Choosing Your Magnetic Latches: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for magnetic latches

The global market for magnetic latches presents a unique set of challenges for B2B buyers seeking reliable and efficient fastening solutions. Sourcing high-quality magnetic latches that meet specific operational needs—whether for industrial applications or consumer goods—can be daunting, especially when navigating diverse suppliers across regions like Africa, South America, the Middle East, and Europe, including key markets like Germany and Brazil. This guide is designed to equip international buyers with essential insights into the various types of magnetic latches available, their applications, and how to effectively vet suppliers.

Our comprehensive resource covers critical factors such as cost considerations, performance metrics, and the latest trends in magnetic latch technology. By delving into the specifics of product features, such as pull strength and installation methods, this guide empowers B2B purchasers to make informed decisions tailored to their unique requirements. Additionally, we explore the nuances of regional supply chains and compliance standards, ensuring that buyers can confidently navigate the complexities of international procurement.

With actionable insights and expert recommendations, this guide serves as a valuable tool for businesses looking to enhance their operational efficiency through quality magnetic latch solutions. By understanding the landscape of magnetic latches, buyers can optimize their sourcing strategies, minimize risks, and ultimately secure the best products for their applications.

Understanding magnetic latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Knock-In Magnetic Catches | Fit into drilled holes, discreet installation | Furniture manufacturing, cabinetry | Pros: Easy installation; Cons: Limited pull strength. |

| Countersunk Magnets | Strong hold, screw-in design for secure installation | Industrial applications, cabinetry | Pros: High pull strength; Cons: Requires more installation effort. |

| Channel Magnets | Exceptional durability, designed for high-performance use | Automotive, aerospace, heavy-duty equipment | Pros: Robust and reliable; Cons: Typically higher cost. |

| Neodymium Cabinet Latches | High magnetic force, various pull strengths available | Retail displays, storage solutions | Pros: Strong performance; Cons: Risk of demagnetization in extreme conditions. |

| Ceramic Latches | Cost-effective, moderate strength, non-corrosive | Residential and light commercial applications | Pros: Affordable; Cons: Weaker hold compared to neodymium. |

What are Knock-In Magnetic Catches and Their Key Features?

Knock-In Magnetic Catches are designed for easy integration into wooden furniture. These latches fit seamlessly into pre-drilled holes, providing a minimalist aesthetic. They are particularly suitable for cabinetry and furniture manufacturing where design integrity is crucial. When considering these latches, buyers should evaluate the required pull strength and installation ease, as these latches may not offer the strongest hold compared to other types.

How Do Countersunk Magnets Stand Out in Magnetic Latch Options?

Countersunk Magnets are characterized by their screw-in design that allows for a secure installation. They are favored in industrial applications where a strong hold is necessary, such as in cabinetry and storage solutions. The key B2B consideration for buyers is the balance between installation effort and the high pull strength they offer, making them ideal for environments that require durability and reliability.

Why Choose Channel Magnets for High-Performance Applications?

Channel Magnets provide exceptional strength and durability, making them ideal for demanding applications such as automotive and aerospace industries. Their robust construction ensures they can withstand significant forces, which is critical in environments subject to vibration and movement. Buyers should weigh the higher cost against the long-term benefits of reliability and performance in high-stress applications.

What Advantages Do Neodymium Cabinet Latches Offer?

Neodymium Cabinet Latches are known for their powerful magnetic force, available in various pull strengths. These latches are commonly used in retail displays and storage solutions, where a strong hold is necessary to secure items effectively. When purchasing, buyers should consider the potential for demagnetization in extreme conditions, as well as the need for appropriate installation to maximize the latch’s effectiveness.

What are the Benefits of Using Ceramic Latches?

Ceramic Latches are a cost-effective option for applications that do not require high strength. They are non-corrosive and suitable for residential and light commercial uses. While they offer affordability, buyers should be mindful of their moderate strength, which may not suffice in more demanding environments. Evaluating the specific application needs against the cost will help buyers make informed decisions.

Key Industrial Applications of magnetic latches

| Industry/Sector | Specific Application of Magnetic Latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Securing cabinet doors and drawers | Enhances user experience with smooth and reliable closures; reduces wear and tear on hinges. | Assess magnetic strength, size, and aesthetic options. |

| Automotive | Closure systems for vehicle compartments | Improves safety and convenience while reducing mechanical failure risks. | Evaluate pull strength and resistance to vibrations. |

| Marine and Recreational Vehicles | Latching systems for storage compartments | Ensures secure storage during transit, enhancing safety and convenience. | Consider corrosion resistance and environmental durability. |

| Retail Display Solutions | Magnetic catches for display cases and signage | Provides a sleek look while ensuring products remain securely displayed. | Focus on design, ease of installation, and strength. |

| Electronics and Appliances | Secure access to electronic device enclosures | Protects sensitive components while allowing easy access for maintenance. | Prioritize size compatibility and magnetic force ratings. |

How Are Magnetic Latches Utilized in Furniture Manufacturing?

In the furniture manufacturing sector, magnetic latches are commonly used to secure cabinet doors and drawers. They provide a seamless user experience by allowing for smooth and reliable closures without the wear and tear typically associated with traditional hinges. For international buyers, especially from regions like Europe and South America, it’s crucial to consider the magnetic strength and aesthetic options available, ensuring that the latches not only function well but also complement the design of the furniture.

