Choosing Your Machine Tool Repair Near Me: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for machine tool repair near me

In an increasingly competitive global market, sourcing reliable machine tool repair services can pose a significant challenge for B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. The need for efficient and cost-effective repair solutions is paramount as businesses strive to minimize downtime and optimize their operations. This comprehensive guide on “machine tool repair near me” aims to equip international buyers with the insights necessary to navigate this complex landscape, ensuring they make informed purchasing decisions.

Throughout this guide, we will explore various types of machine tool repairs, including CNC machines, hydraulic tools, and manual equipment, while highlighting their specific applications across industries such as manufacturing, construction, and energy. Furthermore, we will address key factors in supplier vetting, helping buyers assess the reliability and capabilities of potential partners. Cost considerations will also be examined, providing clarity on pricing structures and potential savings.

By empowering B2B buyers with this essential knowledge, this guide not only facilitates smarter purchasing decisions but also enhances operational efficiency, ensuring that businesses can maintain their competitive edge in the global market.

Understanding machine tool repair near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machine Repair | Focus on computer-controlled machines, specialized tools. | Manufacturing, Aerospace, Automotive | Pros: High precision, specialized service. Cons: Can be expensive, requires skilled technicians. |

| Hydraulic Tool Repair | Specialized in hydraulic systems and components. | Construction, Oil & Gas, Marine | Pros: Essential for heavy machinery, often quicker turnaround. Cons: Limited to hydraulic tools. |

| Electrical Tool Repair | Focused on repairing electrical and battery-operated tools. | Construction, Manufacturing, Electrical Services | Pros: Wide range of tools covered, quick repairs. Cons: May require specific parts, which can delay service. |

| General Tool Repair | Covers a broad range of manual and power tools. | General Construction, Maintenance, DIY Projects | Pros: Versatile service, applicable across industries. Cons: May lack specialization for complex machinery. |

| Preventive Maintenance Services | Regular maintenance to prevent breakdowns and extend life. | Manufacturing, Industrial Operations | Pros: Reduces downtime, enhances tool lifespan. Cons: Ongoing costs, requires consistent scheduling. |

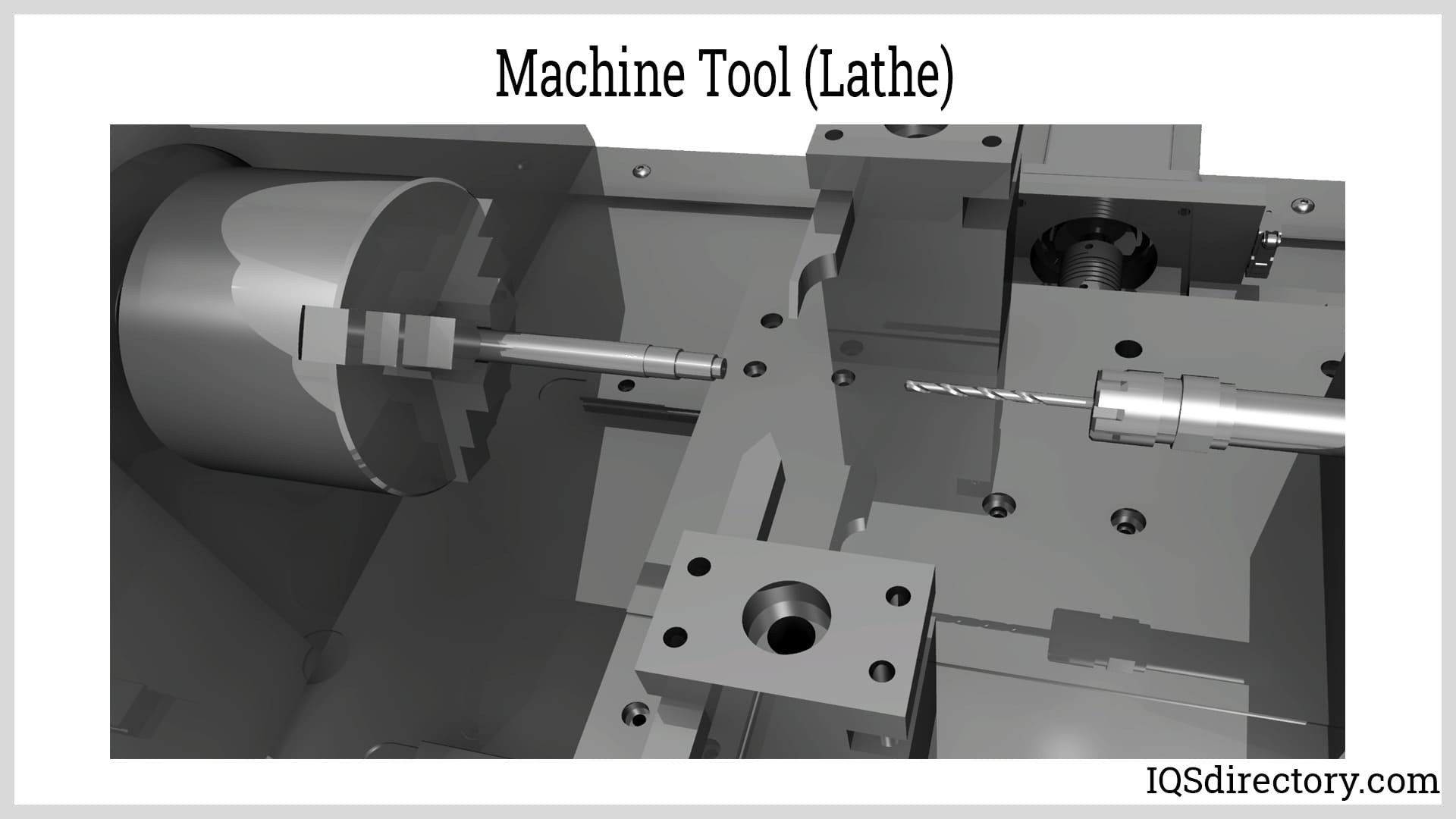

What Are the Key Characteristics of CNC Machine Repair Services?

CNC machine repair services are tailored for computer numerical control machinery, which is critical in industries like manufacturing and aerospace. These services often involve specialized tools and technicians trained in advanced diagnostics and repairs. B2B buyers should consider the technical expertise of the service provider, as well as the availability of replacement parts, which can significantly impact turnaround time and costs.

How Do Hydraulic Tool Repair Services Cater to Specific Industries?

Hydraulic tool repair focuses on the maintenance and repair of hydraulic systems used extensively in construction and oil & gas sectors. This type of repair is crucial for ensuring the safe and efficient operation of heavy machinery. Buyers should evaluate the provider’s experience with specific hydraulic tools and their ability to respond quickly to service requests, as downtime can be costly in these industries.

