Choosing Your Motor Dyno: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for motor dyno

In today’s competitive landscape, sourcing a reliable motor dynamometer (dyno) can be a daunting task for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right type of dyno—be it hysteresis, eddy-current, or powder brake—but also in understanding the specific applications and performance requirements that align with their operational goals. This comprehensive guide aims to demystify the global market for motor dynos, providing essential insights into the various types available, their applications across industries, and best practices for supplier vetting.

By exploring factors such as cost considerations, technological advancements, and regional availability, this guide empowers international buyers to make informed purchasing decisions. Whether you are in Nigeria looking to enhance your automotive testing capabilities or in Saudi Arabia seeking efficient solutions for industrial motor performance, this resource equips you with the knowledge to navigate the complexities of the motor dyno market. Informed decisions can lead to improved operational efficiencies, enhanced product testing, and ultimately, a competitive edge in your respective industry. Let’s delve into the critical aspects of motor dynos that will support your strategic sourcing efforts and drive business success.

Understanding motor dyno Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hysteresis Dynamometers (HD) | Low to medium power range, full torque at zero speed | Testing electric motors, gas engines, gearheads | Pros: Versatile, good for low power applications. Cons: Limited to intermittent duty. |

| Eddy-Current Dynamometers (WB) | High-speed capability, peak torque at rated speed | Automotive, aerospace, and high-performance motors | Pros: Excellent for high-speed testing, low inertia. Cons: More complex and costly. |

| Powder Brake Dynamometers (PB) | Smooth braking torque using magnetic powder | Suitable for low to medium speed applications | Pros: Full torque at zero speed, minimal wear. Cons: Limited cooling capacity. |

| Micro Dyno Systems | Designed for miniature motors, high precision torque measurement | Electronics and micro-motor industries | Pros: Accurate for small motors, compact design. Cons: Specialized, may require custom setup. |

| Inertia Motor Dynometers | Uses flywheel inertia for load generation | R/C car motors, hobbyist applications | Pros: Simple setup, repeatable results. Cons: Limited to specific motor types. |

What Are Hysteresis Dynamometers and Their B2B Suitability?

Hysteresis dynamometers are ideal for low to medium power testing, offering full torque even at zero speed. This feature is particularly beneficial for testing electric motors and gas engines. B2B buyers should consider these dynamometers for applications where a wide range of torque measurements is necessary, but they should note that their intermittent duty cycle may limit continuous operation.

How Do Eddy-Current Dynamometers Excel in High-Speed Testing?

Eddy-current dynamometers are designed for high-speed applications, reaching peak torque at rated speeds. These devices are essential for industries such as automotive and aerospace, where precision and high performance are critical. When purchasing, businesses should evaluate the complexity and cost, as these systems tend to be more sophisticated and require a higher investment.

What Advantages Do Powder Brake Dynamometers Offer?

Powder brake dynamometers utilize magnetic powder to create smooth braking torque, making them suitable for low to medium speed applications. Their ability to deliver full torque at zero speed is advantageous for various testing scenarios. Buyers should consider the limited cooling capacity of these systems when evaluating their suitability for continuous testing.

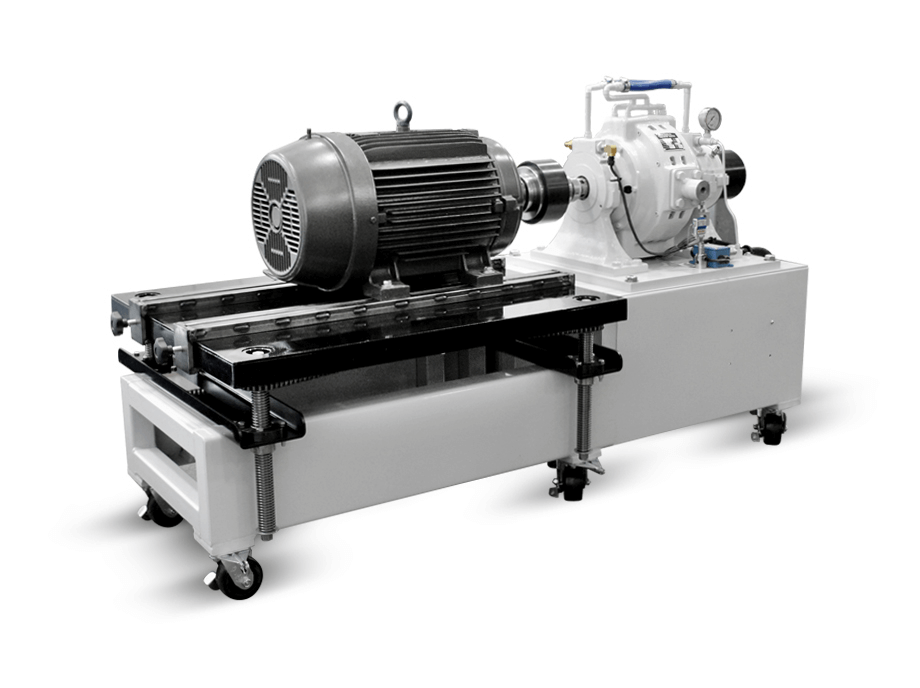

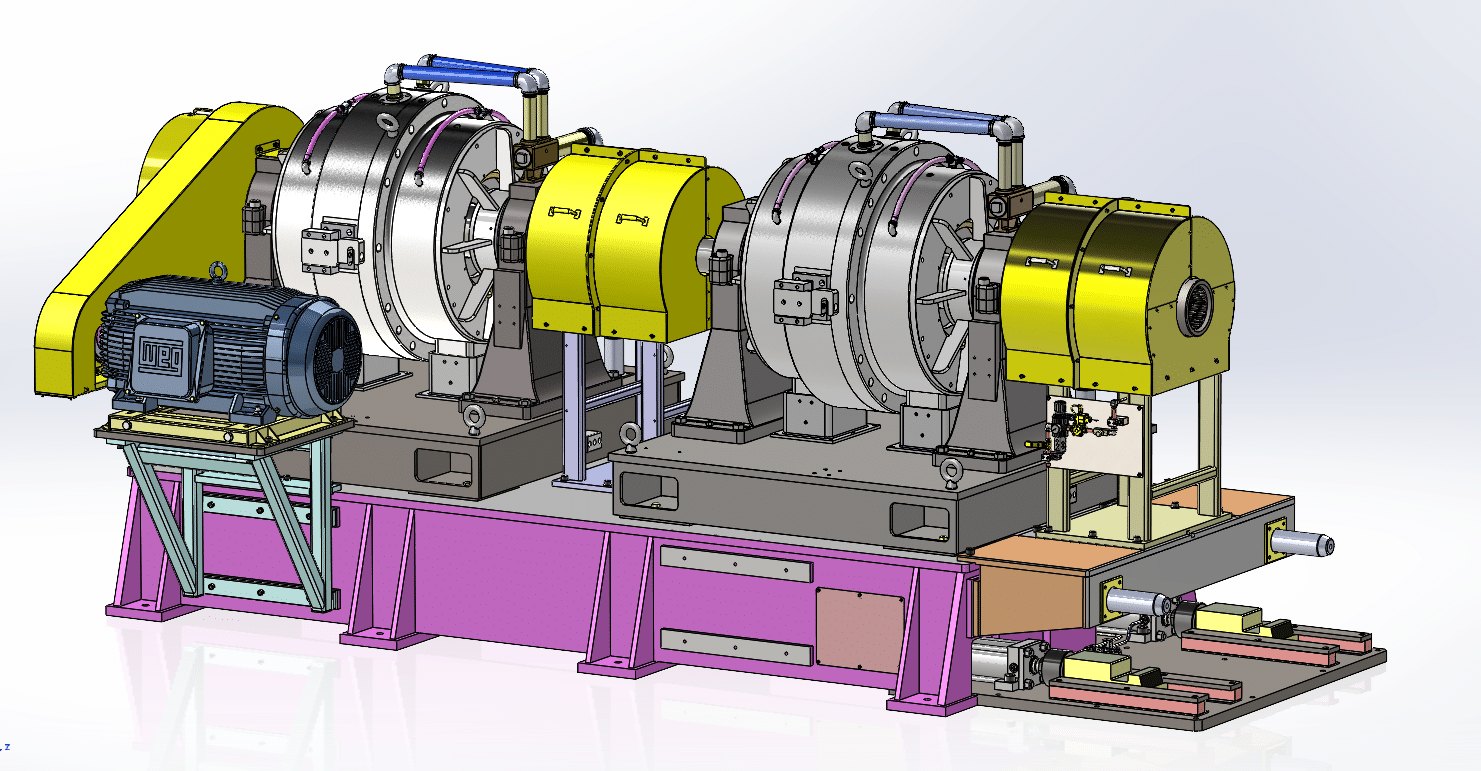

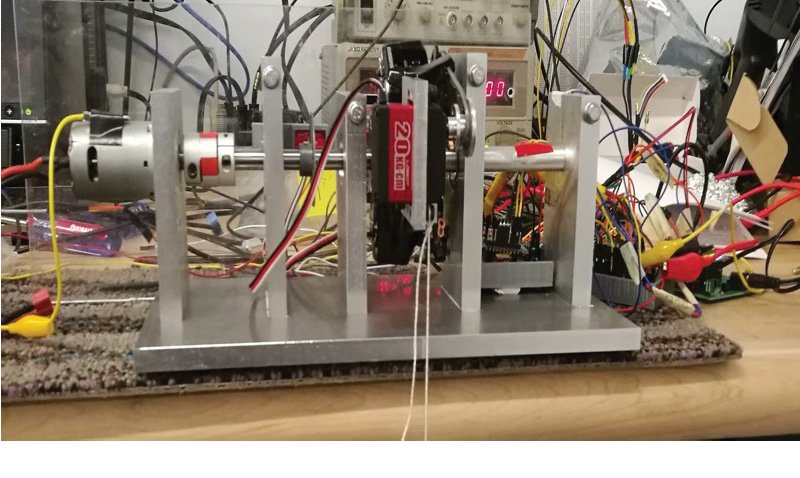

Illustrative image related to motor dyno

Why Choose Micro Dyno Systems for Miniature Motors?

