Choosing Your Lab Bench Work: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for lab bench work

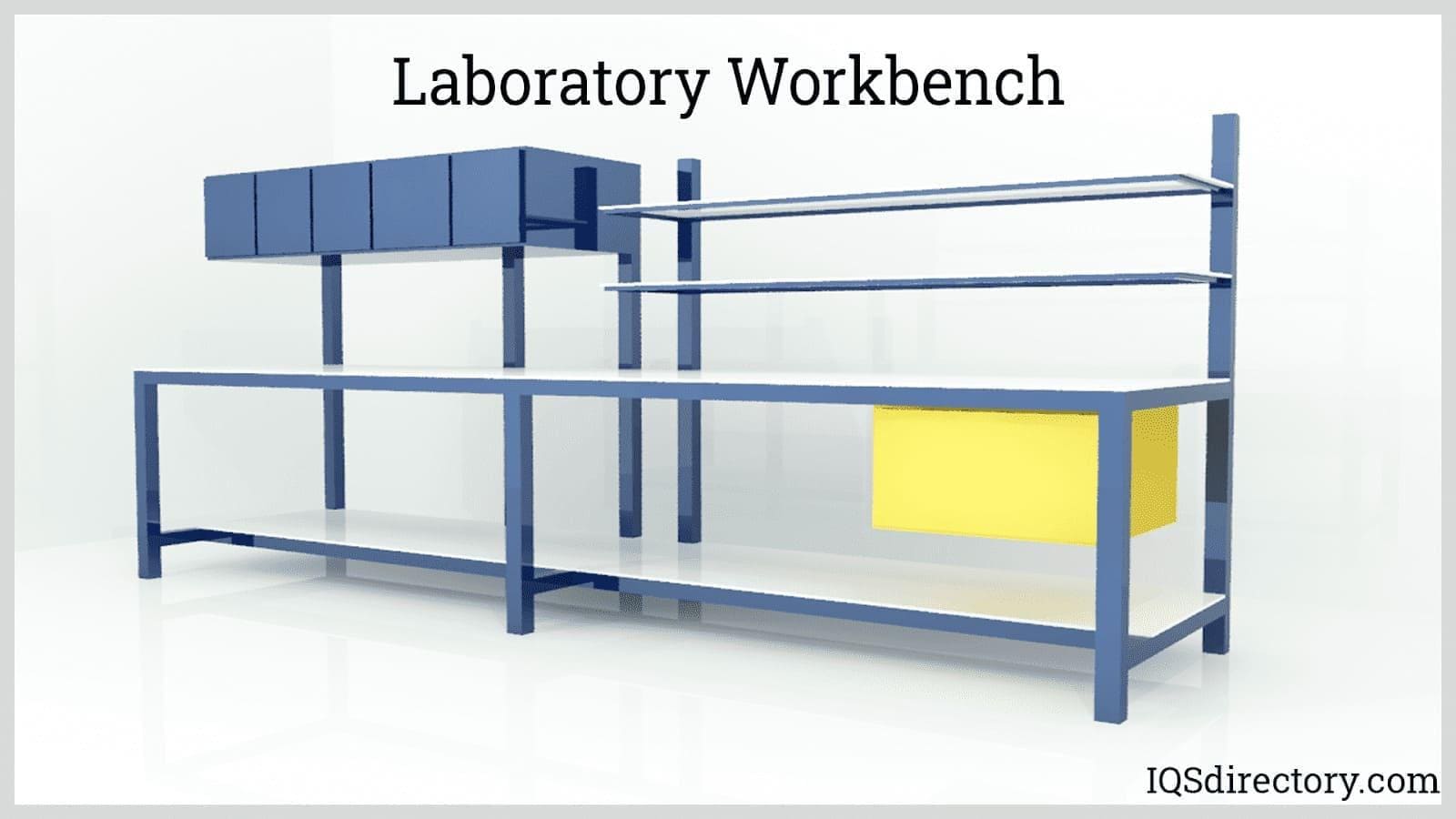

In the dynamic landscape of laboratory operations, sourcing the right lab bench work solutions can pose a significant challenge for international B2B buyers. Whether you’re seeking durable, chemical-resistant surfaces or adjustable-height workstations, the need for reliable and efficient lab furniture is paramount. This guide delves into the multifaceted world of lab bench work, providing insights into various types, applications, and essential features to consider when making a purchase.

From heavy-duty resin tops to specialized cleanroom benches, we explore the breadth of options available to meet diverse laboratory needs. Our comprehensive overview includes supplier vetting strategies, cost assessments, and the latest trends in lab furniture design, ensuring you are well-equipped to navigate the complexities of the global market.

By addressing the specific requirements of buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Saudi Arabia—this guide empowers you to make informed purchasing decisions that enhance your laboratory’s functionality and safety. With a focus on quality and performance, we aim to help you identify the best lab bench work solutions that align with your operational goals and budget constraints.

Understanding lab bench work Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resin Top Lab Workbench | Chemical resistant, solid wood core, heavy load capacity | Laboratories handling chemicals | Pros: Durable, easy to clean. Cons: Heavier, may be costly. |

| Stainless Steel Workbench | Corrosion-resistant, hygienic surface, often mobile | Food processing, pharmaceuticals | Pros: Easy to sanitize, long-lasting. Cons: Higher initial cost. |

| Adjustable Height Workbench | Height flexibility, ergonomic design | Educational labs, multi-user environments | Pros: Customizable for various tasks. Cons: Mechanism can wear over time. |

| Static Control Workbench (ESD) | ESD-safe materials, grounded surfaces | Electronics manufacturing, testing labs | Pros: Protects sensitive components. Cons: Limited to specific applications. |

| Cleanroom Laminate Workbench | Non-porous, smooth surfaces, designed for sterile environments | Biotechnology, pharmaceuticals, research | Pros: Maintains contamination control. Cons: Requires careful maintenance. |

What Are the Characteristics of Resin Top Lab Workbenches?

