Choosing Your N55 Engine For Sale: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for n55 engine for sale

In the competitive landscape of automotive components, sourcing the right BMW N55 engine for sale can pose significant challenges for international B2B buyers. Whether you’re in Africa, South America, the Middle East, or Europe, navigating the complexities of engine specifications, supplier reliability, and logistical considerations is crucial. This guide is designed to empower your purchasing decisions by providing a comprehensive overview of the N55 engine market. From understanding the various types of N55 engines and their applications to effective supplier vetting processes, we cover every aspect essential for making informed choices.

As the demand for high-performance engines increases globally, particularly in regions like Brazil and Nigeria, buyers face the dual challenge of ensuring quality while managing costs. This guide outlines critical factors that influence pricing, such as core charges and rebuild options, and offers insights into performance enhancements that can elevate your vehicle’s capabilities. By detailing the essential steps in sourcing, evaluating, and negotiating with suppliers, we aim to equip you with the knowledge necessary to secure the best deals on N55 engines. With this information at your fingertips, you can confidently navigate the global market, ensuring that your procurement strategy aligns with your business objectives and customer needs.

Understanding n55 engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| OEM-Spec Rebuild | Restores engine to factory specifications using OEM parts. | Replacement for standard BMW models. | Pros: Reliability, factory performance. Cons: Higher cost due to OEM parts. |

| Performance Rebuild | Upgraded components for enhanced power and performance. | Motorsports, performance tuning. | Pros: Increased horsepower, tailored for enthusiasts. Cons: Potentially higher maintenance needs. |

| Used N55 Engine | Pre-owned engines, often inspected and tested for quality. | Cost-effective replacements for various models. | Pros: Lower cost, immediate availability. Cons: Unknown history and potential wear. |

| Remanufactured N55 Engine | Complete disassembly and inspection with replaced components. | Reliable replacements for fleet operations. | Pros: Warranty coverage, thorough inspection. Cons: Core charge may apply. |

| Engine Parts & Upgrades | Individual components for customization or repair. | Engine rebuilds or upgrades for performance. | Pros: Flexibility in customization, targeted repairs. Cons: Requires technical expertise to install. |

What are the Characteristics of an OEM-Spec Rebuild?

An OEM-Spec rebuild is characterized by the use of original equipment manufacturer (OEM) parts, ensuring that the engine is restored to its factory specifications. This type is particularly suitable for businesses looking to maintain the integrity of a BMW vehicle, such as automotive repair shops and fleet operators. Key B2B purchasing considerations include the cost of OEM parts, the warranty offered, and the expected turnaround time for the rebuild. This option is ideal for those prioritizing reliability and performance consistency.

How Does a Performance Rebuild Enhance Engine Functionality?

A Performance Rebuild involves upgrading standard components with high-performance alternatives, such as forged pistons and enhanced bearings. This type of engine is particularly appealing to businesses involved in motorsports or performance tuning. Buyers should consider the cost of upgrades and the expected increase in horsepower when evaluating this option. While it offers significant performance enhancements, it may also lead to higher maintenance demands due to the stress placed on upgraded components.

What Should Buyers Know About Used N55 Engines?

Used N55 engines are pre-owned units that have undergone inspection and testing to ensure they meet performance standards. These engines are often more cost-effective, making them attractive to budget-conscious buyers, such as independent repair shops or small automotive businesses. However, potential buyers must consider the engine’s history, mileage, and any warranties provided. While they offer immediate availability at a lower price, there is an inherent risk regarding wear and longevity.

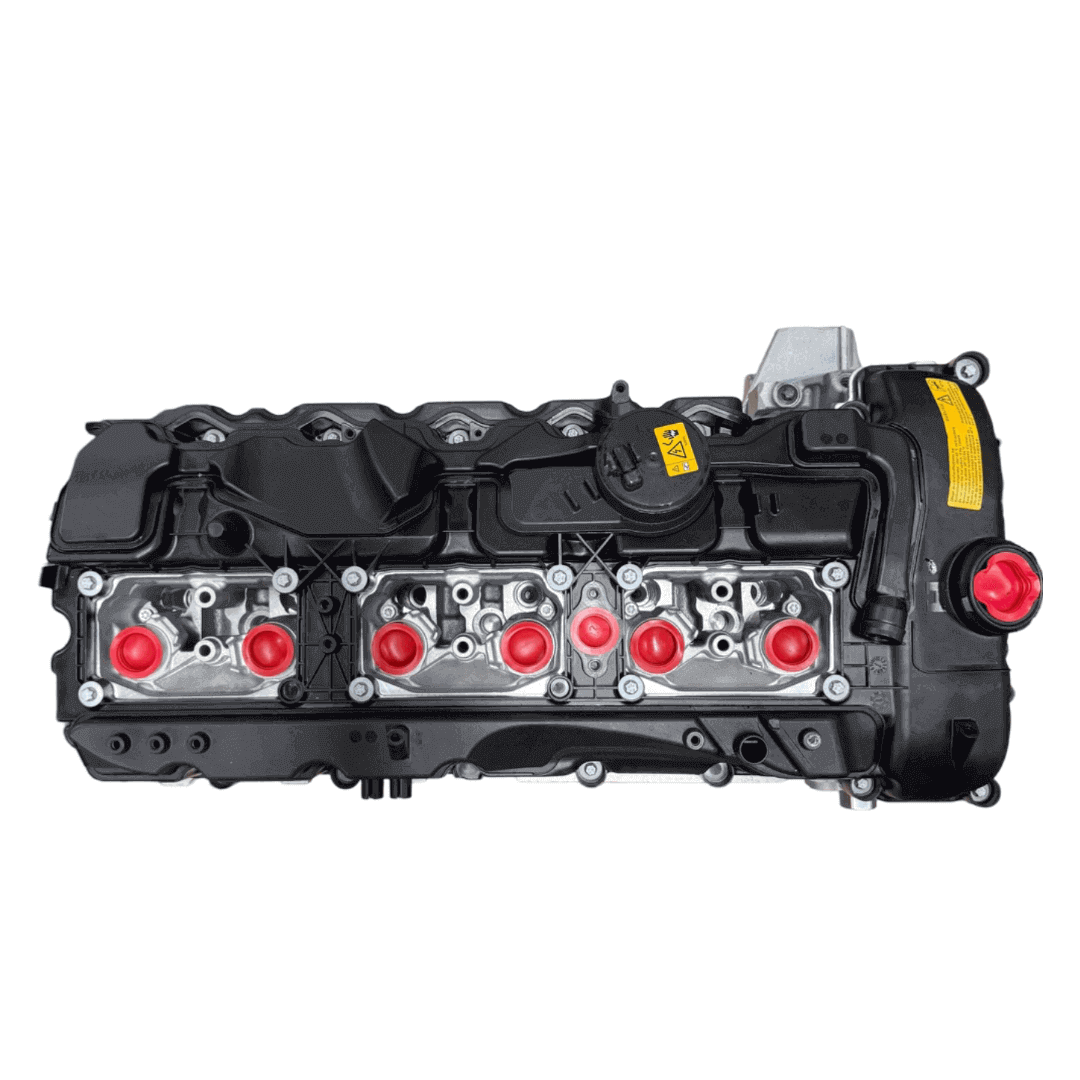

Illustrative image related to n55 engine for sale

Why Choose a Remanufactured N55 Engine?