Micro dyno systems are specifically designed for testing miniature and micro motors, providing high precision in torque measurement. These systems are increasingly relevant in electronics and micro-motor industries. B2B buyers should consider the compact design and accuracy of these systems, although they may require custom setups for specific applications.

How Do Inertia Motor Dynometers Simplify Testing for R/C Motors?

Inertia motor dynamometers employ flywheel inertia to generate load, making them ideal for R/C car motors and hobbyist applications. Their straightforward setup allows for repeatable testing results, which is crucial for performance tuning. However, buyers should be aware that these dynos are primarily limited to specific types of motors, which may restrict their versatility in broader applications.

Key Industrial Applications of motor dyno

| Industry/Sector | Specific Application of motor dyno | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Testing electric and gas engines | Enhanced performance validation and compliance | Precision measurement capabilities, customization options |

| Aerospace | Development of propulsion systems | Improved efficiency and reliability | High-speed testing capabilities, compliance with industry standards |

| Industrial Machinery | Performance testing for electric motors and drives | Optimal energy consumption and reduced downtime | Flexibility for various motor types, robust data acquisition systems |

| Renewable Energy | Evaluation of wind and solar power generators | Maximized energy output and operational efficiency | Adaptability for different energy sources, real-time analytics |

| Robotics and Automation | Testing of servos and actuators | Increased accuracy and performance of robotic systems | Compact design for space-constrained environments, integration with automation systems |

How is a motor dyno used in the automotive industry?

In the automotive sector, motor dynamometers are essential for testing both electric and gas engines. They enable manufacturers to validate engine performance, ensuring that products meet regulatory standards and customer expectations. By simulating various operating conditions, motor dynos help identify inefficiencies and potential failures before market release. For international buyers, particularly in regions like Africa and South America, sourcing a motor dyno that provides accurate measurements and is adaptable to different engine types can significantly enhance product reliability and market competitiveness.