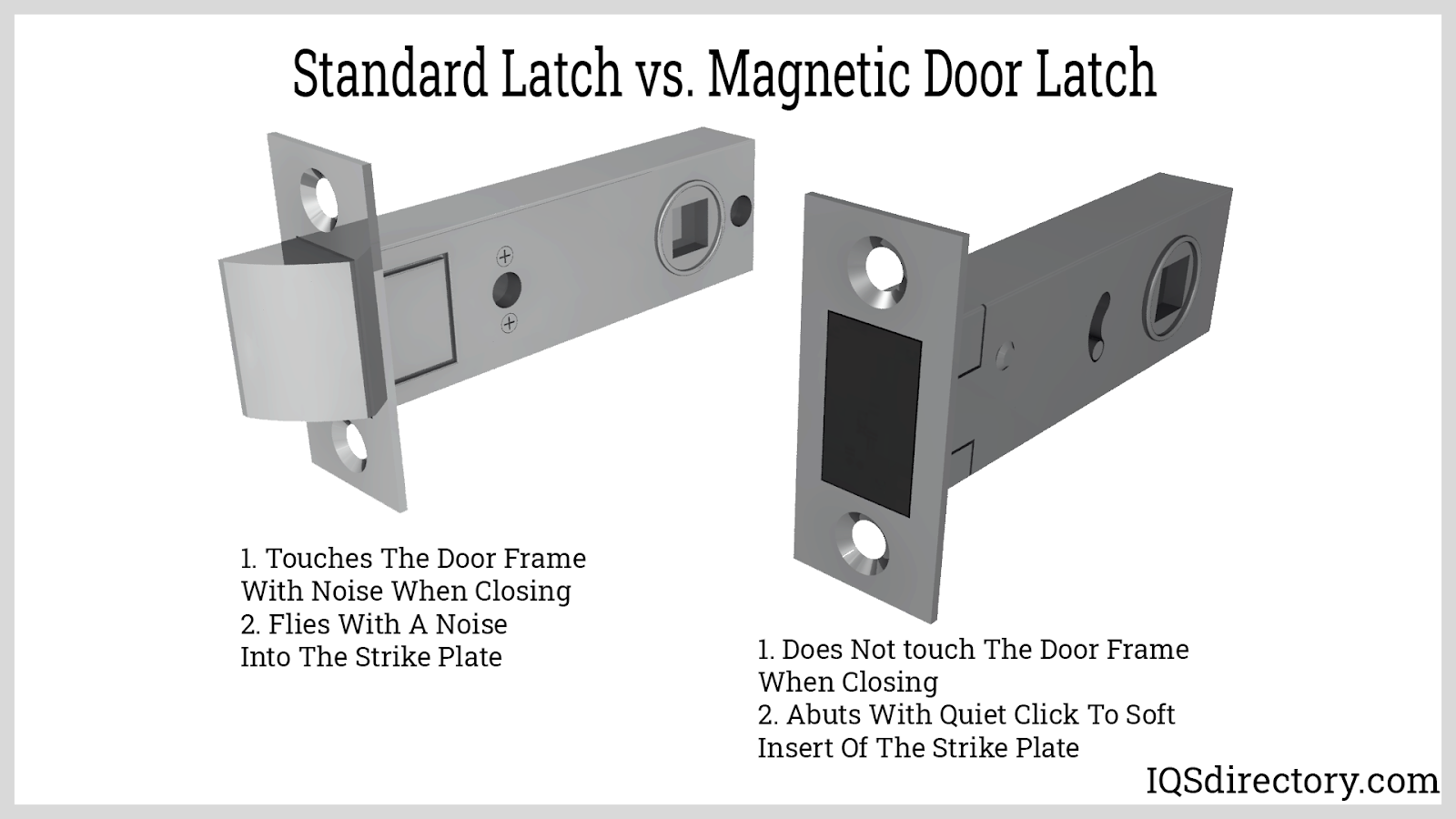

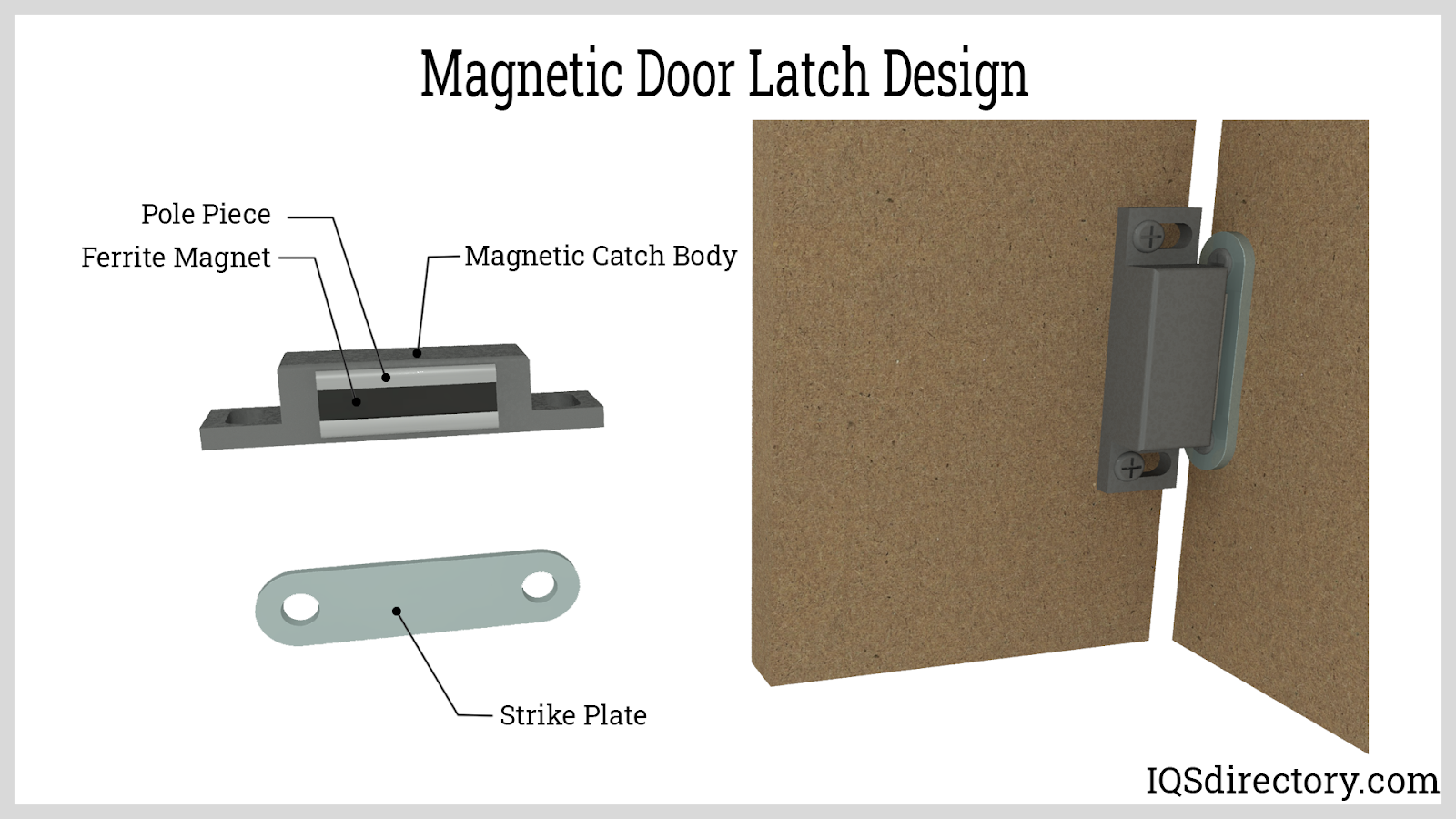

Illustrative image related to magnetic latches

What Role Do Magnetic Latches Play in the Automotive Industry?