Resin top lab workbenches are designed for durability and chemical resistance, making them ideal for laboratories that handle hazardous materials. With a solid wood core and a load capacity that can exceed 6,600 pounds, these benches provide a robust workspace. Buyers should consider the weight and cost, as these benches can be heavier and more expensive than alternatives, but their longevity and ease of cleaning often justify the investment.

Illustrative image related to lab bench work

How Do Stainless Steel Workbenches Stand Out?

Stainless steel workbenches are preferred in environments where hygiene is paramount, such as food processing and pharmaceuticals. Their corrosion-resistant surfaces are easy to sanitize, ensuring compliance with strict health regulations. While the initial purchase price can be higher, the long-term benefits of durability and minimal maintenance make them a wise investment for businesses prioritizing cleanliness and durability.

Why Choose Adjustable Height Workbenches?

Adjustable height workbenches cater to diverse user needs, allowing for ergonomic adjustments that enhance comfort and productivity. They are particularly beneficial in educational settings and multi-user laboratories where various tasks are performed. Buyers should evaluate the mechanism’s durability and ease of adjustment, as these factors can impact long-term usability. While they offer flexibility, the moving parts may require maintenance over time.

What Are the Advantages of Static Control Workbenches (ESD)?

Static control workbenches are essential in environments dealing with sensitive electronic components. Constructed from materials that minimize static electricity, these benches protect against electrostatic discharge, which can damage electronic devices. While they are crucial for electronics manufacturing and testing labs, buyers should be aware that their application is somewhat specialized, limiting their use in other laboratory settings.

When Should You Consider Cleanroom Laminate Workbenches?

Cleanroom laminate workbenches are specifically designed for sterile environments, featuring non-porous surfaces that help maintain contamination control. These benches are commonly used in biotechnology and pharmaceutical labs. While they are effective in preventing contamination, they require careful maintenance to preserve their integrity. Buyers should assess their cleaning protocols and operational needs to ensure these workbenches align with their laboratory requirements.

Key Industrial Applications of lab bench work

| Industry/Sector | Specific Application of lab bench work | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceutical | Drug formulation and testing | Ensures precise measurements and controlled environments | Need for chemical resistance, ESD protection, and compliance with regulations. |

| Biotechnology | Genetic research and sample analysis | Facilitates accurate experimentation and data collection | Bench durability, mobility options, and compatibility with lab equipment. |

| Food and Beverage | Quality control and product testing | Enhances food safety and quality assurance | Requirement for easy-to-clean surfaces and temperature resistance. |

| Environmental Science | Sample collection and analysis | Supports environmental monitoring and compliance efforts | Need for specialized surfaces that resist chemicals and contamination. |

| Education and Training | Hands-on learning and experiments | Provides a practical learning environment for students | Consideration for adjustable height and multi-station configurations. |

How is lab bench work utilized in the pharmaceutical industry?

In the pharmaceutical sector, lab workbenches are essential for drug formulation and testing. These benches provide a stable and controlled environment for scientists to conduct experiments, ensuring precise measurements and compliance with regulatory standards. Buyers in this sector should prioritize benches with chemical-resistant surfaces and features like ESD protection to safeguard sensitive electronic equipment. Additionally, the ability to customize workstations to accommodate various lab instruments is crucial for optimizing workflow.

Illustrative image related to lab bench work

What role does lab bench work play in biotechnology?

Biotechnology heavily relies on lab benches for genetic research and sample analysis. These workbenches facilitate accurate experimentation and data collection, which are vital for developing new treatments and technologies. Buyers should look for durable and mobile workstations that can easily accommodate specialized equipment. Furthermore, benches that allow for easy cleaning and maintenance help maintain sterile conditions, which are critical in biotechnological applications.

How is lab bench work applied in the food and beverage industry?

In the food and beverage industry, lab workbenches are used for quality control and product testing. They ensure that products meet safety standards and regulatory requirements, thus enhancing food safety and quality assurance. Buyers should consider workbenches with easy-to-clean surfaces and those that can withstand temperature fluctuations. Additionally, benches designed to handle heavy loads are beneficial for testing equipment and large samples.

Why is lab bench work important for environmental science?

Lab benches in environmental science are crucial for sample collection and analysis, supporting environmental monitoring and compliance efforts. They provide the necessary workspace for conducting tests on soil, water, and air samples. Buyers should focus on benches that resist chemicals and contamination, as well as those that can be easily sanitized. The ability to customize bench configurations for specific testing needs is also a significant consideration.

How does lab bench work enhance education and training?

In educational settings, lab benches facilitate hands-on learning and experiments for students. These benches create a practical learning environment, encouraging engagement and skill development in scientific disciplines. Buyers should consider adjustable-height benches and multi-station configurations to accommodate diverse learning activities. Additionally, safety features and durable materials are essential to support an active learning environment while ensuring student safety.

