Choosing Your Latch Design: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for latch design

In today’s fast-paced global market, sourcing high-quality latch design solutions can pose significant challenges for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil. The complexity of navigating various standards, specifications, and supplier capabilities makes it crucial for businesses to have access to comprehensive resources that streamline the decision-making process. This guide on latch design is meticulously crafted to address these challenges, providing an in-depth look at the types of latches available, their applications across various industries, and critical factors to consider when vetting suppliers.

Within this guide, buyers will discover essential insights into the different types of latches, including SR, D, JK, and T latches, along with their unique functionalities and advantages. We will also delve into practical applications, helping buyers identify which latch designs best suit their specific operational needs. Furthermore, this guide will cover vital topics such as cost considerations, supplier evaluation criteria, and market trends, equipping readers with the knowledge necessary to make informed purchasing decisions. By empowering B2B buyers with actionable insights and a clear understanding of the latch design landscape, this guide serves as a valuable resource for optimizing procurement strategies and enhancing operational efficiency in a competitive global marketplace.

Understanding latch design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SR Latch | Simple two-input design (Set/Reset) | Basic memory storage, control systems | Pros: Easy to implement; Cons: Undefined state when both inputs are high. |

| Gated SR Latch | Includes an enable signal for controlled operation | Data storage in asynchronous circuits | Pros: Retains previous state when disabled; Cons: More complex than SR latch. |

| D Latch | Single data input that follows clock signal | Temporary data storage, buffering | Pros: Simplifies timing issues; Cons: Requires clock signal for operation. |

| JK Latch | Eliminates undefined state with toggle feature | Flip-flops, counters, state machines | Pros: Versatile operation; Cons: Slightly more complex circuitry. |

| T Latch | Toggles output state when input is high | Frequency dividers, toggle switches | Pros: Simple design; Cons: Limited to toggle functionality. |

What are the Key Characteristics of SR Latch Design?

The SR latch is the foundational element in latch design, characterized by its simple two-input structure—Set (S) and Reset (R). This design allows it to maintain a binary state until it receives a new input. Commonly used in basic memory storage and control systems, the SR latch is easy to implement with minimal components. However, buyers should be cautious of its undefined state when both inputs are activated, which can lead to unpredictable behavior in digital systems. For applications requiring straightforward memory retention without complex timing, the SR latch is a reliable choice.

How Does a Gated SR Latch Enhance Functionality?

The gated SR latch introduces an enable signal that allows for controlled operation, making it suitable for applications in asynchronous circuits where data integrity is crucial. This design enables the latch to retain its previous state when the enable signal is low, enhancing its usability in various data storage scenarios. While it offers significant advantages in retaining data integrity, buyers should consider the added complexity compared to the basic SR latch. This is particularly relevant in systems requiring precise control over data flow and timing.

Why Choose a D Latch for Data Storage Needs?

The D latch, also known as a transparent latch, features a single data input that is monitored by a clock signal. Its output mirrors the input as long as the clock is high, making it ideal for temporary data storage and buffering applications. The D latch simplifies timing issues that can arise in synchronous systems, providing a clear advantage for buyers looking for reliable data handling solutions. However, it is essential to remember that the D latch’s operation is contingent on a clock signal, which may not be suitable for all applications.

What Makes the JK Latch a Versatile Option?

The JK latch is an advanced variation that eliminates the undefined state found in SR latches by incorporating toggle functionality. With two inputs, J and K, the JK latch can set, reset, or toggle its output, making it a versatile choice for flip-flops, counters, and state machines. This adaptability is beneficial for buyers in dynamic environments where circuit behavior needs to change based on varying inputs. Although the JK latch introduces slightly more complexity in design and implementation, its ability to handle multiple states efficiently makes it a preferred option for many digital applications.

When is a T Latch the Right Choice?

The T latch is a specialized type of JK latch where both inputs are tied together. It toggles its output state with every high input signal, making it particularly useful in applications such as frequency dividers and toggle switches. Its straightforward design allows for easy integration into various digital systems. However, potential buyers should consider that its functionality is limited to toggling, which may not meet the needs of applications requiring more complex operations. For projects that benefit from simple toggle functionality, the T latch is an excellent choice.

Key Industrial Applications of latch design

| Industry/Sector | Specific Application of latch design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electronic Control Units (ECUs) | Enhanced reliability and performance in vehicle systems | Compliance with automotive standards and certifications |

| Telecommunications | Data Storage in Network Equipment | Improved data integrity and faster access times | Compatibility with various network protocols and standards |

| Industrial Automation | Control Systems for Manufacturing Processes | Increased efficiency and reduced downtime | Scalability and integration capabilities with existing systems |

| Consumer Electronics | Memory Storage in Smart Devices | Higher performance and better user experience | Low power consumption and compact design requirements |

| Robotics | Feedback Control Systems | Enhanced precision and responsiveness | Robustness against environmental factors and longevity |

How is latch design utilized in the automotive sector for ECUs?

In the automotive industry, latch design is critical for Electronic Control Units (ECUs) that manage various vehicle functions. Latches facilitate the storage and retrieval of data essential for controlling engine performance, safety systems, and infotainment options. By utilizing latches, manufacturers can ensure that data is retained accurately during power fluctuations, enhancing reliability. Buyers in this sector must consider sourcing latches that meet stringent automotive standards, ensuring compatibility with existing vehicle architectures and compliance with safety regulations.

