger operations like Nike Warehouse China.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting the right warehousing solution, B2B buyers must consider their unique operational requirements, budget constraints, and growth ambitions. Nike Warehouse China may provide unparalleled performance and brand alignment for larger companies or those heavily invested in Nike products. Conversely, 3PL providers present a flexible, often cost-effective alternative that can scale with business growth. Lastly, local warehousing solutions are ideal for businesses focused on regional markets needing quick access to inventory. By assessing these factors, buyers can make strategic decisions that enhance their supply chain efficiency and overall business success.

Essential Technical Properties and Trade Terminology for nike warehouse china

What Are the Key Technical Properties Relevant to Nike Warehouse Operations in China?

When engaging with Nike’s supply chain and warehouse operations in China, understanding certain technical properties is crucial for international B2B buyers. These properties not only dictate the quality and efficiency of the products but also influence the overall procurement strategy.

-

Material Grade

Material grade refers to the classification of raw materials based on their properties and performance characteristics. In the context of Nike products, this could involve specific grades of synthetic materials used in footwear and apparel. Understanding material grades helps buyers assess product durability, performance, and compliance with safety standards, ensuring that the products meet market expectations. -

Tolerance Levels

Tolerance levels define the permissible variations in product dimensions during manufacturing. This is particularly important for apparel and footwear, where precise fitting is crucial for customer satisfaction. Buyers must be aware of tolerance specifications to ensure that products will fit correctly and perform as intended, avoiding costly returns and enhancing customer loyalty. -

Lead Time

Lead time is the duration from order placement to product delivery. In a dynamic market like China, where consumer preferences can shift rapidly, understanding lead times can significantly impact inventory management and product availability. Buyers should aim for shorter lead times to respond quickly to market demands and avoid stockouts. -

Stock Keeping Unit (SKU)

An SKU is a unique identifier for each product variant, including size, color, and style. For Nike’s extensive product line, effective SKU management allows for streamlined inventory control and better sales forecasting. Buyers should familiarize themselves with the SKU system to ensure they order the correct products and quantities. -

Quality Assurance Standards

Quality assurance standards dictate the processes and criteria that products must meet before they can be shipped. Nike’s commitment to quality is evident in their rigorous testing protocols. Understanding these standards helps buyers ensure that the products they receive meet their expectations for quality and performance, thereby reducing the risk of returns.

What Trade Terminology Should International Buyers Know When Dealing with Nike Warehouse in China?

In addition to technical properties, familiarizing oneself with industry-specific terminology is vital for effective communication and negotiation with suppliers.

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then marketed by another company under its own brand name. For Nike, engaging with OEMs can streamline production processes and allow for faster market entry. Buyers should understand OEM relationships to navigate sourcing strategies effectively. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Nike warehouse operations, knowing the MOQ can help buyers gauge their purchasing strategy and budget. It’s essential to negotiate MOQs that align with demand forecasts to avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on supplying specific goods or services. Buyers should prepare comprehensive RFQs to ensure they receive accurate pricing and terms from Nike’s suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce that delineate the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms such as FOB (Free on Board) and CIF (Cost, Insurance, and Freight) is essential for understanding shipping costs and risk management in transactions with Nike. -

Lead Time

As mentioned earlier, lead time is the total time taken from order placement to delivery. It is a critical term in logistics and supply chain management. Buyers should leverage lead time insights to optimize inventory levels and meet consumer demand without overstocking.

By understanding these essential technical properties and trade terminologies, B2B buyers can navigate the complexities of sourcing from Nike’s warehouse in China more effectively, ensuring successful procurement and supply chain management.

Navigating Market Dynamics and Sourcing Trends in the nike warehouse china Sector

What Are the Key Trends Influencing the Nike Warehouse China Sector?

The Nike warehouse sector in China is currently shaped by several global drivers and emerging trends that international B2B buyers should be aware of. First, the rapid growth of e-commerce is transforming supply chain dynamics, compelling companies to enhance their logistics and warehousing capabilities. This shift is particularly relevant for buyers from Africa, South America, the Middle East, and Europe, as they seek efficient sourcing channels that can meet increasing consumer demand.

