Choosing Your Lorry Tail Lights: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for lorry tail lights

In the rapidly evolving landscape of the global market for lorry tail lights, sourcing high-quality lighting solutions can present significant challenges for international B2B buyers. As companies in regions such as Africa, South America, the Middle East, and Europe (including key markets like Nigeria and Germany) expand their fleets, they face the critical task of selecting tail lights that not only meet safety standards but also enhance vehicle aesthetics and performance. This comprehensive guide addresses the multifaceted aspects of lorry tail lights, covering various types, applications, and innovative technologies available in the market today.

Throughout this guide, readers will gain insights into the diverse range of lorry tail lights, from traditional halogen options to advanced LED solutions, including specifics on their durability and compliance with international regulations. We will also delve into essential factors for vetting suppliers, ensuring that buyers can identify reliable partners capable of delivering quality products. Cost considerations, including pricing tiers and potential savings, will be explored, allowing businesses to make informed financial decisions.

By empowering B2B buyers with actionable knowledge and strategies, this guide aims to facilitate effective purchasing decisions. Whether you are a fleet manager in Johannesburg or a logistics provider in Berlin, understanding the nuances of lorry tail lights can significantly impact operational safety and efficiency, ultimately driving success in your business endeavors.

Understanding lorry tail lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| LED Tail Lights | High brightness, faster illumination, energy-efficient | Heavy-duty trucks, trailers | Pros: Longer lifespan, better visibility; Cons: Higher upfront cost compared to halogen. |

| Euro Tail Lights | Chrome housing, intricate designs, clear/smoked lenses | European trucks, specialty vehicles | Pros: Aesthetic appeal, unique look; Cons: May not be suitable for all markets due to regulations. |

| Smoked Tail Lights | Darkened lenses, stylish appearance | Custom trucks, off-road vehicles | Pros: Enhanced style; Cons: Can reduce visibility if not compliant with regulations. |

| Standard Halogen | Conventional bulbs, cost-effective | Budget-friendly fleets | Pros: Lower initial cost; Cons: Shorter lifespan, less visibility compared to LEDs. |

| Marker Tail Lights | Smaller, often used for additional visibility | Trailers, utility vehicles | Pros: Increases visibility; Cons: Limited functionality compared to full tail lights. |

What are LED Tail Lights and Their Benefits for B2B Buyers?

LED tail lights are characterized by their high brightness and energy efficiency, making them an ideal choice for heavy-duty trucks and trailers. They illuminate faster than traditional halogen bulbs, enhancing safety on the road. For B2B buyers, the longer lifespan of LED lights means reduced maintenance costs over time, although the initial investment is higher. Companies focused on long-term value will find LED tail lights particularly beneficial, especially in industries where vehicle uptime is critical.

How Do Euro Tail Lights Stand Out for Specialty Vehicles?

Euro tail lights are distinguished by their chrome housing and intricate designs, often featuring clear or smoked lenses. They are popular in European trucks and specialty vehicles, providing a unique aesthetic appeal. B2B buyers should consider local regulations, as these lights may not be compliant in all regions. While they offer a distinct look that can elevate a vehicle’s profile, potential buyers must weigh the aesthetic benefits against regulatory compliance and installation compatibility.

What Makes Smoked Tail Lights a Stylish Choice for Custom Vehicles?

Smoked tail lights feature darkened lenses that provide a stylish appearance, making them popular among custom trucks and off-road vehicles. While they enhance the vehicle’s look, buyers must ensure that they meet local visibility regulations, as reduced light transmission can pose safety risks. For B2B buyers targeting niche markets or customization shops, smoked tail lights offer a unique selling proposition. However, they may not be suitable for all applications, particularly in regions with strict vehicle lighting laws.

Why Choose Standard Halogen Tail Lights for Budget-Friendly Fleets?

Standard halogen tail lights are a conventional choice for budget-conscious fleets, offering a lower initial cost compared to more advanced options. They are widely available and easy to replace, making them a practical solution for companies looking to minimize expenses. However, their shorter lifespan and reduced visibility compared to LEDs may lead to higher long-term costs. B2B buyers focused on immediate budget constraints may find halogen lights appealing, but they should also consider the potential for increased maintenance and safety issues.

What are Marker Tail Lights and When Should They Be Used?

Marker tail lights are smaller lights that enhance vehicle visibility, commonly used on trailers and utility vehicles. They serve a crucial role in improving safety, especially in low-visibility conditions. For B2B buyers, marker tail lights can be an effective addition to a vehicle’s lighting system, providing additional safety without the need for full tail light replacements. However, their limited functionality means they should be used in conjunction with standard tail lights to ensure comprehensive lighting solutions.

Key Industrial Applications of lorry tail lights

| Industry/Sector | Specific Application of lorry tail lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Fleet Management and Vehicle Safety | Enhanced visibility reduces accidents and improves compliance | Ensure compliance with local regulations and standards |

| Construction and Heavy Equipment | Equipment and Vehicle Lighting | Improves operational safety on job sites | Durability and weather resistance are critical |

| Agriculture | Agricultural Vehicle Lighting | Enhances visibility during night operations | Look for products with high durability and low maintenance |

| Mining | Mining Vehicle Tail Light Systems | Ensures safety in low-light environments | Consider LED options for energy efficiency and longevity |

| Emergency Services | Tail Lights for Emergency Response Vehicles | Increases visibility and safety during emergency operations | Fast delivery and compliance with emergency vehicle standards |

How are lorry tail lights utilized in the logistics and transportation sector?

In the logistics and transportation sector, lorry tail lights are crucial for fleet management and vehicle safety. These lights enhance visibility, especially during nighttime or adverse weather conditions, thereby reducing the risk of accidents. For international B2B buyers, especially those operating in regions like Africa and South America, it’s essential to source tail lights that comply with local regulations, ensuring that vehicles remain compliant with safety standards. Additionally, investing in high-quality tail lights can lead to lower insurance premiums due to improved safety.

