Choosing Your Machine Guards: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for machine guards

In today’s rapidly evolving industrial landscape, sourcing effective machine guards poses a significant challenge for international B2B buyers. Ensuring the safety of personnel while complying with varying regional regulations—especially in markets like Africa, South America, the Middle East, and Europe—requires a nuanced understanding of both local and international standards. This guide serves as a comprehensive resource, delving into the myriad types of machine guards available, their diverse applications across industries, and critical factors for supplier vetting.

From fixed guards to presence-sensing devices, we explore the unique features and benefits of each type, providing insights into how they can be tailored to meet specific operational needs. Additionally, we address cost considerations and strategies for maximizing investment in safety equipment. By equipping B2B buyers with the knowledge to navigate supplier options and regulatory requirements, this guide empowers businesses to make informed purchasing decisions that not only protect their workforce but also enhance overall operational efficiency.

Whether you’re based in Nigeria, Saudi Arabia, or anywhere in Europe, understanding the global market for machine guards is essential for maintaining a safe and compliant work environment. Join us as we unravel the complexities of machine guarding solutions, enabling you to safeguard what matters most—your employees and your business.

Understanding machine guards Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Machine Guards | Permanently attached, robust materials, minimal access need | Manufacturing, assembly lines | Pros: Low maintenance, reliable safety. Cons: Limited access for adjustments. |

| Interlocked Machine Guards | Automatically shuts down machinery when opened | Maintenance-heavy operations, loading areas | Pros: Enhanced safety, easy access. Cons: Potential downtime during maintenance. |

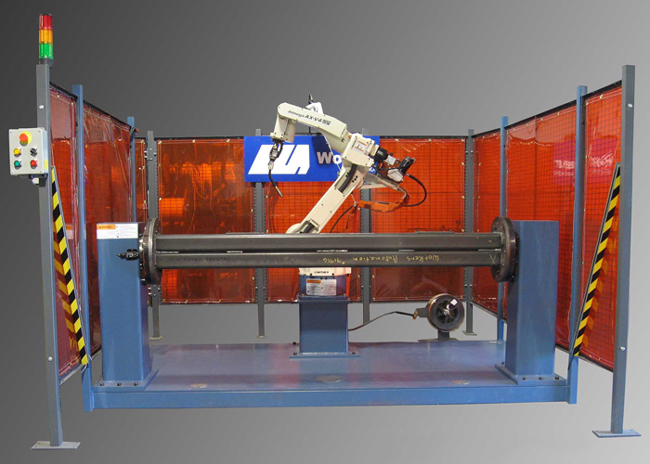

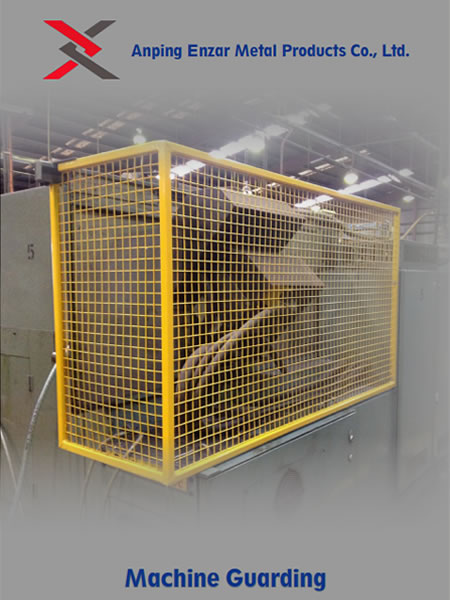

| Perimeter Machine Guards | Encloses entire work area with barriers or fences | Robotic work cells, multi-machine setups | Pros: Comprehensive safety, reduces unauthorized access. Cons: Requires more space and installation effort. |

| Presence-Sensing Machine Guards | Utilizes sensors to detect nearby personnel or objects | Automated systems, high-risk environments | Pros: Immediate response to hazards, reduces human error. Cons: Sensor malfunctions can lead to safety gaps. |

| Power Transmission Guards | Covers moving parts like belts and gears | Heavy machinery, automotive, mining sectors | Pros: Protects against entanglement, enhances worker safety. Cons: May need regular inspection and maintenance. |

