Choosing Your Kymron Excavator: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for kymron excavator

In the ever-evolving landscape of construction and heavy machinery, sourcing the right equipment, such as the Kymron excavator, can present unique challenges for international B2B buyers. With varying regional demands, budget constraints, and the need for reliable performance, making informed purchasing decisions is essential. This guide serves as a comprehensive resource, detailing various Kymron excavator models, their applications across diverse industries, and critical insights into supplier vetting processes.

Buyers from Africa, South America, the Middle East, and Europe will find valuable information regarding cost considerations, warranty options, and parts availability, enabling them to navigate the complexities of the global market effectively. By understanding the specifications and capabilities of Kymron excavators, decision-makers can identify the best machines suited for their projects, whether for urban development, agricultural applications, or environmental remediation.

Empowering international buyers with actionable insights, this guide aims to streamline the procurement process, ensuring that organizations can secure reliable, cost-effective machinery that meets their operational needs. As we delve deeper into the specifics of Kymron excavators, readers will be equipped to make strategic decisions that drive efficiency and productivity in their respective markets.

Understanding kymron excavator Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| XH20D | 22.5HP Yanmar Diesel, Pilot Controls, Side Swing Boom | Residential projects, landscaping | Pros: Compact size, versatile for tight spaces. Cons: Limited lifting capacity compared to larger models. |

| XH42D | 36HP Kubota Diesel, Hydraulic Quick Attach, 4/6 Way Tilt Blade | Medium to large construction sites, utility work | Pros: Enhanced power and attachment flexibility. Cons: Higher initial investment. |

| XH68D | 67.9HP Kubota Diesel, Metal Tracks, 4-Way Tilt Dozer Blade | Heavy-duty excavation, road construction | Pros: Robust performance, suitable for tough terrain. Cons: Heavier, may require more transport resources. |

| RH14G | 14 HP Briggs and Stratton, Side Swing Boom, Upgraded Hydraulic Pump | Small to medium scale projects, DIY tasks | Pros: Affordable entry-level option, ergonomic design. Cons: Limited power for larger jobs. |

| CX10 | 56HP Yanmar Diesel, 10 Ton capacity, High lift height | Industrial applications, heavy lifting | Pros: High capacity and lift height, suitable for heavy tasks. Cons: Larger footprint may limit usability in confined spaces. |

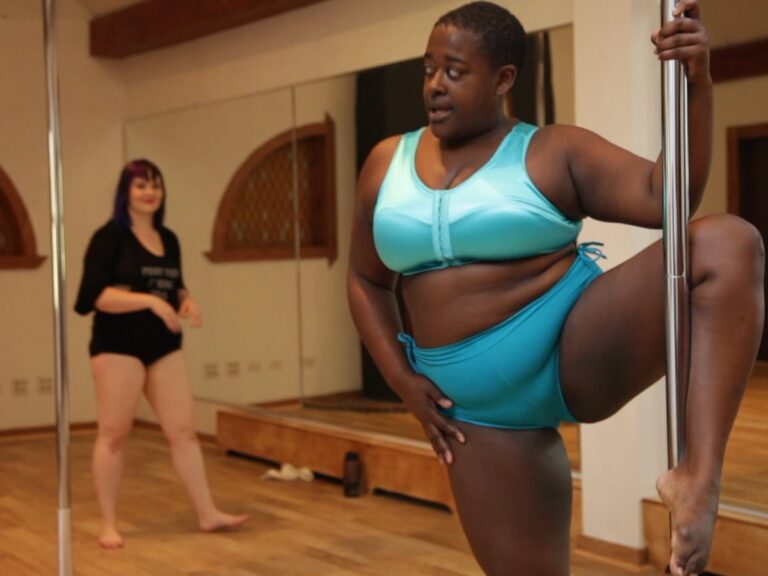

What Are the Key Characteristics of the XH20D Excavator?

The XH20D is designed for versatility in smaller projects, powered by a 22.5HP Yanmar diesel engine. Its pilot controls and side swing boom make it ideal for residential tasks and landscaping. Buyers appreciate its compact size, enabling operation in tight spaces, although its lifting capacity is limited compared to larger excavators.

How Does the XH42D Stand Out for Medium to Large Projects?

The XH42D features a robust 36HP Kubota diesel engine and options for hydraulic quick attachments, making it suitable for medium to large construction sites. Its 4 or 6-way tilt blades enhance operational flexibility, allowing for diverse applications. While it provides excellent power and functionality, the initial investment can be a consideration for budget-conscious buyers.

What Makes the XH68D Ideal for Heavy-Duty Excavation?

With a powerful 67.9HP Kubota diesel engine and metal tracks, the XH68D excels in heavy-duty excavation and road construction. Its 4-way tilt dozer blade enables efficient material handling. This model’s robust performance is ideal for challenging terrains, but its heavier weight may necessitate additional transport resources, impacting logistics.

Why Choose the RH14G for Smaller Scale Projects?

The RH14G is an affordable entry-level mini excavator equipped with a 14 HP Briggs and Stratton engine and a side swing boom, making it suitable for small to medium-scale projects. Its ergonomic design enhances operator comfort, and its upgraded hydraulic pump ensures efficient performance. However, potential buyers should note its limited power for larger tasks.

What Are the Advantages of the CX10 in Industrial Applications?