Why Choose Electrical Tool Repair for Battery-Operated Equipment?

Electrical tool repair services specialize in fixing battery-operated and electrical tools, which are prevalent in construction and manufacturing. These services often include diagnostics for electrical malfunctions and battery replacements. Buyers should assess the range of tools covered, the speed of service, and the availability of OEM parts, as these factors can influence the effectiveness and reliability of repairs.

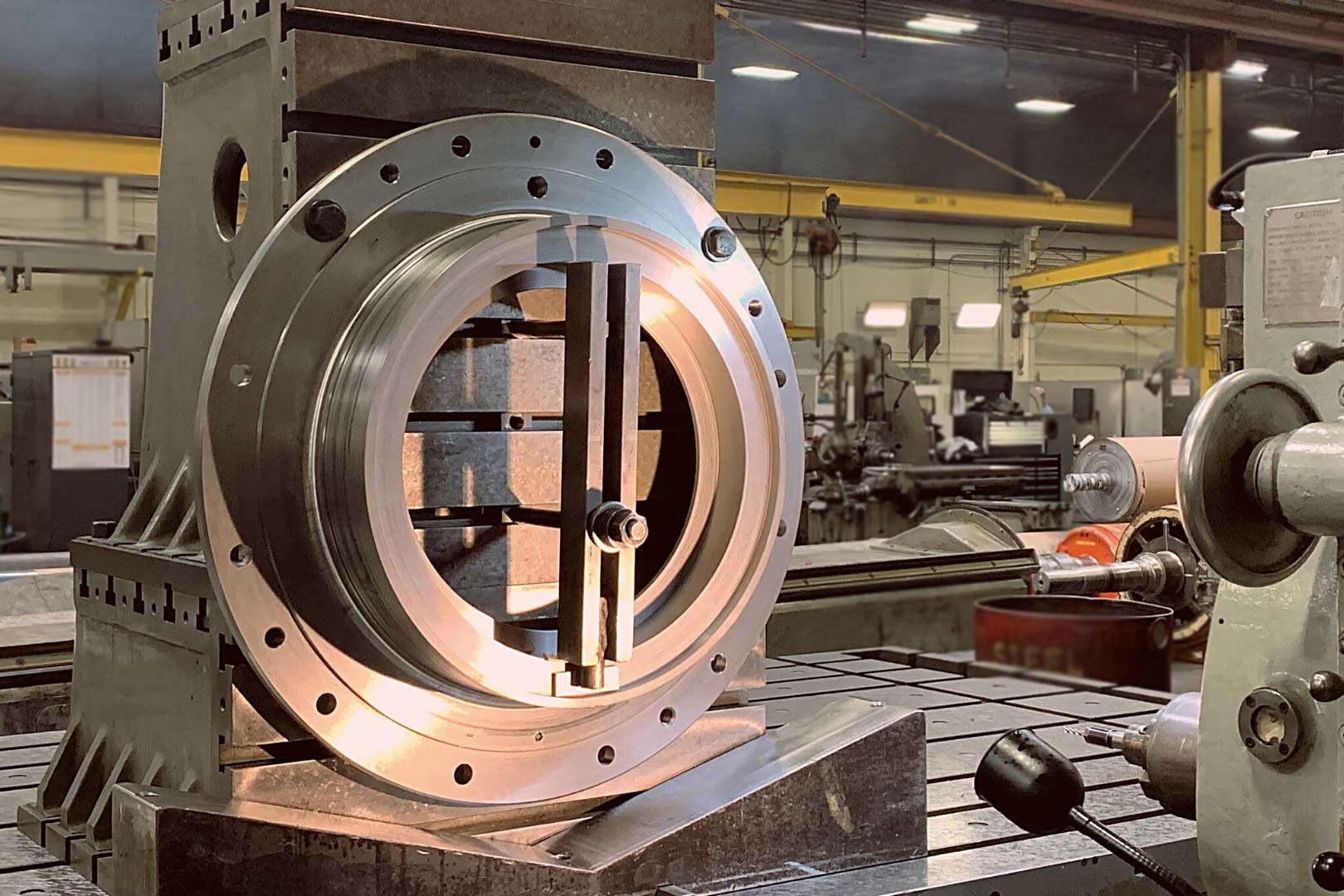

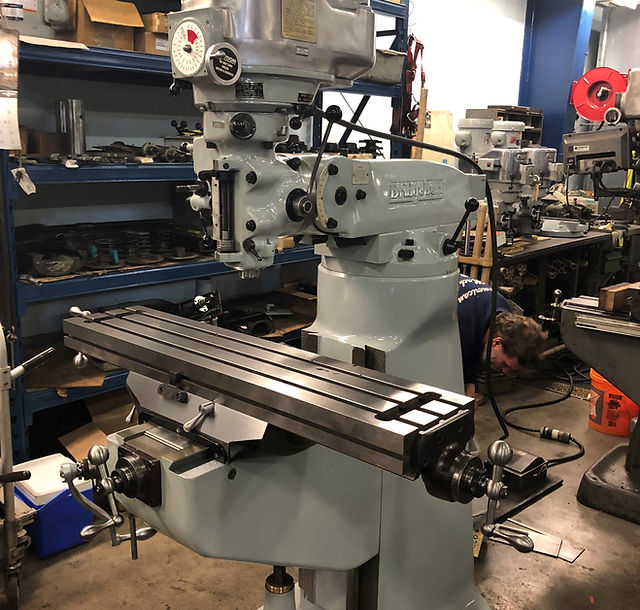

Illustrative image related to machine tool repair near me

What Makes General Tool Repair a Versatile Choice?

General tool repair services encompass a wide variety of manual and power tools, making them suitable for diverse applications across construction and maintenance sectors. This versatility is beneficial for businesses that use various tools but may lack the need for specialized services. Buyers should consider the service provider’s reputation, turnaround times, and the comprehensiveness of their repair offerings to ensure they receive quality service.

How Does Preventive Maintenance Enhance Tool Longevity?

Preventive maintenance services focus on regular check-ups and servicing to prevent tool breakdowns, which is essential for maintaining operational efficiency in industrial settings. This proactive approach can significantly extend the lifespan of tools and reduce unexpected downtimes. B2B buyers should weigh the costs of ongoing maintenance against potential savings from reduced repairs and increased productivity, making it a worthwhile investment in the long run.

Key Industrial Applications of machine tool repair near me

| Industry/Sector | Specific Application of machine tool repair near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machine Repair | Minimizes downtime and enhances production efficiency. | Look for local expertise in CNC systems and quick turnaround times. |

| Oil & Gas | Hydraulic Tool Repair | Ensures operational safety and reliability in harsh environments. | Assess the provider’s experience with specialized hydraulic tools. |

| Construction | Electric and Pneumatic Tool Repair | Reduces costs by extending tool lifespan and performance. | Verify warranty and service agreements for critical tools. |

| Aerospace & Defense | Precision Tool Calibration | Maintains stringent quality standards and compliance. | Seek providers with certification in aerospace standards. |

| Automotive | Machine Tool Maintenance for Fabrication | Enhances product quality and reduces production errors. | Ensure access to OEM parts and specialized technical support. |

How is Machine Tool Repair Used in Manufacturing?