A Remanufactured N55 engine is thoroughly disassembled, inspected, and rebuilt with new components where necessary. This type typically comes with a warranty, making it a reliable option for businesses that require dependable performance, such as those managing fleets. Buyers should factor in the core charge associated with this option and the assurance of quality due to the comprehensive inspection process. This type is ideal for companies seeking a balance between cost and reliability.

How Can Engine Parts & Upgrades Benefit B2B Buyers?

Engine parts and upgrades allow businesses to customize or repair their engines according to specific needs. This option is particularly useful for repair shops or performance enhancement specialists. Buyers can choose targeted repairs or upgrades based on performance goals or budget constraints. However, this approach requires technical expertise for installation, which may pose a challenge for some buyers. The flexibility in customization makes this option appealing for those looking to optimize engine performance.

Key Industrial Applications of n55 engine for sale

| Industry/Sector | Specific Application of n55 engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Engine replacement for BMW vehicles | Restores vehicle performance and reliability | Ensure compatibility with specific BMW models, warranty terms |

| Performance Tuning | High-performance upgrades for racing and modified vehicles | Enhances horsepower and torque for competitive advantage | Consider availability of performance parts and rebuild options |

| Fleet Management | Replacement engines for company-owned BMW fleets | Reduces downtime and maintenance costs | Evaluate total cost of ownership, including core charge policies |

| Export and Resale | Supply of used N55 engines for resale in emerging markets | Meets demand for affordable, reliable engine options | Understand local regulations and compliance for engine imports |

| Custom Build Projects | Engine installations in custom builds and specialty vehicles | Provides unique performance solutions for niche markets | Assess specific customization needs and sourcing timelines |

How is the N55 Engine Used in Automotive Repair?

In the automotive repair sector, the N55 engine is predominantly used for replacing defective engines in various BMW models. This application is vital for maintaining the performance and longevity of vehicles, particularly in regions where BMWs are popular. For businesses in Africa or South America, sourcing a reliable N55 engine can significantly reduce repair times and enhance customer satisfaction. Buyers should prioritize compatibility checks with specific vehicle models and ensure that warranty provisions are clearly outlined to mitigate risks associated with engine replacements.

What Role Does the N55 Engine Play in Performance Tuning?

Performance tuning shops utilize the N55 engine to upgrade the powertrains of BMW vehicles, enhancing their performance for racing or modified applications. By integrating high-performance components, such as forged pistons and upgraded turbochargers, these engines can deliver superior horsepower and torque. For B2B buyers, especially in competitive markets in Europe and the Middle East, understanding the various performance rebuild options available is crucial. It is essential to assess the supplier’s capability to provide quality performance parts and reliable service to ensure optimal engine performance.

How Does Fleet Management Benefit from N55 Engine Replacement?

In fleet management, businesses that operate BMW vehicles benefit from having a dependable source for N55 engine replacements. This is particularly important for minimizing downtime and keeping operational costs low. For companies in regions like Nigeria or Brazil, where vehicle maintenance can be costly, having access to affordable, remanufactured engines ensures that fleet vehicles remain functional and efficient. Buyers should consider the total cost of ownership, including potential core charges and the efficiency of the supply chain, to maintain their fleet effectively.

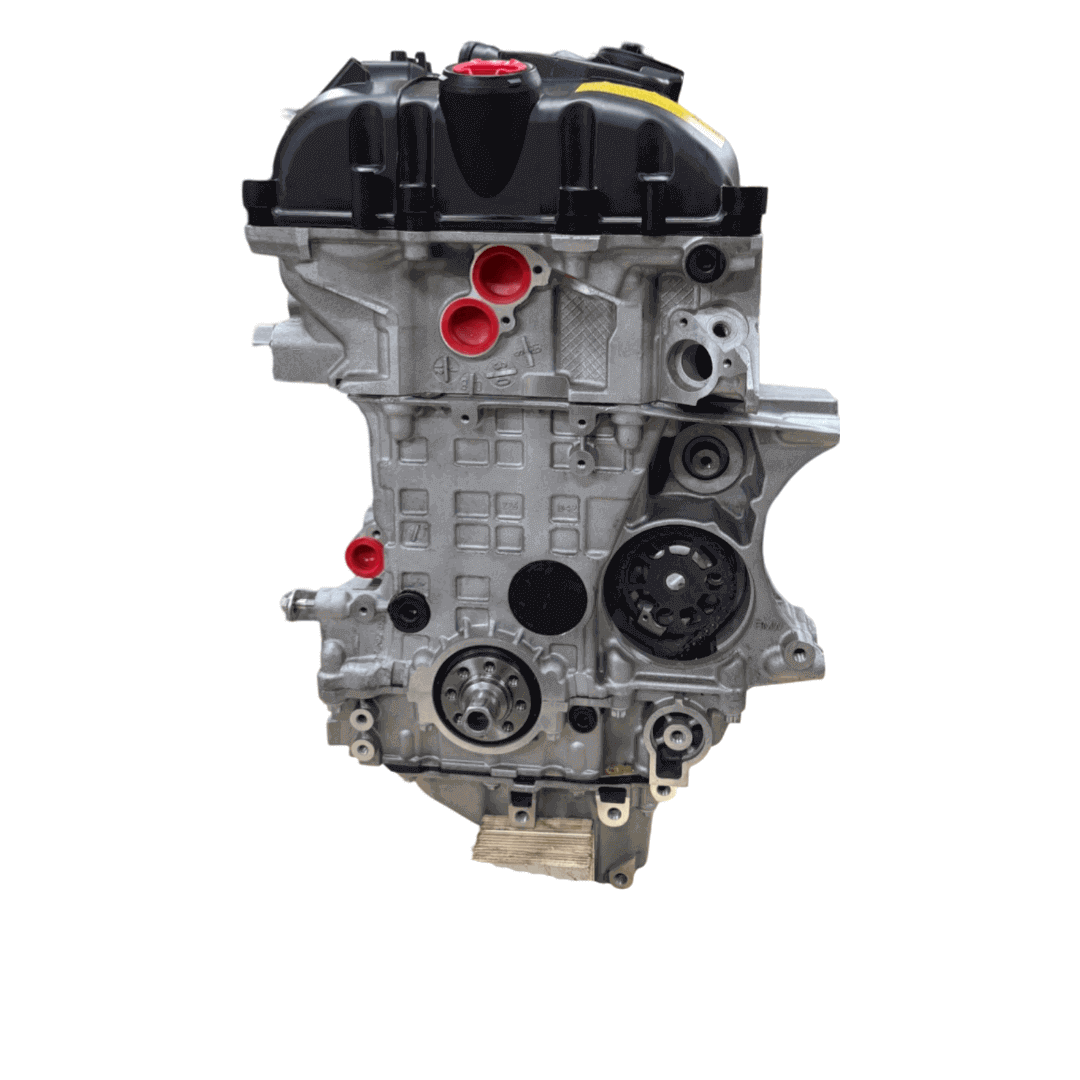

Illustrative image related to n55 engine for sale

What Opportunities Exist for Export and Resale of N55 Engines?