The CX10 features a 56HP Yanmar diesel engine with a 10-ton capacity, making it suitable for industrial applications requiring heavy lifting. Its high lift height and operating weight provide significant advantages in various tasks. However, its larger footprint may limit usability in confined spaces, necessitating careful project planning for effective deployment.

Illustrative image related to kymron excavator

Key Industrial Applications of kymron excavator

| Industry/Sector | Specific Application of kymron excavator | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site preparation and earthmoving | Efficiently clears and levels land, reducing project time and labor costs. | Consider machine size and weight for transport and site access. |

| Landscaping | Digging and trenching for landscaping features | Allows precise installation of features like ponds and pathways, enhancing project quality. | Assess attachment compatibility for diverse landscaping tasks. |

| Agriculture | Land clearing and irrigation installation | Supports agricultural expansion and efficient water management, boosting crop yields. | Evaluate hydraulic capabilities for various farming applications. |

| Infrastructure Development | Utility trenching and road construction | Facilitates the installation of utilities and roadworks, ensuring timely project completion. | Ensure compliance with local regulations and availability of service parts. |

| Mining and Quarrying | Material handling and site excavation | Increases operational efficiency and reduces downtime in extraction processes. | Focus on durability and maintenance support for rugged environments. |

Kymron excavators play a vital role in the construction industry, particularly during site preparation and earthmoving tasks. These machines can efficiently clear and level land, which significantly reduces project time and labor costs. For international buyers, especially in regions like Africa and South America, the ability to transport and operate these machines in diverse terrains is crucial. Buyers should consider the size and weight of the excavator to ensure accessibility to various job sites.

In landscaping, Kymron excavators are instrumental for digging and trenching, allowing contractors to install features such as ponds, pathways, and irrigation systems with precision. This capability not only enhances the aesthetic quality of projects but also ensures functionality. Buyers must assess the compatibility of attachments to maximize the versatility of the excavator for different landscaping tasks.

The agricultural sector benefits from Kymron excavators for land clearing and irrigation installations. These machines support the expansion of farmland and improve water management systems, which can lead to increased crop yields. For agricultural buyers, evaluating the hydraulic capabilities of the excavator is essential to ensure it meets the specific demands of various farming applications.

Infrastructure development projects, such as utility trenching and road construction, also leverage Kymron excavators for their efficiency in installing utilities and completing roadworks. This efficiency is vital for meeting project deadlines. Buyers in this sector should ensure that the excavator complies with local regulations and that replacement parts are readily available to minimize downtime.

Finally, in mining and quarrying, Kymron excavators are used for material handling and site excavation, significantly increasing operational efficiency. Given the rugged environments of these industries, buyers must focus on the durability of the excavator and the availability of maintenance support to ensure sustained performance.

3 Common User Pain Points for ‘kymron excavator’ & Their Solutions

Scenario 1: Managing Equipment Downtime and Repairs Effectively

The Problem: One of the primary challenges faced by B2B buyers of Kymron excavators is managing unexpected downtime due to equipment failure. This situation can arise from various factors such as wear and tear, lack of maintenance, or even the use of incompatible parts. For construction companies operating on tight schedules, any delay in project timelines can lead to significant financial losses and damage to their reputation. Furthermore, sourcing replacement parts quickly can be a logistical nightmare, especially in regions with limited access to quality suppliers.

The Solution: To mitigate the risk of downtime, buyers should establish a proactive maintenance schedule that includes regular inspections and servicing of their Kymron excavators. Understanding the specific components that are most prone to failure, such as hydraulic systems and tracks, allows companies to preemptively replace parts before they cause major issues. Kymron offers reliable parts from established brands like Kubota and Yanmar, ensuring compatibility and quality. Buyers should leverage Kymron’s extensive dealer network to stock essential spare parts, thus enabling rapid repairs. Additionally, investing in training for operators on basic troubleshooting can empower them to identify and resolve minor issues before they escalate, ultimately reducing equipment downtime.

Scenario 2: Overcoming Performance Limitations in Diverse Work Environments

The Problem: B2B buyers often face the challenge of utilizing excavators in varied and challenging work environments, such as tight urban spaces or uneven terrain. Kymron excavators, while versatile, may require specific configurations or attachments to perform optimally in these conditions. Buyers might find that their existing equipment struggles to meet the demands of different job sites, leading to inefficiencies and subpar results.

Illustrative image related to kymron excavator

The Solution: To ensure that Kymron excavators perform effectively across various environments, buyers should consider the machine’s specifications and available attachments carefully. For instance, models like the RH14G feature a side swing boom, which is particularly advantageous for working in tight spaces, as it allows operators to maneuver easily around obstacles. Buyers should also explore the option of hydraulic quick attach systems, which enable quick changes between different attachments, such as buckets and dozer blades, allowing for greater versatility on the job site. Furthermore, conducting a thorough assessment of each job site’s requirements before deployment can help in selecting the right excavator model and attachments, ensuring optimal performance in diverse conditions.

Scenario 3: Navigating Cost-Effectiveness and Budget Constraints

The Problem: Many international buyers, particularly in developing markets, are often constrained by tight budgets and the need to maximize return on investment. While Kymron excavators are competitively priced, the total cost of ownership, including maintenance, parts, and fuel efficiency, can become a significant concern. Buyers may struggle to find a balance between acquiring reliable machinery and managing operational costs.