What role do lorry tail lights play in construction and heavy equipment?

In construction, lorry tail lights are vital for ensuring the safety of vehicles and equipment on job sites. They provide necessary illumination for night work and improve visibility for oncoming traffic. Buyers in this sector should prioritize tail lights that are durable and weather-resistant to withstand harsh working conditions. The right lighting solutions can significantly reduce the likelihood of accidents, thus protecting both personnel and equipment, ultimately resulting in cost savings for construction firms.

How are lorry tail lights used in agriculture?

Agricultural vehicles rely heavily on lorry tail lights to enhance visibility during nighttime operations. These lights are essential for ensuring that farmers can safely navigate fields and transport goods after dark. For B2B buyers in agriculture, sourcing tail lights that offer high durability and low maintenance is crucial, as these vehicles often operate in rugged environments. Investing in quality lighting solutions can lead to increased productivity and safety, which are paramount in the agricultural industry.

Why are lorry tail lights important in the mining industry?

In the mining sector, lorry tail lights are critical for safety in low-light environments. They ensure that vehicles are visible to operators and other personnel, thereby preventing accidents. Buyers in this industry should consider tail lights that utilize LED technology for energy efficiency and longevity, as mining operations often run continuously. Additionally, sourcing products that meet industry-specific safety standards is essential to maintain operational integrity and compliance.

How do lorry tail lights enhance safety for emergency services?

Emergency services utilize specialized lorry tail lights to increase visibility during urgent operations. These lights are designed to be highly visible and durable, ensuring that emergency vehicles can be seen in various conditions, which is vital for the safety of both responders and the public. For B2B buyers in this sector, fast delivery times and compliance with emergency vehicle standards are key considerations when sourcing tail lights. Investing in reliable lighting solutions can significantly enhance operational efficiency and safety during emergency responses.

3 Common User Pain Points for ‘lorry tail lights’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Type of Lorry Tail Lights

The Problem: B2B buyers often face confusion when trying to choose the right type of tail lights for their fleet of lorries. With various options available—such as LED, halogen, smoked, or Euro-style—buyers may struggle to understand which type best fits their operational requirements and local regulations. This indecision can lead to purchasing errors, resulting in increased costs and potential compliance issues. Additionally, differing standards across regions, especially in diverse markets like Africa and Europe, can further complicate the selection process.

Illustrative image related to lorry tail lights

The Solution: To effectively navigate the selection process, buyers should begin by clearly understanding their specific operational needs and regulatory requirements. Conducting a thorough assessment of local regulations concerning vehicle lighting in their target market is crucial. This includes checking brightness standards, color specifications, and any restrictions on certain styles, like smoked or tinted lights. Once compliance is ensured, buyers should prioritize LED tail lights due to their superior brightness, longevity, and energy efficiency compared to halogen alternatives. Establishing a relationship with reputable suppliers who can provide detailed product specifications and recommendations tailored to their fleet’s needs will also streamline the purchasing process. Utilizing comparison tools and customer reviews can provide additional insights into product performance and durability.

Scenario 2: Concerns Over Durability and Weather Resistance

The Problem: Buyers are often worried about the durability of lorry tail lights, particularly in regions with harsh weather conditions or rugged terrain. Frequent exposure to rain, dust, and extreme temperatures can lead to premature failure of tail lights, resulting in costly downtime and safety risks. This concern is amplified for fleets operating in remote areas of Africa or South America, where replacement parts may not be readily available.

The Solution: To address these durability concerns, it is essential for buyers to invest in high-quality, weather-resistant tail lights. Look for products that are specifically designed for heavy-duty applications, featuring sealed and rugged housings that can withstand moisture and dust ingress. Brands that offer extended warranties are often more reliable, as they indicate a manufacturer’s confidence in their product’s longevity. Furthermore, regular maintenance checks should be scheduled to inspect and clean the tail lights, ensuring that any potential issues are addressed before they lead to failure. Partnering with suppliers that provide comprehensive product support, including installation guidance and troubleshooting, can enhance the longevity of the lighting systems.

Scenario 3: Managing Replacement and Repair Costs

The Problem: The costs associated with replacing and repairing lorry tail lights can quickly add up, especially for large fleets. Buyers may find themselves facing unexpected expenses due to frequent replacements caused by subpar products or accidents. This financial strain can significantly impact operational budgets, particularly for businesses in competitive markets where margins are tight.

The Solution: To effectively manage replacement and repair costs, buyers should adopt a proactive approach to sourcing tail lights. This involves investing in higher-quality products upfront, which may have a higher initial cost but offer greater durability and lower lifetime costs. Buyers should also consider bulk purchasing options or long-term contracts with suppliers to secure better pricing and reduce costs per unit. Implementing a systematic maintenance program can further prevent costly repairs by ensuring that tail lights are regularly inspected and maintained. Additionally, offering training to drivers on safe driving practices can minimize accidents and damage to tail lights, further controlling expenses. By making informed decisions about product quality and supplier relationships, buyers can achieve significant savings over time.

Strategic Material Selection Guide for lorry tail lights

What Are the Key Materials Used in Lorry Tail Lights?

When selecting materials for lorry tail lights, several options stand out due to their unique properties and performance characteristics. Understanding these materials is crucial for international B2B buyers, especially those operating in diverse environments such as Africa, South America, the Middle East, and Europe. The following analysis covers four common materials: polycarbonate, glass, aluminum, and stainless steel.

How Does Polycarbonate Perform in Lorry Tail Lights?

Polycarbonate is a popular choice for lorry tail lights due to its excellent impact resistance and lightweight nature. It can withstand high temperatures and is often used in environments where durability is paramount. Polycarbonate tail lights typically have a temperature rating of up to 120°C, making them suitable for various climates.