Additionally, digital transformation is at the forefront, with technologies like AI, IoT, and blockchain improving inventory management and transparency. These technologies not only streamline operations but also enhance the ability to track products throughout the supply chain, which is crucial for compliance and customer satisfaction.

The rising importance of speed-to-market cannot be overlooked. As consumers expect quicker deliveries, Nike’s warehouses in China are optimizing their operations to ensure rapid fulfillment. This trend is especially significant for buyers from fast-paced markets such as Nigeria and Germany, where consumer expectations are continually evolving.

Lastly, the increasing focus on regional sourcing is a notable market dynamic. Global buyers are now looking to establish closer ties with suppliers in China to mitigate risks associated with long-distance logistics and geopolitical tensions. This presents an opportunity for B2B partnerships that prioritize local sourcing strategies while maintaining global standards.

How Is Sustainability Shaping Ethical Sourcing in the Nike Warehouse China Sector?

Sustainability and ethical sourcing are critical considerations for B2B buyers engaging with the Nike warehouse sector in China. As global awareness of environmental issues grows, companies are under increasing pressure to adopt sustainable practices across their supply chains. This involves minimizing the environmental impact of production and logistics, which has become a priority for Nike as part of its corporate responsibility.

Illustrative image related to nike warehouse china

Buyers must pay attention to the importance of ethical supply chains, where transparency and traceability are key. Nike has made significant strides in this area, ensuring that its materials are sourced responsibly and that labor practices meet ethical standards. For international buyers, especially from regions such as Africa and the Middle East, aligning with suppliers that adhere to these ethical standards can enhance brand reputation and foster consumer trust.

Moreover, the use of ‘green’ certifications and sustainable materials is becoming a competitive differentiator. Nike’s commitment to utilizing recycled materials and reducing carbon footprints can influence purchasing decisions. International B2B buyers should seek partnerships with suppliers that prioritize sustainability, as this will not only align with consumer values but also comply with increasing regulatory requirements in their respective markets.

What Is the Historical Context of Nike’s Operations in China?

Nike’s presence in China dates back to the early 1990s, when the company recognized the potential of the Chinese market as a hub for manufacturing and distribution. Over the years, Nike has invested heavily in establishing a robust supply chain infrastructure, including its state-of-the-art warehouse facilities in Shanghai. These facilities are designed to cater to the growing demand for sports apparel and footwear, driven by China’s expanding middle class and increasing interest in sports and fitness.

Illustrative image related to nike warehouse china

The evolution of Nike’s operations in China reflects broader market trends, including the shift towards digitalization and sustainability. By continuously adapting to the changing landscape, Nike has positioned itself as a leader not only in the athletic wear market but also in sustainable practices, setting a benchmark for international B2B buyers looking to engage with the Chinese market effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of nike warehouse china

-

How do I source products from Nike’s warehouse in China?

To source products from Nike’s warehouse in China, begin by establishing a business relationship with an authorized Nike distributor or representative. Reach out through official channels, such as the Nike B2B website, to inquire about product availability and pricing. Ensure you provide details about your business, the markets you serve, and your intended order volume. Once you have a point of contact, negotiate terms and conditions, including minimum order quantities (MOQs) and payment terms, to facilitate a smooth transaction. -

What are the minimum order quantities (MOQs) for Nike products from the China warehouse?

Nike typically has minimum order quantities that vary by product line and type. For bulk orders, MOQs may start at several hundred units, while smaller retailers may face higher MOQs for certain items. It’s essential to discuss specific requirements with your Nike contact or distributor to understand the exact MOQs for the products you are interested in. This will help you plan your inventory and financial commitments effectively. -

What payment terms can I expect when sourcing from Nike’s warehouse in China?