The export and resale market for N55 engines presents significant opportunities, especially in emerging markets where demand for reliable and affordable automotive parts is high. Businesses that specialize in importing engines can cater to a growing customer base looking for cost-effective solutions. Understanding local regulations regarding engine imports is critical for B2B buyers in Africa and South America to ensure compliance and avoid delays. Establishing strong relationships with suppliers can also enhance the ability to meet market demands promptly.

How Can Custom Build Projects Leverage the N55 Engine?

Custom build projects often incorporate the N55 engine to deliver unique performance solutions tailored to specific client needs. This application is particularly appealing to niche markets that seek high-performance vehicles or bespoke builds. B2B buyers engaged in this sector must assess the customization options available and ensure that suppliers can meet specific requirements, including sourcing timelines and compatibility with other performance parts. This attention to detail can significantly enhance the project’s success and customer satisfaction.

3 Common User Pain Points for ‘n55 engine for sale’ & Their Solutions

Scenario 1: Difficulty in Sourcing Genuine N55 Engines

The Problem: One of the most significant challenges faced by B2B buyers in the market for N55 engines is identifying reliable suppliers who offer genuine, high-quality products. With many vendors online, it can be overwhelming to sift through options, and the risk of purchasing counterfeit or substandard engines is high. This problem is particularly pressing for businesses in regions like Africa and South America, where sourcing from reputable suppliers is crucial for maintaining operational integrity and customer satisfaction.

The Solution: To effectively source genuine N55 engines, B2B buyers should establish relationships with well-known distributors and manufacturers. Conduct thorough research on suppliers by checking their reputation, customer reviews, and industry certifications. Additionally, request certifications and warranties for the engines being sold. It’s also beneficial to seek out suppliers who provide comprehensive product documentation, including detailed specifications and testing results. Engaging in industry forums or attending trade shows can also offer valuable insights and connections to reputable suppliers, ensuring a more secure purchasing process.

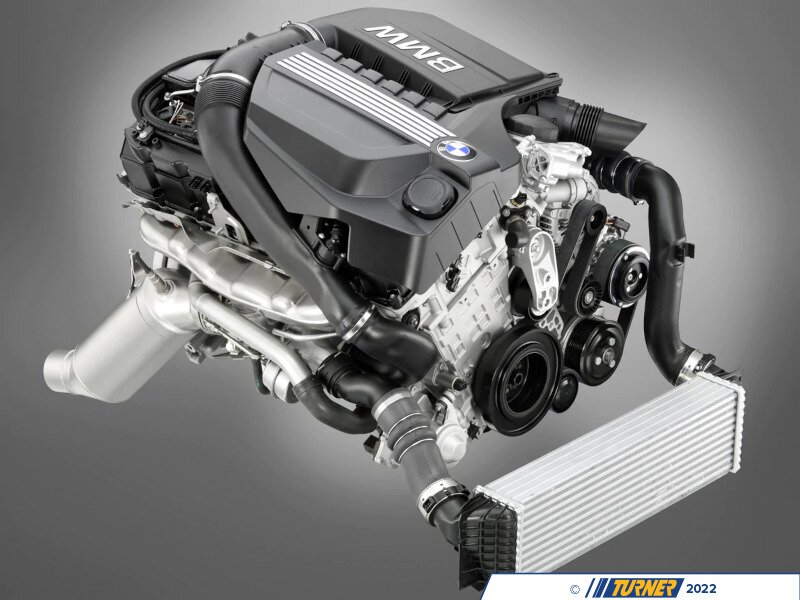

Illustrative image related to n55 engine for sale

Scenario 2: Uncertainty About Engine Compatibility

The Problem: Another common issue is the uncertainty surrounding engine compatibility with specific BMW models. B2B buyers may find themselves unsure whether the N55 engine they are considering will fit the intended vehicle, leading to wasted time and financial loss. This is especially critical for businesses that rely on fleet vehicles or specific models for their operations, as miscalculations can disrupt service and lead to additional costs.

The Solution: To mitigate compatibility issues, B2B buyers should implement a standardized process for verifying engine fitment before making a purchase. This includes cross-referencing the engine’s VIN (Vehicle Identification Number) with compatibility databases or consulting with technical experts. Buyers should also request detailed fitment guides from suppliers, which outline which models the N55 engine is compatible with. Utilizing tools like compatibility checkers or consulting with professional mechanics can further enhance the accuracy of these assessments. Moreover, consider investing in a warranty or return policy that allows for exchanges in case of fitment issues, ensuring that your business is protected against unexpected complications.

Scenario 3: Concerns Over Engine Quality and Longevity

The Problem: Quality assurance is a critical concern for B2B buyers when purchasing N55 engines, especially in markets where engine failures can have severe repercussions on business operations. Buyers are often apprehensive about the longevity and reliability of used or remanufactured engines, particularly those sold at lower price points. This concern is heightened in competitive markets, where the performance of the engine directly impacts customer satisfaction and retention.

The Solution: To ensure the quality and longevity of purchased N55 engines, buyers should prioritize vendors that offer detailed remanufacturing processes and quality assurance practices. Look for suppliers who provide a transparent breakdown of their rebuilding process, including the components replaced and testing protocols followed. Additionally, seeking out engines that come with extended warranties—such as a one-year/12,000-mile internal parts warranty—can offer peace of mind. Conducting independent inspections or requiring third-party quality assessments before finalizing the purchase can further ensure that the engines meet necessary performance and reliability standards. By investing in engines with proven quality assurance measures, businesses can enhance their operational reliability and customer satisfaction.

Strategic Material Selection Guide for n55 engine for sale

What Materials Are Commonly Used in the N55 Engine and Their Properties?

When selecting materials for the BMW N55 engine, several common options stand out due to their unique properties and performance characteristics. Understanding these materials is crucial for B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe.

Aluminum Alloys: The Lightweight Champion

Aluminum alloys are predominantly used for the engine block and cylinder head of the N55 engine. These alloys offer excellent strength-to-weight ratios, making them ideal for high-performance applications. Key properties include good thermal conductivity and resistance to corrosion, which are critical for engine efficiency and longevity.

Pros: Aluminum is lightweight, which helps improve fuel efficiency and performance. Its corrosion resistance also extends the engine’s lifespan, reducing maintenance costs.