Pros:

– High impact resistance, reducing the risk of breakage during transport.

– Lightweight, which contributes to overall vehicle efficiency.

– Cost-effective compared to glass, making it an attractive option for bulk purchases.

Cons:

– Prone to scratching and UV degradation if not treated.

– Lower resistance to chemical exposure compared to glass or metals.

Impact on Application:

Polycarbonate tail lights are compatible with LED technology, enhancing visibility and safety. However, buyers should ensure that the polycarbonate used complies with local regulations regarding UV resistance and durability.

What Benefits Does Glass Offer for Lorry Tail Lights?

Glass has long been a traditional material for lorry tail lights, known for its clarity and aesthetic appeal. It provides excellent optical properties, ensuring high visibility in various lighting conditions. Glass tail lights can withstand high temperatures and have a pressure rating that makes them suitable for heavy-duty applications.

Pros:

– Superior optical clarity, which enhances safety by improving visibility.

– Resistant to scratches and chemical exposure.

– Generally more aesthetically pleasing, appealing to buyers focused on design.

Cons:

– Heavier than polycarbonate, potentially affecting vehicle weight and fuel efficiency.

– More fragile and susceptible to breakage during transport or installation.

Impact on Application:

Glass tail lights are often preferred in markets where aesthetics and visibility are prioritized. However, buyers must consider the additional weight and fragility, especially in regions with rough terrain.

How Does Aluminum Enhance Lorry Tail Light Durability?

Aluminum is increasingly being used in the housing of lorry tail lights due to its lightweight and corrosion-resistant properties. It can withstand harsh environmental conditions, making it suitable for international markets where exposure to moisture and salt is a concern.

Illustrative image related to lorry tail lights

Pros:

– Excellent corrosion resistance, prolonging the lifespan of the tail lights.

– Lightweight, which aids in improving fuel efficiency.

– Easily recyclable, appealing to environmentally conscious buyers.

Cons:

– Higher manufacturing complexity, which can lead to increased costs.

– May require additional coatings for enhanced durability and aesthetics.

Impact on Application:

Aluminum tail lights are particularly advantageous in coastal regions or areas with high humidity. However, buyers should ensure that the aluminum used meets local standards for corrosion resistance.

Why Choose Stainless Steel for Lorry Tail Lights?

Stainless steel offers exceptional durability and resistance to corrosion, making it an ideal material for lorry tail lights in harsh environments. Its robust nature ensures that tail lights can withstand heavy impacts and extreme temperatures.

Pros:

– Extremely durable and resistant to corrosion and rust.

– Long lifespan, reducing the need for frequent replacements.

– Aesthetic appeal due to its sleek finish.

Illustrative image related to lorry tail lights

Cons:

– Higher cost compared to other materials, which may not be feasible for all buyers.

– Heavier than alternatives like polycarbonate, potentially impacting vehicle weight.

Impact on Application:

Stainless steel tail lights are particularly suited for heavy-duty vehicles and those operating in extreme conditions. Buyers should ensure compliance with international standards regarding weight and performance.

Summary Table of Material Selection for Lorry Tail Lights

| Material | Typical Use Case for lorry tail lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Standard lorry tail lights | High impact resistance | Prone to scratching and UV degradation | Medium |

| Glass | Aesthetic-focused lorry tail lights | Superior optical clarity | Heavier and more fragile | Medium |

| Aluminum | Heavy-duty lorry tail lights | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Stainless Steel | Extreme condition lorry tail lights | Extremely durable and long-lasting | Higher cost and weight | High |

This strategic material selection guide provides essential insights for B2B buyers, enabling informed decisions based on performance, cost, and regional considerations.