Illustrative image related to lab bench work

3 Common User Pain Points for ‘lab bench work’ & Their Solutions

Scenario 1: The Challenge of Limited Customization Options in Lab Workbenches

The Problem: Many B2B buyers face significant challenges in finding lab workbenches that meet their specific needs. For instance, a pharmaceutical company in South America might require workbenches that accommodate various laboratory processes, including chemical handling and sample analysis. However, off-the-shelf options often lack the necessary features, such as chemical resistance or adjustable heights, leading to inefficient workflows and potential safety hazards. This lack of customization can frustrate lab managers who are trying to optimize their workspace for productivity and compliance.

The Solution: To address this issue, buyers should seek suppliers who offer customizable lab workbenches. Look for manufacturers that provide a range of materials, sizes, and configurations, allowing for tailored solutions that meet specific laboratory requirements. For example, consider workbenches with phenolic resin tops for chemical resistance or hydraulic lift options for ergonomic adjustments. Additionally, utilize 3D configurators provided by some suppliers to visualize and plan your workspace effectively. Engaging directly with manufacturers or their representatives can also yield insights into custom features that can be integrated, ensuring that the final product aligns perfectly with your operational needs.

Scenario 2: Navigating Compliance and Safety Standards in Laboratory Settings

The Problem: Compliance with safety standards is a significant concern for B2B buyers involved in lab bench work, especially in regions with stringent regulations. For instance, a laboratory in the Middle East may struggle to ensure that their workbenches comply with local health and safety regulations, including materials used and structural integrity. Failure to adhere to these standards can result in penalties, operational shutdowns, and risks to personnel, making it imperative for buyers to understand the compliance landscape.

The Solution: To mitigate compliance-related challenges, buyers should conduct thorough research on applicable regulations and standards in their region. Collaborating with suppliers who specialize in laboratory furniture can provide valuable insights into compliant materials and designs. When sourcing lab workbenches, prioritize those with certifications from recognized bodies, such as ISO or ASTM, which indicate adherence to safety and quality standards. Furthermore, consider training sessions or workshops with suppliers to educate your team on compliance issues, ensuring that everyone is aligned on best practices and safety measures in the laboratory environment.

Scenario 3: Addressing Space Constraints in Laboratory Design

The Problem: Space limitations in laboratory settings are a common pain point for many B2B buyers. Laboratories in Europe, for example, often contend with high real estate costs and limited square footage, necessitating efficient use of space. Standard workbenches may not fit well in smaller or irregularly shaped labs, leading to cluttered environments that hinder productivity and can even pose safety risks.

Illustrative image related to lab bench work

The Solution: Buyers should explore modular and mobile lab workbench solutions that maximize space efficiency. Opt for workbenches designed with compact footprints or those that can be easily reconfigured based on workflow requirements. Mobile workbenches on casters can be moved as needed, allowing for flexibility in layout and ensuring that all areas of the lab are accessible. When designing the lab space, involve an interior lab design consultant who can help optimize layout and recommend specific products that fit the unique dimensions of your facility. By investing in space-saving solutions, laboratories can enhance operational efficiency and create a safer, more organized work environment.

Strategic Material Selection Guide for lab bench work

What Are the Key Properties of Common Materials for Lab Benches?

When selecting materials for lab benches, several factors come into play, including durability, chemical resistance, and cost-effectiveness. Here, we analyze four common materials used in lab bench construction: stainless steel, phenolic resin, laminate, and wood.

How Does Stainless Steel Perform in Lab Bench Applications?

Stainless steel is renowned for its exceptional corrosion resistance and durability. It can withstand high temperatures and is easy to clean, making it ideal for environments where hygiene is critical, such as in pharmaceutical and food laboratories. However, while stainless steel offers high strength and longevity, it can be more expensive than other materials, which may deter budget-conscious buyers.

For international B2B buyers, compliance with standards such as ASTM A240 for stainless steel is crucial. Buyers should also consider local preferences for finishes and grades, as certain regions may favor specific types of stainless steel based on environmental conditions.

What Are the Benefits of Using Phenolic Resin for Lab Benches?

Phenolic resin surfaces are highly resistant to chemicals, heat, and moisture, making them suitable for a variety of laboratory applications. They are particularly effective in environments where aggressive chemicals are handled, such as in chemical or biological labs. The cost of phenolic resin benches is generally moderate, offering a balance between performance and price.

However, while phenolic resin is durable, it can be susceptible to scratching and may not be as aesthetically pleasing as other materials. Buyers in regions with stringent chemical safety regulations should ensure that the phenolic resin meets local compliance standards.

Why Choose Laminate for Lab Bench Work?

Laminate surfaces are popular due to their versatility and cost-effectiveness. They are available in various colors and patterns, allowing for customization to fit the lab’s aesthetic. Laminate is resistant to stains and easy to clean, making it suitable for general laboratory use.

The primary disadvantage of laminate is its lower resistance to heat and chemicals compared to stainless steel or phenolic resin. In high-temperature applications, laminate surfaces may warp or degrade. Buyers should verify that the laminate meets relevant standards, such as those set by DIN or JIS, to ensure quality and performance.

What Role Does Wood Play in Lab Bench Construction?

Wood, particularly hardwoods like maple or oak, is known for its strength and aesthetic appeal. It is often used in educational labs or research settings where a warm, inviting environment is desired. Wood is also relatively inexpensive compared to metals and resins.

Illustrative image related to lab bench work

However, wood is less resistant to chemicals and moisture, which can limit its application in certain environments. Buyers should consider the local climate and typical laboratory conditions when selecting wood. Additionally, compliance with local standards for wood treatment and sustainability should be assessed.