In the automotive industry, magnetic latches are essential for closure systems in vehicle compartments. They enhance safety by ensuring that compartments remain securely closed during transit, thereby reducing the risk of mechanical failures. Buyers in this sector must evaluate the pull strength of the latches and their resistance to vibrations, especially in rugged environments typical in regions such as Africa and the Middle East, where road conditions may vary significantly.

How Do Magnetic Latches Benefit Marine and Recreational Vehicles?

For marine and recreational vehicles, magnetic latches serve as effective latching systems for storage compartments. They ensure that storage remains secure during movement, which is vital for safety and convenience. Buyers should focus on sourcing latches that offer corrosion resistance and durability against harsh environmental conditions, particularly in coastal areas where saltwater exposure is a concern.

Why Are Magnetic Latches Important in Retail Display Solutions?

In retail display solutions, magnetic catches are utilized for display cases and signage. They offer a sleek appearance while ensuring that products remain securely displayed, enhancing customer experience. When sourcing these latches, businesses should prioritize design aesthetics, ease of installation, and the strength of the magnetic hold, which can significantly impact the overall presentation of merchandise.

How Are Magnetic Latches Used in Electronics and Appliances?

Magnetic latches are also crucial for securing access to electronic device enclosures, providing protection for sensitive components while allowing easy access for maintenance. For B2B buyers in this sector, particularly in Europe and South America, it is essential to consider size compatibility and the magnetic force ratings of the latches to ensure they meet the specific requirements of their products. This attention to detail can significantly enhance product longevity and user satisfaction.

Illustrative image related to magnetic latches

3 Common User Pain Points for ‘magnetic latches’ & Their Solutions

Scenario 1: Difficulty in Ensuring Secure Closure in Dynamic Environments

The Problem: B2B buyers in industries such as logistics, transportation, and mobile services often face the challenge of ensuring that doors, drawers, or compartments remain securely closed during transit or movement. Traditional latching systems can fail, leading to potential damage or loss of products. This is particularly problematic in vehicles, shipping containers, or mobile units where vibrations and shifts are common. The need for a reliable closure that can withstand dynamic conditions is critical.

The Solution: To address this issue, B2B buyers should consider sourcing high-strength magnetic latches specifically designed for dynamic environments. Products like channel magnets or heavy-duty neodymium magnetic catches are engineered to provide robust holding power, even under movement. When specifying these latches, it’s essential to evaluate their pull strength and environmental resistance, such as corrosion or moisture exposure. For installation, ensure that the latches are positioned correctly to align with their corresponding magnets, providing a seamless closure. Additionally, conducting regular maintenance checks can ensure the latches continue to perform optimally, minimizing the risk of failures during critical operations.

Scenario 2: Inconsistent Performance of Magnetic Latches in Varying Conditions

The Problem: Many B2B buyers discover that the performance of magnetic latches can vary significantly based on environmental conditions, such as temperature fluctuations or humidity levels. For instance, in industrial settings, high heat or moisture can weaken the magnetic force, leading to unreliable closures. This inconsistency can cause operational delays, safety risks, and increased costs associated with damage control and repairs.

The Solution: To mitigate these risks, it is advisable for B2B buyers to select magnetic latches made from materials that offer enhanced durability and resistance to environmental factors. Options like PTFE-coated or rubber-coated magnetic catches provide additional protection against temperature extremes and moisture. When sourcing, buyers should inquire about the latches’ performance ratings under specific conditions to ensure they meet operational needs. Furthermore, implementing a testing phase in the actual working environment can help identify any potential issues before full-scale deployment. This proactive approach ensures that the latches chosen will maintain consistent performance regardless of external conditions.

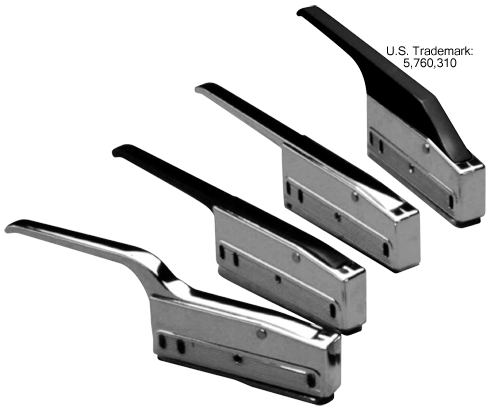

Scenario 3: Complicated Installation and Integration with Existing Systems

The Problem: A common pain point for B2B buyers is the complexity associated with the installation of magnetic latches, especially when integrating them into existing systems. Buyers may find themselves facing challenges such as misalignment, inadequate space for installation, or the need for additional tools or modifications to furniture or equipment. These complications can lead to increased labor costs and project delays.

Illustrative image related to magnetic latches

The Solution: To streamline the installation process, buyers should look for magnetic latches that are designed for easy integration, such as knock-in or countersunk magnetic catches. These types often come with installation kits that include all necessary components, reducing the need for extra tools. Before purchasing, it’s beneficial to review the installation guidelines provided by the manufacturer, ensuring that the selected latches match the specifications of the existing systems. Additionally, investing in training for the installation team can lead to a smoother integration process. This preparation not only reduces the risk of installation errors but also enhances overall efficiency, enabling quicker project completion and minimizing downtime.

Strategic Material Selection Guide for magnetic latches

What Are the Key Materials Used in Magnetic Latches?

When selecting magnetic latches for various applications, the choice of material plays a crucial role in determining performance, durability, and cost-effectiveness. Here, we analyze four common materials used in magnetic latches: Neodymium, Ceramic, Stainless Steel, and Plastic. Each material has unique properties that can significantly impact application suitability and overall performance.

How Does Neodymium Perform in Magnetic Latches?

Neodymium is a rare-earth metal known for its exceptional magnetic strength. This material typically exhibits a high temperature rating, often up to 80°C (176°F), and can withstand significant pressure without losing its magnetic properties.

Pros: Neodymium latches provide superior holding power, making them ideal for applications requiring a strong and secure closure. Their compact size allows for discreet installation, which is particularly beneficial in residential and commercial settings.