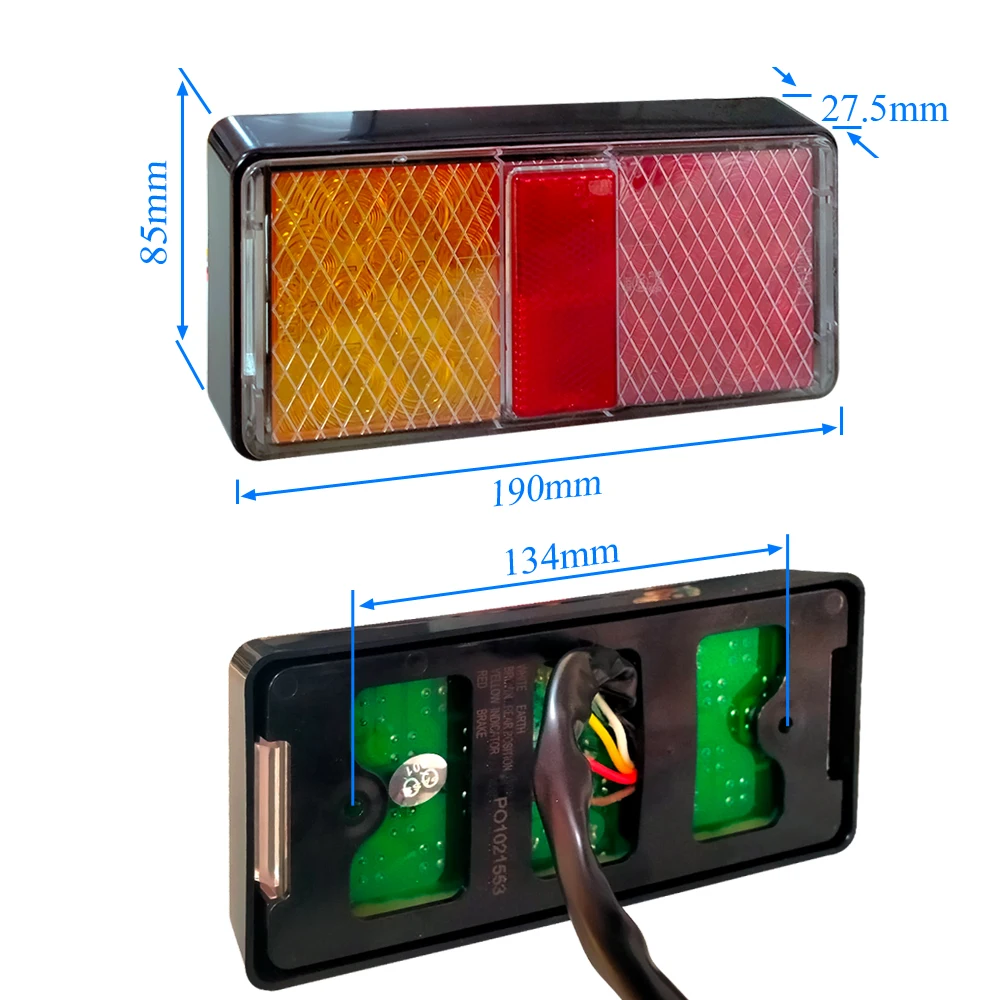

Illustrative image related to lorry tail lights

In-depth Look: Manufacturing Processes and Quality Assurance for lorry tail lights

What Are the Key Stages in the Manufacturing Process of Lorry Tail Lights?

The manufacturing process of lorry tail lights involves several key stages that ensure the final product meets both aesthetic and functional requirements.

-

Material Preparation: The first step involves selecting high-quality raw materials, such as polycarbonate for lenses and aluminum or plastic for housings. These materials are chosen for their durability, impact resistance, and weight. Suppliers often provide material certifications to guarantee compliance with international standards.

-

Forming: This stage includes the shaping of the materials into the desired components. Injection molding is a common technique used for creating housings and lenses, allowing for precise control over dimensions and surface finish. Advanced manufacturers may use computer-aided design (CAD) software to optimize the design before production, ensuring that all components fit together seamlessly.

-

Assembly: In this phase, individual components are assembled into complete units. Automated assembly lines are often employed for efficiency, where robotic arms may handle the placement of LEDs and wiring into the housings. Manual assembly may also be involved, particularly for quality assurance checks. Each assembly line typically has dedicated workers who are trained to handle specific tasks, ensuring consistency in production.

-

Finishing: The final stage includes applying coatings or treatments to enhance the performance and appearance of the tail lights. This may involve applying weather-resistant coatings, polishing lenses for clarity, or adding reflective materials to improve visibility. Finishing processes are crucial for ensuring that the tail lights can withstand harsh environmental conditions, which is especially important for international buyers operating in diverse climates.

How Is Quality Assurance Implemented in Lorry Tail Light Manufacturing?

Quality assurance (QA) in the manufacturing of lorry tail lights is critical for ensuring product reliability and compliance with industry standards.

-

International Standards: Many manufacturers adhere to ISO 9001, which focuses on quality management systems. This certification indicates that the manufacturer maintains consistent quality in their products and processes. Additionally, products may need to comply with specific regional standards, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

-

Industry-Specific Certifications: For tail lights used in commercial vehicles, compliance with additional standards like the American Petroleum Institute (API) or specific automotive regulations may be necessary. These certifications ensure that products meet rigorous safety and performance criteria.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter the production line. Suppliers must provide documentation proving that their materials meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, IPQC ensures that each stage of production is monitored for defects. This may involve visual inspections or automated testing systems that check for dimensional accuracy and functionality.

– Final Quality Control (FQC): Once the tail lights are fully assembled, FQC involves rigorous testing to confirm that the products meet all specifications. Common testing methods include photometric testing for brightness, water resistance tests, and durability tests to simulate real-world conditions.

What Testing Methods Are Commonly Used for Lorry Tail Lights?

Testing methods for lorry tail lights are designed to ensure that the products are safe and perform reliably under various conditions.

-

Photometric Testing: This method measures the light output of tail lights to ensure they meet legal brightness requirements. It assesses the intensity and distribution of light emitted from the tail light to ensure visibility in different environments.

-

Environmental Testing: Tail lights are subjected to various environmental conditions, such as extreme temperatures, humidity, and UV exposure. This testing verifies that the materials used can withstand harsh weather without degrading.

-

Vibration and Shock Testing: Given that lorry tail lights are exposed to vibrations during operation, manufacturers conduct vibration tests to ensure that the lights remain intact and function correctly under stress.

-

Water Ingress Testing: This test determines the effectiveness of seals and coatings in preventing moisture from entering the tail light assembly. It’s essential for ensuring longevity and performance in rainy or humid conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some actionable strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance systems in place. This firsthand assessment can reveal the supplier’s commitment to quality and adherence to industry standards.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and any corrective actions taken for past defects. These reports provide insights into the supplier’s quality management practices.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent entities can evaluate the products and processes without any bias, ensuring that buyers receive reliable and certified products.

-

Understanding Certification Nuances: It is crucial for international buyers, particularly from regions like Africa and South America, to understand the implications of certifications. For example, CE marking in Europe signifies compliance with EU regulations, while UL certification in the U.S. indicates safety. Buyers should ensure that the supplier’s certifications are recognized in their own markets.

What Should B2B Buyers Consider Regarding QC for International Transactions?

When engaging in international transactions, several factors regarding quality control should be considered:

-

Regulatory Compliance: Each region may have different regulations governing automotive lighting. Buyers need to ensure that their suppliers are compliant with the regulations applicable in their target markets, such as Nigeria’s SONCAP certification or Brazil’s Inmetro.

-

Cultural and Communication Barriers: Differences in language and business practices can impact quality assurance. Establishing clear communication channels with suppliers is vital for addressing quality concerns promptly.

-

Lead Times and Logistics: Quality assurance processes can impact lead times. Buyers should factor in the time required for testing and inspections when planning shipments to avoid delays in product availability.