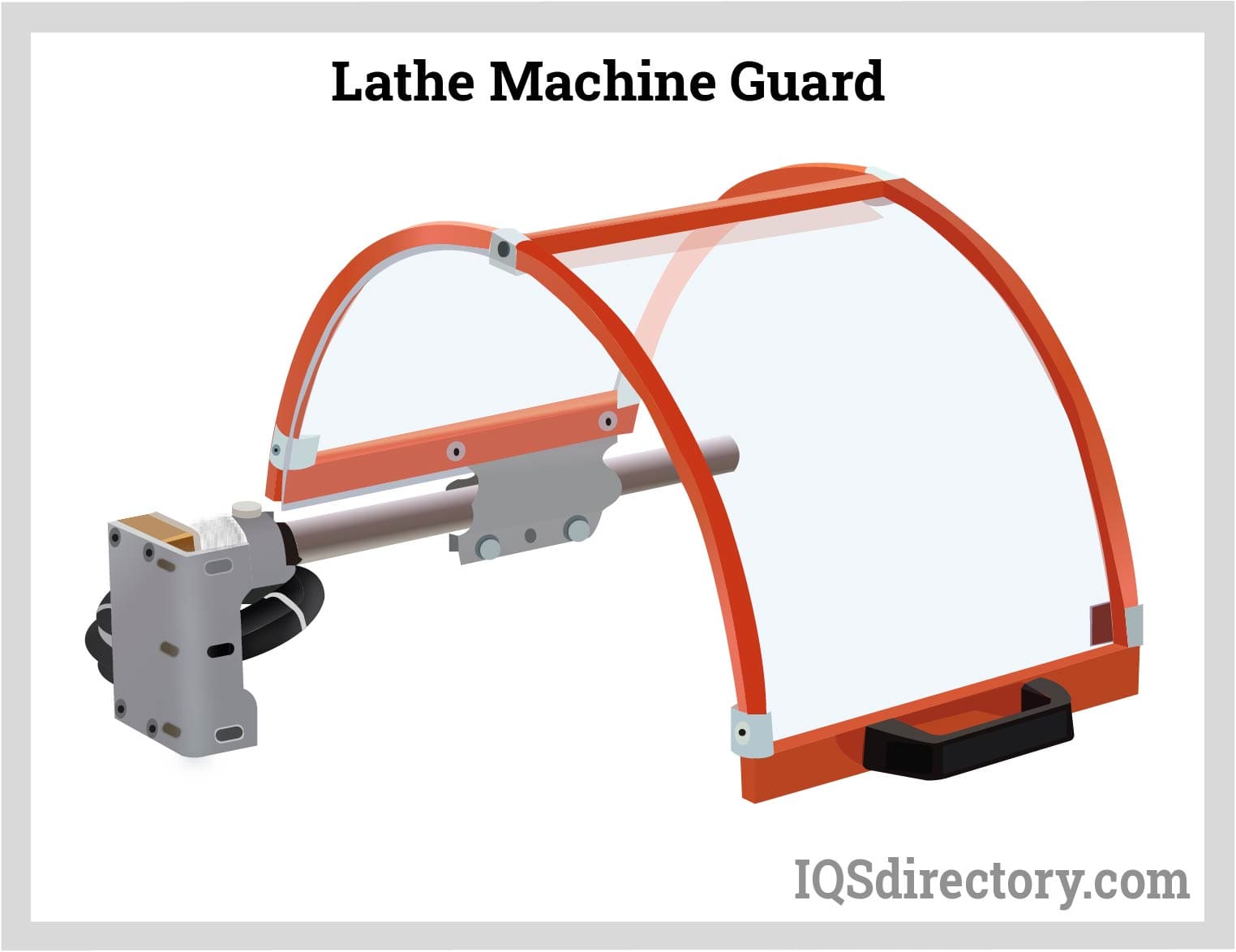

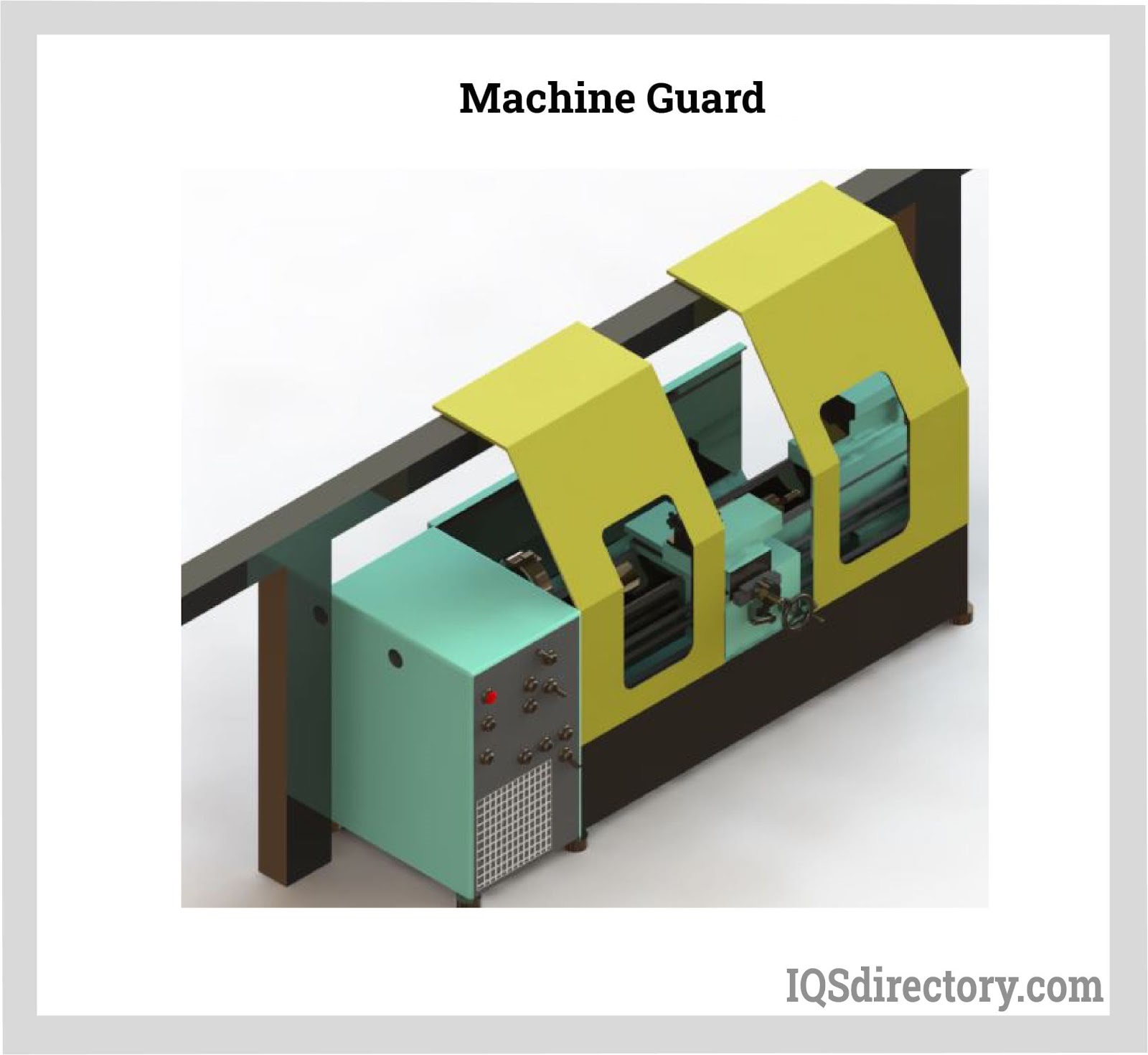

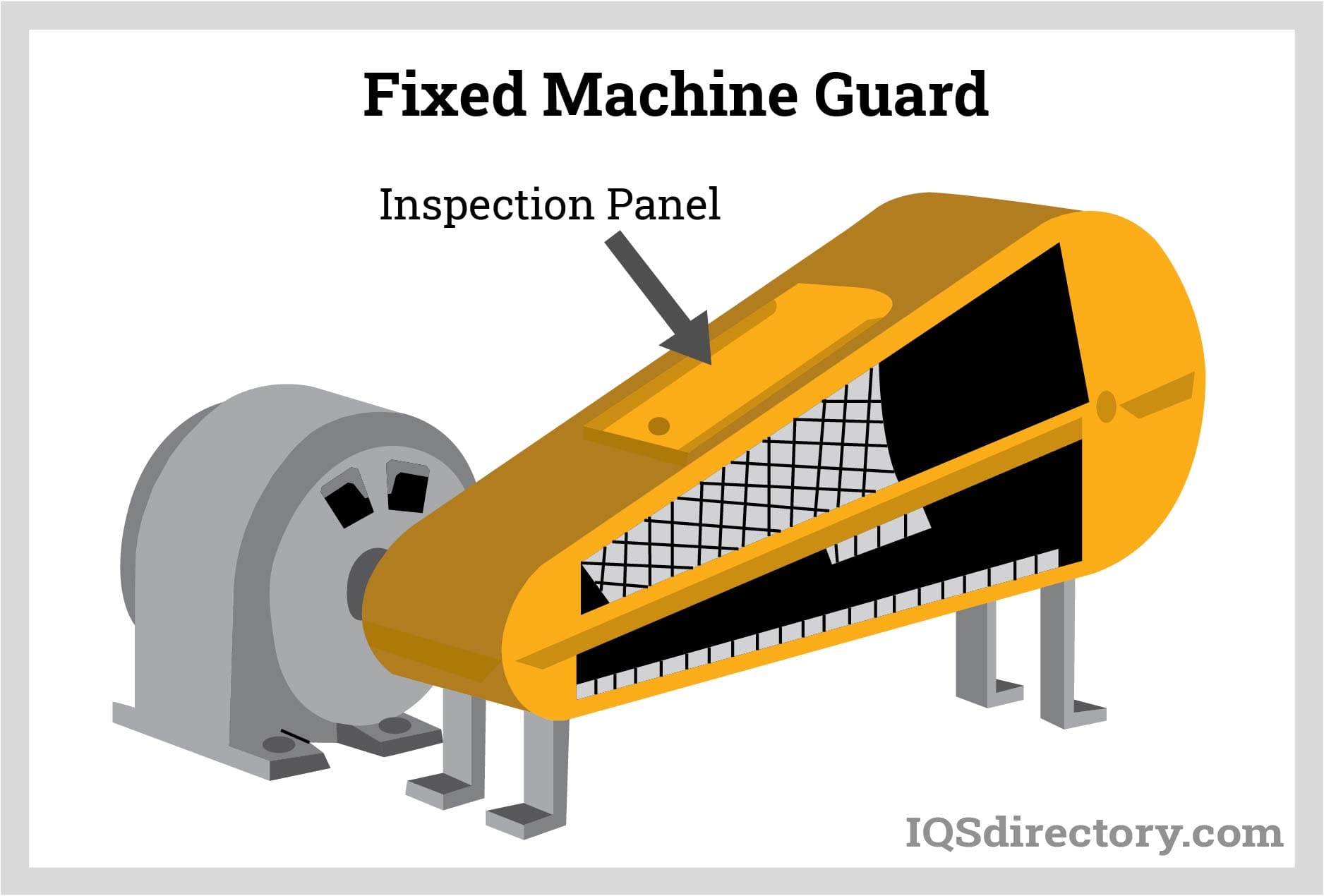

What Are the Characteristics of Fixed Machine Guards?

Fixed machine guards are robust safety devices permanently attached to machinery, designed to prevent access to hazardous areas during operation. They are typically constructed from durable materials such as metal or polycarbonate, ensuring resilience against impacts. Ideal for manufacturing and assembly lines, fixed guards are suitable for machines that do not require frequent adjustments. When considering fixed guards, B2B buyers should evaluate the specific machine requirements and the potential need for maintenance access, as these guards can limit operator interaction.

How Do Interlocked Machine Guards Enhance Safety?

Interlocked machine guards are designed to enhance safety by automatically shutting down machinery when the guard is opened or removed. This feature is particularly beneficial in maintenance-heavy operations where frequent access is necessary for adjustments or material loading. Interlocked guards are commonly used in environments where the risk of accidental machine startup is high. Buyers must consider the operational efficiency, as these guards may lead to downtime during maintenance but significantly reduce the risk of workplace injuries.