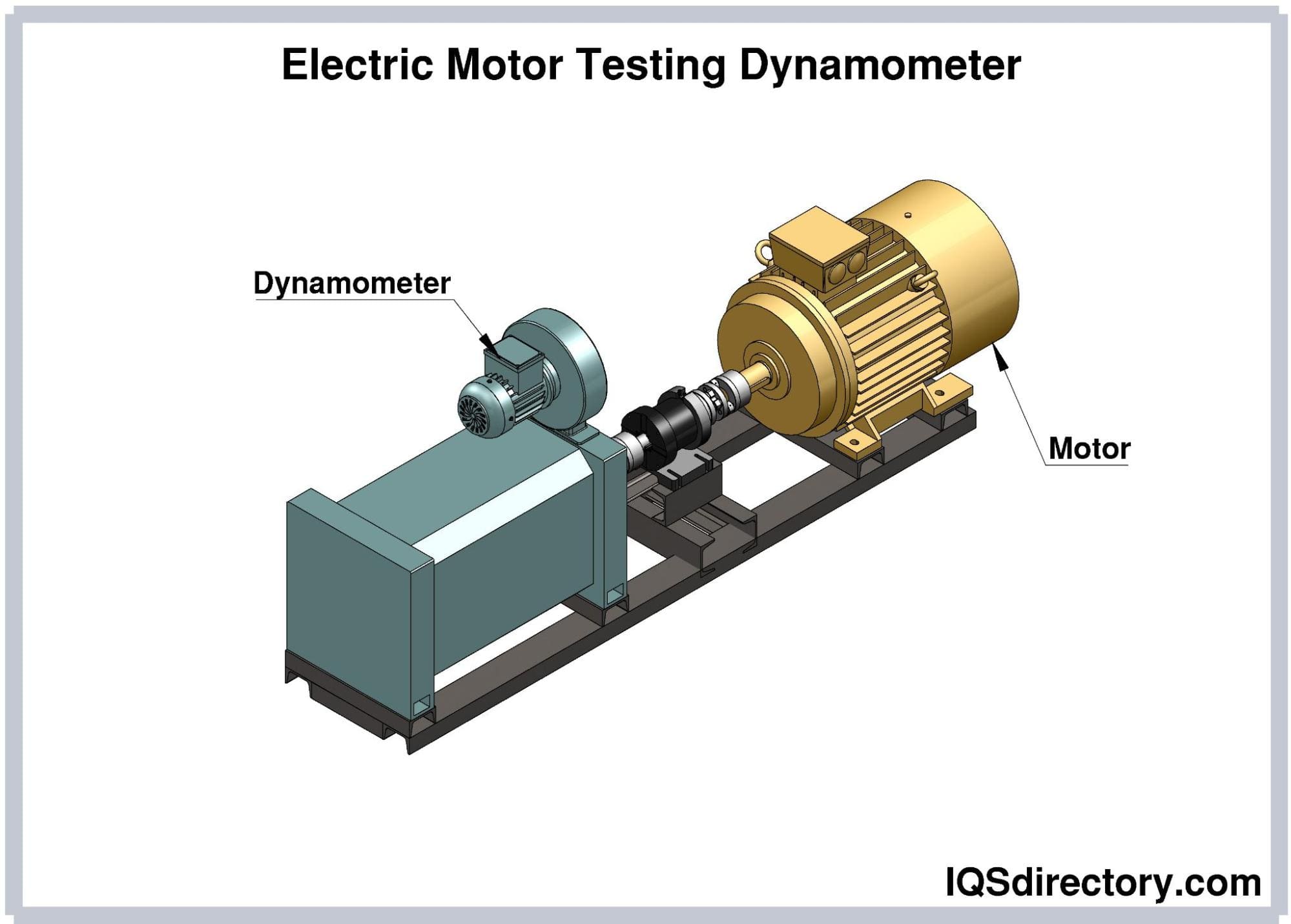

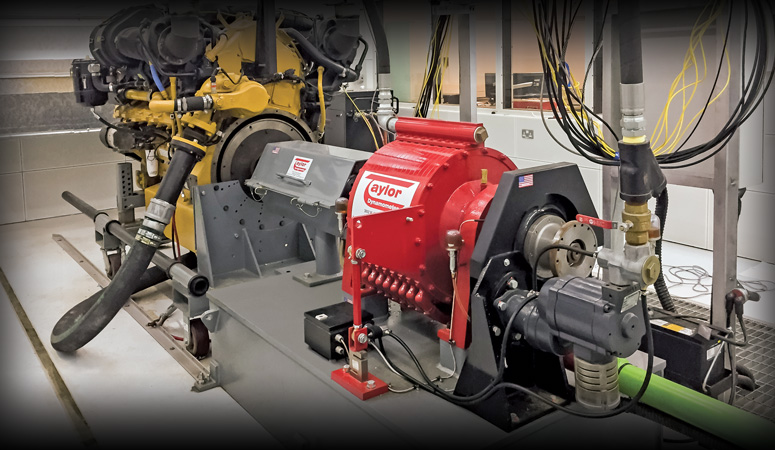

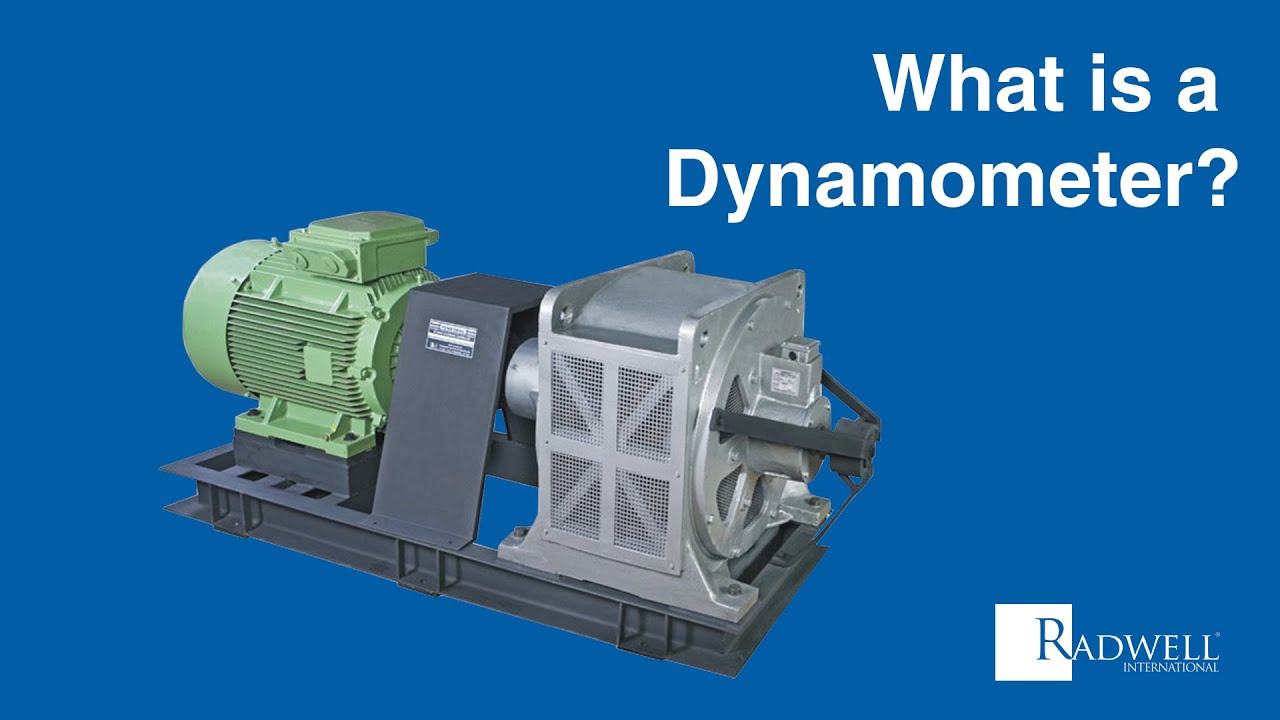

Illustrative image related to motor dyno

What role does a motor dyno play in aerospace applications?

In aerospace, motor dynos are used to develop and test propulsion systems, ensuring they meet rigorous performance and safety standards. These dynamometers allow for precise measurements of torque and power output under various flight conditions, which is critical for optimizing engine efficiency and reliability. Buyers in the Middle East and Europe should consider sourcing dynos that comply with aerospace standards, ensuring high-speed testing capabilities and robust data acquisition to support advanced engineering requirements.

How can industrial machinery benefit from motor dynamometers?

Industrial machinery manufacturers use motor dynos to test electric motors and drives, ensuring optimal performance and energy efficiency. By analyzing torque and power output, businesses can minimize downtime and enhance operational efficiency. For B2B buyers in diverse markets, including Nigeria and Saudi Arabia, selecting a dynamometer that accommodates various motor types and offers robust data analytics can lead to significant cost savings and improved production processes.

Why are motor dynos important in renewable energy?

Motor dynamometers are crucial in evaluating the performance of wind turbines and solar power generators, allowing for the optimization of energy output. By testing the efficiency of these systems, businesses can ensure they meet energy demands and regulatory requirements. For international buyers, especially from regions with growing renewable energy sectors, sourcing a versatile motor dyno that can adapt to different energy technologies and provide real-time analytics can enhance project viability and sustainability.

What is the significance of motor dynos in robotics and automation?

In robotics and automation, motor dynos are used to test servos and actuators, ensuring high levels of accuracy and performance in robotic systems. These tests help in fine-tuning the response and operational efficiency of automated processes. Buyers from Europe and the Middle East should prioritize sourcing compact and flexible motor dynos that can easily integrate with existing automation systems, as this will facilitate smoother operations and enhance overall productivity.

3 Common User Pain Points for ‘motor dyno’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Dynamometer for Specific Applications

The Problem:

B2B buyers often face the challenge of selecting the most suitable motor dynamometer for their specific testing needs. With various types available—such as hysteresis, eddy-current, and powder brake dynamometers—understanding which system best aligns with their application can be overwhelming. For instance, a manufacturer in Nigeria testing small gas engines may not know that an engine dynamometer is specifically designed to handle the high vibration conditions of internal combustion engines, potentially leading to inaccurate results and operational inefficiencies.