Summary of Material Properties for Lab Benches

| Material | Typical Use Case for lab bench work | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical and pharmaceutical labs | Exceptional corrosion resistance | Higher cost | High |

| Phenolic Resin | Chemical handling and biological labs | High chemical resistance | Susceptible to scratching | Medium |

| Laminate | General lab use | Cost-effective and customizable | Lower heat and chemical resistance | Low |

| Wood | Educational and research labs | Aesthetic appeal and affordability | Poor chemical and moisture resistance | Medium |

In conclusion, selecting the right material for lab benches involves balancing performance characteristics with cost and compliance considerations. By understanding the properties, advantages, and limitations of each material, international B2B buyers can make informed decisions tailored to their specific laboratory needs.

In-depth Look: Manufacturing Processes and Quality Assurance for lab bench work

What Are the Key Stages in the Manufacturing Process of Lab Benches?

The manufacturing of lab benches involves several critical stages that ensure durability, functionality, and compliance with industry standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting high-quality materials that meet specific laboratory requirements. Common materials include stainless steel, phenolic resin, and solid wood. Each material undergoes rigorous testing for chemical resistance and durability. Suppliers often pre-cut these materials into specified dimensions to streamline the manufacturing process.

-

Forming: In this stage, the prepped materials are shaped into various components of the lab bench. Techniques such as cutting, bending, and welding are commonly employed. For instance, steel frames may be welded together to create a robust structure, while wood components may be laminated to enhance resistance against spills and chemical exposure.

-

Assembly: After forming, the individual components are assembled. This process can be manual or automated, depending on the scale of production. Quality control checkpoints are crucial at this stage to ensure that all components fit together correctly and meet design specifications. For instance, lab benches designed for heavy-duty use will undergo additional reinforcement during assembly.

-

Finishing: The final stage involves applying protective coatings and finishes to enhance the lab bench’s aesthetic and functional qualities. This could include powder coating for metal surfaces or varnishing wood components. Finishing not only improves appearance but also adds layers of protection against corrosion and chemical damage.

How Is Quality Assurance Implemented in Lab Bench Manufacturing?

Quality assurance (QA) in lab bench manufacturing is crucial for ensuring that products meet international standards and customer expectations. The QA process typically adheres to established standards such as ISO 9001 and industry-specific certifications like CE or API.

Illustrative image related to lab bench work

-

International Standards: ISO 9001 is a widely recognized quality management standard that outlines criteria for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements. For lab benches, adherence to these standards is vital as they must endure demanding laboratory environments.

-

Quality Control Checkpoints: Various checkpoints are incorporated throughout the manufacturing process:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications. Non-compliant materials are rejected to prevent defects in the final product.

– In-Process Quality Control (IPQC): During assembly, ongoing inspections are performed to catch defects early. This can include checking for dimensional accuracy and proper assembly techniques.

– Final Quality Control (FQC): Before shipping, finished products undergo a comprehensive inspection. This includes functional testing to ensure the benches meet load-bearing and durability standards.

What Testing Methods Are Commonly Used for Lab Benches?

Testing methods for lab benches vary based on material and intended use, but several common practices are essential to verify quality and compliance.

-

Load Testing: This method assesses the bench’s ability to support specified weights. For instance, heavy-duty lab benches are tested for load-bearing capacity to ensure they can withstand the demands of laboratory use.

-

Chemical Resistance Testing: Given that lab benches are often exposed to various chemicals, manufacturers conduct tests to evaluate how well materials withstand chemical spills and exposure.

-

Stability and Durability Testing: This testing ensures that the benches remain stable during use and can endure frequent movement or adjustments. Manufacturers may simulate real-world conditions to assess performance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring reliable partnerships.

-

Supplier Audits: Conducting audits of potential suppliers is a proactive way to assess their manufacturing and quality control processes. Buyers should request to see documentation of their ISO certifications, quality manuals, and inspection records.

-

Quality Reports: Suppliers should provide regular quality reports that detail compliance with industry standards and results from testing methods. This transparency helps buyers gauge the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection agencies to conduct independent assessments can provide unbiased insights into the supplier’s quality assurance practices. This is particularly valuable for buyers unfamiliar with local manufacturing standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances in quality control when sourcing lab benches from global suppliers.

-

Understanding Local Standards: Different regions may have specific quality standards and certifications. Buyers should be familiar with these requirements to ensure compliance. For instance, CE marking is crucial for products sold in the European market.

-

Cultural Considerations: Business practices vary across regions. Buyers should consider cultural differences that may impact communication and expectations regarding quality standards. Building a relationship based on mutual understanding can enhance collaboration.

-

Logistics and Supply Chain Integrity: Quality control does not stop at the manufacturing facility. Buyers should ensure that logistics partners maintain product integrity during transportation. This may involve specifying packaging standards that prevent damage during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices for lab benches is crucial for B2B buyers looking to make informed purchasing decisions. By focusing on material quality, rigorous testing, and supplier verification, buyers can ensure they acquire durable and compliant lab workbenches that meet their operational needs.

Illustrative image related to lab bench work

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lab bench work’

This guide aims to provide a systematic approach for B2B buyers to effectively source lab benches tailored to their specific needs. By following these steps, you can ensure that your procurement process is thorough and aligns with your laboratory’s operational requirements.