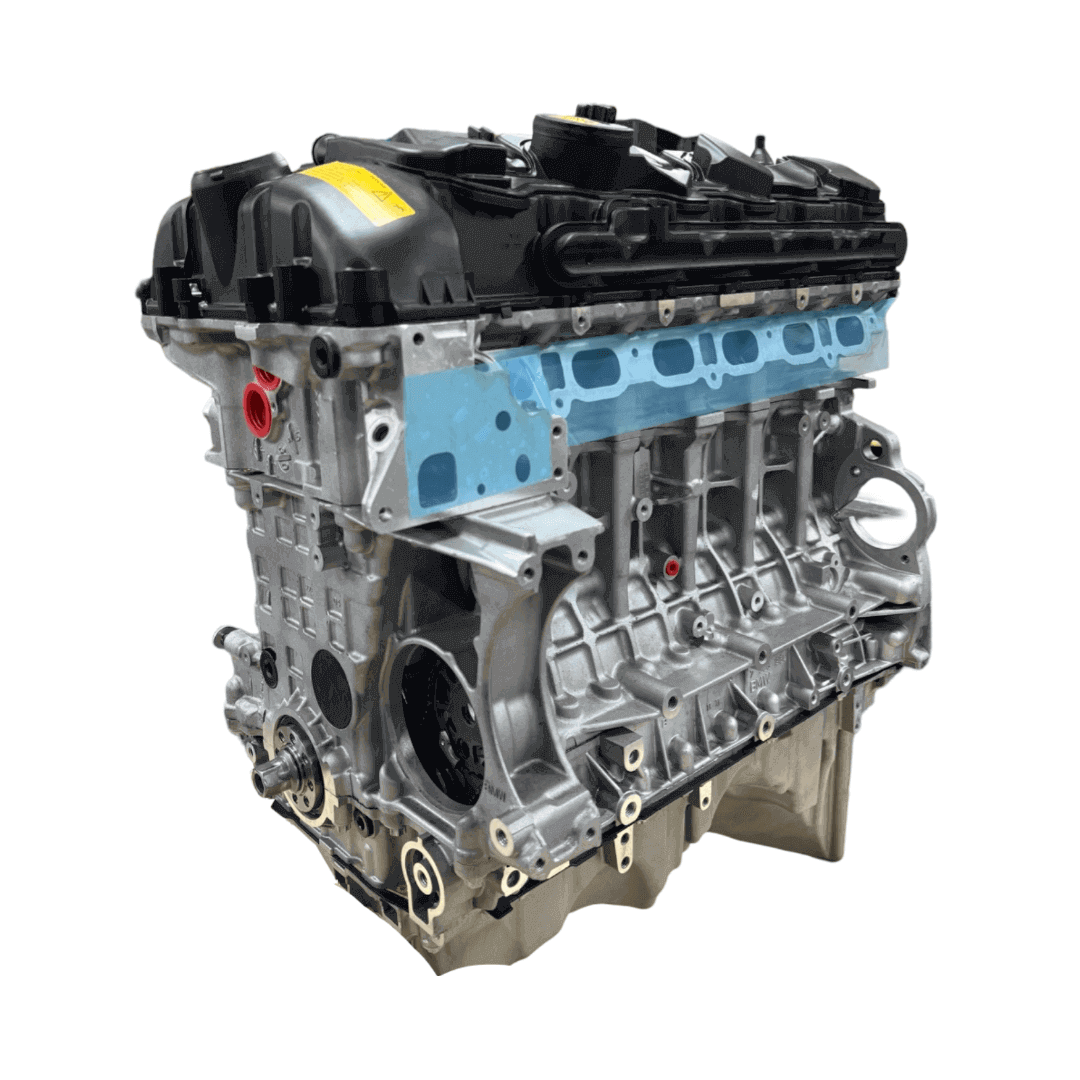

Illustrative image related to n55 engine for sale

Cons: While aluminum is durable, it can be more susceptible to deformation under extreme pressure compared to heavier metals. The manufacturing complexity can also increase costs due to the need for precise machining.

Impact on Application: Aluminum’s compatibility with various engine fluids is vital, as it can withstand high temperatures and pressures without significant degradation.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is essential, especially in regions like Europe where regulations are stringent. Buyers should also consider the availability of aluminum alloys in local markets.

Cast Iron: The Traditional Workhorse

Cast iron is often used for engine components that require high durability and wear resistance, such as the crankshaft and cylinder sleeves. Its key properties include high tensile strength and excellent wear resistance, making it suitable for high-stress applications.

Pros: Cast iron is highly durable and can withstand significant wear and tear, making it ideal for long-term use in engines.

Illustrative image related to n55 engine for sale

Cons: The weight of cast iron can negatively affect fuel efficiency. Additionally, it is more prone to rust if not properly maintained, which can lead to increased costs over time.

Impact on Application: Cast iron’s compatibility with various lubricants and coolants is beneficial, but its weight may necessitate design considerations for overall vehicle performance.

Considerations for International Buyers: Buyers should ensure that the cast iron used meets local standards, as variations in composition can affect performance. Markets in Africa and South America may have different availability and pricing for cast iron components.

Steel Alloys: Strength and Versatility

Steel alloys are commonly used for various engine components, including connecting rods and crankshafts. These materials offer excellent tensile strength and fatigue resistance, making them suitable for high-performance applications.

Illustrative image related to n55 engine for sale

Pros: Steel alloys provide a good balance of strength and weight, offering durability without excessive mass. They are also relatively cost-effective compared to other high-performance materials.

Cons: While steel alloys are strong, they can be susceptible to corrosion if not properly treated. Additionally, the manufacturing process can be complex, leading to higher production costs.

Impact on Application: Steel’s compatibility with engine lubricants and its ability to withstand high temperatures make it an excellent choice for critical engine components.

Considerations for International Buyers: Compliance with standards such as JIS and ASTM is important, especially in regions like the Middle East where quality assurance is critical. Buyers should also consider the sourcing of high-quality steel alloys to ensure performance.

Composite Materials: The Future of Engine Design

Composite materials, including carbon fiber and reinforced plastics, are increasingly being explored for use in engine components due to their lightweight and high-strength properties. These materials are particularly advantageous in applications where weight reduction is critical.

Pros: Composites offer exceptional strength-to-weight ratios and can enhance fuel efficiency. They are also resistant to corrosion, which can lead to lower maintenance costs.

Cons: The primary drawback is the cost, as composites can be significantly more expensive than traditional materials. Additionally, manufacturing processes for composites can be complex and time-consuming.

Impact on Application: Composites can be used in various engine components, but their compatibility with engine fluids must be thoroughly tested to avoid degradation.

Considerations for International Buyers: As composites are not yet widely adopted, buyers in regions such as Africa and South America may face challenges in sourcing these materials. Compliance with international standards is also essential to ensure quality.

Summary Table of Material Selection for N55 Engine

| Material | Typical Use Case for n55 engine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Engine block, cylinder head | Lightweight, corrosion-resistant | Susceptible to deformation under pressure | Medium |

| Cast Iron | Crankshaft, cylinder sleeves | Highly durable, excellent wear resistance | Heavy, prone to rust | Medium |

| Steel Alloys | Connecting rods, crankshafts | Strong, cost-effective | Susceptible to corrosion | Medium |

| Composite Materials | Lightweight components | Exceptional strength-to-weight ratio | High cost, complex manufacturing | High |

This strategic material selection guide serves as a valuable resource for B2B buyers looking to make informed decisions when sourcing components for the N55 engine, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for n55 engine for sale

What Are the Main Stages of Manufacturing the N55 Engine?