In the manufacturing sector, machine tool repair, particularly for CNC machines, is critical for maintaining productivity. These machines are often the backbone of production lines, and any downtime can lead to significant financial losses. Quick and effective repairs can minimize disruptions, ensuring that operations run smoothly. For international buyers, especially in regions like Africa and South America, sourcing local repair services can reduce shipping times and costs, while also ensuring that technicians are familiar with the specific machines in use.

What are the Benefits of Hydraulic Tool Repair in Oil & Gas?

In the oil and gas industry, hydraulic tools are essential for various applications, from drilling to maintenance. Machine tool repair services that specialize in hydraulic equipment help ensure these tools operate safely and efficiently, especially in challenging environments. Regular maintenance and repair can prevent costly accidents and equipment failures. Buyers should consider repair services with experience in hydraulic systems and the ability to provide timely support to avoid operational delays, particularly in remote locations in the Middle East and Africa.

How Does Tool Repair Impact Construction Operations?

For the construction industry, the performance of electric and pneumatic tools directly affects project timelines and budgets. Machine tool repair services that offer quick turnarounds can significantly enhance operational efficiency by extending the lifespan of tools and maintaining their reliability. When sourcing services, construction firms should prioritize providers who offer warranties and comprehensive service agreements to protect their investments, especially in competitive markets like Europe and South America.

Why is Precision Tool Calibration Important in Aerospace & Defense?

In the aerospace and defense sectors, precision is paramount. Machine tool repair services that focus on calibration ensure that tools meet strict industry standards, which is crucial for safety and compliance. Regular calibration and maintenance can prevent defects that could have catastrophic consequences. Buyers in this sector should seek repair providers with certifications and experience in aerospace standards to ensure that all tools are maintained to the highest specifications.

What Role Does Machine Tool Maintenance Play in Automotive Manufacturing?

Machine tool maintenance is vital for automotive manufacturing, where precision and quality are essential for meeting consumer expectations. Regular repairs and maintenance of fabrication tools can lead to improved product quality and reduced errors in production. Automotive manufacturers should look for repair services that offer access to OEM parts and specialized technical support to ensure that their tools operate at peak performance, thereby maintaining their competitive edge in the global market.

3 Common User Pain Points for ‘machine tool repair near me’ & Their Solutions

Scenario 1: Unexpected Downtime Due to Tool Failures

The Problem: A manufacturing facility in Nigeria experiences an unexpected breakdown of a critical CNC machine. This tool is essential for maintaining production schedules, and the resulting downtime threatens to delay deliveries, disrupt operations, and lead to financial losses. The facility’s managers struggle to find a reliable local repair service that can respond quickly and effectively, leading to frustration and uncertainty.

Illustrative image related to machine tool repair near me

The Solution: To mitigate this challenge, B2B buyers should develop partnerships with local machine tool repair services well in advance of emergencies. Start by conducting thorough research to identify reputable repair providers in your area, ensuring they have experience with your specific machinery and can offer timely service. Establishing a maintenance contract with these service providers can guarantee priority response during emergencies, as well as scheduled preventive maintenance that reduces the likelihood of unexpected failures. Additionally, utilizing an online platform that aggregates local repair services can provide insights into customer reviews and service capabilities, allowing for informed decision-making.

Scenario 2: High Repair Costs and Uncertainty Over Tool Viability

The Problem: A construction firm in Saudi Arabia faces a situation where several hydraulic tools require repair. The repair estimates are high, and the firm is uncertain whether it would be more cost-effective to repair or replace these tools. The lack of transparency regarding the condition of the tools and the repair process adds to their stress, leading to potential delays in project timelines.

The Solution: Buyers should actively engage with repair services that offer detailed diagnostics and transparent repair processes. When selecting a repair provider, request a comprehensive evaluation that includes an itemized quote and an assessment of the tools’ viability. Many reputable services will provide a warranty on repairs, which adds an extra layer of assurance. Furthermore, establishing a long-term relationship with a trusted repair partner can facilitate better pricing and quicker turnaround times. Consider leveraging technology, such as asset tracking systems, to maintain a history of repairs and assessments, ensuring better-informed decisions in the future regarding whether to repair or replace tools.

Scenario 3: Inconsistent Quality of Repair Services

The Problem: An industrial manufacturer in Brazil has had frustrating experiences with varying quality levels of machine tool repair services. Some repairs are done quickly, but the quality often fails to meet industry standards, leading to recurring issues and additional costs. This inconsistency hampers productivity and affects the company’s reputation for reliability.

The Solution: To address this pain point, companies should prioritize finding machine tool repair services that have established quality assurance processes. Look for providers that are certified by recognized industry bodies and have a proven track record of consistent, high-quality repairs. Requesting references and reviews from other businesses in your industry can provide valuable insights into their reliability. Additionally, consider services that offer performance guarantees and follow-up inspections, ensuring that the repairs meet specified standards. By investing in a repair service known for quality, you will not only improve operational efficiency but also reduce the likelihood of future issues, thereby protecting your business’s reputation.

Strategic Material Selection Guide for machine tool repair near me

What Are the Key Materials Used in Machine Tool Repair?

When selecting materials for machine tool repair, it is essential to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and compliance with international standards. Below, we analyze four common materials used in machine tool repair, focusing on their key properties, pros and cons, and considerations for international B2B buyers.

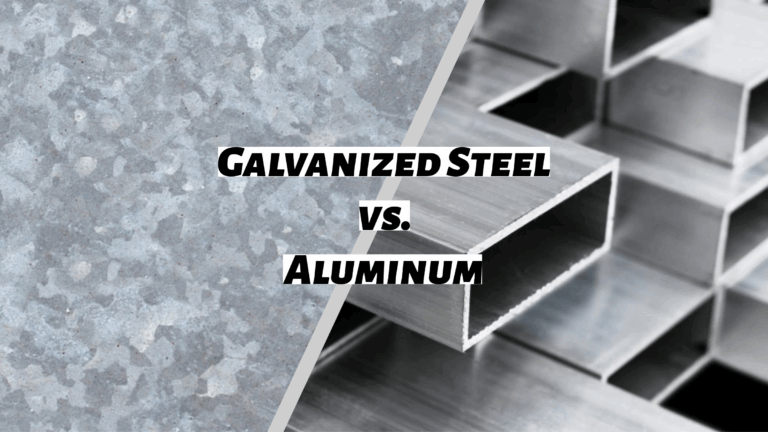

How Does Steel Perform in Machine Tool Repair?