In conclusion, understanding the manufacturing processes and quality assurance measures in lorry tail light production is crucial for B2B buyers. By leveraging insights into manufacturing stages, quality standards, testing methods, and verification strategies, buyers can make informed decisions that ensure they source reliable and compliant products for their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lorry tail lights’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure lorry tail lights. Understanding the various aspects of tail light procurement is crucial for ensuring safety, compliance, and aesthetic appeal in commercial vehicles. By following this checklist, buyers can make informed decisions that align with their operational needs and regulatory requirements.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the tail lights. Consider factors such as size, mounting type, and light configuration (e.g., LED vs. halogen).

– Compatibility: Ensure that the lights are compatible with the specific lorry models in your fleet.

– Regulatory Compliance: Verify that the lights meet local regulations for road safety and visibility.

Step 2: Assess Quality Standards

Evaluate the quality standards of the tail lights you intend to purchase. Look for products that adhere to recognized certifications such as SAE (Society of Automotive Engineers) or DOT (Department of Transportation).

– Durability: Select tail lights made from robust materials like polycarbonate or sealed housings to withstand harsh conditions.

– Warranty: Consider suppliers that offer warranties, indicating confidence in their product quality.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product catalogs, and references from other businesses in your industry.

– Experience: Look for suppliers with a proven track record in providing lorry tail lights.

– Reviews and Testimonials: Seek feedback from other buyers to gauge the supplier’s reliability and service quality.

Step 4: Compare Pricing and Value

Request quotes from multiple suppliers to compare pricing. However, focus on the overall value rather than just the lowest price.

– Cost vs. Quality: Sometimes, cheaper options may compromise quality, leading to higher long-term costs.

– Bulk Discounts: Inquire about bulk purchase discounts, which can significantly reduce your procurement costs.

Step 5: Confirm Availability and Lead Times

Check the availability of the desired tail lights and the expected lead times for delivery. This is particularly crucial if you are operating under tight deadlines or have a fleet that requires immediate replacements.

– Inventory Levels: Confirm that the supplier has sufficient stock to meet your needs.

– Shipping Options: Discuss shipping methods and costs to avoid unexpected expenses.

Step 6: Understand After-Sales Support

Evaluate the after-sales support provided by the supplier. Strong customer support can be invaluable, especially if issues arise post-purchase.

– Technical Assistance: Ensure the supplier offers technical support for installation and troubleshooting.

– Return Policies: Review the return and exchange policies to safeguard against defective products.

Illustrative image related to lorry tail lights

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure that all agreements are documented. Include terms related to pricing, delivery schedules, and warranty coverage.

– Clear Terms: Make sure that all parties understand their obligations to avoid disputes later.

– Payment Terms: Negotiate payment terms that align with your cash flow needs.

By following this checklist, B2B buyers can effectively navigate the procurement process for lorry tail lights, ensuring they select the right products from reliable suppliers while adhering to industry standards.

Comprehensive Cost and Pricing Analysis for lorry tail lights Sourcing

What are the Key Cost Components in Lorry Tail Lights Sourcing?

When sourcing lorry tail lights, understanding the cost structure is crucial for achieving favorable pricing. The primary cost components include:

- Materials: The choice of materials significantly impacts pricing. Common materials like polycarbonate or aluminum for housings, along with LED chips for illumination, can vary in cost based on quality and supplier.

- Labor: Labor costs encompass both direct manufacturing labor and indirect labor costs associated with design, engineering, and assembly.

- Manufacturing Overhead: This includes expenses related to facility operations, utilities, equipment depreciation, and administrative costs that are allocated to production.

- Tooling: Investment in tooling for specialized designs can be a significant upfront cost but may reduce per-unit costs for larger production runs.

- Quality Control (QC): Ensuring compliance with safety and performance standards incurs costs, especially if certifications such as SAE or DOT are required.

- Logistics: Transportation and warehousing costs can fluctuate based on distance, mode of transport, and the complexity of supply chains.

- Margin: Suppliers typically add a profit margin to cover their risks and operational costs, which can vary widely based on market competition.

What Influences the Pricing of Lorry Tail Lights?

Several factors influence the pricing of lorry tail lights that buyers should consider:

- Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs) that can affect pricing flexibility.

- Specifications and Customization: Custom designs or specific technical requirements can increase costs. Tail lights that meet unique specifications, such as advanced LED configurations or special housings, may command higher prices.

- Material Quality and Certifications: Higher-quality materials and adherence to international certifications can increase the price but offer better durability and performance.

- Supplier Factors: The reputation, location, and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record.

- Incoterms: Understanding Incoterms is vital for international buyers as they define the responsibilities of buyers and sellers in shipping, which can impact total costs.

What Tips Can Help International Buyers Negotiate Better Prices for Lorry Tail Lights?

International B2B buyers should consider several strategies to enhance their purchasing efficiency and cost-effectiveness:

Illustrative image related to lorry tail lights

- Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and delivery schedules. Highlighting long-term partnerships can yield better deals.

- Assess Total Cost of Ownership (TCO): Evaluate not just the purchase price but also factors like maintenance, warranty, and expected lifespan. Opting for higher-quality products may result in lower TCO.

- Be Aware of Pricing Nuances: Different regions, such as Africa, South America, the Middle East, and Europe, may have varying market dynamics. For instance, tariffs, import duties, and local regulations can significantly affect the final price.

- Conduct Market Research: Understanding the local market conditions and competitor pricing can empower buyers during negotiations, ensuring they are not overpaying.

- Utilize Technology: Employing procurement software can assist in tracking prices and supplier performance, enabling more informed decision-making.

Disclaimer on Indicative Prices

Pricing for lorry tail lights can vary significantly based on the factors discussed above. The prices found in market research may be indicative and should not be considered fixed. Buyers are encouraged to obtain quotations from multiple suppliers and conduct thorough due diligence to ensure competitive pricing aligned with their specific requirements.