What role does latch design play in telecommunications for data storage?

In telecommunications, latch design is integral to data storage solutions within network equipment. Latches are employed to temporarily hold and quickly access data packets, ensuring smooth data transmission and minimizing latency. This capability is vital for maintaining high data integrity and performance in increasingly complex networks. B2B buyers in this industry should focus on sourcing latches that are compatible with various network protocols and standards, as well as those that can withstand the rigors of high-performance applications.

How does latch design enhance industrial automation control systems?

Latch design is pivotal in industrial automation, where control systems rely on latches to manage processes in manufacturing environments. These latches enable real-time data storage for sensor readings and operational commands, which can significantly boost efficiency and minimize downtime. For international buyers, it is essential to source latches that offer scalability and seamless integration with existing automation frameworks, ensuring compatibility with various machinery and operational protocols.

In what ways do consumer electronics benefit from latch design in memory storage?

In consumer electronics, latch design is utilized for memory storage in smart devices, including smartphones and tablets. Latches allow for rapid data access and retention, which enhances overall device performance and user experience. As consumers demand faster and more efficient devices, sourcing latches that have low power consumption and compact designs becomes crucial for manufacturers looking to stay competitive in the market.

How is latch design critical for robotics in feedback control systems?

In robotics, latch design is essential for feedback control systems that require precise data handling for movement and operations. Latches store critical sensor data that informs decision-making processes, ensuring that robots operate with high accuracy and responsiveness. For international buyers in this sector, sourcing robust latches that can withstand various environmental factors and have a long operational lifespan is vital for maintaining reliable robotic functions in diverse applications.

3 Common User Pain Points for ‘latch design’ & Their Solutions

Scenario 1: Navigating Undefined States in Latch Design

The Problem: One of the most significant challenges B2B buyers face in latch design is the risk of entering undefined states, particularly with SR latches. When both inputs (Set and Reset) are activated simultaneously, it can lead to unpredictable behavior in digital systems. This uncertainty can cause errors in applications where reliability is critical, such as in industrial automation or data storage solutions. Buyers often find it difficult to integrate latches into their systems without a clear understanding of these potential pitfalls, which can result in costly errors and system failures.

The Solution: To mitigate the risk of undefined states in latch design, buyers should opt for JK or T latches instead of traditional SR latches. These alternatives are designed to eliminate the undefined state issue by ensuring that when both inputs are high, the output toggles instead of entering an indeterminate state. Additionally, implementing comprehensive testing protocols during the design phase can help identify any potential issues related to latch states before full-scale production. Buyers should also consider collaborating with experienced design engineers who can assist in selecting the right type of latch for specific applications, thereby enhancing reliability and performance.

Scenario 2: Complexity in Timing Specifications

The Problem: Timing complexity is another pain point that often troubles B2B buyers involved in latch design. Many latches do not operate with a clock signal, making their timing behavior more complex and less predictable than clocked flip-flops. This unpredictability can pose significant challenges in applications requiring precise timing, such as synchronous data processing or high-speed communications. Buyers may struggle to ensure that their systems operate correctly under various conditions, leading to inefficiencies and increased development costs.

The Solution: To address timing challenges, buyers should prioritize the use of gated latches or clocked flip-flops, which provide more predictable timing characteristics. Gated latches, for instance, include an enable signal that controls when the latch should accept new data, thus providing a level of timing control similar to clocked devices. Additionally, utilizing simulation software during the design phase can help visualize timing behavior and identify potential issues before hardware implementation. Buyers should engage with suppliers who offer robust simulation tools and provide detailed specifications to ensure that timing requirements are met efficiently.

Scenario 3: Difficulty in Sourcing Reliable Components

The Problem: Sourcing reliable latch components can be a frustrating experience for B2B buyers, especially when dealing with international suppliers. Variability in quality, lack of standardization, and inconsistent supply chains can lead to delays and subpar performance in end products. Buyers may find themselves overwhelmed by the options available and uncertain about how to ensure the components they select will meet their quality and performance standards.

The Solution: To streamline the sourcing process, buyers should establish partnerships with reputable suppliers known for their quality assurance processes and reliable delivery. Conducting thorough due diligence on potential suppliers, including assessing their certifications and customer reviews, can significantly reduce risks. Additionally, implementing a rigorous testing protocol for incoming components can help ensure that only high-quality latches are used in production. Buyers should also consider engaging in long-term contracts with trusted suppliers to secure better pricing and consistent supply, which can enhance overall project efficiency and reduce lead times.

Strategic Material Selection Guide for latch design

What Are the Best Materials for Latch Design?

When designing latches, selecting the right material is crucial for ensuring optimal performance, durability, and cost-effectiveness. Here we analyze four common materials used in latch design, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Stainless Steel Perform in Latch Design?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high tensile strength, and ability to withstand high temperatures. It typically has a temperature rating up to 800°F (427°C) and can handle significant pressure without deforming.

Pros & Cons: The durability of stainless steel makes it ideal for heavy-duty applications, especially in outdoor or harsh environments. However, it is more expensive than other materials and can be challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel latches are suitable for applications exposed to moisture, chemicals, or extreme temperatures, such as marine and industrial settings.