Cons: However, neodymium is prone to corrosion, necessitating protective coatings, which can increase manufacturing complexity and cost. Additionally, they can be more expensive than other materials, which may be a consideration for budget-sensitive projects.

Impact on Application: Neodymium latches are suitable for environments where strong magnetic force is required, such as in cabinetry or industrial equipment. However, they may not be ideal for outdoor applications without adequate protection against moisture.

Considerations for International Buyers: Buyers from regions like Europe and South America should ensure compliance with relevant standards, such as DIN or ASTM, particularly regarding corrosion resistance and safety.

What Role Does Ceramic Play in Magnetic Latches?

Ceramic magnets are another common choice for magnetic latches. They offer a lower temperature rating, typically around 60°C (140°F), but are highly resistant to corrosion and environmental factors.

Pros: The primary advantage of ceramic latches is their cost-effectiveness, making them suitable for high-volume applications. They are also less prone to demagnetization over time compared to neodymium, ensuring longevity.

Cons: However, ceramic magnets generally provide weaker magnetic strength compared to neodymium, which may limit their use in applications requiring robust holding power. They are also more brittle, which can lead to breakage during installation or use.

Impact on Application: Ceramic latches are ideal for lightweight applications such as cabinet doors or drawers in dry environments. Their durability makes them a preferred choice for budget-conscious projects.

Considerations for International Buyers: Buyers should consider local manufacturing capabilities and standards, as ceramic latches may be more readily available in certain regions, including Brazil and Germany.

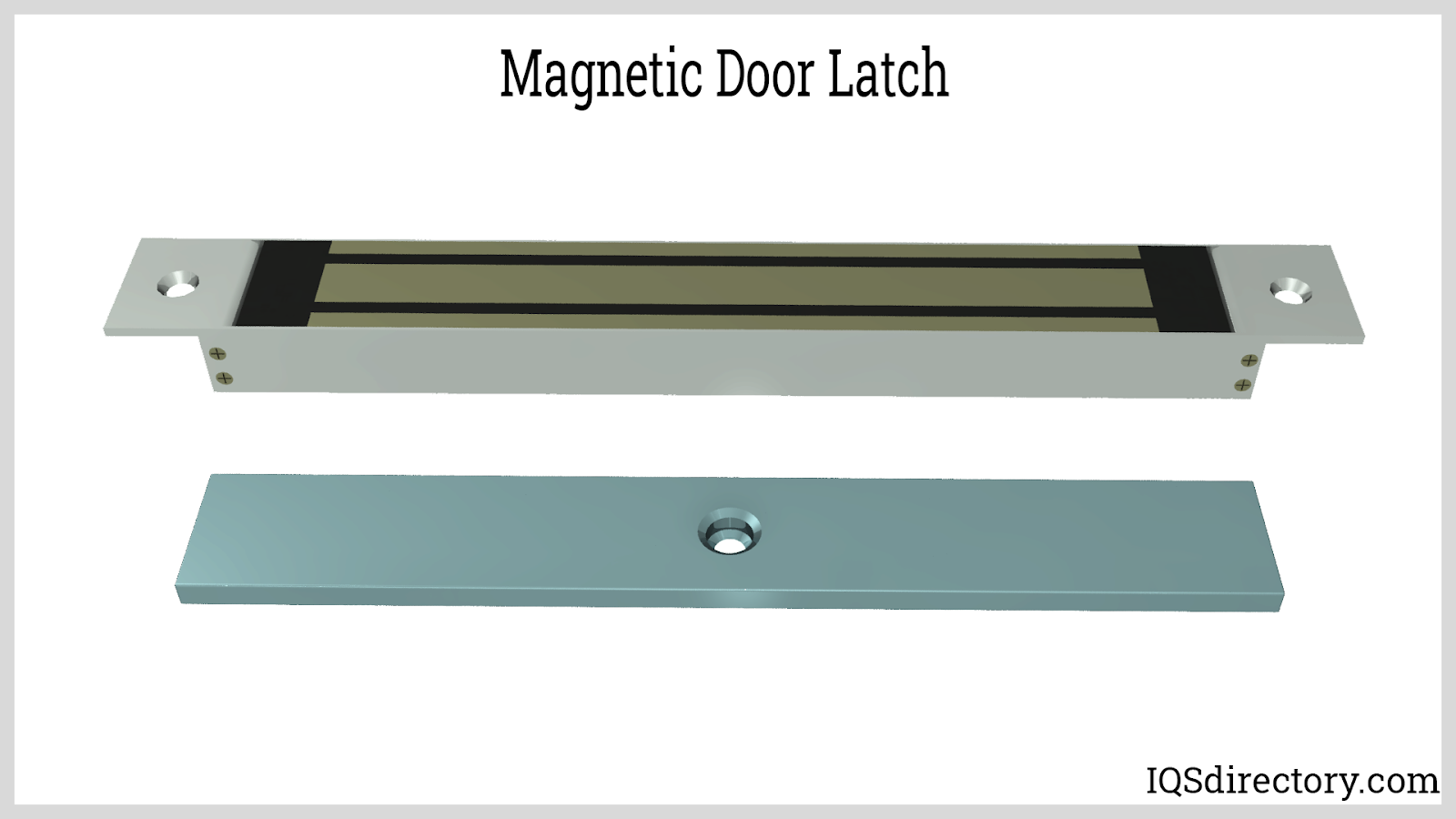

How Does Stainless Steel Enhance Magnetic Latch Performance?

Stainless steel is often used for the housing or casing of magnetic latches, providing structural integrity and corrosion resistance. It typically withstands temperatures up to 300°C (572°F).

Pros: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor applications or environments with high humidity. Its strength allows for reliable performance in demanding conditions.

Cons: However, stainless steel can be more expensive than plastic or ceramic options, and its manufacturing process can be more complex. This may lead to higher overall costs for the end product.

Impact on Application: Stainless steel latches are suitable for industrial applications, outdoor furniture, and marine environments where corrosion resistance is critical.

Considerations for International Buyers: Compliance with international standards such as JIS or ASTM is essential, especially for buyers in the Middle East, where environmental factors can significantly impact product longevity.

Illustrative image related to magnetic latches

What Advantages Does Plastic Offer in Magnetic Latches?

Plastic magnetic latches are lightweight and versatile, often used in consumer products and light-duty applications. They typically have a lower temperature rating, around 50°C (122°F).