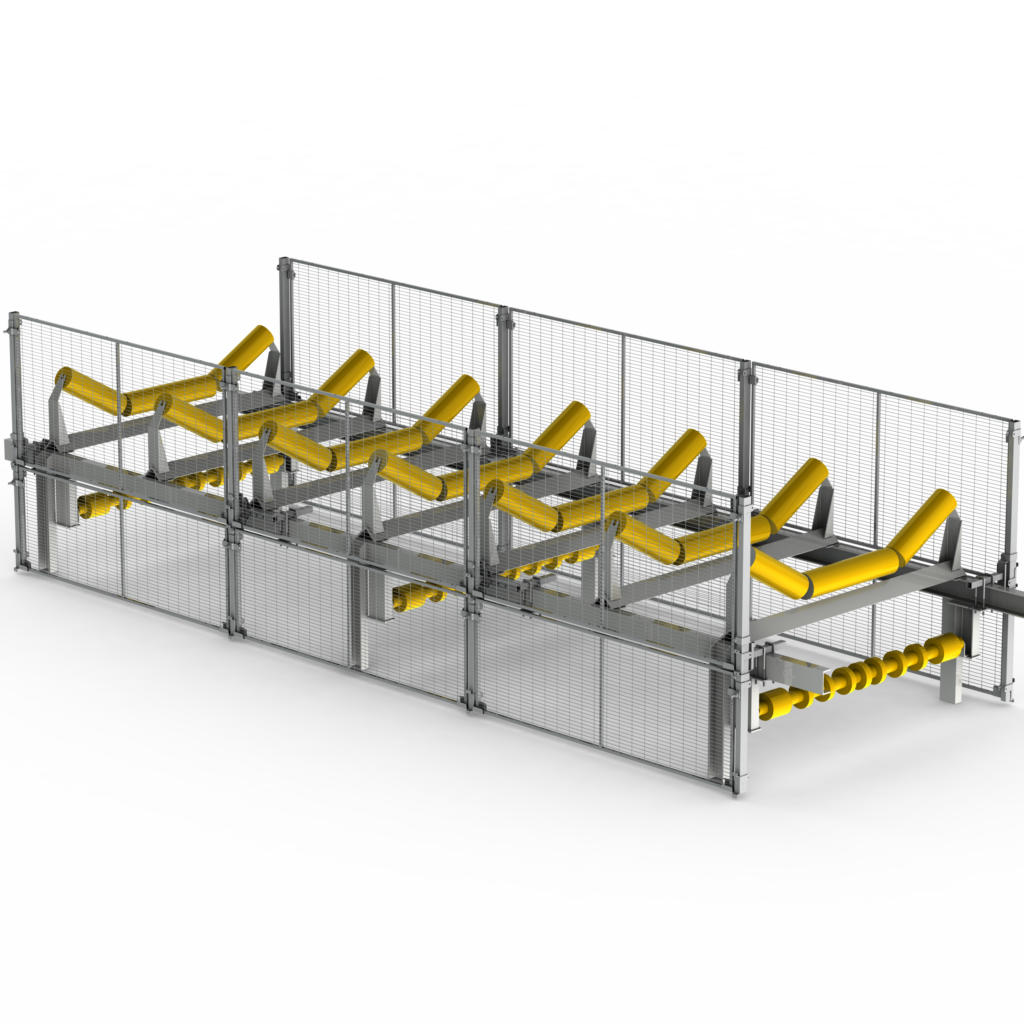

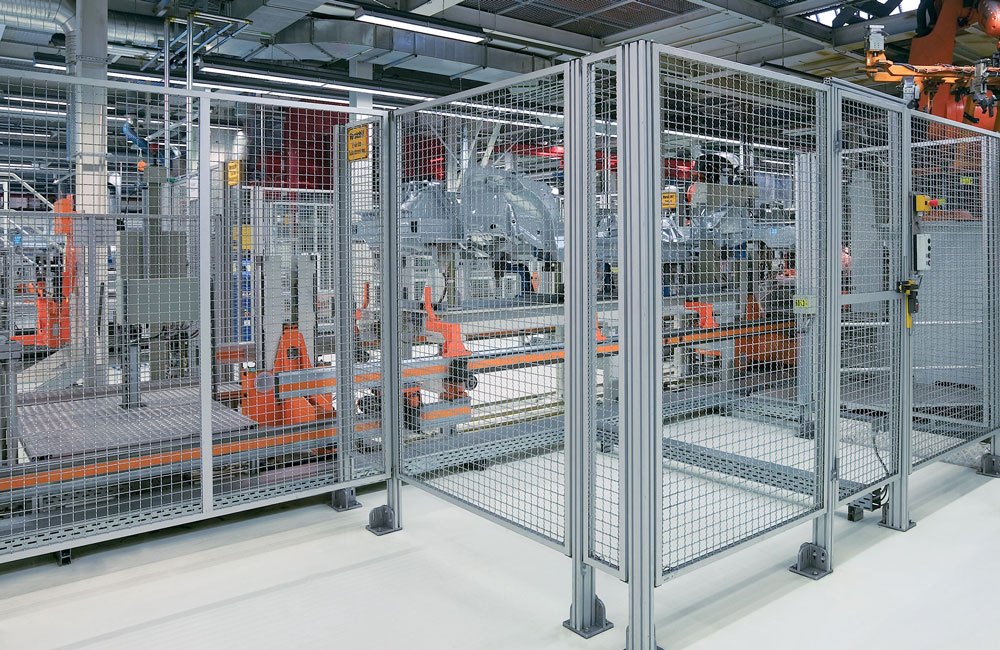

Why Choose Perimeter Machine Guards for Safety?

Perimeter machine guards are comprehensive safety solutions that restrict access to an entire machine or work area. Typically consisting of fences, railings, or barriers, they are ideal for robotic work cells or environments with multiple machines. These guards effectively prevent unauthorized access, enhancing overall workplace safety. However, buyers should be mindful of the space requirements and installation complexity, as perimeter guards necessitate a larger footprint and careful planning to integrate with existing operations.

与machine guards相关的说明性图片

What Are the Benefits of Presence-Sensing Machine Guards?

Presence-sensing machine guards use advanced sensor technology to detect the presence of individuals or objects in a machine’s hazard zone, automatically stopping the machine if necessary. This type of guard is particularly effective in automated systems and high-risk environments, where human error can lead to accidents. While they provide immediate safety responses, B2B buyers should assess the reliability of the sensor technology, as malfunctions can create safety gaps that may compromise worker protection.