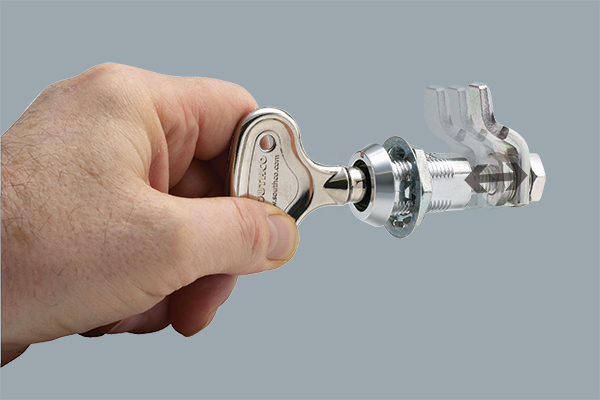

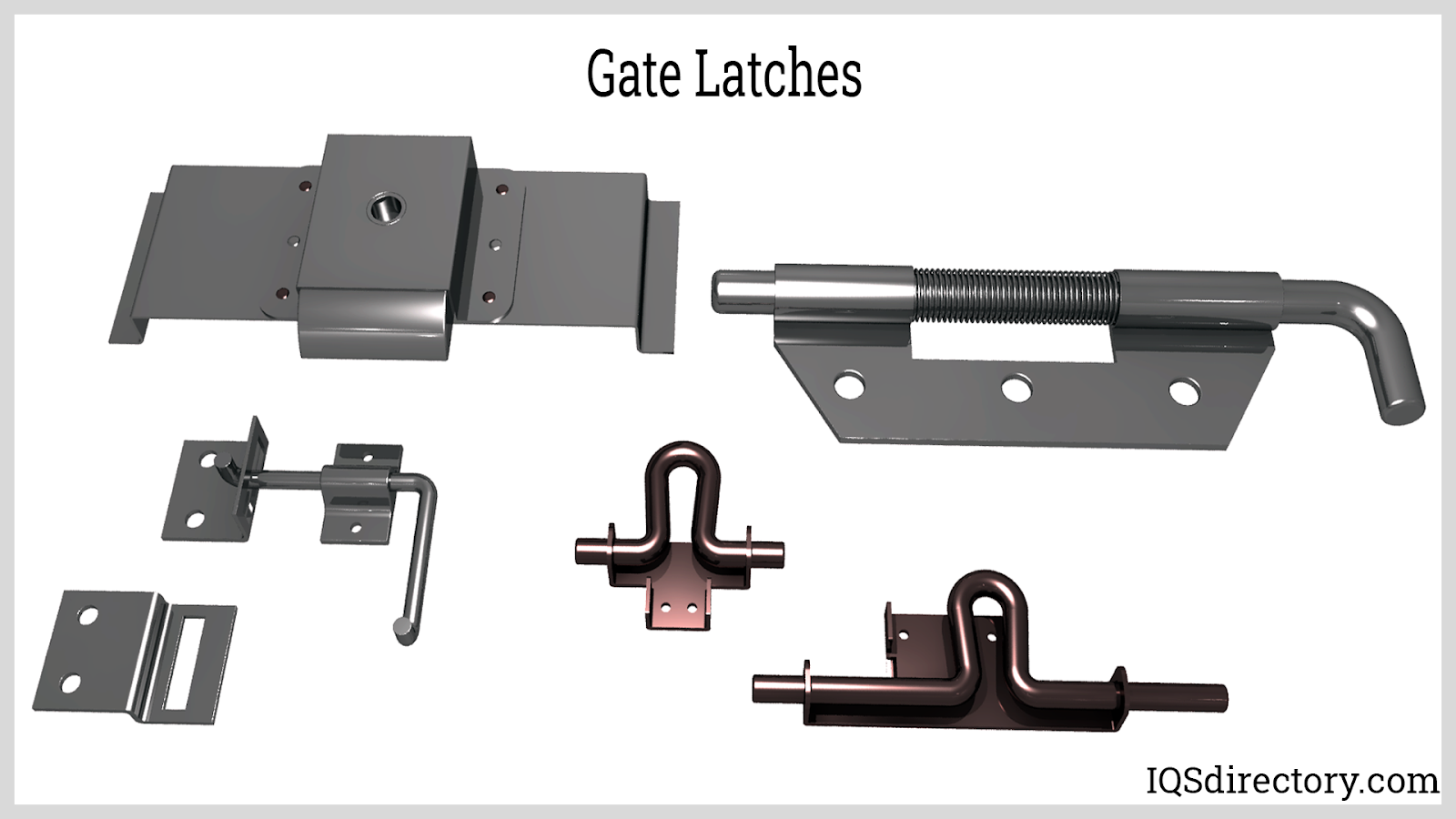

Illustrative image related to latch design

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial, particularly in regions such as Europe and the Middle East. Buyers should ensure that the stainless steel grade meets local regulations and industry standards.

What Role Does Aluminum Play in Latch Design?

Key Properties: Aluminum is lightweight and has good corrosion resistance, particularly when anodized. It typically has a lower temperature rating than stainless steel, around 400°F (204°C), but is still suitable for many applications.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install, reducing shipping costs. However, it has lower tensile strength compared to stainless steel, which may limit its use in heavy-duty applications.

Impact on Application: Aluminum latches are ideal for applications where weight is a concern, such as in aerospace or automotive industries. They are also commonly used in consumer products due to their aesthetic appeal.

Illustrative image related to latch design

Considerations for International Buyers: Buyers in regions like Africa and South America should consider the availability of aluminum grades that comply with local standards. Anodizing processes may also vary, affecting corrosion resistance.