Alternatives Analysis: Comparing lorry tail lights With Other Solutions

Exploring Alternatives to Lorry Tail Lights

In the realm of heavy-duty transportation, lorry tail lights are essential for ensuring safety and compliance with road regulations. However, various alternatives can also serve similar functions, either enhancing visibility or providing additional features. This section evaluates lorry tail lights against other viable solutions, helping B2B buyers make informed decisions based on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Lorry Tail Lights | LED Tail Lights | Reflective Tape |

|---|---|---|---|

| Performance | High visibility; compliant with regulations | Brighter, faster illumination; energy-efficient | Passive visibility; relies on light sources |

| Cost | Moderate to high, depending on brand and features | Generally higher upfront cost, but lower energy costs | Low initial investment; minimal long-term costs |

| Ease of Implementation | Simple installation; often plug-and-play | Requires some electrical work; may need specialized tools | Very easy to apply; adhesive backing |

| Maintenance | Regular checks needed for bulb replacement | Longer lifespan; minimal maintenance required | No maintenance; however, may degrade over time |

| Best Use Case | Ideal for standard heavy-duty vehicles needing compliance | Best for high-visibility situations or aesthetic upgrades | Suitable for low-budget solutions or as a temporary measure |

In-Depth Look at Alternatives

LED Tail Lights

LED tail lights represent a modern evolution in vehicle lighting technology. They provide superior brightness and faster response times compared to traditional lorry tail lights. With lower energy consumption, these lights can lead to cost savings in the long run. However, the initial investment is typically higher, and installation may require specialized knowledge or tools, which could complicate the implementation process. For fleets looking for durability and reduced maintenance, LED options can be an excellent choice.

Reflective Tape

Reflective tape is a cost-effective alternative that enhances visibility without the need for electrical components. It is particularly useful for low-budget operations or temporary solutions, as it can be easily applied to various surfaces. The tape relies on existing light sources, meaning it does not require any power supply. However, it may not provide the same level of visibility as active lighting solutions, especially in low-light conditions. Its lack of maintenance needs is a significant advantage, although it may degrade over time and require periodic replacement.

Making the Right Choice for Your Fleet

When selecting the best lighting solution for lorries, B2B buyers should consider the specific needs of their operations. If compliance and high visibility are paramount, traditional lorry tail lights or LED alternatives may be the best fit. On the other hand, if budget constraints are significant or temporary solutions are required, reflective tape can provide a practical, low-cost option. Understanding the nuances of each alternative will empower buyers to make informed choices that align with their operational requirements and financial goals.

Essential Technical Properties and Trade Terminology for lorry tail lights

What Are the Key Technical Properties of Lorry Tail Lights?

When sourcing lorry tail lights, understanding critical technical specifications can significantly influence purchasing decisions. Here are some essential properties:

1. Material Grade

The material used in tail light construction, such as polycarbonate or acrylic, affects durability and visibility. Polycarbonate is often preferred for its impact resistance and lightweight properties, making it ideal for heavy-duty applications. Understanding material grades helps buyers select lights that can withstand harsh environmental conditions, particularly in regions with extreme weather.

2. IP Rating (Ingress Protection)

The IP rating indicates the level of protection against dust and water ingress. For example, an IP67 rating signifies complete dust protection and the ability to withstand immersion in water up to 1 meter for 30 minutes. This specification is crucial for lorry tail lights operating in diverse climates, ensuring longevity and reducing maintenance costs.

3. Lumens Output

Lumens measure the brightness of the tail lights. Higher lumens indicate brighter lights, which improve visibility and safety on the road. B2B buyers should prioritize lights that meet or exceed the legal brightness requirements in their region, enhancing safety and compliance with regulations.

4. Voltage Compatibility

Tail lights typically operate on a 12V or 24V electrical system, depending on the vehicle type. Ensuring compatibility with the vehicle’s electrical system is essential for seamless installation and functionality. This specification can prevent costly errors and installation delays.

5. Certifications (e.g., SAE, DOT)

Certifications from recognized authorities, such as the Society of Automotive Engineers (SAE) or the Department of Transportation (DOT), ensure that the tail lights meet safety and performance standards. Purchasing certified products helps businesses comply with legal requirements and avoid liability issues.

Illustrative image related to lorry tail lights

6. Warranty Period

A warranty period reflects the manufacturer’s confidence in their product quality. A longer warranty often indicates robust construction and reliability. Buyers should consider the warranty as part of their risk assessment when investing in tail lights.

What Are Common Trade Terms Associated with Lorry Tail Lights?

Familiarity with industry jargon can streamline communication and negotiations in the procurement process. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle. In the context of lorry tail lights, OEM components are designed to fit perfectly and function as intended, making them a reliable choice for replacements. Buyers often prefer OEM parts for quality assurance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell. Understanding MOQ is vital for buyers as it affects inventory management and cost efficiency. For companies operating on tight budgets, negotiating MOQ can lead to significant savings.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued to suppliers requesting a quote for specific products or services. For buyers of lorry tail lights, an RFQ can clarify pricing, lead times, and specifications, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and potential costs, ensuring smooth transactions and compliance with international trade laws.

5. Aftermarket

The aftermarket refers to parts and accessories not supplied by the original vehicle manufacturer. Aftermarket tail lights can offer cost-effective alternatives with various styles and features. Buyers should evaluate the quality and compatibility of aftermarket options before making a purchase.

6. Lead Time

Lead time is the period between placing an order and receiving the goods. Knowing the lead time for lorry tail lights is crucial for planning and inventory management, particularly in industries where timely delivery is critical to operations.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions, ensuring they select the best lorry tail lights for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the lorry tail lights Sector

What Are the Key Market Dynamics and Trends Influencing the Lorry Tail Lights Sector?