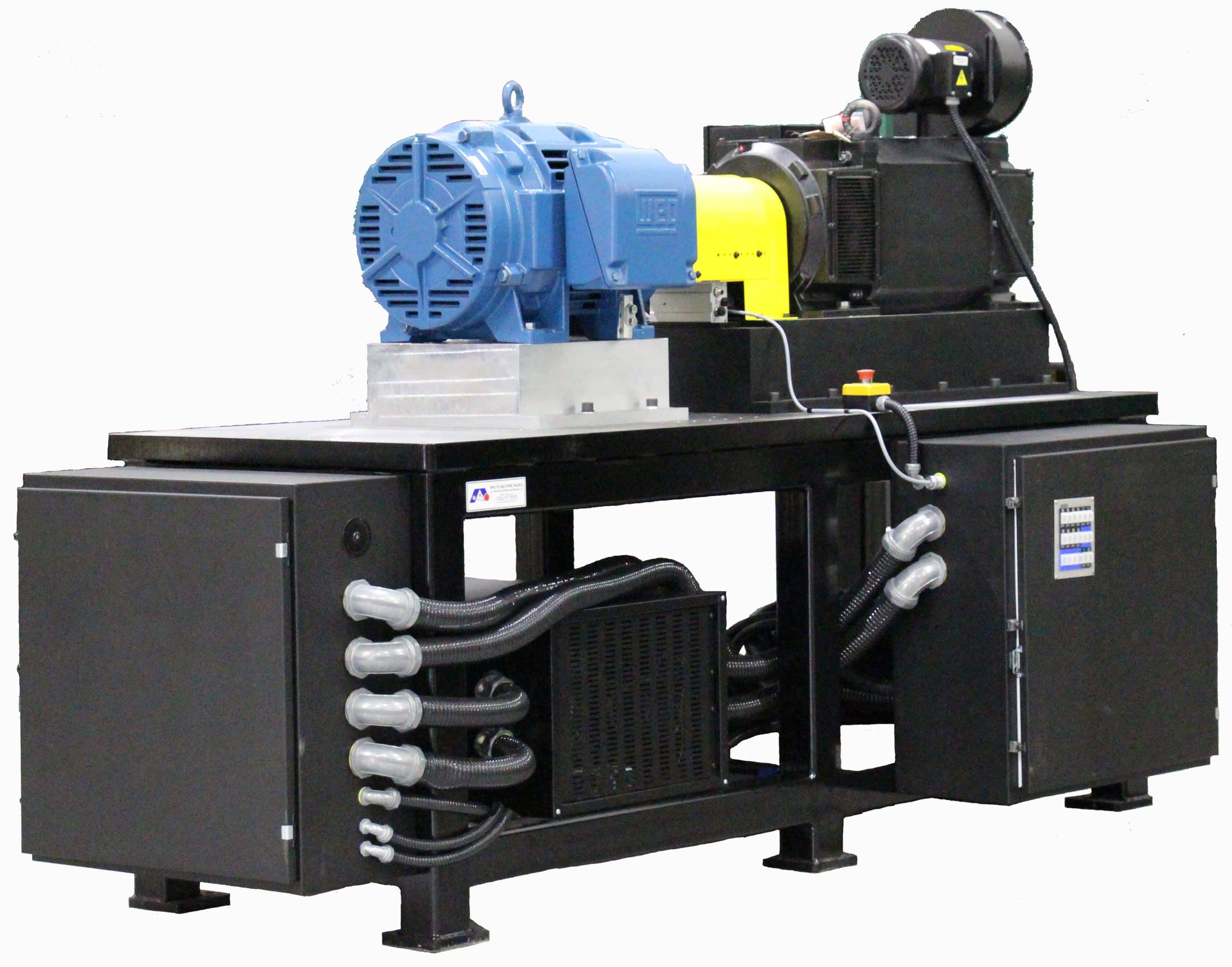

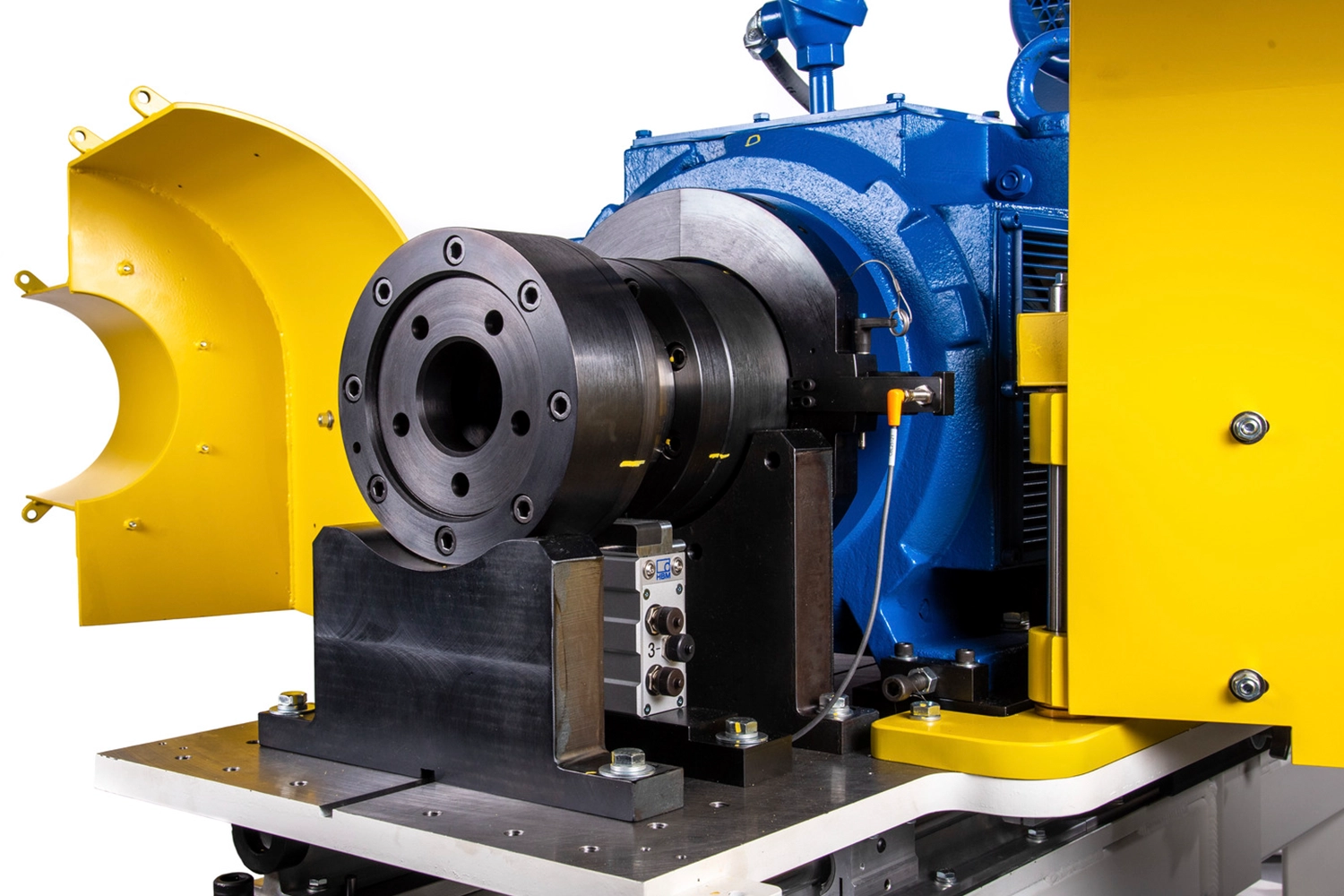

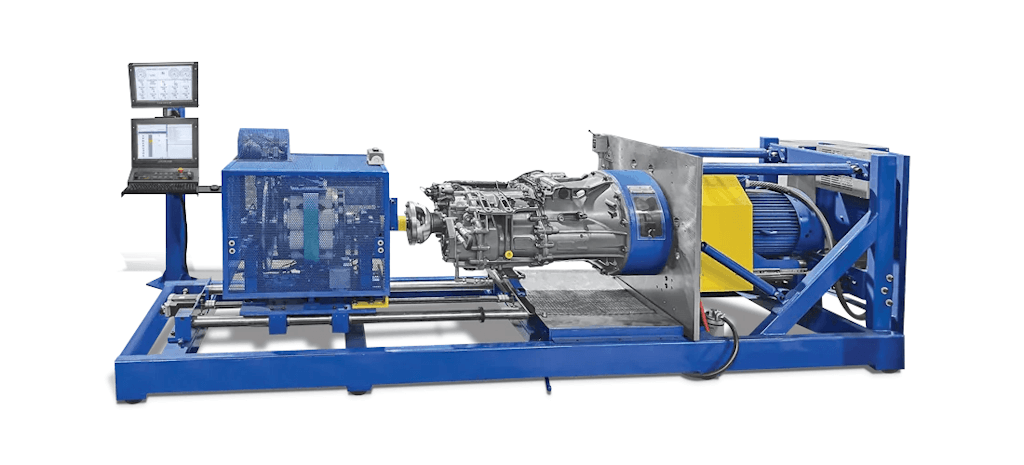

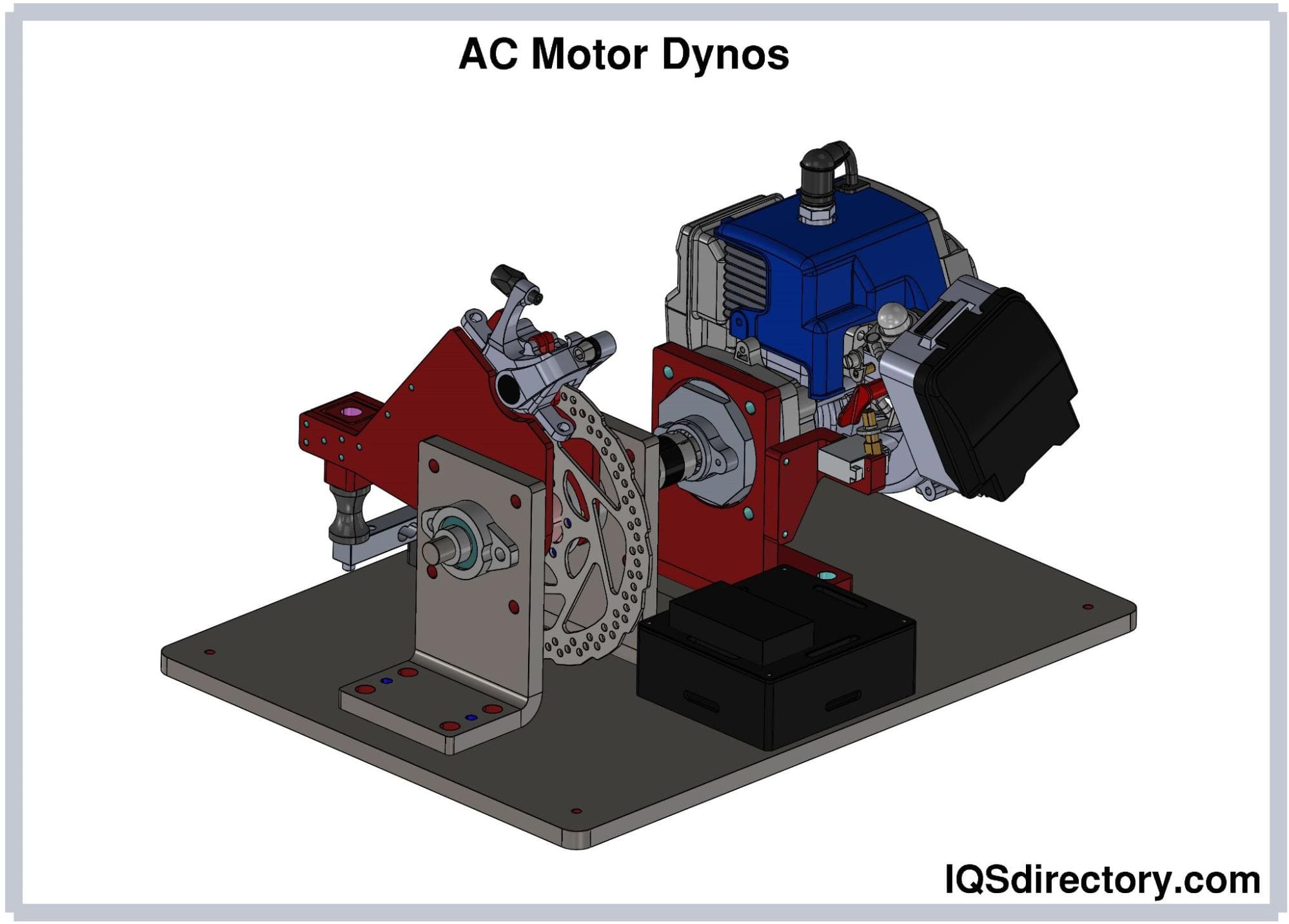

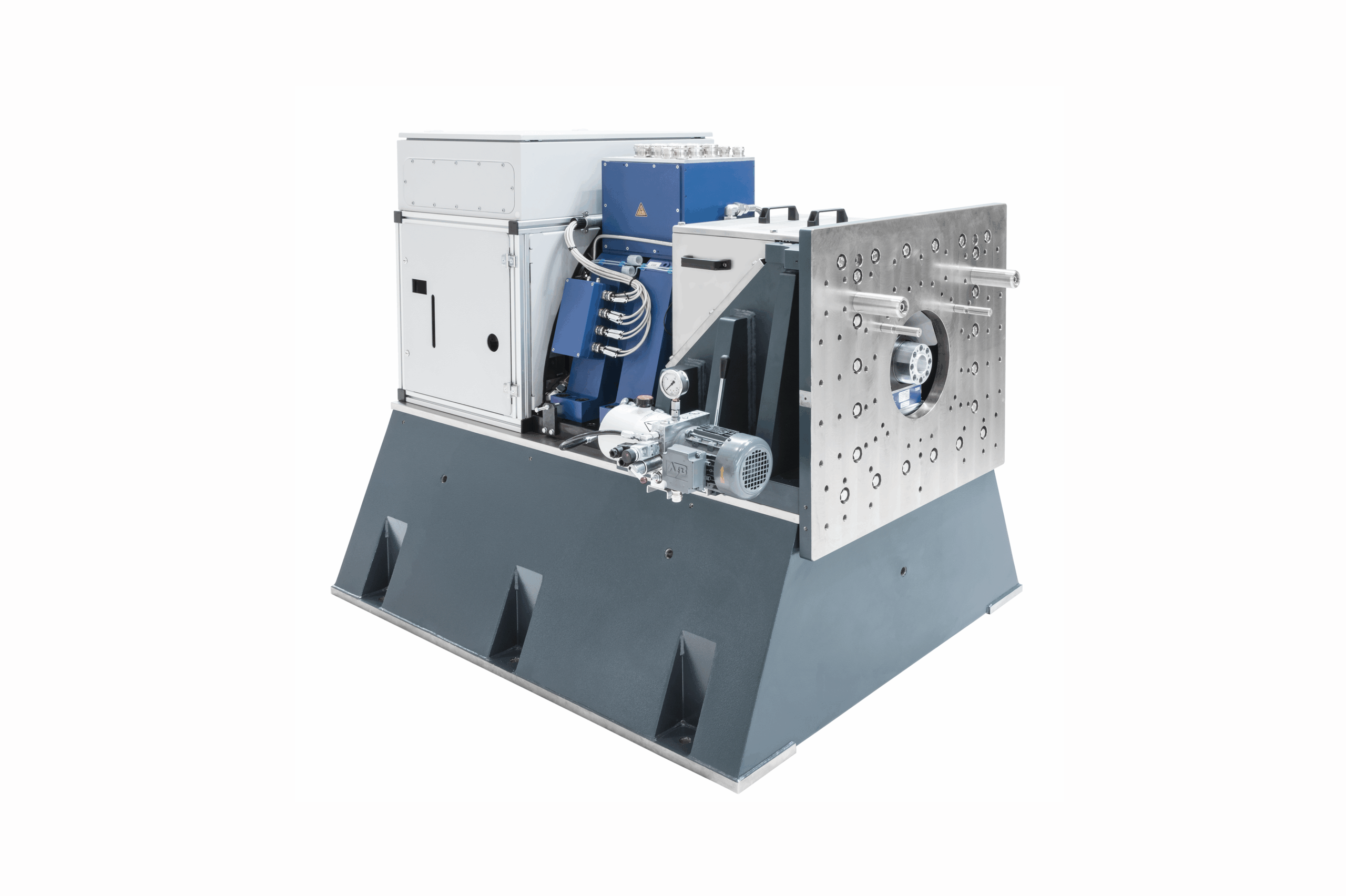

Illustrative image related to motor dyno

The Solution:

To effectively choose the right dynamometer, buyers should start by conducting a thorough needs assessment based on their testing criteria—power range, torque requirements, speed capabilities, and the types of motors to be tested. Creating a comprehensive checklist that outlines these requirements can significantly aid the decision-making process. Engaging with manufacturers or suppliers who offer customized motor test systems (CMTS) can also provide tailored solutions that fit unique operational needs. Additionally, seeking demonstrations or trial periods can help buyers understand the dynamometer’s performance in real-world scenarios, ensuring they invest in equipment that meets their specific requirements.

Scenario 2: Ensuring Accurate and Repeatable Testing Results

The Problem:

Achieving consistent and accurate testing results is a critical pain point for businesses relying on motor dynos. A manufacturer in Saudi Arabia, for example, may find that varying environmental conditions or improper setup leads to discrepancies in test outcomes, affecting product quality and reliability. Such inconsistencies can undermine confidence in the testing process and impact decision-making regarding product development and improvements.

The Solution:

To enhance the accuracy and repeatability of test results, it is vital to establish a standardized testing protocol. This includes maintaining consistent environmental conditions, such as temperature and humidity, during testing. Implementing a robust calibration schedule for the dynamometer ensures that the equipment remains in optimal working condition. Furthermore, utilizing data acquisition systems with advanced software can facilitate real-time monitoring and analysis of test data, enabling users to identify and rectify any anomalies immediately. Regular training for personnel on best practices for motor testing can also foster a culture of quality assurance, resulting in reliable and repeatable outcomes.

Scenario 3: Managing Maintenance and Downtime of Motor Dynos

The Problem:

Unplanned downtime due to equipment failure can severely disrupt production schedules and lead to significant financial losses. Companies in South America often struggle with the maintenance of their motor dynos, especially when spare parts are not readily available or when technical support is lacking. This situation can lead to extended periods of inactivity, delaying project timelines and frustrating stakeholders.

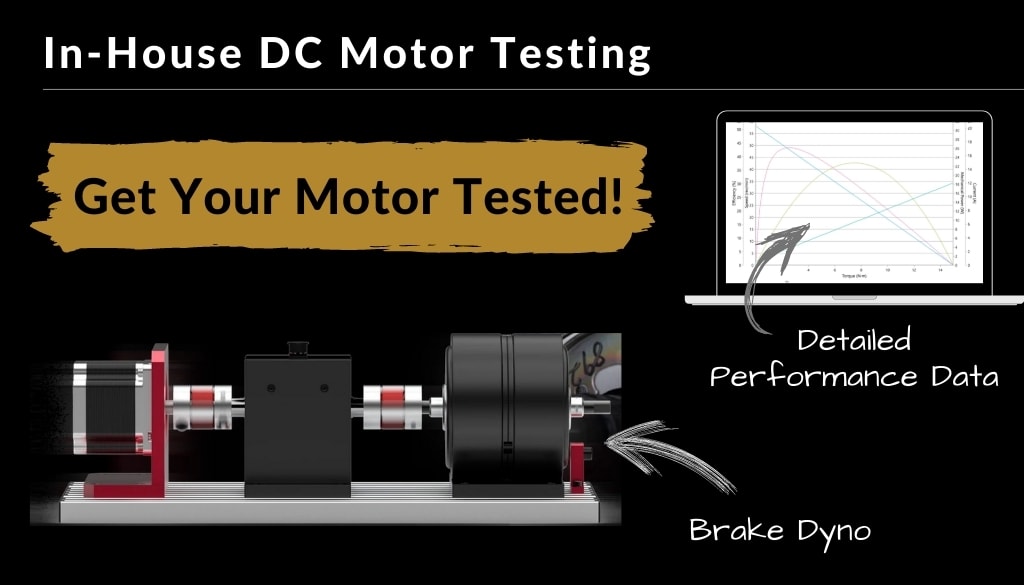

Illustrative image related to motor dyno

The Solution:

To mitigate the risks associated with equipment downtime, businesses should prioritize a proactive maintenance strategy that includes regular inspections, cleaning, and servicing of the dynamometer. Establishing a partnership with a reliable supplier who can provide timely access to spare parts and technical support is crucial. Additionally, implementing a preventive maintenance program, which includes routine checks based on the manufacturer’s guidelines, can extend the life of the equipment and reduce the likelihood of unexpected failures. Training in-house technicians on basic troubleshooting techniques can also empower teams to resolve minor issues quickly, thus minimizing disruption to operations. By investing in a comprehensive maintenance plan, companies can enhance the reliability of their motor dynos and ensure smoother operational workflows.