Key Properties: Steel is known for its high tensile strength and durability. It can withstand high temperatures and pressures, making it suitable for various machine tool applications. Additionally, different grades of steel offer varying levels of corrosion resistance.

Pros & Cons: The primary advantage of steel is its strength and ability to handle heavy loads. However, it can be susceptible to rust if not properly treated, which may limit its lifespan in corrosive environments. The manufacturing complexity can vary depending on the steel grade, affecting production costs.

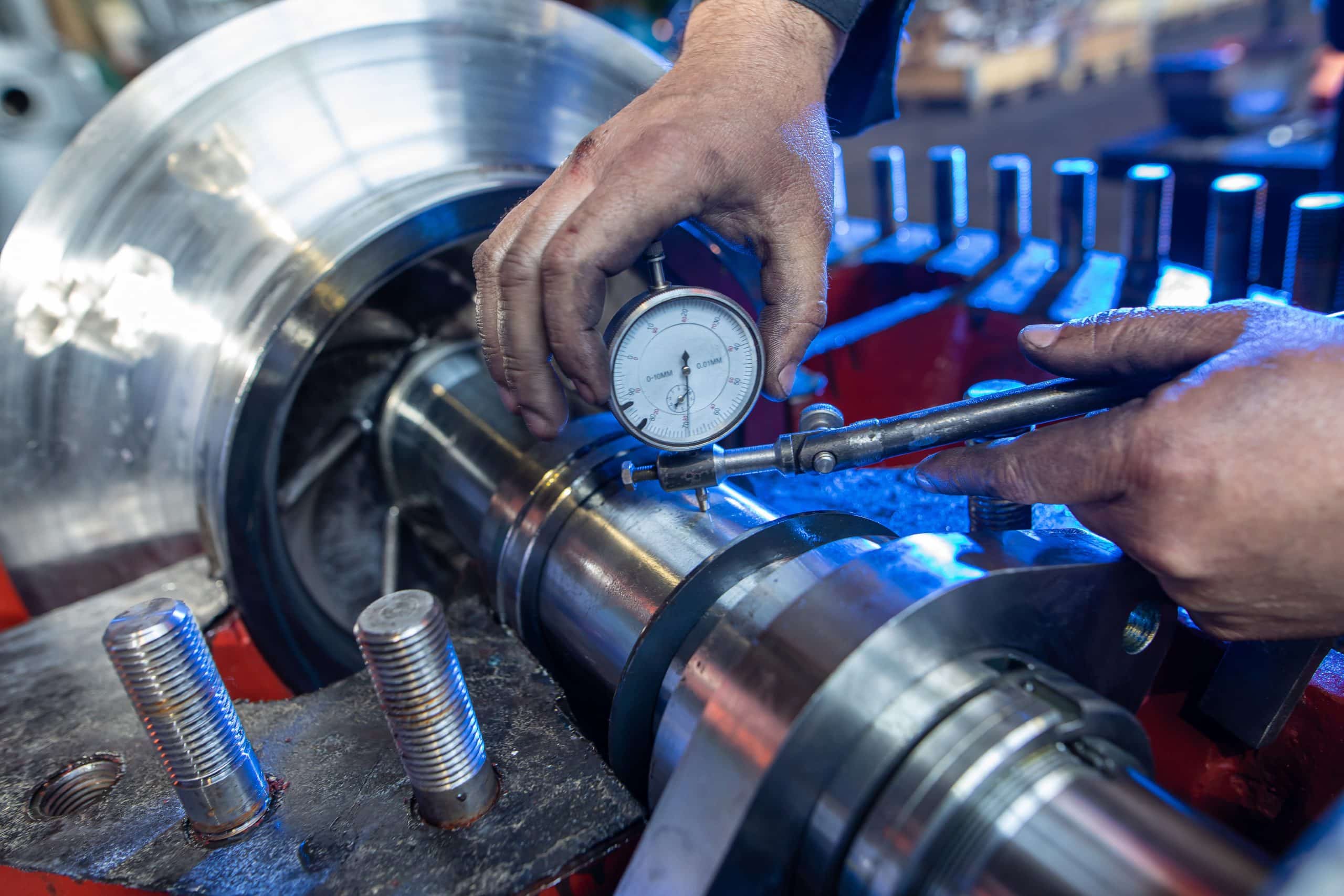

Illustrative image related to machine tool repair near me

Impact on Application: Steel is commonly used for structural components and machine frames. Its compatibility with various media, including oils and coolants, makes it a reliable choice for many industrial applications.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial when sourcing steel. Buyers from regions like Africa and the Middle East should be aware of local regulations regarding material specifications and certifications.

What Are the Advantages of Aluminum in Machine Tool Repair?

Key Properties: Aluminum is lightweight and offers excellent corrosion resistance. It is also a good conductor of heat, which can be beneficial in applications requiring thermal management.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce overall machine weight and improve efficiency. However, aluminum is generally less strong than steel and may not be suitable for high-load applications. Manufacturing processes for aluminum can be more complex, potentially increasing costs.

Impact on Application: Aluminum is often used in components that require a balance of strength and weight, such as housings and brackets. Its compatibility with various coolants and lubricants makes it a versatile choice.

Illustrative image related to machine tool repair near me

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant international standards, such as JIS or ISO, particularly when exporting to regions like Europe and South America.

Why Is Plastic Important in Machine Tool Repair?

Key Properties: Plastics are lightweight, resistant to corrosion, and can be molded into complex shapes. They also offer good insulation properties, making them suitable for electrical applications.

Pros & Cons: The primary advantage of plastic is its versatility and low cost. However, its durability can be a concern, particularly in high-stress applications. Plastics may also have limitations in temperature resistance compared to metals.

Impact on Application: Plastics are often used for non-structural components, such as covers, insulators, and guides. Their chemical resistance makes them suitable for various media, including certain oils and solvents.

Considerations for International Buyers: Compliance with environmental regulations regarding plastic materials is essential, especially in regions with strict recycling laws. Buyers should also consider the availability of specific plastic grades that meet international standards.

How Does Composite Material Enhance Machine Tool Repair?

Key Properties: Composite materials combine different substances to achieve superior strength-to-weight ratios and enhanced durability. They are often resistant to chemicals and corrosion.

Pros & Cons: The key advantage of composites is their ability to outperform traditional materials in specific applications, particularly in terms of weight and resistance to environmental factors. However, they can be more expensive and complex to manufacture, which may deter some buyers.

Impact on Application: Composites are ideal for applications requiring high strength and low weight, such as aerospace components and specialized tooling. Their compatibility with various media makes them suitable for diverse industrial environments.