Pros: The main advantage of plastic latches is their low cost and ease of manufacturing. They can be molded into various shapes and sizes, allowing for customization.

Cons: However, plastic latches may not offer the same level of strength or durability as metal options. They are also more susceptible to wear and tear over time, particularly in high-stress environments.

Impact on Application: Plastic latches are ideal for lightweight applications, such as toy boxes or lightweight cabinet doors. They are best suited for indoor use or environments with minimal exposure to the elements.

Considerations for International Buyers: Buyers should be aware of regional preferences for materials, as certain markets may favor metal over plastic for durability reasons.

Summary Table of Material Selection for Magnetic Latches

| Material | Typical Use Case for Magnetic Latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neodymium | High-security cabinets, industrial equipment | Superior holding power | Prone to corrosion, higher cost | High |

| Ceramic | Lightweight cabinets, drawers | Cost-effective, long-lasting | Weaker magnetic strength, brittle | Low |

| Stainless Steel | Outdoor furniture, industrial applications | Durable, corrosion-resistant | Higher manufacturing complexity | Medium |

| Plastic | Toy boxes, lightweight cabinets | Low cost, easy to manufacture | Less durable, susceptible to wear | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in magnetic latches, enabling informed purchasing decisions tailored to specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for magnetic latches

What Are the Key Stages in the Manufacturing Process of Magnetic Latches?

Manufacturing magnetic latches involves a series of structured processes designed to ensure high-quality output. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting suitable materials, typically high-grade metals like stainless steel or neodymium magnets. Suppliers must ensure that these materials meet industry standards and specifications. Proper handling and storage of raw materials are crucial to prevent contamination and degradation.

-

Forming: This stage encompasses various techniques such as stamping, molding, and machining. For example, magnets may be produced using sintering processes that compress powdered materials into solid forms. This is crucial for achieving the desired strength and durability. Precision in this stage is vital, as any inaccuracies can lead to compromised product functionality.

-

Assembly: After forming, components are assembled, often utilizing automated machinery for efficiency. This includes integrating the magnetic parts with housings or other mechanisms. Skilled workers may perform additional manual assembly to ensure proper fit and function, especially for complex designs.

-

Finishing: The final stage involves surface treatment processes such as coating, plating, or polishing. These treatments enhance the aesthetic appeal and protect against corrosion, which is particularly important for magnetic latches used in outdoor or marine environments. Quality control during this stage is crucial to ensure that the finish meets the required specifications.

What Quality Control Measures Are Important in Magnetic Latch Production?

Quality assurance is essential in the manufacturing of magnetic latches to ensure reliability and safety. International standards, such as ISO 9001, provide a framework for quality management systems, while industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are also relevant.

-

Key QC Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified criteria. Failure to adhere to standards at this stage can lead to defects in the final product.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps to identify and rectify issues early. Techniques such as statistical process control (SPC) may be employed to analyze production data.

– Final Quality Control (FQC): Before products are shipped, a thorough inspection of finished goods is conducted. This includes functional testing of magnetic strength, durability, and dimensional accuracy. -

Common Testing Methods: Various testing methods can be applied, including:

– Pull Tests: To measure the strength of magnetic attraction.

– Fatigue Tests: To assess the longevity and durability of the latch under repeated use.

– Corrosion Resistance Tests: Especially for products intended for outdoor use, this ensures they can withstand environmental factors.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must be proactive in verifying the quality control processes of their suppliers. This can be accomplished through several methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control practices directly. This provides insight into the supplier’s operational capabilities and adherence to quality standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance metrics, including defect rates and compliance with international standards.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These agencies often conduct pre-shipment inspections and can validate compliance with required standards.

What Are the Nuances of Quality Control Certification for International B2B Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control certification is critical.

-

Regional Standards Compliance: Different regions may have specific compliance requirements. For instance, products exported to Europe must meet CE marking requirements, which indicate conformity with health, safety, and environmental protection standards.

-

Documentation and Traceability: Buyers should ensure that suppliers maintain comprehensive documentation of quality control processes, including traceability of materials and components. This is particularly important for industries like automotive and aerospace, where safety is paramount.

-

Cultural Sensitivity in Communication: When dealing with suppliers across different regions, cultural differences can impact quality expectations and communication. Establishing clear guidelines and expectations from the outset can help mitigate misunderstandings and ensure alignment on quality standards.

Conclusion: Ensuring Quality in Magnetic Latch Procurement

In summary, the manufacturing processes and quality assurance measures for magnetic latches are integral to ensuring product reliability and safety. By understanding the stages of production and engaging in thorough quality verification, B2B buyers can make informed decisions when sourcing magnetic latches from suppliers globally. This diligence is particularly essential when navigating the complexities of international trade and diverse regulatory environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘magnetic latches’

Introduction

This guide provides a practical checklist for B2B buyers seeking to procure magnetic latches. Magnetic latches are essential components in various applications, from cabinetry to industrial settings, offering secure yet convenient closures. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their operational needs and standards.

Illustrative image related to magnetic latches

1. Define Your Technical Specifications

Before initiating your search, clearly outline your technical requirements. Consider factors such as the size, material, pull strength, and environmental conditions where the latches will be used.

- Material Considerations: For instance, stainless steel may be preferred for outdoor applications due to its corrosion resistance.

- Strength Requirements: Identify the required pull force to ensure the latch can withstand operational stresses.

2. Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in magnetic latches. Look for companies with a proven track record and a robust product range.

- Industry Experience: Suppliers with experience in your specific industry can offer insights and solutions tailored to your needs.

- Product Variety: A diverse product range indicates a supplier’s capability to meet various application requirements.

3. Evaluate Product Quality and Standards

Quality is paramount when sourcing magnetic latches. Ensure the products meet relevant industry standards and certifications.

- Certifications: Look for compliance with international standards (e.g., ISO, ASTM) to guarantee product reliability.

- Material Quality: Investigate the materials used in the latches to ensure they are suitable for your application.

4. Request Samples for Testing

Before finalizing your order, request samples of the magnetic latches. Testing samples allows you to assess their performance and suitability firsthand.

- Performance Evaluation: Check the latch’s magnetic strength, ease of use, and durability in real-world conditions.

- Compatibility Check: Ensure the latch fits seamlessly with your existing hardware or design.

5. Verify Supplier Certifications

It is crucial to verify the certifications and quality assurance processes of potential suppliers. This step ensures that the products you purchase are reliable and consistent.