Strategic Material Selection Guide for motor dyno

What Are the Key Materials Used in Motor Dynos?

When selecting materials for motor dynamometers (dynos), it’s essential to consider properties that directly impact performance, durability, and cost. Below, we analyze four common materials used in the construction of motor dynos, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent thermal conductivity and resistance to corrosion. It can withstand moderate temperatures and pressures, making it suitable for various dyno applications.

Pros & Cons: The primary advantage of aluminum is its low weight, which facilitates easier handling and installation. Additionally, it’s relatively inexpensive compared to other metals. However, aluminum can be less durable under extreme conditions and may require protective coatings to enhance its lifespan.

Impact on Application: Aluminum is compatible with a wide range of media, including oils and coolants, which are commonly used in motor testing. Its lightweight nature allows for rapid acceleration measurements, which is crucial in performance testing.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial for ensuring quality. Buyers from regions like Africa and South America may prefer aluminum for its cost-effectiveness, while those in Europe may require specific certifications for aerospace or automotive applications.

2. Steel

Key Properties: Steel offers high tensile strength and excellent durability, with the ability to withstand high temperatures and pressures. It also exhibits good wear resistance, making it ideal for high-load applications.

Pros & Cons: The main advantage of steel is its robustness, which ensures longevity and reliability in demanding environments. However, it is heavier than aluminum, which can complicate installation and transport. Additionally, steel is prone to corrosion unless properly treated or coated.

Illustrative image related to motor dyno

Impact on Application: Steel’s strength makes it suitable for high-torque applications, ensuring accurate and repeatable results in motor testing. Its compatibility with various lubricants and coolants further enhances its application range.

Considerations for International Buyers: Buyers should be aware of the varying grades of steel and their compliance with local standards. In the Middle East, for instance, the demand for high-grade steel may be influenced by the region’s climate and environmental conditions.

3. Composite Materials

Key Properties: Composites, such as carbon fiber or fiberglass, are known for their high strength-to-weight ratios and excellent fatigue resistance. They can also be engineered to provide specific thermal and electrical properties.

Pros & Cons: The primary advantage of composites is their lightweight nature combined with high strength, making them ideal for precision applications where weight is a concern. However, they can be more expensive to manufacture and may require specialized processes for fabrication.