Illustrative image related to machine tool repair near me

Considerations for International Buyers: Buyers should be aware of the specific certifications required for composite materials, particularly in regulated industries. Understanding the local market’s acceptance of composites is crucial for successful procurement.

Summary Table of Material Selection for Machine Tool Repair

| Material | Typical Use Case for machine tool repair near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, machine frames | High strength and durability | Susceptible to rust | Medium |

| Aluminum | Housings, brackets | Lightweight and corrosion-resistant | Less strength than steel | Medium |

| Plastic | Covers, insulators, guides | Versatile and low cost | Durability concerns in high-stress use | Low |

| Composite | Aerospace components, specialized tooling | Superior strength-to-weight ratio | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides actionable insights for international B2B buyers, helping them make informed decisions when sourcing materials for machine tool repair.

In-depth Look: Manufacturing Processes and Quality Assurance for machine tool repair near me

What Are the Main Stages of Manufacturing Processes in Machine Tool Repair?

The manufacturing processes involved in machine tool repair are critical to ensuring high-quality outcomes. These processes generally encompass four main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to machine tool repair near me

-

Material Preparation: In this initial stage, the tools and components are assessed for damage and wear. Components that are beyond repair are documented, while those that can be salvaged are cleaned and prepped for subsequent stages. This may involve removing rust, grease, and other contaminants to ensure a clean working surface.

-

Forming: This stage involves the actual repair or replacement of damaged components. Techniques such as machining, welding, and laser cutting are common. For instance, CNC machining may be used to create new parts or to restore the dimensions of worn components. Welding can be employed to mend fractures in metal parts, ensuring structural integrity.

-

Assembly: Once the individual components are repaired or newly manufactured, they are assembled back together. This requires precision to ensure that all parts fit correctly and function as intended. The assembly process may involve the use of jigs or fixtures to maintain alignment during the process.

-

Finishing: The final stage involves surface treatment to enhance durability and performance. This may include painting, coating, or polishing the repaired tools. Finishing not only improves aesthetics but also provides a protective layer against environmental factors such as moisture and corrosion.

How Is Quality Assurance Implemented in Machine Tool Repair?

Quality assurance (QA) is an essential aspect of the machine tool repair process, ensuring that repairs meet specific standards and perform reliably. This involves adhering to international standards such as ISO 9001 and industry-specific regulations like CE and API.

-

International Standards: ISO 9001 is a global benchmark for quality management systems, focusing on consistent quality in products and services. Compliance with ISO 9001 can help B2B buyers verify that a repair service follows systematic processes to enhance customer satisfaction.

-

Industry-Specific Standards: Depending on the industry, other certifications may be relevant. For example, the CE marking indicates conformity with health, safety, and environmental protection standards within the European Economic Area (EEA). API standards are crucial in the oil and gas sector, ensuring that tools meet specific performance and safety criteria.

What Are the Key QC Checkpoints in Machine Tool Repair?

Quality control (QC) checkpoints are integral in monitoring the repair process to ensure that each stage meets the required standards. The common QC checkpoints include:

-

Incoming Quality Control (IQC): This checkpoint occurs when the tools arrive at the repair facility. An initial inspection is conducted to assess the condition of the tools and components before any work begins. This step may include measuring dimensions and checking for visible damage.

-

In-Process Quality Control (IPQC): Throughout the repair process, ongoing inspections are performed to ensure compliance with specifications. This includes monitoring the machining processes, welding quality, and assembly accuracy. Real-time adjustments can be made to address any issues immediately.

-

Final Quality Control (FQC): After repairs are completed, a thorough inspection is conducted before the tools are returned to the client. This includes functional testing and performance evaluations to confirm that the tools operate as intended. Documentation of these tests is often provided to the buyer as assurance of quality.

What Common Testing Methods Are Used in Machine Tool Repair?

Testing methods play a vital role in validating the integrity and performance of repaired tools. Common testing methods include:

-

Functional Testing: Ensures that the repaired tool operates according to its specifications. This may involve running the tool under load conditions similar to its intended use.

-

Dimensional Testing: Measurements are taken using precision tools such as calipers and micrometers to ensure that all components meet required tolerances.

-

Nondestructive Testing (NDT): Techniques such as ultrasonic testing, dye penetrant testing, and magnetic particle testing are used to detect internal flaws without damaging the components.

-

Load Testing: Particularly relevant for lifting equipment, this testing ensures that tools can handle their rated loads without failure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of machine tool repair suppliers is crucial. Here are several actionable steps:

-

Conduct Audits: Request to conduct an audit of the repair facility. This provides firsthand insight into the processes, equipment, and quality assurance practices in place.

-

Review Quality Reports: Ask suppliers to provide quality assurance documentation, including inspection reports and compliance certificates. These documents should outline their adherence to international and industry-specific standards.

-

Engage Third-Party Inspectors: Consider hiring third-party inspection agencies to evaluate the repair facility and its processes. These independent assessments can provide an objective view of the supplier’s quality management systems.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing machine tool repair services internationally, buyers must be aware of specific nuances related to quality control and certification. Factors to consider include:

-

Compliance with Local Regulations: Different countries may have varying regulations governing tool repair and safety standards. Buyers should ensure that their suppliers comply with both local and international standards.

-

Language and Documentation: Ensure that quality documentation is available in a language that is understood by all stakeholders involved in the procurement process. This reduces the risk of misunderstandings related to quality expectations.

-

Cultural Differences: Be mindful of cultural practices that may affect business operations. Understanding the local context can improve communication and foster stronger supplier relationships.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting machine tool repair services. This knowledge not only enhances procurement efficiency but also ensures the reliability and longevity of their tools.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine tool repair near me’

In today’s competitive industrial landscape, sourcing reliable machine tool repair services is critical for maintaining operational efficiency. This guide provides a structured checklist for B2B buyers seeking to procure machine tool repair services in their vicinity. By following these steps, you can ensure that your tools are serviced by qualified professionals, minimizing downtime and maximizing productivity.

Step 1: Identify Your Repair Needs

Understanding the specific repairs required for your machine tools is the first step in the sourcing process. Take inventory of the tools that need servicing and categorize them by type—whether they are CNC machines, manual tools, or specialized equipment. This clarity will help you communicate effectively with potential repair providers and ensure they have the necessary expertise.

Illustrative image related to machine tool repair near me

Step 2: Research Local Providers

Conduct thorough research to identify machine tool repair companies in your area. Utilize online directories, industry forums, and local business listings to compile a list of potential suppliers. Focus on those with a solid reputation and positive customer reviews, as they are more likely to provide reliable service.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for evidence of expertise in your specific type of tools and inquire about their experience with similar projects to ensure they can meet your needs effectively.

Step 4: Verify Certifications and Compliance

Ensure that the repair service providers you are considering are certified and compliant with industry standards. Certifications can indicate that a company adheres to best practices in safety and quality. Additionally, inquire about warranties on repairs, which can provide peace of mind regarding the durability and reliability of the services rendered.