Manufacturing the BMW N55 engine is a complex and precise process that involves several key stages, each critical to ensuring performance and reliability.

1. Material Preparation

The first stage focuses on sourcing high-quality materials, primarily aluminum and steel, which are essential for the engine’s components. The materials are inspected for compliance with specifications, and any non-conforming materials are rejected. Advanced techniques, such as chemical analysis and mechanical testing, are employed to verify the integrity of the raw materials.

2. Forming

Once materials are approved, they undergo various forming processes. Techniques like die casting and machining are utilized to create engine blocks and cylinder heads. CNC (Computer Numerical Control) machines ensure that each part is crafted to exact specifications, achieving the necessary tolerances for optimal performance. Forming processes also include forging for components like crankshafts and connecting rods, ensuring strength and durability.

3. Assembly

The assembly stage is where precision engineering comes into play. Components such as pistons, crankshafts, and camshafts are meticulously assembled in a cleanroom environment to minimize contamination. Each assembly station is equipped with torque wrenches and gauges to ensure that all fasteners are tightened to specified values. This stage often includes automated assembly lines, but skilled technicians oversee the process to address any anomalies.

Illustrative image related to n55 engine for sale

4. Finishing

Finishing processes include surface treatment, polishing, and coating. Parts are often treated with protective coatings to enhance corrosion resistance and reduce friction. Additionally, balancing of rotating components is performed to minimize vibrations during engine operation. Finally, engines undergo a thorough cleaning process to ensure they are free from debris before they are packed for shipment.

How Is Quality Control Implemented in N55 Engine Manufacturing?

Quality control (QC) is integral to the manufacturing process of the N55 engine, ensuring that each unit meets stringent performance standards and regulatory requirements.

What International Standards Guide Quality Assurance?

Manufacturers often adhere to international standards such as ISO 9001, which emphasizes a quality management system that ensures consistent quality in products and services. Other relevant standards include CE marking for compliance with European safety regulations and API standards for performance in automotive applications. Compliance with these standards not only guarantees quality but also builds trust with international B2B buyers.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are established throughout the manufacturing process, typically categorized into three main types:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials upon arrival. Suppliers must provide certification documents that detail the material specifications and test results.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure that processes remain within specified tolerances. This includes regular inspections of dimensions and functional testing at various stages of assembly.

-

Final Quality Control (FQC): Before shipment, each engine undergoes a comprehensive testing phase, which may involve dynamometer testing to assess performance metrics like horsepower and torque. This final inspection ensures that the engine meets all operational specifications.

What Common Testing Methods Are Used in N55 Engine Quality Assurance?

Testing methods play a crucial role in validating the performance and reliability of the N55 engine. Common testing techniques include:

Illustrative image related to n55 engine for sale

-

Dynamometer Testing: This measures engine performance under simulated driving conditions, assessing parameters like power output, fuel efficiency, and emissions.

-

Leak Testing: Pressure tests are conducted to identify any potential leaks in the engine system, particularly in the oil and coolant passages.

-

Vibration Analysis: This is performed to detect any irregularities in engine balance that could lead to premature wear or failure.

-

Thermal Imaging: Used to monitor temperature distribution across engine components, ensuring that no overheating issues arise during operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential for making informed purchasing decisions.

What Steps Should Buyers Take to Ensure Compliance?

-

Supplier Audits: Conducting audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can include reviewing their certifications, training programs, and adherence to international standards.

-

Requesting Quality Reports: Buyers should ask suppliers for documented evidence of their quality control practices, including inspection reports, testing results, and compliance certificates. This documentation serves as proof of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These organizations can conduct independent assessments of manufacturing practices, material quality, and final product testing.

-

Understanding Core Charge Policies: When purchasing engines, it’s crucial to understand the core charge policies. Buyers should ensure that the supplier’s policies on core returns are clear and that they align with local regulations, particularly in the context of international transactions.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B transactions often involve navigating various regulations and standards, which can vary significantly by region. Buyers must be aware of the following nuances:

-

Regulatory Compliance: Different countries have specific automotive regulations that may require additional certifications. Buyers should familiarize themselves with these requirements to avoid compliance issues.

-

Cultural Considerations: Understanding the business culture in the supplier’s region can facilitate smoother negotiations and build stronger partnerships. This is particularly relevant in regions like Africa and South America, where local practices may differ from those in Europe or the Middle East.

-

Logistical Challenges: Shipping and customs regulations can affect the delivery of engines and parts. Buyers should work closely with suppliers to ensure that all necessary documentation is in place to avoid delays.

By paying close attention to these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing N55 engines, ensuring they receive high-quality products that meet their specific needs.

Illustrative image related to n55 engine for sale

Practical Sourcing Guide: A Step-by-Step Checklist for ‘n55 engine for sale’

To assist international B2B buyers in successfully procuring an N55 engine, this practical sourcing guide outlines essential steps to consider during the purchasing process. Following this checklist will help ensure that you make informed decisions, leading to successful transactions and quality products.

Step 1: Define Your Technical Specifications

Begin by clearly identifying the technical specifications required for the N55 engine. This includes understanding the engine type (3.0L inline-6, TwinPower Turbo), horsepower, torque, and compatibility with specific BMW models. Having precise specifications will streamline your search and help you communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of N55 engines. Look for suppliers with a strong market presence and positive reviews from previous customers. Utilize industry forums, business directories, and trade shows to gather insights and recommendations.

- Check Online Reviews: Platforms like Trustpilot or industry-specific forums can provide valuable feedback on supplier reliability.

- Assess Supplier Credentials: Verify if the supplier holds any industry certifications that indicate adherence to quality standards.

Step 3: Evaluate Supplier Certifications

Before finalizing your supplier, ensure they possess the necessary certifications that guarantee the quality and authenticity of their engines. Certifications such as ISO 9001 or other relevant automotive standards indicate a commitment to quality and consistency in manufacturing processes.

- Request Documentation: Ask for copies of certifications to verify their validity.

- Understand Warranty Policies: Ensure the supplier offers a comprehensive warranty that covers parts and labor, providing peace of mind with your purchase.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, core charges, and shipping costs. Pay attention to what is included in the price, such as any warranties or return policies on core engines.

- Compare Costs: Analyze quotes not just on price but also on the value offered, including warranties and service agreements.

- Clarify Payment Terms: Ensure you understand the payment structure, including deposits, full payments, and any financing options available.

Step 5: Assess Engine Condition and Quality

Whether you are purchasing a new or used N55 engine, it’s essential to assess the condition and quality. For used engines, request a history report and any testing or inspection results to ensure the engine’s reliability.

- Inquire About Rebuilds: If considering rebuilt engines, understand the rebuild process, including the components replaced and the warranty on internal parts.

- Request Visual Documentation: Ask for images or videos of the engine being tested to confirm operational integrity.

Step 6: Confirm Shipping and Handling Procedures

Understand the logistics involved in shipping the N55 engine to your location. Confirm the shipping methods, estimated delivery times, and any customs documentation required for international shipments.