Impact on Application: Composites are often used in high-performance dynos where minimizing weight is critical, such as in racing applications. Their corrosion resistance makes them suitable for environments where exposure to chemicals is a concern.

Illustrative image related to motor dyno

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region, as well as the necessary expertise for installation and maintenance. Compliance with international standards for composites is also vital, especially in regulated industries.

4. Brass

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for specific components of motor dynos.

Pros & Cons: The main advantage of brass is its resistance to corrosion, particularly in humid or wet environments. However, it is not as strong as steel or aluminum, which may limit its use in high-load applications. Additionally, brass can be more expensive than aluminum.

Impact on Application: Brass is often used in connectors and fittings within motor dynos due to its excellent electrical conductivity. This makes it suitable for applications involving electronic measurements and controls.

Considerations for International Buyers: Buyers should be aware of the cost implications of using brass, especially in bulk applications. Compliance with standards regarding the use of copper alloys is also important, particularly in regions with stringent regulations.

Summary Table

| Material | Typical Use Case for motor dyno | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight dyno frames | Low weight and cost | Less durable under extreme conditions | Low |

| Steel | High-torque applications | High strength and durability | Heavier, prone to corrosion | Med |

| Composite | Precision racing dynos | High strength-to-weight ratio | Higher manufacturing costs | High |

| Brass | Connectors and fittings | Excellent corrosion resistance | Limited strength for heavy loads | Med |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing components for motor dynos, ensuring that they meet performance requirements while considering regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for motor dyno

What Are the Main Stages in the Manufacturing Process of Motor Dynos?

Manufacturing a motor dynamometer involves several key stages, each critical to ensuring that the final product meets high standards of performance and reliability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: Ensuring Quality from the Start

The manufacturing process begins with the selection of high-quality raw materials, typically metals like aluminum and steel, as well as polymers for non-structural components. These materials are assessed for their mechanical properties, such as tensile strength and thermal conductivity, which are essential for the dynamometer’s performance.

Illustrative image related to motor dyno

Once selected, the materials undergo a rigorous preparation process that may include cutting, machining, and surface treatments. For instance, aluminum components might be anodized to enhance corrosion resistance, while steel parts may undergo heat treatment to improve durability. Proper material preparation is fundamental to achieving the desired performance characteristics in the final product.

How Are Motor Dynos Formed? Key Techniques in Shaping Components

The forming stage involves various techniques to create components that will comprise the dynamometer. Common methods include CNC machining, casting, and forging. CNC machining is particularly favored for its precision, allowing for intricate designs that ensure the components fit together perfectly.

In the case of dynamometers, components such as the rotor, stator, and braking systems are often produced using CNC techniques. This level of precision is essential because even minor deviations can lead to significant inaccuracies in performance measurements. Additionally, processes like injection molding may be used for plastic components, ensuring consistent quality and repeatability.

What Does the Assembly Process Entail for Motor Dynos?

The assembly process is where individual components come together to form a functional dynamometer. This stage typically involves several sub-processes, including the installation of electronic systems, wiring, and calibration of sensors.

During assembly, teams adhere to strict protocols to ensure that components are installed correctly. This may include the use of torque wrenches to secure fasteners to specified values, thereby preventing mechanical failures during operation. Additionally, the integration of software systems is crucial for data acquisition and analysis, allowing users to obtain accurate performance metrics.

Illustrative image related to motor dyno

What Are the Final Finishing Touches in Motor Dyno Production?

Finishing processes enhance the aesthetic and functional aspects of the motor dyno. This stage may involve painting, powder coating, or applying protective films to safeguard against environmental factors.

Moreover, final assembly includes rigorous testing of all electronic and mechanical components. Each dynamometer is subjected to a series of performance tests to verify that it meets specified criteria, such as torque output and speed accuracy. This comprehensive approach ensures that the product is not only visually appealing but also ready for rigorous use in various applications.

How Is Quality Assurance Integrated into Motor Dyno Manufacturing?

Quality assurance is a critical aspect of manufacturing motor dynamometers, ensuring that products meet both international standards and customer expectations. The quality assurance process typically involves multiple checkpoints throughout production.

What International Standards Apply to Motor Dyno Manufacturing?

To maintain high-quality standards, manufacturers often comply with international certifications such as ISO 9001, which outlines requirements for a quality management system. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for products used in oil and gas applications may also apply.

Compliance with these standards not only ensures product reliability but also builds trust with international buyers. Understanding these certifications is particularly important for B2B buyers from regions like Africa, South America, and the Middle East, where regulatory requirements may differ significantly.

What Are the Key Quality Control Checkpoints in Production?

Quality control (QC) is integrated into the manufacturing process through several checkpoints, including:

-

Incoming Quality Control (IQC): This initial stage assesses raw materials and components for compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that processes are followed correctly and that components meet dimensional and performance criteria.

-

Final Quality Control (FQC): Once the motor dynamo is fully assembled, it undergoes comprehensive testing to verify that it meets all performance metrics. This may involve operational tests, calibration checks, and safety assessments.

These checkpoints serve to catch any defects early in the production process, reducing the risk of costly recalls or customer dissatisfaction.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control processes is crucial. Here are several effective strategies:

What Steps Can Buyers Take to Assess Supplier Quality?

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to evaluate their manufacturing processes, quality control systems, and adherence to international standards. This firsthand observation can provide valuable insights into the supplier’s operational capabilities.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. These documents can reveal the supplier’s commitment to maintaining high standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s operations and product quality. These services can conduct tests and evaluations on behalf of the buyer, ensuring that products meet specified criteria before shipment.

-

Certifications Verification: Buyers should verify the authenticity of certifications such as ISO 9001 or CE by checking with the issuing organizations. This step ensures that the supplier is genuinely compliant with industry standards.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should be aware of specific nuances in quality control. These may include:

Illustrative image related to motor dyno

-

Understanding Local Regulations: Different regions may have unique regulatory requirements that impact product specifications and quality standards. Buyers must ensure that their suppliers are compliant with local laws to avoid potential issues.

-

Cultural and Communication Barriers: Effective communication is vital for ensuring quality. Buyers should establish clear lines of communication with suppliers and, if necessary, utilize translation services to bridge any gaps.

-

Logistical Considerations: Transportation and shipping can impact product quality. Buyers should consider how products are packaged and shipped, ensuring that they arrive in optimal condition.

By taking these factors into account, B2B buyers can enhance their procurement strategies and ensure they partner with reliable suppliers who prioritize quality assurance throughout the manufacturing process.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘motor dyno’

To successfully procure a motor dynamometer (dyno), it is essential to follow a structured approach that considers technical specifications, supplier reliability, and operational needs. This guide provides a step-by-step checklist designed to streamline the sourcing process for international B2B buyers.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical requirements for your motor dyno. Consider factors such as the types of motors you will be testing (e.g., electric, pneumatic, gas), the power range, and the desired accuracy.

– Torque and Speed Requirements: Specify the maximum torque and speed you need, as different dyno types (hysteresis, eddy-current, etc.) cater to varying applications.

– Testing Capabilities: Determine if you need additional features like temperature measurement or data acquisition systems.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to ensure they can meet your specifications. Look for manufacturers with a proven track record in producing high-quality dynamometers.

– Industry Reputation: Check for reviews, testimonials, and case studies that demonstrate their expertise and customer satisfaction.

– Product Range: Ensure the supplier offers a variety of models and customization options to suit your specific testing needs.

Step 3: Evaluate Supplier Certifications

Verify that the suppliers hold relevant certifications and adhere to international quality standards. This step is crucial for ensuring the reliability and safety of the equipment.

– Quality Management Systems: Look for ISO certifications that indicate adherence to quality standards in manufacturing.

– Compliance with Regional Regulations: Ensure that the equipment complies with safety and operational regulations in your region, particularly if you are sourcing from different continents.

Illustrative image related to motor dyno

Step 4: Request Technical Documentation

Once you have shortlisted potential suppliers, request comprehensive technical documentation for their dyno models. This should include user manuals, specifications, and maintenance guides.

– Understanding Features: Technical documentation will help you understand the capabilities and limitations of each model.

– Maintenance and Support: Assess the maintenance requirements and support offered, which can significantly impact operational efficiency.

Step 5: Ask for a Demonstration

If possible, arrange for a demonstration of the motor dyno. This step allows you to assess the performance and usability of the equipment in real-world conditions.

– Hands-On Experience: A demonstration provides insight into how the dyno operates, helping you evaluate user-friendliness and functionality.

– Comparative Analysis: Use this opportunity to compare different models and features directly, which can aid in your final decision.

Step 6: Negotiate Terms and Conditions

Before finalizing your purchase, carefully negotiate the terms and conditions with the supplier. This includes pricing, warranty, delivery timelines, and after-sales support.

– Warranty and Service Agreements: Ensure that you understand the warranty coverage and what after-sales services are included, such as technical support and spare parts availability.

– Payment Terms: Discuss payment options that align with your budget and financial planning.

Illustrative image related to motor dyno

Step 7: Plan for Installation and Training

After procurement, consider the installation and training requirements for your team. Proper setup and training are vital for maximizing the effectiveness of your new motor dyno.

– Installation Support: Check if the supplier offers installation services or if you need to engage a third party.