The lorry tail lights market is experiencing a dynamic shift driven by several global factors. Increasing regulatory standards for vehicle safety and lighting efficiency are compelling manufacturers to innovate. LED technology is gaining traction due to its longer lifespan and energy efficiency compared to traditional halogen bulbs. This shift is particularly relevant for international buyers, as regions like Europe are leading the charge towards stricter lighting regulations, influencing sourcing decisions across Africa and South America as they look to modernize their fleets.

Emerging trends also highlight a growing preference for customization. Buyers are increasingly seeking tail lights that not only meet functional needs but also enhance the aesthetic appeal of vehicles. This trend is particularly pronounced in markets such as Nigeria and Germany, where brand image and vehicle aesthetics play a crucial role in purchasing decisions. Additionally, advancements in smart technology are paving the way for integrated lighting systems that offer features such as adaptive lighting and enhanced visibility, further influencing buyer choices.

Furthermore, the shift towards online procurement platforms is transforming the sourcing landscape. B2B buyers can now easily compare products, access reviews, and negotiate pricing, making informed decisions more accessible than ever. This trend is particularly beneficial for buyers in emerging markets who may have previously faced challenges accessing quality products.

How Is Sustainability and Ethical Sourcing Impacting the Lorry Tail Lights Market?

Sustainability and ethical sourcing are becoming paramount in the lorry tail lights sector as environmental concerns gain traction globally. The production of automotive lighting, including tail lights, can have significant environmental impacts, particularly related to energy consumption and waste generation. As a result, companies are increasingly adopting sustainable practices throughout their supply chains. For B2B buyers, this means sourcing from manufacturers who prioritize eco-friendly materials and processes.

Ethical sourcing is also gaining importance, with buyers seeking suppliers who adhere to responsible labor practices and contribute positively to their local communities. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are becoming essential indicators for buyers looking to ensure that their suppliers maintain high standards.

Illustrative image related to lorry tail lights

In the context of lorry tail lights, materials such as recyclable plastics and low-emission manufacturing processes are becoming more prevalent. Buyers are encouraged to inquire about the environmental impact of the products they source and to seek out suppliers who can provide transparency in their sourcing practices. This focus not only aligns with global sustainability goals but also meets the increasing demand from consumers for responsible products.

What Is the Evolution of the Lorry Tail Lights Market and Its Relevance to B2B Buyers?

The evolution of lorry tail lights has been marked by significant technological advancements and changing consumer preferences. Initially, tail lights were predominantly halogen-based, providing basic functionality for vehicle lighting. However, the introduction of LED technology revolutionized the market by offering improved brightness, energy efficiency, and durability. This shift has been particularly beneficial for B2B buyers, as LEDs significantly reduce maintenance costs and enhance vehicle safety.

Moreover, the rise of customization options has transformed the landscape, allowing buyers to select tail lights that reflect their brand identity and meet specific operational needs. The market has seen a diversification in product offerings, from traditional designs to innovative styles that integrate modern technology.

As the lorry tail lights market continues to evolve, B2B buyers must remain aware of these trends and advancements. Understanding the historical context and the trajectory of product development will enable buyers to make informed decisions that align with their operational requirements and sustainability goals.

Illustrative image related to lorry tail lights

Frequently Asked Questions (FAQs) for B2B Buyers of lorry tail lights

-

How do I solve issues with tail light compatibility for my lorries?

To address compatibility issues with tail lights for your lorries, ensure that you have the correct specifications for your vehicle model. Start by identifying the make, model, and year of the lorry. Consult with your supplier or manufacturer for compatibility charts or guidelines. Additionally, consider whether you need OE (original equipment) replacements or aftermarket options, which may provide enhanced features or aesthetics. It’s also prudent to request samples or conduct a trial installation if possible to verify fitment before placing a bulk order. -

What is the best type of tail light for heavy-duty lorries?

For heavy-duty lorries, LED tail lights are often the best choice due to their durability and efficiency. They provide brighter illumination, quicker response times, and longer lifespans compared to traditional halogen lights. Look for products that are SAE and DOT approved to ensure compliance with safety standards. Additionally, consider weather-resistant designs to withstand harsh environments, especially if operating in regions with extreme weather conditions. Brands like Truck-Lite and AlphaRex are recommended for their robust offerings in heavy-duty applications. -

What customization options are available for lorry tail lights?

Customization options for lorry tail lights can include variations in color, lens type (clear, smoked, or tinted), and additional features such as integrated LED indicators or sequential lighting. Many manufacturers offer bespoke solutions tailored to specific fleet needs. When sourcing, inquire about minimum order quantities for custom designs and the lead time for production. Ensure that any customizations comply with local regulations in your target market to avoid legal issues. -

How do I vet suppliers for lorry tail lights?

To vet suppliers effectively, start by researching their reputation and reliability through online reviews and industry references. Request certifications that demonstrate compliance with international quality standards, such as ISO or CE markings. Additionally, assess their experience in exporting to your region, especially if you are in Africa or South America, where logistics can be complex. A good supplier should be transparent about their production processes, quality assurance measures, and offer customer support for post-purchase inquiries. -

What are the typical payment terms for international orders of tail lights?

Payment terms can vary significantly among suppliers, but common practices include a deposit (often 30-50%) upfront with the balance due before shipment. Some suppliers may offer letters of credit or payment through escrow services for larger orders. It’s essential to clarify these terms before committing to a purchase and ensure that they align with your cash flow capabilities. Also, consider the implications of currency exchange rates and potential transaction fees when dealing with international suppliers. -

What are the minimum order quantities (MOQ) for lorry tail lights?

Minimum order quantities (MOQ) for lorry tail lights can range from a few dozen to several hundred units, depending on the supplier and the specific product line. When negotiating, consider your immediate needs and future purchasing potential to establish a favorable MOQ. Some manufacturers may be flexible with MOQs for first-time orders or if you are willing to pay a premium. Always communicate your requirements clearly to ensure the supplier can accommodate your order size. -

How can I ensure quality assurance for the tail lights I purchase?