Illustrative image related to magnetic latches

- Quality Assurance Processes: Understand the supplier’s quality control measures, including testing and inspection procedures.

- Sustainability Practices: Inquire about the supplier’s commitment to sustainability and eco-friendly practices, which can be important in certain markets.

6. Consider Logistics and Delivery Times

Evaluate the supplier’s logistics capabilities and delivery timelines. Efficient logistics are vital for maintaining your project schedules.

- Shipping Options: Check if the supplier offers various shipping methods to accommodate your timelines.

- Lead Times: Understand the expected lead times for order fulfillment, particularly if you are working on tight deadlines.

7. Establish Clear Communication Channels

Effective communication with your supplier is essential for a successful partnership. Establish clear lines of communication for inquiries, orders, and support.

- Point of Contact: Ensure you have a dedicated contact person for your account to streamline communications.

- Feedback Mechanisms: Discuss how the supplier handles feedback and potential issues during the procurement process.

By following this checklist, B2B buyers can navigate the procurement of magnetic latches confidently, ensuring they secure the right products for their needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for magnetic latches Sourcing

What Are the Key Cost Components in Magnetic Latch Sourcing?

When sourcing magnetic latches, understanding the cost structure is crucial for effective budgeting and supplier negotiations. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Neodymium, a common choice for high-strength applications, is more expensive than ceramic or plastic. The quality of coatings (such as PTFE or rubber) also affects pricing.

-

Labor: Labor costs encompass the expenses related to manufacturing processes, including assembly and quality control. Regions with lower labor costs can offer competitive pricing, but this might come with trade-offs in quality and consistency.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help mitigate these expenses.

-

Tooling: Custom tooling for specific latch designs can incur substantial upfront costs. However, once amortized over large production runs, these costs can be distributed effectively.

-

Quality Control (QC): Ensuring that each batch meets quality standards is vital, especially for applications requiring reliability. Enhanced QC processes may lead to higher costs but result in reduced returns and increased customer satisfaction.

-

Logistics: Transportation costs can vary significantly based on the distance from the supplier to the buyer. Factors such as shipping mode (air vs. sea), packaging, and storage can also influence overall logistics costs.

-

Margin: Suppliers typically add a margin on top of production costs to ensure profitability. Understanding typical margin ranges in the industry can help buyers evaluate pricing offers more effectively.

How Do Price Influencers Affect Magnetic Latch Costs?

Several factors can influence the pricing of magnetic latches:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Larger orders usually lead to discounts due to economies of scale, while smaller orders may incur higher per-unit costs.

-

Specifications/Customization: Custom designs or specific performance specifications can increase costs. Buyers should evaluate whether the added functionality justifies the additional expense.

-

Material Quality and Certifications: Premium materials and certifications (e.g., ISO standards) often lead to higher costs. Buyers seeking high-quality products should be prepared for these price differences.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Suppliers with advanced technology or superior customer service may charge a premium.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they dictate who is responsible for shipping costs and risks. This can significantly affect the total landed cost of the product.

What Tips Can Help Buyers Optimize Costs in Magnetic Latch Sourcing?

To navigate the complexities of sourcing magnetic latches effectively, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage your purchasing power to negotiate better terms or discounts.

-

Focus on Cost-Efficiency: Assess not just the purchase price, but also the total cost of ownership (TCO). This includes installation, maintenance, and potential replacement costs.

-

Understand Pricing Nuances for International Purchases: International buyers, particularly in Africa, South America, and the Middle East, should account for potential tariffs, customs duties, and currency fluctuations that can affect overall pricing.

-

Supplier Diversification: Establish relationships with multiple suppliers to mitigate risks and foster competitive pricing. This strategy can also provide alternative sources in case of supply chain disruptions.

-

Market Research: Regularly analyze market trends and pricing benchmarks. Staying informed about changes in material costs or industry standards can empower buyers to make more strategic sourcing decisions.

Disclaimer

The pricing mentioned in this analysis is indicative and may vary based on market conditions, specific supplier negotiations, and individual buyer requirements. Always conduct thorough market research and supplier evaluations to ensure the best purchasing decisions.

Alternatives Analysis: Comparing magnetic latches With Other Solutions

Exploring Alternatives to Magnetic Latches in Industrial Applications

In the quest for effective closure solutions, businesses often evaluate various technologies to determine the best fit for their operational needs. Magnetic latches are widely recognized for their ease of use and secure fastening capabilities, but alternatives exist that may offer unique advantages depending on specific applications. Below, we compare magnetic latches to two viable alternatives: traditional mechanical latches and electronic locking mechanisms.

| Comparison Aspect | Magnetic Latches | Mechanical Latches | Electronic Locking Mechanisms |

|---|---|---|---|

| Performance | Strong holding force, quick release | Reliable but may require more effort to operate | High security, programmable access |

| Cost | Generally low-cost | Moderate cost; varies by complexity | Higher initial investment |

| Ease of Implementation | Simple installation; minimal tools needed | Requires more tools and expertise | Requires electrical setup; complex |

| Maintenance | Low maintenance; durable materials | Moderate; may need lubrication | Higher maintenance due to electronics |

| Best Use Case | Residential and light commercial applications | General-purpose use in various settings | High-security environments or smart applications |

What Are the Advantages and Disadvantages of Mechanical Latches?

Mechanical latches provide a straightforward solution with proven reliability. Their primary advantage lies in their simplicity and durability. They require no electrical components, making them less susceptible to failure due to power outages or environmental factors. However, they often necessitate manual operation, which may not be ideal in situations requiring frequent access. Additionally, they can be cumbersome to install compared to magnetic latches, which are often more user-friendly.

What Are the Benefits and Drawbacks of Electronic Locking Mechanisms?

Electronic locking mechanisms stand out in terms of security and versatility. They can be programmed for multiple users, providing a higher level of access control, which is essential for sensitive environments. However, the complexity of installation and the need for a power source can be significant drawbacks, particularly in remote locations. Moreover, maintenance can be more demanding, as electronic components may require regular checks and updates. The higher upfront costs may also deter businesses with tighter budgets.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting a closure solution, B2B buyers should assess their specific requirements, including performance needs, budget constraints, and installation capabilities. Magnetic latches are ideal for applications where ease of use and low maintenance are priorities, making them suitable for residential and light commercial use. In contrast, mechanical latches may be more appropriate for general-purpose applications where durability is key, while electronic locking mechanisms excel in high-security settings where access control is critical.