How Do Plastics Compare in Latch Design?

Key Properties: Engineering plastics, such as nylon and polycarbonate, offer good chemical resistance and can operate within a temperature range of -40°F to 200°F (-40°C to 93°C).

Pros & Cons: Plastics are lightweight, cost-effective, and can be molded into complex shapes, providing design flexibility. However, they may not be suitable for high-stress applications due to lower strength and durability compared to metals.

Impact on Application: Plastic latches are often used in consumer goods and lightweight applications, such as electronics and furniture. Their resistance to chemicals makes them suitable for use in environments where metal latches might corrode.

Considerations for International Buyers: Compliance with safety and environmental regulations is critical, especially in Europe where REACH and RoHS directives apply. Buyers should verify that the plastics used meet these standards.

What Advantages Do Composites Offer in Latch Design?

Key Properties: Composite materials, such as fiberglass-reinforced plastics, combine lightweight properties with high strength and excellent corrosion resistance. They can withstand temperatures up to 300°F (149°C).

Pros & Cons: Composites offer a unique balance of strength and weight, making them suitable for specialized applications. However, they can be more expensive to produce and may require specialized manufacturing techniques.

Impact on Application: Composite latches are ideal for aerospace and automotive applications where weight savings are critical without sacrificing strength. Their resistance to environmental factors also makes them suitable for outdoor use.

Considerations for International Buyers: Buyers should consider the availability of composite materials that meet specific industry standards in their region, especially in terms of fire resistance and mechanical properties.

Summary Table of Material Selection for Latch Design

| Material | Typical Use Case for latch design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty outdoor applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace and automotive | Lightweight and cost-effective | Lower strength than metals | Medium |

| Plastics | Consumer products and electronics | Design flexibility and low cost | Limited strength and durability | Low |

| Composites | Aerospace and specialized applications | High strength-to-weight ratio | Higher production costs | High |

This guide provides actionable insights into material selection for latch design, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for latch design

What Are the Main Stages of Manufacturing Processes for Latch Design?

Manufacturing latches involves several key stages that ensure the final product meets both functional and quality standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves selecting the appropriate materials for the latch, typically metals like stainless steel or aluminum, which offer durability and resistance to corrosion. Suppliers must ensure that materials meet specified standards, such as ASTM or ISO, to guarantee performance. This stage also includes cutting and machining the materials to the required dimensions.

-

Forming: In this stage, the prepared materials undergo various forming processes, such as stamping, bending, or extrusion, depending on the latch design. Stamping is particularly common for producing the latch body, where sheets of metal are cut and shaped into the desired form using dies. Advanced forming techniques like CNC machining may also be employed for precision components, ensuring tight tolerances.

-

Assembly: Once the individual components are formed, they are assembled to create the final latch product. This may involve welding, riveting, or using adhesives to join parts together. Automation is increasingly used in this phase to improve efficiency and consistency, particularly in high-volume production settings. Quality control measures during assembly are critical to ensure proper fit and function.

-

Finishing: The final stage involves surface treatments such as plating, powder coating, or painting to enhance aesthetics and provide additional protection against wear and corrosion. The finishing process must adhere to international standards, ensuring that the coating does not compromise the latch’s functionality.

How is Quality Assurance Integrated into Latch Manufacturing?

Quality assurance (QA) is a crucial component in the manufacturing process of latches, ensuring that every product meets the required specifications and standards. This is particularly important for B2B buyers who rely on consistent quality for their applications.

-

Relevant International Standards: Adhering to international standards such as ISO 9001 ensures that manufacturers implement effective quality management systems. These standards help in maintaining a consistent quality level across production processes. Industry-specific certifications like CE marking in Europe or API standards in the oil and gas sector are also critical for latches used in specialized applications.

-

Quality Control Checkpoints: The QA process includes several checkpoints throughout the manufacturing cycle:

– Incoming Quality Control (IQC): At this stage, raw materials are inspected to ensure they meet specifications before being used in production. This prevents defects from entering the manufacturing process.

– In-Process Quality Control (IPQC): During production, regular inspections and tests are conducted to monitor the quality of components and assemblies. This helps in identifying and addressing issues in real-time.

– Final Quality Control (FQC): Before products are shipped, a final inspection ensures that each latch meets the required specifications and functions correctly. This may involve functional testing, dimensional checks, and visual inspections.

What Common Testing Methods Are Used in Latch Quality Assurance?

To ensure that latches perform reliably under various conditions, manufacturers employ a range of testing methods. These tests can include:

- Mechanical Testing: This involves assessing the strength, durability, and fatigue resistance of the latch under simulated operational conditions.

- Corrosion Resistance Testing: Latches intended for outdoor or harsh environments undergo tests such as salt spray tests to evaluate their resistance to corrosion.

- Functional Testing: This verifies that the latch operates correctly, engaging and disengaging as intended without failure.

- Dimensional Inspection: Using precision measuring tools, manufacturers check that all components meet specified dimensions and tolerances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must have confidence in their suppliers’ quality control processes. Here are several strategies to ensure that suppliers maintain high-quality standards:

-

Audits: Conducting regular audits of suppliers’ facilities can provide insight into their manufacturing processes and quality control measures. This helps verify compliance with international standards and internal quality benchmarks.