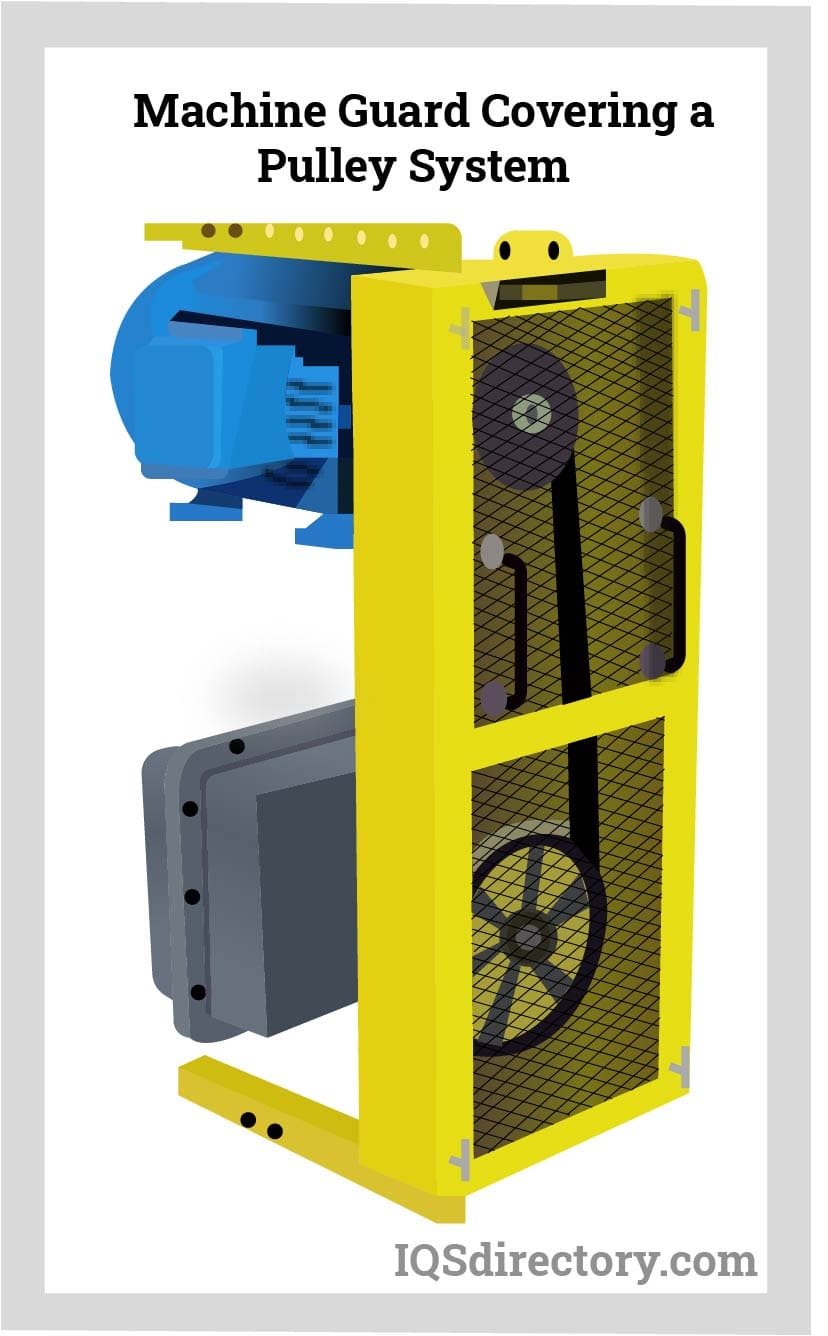

How Do Power Transmission Guards Protect Workers?

Power transmission guards are specifically designed to cover moving components such as belts, gears, and chains, mitigating the risk of entanglement and injury. These guards are essential in industries that rely on heavy machinery, including automotive and mining sectors. When evaluating power transmission guards, buyers should prioritize regular inspections and maintenance to ensure ongoing effectiveness, as wear and tear can compromise safety over time.

Key Industrial Applications of machine guards

| Industry/Sector | Specific Application of machine guards | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Fixed guards for assembly lines | Enhances worker safety and reduces downtime due to injuries | Compliance with OSHA standards; durability under high usage |

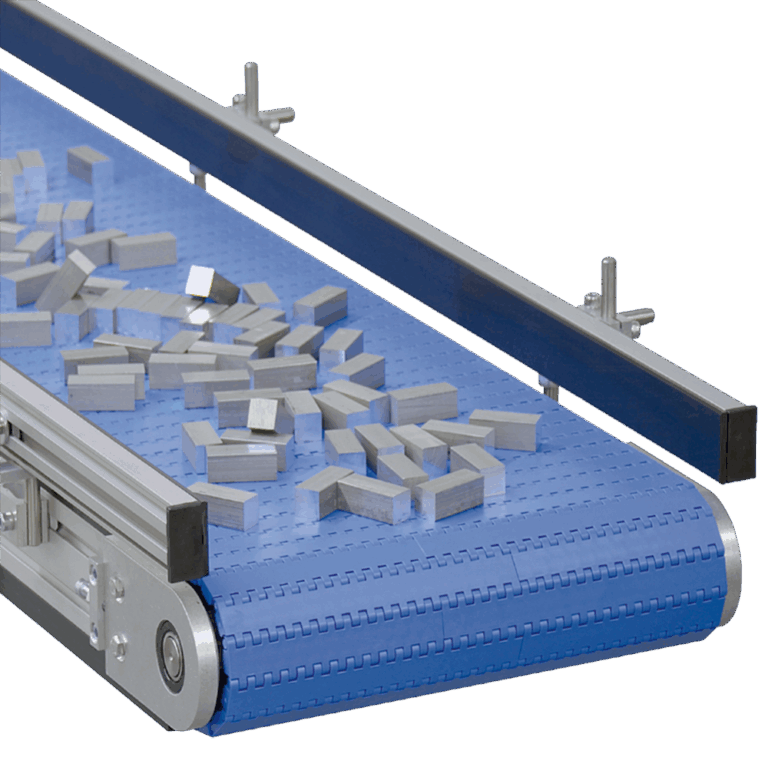

| Food Processing | Food-grade plastic guards for conveyor systems | Prevents contamination and ensures compliance with health regulations | Material certifications; resistance to chemicals and cleaning agents |

| Agriculture | Protective guards for machinery like harvesters | Minimizes risk of accidents, improving operational efficiency | Customization for diverse equipment; weather resistance |

| Power Generation | Interlocked guards for turbine maintenance | Prevents accidental startups, ensuring worker safety during maintenance | Compatibility with existing safety systems; ease of installation |

| Automotive | Presence-sensing guards in robotic assembly lines | Reduces human error and enhances safety in high-speed operations | Reliability of sensors; integration with automation systems |

How Are Machine Guards Used in Manufacturing, and What Problems Do They Solve?

In the manufacturing sector, fixed guards are commonly employed on assembly lines to protect workers from moving parts. These guards prevent accidental contact with machinery, thereby reducing the risk of injuries and associated downtime. For international buyers, especially in regions like Africa and South America, sourcing durable guards that comply with OSHA standards is crucial to ensure safety and minimize liability. Additionally, considering the operational environment, guards must withstand high usage and potential impacts.

Why Are Food-Grade Plastic Guards Essential in the Food Processing Industry?

Food processing facilities utilize food-grade plastic guards on conveyor systems to prevent contamination. These guards not only protect workers from machinery hazards but also ensure compliance with stringent health regulations. Buyers in this sector should prioritize sourcing materials that are certified for food safety and resistant to chemicals used in cleaning. Ensuring that the guards are easy to clean and maintain is essential to uphold hygiene standards.

What Role Do Machine Guards Play in Agricultural Equipment Safety?

In agriculture, protective guards are vital for machinery like harvesters, where they minimize the risk of accidents involving moving parts. The dynamic nature of agricultural operations requires guards that can be customized for various equipment types. Buyers from regions like the Middle East should consider sourcing guards that are resistant to harsh weather conditions and can be tailored to fit diverse machinery. This customization helps improve operational efficiency and worker safety.

与machine guards相关的说明性图片

How Do Interlocked Guards Enhance Safety in Power Generation?

Interlocked guards are crucial in the power generation industry, particularly for turbine maintenance. These guards automatically shut down machinery when opened, preventing accidental startups during maintenance. For businesses in Europe and the Middle East, ensuring compatibility with existing safety systems is essential. Buyers should look for guards that offer ease of installation and high reliability to maintain operational safety without significant disruptions.

How Can Presence-Sensing Guards Improve Safety in the Automotive Sector?

Presence-sensing guards are increasingly used in automotive assembly lines, particularly with robotic systems. These guards detect human presence and halt operations, significantly reducing the risk of accidents in high-speed environments. For B2B buyers in Africa and Europe, sourcing reliable sensors that integrate seamlessly with existing automation systems is vital. This technology not only enhances worker safety but also improves overall production efficiency, making it a worthwhile investment.

3 Common User Pain Points for ‘machine guards’ & Their Solutions

Scenario 1: Struggling with Compliance to Safety Standards

The Problem: Many B2B buyers face the daunting task of ensuring that their machinery adheres to local and international safety standards, such as those set by OSHA. For companies operating in regions like Africa or South America, where regulatory frameworks can be inconsistent or less stringent, the challenge intensifies. Buyers often worry about the potential legal ramifications and financial penalties associated with non-compliance, which can lead to costly shutdowns and damage to reputation. Additionally, the fear of workplace accidents due to inadequate guarding measures can weigh heavily on management, leading to stress and uncertainty.

The Solution: To navigate compliance issues effectively, B2B buyers should start by conducting a comprehensive risk assessment of their machinery and operations. This assessment should identify all potential hazards, including moving parts and areas where human interaction occurs. Once the risks are identified, buyers can consult with industry experts or safety consultants who specialize in machine guarding solutions. This collaboration will help in selecting guards that not only meet but exceed regulatory requirements. When sourcing machine guards, it is crucial to ensure they are certified to meet relevant safety standards, such as OSHA guidelines. Investing in high-quality, durable guards, such as non-metallic options that are corrosion-resistant and lightweight, can significantly enhance workplace safety while ensuring compliance.