- Check for Insurance: Ensure the shipment is insured against damage or loss during transit.

- Discuss Return Policies: Clarify the return policy in case the engine does not meet your specifications upon arrival.

Step 7: Establish Communication Channels

Finally, establish clear communication channels with your supplier. Effective communication will facilitate a smooth purchasing process, enabling you to address any questions or concerns promptly.

Illustrative image related to n55 engine for sale

- Designate a Point of Contact: Identify a specific person at the supplier’s organization who will handle your order.

- Set Up Regular Updates: Schedule periodic updates regarding the order status, shipping, and any potential issues.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing an N55 engine effectively, ensuring they secure a quality product that meets their operational needs.

Comprehensive Cost and Pricing Analysis for n55 engine for sale Sourcing

Understanding the cost structure and pricing dynamics for sourcing the BMW N55 engine is crucial for international B2B buyers. This analysis will help you navigate the complexities of the market, ensuring you make informed purchasing decisions.

What Are the Key Cost Components for the N55 Engine?

When evaluating the cost of an N55 engine, several components come into play:

-

Materials: The N55 engine comprises high-quality materials such as aluminum for the block and head, which contributes to its lightweight design. The cost of raw materials can fluctuate based on market conditions, impacting the overall engine price.

-

Labor: Skilled labor is required for both manufacturing and rebuilding the engine. The complexity of the engine assembly and the level of expertise needed can drive up labor costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance of machinery. Efficient manufacturing processes can help reduce these overhead costs, leading to more competitive pricing.

-

Tooling: Specialized tools and equipment needed for the production and assembly of the N55 engine add to the initial setup costs. These costs are typically amortized over the production volume.

-

Quality Control (QC): Ensuring that each engine meets stringent quality standards is essential. QC processes require investment in testing equipment and personnel, which are factored into the engine’s final price.

-

Logistics: Transportation costs, including shipping and customs clearance, can significantly impact pricing, especially for international buyers. Incoterms play a crucial role in defining who bears these costs.

-

Margin: Suppliers typically apply a profit margin to cover their operational costs and ensure business sustainability. This margin can vary based on market demand and competition.

What Influences the Pricing of the N55 Engine?

Several factors can influence the pricing of the N55 engine in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, making it essential for buyers to consider their procurement strategy. Understanding the MOQ can lead to better pricing agreements.

-

Specifications and Customization: Custom-built engines or those with specific performance upgrades will generally command higher prices. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Quality and Certifications: Engines that come with OEM certifications or high-performance guarantees may be priced higher due to the assurance of quality. Buyers should weigh the benefits against the cost.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service levels.

-

Incoterms: Understanding the terms of trade is vital for international transactions. Incoterms dictate responsibilities for shipping costs, insurance, and customs duties, impacting the total cost of ownership.

What Are Effective Buyer Tips for Negotiating N55 Engine Prices?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings:

Illustrative image related to n55 engine for sale

-

Leverage Volume Discounts: If your business can commit to larger orders, use this as leverage in negotiations. Suppliers are often willing to provide better pricing for bulk purchases.

-

Assess Total Cost of Ownership (TCO): Consider not just the upfront cost but also long-term expenses such as maintenance, fuel efficiency, and potential downtime. A higher initial investment may yield lower TCO in the long run.

-

Investigate Alternative Suppliers: Don’t settle for the first quote. Comparing prices and services from multiple suppliers can reveal market standards and help negotiate better terms.

-

Focus on Quality Assurance: Prioritize suppliers that offer robust warranties and quality guarantees. This may slightly increase initial costs but can save money on repairs and replacements.

-

Understand Market Trends: Stay informed about market fluctuations in raw materials and labor. This knowledge can provide a basis for negotiating prices based on current economic conditions.

Final Thoughts on N55 Engine Pricing

While indicative prices for the N55 engine range from $3,800 to $6,000 depending on the condition and specifications, actual costs can vary. Buyers should conduct thorough research and engage in strategic negotiations to secure the best possible deal while ensuring quality and reliability in their purchases.

Alternatives Analysis: Comparing n55 engine for sale With Other Solutions

Exploring Alternatives to the N55 Engine for Sale

In the competitive landscape of engine solutions, B2B buyers must consider various alternatives to the N55 engine. While the N55 engine, known for its robust performance and efficiency, is a solid choice for many applications, there are other options available that may better suit specific business needs. This analysis will compare the N55 engine with two viable alternatives: the BMW N54 engine and aftermarket performance engine upgrades.

| Comparison Aspect | N55 Engine For Sale | BMW N54 Engine | Aftermarket Performance Upgrades |

|---|---|---|---|

| Performance | 300 hp, 400 Nm torque | 335 hp, 450 Nm torque | Varies by components, often exceeding N55 specs |

| Cost | $3,800 – $5,500 | $3,950 – $4,500 | $5,200 (base rebuild) + upgrades |

| Ease of Implementation | Moderate; requires core return | Similar complexity; core return needed | High; depends on upgrades selected |

| Maintenance | Standard; 1-year warranty | Standard; similar warranty | Varies; performance parts may require more frequent servicing |

| Best Use Case | General use in multiple BMW models | High-performance applications | Racing or performance-focused vehicles |

What Are the Advantages and Disadvantages of the BMW N54 Engine?

The BMW N54 engine is a popular alternative to the N55, providing slightly higher horsepower and torque figures. It is also known for its tuning potential, making it a favorite among performance enthusiasts. However, the N54 may require more frequent maintenance, especially concerning its turbochargers, which can be a concern for businesses seeking reliability in their fleet. The cost is slightly lower than the N55, making it an attractive option for budget-conscious buyers.

How Do Aftermarket Performance Upgrades Compare to the N55 Engine?

Aftermarket performance upgrades for engines, including the N55, can significantly enhance power output and overall performance. These upgrades often include high-performance pistons, rods, and turbochargers. However, the complexity and cost can vary widely based on the components chosen. While these upgrades can potentially exceed the N55’s performance, they may also introduce reliability concerns and require more rigorous maintenance schedules. This option is best suited for businesses focused on racing or high-performance applications where maximizing engine output is critical.

Conclusion: Choosing the Right Engine Solution for Your Business Needs

When evaluating alternatives to the N55 engine for sale, it is essential for B2B buyers to consider their specific requirements, including performance needs, budget constraints, and maintenance capabilities. The N54 engine offers a compelling mix of performance and cost, while aftermarket upgrades present an opportunity for enhanced output at the risk of increased complexity and maintenance. Ultimately, the decision should align with the operational goals of your business, ensuring that the chosen engine solution meets both performance expectations and long-term reliability.

Illustrative image related to n55 engine for sale

Essential Technical Properties and Trade Terminology for n55 engine for sale

What Are the Key Technical Properties of the N55 Engine for Sale?