-

Quality Reports: Requesting quality reports from suppliers, including data on defect rates, inspection results, and corrective actions taken, can help buyers assess the reliability of the supplier’s quality control practices.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control processes and the quality of the products being manufactured. This adds an extra layer of assurance.

-

Certifications: Reviewing certifications held by suppliers, such as ISO 9001 or specific industry-related certifications, can indicate their commitment to quality and adherence to recognized standards.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is vital. Different regions may have varying standards and expectations regarding quality assurance.

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements specific to their region, such as CE marking in Europe or local certifications in South America. Ensuring that suppliers comply with these regulations is crucial for market entry.

-

Cultural Considerations: Different cultures may have varying approaches to quality and reliability. Understanding these differences can help buyers communicate effectively with suppliers and set clear expectations.

-

Logistics and Supply Chain: Quality control processes may also be impacted by logistics and supply chain considerations, such as transportation conditions and storage facilities. Buyers should work closely with suppliers to ensure that products remain compliant and undamaged throughout the supply chain.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing latches, ensuring they meet their operational requirements and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch design’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure latch designs. Latches are critical components in various industries, including electronics, automotive, and manufacturing. Understanding the sourcing process can help ensure that you select the best suppliers and products that meet your specific needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for the latch design you need. Consider factors such as size, material, load capacity, and intended application. Clearly defined specifications will not only streamline the procurement process but also help suppliers provide you with accurate quotes and suitable options.

- Material Requirements: Specify if you need materials that are corrosion-resistant, lightweight, or have specific thermal properties.

- Performance Metrics: Identify any performance standards that must be met, such as durability under specific environmental conditions.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in latch designs. Look for companies with a proven track record in your industry and positive customer reviews. This step is crucial to ensure that you are engaging with reputable manufacturers who can meet your needs.

- Industry Experience: Focus on suppliers who have experience with similar products or industries.

- Geographical Considerations: Consider suppliers located in regions with established supply chains that can reduce shipping times and costs.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate compliance with industry standards. Certifications such as ISO 9001 for quality management can be indicative of a supplier’s commitment to excellence.

- Quality Assurance: Look for suppliers who have quality control processes in place.

- Safety Standards: Ensure that the supplier meets safety regulations pertinent to your industry, especially if the latches will be used in critical applications.

Step 4: Request Samples and Prototypes

Before making a bulk purchase, request samples or prototypes of the latch designs. This allows you to assess the quality, functionality, and fit of the product in your specific application.

- Testing for Compatibility: Ensure that the samples can be tested in real-world conditions to validate performance.

- Feedback Loop: Utilize feedback from your engineering or design teams to inform any necessary adjustments before finalizing your order.

Step 5: Review Pricing and Payment Terms

Gather detailed pricing information from each supplier and compare it against your budget. Understand the payment terms, including any upfront costs, payment schedules, and potential discounts for bulk orders.

- Cost Breakdown: Ask for a breakdown of costs to understand pricing structures, including shipping and handling fees.

- Negotiation Opportunities: Look for opportunities to negotiate better terms based on order volume or long-term partnership potential.

Step 6: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier. Clear communication is vital for addressing any questions, concerns, or changes that may arise during the procurement process.

- Point of Contact: Identify a primary contact person on both sides to streamline communication.

- Regular Updates: Establish a schedule for regular updates on order status, production timelines, and delivery schedules.

Step 7: Finalize Contracts and Place Orders

Once you have selected a supplier, finalize contracts that outline all agreed-upon terms, including delivery timelines, quality standards, and payment conditions. This legal documentation protects both parties and ensures clarity.

- Review Terms: Ensure that all terms are clearly stated and understood to avoid future disputes.

- Order Confirmation: Obtain a formal confirmation of your order along with expected delivery dates and tracking information.

By following this checklist, B2B buyers can confidently navigate the sourcing process for latch designs, ensuring a successful procurement experience that meets their operational needs.

Illustrative image related to latch design

Comprehensive Cost and Pricing Analysis for latch design Sourcing

What Are the Key Cost Components in Latch Design Sourcing?

When sourcing latches, understanding the cost structure is crucial for international buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts both cost and performance. Common materials for latches include metals (like stainless steel and aluminum) and plastics (such as polycarbonate and nylon). The price volatility of these materials can vary significantly based on global market trends and regional availability.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of the latch design. Regions with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. It’s essential to evaluate the skill level of the workforce involved in production to ensure quality standards are met.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. Overhead can vary widely depending on the supplier’s operational efficiency and location.

-

Tooling: Custom tooling for latch production can be a significant upfront investment. The complexity of the design and the materials used will influence tooling costs. Buyers should consider whether the supplier has the necessary tooling already in place or if new tooling will need to be developed.

-

Quality Control (QC): Implementing robust QC measures is essential, particularly for buyers in regulated industries. The costs associated with QC processes, such as testing and certification, should be factored into the overall pricing structure.

-

Logistics: Shipping costs can greatly affect the final price, particularly for international transactions. Factors include the distance from the supplier, the mode of transportation, and any tariffs or duties that may apply.

-

Margin: Supplier profit margins vary based on market positioning and competition. Understanding the typical margins within the industry can provide insight into pricing strategies.

How Do Price Influencers Affect Latch Design Sourcing?

Several factors can influence the pricing of latches:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes can lead to reduced per-unit costs. Negotiating favorable terms based on projected sales can help buyers achieve better pricing.