与machine guards相关的说明性图片

Scenario 2: Difficulty in Customization for Unique Equipment

The Problem: Many manufacturers use specialized machinery that doesn’t fit standard guard sizes, leading to inadequate protection and increased risk of accidents. Buyers often struggle to find machine guards that can be tailored to their unique equipment configurations, resulting in a reliance on makeshift solutions that compromise safety. This not only puts workers at risk but also raises concerns about the integrity of the manufacturing process and product quality.

The Solution: Buyers should look for suppliers that offer custom machine guarding solutions tailored to specific machinery. When engaging with a vendor, it’s essential to communicate the exact dimensions, types of hazards, and operational needs of the equipment. Suppliers that specialize in custom solutions, such as thermoformed guards or fabricated plastic covers, can provide tailored options that fit securely and effectively. Additionally, consider utilizing a modular guarding system that allows for flexibility and adaptability as machinery changes. Regularly reviewing and updating the guarding solutions in line with equipment modifications will ensure ongoing safety and compliance.

Scenario 3: Employee Resistance to Safety Measures

The Problem: Implementing machine guards can sometimes face resistance from employees who may feel that these safety measures hinder their efficiency or complicate their workflows. This resistance can stem from a lack of understanding about the importance of safety measures or from previous experiences where safety protocols were not effectively communicated. Such pushback can lead to non-compliance with safety protocols and increase the risk of workplace accidents.

与machine guards相关的说明性图片

The Solution: To address employee resistance, it is crucial to foster a culture of safety within the organization. Buyers should prioritize training sessions that educate employees on the importance of machine guards and how they protect them from potential hazards. Incorporating hands-on demonstrations can help employees understand how to work efficiently within the safety parameters set by the guards. Additionally, involving employees in the selection and customization process of machine guards can create a sense of ownership and responsibility towards safety practices. Providing regular feedback sessions and encouraging open dialogue about safety concerns can further enhance acceptance and adherence to machine guarding protocols. By emphasizing that safety measures ultimately benefit everyone, organizations can turn resistance into cooperation, leading to a safer and more productive work environment.

Strategic Material Selection Guide for machine guards

What Are the Key Properties of Common Materials Used for Machine Guards?

When selecting materials for machine guards, it is essential to consider their properties, performance, and suitability for specific applications. Here, we analyze four common materials: metal, plastic, polycarbonate, and composite materials.

How Does Metal Perform as a Material for Machine Guards?

Metal is one of the most traditional materials used for machine guards. Its key properties include high strength, durability, and resistance to wear and tear. Metals like steel and aluminum can withstand high temperatures and pressures, making them suitable for heavy-duty applications.

Pros: Metal guards offer excellent durability and impact resistance, making them ideal for environments with heavy machinery. They are also compliant with various international safety standards, which is crucial for B2B buyers in regulated markets.

与machine guards相关的说明性图片

Cons: The main drawbacks include higher costs and the potential for corrosion if not properly treated or coated. Additionally, metal guards can be heavy, complicating installation and maintenance.

Impact on Application: Metal guards are particularly effective in environments where high mechanical stress is expected, such as manufacturing and automotive sectors. However, they may not be suitable for food processing applications due to hygiene concerns.

Considerations for International Buyers: Buyers in regions such as Africa and the Middle East should be aware of local compliance standards, such as ASTM or DIN, and consider the availability of corrosion-resistant coatings to ensure longevity in harsh climates.

What Advantages Do Plastic Machine Guards Offer?

Plastic materials, particularly engineered plastics, are increasingly popular for machine guards due to their lightweight and corrosion-resistant properties. They can also be manufactured to meet specific safety standards.

Pros: The primary advantages of plastic guards include their lightweight nature and resistance to corrosion and chemicals. They can be molded into complex shapes, allowing for custom-fit solutions.

与machine guards相关的说明性图片

Cons: While they are generally less expensive than metal, plastic guards may not offer the same level of impact resistance and durability, especially in high-stress environments.

Impact on Application: Plastic guards are particularly suitable for food processing and pharmaceutical applications, where hygiene and corrosion resistance are paramount. They can also be made in food-grade and metal-detectable versions.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with local food safety regulations, especially in markets like South America and Europe, where stringent standards are enforced.

Why Choose Polycarbonate for Machine Guards?

Polycarbonate is a high-performance plastic known for its excellent impact resistance and transparency. It is often used in applications where visibility is essential.

Pros: Polycarbonate guards provide high durability and can withstand significant impacts without shattering. Their transparency allows for visibility of the machinery, which can enhance safety.

Cons: The main disadvantage is that polycarbonate can be more expensive than other plastics. Additionally, it may be susceptible to scratching, which can impair visibility over time.

Impact on Application: Polycarbonate is ideal for environments where monitoring machinery operation is critical, such as in automated assembly lines. Its impact resistance makes it suitable for high-risk areas.

Considerations for International Buyers: Buyers should verify that polycarbonate products meet relevant safety standards and consider the environmental impact of disposal, as regulations vary significantly across regions.

What Role Do Composite Materials Play in Machine Guarding?

Composite materials combine various materials to enhance performance characteristics. They are often used in applications requiring a balance between strength and weight.

与machine guards相关的说明性图片

Pros: Composites can offer excellent strength-to-weight ratios and resistance to corrosion and chemicals. They are also customizable to meet specific operational needs.

Cons: The manufacturing process for composites can be more complex and costly, which may deter some buyers. Additionally, their long-term durability can vary depending on the specific formulation.

Impact on Application: Composites are suitable for a wide range of applications, including aerospace and automotive, where weight savings are crucial. They can also be tailored for specific environments, such as marine applications.

Considerations for International Buyers: Buyers should be aware of the certifications required for composite materials in their specific industries, as compliance can be a significant factor in procurement decisions.

Summary Table of Material Selection for Machine Guards

| Material | Typical Use Case for Machine Guards | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metal | Heavy machinery protection | High durability and impact resistance | Prone to corrosion; heavier weight | High |

| Plastic | Food processing and pharmaceuticals | Lightweight and corrosion-resistant | Lower impact resistance | Medium |

| Polycarbonate | Automated assembly lines | High impact resistance and visibility | Susceptible to scratching | Medium to High |

| Composite | Aerospace and automotive | Excellent strength-to-weight ratio | Complex manufacturing process | High |

This strategic material selection guide provides B2B buyers with valuable insights into the properties, advantages, and limitations of various materials for machine guards, helping them make informed decisions tailored to their specific operational needs.

与machine guards相关的说明性图片

In-depth Look: Manufacturing Processes and Quality Assurance for machine guards

What Are the Key Stages in the Manufacturing Process of Machine Guards?

The manufacturing of machine guards involves several critical stages to ensure that the final product meets both safety and quality standards. Understanding these stages helps B2B buyers evaluate the capabilities of potential suppliers.

Material Preparation: What Materials Are Used for Machine Guards?

The first step in the manufacturing process is selecting the appropriate materials. Commonly used materials include:

- Plastic: Lightweight and corrosion-resistant, plastic guards are often preferred for their safety features, such as the absence of sharp edges and conductivity issues. They can also be food-grade and metal-detectable.

- Metal: Steel and aluminum are frequently used for fixed guards due to their strength and durability.

- Composite Materials: These materials combine the benefits of both plastic and metal, offering enhanced durability while maintaining lightweight characteristics.

Once the materials are selected, they undergo preparation, which may involve cutting, milling, or other processes to ensure they meet specifications before moving on to forming.

与machine guards相关的说明性图片

How Are Machine Guards Formed?

Forming is a pivotal stage where the prepared materials are shaped into the desired guard configurations. Key techniques include:

- Thermoforming: This technique is commonly used for plastic guards, where heated plastic sheets are molded into specific shapes.

- Injection Molding: Ideal for producing complex shapes in plastic, this method allows for high-volume production with consistent quality.

- Metal Fabrication: For metal guards, processes such as welding, bending, and punching are employed to create robust structures.

The choice of forming technique directly impacts the guard’s performance, so understanding these options is vital for B2B buyers seeking tailored solutions.

What Is Involved in the Assembly of Machine Guards?

Once the components are formed, the next stage is assembly. This may involve:

- Joining Components: Different parts are assembled using various methods such as welding, screws, or adhesives, depending on the materials and design.