The Solution: To navigate budget constraints effectively, buyers should conduct a comprehensive cost analysis that includes initial purchase price, expected maintenance costs, and fuel efficiency of the Kymron excavators. Kymron’s focus on affordable pricing, coupled with lower parts costs compared to competitors, can significantly reduce the total cost of ownership. Buyers should also inquire about financing options or leasing arrangements that can spread out the capital expenditure over time. Additionally, implementing fuel-efficient practices, such as proper operator training and regular maintenance checks, can further reduce operating costs. By focusing on long-term value and cost savings, buyers can make informed decisions that align with their budgetary goals while still obtaining high-quality excavators.

Illustrative image related to kymron excavator

Strategic Material Selection Guide for kymron excavator

What Are the Key Materials Used in Kymron Excavators?

When selecting materials for Kymron excavators, it is crucial to consider their performance characteristics, manufacturing complexities, and suitability for various applications. Here, we analyze four common materials used in Kymron excavators: high-strength steel, hydraulic components (aluminum and composite materials), rubber, and electrical components.

How Does High-Strength Steel Enhance Excavator Performance?

High-strength steel is a primary material used in the structural components of Kymron excavators. Its key properties include excellent tensile strength and durability, allowing it to withstand significant loads and impacts during operation. High-strength steel is also resistant to deformation under stress, making it ideal for heavy-duty applications.

Pros: This material offers exceptional durability and longevity, reducing the frequency of replacements. It is also relatively cost-effective compared to specialized alloys.

Cons: High-strength steel can be heavier than alternative materials, potentially affecting fuel efficiency. Additionally, it requires advanced manufacturing techniques, which may increase production costs.

Impact on Application: High-strength steel is compatible with various media, including soil, gravel, and demolition debris, making it versatile for different excavation tasks.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers from regions like Africa and South America should ensure that the steel used meets local regulations for construction equipment.

What Role Do Hydraulic Components Play in Kymron Excavators?

Hydraulic systems in Kymron excavators often utilize aluminum and composite materials for their components. These materials are lightweight yet strong, providing efficient power transfer and reducing the overall weight of the machine.

Illustrative image related to kymron excavator

Pros: Aluminum and composites offer excellent corrosion resistance, which is critical in harsh environments. Their lightweight nature enhances fuel efficiency and maneuverability.

Cons: While effective, these materials can be more expensive than traditional steel. Additionally, they may require specialized manufacturing processes, which could complicate production.

Impact on Application: The hydraulic components must be compatible with various hydraulic fluids, ensuring optimal performance under different operating conditions.

Illustrative image related to kymron excavator

Considerations for International Buyers: Buyers should verify that the hydraulic components comply with global standards, such as JIS and ISO. This is particularly relevant for buyers in the Middle East and Europe, where stringent regulations govern equipment safety and performance.

How Does Rubber Contribute to Excavator Functionality?

Rubber is predominantly used in tracks and tires for Kymron excavators. Its key properties include flexibility, shock absorption, and resistance to wear, making it ideal for outdoor applications.

Pros: Rubber tracks provide excellent traction and stability on uneven terrain, enhancing the excavator’s performance in various environments. They also minimize noise and vibration, improving operator comfort.

Cons: Rubber can degrade over time due to exposure to UV light and extreme temperatures, leading to a shorter lifespan compared to metal components.

Impact on Application: Rubber is suitable for use in diverse terrains, from soft soil to rocky surfaces, making it a versatile choice for excavation tasks.

Considerations for International Buyers: Buyers should consider the climate and environmental conditions in their regions. For example, those in hotter climates may need to prioritize UV-resistant rubber options.

What Are the Key Electrical Components Used in Kymron Excavators?

Electrical components in Kymron excavators are typically made from high-quality copper and plastic materials. These materials are essential for efficient power distribution and control systems.

Pros: Copper offers excellent conductivity, ensuring reliable electrical performance. Plastic components are lightweight and resistant to corrosion, enhancing the overall durability of the electrical system.

Cons: While effective, copper can be expensive, and its price can fluctuate based on market conditions. Additionally, plastic components may not withstand extreme temperatures as well as metals.

Impact on Application: The electrical system must be compatible with various operational controls and sensors, which are crucial for modern excavator functionality.

Considerations for International Buyers: Compliance with electrical safety standards is vital, particularly in Europe and the Middle East, where regulations may differ significantly from those in Africa and South America.

Summary Table of Material Selection for Kymron Excavators

| Material | Typical Use Case for Kymron Excavator | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Strength Steel | Structural components | Exceptional durability | Heavier than alternatives | Medium |

| Hydraulic Components | Hydraulic systems | Lightweight and corrosion-resistant | Higher manufacturing costs | High |

| Rubber | Tracks and tires | Excellent traction and shock absorption | Degrades over time | Medium |

| Electrical Components | Power distribution and control systems | High conductivity and lightweight | Price fluctuations for copper | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring informed decisions that align with performance requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for kymron excavator

What Are the Key Stages in the Manufacturing Process of Kymron Excavators?

The manufacturing process for Kymron excavators involves several critical stages, ensuring that each machine is built to meet rigorous quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Illustrative image related to kymron excavator

-

Material Preparation: The manufacturing process begins with sourcing high-quality raw materials. Kymron emphasizes using durable metals and components, including steel and aluminum alloys, which are essential for the longevity of the excavators. These materials undergo rigorous testing to ensure they meet specific mechanical properties.