To ensure quality assurance, request samples before placing a bulk order. Additionally, inquire about the supplier’s quality control processes, including testing for durability, weather resistance, and compliance with safety standards. Look for products that come with warranties or guarantees, which indicate the manufacturer’s confidence in their quality. Establishing a clear communication channel with the supplier can also facilitate quick resolution of any issues that arise post-purchase. -

What logistics considerations should I keep in mind when sourcing lorry tail lights internationally?

When sourcing lorry tail lights internationally, consider shipping methods, costs, and transit times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Assess the supplier’s ability to handle customs documentation and whether they offer door-to-door delivery services. Additionally, factor in the potential for import duties and taxes based on your country’s regulations. Establishing a reliable logistics partner can streamline the process and minimize delays in receiving your order.

Top 8 Lorry Tail Lights Manufacturers & Suppliers List

1. RealTruck – Tail Lights

Domain: realtruck.com

Registered: 1998 (27 years)

Introduction: Tail Lights available in OE-Replacement, Smoked, and Chrome styles. Key features include: Lens options (Smoked, Clear, Red, Smoked Red, Smoked Black), Bulb Type (LED), Housing options (Black, Chrome, Red), Price ranges ($0 – $50, $50 – $100, $100 – $250, $250 – $500, $500 – $750, $750 – $1,000), and Brands (Recon, AlphaRex, SPEC-D Tuning, Winjet, Oracle Lighting, Anzo USA, IPCW, Renegade, Form Lig…

2. Truck-Lite – Stop/Turn/Tail Light Kits

Domain: easternmarine.com

Registered: 1999 (26 years)

Introduction: [{‘name’: ‘TRUCK-LITE Super 60™ Red Stop/Turn/Tail Light Kit’, ‘stock_number’: ‘1569140’, ‘dimensions’: ‘W = 6.50″ H = 2.25″ D = 2.50″‘, ‘price’: ‘$19.95’}, {‘name’: ‘TRUCK-LITE Model 40® Red Stop/Turn/Tail Light Kit’, ‘stock_number’: ‘1569111’, ‘dimensions’: ‘W = 4.31″ D = 2.11″‘, ‘price’: ‘$17.45’}, {‘name’: ‘TRUCK-LITE Super 44® Red LED Stop/Turn/Tail Light Kit’, ‘stock_number’: ‘1569126’, ‘dim…

3. LMC Truck – Stylish Tail Lights

Domain: lmctruck.com

Registered: 1997 (28 years)

Introduction: This company, LMC Truck – Stylish Tail Lights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Truck-Lite – Stop/Turn/Tail Lights

Domain: truck-lite.com

Registered: 1996 (29 years)

Introduction: Stop/Turn/Tail Lights: Various models including Bus and 40 Series, available in incandescent and LED options. Common features include: Red color, rectangular or round shapes, 1 bulb configuration, 12V or 24V voltage options, and various mounting types (grommet, screw). Products include part numbers such as 07081, 07092, 40002R, and 40009R. Additional specifications may include bulb wattage, housin…

5. Stainless Tail Panel – Semi Trucks

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1. Rear Stainless Center Tail Panel w/ Red LED Lights, Red Lenses – Semi Trucks: Brand New, Price: $244.99, Delivery: +$30.00, Location: United States, Condition: Almost gone.

2. Rear Stainless Center Tail Panel w/ Red LED Lights, Clear Lenses – Semi Trucks: Brand New, Price: $244.99, Delivery: +$30.00, Location: United States, Condition: Almost gone.

3. 5pcs 2″ Round 4 LED Side Marker Clearance T…

6. Reddit – Safe Driving Tips for Truckers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The best way to get a trucker’s attention when their tail lights are out is to pass safely and use a combination of hazard lights and flashing driving lights. In situations where visibility is low, such as at night with rain and fog, it may be difficult to ensure the truck driver sees or hears you. During the day, making eye contact by driving alongside the cab is recommended.

7. Gorecon – Aftermarket LED Truck Tail Lights

Domain: gorecon.com

Registered: 2007 (18 years)

Introduction: Aftermarket LED Truck Tail Lights, Buy 3+ Save 15%, FREE Shipping on Orders $300+, Flat Rate Shipping Under $300: $19.99 (Continental USA), $45 Flat Rate Outside Continental USA. Product Types include LED Tail Lights, LED 3rd Brake Lights, LED Fog Lights, LED Dome Lights, LED Bed Lights, and more. Shop by Make: Ford, Dodge (RAM), Chevy, GMC, Jeep, Toyota. Popular Categories: Projector Headlights, …

8. M-Grill – Lorry Tail Lights

Domain: m-grill.com

Registered: 2003 (22 years)

Introduction: Lorry Tail Lights, Brake and Reverse Trailer Lights for RVs and Trucks

Strategic Sourcing Conclusion and Outlook for lorry tail lights

As the demand for lorry tail lights continues to grow across global markets, strategic sourcing emerges as a pivotal strategy for B2B buyers seeking quality, reliability, and compliance with regional regulations. Understanding the diverse offerings—from traditional halogen to advanced LED technologies—enables buyers to make informed purchasing decisions that align with both operational requirements and aesthetic preferences.

Investing in reputable brands known for their quality and durability, such as Truck-Lite and Anzo, can significantly enhance vehicle safety and longevity. Additionally, ensuring compliance with local standards, especially in regions like Africa and Europe, is crucial for seamless market entry and customer satisfaction.

Looking ahead, international buyers are encouraged to leverage technological advancements and supplier partnerships to optimize their procurement processes. By staying attuned to industry trends and innovations, businesses can not only meet current demands but also anticipate future needs in an ever-evolving marketplace. Embrace this opportunity to enhance your fleet’s safety and performance through strategic sourcing of high-quality lorry tail lights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.