Step 1: Define Your Technical Specifications

Begin by identifying the specific needs of your laboratory workbench. Consider the types of experiments or tasks that will be performed, as this will influence the materials and design features required.

– Load Capacity: Assess the maximum weight that the bench must support.

– Surface Material: Choose between options like phenolic resin, stainless steel, or laminate based on chemical resistance and durability.

Step 2: Research Regulatory Compliance and Safety Standards

It is vital to ensure that the lab benches you consider meet relevant safety and regulatory standards for your region. This will help avoid potential liabilities and ensure a safe working environment.

– Certifications: Look for products that comply with international standards such as ISO or ANSI.

– Safety Features: Investigate features like rounded edges, stability ratings, and ESD (Electrostatic Discharge) protection if applicable.

Illustrative image related to lab bench work

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. This evaluation helps ensure that you are partnering with reputable companies that can meet your needs effectively.

– Company Profile: Request detailed information about the supplier’s background, years in business, and areas of expertise.

– References and Reviews: Seek testimonials from other businesses in your industry to gauge their reliability and service quality.

Step 4: Compare Pricing and Value-Added Services

While cost is an important factor, consider the overall value being offered. This includes warranty terms, after-sales support, and additional services that could enhance your purchase.

– Price Range: Gather quotes from multiple suppliers to understand the market rate for the specifications you need.

– Support Services: Inquire about installation, maintenance, and training that might be included or available for an additional fee.

Step 5: Assess Delivery and Lead Times

Understanding the logistics of your order is crucial, particularly if you are operating under tight deadlines. Ensure that your suppliers can meet your timelines effectively.

– Shipping Options: Check if suppliers offer expedited shipping or have local warehouses for faster delivery.

– Lead Time Estimates: Ask for specific timeframes for production and delivery to avoid delays in your laboratory setup.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in discussions to finalize terms and conditions. This step is vital for establishing a mutually beneficial agreement.

– Payment Terms: Discuss payment options, including deposits, credit terms, or bulk discounts.

– Return Policy: Ensure clarity on the return or exchange policy in case the delivered products do not meet your expectations.

Illustrative image related to lab bench work

Step 7: Finalize Your Purchase and Confirm Order Details

After negotiating, confirm your order details in writing. This includes all specifications, prices, and delivery timelines.

– Order Confirmation: Ensure that the supplier sends a formal order confirmation that outlines everything discussed.

– Documentation: Keep records of all communications and agreements for future reference.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing lab benches, ensuring they make informed decisions that meet their laboratory’s needs effectively.

Comprehensive Cost and Pricing Analysis for lab bench work Sourcing

What Are the Key Cost Components in Lab Bench Work Sourcing?

When sourcing lab workbenches, understanding the cost structure is essential for effective budgeting and financial planning. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common options range from basic laminates to high-performance phenolic resin and stainless steel, with prices varying accordingly. For instance, a basic laminated workbench may start at around $388, while heavy-duty stainless steel options can exceed $1,100.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is required to ensure high-quality construction, particularly for customized or specialty benches. This cost can be influenced by the local labor market conditions in the supplier’s region.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and administrative expenses. Overhead can vary significantly based on the supplier’s location and operational efficiency.

-

Tooling: For custom designs or specialized features, tooling costs can be substantial. These costs are typically amortized over the production run, making it crucial to consider the volume of your order.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet industry standards and specifications, which can add to the overall cost but is essential for maintaining reliability and safety in lab environments.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and international regulations. For global buyers, understanding Incoterms is vital to determine who bears the risk and cost of shipping.

-

Margin: Suppliers typically add a markup to cover their costs and generate profit. This margin can vary based on competition, supplier reputation, and the value-added features of the workbench.

How Do Price Influencers Impact Lab Bench Work Pricing?

Several factors influence the final price of lab benches, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to better pricing. Suppliers often have MOQs that can affect pricing, so understanding these thresholds is crucial for cost-effective purchasing.

-

Specifications and Customization: Custom designs or specific requirements, such as ESD protection or cleanroom compliance, can increase costs. Buyers should clearly define their needs to avoid unexpected price hikes.

-

Materials and Quality Certifications: Premium materials and certified products (e.g., ISO certifications) often come at a higher price but ensure durability and compliance with safety standards.

-

Supplier Factors: The supplier’s reputation, production capacity, and experience level can influence pricing. Established suppliers with a track record of quality may charge more, but they also reduce risk.

-

Incoterms: Understanding the shipping terms can help buyers manage costs effectively. For example, choosing EXW (Ex Works) may lower upfront costs but could lead to higher logistics expenses later.

What Tips Can Help Buyers Achieve Cost-Efficiency in Lab Bench Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, navigating the procurement landscape can be complex. Here are some actionable tips:

-

Negotiate Terms: Don’t hesitate to negotiate pricing and terms. Suppliers may offer discounts for bulk purchases or favorable payment terms if approached strategically.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, durability, and potential replacement costs over time. Investing in higher-quality benches may yield savings in the long run.

-

Research and Compare Suppliers: Conduct thorough research to compare different suppliers based on pricing, quality, and customer reviews. This will help identify the best value for money.

-

Understand Local Regulations: Familiarize yourself with import duties, taxes, and compliance regulations in your country to avoid unexpected expenses.

-

Plan for Logistics: Factor in shipping times and costs into your purchasing decision. Utilize local suppliers when possible to minimize logistics issues and costs.