-

Forming: In this stage, materials are shaped into various components using advanced technologies such as CNC machining, laser cutting, and bending. Kymron employs automated systems to enhance precision in forming parts, ensuring that each component aligns with design specifications. This precision is vital for the overall functionality and safety of the excavators.

-

Assembly: The assembly process is where all components come together. Kymron uses a combination of skilled labor and automated assembly lines to ensure efficiency and consistency. Each excavator is assembled with attention to detail, integrating components such as engines, hydraulic systems, and control systems. This stage also includes the installation of user-friendly features, such as ergonomic controls and safety systems, enhancing operator comfort and safety.

-

Finishing: After assembly, the excavators undergo a finishing process, which includes painting, coating, and quality checks. Kymron uses high-quality paint and protective coatings to enhance the durability of the machines against environmental factors. This stage also involves final inspections to ensure that all components function correctly and meet the required aesthetic standards.

How Is Quality Assurance Implemented Throughout the Manufacturing Process?

Quality assurance is a cornerstone of Kymron’s manufacturing philosophy. The company adheres to international quality standards, such as ISO 9001, as well as industry-specific certifications like CE and API. This commitment to quality ensures that the excavators not only perform well but also comply with safety regulations in various markets.

-

International Standards: Kymron’s adherence to ISO 9001 signifies a robust quality management system, ensuring continuous improvement and customer satisfaction. This certification is particularly important for international buyers who require assurance that the products meet global quality benchmarks.

-

Quality Control Checkpoints: Throughout the manufacturing process, Kymron implements various quality control checkpoints, including:

– Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During the assembly and forming stages, regular inspections are conducted to identify and rectify any issues immediately, preventing defects from progressing down the line.

– Final Quality Control (FQC): Once the excavators are fully assembled, they undergo comprehensive testing to ensure all systems operate correctly and meet performance criteria. -

Testing Methods: Common testing methods employed by Kymron include hydraulic system testing, engine performance assessments, and safety feature evaluations. These tests are designed to simulate real-world operating conditions to ensure reliability and safety.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers like Kymron is essential. Here are several actionable steps buyers can take:

-

Supplier Audits: Conducting supplier audits is a proactive approach to understanding a manufacturer’s quality control processes. Buyers can request to visit Kymron’s manufacturing facilities to observe the production process and assess compliance with quality standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can provide insights into the manufacturing process and any quality issues encountered. These reports often include information on testing results and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can help validate a supplier’s quality claims. These independent inspections can be conducted at various stages of production, providing an unbiased assessment of compliance with international standards.

-

Certifications and Compliance: Buyers should verify that Kymron holds relevant certifications, such as ISO 9001 and CE, which indicate adherence to recognized quality standards. This verification can often be done through official certification bodies or industry associations.

What Nuances Should International Buyers Consider Regarding Quality Control?

When dealing with international suppliers like Kymron, buyers should be aware of specific nuances that may affect quality control and product delivery:

-

Regulatory Compliance: Different countries have varying regulations regarding construction equipment. Buyers should ensure that Kymron’s products comply with local regulations in their respective markets, particularly concerning safety and environmental standards.

-

Cultural Differences: Cultural differences in business practices may influence communication and quality expectations. Buyers should establish clear communication channels and expectations regarding quality standards from the outset.

-

Logistics and Supply Chain Considerations: Understanding the logistics involved in transporting excavators from the manufacturer to the buyer’s location is crucial. Delays or damage during transit can affect the perceived quality of the product. Buyers should consider insurance and quality checks upon delivery to mitigate these risks.

-

After-Sales Support: Quality assurance doesn’t end with delivery. Buyers should assess the after-sales support offered by Kymron, including warranty terms, availability of spare parts, and service support. A robust after-sales program can significantly enhance the overall ownership experience and ensure the longevity of the equipment.

In conclusion, Kymron’s commitment to quality through stringent manufacturing processes and quality assurance practices provides B2B buyers with confidence in their investment. By understanding and verifying these processes, buyers can ensure they are making informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kymron excavator’

In the competitive landscape of construction equipment procurement, sourcing a KYMRON excavator requires a strategic approach to ensure quality, reliability, and value for your investment. This guide provides a step-by-step checklist for B2B buyers to navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Determine the size, weight capacity, engine type, and additional features such as hydraulic attachments or side swing capabilities that align with your project needs. This clarity will help streamline your options and ensure that the excavator meets your operational requirements.

Step 2: Research the KYMRON Product Range

Familiarize yourself with the various models offered by KYMRON, such as the RH14G, XH20D, and XH68D. Each model has unique attributes, including engine power, lifting capacity, and warranty terms. Understanding these distinctions will allow you to choose the right machine tailored to your specific applications, whether for residential tasks or larger construction projects.

Illustrative image related to kymron excavator

Step 3: Evaluate Potential Suppliers

Before making a purchasing decision, thoroughly vet potential suppliers. Request company profiles, customer testimonials, and case studies relevant to your industry or region. This evaluation will help ascertain the supplier’s credibility, reliability, and service support, which are crucial for a smooth procurement process.

- Look for an extensive dealer network to ensure local service and support availability.

- Assess their warranty and after-sales service offerings to gauge long-term support.