Illustrative image related to magnetic latches

In conclusion, understanding the strengths and limitations of each alternative is essential for making an informed decision. By aligning the chosen solution with operational needs and environmental factors, businesses can enhance security, efficiency, and user satisfaction in their applications.

Essential Technical Properties and Trade Terminology for magnetic latches

What Are the Key Technical Properties of Magnetic Latches?

When selecting magnetic latches for various applications, understanding their technical properties is crucial. Here are some essential specifications that B2B buyers should consider:

Material Grade

The material grade of a magnetic latch primarily affects its durability and performance. Common materials include neodymium, ceramic, and stainless steel. Neodymium offers high magnetic strength, making it suitable for applications requiring compact designs and robust holding power. Stainless steel latches provide corrosion resistance, which is vital for outdoor or humid environments. Selecting the appropriate material ensures longevity and reliability, minimizing the need for replacements and enhancing overall operational efficiency.

Pull Strength

Pull strength refers to the maximum weight a magnetic latch can hold when closed. This specification is typically measured in pounds (lbs) and varies across different models. For instance, a latch with a pull strength of 30 lbs can securely hold cabinet doors, while those with 100 lbs or more are ideal for industrial applications. Understanding pull strength is essential for ensuring that the latch meets the safety and functionality requirements of specific applications, particularly in sectors such as automotive and aerospace.

Tolerance

Tolerance is the permissible limit of variation in a latch’s dimensions. It plays a critical role in ensuring that magnetic latches fit correctly within their intended applications. A tighter tolerance typically results in a better fit, reducing the risk of misalignment or failure during operation. In high-precision industries, such as electronics or aerospace, maintaining strict tolerances is vital for operational integrity and safety.

Temperature Resistance

Temperature resistance indicates the range of temperatures within which a magnetic latch can operate effectively. This property is particularly important in environments that experience extreme heat or cold. For example, latches used in outdoor applications may need to withstand temperatures ranging from -40°F to 185°F. Choosing latches with appropriate temperature ratings ensures that they will perform reliably under varying environmental conditions, thus reducing maintenance costs.

Finish and Coating

The finish or coating of a magnetic latch affects its appearance and resistance to environmental factors such as corrosion, wear, and UV radiation. Common finishes include zinc plating, powder coating, and rubberized coatings. A well-chosen finish not only enhances the aesthetic appeal of the latch but also extends its lifespan, especially in harsh conditions. For B2B buyers, this means fewer replacements and lower total cost of ownership.

What Are Common Trade Terms Related to Magnetic Latches?

Navigating the procurement process for magnetic latches involves understanding specific industry jargon. Here are several key terms that B2B buyers should be familiar with:

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold under another company’s brand. In the context of magnetic latches, buyers may source products from OEMs to ensure quality and compatibility with their existing systems. Understanding OEM relationships can help buyers negotiate better prices and terms.

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for buyers looking to manage inventory costs. Understanding MOQ helps businesses determine whether a supplier can meet their needs without overcommitting to inventory that may not sell.

Illustrative image related to magnetic latches

RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers. This process is essential for buyers looking to compare costs and services among multiple vendors. A well-structured RFQ can streamline the procurement process, ensuring that buyers receive competitive bids that meet their specifications.

Incoterms

Incoterms (International Commercial Terms) are a set of rules that define the responsibilities of buyers and sellers in international trade. These terms specify who is responsible for shipping, insurance, and tariffs, which can significantly affect overall costs. Familiarity with Incoterms enables buyers to negotiate better shipping arrangements and understand their liabilities.

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the products. This factor is crucial for project planning and inventory management. A shorter lead time can be advantageous for businesses with tight deadlines, while longer lead times may require more proactive inventory strategies.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when procuring magnetic latches, ensuring that they select the right products for their specific needs while optimizing costs and operational efficiency.

Illustrative image related to magnetic latches

Navigating Market Dynamics and Sourcing Trends in the magnetic latches Sector

What Are the Key Trends Shaping the Magnetic Latches Market?

The global market for magnetic latches is experiencing robust growth, driven by an increasing demand for efficient and secure fastening solutions across various sectors, including furniture, automotive, and industrial applications. Notably, the rise of smart homes and automated systems is propelling the adoption of advanced magnetic latches that integrate seamlessly with electronic locking mechanisms. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should note that customization is becoming a critical factor. Suppliers are increasingly offering tailored solutions to meet specific client needs, from varying pull strengths to unique designs suited for distinct applications.

Emerging technologies, such as 3D printing, are revolutionizing how magnetic latches are manufactured, enabling rapid prototyping and reducing lead times. This shift is particularly advantageous for B2B buyers seeking quick turnaround times for specialized projects. Additionally, the trend towards multifunctional products is gaining traction; magnetic latches are now being designed to serve dual purposes, such as providing both security and aesthetic appeal. Buyers should also be aware of the competitive landscape, which is characterized by both established manufacturers and innovative startups, offering diverse product ranges and pricing strategies.

How Is Sustainability Influencing the Sourcing of Magnetic Latches?

Sustainability is becoming a pivotal concern for B2B buyers in the magnetic latches sector. The environmental impact of manufacturing processes and materials used in these products is under scrutiny, prompting buyers to seek suppliers that prioritize eco-friendly practices. This includes the use of recyclable materials and adherence to green manufacturing standards. Buyers from regions like Europe are particularly influenced by stringent regulations regarding sustainability, pushing them to partner with manufacturers who demonstrate a commitment to reducing their carbon footprint.

Illustrative image related to magnetic latches

Ethical sourcing is equally critical; buyers are increasingly looking for suppliers that ensure fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable materials are becoming essential criteria for procurement decisions. Implementing a sustainable sourcing strategy not only enhances a company’s brand reputation but can also result in cost savings through efficient resource use and waste reduction. For international buyers, aligning with suppliers that embrace sustainability can foster long-term partnerships and improve supply chain resilience.

What Is the Historical Context of Magnetic Latches in B2B Applications?

The evolution of magnetic latches can be traced back to their initial use in furniture and cabinetry, where they offered a simple yet effective solution for closing doors and drawers. Over time, advancements in magnetic technology, particularly the introduction of neodymium magnets in the late 20th century, significantly enhanced the strength and reliability of these latches. This development allowed for a broader range of applications, including automotive and industrial uses, where security and durability are paramount.