– Training Programs: Ensure that training is available for your staff to familiarize them with the equipment, enhancing operational efficiency and safety.

By following this checklist, international B2B buyers can streamline the procurement process for motor dynamometers, ensuring that they select the right equipment and supplier for their specific needs.

Comprehensive Cost and Pricing Analysis for motor dyno Sourcing

What Are the Key Cost Components in Motor Dyno Manufacturing?

When sourcing motor dynamometers, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality components such as aluminum for the frame, specialized steel for gears, and advanced electronics for measurement systems can elevate expenses. Customization may also require unique materials, further increasing costs.

-

Labor: Labor costs encompass not only direct assembly but also skilled engineering for design and customization. Regions with lower labor costs may offer competitive pricing, but ensure that the quality of workmanship meets your specifications.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs, translating to better pricing for buyers.

-

Tooling: Initial tooling costs can be significant, especially for customized solutions. If a buyer needs a specific design, they may incur additional expenses for mold creation or specialized tooling.

-

Quality Control (QC): Ensuring that the motor dyno meets industry standards requires rigorous QC processes. This may involve testing equipment, certification fees, and compliance with international standards, all of which can affect pricing.

-

Logistics: Shipping costs can vary dramatically based on the origin and destination of the product. Factors such as distance, shipping mode, and customs duties must be considered, especially for international buyers.

-

Margin: Suppliers will typically add a profit margin to their costs. This can vary widely based on market competition, brand reputation, and the perceived value of the product.

How Do Price Influencers Affect Motor Dyno Costs?

Several factors influence the pricing of motor dynos, particularly for international B2B transactions:

-

Volume/MOQ: Higher order volumes generally yield better pricing. Suppliers often offer discounts for bulk purchases, which can significantly reduce the per-unit cost.

-

Specifications/Customization: Custom features or specific performance requirements can raise costs. Be clear about your needs to avoid unnecessary customization expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications, such as ISO or CE, justify higher prices. However, they also ensure reliability and longevity, which are critical for performance testing.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more due to their quality assurance and customer service.

-

Incoterms: International shipping terms (Incoterms) will dictate who is responsible for shipping costs, insurance, and import duties. Understanding these terms can help you avoid unexpected expenses.

What Are the Best Negotiation Tips for B2B Buyers in Motor Dyno Sourcing?

To achieve a cost-efficient purchase, B2B buyers should adopt strategic negotiation techniques:

-

Understand Total Cost of Ownership (TCO): Consider not just the initial purchase price, but also maintenance, operational costs, and potential downtime. A higher upfront cost may lead to lower long-term expenses.

-

Leverage Volume Discounts: If your organization plans to make repeated purchases, negotiate for bulk pricing or long-term contracts. Suppliers may be more willing to offer favorable terms to secure ongoing business.

-

Research Market Prices: Familiarize yourself with market pricing trends for various motor dyno models. This knowledge empowers you to negotiate effectively and recognize fair pricing.

-

Build Relationships: Establishing a rapport with suppliers can lead to better terms and reliability in delivery schedules. A long-term relationship may also yield insights into upcoming promotions or pricing adjustments.

-

Consider Local Suppliers: For international buyers, sourcing from local suppliers can reduce logistics costs and simplify the import process. This can be particularly beneficial in regions like Africa and South America, where shipping logistics can be complex.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

International B2B buyers should remain aware of the nuances in pricing when sourcing motor dynos:

-

Fluctuating Exchange Rates: Currency fluctuations can affect pricing, making it important to consider exchange rates when negotiating contracts.

-

Import Duties and Taxes: Different countries have varying import duties that can significantly add to the cost. Understanding these can help in budgeting accurately.

-

Regulatory Compliance: Ensure that the motor dynos comply with local regulations, which can affect both pricing and usability in your specific market.

Disclaimer on Pricing Information

Prices for motor dynos can vary widely based on specific requirements, customization, and supplier factors. The information provided here is indicative and should be verified with suppliers for the most accurate and current pricing. Always request detailed quotations and be prepared for potential changes based on market conditions.

Illustrative image related to motor dyno

Alternatives Analysis: Comparing motor dyno With Other Solutions

Exploring Alternatives to Motor Dynos: What Are Your Options?

When evaluating motor testing solutions, it’s essential to consider alternatives to motor dynos. While motor dynos offer precise measurements of torque, speed, and power, other technologies may also meet specific testing needs, often with varying benefits and constraints. This section compares motor dynos with two viable alternatives: Load Banks and Torque Meters.

Comparison Table

| Comparison Aspect | Motor Dyno | Load Bank | Torque Meter |

|---|---|---|---|

| Performance | High precision in torque and power measurements across a range of motors. | Provides consistent load testing; ideal for power systems. | Measures torque directly but may lack comprehensive motor performance data. |

| Cost | Typically higher initial investment, often justified by accuracy and versatility. | Generally lower cost, but may require additional equipment for detailed analysis. | Lower cost, but limited in scope; primarily focused on torque measurement. |

| Ease of Implementation | Moderate complexity; requires setup and calibration. | Simple to install and operate, particularly in power testing scenarios. | Straightforward installation; usually portable and user-friendly. |

| Maintenance | Requires regular calibration and potential repairs; more complex systems may need specialized service. | Low maintenance; primarily electrical components that require minimal upkeep. | Minimal maintenance; primarily involves checking calibration. |

| Best Use Case | Ideal for comprehensive motor testing across various applications, including R&D and quality control. | Best for testing power systems and ensuring electrical load capacity without detailed motor performance data. | Suitable for applications where only torque measurement is necessary, such as in line testing. |

In-Depth Analysis of Alternatives

Load Banks

Load banks simulate electrical loads to test the performance and reliability of power sources, making them essential for power system testing. Their primary advantage lies in their ability to safely test generators and UPS systems under controlled conditions. However, while load banks excel in power testing, they do not provide the detailed performance metrics of motors, such as torque and RPM, which limits their use in comprehensive motor analysis.

Torque Meters

Torque meters are devices specifically designed to measure the torque output of motors. They are typically less expensive and easier to implement than motor dynos, making them attractive for small-scale operations or applications where space is limited. However, torque meters may not provide the full range of performance data that a motor dyno does, such as power curves or efficiency ratings. This can make them less suitable for applications requiring in-depth analysis of motor performance.

Making the Right Choice for Your Business Needs

When selecting the right testing solution, B2B buyers should carefully consider their specific requirements. If comprehensive motor performance analysis is critical, investing in a motor dyno may be the best choice despite the higher cost. On the other hand, if the primary need is for straightforward torque measurement or power system testing, a torque meter or load bank could offer a more cost-effective solution. Ultimately, aligning the testing solution with the operational goals and budget constraints will guide buyers to the most suitable option for their business needs.

Essential Technical Properties and Trade Terminology for motor dyno

What Are the Essential Technical Properties of Motor Dynos?

Understanding the technical specifications of motor dynamometers (dynos) is crucial for B2B buyers. These specifications directly impact performance, reliability, and suitability for specific applications. Here are some key properties to consider:

Illustrative image related to motor dyno

-

Torque Measurement Range

Torque is a critical parameter for assessing motor performance. A dyno’s torque measurement range indicates its capability to measure the output torque of various motors, from low-torque micro motors to high-torque industrial engines. Selecting a dyno with an appropriate torque range ensures accurate testing without overloading the equipment, which can lead to damage or inaccurate readings. -

Speed Measurement Capability

The maximum speed at which a dyno can operate is vital for applications involving high-speed motors. For example, some eddy-current dynos can handle speeds up to 80,000 RPM. Understanding speed capabilities allows buyers to choose a dyno that fits their testing requirements, particularly in sectors like automotive or aerospace where high-speed performance is critical. -

Cooling Mechanism

Many dynamometers feature built-in cooling systems, such as air or liquid cooling, to dissipate heat generated during testing. Effective cooling is essential to maintain the integrity and lifespan of the motor under test, particularly in high-power applications. Buyers should evaluate the cooling options based on their testing duration and power levels to prevent overheating. -

Data Acquisition and Control Systems

Advanced dynos come equipped with sophisticated data acquisition systems that provide real-time monitoring of torque, speed, and other performance metrics. This feature is significant for ensuring accurate test results and for troubleshooting motor performance issues. A robust data acquisition system aids in making informed decisions based on precise data, enhancing product development. -

Material Quality and Construction

The materials used in the construction of a dyno, such as aluminum or high-grade steel, impact its durability and performance. High-quality materials can withstand greater stress and provide more accurate measurements over time. Buyers should assess the construction quality to ensure longevity and reliability, especially when considering the operational environment (e.g., high temperatures or heavy vibrations).

What Are Common Trade Terms Related to Motor Dynos?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions in the B2B marketplace. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of motor dynos, buyers may source parts from OEMs to ensure compatibility and quality. Understanding OEM specifications can help buyers make better purchasing decisions. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory costs and cash flow. Knowing the MOQ helps businesses plan their purchases, especially when scaling operations or introducing new products. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. This term is essential for B2B transactions, enabling buyers to compare prices and negotiate better terms. A well-prepared RFQ can lead to favorable pricing and terms for motor dyno purchases. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for buyers to clarify shipping, risk, and cost responsibilities. Proper knowledge of Incoterms can help mitigate disputes and ensure smooth logistics. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is critical for production planning and inventory management. Buyers should consider lead times when sourcing motor dynos to ensure that they can meet production schedules and customer demands. -

Calibration

Calibration is the process of configuring an instrument to provide a result for a sample within an acceptable range. For motor dynos, regular calibration is essential for maintaining accuracy in measurements. Buyers should ensure that their chosen supplier offers calibration services or has easily accessible support for this process.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when investing in motor dynamometers, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the motor dyno Sector

What Are the Current Market Dynamics and Key Trends Affecting Motor Dyno Buyers?