When considering the purchase of an N55 engine, understanding its technical specifications is crucial for B2B buyers. Here are some critical specifications that highlight the engine’s performance and reliability:

-

Engine Code: N55B30

The N55B30 is the specific engine code for the BMW N55, indicating its unique identification within the BMW engine family. This code helps buyers ensure compatibility with various BMW models, which is essential for procurement and inventory management. -

Displacement: 3.0L (2,979 cc)

The engine’s displacement directly impacts its power output and efficiency. The N55’s 3.0L capacity signifies a robust powertrain capable of delivering 300 horsepower at 5,800 RPM. Buyers should consider displacement when assessing an engine’s suitability for performance applications or vehicle upgrades. -

Torque: 400 Nm @ 1,200-5,000 RPM

Torque is a critical factor for engine performance, particularly in terms of acceleration and towing capacity. The N55’s torque curve provides strong performance across a wide RPM range, making it an appealing option for both everyday driving and high-performance applications. -

Turbocharger: Single Twin-Scroll Turbocharger

This feature enhances the engine’s responsiveness and power delivery. The twin-scroll design helps minimize turbo lag, allowing for quicker throttle response. For B2B buyers, understanding turbocharger specifications is vital for evaluating performance potential and compatibility with aftermarket modifications. -

Material Composition: Aluminum Block and Cylinder Head

The lightweight aluminum construction contributes to improved fuel efficiency and handling. This specification is essential for buyers looking for engines that combine performance with weight savings, particularly in sports or luxury vehicles. -

Compression Ratio: 10.2:1

A higher compression ratio can lead to better thermal efficiency and performance. For B2B buyers, this ratio is an important consideration when assessing fuel requirements and overall engine efficiency.

What Are Common Trade Terminology and Jargon Associated with N55 Engine Sales?

Understanding trade terminology is crucial for effective communication and negotiations in the B2B landscape. Here are some key terms relevant to the sale of the N55 engine:

-

OEM (Original Equipment Manufacturer)

OEM refers to components made by the original manufacturer of the vehicle. In the context of the N55 engine, using OEM parts ensures compatibility and reliability. B2B buyers often prefer OEM parts for rebuilding or replacing engines to maintain warranty and quality standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell. For B2B transactions involving N55 engines, understanding MOQ helps buyers plan their inventory and manage costs effectively, ensuring they meet demand without overstocking. -

RFQ (Request for Quotation)

An RFQ is a document used to invite suppliers to provide pricing for specific products. B2B buyers should issue an RFQ when seeking N55 engines to obtain competitive pricing and terms, allowing for informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers involved in cross-border purchases of N55 engines to understand shipping responsibilities, risk, and costs. -

Core Charge

This is a fee added to the price of the engine that is refundable upon the return of a used engine core. Understanding the core charge is important for buyers as it affects the total cost of the engine purchase and incentivizes the return of old engines for remanufacturing. -

Warranty Period

The warranty period specifies the duration for which the supplier guarantees the engine’s performance. For B2B buyers, a clear understanding of warranty terms is crucial for assessing the risk associated with purchasing an N55 engine and planning for future service needs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing N55 engines, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the n55 engine for sale Sector

What Are the Current Market Dynamics and Key Trends Influencing the N55 Engine for Sale Sector?

The global market for the BMW N55 engine is witnessing significant growth, driven by the increasing demand for high-performance vehicles and the rising popularity of engine remanufacturing. With its robust specifications, including a 3.0L TwinPower Turbo inline-six design, the N55 engine appeals to a wide array of international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. In these markets, the demand for quality automotive components is escalating due to a growing middle class and expanding automotive sectors.

Emerging technologies in sourcing, such as digital supply chain management and e-commerce platforms, are reshaping how buyers access N55 engines. These tools facilitate streamlined procurement processes, offering real-time inventory checks and competitive pricing. Additionally, the trend towards performance upgrades is gaining traction, with buyers increasingly seeking options that enhance engine performance through aftermarket parts and modifications. This trend not only supports vehicle longevity but also aligns with the growing consumer preference for customized automotive solutions.

Illustrative image related to n55 engine for sale

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the N55 Engine Market?

Sustainability is becoming a critical concern for B2B buyers in the automotive sector, including those sourcing N55 engines. The environmental impact of engine manufacturing, particularly regarding emissions and resource depletion, is prompting companies to seek suppliers committed to ethical practices. Buyers should prioritize partnerships with manufacturers that utilize sustainable materials and processes.

Certifications such as ISO 14001 for environmental management can serve as indicators of a supplier’s commitment to sustainable practices. Moreover, opting for rebuilt or remanufactured engines can significantly reduce waste and resource consumption compared to sourcing entirely new units. Engaging with suppliers that emphasize recycling and responsible sourcing of materials helps reinforce a company’s commitment to sustainability, ultimately enhancing brand reputation in increasingly eco-conscious markets.

What Has Been the Evolution of the N55 Engine and Its Impact on B2B Sourcing?

The BMW N55 engine, introduced in 2009, represents a significant advancement in automotive engineering, blending performance with efficiency. Its development marked a shift in BMW’s engine design philosophy, moving from naturally aspirated engines to turbocharged units that offer greater power and fuel economy. This evolution has made the N55 a sought-after option for performance enthusiasts and everyday drivers alike, solidifying its place in the automotive market.

As the demand for the N55 engine grew, so did the landscape for B2B sourcing. The rise of the aftermarket parts industry, coupled with the availability of remanufactured engines, has expanded options for buyers looking to enhance vehicle performance or replace aging components. This evolution has not only diversified the supply chain but has also fostered a competitive environment where quality and price are paramount, enabling buyers to make informed purchasing decisions. The N55 engine’s legacy continues to influence sourcing strategies, driving a focus on quality, performance, and sustainability in the B2B marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of n55 engine for sale

-

How do I ensure the N55 engine I purchase is compatible with my vehicle?

To ensure compatibility, cross-reference the engine’s specifications with your vehicle’s VIN. Each N55 engine is designed for specific BMW models, including the 135i, 335i, and X5. Consulting with a qualified mechanic can provide additional assurance, as they can confirm fitment and any necessary modifications. It’s crucial to verify these details before completing a purchase to avoid costly errors and ensure optimal engine performance. -

What is the best way to evaluate suppliers for purchasing N55 engines?

When evaluating suppliers, consider their reputation, years in business, and customer reviews. Request references from previous clients and verify their warranty policies. Look for suppliers who provide detailed information about their engine remanufacturing processes, including quality control measures. Engaging in direct communication can also help gauge their responsiveness and willingness to address your specific needs, which is essential for a successful B2B relationship. -

What are the payment terms typically offered for N55 engine purchases?

Payment terms vary by supplier but often include options like upfront payment, partial deposits, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Always clarify payment terms before finalizing your order to ensure that both parties are aligned and to avoid any misunderstandings. -

Are there minimum order quantities (MOQ) for purchasing N55 engines?

Many suppliers may have a minimum order quantity, especially for bulk purchases. This is often influenced by manufacturing processes and shipping logistics. If you’re a smaller buyer, inquire about the possibility of purchasing a single unit or a smaller batch. Some suppliers may offer flexibility, especially if you demonstrate a commitment to future orders or ongoing business relationships. -

What kind of warranty should I expect with my N55 engine purchase?