Step 5: Assess Turnaround Times and Service Efficiency

Understanding the expected turnaround time for repairs is essential for planning your operations. Ask potential suppliers about their average repair timelines and any expedited service options they may offer. A quick turnaround can significantly reduce downtime and keep your operations running smoothly.

Step 6: Inquire About Maintenance Contracts

Consider whether the repair provider offers maintenance contracts for ongoing support. Such agreements can facilitate regular inspections and preventive maintenance, helping to extend the lifespan of your tools and reduce the likelihood of costly breakdowns. Evaluate the terms of these contracts carefully to ensure they align with your operational needs.

Illustrative image related to machine tool repair near me

Step 7: Compare Quotes and Finalize the Supplier

Once you’ve narrowed down your options, request detailed quotes from the shortlisted suppliers. Compare not just the prices, but also the services included, warranties offered, and any additional fees. Make your decision based on a combination of value, service quality, and reliability to ensure you partner with the best supplier for your machine tool repair needs.

By following this structured checklist, you can streamline your sourcing process and choose the right machine tool repair provider to maintain your equipment effectively. This proactive approach can lead to significant cost savings and improved operational efficiency.

Comprehensive Cost and Pricing Analysis for machine tool repair near me Sourcing

What Are the Key Cost Components in Machine Tool Repair Services?

When evaluating the costs associated with machine tool repair, several key components come into play. Understanding these can help international B2B buyers make informed decisions.

-

Materials: The cost of replacement parts is often a significant factor. This includes OEM (Original Equipment Manufacturer) parts, which tend to be more expensive but provide assurance of quality and compatibility. Buyers should consider the balance between cost and quality, as cheaper alternatives may lead to increased failure rates.

-

Labor: Labor costs can vary widely depending on the complexity of the repair and the expertise required. Skilled technicians, especially those with specialized training in CNC or other complex machinery, may command higher wages. It’s essential for buyers to inquire about the technician’s qualifications and experience level.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, equipment maintenance, and administrative expenses. Buyers should consider how these overheads are reflected in the pricing structure of repair services.

-

Tooling: The cost of specialized tools necessary for repairs can also influence pricing. Some repair centers may have invested heavily in advanced diagnostic and repair tools, which can justify higher service rates.

-

Quality Control (QC): Implementing stringent QC processes adds to the overall cost but ensures that repairs meet safety and performance standards. Buyers should ask about the QC measures employed by repair service providers.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Understanding the logistics involved in transporting machinery for repairs can help avoid unexpected expenses.

-

Margin: Finally, service providers will include a profit margin in their pricing. This can vary by region and service provider, influenced by competition and market demand.

How Do Price Influencers Affect Machine Tool Repair Costs?

Several factors can significantly influence the pricing of machine tool repair services:

-

Volume and Minimum Order Quantity (MOQ): Bulk repairs may attract discounts, making it advantageous for companies with multiple machines needing service. Establishing a long-term relationship with a service provider can also lead to better pricing.

-

Specifications and Customization: Unique machinery or specific repair requirements can lead to increased costs. Custom repairs necessitate additional time and expertise, so clear communication about needs is essential.

-

Materials and Quality Certifications: The use of high-quality materials or certified components can elevate costs but often results in longer-lasting repairs. Buyers should weigh the benefits of investing in quality against the immediate financial impact.

-

Supplier Factors: The reputation and experience of the repair service can affect pricing. Established providers with a proven track record may charge more but offer reliability that mitigates future costs.

-

Incoterms: Understanding shipping terms and responsibilities can help buyers manage logistics costs. For international transactions, clarity on who bears the shipping costs can prevent surprises.

What Negotiation Strategies Can Help Reduce Costs for International Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic negotiation can yield significant savings:

-

Establish Long-Term Partnerships: Building a relationship with a repair service provider can lead to better pricing and priority service. Consider contracts that include regular maintenance to lock in favorable rates.

-

Inquire About Discounts: Don’t hesitate to ask for volume discounts or loyalty programs. Many service providers are willing to negotiate, especially if they see the potential for ongoing business.

-

Evaluate Total Cost of Ownership (TCO): Consider the long-term implications of repair costs, including downtime, shipping, and potential rework. Sometimes, opting for a higher initial cost can lead to lower TCO.

-

Understand Pricing Nuances: Be aware that different regions may have varying pricing structures influenced by local economies, labor costs, and availability of parts. Understanding these nuances can aid in negotiating better deals.

Conclusion: What Should International Buyers Keep in Mind?

For B2B buyers engaging in machine tool repair services, a thorough understanding of cost structures, price influencers, and negotiation strategies is essential. While indicative pricing can provide a baseline, it’s crucial to conduct due diligence and seek multiple quotes to ensure competitive rates. By focusing on these aspects, buyers can effectively manage their repair expenses and enhance the operational efficiency of their machinery.

Illustrative image related to machine tool repair near me

Alternatives Analysis: Comparing machine tool repair near me With Other Solutions

Understanding Alternative Solutions to Machine Tool Repair

In the dynamic world of manufacturing and industrial operations, efficient tool management is crucial. While “machine tool repair near me” offers a localized solution for businesses needing quick repairs, there are alternative methods that can also address tool maintenance and functionality. These alternatives can be evaluated based on various aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Machine Tool Repair Near Me | Tool Replacement Program | Equipment Rental Services |

|---|---|---|---|

| Performance | High-quality repairs by local experts | New tools with guaranteed performance | Varies based on rental equipment quality |

| Cost | Moderate repair costs, potential savings vs. new purchase | Higher initial investment for new tools | Flexible costs, pay-per-use model |

| Ease of Implementation | Quick turnaround with local service | Straightforward, but requires upfront planning | Immediate availability, but depends on stock |

| Maintenance | Regular maintenance contracts available | Minimal, as new tools come with warranties | Maintenance handled by rental company |

| Best Use Case | When tools are still valuable but need repairs | For outdated or frequently failing tools | For short-term projects or trials of new equipment |

What Are the Pros and Cons of Tool Replacement Programs?

Tool replacement programs provide businesses with the option to swap out old tools for new ones. This solution is particularly beneficial when tools have reached the end of their useful life or are no longer efficient. The primary advantage is that new tools typically come with warranties, ensuring reliability and performance. However, the initial investment can be significant, and companies must plan for the costs associated with replacing tools in their inventory.

How Do Equipment Rental Services Compare?

Equipment rental services offer an appealing alternative for businesses that require tools for a limited time or specific projects. This model allows companies to access high-quality machinery without the burden of ownership, which includes maintenance and storage costs. Rentals can be arranged quickly, making it easy to meet immediate project needs. On the downside, rental costs can accumulate over time, and the equipment’s availability may fluctuate based on demand.