-

Specifications/Customization: Custom designs typically incur higher costs due to the need for specialized tooling and manufacturing processes. Clearly defining specifications upfront can mitigate unexpected costs.

-

Materials: The choice of materials not only affects cost but also the functionality and longevity of the latch. Buyers should balance cost with performance requirements when selecting materials.

-

Quality/Certifications: Compliance with international standards and certifications can add to costs but may be necessary for specific markets, particularly in Europe and North America. Buyers should assess whether these certifications are essential for their target market.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge a premium for their proven quality and service.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics costs and responsibilities. Understanding these terms can help buyers avoid unexpected charges and delays.

What Are the Best Buyer Tips for Cost Efficiency in Latch Design Sourcing?

-

Negotiate Effectively: Leverage volume commitments and long-term relationships to negotiate better pricing. Building a partnership with suppliers can lead to more favorable terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term costs associated with maintenance, replacement, and operational efficiency. A slightly higher upfront cost may result in lower TCO if the latch is more durable and requires less maintenance.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of potential tariffs, customs fees, and currency fluctuations that could impact overall costs. Partnering with local experts can provide valuable insights into these factors.

-

Conduct Market Research: Regularly review market trends and supplier offerings to stay informed about pricing fluctuations and emerging suppliers that may offer competitive rates.

-

Request Samples: Before committing to large orders, request samples to assess quality and suitability. This can prevent costly mistakes and ensure that the product meets specifications.

Disclaimer

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and economic factors. Buyers are encouraged to conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing latch design With Other Solutions

Exploring Alternatives to Latch Design in Digital Systems

In the realm of digital circuit design, latch technology serves as a fundamental element for data storage and processing. However, several alternative solutions exist that offer distinct advantages and disadvantages depending on the specific requirements of the application. This section compares latch design with two viable alternatives: flip-flops and static random-access memory (SRAM).

| Comparison Aspect | Latch Design | Flip-Flop | SRAM |

|---|---|---|---|

| Performance | High speed, level-sensitive operation | Slower than latches, edge-sensitive operation | High-speed read/write operations |

| Cost | Low-cost, simple implementation | Moderate cost due to complexity | Higher cost, requires more components |

| Ease of Implementation | Easy with basic gates | More complex, requires clock synchronization | Moderate complexity, needs additional control logic |

| Maintenance | Low maintenance, simple circuitry | Moderate maintenance, clock signal dependency | Higher maintenance, more components to manage |

| Best Use Case | Temporary storage, control circuits | Reliable data storage in synchronized systems | High-speed data access in computing applications |

What are the Pros and Cons of Flip-Flops Compared to Latch Design?

Flip-flops represent a more advanced alternative to latches, particularly in synchronous circuit designs. They are edge-triggered devices that only change state at specific points in a clock cycle, making them more predictable in terms of timing. This characteristic is beneficial for applications requiring precise synchronization, such as in microprocessors and digital signal processors. However, flip-flops are generally more complex and costly to implement than latches, as they need additional components like clock signals. Additionally, their slower performance relative to latches can be a drawback in high-speed applications.

How Does SRAM Compare to Latch Design?

Static Random-Access Memory (SRAM) is another alternative that excels in certain applications, particularly in high-speed computing environments. SRAM allows for rapid read and write operations, making it suitable for cache memory in processors. While it offers superior performance compared to latches and flip-flops, SRAM also comes with a higher cost and complexity due to the number of transistors required to maintain each bit of information. Maintenance can be more demanding because of the intricate circuitry involved, making it less ideal for simpler applications where latches may suffice.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between latch design and its alternatives, B2B buyers must carefully assess their specific requirements. For applications demanding quick, simple data storage without the need for clock synchronization, latches provide an excellent, cost-effective solution. Conversely, if precise timing and reliability are paramount, flip-flops may be the better choice, despite their higher complexity and cost. In scenarios where high-speed data access is essential, SRAM stands out but may not be necessary for simpler tasks. Ultimately, understanding the unique characteristics of each technology will empower buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for latch design

What Are the Key Technical Properties in Latch Design?

When designing latches for various applications, understanding the critical technical properties is essential for ensuring performance, reliability, and compliance with industry standards. Here are some key specifications to consider:

-

Material Grade

The choice of material significantly impacts the latch’s durability and functionality. Common materials include stainless steel, zinc alloy, and plastics, each offering different strength, corrosion resistance, and weight properties. For example, stainless steel latches are ideal for outdoor applications due to their resistance to rust and environmental factors, making them a preferred choice in regions with high humidity. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In latch design, tight tolerances are crucial for ensuring proper fit and function within a system. Tighter tolerances typically lead to higher manufacturing costs but are essential for high-precision applications, such as in automotive or aerospace industries, where even minor discrepancies can lead to failures. -

Load Capacity

Load capacity indicates the maximum weight or force a latch can handle without failure. This property is vital in applications where latches are subjected to significant mechanical stress. Understanding the load requirements helps in selecting the appropriate latch type and material, ensuring safety and functionality in various applications, from industrial machinery to consumer products. -

Environmental Resistance

This property assesses how well a latch can withstand various environmental conditions, such as temperature fluctuations, humidity, and exposure to chemicals. For instance, latches used in marine applications must be resistant to saltwater corrosion, while those in food processing must meet hygiene standards. Selecting latches with appropriate environmental resistance ensures longevity and reliability. -

Actuation Mechanism

The actuation mechanism describes how the latch is engaged or disengaged. Options include manual, automatic, or electronic actuation. Understanding the actuation mechanism is crucial for compatibility with existing systems and for ensuring ease of use in the intended application. For instance, electronic latches may offer enhanced security features but require a power source, which may not be ideal for all environments. -

Finish and Coating

The finish of a latch can affect both its aesthetic appeal and performance. Options such as powder coating, anodizing, or plating can enhance corrosion resistance and provide a visually appealing surface. In B2B transactions, specifying the desired finish can prevent misunderstandings and ensure the final product meets the buyer’s expectations.