Warranties can vary significantly by supplier. Generally, a reputable supplier will offer a warranty period ranging from 1 year to 12,000 miles, covering internal parts. Ensure you understand the warranty’s terms, including any requirements for core engine returns. A solid warranty indicates the supplier’s confidence in their product quality and can provide peace of mind for your investment. -

How can I customize my N55 engine purchase to meet specific performance needs?

Customization options often include performance upgrades such as enhanced turbochargers, forged pistons, or advanced tuning. Discuss your performance goals with the supplier to explore available modifications. Some suppliers may offer tailored rebuild options, allowing you to choose between OEM specifications or performance enhancements, ensuring your engine meets your operational requirements. -

What logistics considerations should I keep in mind when importing N55 engines?

When importing engines, consider shipping methods, customs regulations, and potential tariffs in your destination country. Engage a logistics partner experienced in international trade to ensure compliance with local laws and to facilitate smooth transportation. Additionally, factor in lead times for shipping, as engine deliveries may be subject to delays due to customs inspections or other logistical challenges. -

What quality assurance practices should I look for in N55 engine suppliers?

Reputable suppliers should have established quality assurance protocols, including comprehensive inspections and testing of engines before sale. Inquire about their remanufacturing processes, such as component cleaning, inspection, and replacement. Certifications from recognized organizations, such as ISO, can also indicate adherence to industry standards, providing further assurance of the engine’s quality and reliability.

Top 7 N55 Engine For Sale Manufacturers & Suppliers List

1. Carbahn – N55 Stage 1 High Performance Engine

Domain: carbahn.com

Registered: 2009 (16 years)

Introduction: [{‘name’: ‘N55 Stage 1 High Performance Engine’, ‘fits_make’: ‘BMW’, ‘fits_models’: [‘335i’, ‘335i xDrive’, ‘335is’, ‘435i’, ‘435i xDrive’, ‘M2’, ‘M235i’, ‘M235i xDrive’, ‘M135i’], ‘fits_chassis’: [‘E90’, ‘F32’, ‘F33’, ‘F87’, ‘F44’], ‘fits_years’: ‘2013 – 2018’, ‘part_number’: ‘CBN55-6001’, ‘price’: ‘$18,995.00’}, {‘name’: ‘N55 Stage 2 High Performance Engine (Up to 750 HP)’, ‘fits_make’: ‘BMW’, ‘…

2. BMW – N55 Engine Listings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: N55 Engine listings on eBay include various OEM BMW engines with details such as: 1. OEM BMW F25 F26 X3 X4 AWD Long Block N55 Engine Motor – 69k Miles, Pre-Owned, $3,799.95 + $300.00 delivery. 2. 14-16 OEM BMW F22 F23 M235i RWD Long Block N55 COMPLETE ENGINE MOTOR – 136k Miles, Pre-Owned, $3,491.00 + $295.95 delivery. 3. OEM BMW F15 F16 X5 X6 Complete Engine Assembly N55 – 103k Miles, Tested, Pre-…

3. Miami Engines – BMW N55 Engine Rebuild Options

Domain: miamiengines.com

Registered: 2017 (8 years)

Introduction: BMW N55 Engine Rebuild Options: 1. OEM-Spec Rebuild – Uses genuine OEM BMW components to restore engine to factory specifications. 2. Performance Rebuild – Upgrades with SP Components or CP-Carrillo forged connecting rods, CP pistons, and Calico-Coated bearings. Pricing: Engine Price: $5,500 (shelf stock rebuilt N55 engine, does not include core charge). Core Charge: +$1,500 (refundable, inspected…

4. BMW – N55 Engine

Domain: nearautosparts.com

Registered: 2022 (3 years)

Introduction: {“name”:”BMW N55 Engine”,”type”:”Used Engine”,”engine_code”:”N55B30″,”engine_type”:”Inline-6, TwinPower Turbo”,”displacement”:”3.0L (2,979 cc)”,”horsepower”:”300 hp @ 5,800 RPM”,”torque”:”400 Nm @ 1,200-5,000 RPM”,”fuel_type”:”Petrol”,”fuel_injection”:”Direct fuel injection”,”turbocharger”:”Single twin-scroll turbocharger”,”compression_ratio”:”10.2:1″,”cylinder_head_material”:”Aluminum”,”block_mat…

5. Precision Sport – N55 Stage 2 High Performance Engine

Domain: precision-sport.com

Registered: 2008 (17 years)

Introduction: {“name”: “N55 Stage 2 High Performance Engine”,”horsepower”: “Up to 750 HP”,”price”: “$19,995.00″,”torque”: “750 lb-ft”,”features”: [“Carrillo Forged Racing Connecting Rods”,”CP Forged Racing Pistons”,”CarBahn Pinned Crankshaft”,”Full Circle Thrust Main Bearing”,”Performance Valve Springs”,”Cylinder Head Porting”,”Lowered Compression Ratio”,”Complete Engine Overhaul (Blueprinting & Balancing)”],”w…

6. BMW – N55 Engine for Sale

Domain: g42.bimmerpost.com

Registered: 2006 (19 years)

Introduction: N55 Engine for Sale – Used engine from a 2008 BMW 335i with 95,000 miles. The engine runs but has a blown head gasket. Available for part out or purchase.

7. BMW – N55 Engine Motor

Domain: oe-mgarage.com

Registered: 2023 (2 years)

Introduction: Engines N55 PWG – OEM BMW E82 E90 E92 E93 135i 335i Long Block RWD N55 ENGINE MOTOR PWG RAN! Regular price $1,995.95 USD. OEM BMW E82 E90 E92 E93 135i 335i RWD N55 ENGINE MOTOR Complete PWG RAN Regular price $1,995.95 USD. 11-13 BMW F01 F02 F06 RWD N55 PWG Engine Complete Assembly 209k Ran! Regular price $2,399.95 USD. OEM BMW E82 E90 E92 E93 135i 335i AWD N55 ENGINE MOTOR Complete PWG RAN! 153k R…

Strategic Sourcing Conclusion and Outlook for n55 engine for sale

In conclusion, the strategic sourcing of the BMW N55 engine offers significant advantages for B2B buyers looking to enhance their vehicle offerings or service capabilities. With its robust performance and compatibility across multiple BMW models, the N55 engine stands out as a versatile solution for automotive businesses in diverse markets, including Africa, South America, the Middle East, and Europe.

Illustrative image related to n55 engine for sale

Buyers should consider the value of sourcing from reputable suppliers who provide comprehensive rebuild options and warranty assurances, ensuring long-term reliability and performance. Engaging with suppliers that offer both OEM and performance rebuilds can cater to varying customer needs, from standard replacements to high-performance enhancements.

As the demand for reliable and efficient engines continues to grow globally, now is the time for international buyers to seize opportunities in this lucrative market. By leveraging strategic sourcing practices, businesses can not only optimize their inventory but also enhance customer satisfaction through high-quality engine solutions. Explore your options today and position your business for success in the evolving automotive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to n55 engine for sale

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.