- Integration of Safety Features: Many machine guards include additional safety features such as interlocks, locks, or sensors, which are integrated during this stage.

- Custom Modifications: If a custom solution is required, adjustments can be made during assembly to meet specific client needs.

Effective assembly ensures that the guards are not only functional but also compliant with safety regulations.

与machine guards相关的说明性图片

What Finishing Processes Are Applied to Machine Guards?

The finishing stage enhances the durability and aesthetics of machine guards. Typical processes include:

- Surface Treatment: Techniques such as powder coating or painting improve corrosion resistance and provide a finished look.

- Quality Checks: As part of the finishing process, guards undergo inspections to ensure they meet design specifications and safety standards.

This stage is crucial for ensuring that the guards can withstand the rigors of their operating environment, which is particularly important for international buyers in diverse climates.

How Is Quality Assurance Implemented in the Manufacturing of Machine Guards?

Quality assurance (QA) is essential in the manufacturing process to ensure the safety and reliability of machine guards. A robust QA system involves several international standards and industry-specific regulations.

与machine guards相关的说明性图片

What International Standards Govern Machine Guard Manufacturing?

ISO 9001 is the most recognized quality management standard, ensuring that manufacturers maintain consistent quality throughout their processes. Compliance with ISO 9001 involves:

- Documented Procedures: Manufacturers must document their processes and ensure they follow them consistently.

- Continuous Improvement: Companies are encouraged to regularly evaluate and improve their processes based on feedback and performance metrics.

In addition to ISO standards, regional certifications such as CE marking in Europe and API standards in specific industries may also apply, depending on the market.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are critical to maintaining high standards throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, various checks are conducted to monitor the quality of the components being manufactured.

- Final Quality Control (FQC): Before products are shipped, a final inspection is performed to verify that all specifications and standards have been met.

Implementing these checkpoints helps prevent defects and ensures that the final product is safe and reliable.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control practices is crucial. Here are several methods to do so:

与machine guards相关的说明性图片

- Audits: Conducting supplier audits can provide insights into their manufacturing processes and quality assurance systems.

- Quality Reports: Requesting documentation of quality control practices, including test results and compliance certificates, can help assess a supplier’s reliability.

- Third-Party Inspections: Engaging independent inspection services can validate the quality of the products and ensure compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control when sourcing machine guards. These include:

- Understanding Local Regulations: Different regions may have specific requirements for safety and quality that suppliers must meet. Buyers should familiarize themselves with these regulations to ensure compliance.

- Cultural Considerations: Communication styles and business practices can vary significantly across regions. Understanding these cultural differences can enhance collaboration and ensure clearer expectations regarding quality.

- Logistical Challenges: Shipping products across borders may introduce additional risks. Buyers should consider how these logistics might affect product quality during transit and ensure proper packaging and handling.

By being aware of these factors, B2B buyers can make informed decisions when selecting suppliers for machine guards, ultimately leading to enhanced safety and operational efficiency in their businesses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘machine guards’

Introduction

In the industrial sector, ensuring worker safety while maintaining operational efficiency is paramount. This guide serves as a practical checklist for B2B buyers seeking to procure machine guards. By following these steps, you can make informed decisions that align with safety standards and operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to identify the right type of machine guard for your operations. Consider the machine’s size, type, and specific hazards it presents. This will help you determine the necessary materials, dimensions, and design features required for effective protection.

- Hazard Assessment: Identify potential risks such as moving parts, pinch points, and debris.

- Access Requirements: Determine how often operators need to access the machine for maintenance or operation.

Step 2: Research Compliance Standards

Ensure that the machine guards you consider comply with relevant safety standards, such as OSHA in the U.S. or other local regulations applicable in your region, including Africa, South America, the Middle East, and Europe. Compliance not only protects workers but also mitigates legal risks for your business.

- Documentation Review: Request certifications and documentation confirming compliance.

- Industry-Specific Standards: Be aware of any specific regulations that may apply to your industry, such as food processing or manufacturing.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting thorough evaluations is critical. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and quality.

与machine guards相关的说明性图片

- Supplier Background: Investigate the supplier’s history and experience in manufacturing machine guards.

- Customer Feedback: Look for reviews or testimonials that highlight the supplier’s service quality and product performance.

Step 4: Assess Material Options

Different materials offer varying levels of protection and durability. Evaluate options such as plastic, metal, or composite materials based on your operational environment and safety needs.

- Material Properties: Consider factors like corrosion resistance, weight, and the presence of sharp edges.

- Custom Solutions: If standard options do not meet your needs, inquire about custom fabrication capabilities.

Step 5: Check for Customization Capabilities

In many cases, standard machine guards may not fit specific machinery configurations. Assess whether suppliers can provide custom solutions tailored to your operational needs.

- Design Flexibility: Ask about the supplier’s ability to create guards with unique dimensions, holes, or features.

- Rapid Prototyping: Determine if the supplier can deliver prototypes for testing before full-scale production.

Step 6: Analyze Cost vs. Value

While cost is an important factor, consider the overall value a machine guard brings to your operations. Cheaper options may compromise safety, leading to higher costs in the long run due to accidents or compliance issues.

- Total Cost of Ownership: Factor in installation, maintenance, and potential downtime.

- Long-Term Investment: Evaluate how the guard contributes to workplace safety and productivity.

Step 7: Plan for Installation and Maintenance

Once you’ve selected a supplier and product, plan for the installation and ongoing maintenance of the machine guards. Proper installation ensures maximum effectiveness, while regular maintenance keeps guards in optimal condition.

- Installation Support: Check if the supplier offers guidance or services for proper installation.

- Maintenance Schedule: Develop a routine maintenance plan to inspect and repair guards as necessary to ensure continued compliance and safety.

By following this checklist, B2B buyers can confidently navigate the procurement process for machine guards, enhancing workplace safety and operational efficiency.

与machine guards相关的说明性图片

Comprehensive Cost and Pricing Analysis for machine guards Sourcing

What Are the Key Cost Components in Sourcing Machine Guards?

When sourcing machine guards, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Non-metallic options like plastics can be more cost-effective than metals, particularly when corrosion resistance and weight are considerations. For specialized applications, such as food processing, food-grade materials may be necessary, which can increase costs.

-

Labor: Labor costs encompass the workforce involved in manufacturing and custom fabrication. Highly skilled labor may be required for intricate designs or custom solutions, raising overall expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can lower overhead, but custom orders may require additional resources.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider whether the investment in tooling will be offset by the expected volume of orders.

-

Quality Control (QC): Ensuring the safety and effectiveness of machine guards is paramount. Rigorous QC processes can add to costs but ultimately protect businesses from potential liabilities.

-

Logistics: Transportation costs are influenced by distance, weight, and shipping methods. International buyers must be aware of potential tariffs and fees associated with shipping machine guards across borders.

-

Margin: Suppliers typically add a profit margin to cover risks and business sustainability. Understanding the typical margins in your industry can aid in negotiation.

How Do Price Influencers Affect Machine Guard Costs?

Several factors can influence the pricing of machine guards, including:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to lower per-unit costs. Buyers should negotiate MOQs that align with their operational needs to optimize pricing.

-

Specifications and Customization: Custom designs can significantly increase costs. Buyers should clearly outline their needs to avoid unnecessary expenses and ensure that customizations are essential for their operations.

-

Material Quality and Certifications: Higher-quality materials and relevant safety certifications may raise costs but are vital for compliance with safety regulations, particularly in industries with stringent standards.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more for their proven quality and service, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for international buyers. These terms dictate who bears shipping costs and risks, impacting the total cost of ownership.

What Are Effective Buyer Tips for Sourcing Machine Guards?

B2B buyers can implement several strategies to ensure cost-efficiency when sourcing machine guards:

-

Negotiate Pricing: Engage suppliers in discussions about pricing structures. Highlighting long-term purchasing agreements or bulk orders can lead to favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also maintenance, replacement, and compliance costs over the guard’s lifespan. Investing in higher-quality guards may reduce long-term expenses related to safety incidents and regulatory fines.

-

Research Regional Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and supplier capabilities. Local suppliers may offer advantages in terms of logistics and compliance with regional standards.

-

Assess Customization Needs: Before ordering, determine if customizations are necessary. Standard guards may suffice for many applications, reducing costs significantly.