Making the Right Choice for Your Business Needs

When determining the best solution for machine tool management, B2B buyers must consider their specific needs, budget constraints, and operational goals. If tools are still functional and valuable, localized repair services can extend their life at a moderate cost. Conversely, businesses that frequently experience tool failures might benefit from a replacement program. For projects with variable tool requirements, rental services can provide flexibility without the long-term financial commitment. Ultimately, the right choice will depend on the unique circumstances of each operation and its long-term strategy.

Illustrative image related to machine tool repair near me

Essential Technical Properties and Trade Terminology for machine tool repair near me

What Are the Key Technical Properties in Machine Tool Repair?

When considering machine tool repair, understanding critical technical specifications can significantly influence operational efficiency and cost-effectiveness. Here are some essential properties:

1. Material Grade

Material grade refers to the classification of materials used in tool manufacturing based on their mechanical properties. High-grade materials provide better durability and resistance to wear, which is crucial for maintaining tool functionality. For B2B buyers, selecting tools made from superior materials ensures longevity and reduced replacement costs, ultimately enhancing productivity.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension of a tool. In the context of machine tools, maintaining tight tolerances is vital for precision engineering applications. For businesses, understanding tolerance levels helps ensure that repaired tools meet operational specifications, which is critical for quality assurance and reducing rework.

Illustrative image related to machine tool repair near me

3. Load Capacity

Load capacity indicates the maximum weight or force a tool can handle safely. This property is particularly important for hydraulic and mechanical tools, as exceeding load capacity can lead to tool failure or accidents. B2B buyers must assess load capacity to ensure tools can perform their intended functions without risking safety or efficiency.

4. Power Rating

Power rating measures the tool’s output capability, typically expressed in watts or horsepower. It directly correlates to the tool’s performance and operational speed. For businesses, selecting tools with appropriate power ratings ensures they meet production demands and minimize downtime during repair or maintenance activities.

5. Warranty Period

The warranty period is a commitment from the manufacturer or repair service regarding the reliability and performance of the repaired tool. A longer warranty often indicates confidence in the quality of repair work. B2B buyers should consider warranty terms as they provide a safety net against unexpected failures, thereby protecting investment.

Illustrative image related to machine tool repair near me

What Are Common Trade Terms in Machine Tool Repair?

Familiarity with industry jargon can enhance communication and decision-making in machine tool repair. Here are some critical terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In machine tool repair, understanding OEM components ensures that replacement parts are of high quality and compatible with existing machinery, which is essential for maintaining operational integrity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects purchasing decisions and inventory management. Understanding MOQ helps in negotiating better deals, especially when sourcing replacement parts or tools for large-scale operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific services or products. For businesses seeking machine tool repair, submitting an RFQ can facilitate competitive bidding and help secure the best prices and service conditions, thereby optimizing repair budgets.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. For B2B buyers in regions like Africa or South America importing machine tools, understanding these terms is vital for clarifying shipping costs, risks, and delivery responsibilities, ultimately streamlining the procurement process.

Illustrative image related to machine tool repair near me

5. Calibration

Calibration involves adjusting tools and equipment to ensure their accuracy and performance meet specified standards. This process is essential in machine tool repair to maintain precision and operational reliability. B2B buyers should prioritize calibration services to ensure tools deliver consistent results and comply with industry standards.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions regarding machine tool repair, ensuring efficient operations and optimal investment returns.

Navigating Market Dynamics and Sourcing Trends in the machine tool repair near me Sector

What Are the Key Market Dynamics and Trends in Machine Tool Repair?

The global machine tool repair market is witnessing significant growth driven by advancements in technology, increasing automation, and the need for improved operational efficiency. As industries across Africa, South America, the Middle East, and Europe continue to modernize, the demand for reliable and efficient machine tool repair services is surging. The rise of Industry 4.0 and smart manufacturing is fostering a need for predictive maintenance solutions, which allow companies to anticipate equipment failures before they occur, reducing downtime and associated costs.

Emerging technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and advanced analytics are becoming integral to machine tool repair. These technologies facilitate real-time monitoring of equipment health, enabling proactive maintenance and enhancing the lifespan of tools. Furthermore, international B2B buyers are increasingly favoring suppliers that offer comprehensive service packages, including asset tracking and compliance management, which streamline their operations and improve transparency.

Another critical trend is the shift towards localized sourcing. Buyers are seeking repair services within their geographical vicinity to minimize logistics costs and turnaround times. In regions like Nigeria and Saudi Arabia, where local manufacturing is burgeoning, this trend is particularly pronounced, as companies prioritize partnerships with local service providers for quick and efficient tool maintenance.

Illustrative image related to machine tool repair near me

How Is Sustainability Impacting the Machine Tool Repair Sector?

Sustainability has become a cornerstone of modern B2B practices, and the machine tool repair sector is no exception. International buyers are increasingly aware of the environmental impact of their operations, prompting a shift towards more sustainable practices. Companies are now prioritizing suppliers that adhere to ethical sourcing and sustainable repair methods, which not only minimize waste but also align with global sustainability goals.

The use of eco-friendly materials and processes in tool repair, such as biodegradable lubricants and energy-efficient machinery, is gaining traction. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming critical benchmarks for suppliers. Buyers are encouraged to seek out repair services that are transparent about their sustainability practices and can demonstrate a commitment to reducing their carbon footprint.

Moreover, the trend towards recycling and refurbishing tools is reshaping the market. By opting for repair over replacement, businesses can significantly reduce waste and conserve resources. This not only enhances the sustainability of their operations but also provides a cost-effective solution to maintaining their machinery.

What Is the Historical Context of Machine Tool Repair?

The evolution of machine tool repair can be traced back to the industrial revolution, when the advent of mechanized production necessitated the establishment of maintenance practices for heavy machinery. Initially, repairs were rudimentary and often involved manual labor without the aid of sophisticated tools or techniques. As industries expanded, particularly in the 20th century, the demand for specialized repair services grew, leading to the emergence of dedicated repair shops.

With the introduction of computerized systems and automation in the late 20th century, machine tool repair began to incorporate more advanced diagnostics and repair methodologies. This evolution paved the way for the modern practices we see today, characterized by a focus on efficiency, precision, and sustainability. The current landscape reflects a culmination of these historical advancements, with an emphasis on leveraging technology to enhance service delivery and meet the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of machine tool repair near me

-

How do I identify a reliable machine tool repair service near me?

To identify a reliable machine tool repair service, start by researching local providers online and reading customer reviews. Look for companies with industry certifications and experience in repairing the specific types of machines you use. It’s also beneficial to request quotes and inquire about warranties on repairs. A trustworthy provider will be transparent about their processes and provide detailed estimates. Additionally, consider their response time for urgent repairs, as prompt service is crucial in minimizing downtime. -

What are the key factors to consider when selecting a machine tool repair provider?