Step 4: Verify Certifications and Compliance

Ensure that the supplier and the KYMRON excavators comply with relevant industry standards and certifications. This step is vital for avoiding potential legal issues and ensuring safety compliance in your operations. Check for certifications related to environmental standards, operator safety, and equipment quality.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations. These should include the total cost, payment terms, delivery timelines, and warranty information. Comparing these aspects across different suppliers will help you assess the overall value proposition and make an informed decision.

Illustrative image related to kymron excavator

- Consider hidden costs such as shipping, installation, and maintenance.

- Evaluate financing options if upfront costs are a concern.

Step 6: Conduct a Site Visit or Product Demonstration

If possible, arrange a site visit or a product demonstration before finalizing the purchase. Observing the KYMRON excavator in action will provide insights into its performance, ease of operation, and suitability for your projects. This hands-on experience can be a decisive factor in your procurement decision.

Step 7: Finalize the Purchase Agreement

After selecting the supplier and model, review and finalize the purchase agreement. Ensure that all terms, including warranties, delivery schedules, and support services, are clearly outlined. This step is crucial for protecting your investment and ensuring that all parties are aligned on expectations.

By following this structured checklist, B2B buyers can make informed decisions when sourcing a KYMRON excavator, ultimately leading to successful project outcomes and enhanced operational efficiency.

Comprehensive Cost and Pricing Analysis for kymron excavator Sourcing

What Are the Key Cost Components in Sourcing Kymron Excavators?

When evaluating the total cost of sourcing Kymron excavators, several key components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

Illustrative image related to kymron excavator

-

Materials: Kymron uses high-quality components from reputable suppliers like Briggs and Stratton, Kubota, and Yanmar. The choice of materials directly influences the durability and performance of the excavators, which can affect long-term operational costs.

-

Labor: Labor costs encompass the workforce required for assembly, quality assurance, and testing. Skilled labor is essential to ensure that the equipment meets stringent quality standards.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, impacting the final price.

-

Tooling: The cost of specialized tools and equipment used in the manufacturing process is also a factor. Investing in advanced tooling can enhance production efficiency and product quality.

-

Quality Control: Kymron’s commitment to quality involves rigorous testing and inspection processes. This adds to the overall cost but ensures that buyers receive reliable equipment.

-

Logistics: Shipping and handling costs can vary significantly depending on the destination. International buyers should account for freight costs, customs duties, and potential delays.

-

Margin: The supplier’s profit margin is built into the pricing structure. Understanding the typical margin for excavators can aid in negotiations.

How Do Price Influencers Impact Kymron Excavator Pricing?

Several factors influence the pricing of Kymron excavators, which are crucial for international B2B buyers to understand.

-

Volume/MOQ: Larger orders often attract discounts due to economies of scale. Buyers looking to procure multiple units should negotiate terms based on their volume to maximize savings.

-

Specifications/Customization: Custom features, such as additional attachments or modified specifications, can affect pricing. Buyers should clearly communicate their needs to receive accurate quotes.

-

Materials: The quality and source of materials can influence the final price. Buyers should inquire about the specifications to ensure they align with their requirements.

-

Quality and Certifications: Equipment that meets international standards or certifications may command higher prices. Buyers should weigh the benefits of certified equipment against potential cost savings from non-certified options.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more, but they often provide better after-sales support and warranty services.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) can significantly affect total costs. Buyers should clarify these terms during negotiations to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficiency in Kymron Excavator Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are several strategies to enhance cost-efficiency when sourcing Kymron excavators.

-

Negotiation: Engage in thorough negotiations with suppliers to secure the best possible price. Highlighting your volume and long-term business potential can strengthen your bargaining position.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance, fuel efficiency, and potential resale value. A lower initial cost may lead to higher long-term expenses if the equipment is less reliable.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import taxes, and tariffs that may affect the final cost. Additionally, establish a clear understanding of shipping times and logistics to avoid delays.

-

Replacement Parts and Service: Ensure that the supplier provides readily available replacement parts and reliable service. Kymron’s competitive parts pricing can lead to significant savings over time, compared to other brands.

Disclaimer on Indicative Prices

Prices mentioned for Kymron excavators, such as the RH14G model at approximately $9,200, are indicative and subject to change based on market conditions, customization, and other factors. Buyers should consult directly with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing kymron excavator With Other Solutions

Understanding Alternatives in Excavation Equipment

When considering excavation equipment, businesses often find themselves weighing multiple options to determine the best fit for their operational needs. The Kymron excavator, known for its economical pricing and robust features, faces competition from various alternatives. This analysis will compare the Kymron excavator with two viable alternatives: the Bobcat E165 and the Caterpillar 303.5E CR. Each of these options has unique advantages and potential drawbacks that can influence purchasing decisions.

Comparison Table

| Comparison Aspect | Kymron Excavator | Bobcat E165 | Caterpillar 303.5E CR |

|---|---|---|---|

| Performance | 14-68 HP engines, versatile digging capabilities | 61 HP, strong lifting capacity | 40.2 HP, efficient in tight spaces |

| Cost | $8,500 – $64,900 | Starting at $36,000 | Starting at $40,000 |

| Ease of Implementation | Simple setup; dealer support available | User-friendly controls; robust dealer network | Compact design ideal for urban jobs |

| Maintenance | Lower parts costs; readily available | Moderate; higher parts pricing | Higher due to brand reputation |

| Best Use Case | Residential to commercial projects | Construction, landscaping | Urban construction, utility work |

Detailed Breakdown of Alternatives

Bobcat E165

The Bobcat E165 is a popular choice in the compact excavator market, offering 61 HP and exceptional digging and lifting capabilities. Its user-friendly controls make it accessible for operators of varying skill levels. However, the starting price of approximately $36,000 may deter budget-conscious buyers. Maintenance costs can also be higher due to the premium nature of Bobcat parts. The E165 excels in construction and landscaping tasks, making it suitable for projects that require consistent performance and reliability.