Disclaimer for Indicative Prices

The prices mentioned are indicative and can fluctuate based on market conditions, supplier negotiations, and additional customization requests. Always request a formal quote from suppliers for accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing lab bench work With Other Solutions

Exploring Alternatives to Lab Bench Work: What Are Your Options?

In the realm of laboratory settings, selecting the right workspace is crucial for productivity and efficiency. While traditional lab bench work is a common choice, there are alternative solutions that may better suit the specific needs of a laboratory. This section will explore viable alternatives, including modular workstations and mobile lab carts, providing a comprehensive comparison to help B2B buyers make informed decisions.

Comparison Table of Lab Bench Work and Alternatives

| Comparison Aspect | Lab Bench Work | Modular Workstations | Mobile Lab Carts |

|---|---|---|---|

| Performance | High durability, customizable | Flexible configurations, optimized for collaboration | Portable, adaptable for various tasks |

| Cost | Moderate ($388 – $1,108) | Higher initial investment, long-term savings | Lower initial cost, varies widely ($200 – $800) |

| Ease of Implementation | Requires assembly, static placement | Quick setup, versatile layout options | Minimal setup, easy to relocate |

| Maintenance | Regular upkeep needed | Low maintenance, durable materials | Requires periodic checks, mobility can wear down components |

| Best Use Case | Ideal for chemical and static work | Excellent for collaborative projects and changing tasks | Suitable for fieldwork and mobile testing environments |

Detailed Breakdown of Alternatives

Modular Workstations

Modular workstations are designed for flexibility, allowing users to customize their setup based on the specific requirements of their tasks. These workstations can be reconfigured easily to accommodate different projects, making them ideal for labs that require collaboration among multiple teams. The downside is that while the initial cost may be higher, they offer long-term savings due to their adaptability and efficiency in space usage.

Mobile Lab Carts

Mobile lab carts are an excellent choice for laboratories that require mobility and versatility. They can be used for various tasks, from transporting samples to setting up temporary workspaces in different areas of the lab. The affordability of these carts makes them an attractive option for smaller laboratories or those with limited budgets. However, they may lack the stability and durability of traditional lab benches, and regular maintenance is necessary to ensure their longevity.

Illustrative image related to lab bench work

Conclusion: Choosing the Right Solution for Your Laboratory Needs

When considering the best solution for your laboratory, it’s essential to weigh the specific needs and operational requirements of your environment. Traditional lab bench work offers a robust and stable platform for various tasks, while modular workstations provide flexibility and adaptability for collaborative efforts. Mobile lab carts, on the other hand, cater to the need for mobility and convenience. By assessing factors such as performance, cost, ease of implementation, and maintenance, B2B buyers can select the option that aligns best with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for lab bench work

What Are the Key Technical Properties for Lab Benches?

When selecting lab benches for industrial or research purposes, several technical specifications are critical to ensure they meet operational needs. Understanding these properties can significantly impact productivity and safety in laboratory environments.

-

Material Grade

The material used in lab benches, such as stainless steel, phenolic resin, or laminated wood, directly affects durability and resistance to chemicals and wear. Stainless steel, for example, offers excellent corrosion resistance and is easy to clean, making it ideal for laboratories that handle hazardous materials. In contrast, phenolic resin provides a non-porous surface, suitable for environments involving spills of corrosive substances. -

Load Capacity

The load capacity indicates how much weight a bench can safely support. This specification is crucial for labs that utilize heavy equipment or store substantial quantities of materials. For instance, benches designed to support 2,000 lbs or more are essential in settings where heavy analytical instruments are used. Ensuring the right load capacity helps prevent accidents and equipment damage. -

Height Adjustment Mechanism

Adjustable height benches allow flexibility for various tasks and user preferences, enhancing ergonomics. Hydraulic or manual lift mechanisms enable users to modify the bench height easily, accommodating different applications or user heights. This feature is particularly beneficial in multi-user environments, promoting comfort and reducing strain. -

Chemical Resistance

Benches must withstand exposure to various chemicals without degradation. This property is vital for laboratories dealing with corrosive substances. A bench with high chemical resistance will not only last longer but also maintain a safe working environment by preventing contamination from spills. -

Static Control (ESD)

Electrostatic discharge (ESD) can damage sensitive electronic components. Lab benches designed with static control features minimize this risk. Conductive or dissipative surfaces are crucial in electronics laboratories to protect equipment and ensure reliable operations.

Which Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon can facilitate smoother transactions and enhance communication between suppliers and buyers in the laboratory equipment sector.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers assess product quality and compatibility, particularly when sourcing custom solutions. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is critical for budget-conscious buyers, as it impacts inventory management and cash flow. Knowing the MOQ helps buyers negotiate better terms and avoid overstocking. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers. By issuing an RFQ, buyers can compare offers, ensuring they receive competitive pricing and favorable conditions, essential for strategic procurement. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, covering aspects like shipping, insurance, and delivery. Familiarity with Incoterms helps buyers understand their obligations and reduces the risk of misunderstandings during cross-border purchases. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. This metric is crucial for planning and inventory management, especially in industries with stringent timelines. Buyers should consider lead times when scheduling projects to ensure they have the necessary equipment available when needed. -

Warranty Period

The warranty period specifies the duration during which the manufacturer will repair or replace defective products. Understanding warranty terms is essential for assessing product reliability and long-term costs, providing peace of mind for buyers making significant investments in lab equipment.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring their laboratory environments are equipped to meet operational demands effectively.

Navigating Market Dynamics and Sourcing Trends in the lab bench work Sector

What are the Global Drivers and Key Trends in the Lab Bench Work Market?