As industries have become more automated, the role of magnetic latches has expanded further. Today, they are integral to various technological applications, from electronic locks in smart homes to safety mechanisms in mobile environments like RVs and boats. This historical progression highlights the adaptability of magnetic latches, making them a vital component in modern B2B supply chains, where innovation and efficiency are key drivers of success.

Frequently Asked Questions (FAQs) for B2B Buyers of magnetic latches

-

1. How do I choose the right magnetic latch for my application?

Selecting the right magnetic latch requires assessing the specific needs of your application. Consider factors like the weight and type of door or drawer, the required pull strength, and the environmental conditions (e.g., moisture, temperature). Evaluate the installation space and whether you need a concealed or surface-mounted solution. Additionally, consult product specifications from suppliers to ensure compatibility with your design requirements. -

2. What is the best magnetic latch for outdoor applications?

For outdoor applications, such as gates or cabinets exposed to the elements, opt for magnetic latches with high corrosion resistance, often made from materials like stainless steel or specially coated neodymium. A channel magnet design may provide superior strength and durability under varying weather conditions. Ensure the latch has a sufficient pull force to withstand wind or movement while remaining easy to operate. -

3. What are the minimum order quantities (MOQs) for magnetic latches?

Minimum order quantities vary by supplier and can depend on the type of magnetic latch and its application. Many manufacturers may have MOQs ranging from 50 to 500 units, especially for customized products. When sourcing, inquire directly with suppliers for their specific MOQs, as they may offer flexibility based on your purchasing needs or establish terms for bulk orders. -

4. How can I vet suppliers for magnetic latches?

To effectively vet suppliers, conduct thorough research on their industry reputation, product quality, and customer service. Request samples to assess product performance and build quality. Check for certifications that ensure compliance with international standards. Additionally, seek references from previous clients or review testimonials. Engaging in direct communication can also help gauge their responsiveness and reliability. -

5. What payment terms should I expect when ordering magnetic latches internationally?

Payment terms can vary significantly between suppliers and regions. Common terms include upfront payment, net 30 or 60 days, or letters of credit for larger orders. Discussing payment methods such as bank transfers, credit cards, or escrow services is crucial to ensure security. Always clarify the terms in your contract to avoid misunderstandings and ensure compliance with international trade regulations. -

6. What quality assurance measures should I consider when sourcing magnetic latches?

When sourcing magnetic latches, ensure suppliers have robust quality assurance processes in place. This includes regular inspections during manufacturing and final testing of products to meet specified pull strengths and durability standards. Request documentation of their quality control procedures and any certifications that indicate compliance with international quality standards, such as ISO certifications. -

7. How does international shipping affect the cost of magnetic latches?

International shipping can significantly impact the overall cost of magnetic latches due to freight charges, customs duties, and import taxes. Factors such as shipping method (air vs. sea), delivery speed, and destination can influence costs. To optimize expenses, consider consolidating shipments or negotiating shipping terms with suppliers. Always factor in these costs during your budgeting process for accurate financial planning. -

8. Can I customize magnetic latches to fit my specific requirements?

Yes, many suppliers offer customization options for magnetic latches, including size, pull strength, and materials used. This flexibility allows you to tailor products to your specific application needs. When discussing customization, provide detailed specifications and requirements to ensure the supplier can meet your expectations. Be aware that custom orders may have longer lead times and potentially higher costs.

Top 4 Magnetic Latches Manufacturers & Suppliers List

1. First4Magnets – Magnetic Catches and Closures

Domain: first4magnets.com

Registered: 2007 (18 years)

Introduction: Magnetic catches and closures are essential components for securing doors, cabinets, and other enclosures. They provide a reliable and efficient way to keep items closed while allowing for easy access. Available in various sizes and strengths, these magnetic solutions are suitable for both residential and commercial applications. Features include easy installation, durability, and a range of finis…

2. Magnetics – Rare Earth Magnetic Latches

Domain: magnetics.com

Registered: 1995 (30 years)

Introduction: Magnetic Latches are extremely powerful Rare Earth magnetic latches designed for securing cabinet doors and mounting displays that can be easily taken down or changed out. They feature a thin profile, making them ideal for door and cabinet applications, as well as for mounting panels, signs, and pictures. The latches are made with plated magnets, washers, and screws to reduce corrosion, and the wa…

3. Hardware Decor – Magnetic Touch Latch 512, Black

Domain: hardware-decor.com

Registered: 2010 (15 years)

Introduction: Touch latches, also known as magnetic latches, provide a convenient way to open cabinets and drawers with a simple touch. The selection includes soft close latches for smooth operation and options for single, double, and mini touch latches. Key products include: 1. Magnetic Touch Latch 512, Black – $1.19 2. Single Magnetic Touch Latch 507, Black – $2.85 3. Single Magnetic Touch Latch 507, White – …

4. Lee Valley – Magnetic Touch Latches

Domain: leevalley.com

Registered: 1996 (29 years)

Introduction: {“products”:[{“name”:”Double Magnetic Touch Latch”,”price”:”$4.50″,”availability”:”Online: Available”},{“name”:”Panel Magnet Cup”,”price”:”$4.50″,”availability”:”Online: Available”},{“name”:”Magnetic Touch Latches”,”price”:”$3.20″,”availability”:”Online: Available”},{“name”:”Latch Plates for Glass Doors”,”price”:”$2.00″,”availability”:”Online: Available”},{“name”:”Brass Magnetic Catch”,”price”:”$9…

Strategic Sourcing Conclusion and Outlook for magnetic latches

In navigating the dynamic landscape of magnetic latches, strategic sourcing emerges as a pivotal factor for international B2B buyers. By prioritizing quality and reliability, companies can secure superior products that enhance operational efficiency across various applications, from residential to industrial settings. The diverse range of magnetic latches—featuring options like neodymium and ceramic—ensures that businesses can find tailored solutions to meet specific needs, whether for doors, gates, or cabinetry.

Investing in strategic sourcing not only fosters strong supplier relationships but also enables companies to adapt to shifting market demands and technological advancements. As global markets continue to evolve, the emphasis on innovation and sustainability will shape future product offerings. Buyers from Africa, South America, the Middle East, and Europe should leverage these trends to enhance their procurement strategies.

Looking ahead, we encourage international buyers to explore partnerships with reliable manufacturers and distributors. By doing so, they can capitalize on the benefits of high-quality magnetic latches, ensuring secure and efficient operations that meet the demands of a competitive marketplace. Embrace the potential of strategic sourcing today to stay ahead in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.