What Are Common Trade Terms Used in Latch Design?

Understanding industry terminology is crucial for effective communication between manufacturers and buyers. Here are some common trade terms relevant to latch design:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In latch design, OEMs play a critical role in providing specialized latches tailored for specific applications. Understanding OEM relationships can help buyers ensure they source high-quality, compatible components. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is important for buyers to consider, as it impacts inventory costs and supply chain management. Negotiating MOQs can provide opportunities for cost savings, especially for bulk purchases. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to request pricing and terms from suppliers for specific products or services. When initiating an RFQ for latches, buyers should include detailed specifications, quantities, and delivery timelines to ensure accurate responses from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping and delivery. Understanding these terms is crucial for managing shipping costs, risks, and logistics. For example, terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping costs and insurance during transit. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. In the latch design industry, lead times can vary significantly based on factors such as manufacturing processes and material availability. Being aware of lead times helps buyers plan their projects more effectively and avoid delays. -

Certification Standards

Certification standards refer to industry-specific requirements that products must meet to ensure safety and quality. Common standards include ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials). Familiarity with these standards can help buyers select compliant products, ensuring safety and reliability in their applications.

Understanding these technical properties and industry terms enables buyers to make informed decisions, fostering better collaboration and successful outcomes in latch design projects.

Navigating Market Dynamics and Sourcing Trends in the latch design Sector

What Are the Current Market Dynamics and Key Trends in Latch Design?

The latch design sector is currently experiencing significant transformation driven by advancements in technology and shifts in market demands. A surge in automation across industries, particularly in manufacturing and automotive, is propelling the demand for reliable and efficient latch systems. In regions like Africa and South America, where industrial growth is accelerating, international B2B buyers are increasingly looking for innovative latch solutions that enhance operational efficiency and reduce downtime.

In Europe, particularly Germany, the focus is on high-quality materials and precision engineering, which are essential for meeting stringent safety and quality standards. The integration of smart technologies is another emerging trend, with latches being designed to work seamlessly with IoT devices, enabling remote monitoring and control. This trend is gaining traction in the Middle East as businesses seek to modernize and optimize their operations.

Moreover, there is a growing emphasis on customization, where manufacturers are providing tailored solutions to meet specific client needs. This shift towards bespoke designs is critical for B2B buyers who require latches that fit unique applications, ranging from heavy machinery to consumer electronics. As the market evolves, buyers should prioritize suppliers that demonstrate flexibility and a capacity for innovation, ensuring they remain competitive in their respective industries.

How Is Sustainability and Ethical Sourcing Shaping the Latch Design Sector?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the latch design sector. The environmental impact of manufacturing processes is under scrutiny, with companies facing pressure to minimize waste and reduce carbon footprints. This trend is particularly pronounced in Europe, where regulatory frameworks are increasingly stringent regarding environmental standards.

Buyers are now seeking suppliers who prioritize sustainable materials and practices. This includes the use of recyclable materials in latch production and energy-efficient manufacturing processes. Certifications such as ISO 14001 for environmental management and initiatives focused on reducing harmful emissions are becoming essential criteria for supplier selection.

Moreover, ethical sourcing is gaining traction, with buyers favoring companies that ensure fair labor practices and transparency within their supply chains. In regions like Africa and South America, where socio-economic factors can complicate labor conditions, buyers must be vigilant about the ethical implications of their sourcing decisions. By partnering with suppliers committed to sustainability and ethical practices, businesses not only enhance their brand reputation but also contribute positively to the global effort toward responsible manufacturing.

What Is the Evolution of Latch Design in the B2B Context?

The evolution of latch design has been marked by a continuous quest for innovation and efficiency. Initially, latches were simple mechanical devices used to secure doors and containers. Over time, advancements in materials science and engineering led to the development of more complex designs, including electronic and smart latches that integrate with modern technology.

The transition from purely mechanical systems to digital latches reflects broader trends in automation and smart technology. As industries embraced digital transformation, latch design evolved to incorporate features such as remote access control and IoT connectivity. This evolution has enabled manufacturers to create products that not only meet traditional security needs but also offer enhanced functionality and user convenience.

Today, latch designs are not just about securing physical spaces; they are integral components of sophisticated systems that enhance operational efficiency and safety across various sectors. This historical progression underscores the importance of innovation in meeting the demands of modern B2B buyers, who seek reliable, efficient, and technologically advanced solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of latch design

-

How do I choose the right latch design for my application?

Choosing the right latch design involves understanding the specific needs of your application, such as the type of data being stored and the required speed of operation. Consider factors like the latch type (SR, D, JK, etc.), power consumption, and the operating environment. Engage with suppliers who can provide samples for testing, and assess their ability to meet your technical requirements while ensuring compliance with international standards. -

What is the best latch type for digital circuits in high-speed applications?