The lab bench work sector is currently experiencing transformative changes, driven by advancements in technology, increasing demand for specialized laboratory environments, and a growing emphasis on safety and compliance. Key trends include the rise of modular and customizable lab workbenches that cater to diverse applications, from chemical research to cleanroom environments. International B2B buyers are increasingly seeking high-quality, durable materials such as stainless steel and phenolic resin that ensure longevity and safety in demanding lab settings. Additionally, the shift towards automation and smart laboratories is influencing sourcing decisions, as companies look for integrated solutions that can enhance operational efficiency.

Regions like Africa and South America are witnessing a surge in investment in laboratory infrastructure, supported by governmental initiatives aimed at improving healthcare and scientific research capabilities. In contrast, Europe and the Middle East are focusing on compliance with stringent regulatory frameworks, pushing buyers to prioritize products that meet international safety standards. Emerging markets are also leveraging digital platforms for sourcing, allowing buyers to compare products, prices, and supplier credentials more efficiently, thus facilitating informed decision-making.

How is Sustainability and Ethical Sourcing Impacting Lab Bench Work Purchases?

Sustainability is becoming a crucial consideration in the lab bench work sector. As global awareness around environmental impact increases, B2B buyers are prioritizing suppliers that demonstrate commitment to sustainable practices. This includes sourcing materials that are recyclable, energy-efficient, and manufactured through processes that minimize environmental harm. For instance, lab workbenches made from sustainably sourced wood or recycled metals not only fulfill functional requirements but also align with corporate social responsibility goals.

Ethical sourcing practices are equally vital, as buyers seek assurance that their suppliers adhere to fair labor practices and ethical supply chain standards. Certifications such as ISO 14001 (Environmental Management) and Greenguard can serve as indicators of a supplier’s commitment to sustainability. Buyers should also inquire about the lifecycle of products, including end-of-life disposal options, to ensure that their purchases contribute positively to both the environment and society.

Illustrative image related to lab bench work

What is the Evolution of Lab Bench Work and Its Relevance to B2B Buyers?

The evolution of lab bench work can be traced back to the late 19th century when the demand for organized laboratory spaces began to grow alongside advancements in scientific research. Initially, lab benches were rudimentary, focusing primarily on functionality. However, as technology progressed, so did the complexity and specialization of laboratory environments. The introduction of materials like epoxy resin and stainless steel revolutionized lab bench design, offering increased durability and resistance to chemical exposure.

In recent decades, the focus has shifted toward ergonomics and modular design, enabling greater flexibility in lab setups. This evolution is particularly relevant for B2B buyers today, as they seek workbenches that not only meet current research needs but also adapt to future requirements. Understanding the historical context of lab bench work can provide valuable insights into selecting products that align with both present-day applications and long-term strategic goals.

Frequently Asked Questions (FAQs) for B2B Buyers of lab bench work

-

How do I choose the right lab bench for my needs?

When selecting a lab bench, consider the specific tasks it will support, such as chemical handling, electronics work, or general research. Evaluate the materials—like stainless steel for corrosion resistance or ESD laminate for static control—and the bench’s weight capacity based on your equipment. Additionally, assess the required dimensions and whether you need adjustable height options. Consulting with suppliers about your specific applications can also help ensure you make the best choice. -

What is the best material for a lab bench in a chemical environment?

For chemical environments, a bench with a phenolic resin or epoxy top is recommended due to their resistance to corrosive substances. Stainless steel benches are also a durable choice, offering easy cleaning and resistance to rust. Always confirm the chemical compatibility of the materials with the substances you will be using to prevent degradation and ensure longevity. -

What customization options are available for lab benches?

Many suppliers offer customization options, including bench dimensions, materials, and additional features like drawers or shelving. You can also specify load capacities and finishes. It’s beneficial to communicate your specific requirements during the initial discussions to ensure the final product meets your operational needs and complies with local safety regulations. -

What is the typical minimum order quantity (MOQ) for lab benches?

The MOQ for lab benches can vary significantly depending on the manufacturer and the specific product line. Generally, it ranges from a single unit for standard items to bulk orders for customized solutions. Always inquire directly with suppliers to understand their policies, as many are willing to negotiate based on your needs and the potential for future orders. -

How can I ensure the quality of lab benches before purchase?

To ensure quality, request product specifications, certifications, and compliance with international standards such as ISO or ASTM. Additionally, consider asking for samples or visiting a showroom to examine the benches firsthand. Reading reviews and testimonials from other B2B buyers can also provide insights into the reliability and durability of the products. -

What payment terms should I expect when purchasing lab benches internationally?

Payment terms can vary widely among suppliers. Typically, you might encounter options like upfront payment, a deposit with the balance due upon delivery, or payment after inspection. It’s crucial to clarify these terms before finalizing your order and to understand any additional costs, such as shipping and customs duties, which could impact your overall budget. -

What logistics considerations should I keep in mind when sourcing lab benches internationally?

When sourcing internationally, consider shipping methods, lead times, and customs clearance processes. It’s essential to work with suppliers who have experience in international logistics to ensure timely delivery. Additionally, verify the shipping costs and whether the supplier offers support in handling customs documentation to avoid delays. -

How do I vet suppliers for quality and reliability in lab bench manufacturing?

To vet suppliers, research their industry reputation through online reviews and professional networks. Request references from previous clients and inquire about their manufacturing processes and quality control measures. Additionally, verify certifications and compliance with international standards to ensure that the supplier meets your quality requirements and can deliver products that align with your needs.