-

Stay Informed on Safety Regulations: Familiarize yourself with safety standards like OSHA or local equivalents, which may affect the choice of materials and designs, influencing overall pricing.

Disclaimer on Indicative Prices

Pricing for machine guards can vary widely based on the factors discussed above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing machine guards With Other Solutions

Exploring Alternative Solutions to Machine Guards

When it comes to ensuring worker safety in industrial environments, machine guards are a common solution. However, there are alternative methods and technologies that can also provide protection against machinery hazards. This section compares machine guards with two viable alternatives: safety interlocks and presence-sensing devices. Each option has its own advantages and drawbacks, which can significantly impact operational safety, efficiency, and costs.

| Comparison Aspect | Machine Guards | Safety Interlocks | Presence-Sensing Devices |

|---|---|---|---|

| Performance | Highly effective at blocking access to hazards. | Automatically shut down machines when access is attempted. | Stops machines when a person is detected in danger zones. |

| Cost | Moderate initial investment; ongoing maintenance costs. | Generally higher due to installation and technology costs. | Variable cost depending on sensor technology; potential integration costs. |

| Ease of Implementation | Requires installation and may need customization for specific machines. | Can be complex to install; requires integration with machine controls. | Installation can be straightforward, but may require adjustments to existing systems. |

| Maintenance | Regular inspections needed to ensure integrity. | Requires periodic testing to ensure reliability. | Needs calibration and routine checks for sensor accuracy. |

| Best Use Case | Ideal for machines with fixed access points and minimal adjustments. | Best for machines needing frequent access for maintenance. | Suitable for dynamic environments where personnel frequently move near hazards. |

In-Depth Analysis of Alternative Solutions

What are the Advantages and Disadvantages of Safety Interlocks?

Safety interlocks are devices that automatically shut down machinery when access is attempted. This method provides a high level of safety, ensuring that machines cannot operate unless they are securely in place. The primary advantage of safety interlocks is their ability to prevent accidental machine operation, which is crucial for machines requiring regular maintenance. However, the complexity of installation and higher upfront costs can be a disadvantage, particularly for smaller operations. Additionally, if the interlock system fails, it could lead to unintentional machine restarts, posing safety risks.

How Do Presence-Sensing Devices Enhance Safety?

Presence-sensing devices use various technologies, such as light curtains or pressure mats, to detect the presence of personnel in hazardous areas. These devices offer the advantage of stopping machinery immediately upon detecting someone in a dangerous zone, significantly reducing the risk of injury. Their flexibility allows them to be used in dynamic environments where personnel may frequently move around machinery. However, the reliability of these systems depends heavily on proper calibration and maintenance. Moreover, initial costs can vary significantly based on the technology used, potentially making them a more expensive option in some cases.

与machine guards相关的说明性图片

How to Choose the Right Solution for Your Industrial Needs

When selecting between machine guards and alternative safety solutions, B2B buyers should carefully consider their specific operational requirements. Factors such as the nature of the machinery, the frequency of operator access, and the potential risks involved should guide decision-making. For example, in environments where machines require frequent maintenance, safety interlocks may offer the best solution. Conversely, for high-traffic areas with constant personnel movement, presence-sensing devices might be more effective. Ultimately, the right choice will depend on a comprehensive risk assessment and a clear understanding of the operational context, ensuring that worker safety remains the top priority.

Essential Technical Properties and Trade Terminology for machine guards

What Are the Essential Technical Properties of Machine Guards?

When selecting machine guards, understanding their technical properties is crucial for ensuring compliance, safety, and operational efficiency. Here are several key specifications that B2B buyers should consider:

1. Material Grade

Machine guards are typically constructed from materials such as metal, polycarbonate, or plastic. The material grade impacts durability, weight, and corrosion resistance. For instance, high-grade polycarbonate offers excellent impact resistance while being lightweight, making it suitable for environments where safety and ease of installation are paramount. Choosing the right material ensures long-lasting performance and compliance with safety regulations.

2. Tolerance Levels

Tolerance refers to the permissible limits of variation in a physical dimension. In machine guards, precise tolerances ensure proper fit and function, which is vital for safety. Guards that do not fit correctly can create gaps, allowing access to hazardous areas. Therefore, specifying tight tolerance levels during the procurement process mitigates risks and enhances worker safety.

3. Safety Compliance Standards

Compliance with industry safety standards, such as those set by OSHA or ANSI, is non-negotiable. These standards dictate the design, installation, and maintenance of machine guards. Ensuring that the guards meet these regulations not only protects workers but also helps organizations avoid legal liabilities and potential fines. Buyers should request certification documentation from suppliers to validate compliance.

4. Weight Capacity

Different machines have varying operational demands, which can affect the type of guard required. Understanding the weight capacity of the guard is essential for ensuring it can withstand operational stresses and impacts without failure. This is particularly important in heavy machinery environments where guards may be subjected to significant forces.

5. Customization Options

Many industrial applications require tailored solutions to effectively mitigate specific risks. Customization options include modifications for size, shape, and additional features like interlocks or sensors. Having the ability to adapt guards to unique equipment setups is critical for maximizing safety and operational efficiency.

6. Installation and Maintenance Requirements

Ease of installation and maintenance is a key consideration. Guards that are difficult to install or maintain can lead to operational downtime and increased labor costs. Buyers should inquire about the installation processes and any maintenance protocols to ensure that their selected guards will not impede productivity.

What Are Common Trade Terms Related to Machine Guards?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with machine guards:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of machine guards, understanding whether a supplier is an OEM can affect the quality and compatibility of the guards with existing machinery.

与machine guards相关的说明性图片

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory management, especially when evaluating suppliers for bulk purchases of machine guards.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. This is an essential step in the procurement process, allowing buyers to compare costs and terms from multiple vendors for machine guards, ensuring they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for international buyers to manage logistics and costs effectively.

5. Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order from the moment it is placed. Knowing the lead time for machine guards is critical for production planning and avoiding delays in operational processes.

6. Warranty

A warranty is a promise by the supplier regarding the condition of the machine guards and the terms under which they will repair or replace defective products. Understanding warranty terms can protect buyers from future costs and ensure product reliability.

By familiarizing themselves with these technical properties and industry terms, B2B buyers can make informed decisions that enhance workplace safety and operational efficiency.

与machine guards相关的说明性图片

Navigating Market Dynamics and Sourcing Trends in the machine guards Sector

What Are the Key Market Dynamics and Trends Impacting Machine Guards?

The global market for machine guards is witnessing significant growth, driven by increasing industrial automation, stringent safety regulations, and a rising awareness of workplace safety. In regions like Africa, South America, the Middle East, and Europe, businesses are increasingly investing in advanced safety solutions to comply with regulations set by organizations such as OSHA and local equivalents. For instance, in countries like Nigeria and Saudi Arabia, government initiatives to enhance industrial safety standards are propelling demand for effective machine guarding solutions.

Emerging technologies, including IoT and smart sensors, are transforming the machine guards sector. These innovations enable real-time monitoring and predictive maintenance, enhancing safety and operational efficiency. Additionally, manufacturers are focusing on developing customizable and modular guarding solutions that cater to the unique needs of various industries, from food processing to heavy machinery. International B2B buyers should prioritize suppliers that offer versatile solutions capable of adapting to different operational environments.

Another key trend is the increasing adoption of non-metallic materials, such as plastics, which provide safer alternatives to traditional metal guards. These materials are lightweight, corrosion-resistant, and can be designed for food-grade applications, making them ideal for diverse industrial settings. As the market evolves, buyers should be vigilant in assessing the latest product offerings and their compliance with international safety standards to ensure optimal protection for their workforce.

How Is Sustainability and Ethical Sourcing Influencing Machine Guard Purchases?

In today’s environmentally-conscious market, sustainability and ethical sourcing are becoming critical factors for B2B buyers in the machine guards sector. The production of machine guards can have significant environmental impacts, including resource depletion and waste generation. Therefore, companies are increasingly seeking suppliers who prioritize sustainable practices in their manufacturing processes.

Buyers should look for machine guards made from environmentally-friendly materials, such as recycled plastics or biodegradable composites. Additionally, certifications such as ISO 14001 (Environmental Management) and other “green” labels can provide assurance of a supplier’s commitment to sustainability. These certifications not only reflect a supplier’s dedication to reducing their environmental footprint but also enhance the buyer’s brand image in markets that value corporate social responsibility.