When selecting a machine tool repair provider, consider their expertise in your specific machine types and the range of services offered. Evaluate their reputation through customer testimonials and case studies, focusing on their reliability and quality of work. Ensure they provide warranties on repairs and have a clear pricing structure. It’s also important to check their turnaround time for repairs, as well as their ability to source OEM parts, ensuring your tools maintain optimal performance. -

What types of machine tools can typically be repaired?

Most machine tool repair services handle a wide variety of equipment, including CNC machines, lathes, milling machines, and fabrication tools. They often specialize in both mechanical and electrical repairs, ensuring comprehensive support for your machinery. It’s essential to confirm that the repair service has experience with your specific models and brands, as some may require specialized knowledge or parts for effective repairs. -

How does international shipping work for machine tool repairs?

International shipping for machine tool repairs involves several steps. First, you’ll need to coordinate with the repair service to ensure they can handle international logistics. They will often provide guidance on shipping methods and costs. Ensure that you understand any customs regulations and duties applicable to your tools. It’s advisable to use a shipping service that offers tracking and insurance to protect your investment during transit. -

What are the typical payment terms for machine tool repair services?

Payment terms for machine tool repair services can vary widely. Some providers may require a deposit upfront, while others may allow payment upon completion of the work. It’s important to clarify these terms before proceeding. Additionally, inquire about any financing options or payment plans that may be available, especially if the repair costs are significant. Understanding the payment process can help avoid any surprises and ensure a smooth transaction. -

Can I customize the repair services to suit my specific needs?

Yes, many machine tool repair services offer customizable options to cater to your specific needs. You can discuss your requirements with the provider, such as expedited repair timelines or particular maintenance procedures. Some companies may also offer preventive maintenance contracts tailored to your operational schedule, helping you reduce unexpected breakdowns and prolong the lifespan of your machinery. -

What quality assurance measures should I expect from a machine tool repair service?

A reputable machine tool repair service should have strict quality assurance measures in place. This includes thorough inspections of the tools before and after repairs, adherence to OEM specifications, and testing equipment to ensure it operates correctly. Look for providers who offer warranties on their repairs, as this indicates confidence in their workmanship. Additionally, inquire about their procedures for tracking repairs and maintaining documentation for compliance and auditing purposes. -

What logistics support can I expect when using a machine tool repair service?

Logistics support from a machine tool repair service often includes pickup and delivery options, making the process convenient for your business. Some providers may offer to handle all shipping logistics, including packaging and customs clearance for international clients. It’s beneficial to confirm these services in advance, as they can significantly reduce downtime. Additionally, ask about their tracking systems, which allow you to monitor the progress of your repairs and ensure timely delivery.

Top 7 Machine Tool Repair Near Me Manufacturers & Suppliers List

1. Yelp – Best Machine Shops

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Machine Shops, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mechamatic – Machine Tool Parts & Service

Domain: mechamatic.com

Registered: 2015 (10 years)

Introduction: Mechamatic provides parts, service, and preventive maintenance for machine tools and manufacturing equipment. They serve the OKC metro and surrounding communities up to 2 hours from their headquarters in Tuttle, OK. Their clientele includes manufacturers, job shops, fabricators, and various industries requiring technical skills and locally stocked parts. The service rate for 2023 is $150/hr with a…

3. The Werks C&C – Machine Maintenance & Repair Services

Domain: thewerkscandc.com

Registered: 2002 (23 years)

Introduction: The Werks C&C Inc. offers a range of services including machine maintenance and refurbishing, reverse part engineering, manual machining services, and full-service machine repair for businesses and home machine shops across Arizona. They provide repair services for gearboxes, hydraulic systems, machine frames, mills, lathes, and rollformers, as well as Genie and Sumner material lift sales and repa…

4. Hillary Machinery – CNC Machine Tools & Repair Services

Domain: hillarymachinery.com

Registered: 2011 (14 years)

Introduction: Hillary Machinery offers a wide range of CNC machine tools and repair services in Tulsa and Oklahoma City. Key product categories include:

– Turning Centers & CNC Lathes: 2-Axis CNC Lathes, 3-Axis Live Tool CNC Lathes, Multi-Axis CNC Lathes, Multi-Spindle Multi-Turret Vertical Turning Lathes, Automated Turning Centers.

– Machining Centers & CNC Mills: Vertical Machining Centers, Horizontal Mac…

5. Martin Supply – Tool Repair Services

Domain: martinsupply.com

Registered: 1996 (29 years)

Introduction: Tool Repair Services offered by Martin Supply include servicing and repairing air/pneumatic, electric, and hydraulic tools. They are an authorized service center for several leading tool brands, providing direct access to manufacturers for parts and support. Customers can drop off tools for repair or schedule pickups at their site. The service covers various brands such as Ingersoll-Rand, Chicago …

6. Prime Machine – Machine Tool Repair & Calibration

Domain: primemachine.com

Registered: 1997 (28 years)

Introduction: Machine Tool Repair and Calibration services offered by Prime Machine, Inc. include skilled craftsmen and modern tools for complete rebuilds. Services include vibration analysis, ball bar measurements for checking machine encoders and drives, and laser trackers for measuring overall machine geometry. Technicians are trained in scraping ways, setting horizontal tables on newly ground ways, and adju…

7. Machine Tool Repair – CNC & Manual Equipment Services

Domain: machinetoolrepairservice.net

Registered: 2006 (19 years)

Introduction: MACHINE TOOL REPAIR, LLC offers service for CNC Machine Repair and Manual Equipment needs. They are based in Hazel Green, AL, and provide services throughout the Southeastern United States. Key offerings include installations, emergency repairs, scheduled repairs, preventive maintenance, draw force analysis, and ball bar analysis. They service various machine brands including Okuma, Mazak, Mori Se…

Strategic Sourcing Conclusion and Outlook for machine tool repair near me

In conclusion, the importance of strategic sourcing for machine tool repair cannot be overstated, especially for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe. By engaging with reputable repair services, businesses can significantly reduce downtime and repair costs while enhancing operational efficiency. The diverse range of services available, from preventive maintenance to asset tracking, allows companies to tailor their sourcing strategy to meet specific needs and ensure compliance with industry standards.

Moreover, selecting local repair partners can streamline logistics and improve turnaround times, ultimately leading to better resource management. As industries across the globe continue to evolve, investing in reliable machine tool repair services will be pivotal in maintaining competitive advantage.

Illustrative image related to machine tool repair near me

Looking ahead, B2B buyers are encouraged to explore local and regional repair solutions that align with their operational requirements. Establishing long-term partnerships with trusted repair service providers will not only enhance productivity but also foster innovation within your manufacturing processes. Begin your strategic sourcing journey today and unlock the full potential of your machinery assets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.