The motor dynamometer market is experiencing significant growth driven by technological advancements and rising demand for precision testing across various sectors, including automotive, aerospace, and manufacturing. As electric and hybrid vehicles gain traction, the need for high-performance motor testing equipment becomes critical. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly focused on sourcing dynamometers that can accommodate diverse motor types, from traditional gas engines to modern electric motors.

Illustrative image related to motor dyno

Emerging trends in the motor dyno sector highlight the integration of smart technologies, such as IoT-enabled devices that allow for real-time monitoring and data analysis. This technological shift not only enhances testing accuracy but also optimizes operational efficiency, making it essential for B2B buyers to consider suppliers that offer these advanced features. Additionally, the demand for customized motor test systems is rising, as businesses seek solutions tailored to their unique testing needs, further shaping sourcing strategies.

Market dynamics are influenced by regional factors; for instance, buyers from Nigeria and Saudi Arabia may prioritize cost-effectiveness and local support, while European buyers might focus on compliance with stringent quality and environmental standards. Understanding these regional nuances enables B2B buyers to make informed sourcing decisions that align with their operational requirements and market conditions.

How Can Sustainability and Ethical Sourcing Impact Your Motor Dyno Supply Chain?

Sustainability is becoming a cornerstone of the procurement process in the motor dyno sector. B2B buyers are increasingly aware of the environmental impact associated with manufacturing and sourcing practices. Companies that prioritize sustainable materials and ethical supply chains not only enhance their corporate social responsibility (CSR) profiles but also appeal to environmentally conscious clients and consumers.

The use of ‘green’ certifications, such as ISO 14001 for environmental management and LEED for sustainable building practices, can significantly influence purchasing decisions. Buyers should seek suppliers that demonstrate a commitment to reducing their carbon footprint, whether through energy-efficient manufacturing processes or the use of recyclable materials in their products.

Illustrative image related to motor dyno

Furthermore, as regulations around environmental impact tighten globally, being proactive in sustainability can mitigate risks associated with non-compliance. By partnering with manufacturers who prioritize eco-friendly practices, B2B buyers can ensure that their sourcing strategies align with both regulatory demands and market expectations, ultimately enhancing their brand reputation.

How Has the Motor Dyno Sector Evolved Over Time?

The evolution of the motor dynamometer sector reflects broader technological advancements and shifts in industry requirements. Initially, dynamometers were primarily mechanical devices used to measure torque and horsepower in internal combustion engines. However, as the automotive industry transitioned towards electric and hybrid technologies, the design and functionality of dynamometers evolved to accommodate this shift.

Modern dynamometers now incorporate advanced electronic components, allowing for precise measurements of torque, speed, and power across a wider range of motor types. The introduction of software solutions for data analysis has further transformed the landscape, enabling more sophisticated testing methodologies and better performance insights. This evolution underscores the importance of selecting suppliers who not only provide reliable equipment but also stay at the forefront of technological advancements, ensuring that B2B buyers can meet the demands of an ever-changing market.

Illustrative image related to motor dyno

Frequently Asked Questions (FAQs) for B2B Buyers of motor dyno

1. How do I select the right motor dynamometer for my specific testing needs?

When selecting a motor dynamometer, consider the type of motor you need to test—electric, pneumatic, or gas engines. Assess the required power range, speed capabilities, and torque measurement needs. For high-speed applications, an Eddy-current dynamometer may be suitable, while hysteresis or powder brake types work better for lower speeds. Additionally, inquire about customization options to ensure the dynamometer meets your specific testing parameters and operational requirements.

2. What are the key features to look for in a motor dynamometer?

Key features to consider include the dynamometer’s braking system (hysteresis, Eddy-current, or powder), power and speed ratings, and accuracy in torque measurements. Look for models that offer real-time data acquisition capabilities, compatibility with various sensors, and ease of use in setup and operation. Additionally, check for safety features, such as protective covers and low-friction bearings, which enhance durability and performance.

3. How can I ensure the quality of the motor dynamometer before purchasing?

To ensure quality, request detailed specifications and performance data from the supplier. Verify the manufacturer’s reputation by reading reviews and case studies. It’s also advisable to ask for references from other clients who have used the same equipment. Consider arranging a demonstration or trial period to assess performance firsthand. Additionally, inquire about warranty terms and post-purchase support services.

4. What are the typical minimum order quantities (MOQ) for motor dynamometers?

Minimum order quantities can vary significantly based on the manufacturer and the model of the dynamometer. Generally, for bulk orders, MOQs might range from one unit for specialized models to several units for standard offerings. Be sure to discuss your requirements with the supplier to understand their MOQ policies, as some manufacturers may offer flexibility for first-time buyers or large projects.

5. What payment terms should I expect when purchasing motor dynamometers internationally?

Payment terms for international purchases can include various options such as upfront payments, letters of credit, or payment upon delivery. It’s common for suppliers to require a deposit (often 30% to 50%) before manufacturing, with the balance due upon completion or prior to shipping. Always clarify the payment terms and any potential foreign transaction fees, and consider using escrow services for added security.

6. How do logistics and shipping impact my motor dynamometer purchase?

Logistics and shipping are crucial factors, especially for international buyers. Discuss shipping options with your supplier, including air freight for faster delivery or sea freight for cost-effectiveness. Be aware of customs regulations in your country, potential import duties, and insurance for high-value equipment. Ensure the supplier provides proper packaging to prevent damage during transit, and consider tracking options for visibility throughout the shipping process.

7. Can I customize my motor dynamometer for specific applications?

Yes, many manufacturers offer customization options to tailor dynamometers to specific applications. This can include adjustments in power ratings, speed capabilities, braking systems, and additional features like integrated sensors. When discussing customization, provide detailed specifications about your testing requirements, and request a quote for any additional costs associated with the modifications.

8. What should I know about after-sales support for motor dynamometers?

After-sales support is vital for ensuring the longevity and performance of your motor dynamometer. Inquire about warranty terms, technical support availability, and options for maintenance services. Some manufacturers may offer training for your team on how to use the equipment effectively. Always check if they provide a comprehensive user manual and access to online resources or customer service for troubleshooting and guidance.

Top 3 Motor Dyno Manufacturers & Suppliers List

1. Magtrol – Key Dynamometers

Domain: magtrol.com

Registered: 1995 (30 years)

Introduction: Magtrol offers three types of Dynamometers: Hysteresis, Eddy-current, and Powder. These dynamometers are used for testing electric and pneumatic motors, gas engines, gearheads, servo drives, and inverters. Key products include:

1. HD Series – Hysteresis Dynamometers: Ideal for low to medium power range (max 14 kW intermittent duty), does not require speed to create torque.

2. WB Series – Eddy-Cu…

2. International DYNO® – Marine Dynamometer

Domain: internationaldyno.com

Registered: 2000 (25 years)

Introduction: International DYNO® Marine Dynamometer is a closed hydraulic system designed for fully loading marine outboard and sterndrive engines for diagnostic and performance tuning. It allows precise adjustment of load and measurement of output across the engine’s entire RPM range. The dynamometer can simulate on-water conditions in a shop environment, improving service profits by reducing costs and increa…

3. Taylor Dyno – Engine Dynamometers

Domain: taylordyno.com

Registered: 1997 (28 years)

Introduction: Taylor Dyno offers a variety of engine dynamometers including hydraulic (water brake), eddy current, AC, portable, and small engine dynos. They provide mobile test centers and accessories. Key features include:

– Best overall value in engine dynamometers

– Designed to drive productivity and ensure uptime

– Rapid return on investment

– Applications include verifying repairs, validating specificatio…

Strategic Sourcing Conclusion and Outlook for motor dyno

In conclusion, the strategic sourcing of motor dynamometers is crucial for businesses aiming to enhance their testing capabilities and optimize motor performance. By leveraging the diverse offerings in dynamometer technology—such as hysteresis, eddy-current, and powder brake systems—buyers can select equipment tailored to their specific operational needs. This not only ensures accurate measurements but also promotes efficiency in motor testing across a wide range of applications, from electric motors to high-speed tools.

For international B2B buyers in regions like Africa, South America, the Middle East, and Europe, the importance of investing in high-quality dynamometers cannot be overstated. As industries evolve and demand for precision increases, sourcing reliable and innovative testing solutions will be a key differentiator in maintaining competitive advantage.

Illustrative image related to motor dyno

Looking ahead, businesses should prioritize partnerships with reputable suppliers that offer customizable solutions and robust support. Embracing the advancements in motor testing technology will empower organizations to drive innovation, enhance product quality, and ultimately achieve sustainable growth. Start your journey today by exploring the latest dynamometer technologies and positioning your business at the forefront of the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.