Top 5 Lab Bench Work Manufacturers & Suppliers List

1. Bench Depot – Lab Workbenches

Domain: benchdepot.com

Registered: 2004 (21 years)

Introduction: Lab Workbenches offered by Bench Depot include various series such as Kennedy, Roosevelt, Dewey, Harding, Grant, and Tower. Key features include:

– Kennedy Series: Best seller, tested to 6,600 lbs, 1.2″ solid wood core, apron 2″ x 1″ tube, average price $552.

– Roosevelt Series: Economy design, tested to 1,200 lbs, 1.2″ solid wood core, legs .09″ steel, average price $388.

– Dewey Series: Recessed…

2. Lab Tech Supply Co – High-Quality Lab Benches & Workstations

Domain: labtechsupplyco.com

Registered: 2014 (11 years)

Introduction: High-Quality Lab Bench and Lab Workstation for Industrial Use; Made in the USA; Fast Shipping Options; Customizable designs for various laboratory applications; Durable and task-specific; Modular options available; Work surface choices: high pressure laminate, epoxy resin, butcher block, phenolic resin, stainless steel, high density polyethylene; Configurations: corner stations, U shapes, L shapes…

3. Fisher Scientific – Laboratory Benches and Tables

Domain: fishersci.com

Registered: 1995 (30 years)

Introduction: Laboratory benches and tables designed for safe laboratory tasks and handling of reagents and samples. Features include corrosion-resistant and vibration-resistant finishes, with options for mobile units. Available colors: Almond, Amber Stain, Auburn Stain, Black, Gray, Gray Maple, Green, Harvest Stain, Honey Stain, Light Gray, Maple, Mocha Stain, Natural Maple, Natural Stain, Oak, Oak Black, Silv…

4. Student Doctor Forum – Undergraduate Research Experience

Domain: forums.studentdoctor.net

Registered: 1999 (26 years)

Introduction: Undergraduate research experience in a lab involving tasks such as passaging, freezing, staining, differentiating stem cells, learning qRT-PCR, RNA isolation, and cDNA synthesis. The individual has been in the lab for 1.5 years and is expected to contribute to publications, with a promise of being responsible for qRT-PCR in a main project. The experience includes some level of intellectual contrib…

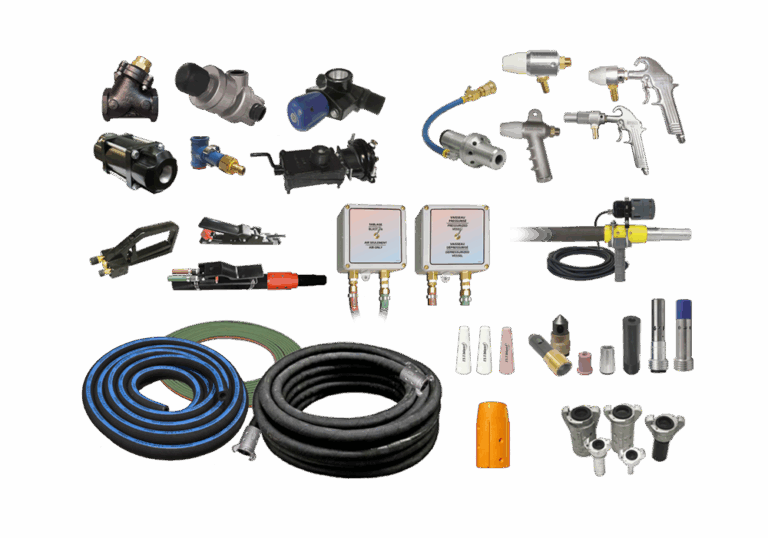

5. Uline – Lab Workbenches

Domain: uline.com

Registered: 1995 (30 years)

Introduction: {‘description’: ‘Lab workbenches designed for labs, chemical plants, and science classrooms.’, ‘features’: [‘Stands up to corrosive chemicals’, ‘Phenolic top resists heat up to 350°F’, ‘Non-porous, scratch and impact resistant’, ‘1″ thick’, ‘Withstands harsh acids, moisture, and bacteria’, ‘Heavy-gauge steel frame with sturdy square tube legs’, ‘Adjustable height from 29 to 39″ in 2″ increments’],…

Strategic Sourcing Conclusion and Outlook for lab bench work

In the evolving landscape of laboratory workbench solutions, strategic sourcing emerges as a pivotal element for international B2B buyers. Understanding the diverse range of lab bench types—such as chemical-resistant, static control, and adjustable height models—enables organizations to tailor their investments to specific operational needs. By prioritizing quality, durability, and functionality, businesses can enhance productivity and safety in their lab environments.

Illustrative image related to lab bench work

Furthermore, with the global supply chain becoming increasingly interconnected, buyers from Africa, South America, the Middle East, and Europe must leverage strategic partnerships with reputable suppliers. This approach not only ensures access to the latest innovations in lab furniture but also fosters competitive pricing and reliable delivery times.

As we look to the future, the demand for high-quality, customizable lab workbenches will continue to rise. Embracing a proactive sourcing strategy will empower organizations to stay ahead of industry trends and regulatory requirements. We encourage buyers to assess their laboratory needs critically, engage with trusted suppliers, and invest in workbench solutions that drive efficiency and innovation. The right strategic sourcing decisions today will position your organization for success in the dynamic world of lab bench work tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to lab bench work

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.