Caterpillar 303.5E CR

Caterpillar is synonymous with quality in heavy equipment, and the 303.5E CR is no exception. With 40.2 HP, this compact excavator is designed for efficiency in tight spaces, making it ideal for urban construction and utility work. Its starting price is around $40,000, which reflects its brand value but may not be feasible for all budgets. While it offers great durability and performance, the higher maintenance costs associated with Caterpillar parts could be a drawback for some buyers. The 303.5E CR is an excellent option for projects requiring precision and maneuverability.

Conclusion: How to Choose the Right Excavation Equipment

Selecting the right excavation equipment involves evaluating specific project needs, budget constraints, and long-term operational goals. The Kymron excavator presents a cost-effective solution with a wide range of models suitable for various applications, from residential projects to larger commercial jobs. In contrast, alternatives like the Bobcat E165 and Caterpillar 303.5E CR offer brand reliability and performance but come with higher price tags and maintenance costs. Buyers should assess their unique requirements and consider factors such as performance, cost, and ease of maintenance to make an informed decision that aligns with their operational objectives.

Illustrative image related to kymron excavator

Essential Technical Properties and Trade Terminology for kymron excavator

What Are the Key Technical Specifications of Kymron Excavators?

Understanding the essential technical specifications of Kymron excavators is crucial for making informed purchasing decisions. Here are some of the critical specifications to consider:

-

Engine Power (HP): Kymron excavators range from 14 HP to over 67 HP, depending on the model. The horsepower is vital as it determines the machine’s capability to perform heavy-duty tasks. Higher horsepower means increased efficiency in excavation, lifting, and digging operations, which is particularly important for large-scale projects.

-

Operating Weight: The operating weight of Kymron excavators varies from about 2,200 lbs for the RH14G model to over 68,000 lbs for larger models. This specification impacts stability, lifting capacity, and suitability for various terrains. A heavier excavator generally provides better stability and digging power, while lighter models are more maneuverable for tight spaces.

-

Max Digging Depth and Height: Specifications like max digging depth (up to 5’5″) and max dumping height (up to 8’7″) are essential for evaluating the excavator’s suitability for specific tasks. These metrics help determine how deep the machine can dig and how high it can lift materials, which is critical in construction and landscaping projects.

-

Hydraulic System Performance: Kymron excavators are equipped with advanced hydraulic systems, including options for hydraulic quick attachments and auxiliary hydraulics. A robust hydraulic system enhances operational versatility, allowing for the use of various attachments like thumbs and buckets, which can increase productivity on the job site.

-

Warranty and Support: Kymron offers warranties that range from one to three years on various models, covering key components like the powertrain. Understanding warranty terms is important for B2B buyers as it reflects the manufacturer’s confidence in their product and provides reassurance regarding long-term maintenance costs.

-

Material Quality: The use of high-quality materials, such as those sourced from recognized brands like Yanmar and Kubota, ensures durability and reliability. This is particularly significant for B2B buyers who prioritize long-term investments, as high-quality materials reduce the risk of breakdowns and maintenance costs.

What Are Common Trade Terms Related to Kymron Excavators?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to the company that manufactures the original parts or equipment. In the context of Kymron excavators, understanding OEM parts ensures that buyers receive quality replacements that meet performance standards.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity a supplier is willing to sell. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management, particularly when planning for large-scale projects.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing for specific products or services. For Kymron excavator buyers, issuing an RFQ can help compare costs and negotiate better deals.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risk management.

-

Lead Time: This term refers to the time taken from placing an order until delivery. Knowing the lead time for Kymron excavators can help businesses plan their projects effectively, ensuring that equipment arrives when needed.

-

TCO (Total Cost of Ownership): TCO encompasses all costs associated with owning an excavator, including purchase price, maintenance, repairs, and operating costs. B2B buyers should consider TCO to evaluate the long-term financial implications of their investment in Kymron equipment.

By understanding these technical properties and trade terminology, B2B buyers can make more informed decisions, ensuring that they select the right Kymron excavator for their specific needs and operational contexts.

Navigating Market Dynamics and Sourcing Trends in the kymron excavator Sector

What Are the Key Market Drivers Influencing the Kymron Excavator Sector?

The Kymron excavator sector is experiencing significant growth driven by the global demand for construction and infrastructure development, particularly in emerging markets such as Africa, South America, and the Middle East. The increasing urbanization and industrialization in these regions are prompting investments in heavy machinery, with Kymron’s range of excavators being positioned as cost-effective solutions. The machines cater to diverse applications, from residential projects to large-scale construction, making them attractive to a wide array of international buyers.

Technological advancements are also reshaping the sourcing landscape. Innovations such as telematics and automated controls are becoming standard features in Kymron excavators, enhancing operational efficiency and reducing labor costs. Additionally, the rise of e-commerce platforms has streamlined procurement processes, allowing buyers to easily compare specifications and prices, facilitating quicker decision-making.