For high-speed applications, D latches or JK latches are generally the best choices. D latches offer transparency, allowing the output to follow the input as long as the clock signal is high, making them suitable for applications requiring quick data transfer. JK latches prevent undefined states and can toggle outputs, providing versatility in design. Evaluate your circuit’s specific needs and consult with manufacturers to find the most suitable option. -

What are the minimum order quantities (MOQ) for latch designs?

Minimum order quantities for latch designs can vary significantly based on the manufacturer and the complexity of the design. Typically, MOQs range from 100 to 1,000 units for standard designs, while custom designs may require larger orders to justify production costs. It’s essential to discuss your specific needs with suppliers to negotiate MOQs that align with your procurement strategy. -

How can I ensure quality assurance in my latch design procurement?

To ensure quality assurance, select suppliers who adhere to international quality standards, such as ISO 9001. Request samples for testing before placing large orders, and establish clear specifications for your latch designs. Additionally, consider implementing a third-party quality inspection service to verify that the products meet your standards before shipment, especially when dealing with international suppliers. -

What payment terms should I expect when sourcing latch designs internationally?

Payment terms can vary by supplier and region but typically include options such as advance payment, net 30, or letter of credit. It’s common for suppliers to require a deposit upfront, especially for custom orders. Establishing clear payment terms upfront can help mitigate risks and ensure a smooth transaction. Always confirm the payment methods accepted by the supplier and consider currency fluctuations in your financial planning. -

What logistics considerations should I keep in mind when importing latches?

When importing latches, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate the total landed cost, including freight, duties, and taxes. Partnering with a logistics provider experienced in international trade can streamline the process and help you navigate any potential challenges. Always ensure that your supplier can provide the necessary documentation for customs clearance. -

How can I vet suppliers for latch design effectively?

To vet suppliers, start by checking their credentials, such as certifications and industry experience. Request references from previous clients and assess their capacity to meet your design specifications. Conduct site visits or audits if possible, and evaluate their manufacturing processes and quality control measures. Utilizing platforms like Alibaba or industry-specific trade shows can also provide insights into a supplier’s reputation and reliability. -

What customization options are typically available for latch designs?

Customization options for latch designs can include variations in size, material, and functionality to meet specific application requirements. Many manufacturers offer tailored solutions based on your technical specifications, such as unique latch configurations or enhanced durability features. Discuss your specific needs with potential suppliers to explore the range of customization options they can provide, ensuring that the final product aligns perfectly with your project goals.

Top 5 Latch Design Manufacturers & Suppliers List

1. LATCH – Organizing Information

Domain: medium.com

Registered: 1998 (27 years)

Introduction: This company, LATCH – Organizing Information, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reddit – Innovative Latch Design Ideas

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Innovative Latch Design Ideas, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reid Supply – Latches

Domain: reidsupply.com

Registered: 2004 (21 years)

Introduction: Types of Latches: 1. Cam Latches – Simple mechanical devices with a body attached to a cabinet door and a cam lever; actuated by a quarter-turn motion. 2. Compression Latches – Similar to cam latches but designed to compress a gasket for a tight seal against moisture and dust; available in fixed and adjustable types. 3. Slam Latches – Spring-loaded latches with a slide bolt; secured when the door …

4. Electronics Stack Exchange – Latch Applications in VLSI Design

Domain: electronics.stackexchange.com

Registered: 2009 (16 years)

Introduction: Latches are used in VLSI design for several applications: 1. They allow for single-cycle circuits, as opposed to flip-flops which require two cycles for input to output. 2. Latches enable ‘time-borrowing’, providing flexibility in circuit design. 3. They are utilized in clock or power gating circuits, requiring less area and power than flip-flops. 4. Latches can mimic flip-flop behavior when pulse…

5. DesignNews – Key Considerations for Selecting Latches

Domain: designnews.com

Registered: 1995 (30 years)

Introduction: Key considerations for selecting latches for enclosures include grip dimension, distance from latch centerline to door frame, space for latch mechanism, and operator handhold clearance. Types of latches discussed are: 1. Cam Latches – Simple, economical, easy to install, adjustable grip options available, suitable for basic applications. 2. Compression Latches – Provide tight closure, reduce rattl…

Strategic Sourcing Conclusion and Outlook for latch design

In the dynamic landscape of latch design, strategic sourcing emerges as a critical factor for international B2B buyers. By understanding the diverse types of latches—including SR, gated SR, D, and JK latches—businesses can identify the most suitable components for their applications, ensuring efficiency and cost-effectiveness. The advantages of latches, such as low power consumption and high-speed operation, provide compelling reasons for their widespread adoption across various industries, from automotive to consumer electronics.

Furthermore, the global market for latch components is evolving, driven by innovations and increasing demand for reliable digital systems. Buyers should leverage strategic sourcing practices to establish robust relationships with suppliers, ensuring access to quality materials and cutting-edge technologies. This not only mitigates risks but also enhances competitiveness in their respective markets.

As we look to the future, it is essential for B2B buyers from Africa, South America, the Middle East, and Europe to remain proactive in their sourcing strategies. Engage with suppliers who prioritize innovation and sustainability to stay ahead in this rapidly changing environment. By doing so, you will not only fulfill immediate operational needs but also position your business for long-term success in the latch design arena.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.