与machine guards相关的说明性图片

Ethical sourcing is also crucial, as buyers are more inclined to partner with suppliers who ensure fair labor practices and safe working conditions throughout their supply chain. By choosing suppliers that adhere to ethical standards, companies can mitigate risks associated with reputational damage while fostering a more sustainable and responsible business environment.

What Is the Historical Context Behind the Evolution of Machine Guards?

The concept of machine guarding has evolved significantly since the early industrial era. Initially, safety measures were rudimentary, often resulting in high rates of workplace accidents. As industrialization progressed, the need for more sophisticated safety solutions became evident, leading to the development of various types of machine guards designed to protect workers from specific hazards.

In the mid-20th century, the establishment of regulatory bodies like OSHA marked a turning point in workplace safety standards. The introduction of comprehensive guidelines necessitated the design and implementation of effective machine guarding solutions across industries. This evolution has led to a diversified market, where modern guards not only comply with safety regulations but also incorporate advanced technologies and materials to enhance worker safety and operational efficiency.

Today, the machine guards sector continues to innovate, with a focus on integrating smart technologies and sustainable practices, reflecting the changing landscape of industrial safety and corporate responsibility. International B2B buyers must stay informed about these historical developments to make educated purchasing decisions that align with contemporary safety and sustainability standards.

Frequently Asked Questions (FAQs) for B2B Buyers of machine guards

-

How do I ensure compliance with safety standards when sourcing machine guards?

To ensure compliance with safety standards when sourcing machine guards, first familiarize yourself with the relevant regulations in your region, such as OSHA standards in the U.S. or EU directives in Europe. Look for suppliers that provide documentation demonstrating compliance with these standards. Additionally, consider requesting samples or certifications from manufacturers to verify the quality and safety of their products. Engaging with suppliers who have a strong track record in safety compliance can further assure adherence to industry regulations. -

What is the best type of machine guard for my specific machinery?

The best type of machine guard depends on the specific machinery and its operational environment. Fixed guards are suitable for machines with minimal access needs, while interlocked guards are ideal for equipment requiring frequent maintenance. Evaluate the hazards associated with your machinery, including moving parts and pinch points, and consult with safety experts or suppliers who can recommend the most effective guarding solutions tailored to your needs. Conducting a risk assessment can also provide insights into the most appropriate guard type. -

How can I customize machine guards for unique machinery configurations?

Many suppliers offer customization options for machine guards to fit unique machinery configurations. Start by discussing your specific requirements with potential manufacturers, including dimensions, materials, and any additional features needed. Custom guards can include thermoformed designs, specific cutouts for access, or branding elements. Ensure that the supplier has experience in creating custom solutions and can provide examples of previous projects, which will help you assess their capability to meet your needs. -

What are the minimum order quantities (MOQs) for machine guards from suppliers?

Minimum order quantities (MOQs) for machine guards can vary significantly among suppliers, often depending on the type of guard and the materials used. While some manufacturers may offer MOQs as low as one unit for standard products, custom guards typically require larger orders to justify production costs. When negotiating with suppliers, inquire about their MOQs and explore options for bulk purchasing or combining orders to meet the requirements. Always consider the potential for future needs when placing an order. -

What payment terms should I expect when purchasing machine guards internationally?

Payment terms for international machine guard purchases can vary based on the supplier’s policies and your relationship with them. Common payment methods include wire transfers, letters of credit, or payment through escrow services. Be prepared to negotiate terms that suit both parties, considering factors like order size and delivery timelines. It’s advisable to establish clear payment milestones based on production progress and shipment dates to mitigate risks associated with international transactions. -

How do I vet suppliers for machine guards effectively?

Vetting suppliers for machine guards involves several steps to ensure reliability and quality. Start by researching potential suppliers, checking their industry reputation, certifications, and customer reviews. Request references from previous clients and inquire about their experience with the supplier. Evaluate their production capabilities, lead times, and compliance with international safety standards. Engaging in direct communication to discuss your specific needs can also help assess their expertise and responsiveness. -

What logistics considerations should I be aware of when importing machine guards?

When importing machine guards, logistics considerations include shipping methods, customs regulations, and potential tariffs or duties. Assess the most cost-effective and timely shipping options based on your location and supplier’s proximity. Familiarize yourself with the import regulations in your country to ensure compliance, and consider working with a freight forwarder to navigate the complexities of international shipping. Additionally, plan for potential delays in customs processing and ensure that all necessary documentation is in order. -

What quality assurance measures should be in place for machine guard production?

Quality assurance (QA) measures for machine guard production should include comprehensive testing and inspection protocols at various stages of manufacturing. Suppliers should implement standardized procedures to assess material quality, dimensional accuracy, and safety compliance. Request documentation of QA processes, including certifications and test reports, to verify the quality of the guards you are purchasing. Establishing a clear communication channel with the supplier for quality-related inquiries can also help ensure that the final products meet your expectations.

Top 6 Machine Guards Manufacturers & Suppliers List

1. Machine Guard – Non-Metallic Safety Guards

Domain: machineguard.com

Registered: 1996 (29 years)

Introduction: Machine Guard offers a complete line of non-metallic safety guards and bearing covers designed for industrial power transmission systems. Key products include: 2-Bolt Bearing Covers, 3-Bolt Bearing Covers, 4-Bolt Bearing Covers, Pillow Block Bearing Covers, Take-Up Bearing Covers, Curved and Straight Conveyor Covers, Coupling Covers (1 & 2 piece), Rectangular Guards (flanged and unflanged), Round …

2. McMaster-Carr – Machine Guards

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster-Carr – Machine Guards, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Axelent – Machine Guards

Domain: axelentusa.com

Registered: 2004 (21 years)

Introduction: Axelent is a leading manufacturer of machine guards, providing a complete system that meets current directives and standards. Key product categories include: 1. Panels – Mesh panels for industrial and warehouse environments. 2. Posts – Support structures for machine guarding systems. 3. Doors – Access points integrated into machine guarding solutions. 4. Locks & Switches – Safety mechanisms for se…

4. Uline – Machine Guards

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Machine Guards are designed to protect personnel from moving machinery parts. They are made of durable materials and come in various sizes to fit different machines. The guards are easy to install and provide a clear view of the machine’s operation. They help to enhance workplace safety and comply with safety regulations.

5. Rite-Hite – Machine Guarding Solutions

Domain: ritehite.com

Registered: 1995 (30 years)

Introduction: Machine guarding is essential for workplace safety, safeguarding employees from hazards near machinery or robots, and ensuring compliance with OSHA and EN/ISO standards. Rite-Hite offers a range of solutions including automated barrier doors, automated curtains, safety fencing, and retractable screens. These solutions are designed to enhance productivity while maintaining safety, minimizing workpl…

6. ATS Safety – Custom Machine Guards

Domain: atssafety.com

Registered: 2004 (21 years)

Introduction: Custom-Built Machine Guards, including: Custom Lathe Guards, Drill Press Guards, Electrical Control Boxes, Grinder Safety Guards, Hydraulic Press Guards, Surface Grinder Guards, Vertical Band Saw Guards, Replacement Parts, Safety Signs, Safety Switches, and LED Lights.

Strategic Sourcing Conclusion and Outlook for machine guards

In the rapidly evolving industrial landscape, the strategic sourcing of machine guards is not just a regulatory necessity; it’s a critical investment in workforce safety and operational efficiency. By understanding the various types of machine guards—such as fixed, interlocked, and presence-sensing guards—B2B buyers can make informed decisions that enhance workplace safety while complying with OSHA and international safety standards.

与machine guards相关的说明性图片

Investing in high-quality, custom-fit solutions not only mitigates the risk of injuries but also minimizes potential downtime due to accidents. For buyers in regions like Africa, South America, the Middle East, and Europe, leveraging local suppliers who understand regional compliance and operational challenges can further streamline procurement processes.

As industries continue to prioritize safety, the demand for innovative machine guarding solutions is set to grow. Now is the time to evaluate your current safety measures and engage with suppliers who can provide tailored solutions to meet your specific needs. Embrace this opportunity to safeguard your workforce while positioning your business for future growth and success. Reach out to trusted manufacturers today to explore customized machine guard options that align with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

与machine guards相关的说明性图片

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.