Another notable trend is the increasing importance of after-sales service and parts availability, particularly in remote regions. Kymron’s robust dealer network ensures that international buyers can access reliable support and spare parts, which is crucial for maintaining machine uptime and optimizing investment returns. Overall, the Kymron excavator sector is poised for growth, driven by these market dynamics and the evolving needs of B2B buyers globally.

How Is Sustainability Shaping the Sourcing Decisions for Kymron Excavators?

Sustainability is becoming a pivotal factor in sourcing decisions for international B2B buyers in the Kymron excavator sector. Companies are increasingly aware of their environmental impact and are seeking suppliers that prioritize ethical sourcing and sustainable manufacturing practices. Kymron is responding to this trend by focusing on environmentally friendly materials and processes, which not only reduce the ecological footprint but also enhance the brand’s reputation.

Buyers are particularly interested in excavators that come with certifications for sustainability, such as ISO 14001 for environmental management. Kymron’s commitment to using reliable parts from reputable manufacturers, like Yanmar and Kubota, ensures that the equipment meets stringent environmental standards. Furthermore, the efficiency of Kymron excavators translates to reduced fuel consumption and lower emissions during operation, aligning with the goals of companies looking to enhance their sustainability profiles.

The importance of ethical supply chains cannot be overstated, as B2B buyers are increasingly scrutinizing their suppliers’ practices. Kymron’s transparent sourcing of materials and commitment to ethical labor practices resonate well with companies aiming to bolster their corporate social responsibility (CSR) initiatives. By choosing Kymron, buyers not only invest in durable machinery but also contribute to sustainable development goals.

What Historical Context Should B2B Buyers Consider When Sourcing Kymron Excavators?

The Kymron brand has evolved significantly since its inception, focusing on providing high-quality and affordable heavy machinery. Initially targeting the domestic market, Kymron has expanded its reach, establishing a reputation for reliability and performance that appeals to international buyers. Over the years, the company has invested in research and development, leading to the introduction of innovative features in its excavators, such as advanced hydraulic systems and ergonomic designs.

This evolution reflects a broader trend in the construction equipment sector, where competition drives continual improvements in technology and customer service. For B2B buyers, understanding this history is crucial as it highlights Kymron’s commitment to quality and adaptability in a rapidly changing market. This legacy of innovation and customer focus positions Kymron as a reliable partner for companies looking to invest in excavation equipment that meets modern demands.

Frequently Asked Questions (FAQs) for B2B Buyers of kymron excavator

-

How do I choose the right Kymron excavator for my project?

Choosing the right Kymron excavator depends on several factors, including the type of work you need to perform, the weight capacity required, and the terrain conditions. For lighter tasks, models like the RH14G, which weighs 2,200 lbs and has a lifting capacity of 1,500 lbs, may suffice. For larger projects, consider the XH68D with a 67.9HP engine and robust features. Assess your project’s specific requirements, including digging depth and height, to ensure the selected model aligns with your operational needs. -

What are the warranty terms for Kymron excavators?

Kymron excavators typically come with a powertrain warranty ranging from one to three years, depending on the model. For example, the RH14G includes a one-year powertrain warranty, while larger models like the XH42D may offer extended coverage. It’s crucial to review the warranty details carefully to understand what is covered and for how long, as this can impact your long-term operational costs and maintenance planning. -

What payment terms can I expect when purchasing Kymron excavators?

Payment terms for Kymron excavators may vary by dealer and region but generally include options for upfront payment, financing, or leasing. Many international buyers can negotiate payment terms based on the total purchase price and their financial capabilities. Be sure to discuss any potential interest rates, down payments, and payment schedules with your supplier to establish a clear understanding before finalizing your order. -

Can I customize my Kymron excavator?

Yes, Kymron offers customization options for many of their excavators to better suit specific project needs. Options may include attachments like hydraulic thumbs, different bucket sizes, and retractable tracks. When discussing your purchase with a dealer, be sure to inquire about available customization options and any associated costs, as these can enhance the machine’s versatility and efficiency on the job site. -

What are the logistics involved in importing Kymron excavators?

Importing Kymron excavators involves several logistical considerations, including shipping methods, customs clearance, and delivery timelines. It’s essential to work with a reliable freight forwarder familiar with heavy machinery to handle transport and customs documentation. Additionally, factor in potential duties and taxes imposed by your country, which can affect the overall cost of acquisition. -

How do I ensure the quality of Kymron excavators before purchasing?

To ensure the quality of Kymron excavators, request detailed specifications, warranty information, and any certifications from the manufacturer or dealer. If possible, arrange for a demonstration or visit a local dealer to inspect the equipment firsthand. Additionally, consider customer reviews and testimonials from other B2B buyers, particularly those in your region, to gauge the reliability and performance of the machines. -

What should I know about after-sales support for Kymron excavators?

After-sales support is crucial for maintaining the performance of your Kymron excavator. Ensure your dealer provides reliable access to spare parts and service support in your region. Kymron’s extensive dealer network typically offers local service, making it easier to obtain maintenance and repairs. Ask about the availability of trained technicians and the response times for service requests to ensure minimal downtime for your operations. -

What are the minimum order quantities (MOQs) for Kymron excavators?