Payment terms when sourcing from Nike’s warehouse can vary based on your negotiation and the nature of your business relationship. Common practices include advance payments, letters of credit, or payment upon delivery. Be prepared to discuss your payment capabilities and preferences during negotiations. Establishing a solid credit history with Nike or your distributor may also influence the payment terms offered. -

How can I ensure product quality when sourcing from Nike’s warehouse in China?

To ensure product quality, conduct thorough due diligence on Nike’s quality assurance processes and standards. Request product samples before placing bulk orders to evaluate quality firsthand. Additionally, consider third-party quality inspections to verify that products meet Nike’s specifications. Establish clear quality expectations in your purchase agreements, and maintain open communication with your Nike representative throughout the sourcing process. -

What logistics options are available for shipping Nike products from China?

Logistics options for shipping Nike products from China include air freight, sea freight, and express courier services. The choice depends on factors such as order size, budget, and delivery urgency. For larger orders, sea freight is generally more economical but takes longer. Conversely, air freight is faster but more costly. Discuss logistics solutions with your supplier to find the best fit for your needs, ensuring you consider customs clearance and import regulations in your country. -

Can I customize Nike products when sourcing from the warehouse in China?

Customization options for Nike products are limited and typically depend on the specific product line and Nike’s policies. Some products may allow for branding or design alterations, while others may not. To explore customization possibilities, discuss your requirements with your Nike contact. Be prepared to meet minimum order thresholds for customized products, and factor in additional lead times for production and delivery. -

What are the common challenges faced when sourcing from Nike’s warehouse in China?

Common challenges include navigating language barriers, understanding local regulations, and managing logistics complexities. Additionally, fluctuating currency rates can impact pricing and profitability. To mitigate these challenges, work closely with a local agent or logistics partner who understands the intricacies of international trade. Establishing a strong communication channel with your Nike representative can also help address issues as they arise. -

How do I verify the authenticity of Nike products from the China warehouse?

To verify the authenticity of Nike products, request documentation and certificates that prove the products are sourced directly from Nike’s authorized channels. Check for brand markings, quality seals, and packaging consistency. Additionally, familiarize yourself with Nike’s official product lines and specifications. Conducting regular audits and working closely with trusted suppliers can further ensure that you receive genuine products, helping to maintain your brand reputation.

Top 3 Nike Warehouse China Manufacturers & Suppliers List

1. Nike – Greater China Headquarters

Domain: about.nike.com

Registered: 1995 (30 years)

Introduction: This company, Nike – Greater China Headquarters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. ScrapingDog – Instagram Data Scraping

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

3. Nike – Key Footwear Products

Domain: aaashoeschina.com

Registered: 2015 (10 years)

Introduction: Key products include: Nike Air Jordan (various models: Jordan 1-15, 18, 37, 38, Big Sizes), Nike Air Max (various models: VaporMax 2023, 2021, 2019, Plus, Scorpion, 2021, 2017, 270, 95, 97, etc.), Nike Dunk SB (various sizes), Air Force One (various models), Nike Shox, Nike Free Metcon, Nike Pegasus Premium, Nike Air Foamposite One, Nike Kyrie, Nike Trainer, and Nike Cortez (for kids and adults). …

Strategic Sourcing Conclusion and Outlook for nike warehouse china

As the global marketplace continues to evolve, Nike’s warehouse operations in China present a strategic opportunity for international B2B buyers. The emphasis on innovation, sustainability, and efficiency within Nike’s supply chain underscores the importance of strategic sourcing. By leveraging Nike’s extensive distribution network, businesses can gain access to high-quality products and responsive logistics that meet the demands of diverse markets.

Key takeaways for buyers include understanding Nike’s commitment to performance and environmental stewardship, which can enhance brand reputation and consumer trust in emerging markets. Furthermore, the centralized operations in China allow for streamlined procurement processes that can help reduce costs and improve lead times.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should actively consider partnerships with Nike’s warehouse operations. Engaging with Nike not only opens doors to premium athletic products but also aligns businesses with a brand recognized for its leadership in innovation and sustainability. Seize this opportunity to strengthen your supply chain and elevate your market presence by tapping into Nike’s extensive resources and expertise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.