Minimum order quantities for Kymron excavators can vary based on the dealer and your specific needs. While some dealers may allow the purchase of a single unit, others might have MOQs that require bulk purchases for better pricing or availability. It’s advisable to discuss your requirements directly with the dealer to understand their policies and explore potential discounts for larger orders, which could benefit your overall budget.

Top 7 Kymron Excavator Manufacturers & Suppliers List

1. Kymron – Chinese Excavators & Mini Skids

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Chinese Excavators and Mini Skids, Kymron machine

2. Kymron – YH20D Mini Excavator

Domain: greentractortalk.com

Registered: 2011 (14 years)

Introduction: Kymron YH20D Mini Excavator, 20 HP Kubota D722 diesel engine, Side Swing Boom standard feature, Hydraulic Thumb, priced at $17K new, sold by K&R Equipment in Muskogee, Oklahoma.

3. Parsley Equipment – 1-Ton Excavator

Domain: parsleyequipment.com

Registered: 2023 (2 years)

Introduction: {“Excavators”: {“Sizes”: “From 1 ton units to 8 ton”, “Motors”: [“Briggs & Stratton”, “Kubota”, “Yanmar”], “14 SERIES”: {“Description”: “1-ton excavator, economical gas powered mini’s for the homeowner”, “Standard Equipment”: [“13.5 HP Briggs & Stratton”, “Hydraulic Thumb”, “16” Bucket”, “HD Pump”, “Dozer Blade”, “Smooth Spool Valve”], “Optional Equipment”: [“Side-swing Boom”, “Retractable Tracks”…

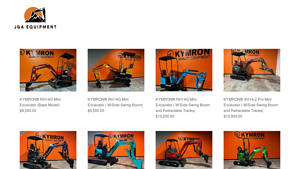

4. JA Equipment – KYMRON® RH14G Mini Excavator

Domain: jaequipment.com

Registered: 2024 (1 years)

Introduction: [{‘model’: ‘KYMRON® RH14G Mini Excavator (Base Model)’, ‘price’: ‘$8,500.00’}, {‘model’: ‘KYMRON® RH14G Mini Excavator (W/Side Swing Boom)’, ‘price’: ‘$9,500.00’}, {‘model’: ‘KYMRON® RH14G Mini Excavator (W/Side Swing Boom and Retractable Tracks)’, ‘price’: ‘$10,200.00’}, {‘model’: ‘KYMRON® XH14-2 Pro Mini Excavator (W/Side Swing Boom and Retractable Tracks)’, ‘price’: ‘$12,900.00’}, {‘model’: ‘KY…

5. M Cross C Equipment – Kymron Mini Excavators

Domain: mcrossc-equipment.com

Registered: 2024 (1 years)

Introduction: M Cross C Equipment, LLC offers a wide selection of Kymron mini excavators for sale throughout the Western United States. These mini excavators are known for their reliability, performance, and versatility, making them suitable for landscaping, plumbing, and construction projects. Key features include robust construction, advanced technology, compact design for excellent maneuverability, and power…

6. KYMRON – RH14G Mini Excavator

Domain: dronesafestores.com

Registered: 2024 (1 years)

Introduction: [{‘name’: ‘KYMRON® RH14G Mini Excavator (Base Model)’, ‘original_price’: 7900, ‘current_price’: 3160, ‘description’: ‘The Kymron RH14G is a reliable and efficient compact excavator, perfect for small to medium jobs.’}, {‘name’: ‘KYMRON® RH14G Mini Excavator (w/ Side Swing Boom & Retractable Tracks)’, ‘original_price’: 9900, ‘current_price’: 3960, ‘description’: ‘The Kymron RH14G Mini Excavator com…

7. KYMRON – Mini Excavator Overview

Domain: cn-sinotruk.com

Registered: 2018 (7 years)

Introduction: Kymron Excavators Overview:

– Brand: KYMRON

– Weight Classes: Mini (1-6 tons), Compact (6-10 tons), Standard (10-20 tons), Large (20+ tons)

– Common Applications: Landscaping, Utility work, Construction, Heavy construction, Mining

Recommended Models:

1. KYMRON RH14G

– Type: Mini Excavator

– Weight: 1.4 tons

– Engine Power: 14 HP

– Max Digging Depth: 8 ft

– Price Range: $2…

Strategic Sourcing Conclusion and Outlook for kymron excavator

In today’s competitive landscape, strategic sourcing of KYMRON excavators presents a unique opportunity for international B2B buyers. With a diverse range of models—from compact mini excavators like the RH14G to robust options like the XH68D—KYMRON offers equipment tailored to various operational needs. The emphasis on affordability, backed by quality components from reputable manufacturers such as Kubota and Yanmar, ensures that buyers can achieve both cost efficiency and reliability.

By leveraging KYMRON’s extensive dealer network, businesses across Africa, South America, the Middle East, and Europe can access expert support and reliable parts, minimizing downtime and maximizing productivity. Furthermore, the potential for significant cost savings compared to traditional brands makes KYMRON an attractive option for companies looking to optimize their equipment investments.

Illustrative image related to kymron excavator

Looking ahead, now is the time for international buyers to evaluate their equipment sourcing strategies. Investing in KYMRON excavators not only enhances operational capabilities but also positions companies for long-term success in a rapidly evolving market. Explore your options today and discover how KYMRON can elevate your construction projects to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.