Choosing Your Injection Molding Rubber: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for injection molding rubber

In the ever-evolving landscape of industrial manufacturing, sourcing high-quality injection molding rubber can be a daunting challenge for international B2B buyers. With various molding techniques available—each catering to specific needs and applications—understanding the nuances of rubber injection molding is crucial for making informed purchasing decisions. This comprehensive guide delves into the diverse types of rubber injection molding processes, including organic, liquid silicone, and thermoplastic rubber injection, highlighting their unique advantages and limitations.

Moreover, we will explore critical considerations such as application suitability, cost implications, and the intricacies of supplier vetting. For B2B buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—this guide serves as an invaluable resource, empowering you to navigate the complexities of sourcing molded rubber parts effectively. By equipping you with actionable insights and practical knowledge, we aim to enhance your procurement strategy, ensuring that you select the right materials and partners to meet your manufacturing goals. Whether you are in automotive, medical, or industrial sectors, understanding the intricacies of injection molding rubber will position you for success in the global market.

Understanding injection molding rubber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Organic Rubber Injection | Eliminates pre-forms; utilizes heated rubber for efficient flow | Automotive parts, seals, gaskets | Pros: Faster cycle times; reduced labor; high precision. Cons: Limited to specific rubber types. |

| Liquid Silicone Rubber (LSR) | Closed system reduces contamination; rapid curing process | Medical devices, consumer products | Pros: High purity; excellent detail; short cycle times. Cons: Higher initial costs; specialized equipment needed. |

| Thermoplastic Rubber Injection | Processes elastomers like plastics; recyclable and colorable | Toys, automotive, consumer goods | Pros: Versatile; eliminates vulcanization steps. Cons: Limited to high-temperature applications. |

| Compression Molding | Traditional method; uses pre-forms in open molds | Seals, O-rings, larger parts | Pros: Strong materials; suitable for low volumes. Cons: Longer curing times; requires large molds. |

| Transfer Molding | Suitable for intricate designs; uses a closed mold system | Complex parts in automotive, aerospace | Pros: High dimensional accuracy; fewer pre-forms. Cons: More waste; potential for higher costs. |

What Are the Characteristics and Suitability of Organic Rubber Injection?

Organic Rubber Injection is a modern method that leverages pre-heated rubber, allowing for efficient filling of mold cavities without the need for pre-forms. This process is particularly suitable for high-precision applications in the automotive sector, where components like seals and gaskets are critical. Buyers should consider the material types available, as the process may be limited to certain rubber compounds. The elimination of pre-forms not only speeds up production but also reduces labor costs, making it an attractive option for manufacturers aiming for efficiency.

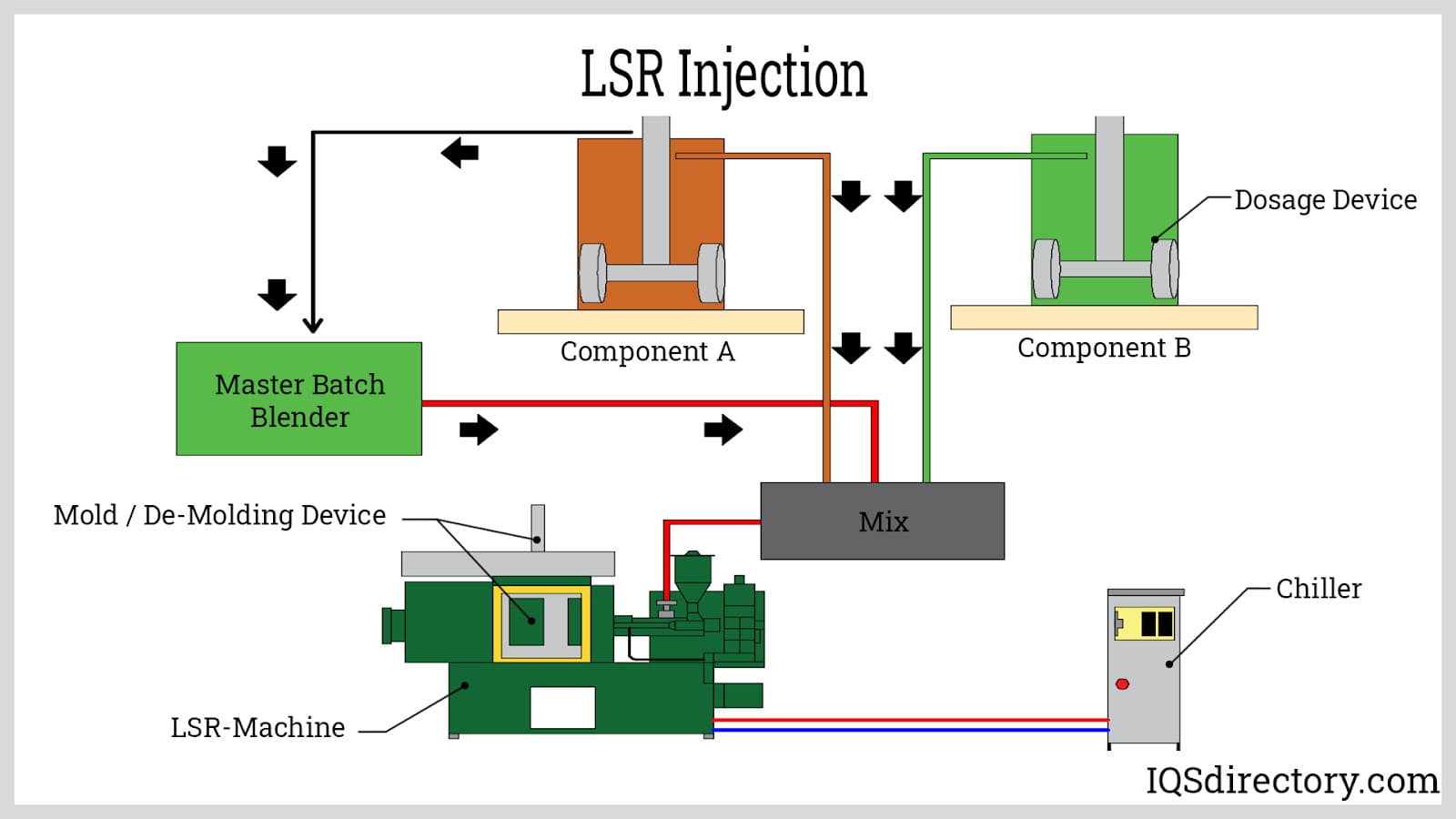

How Does Liquid Silicone Rubber (LSR) Stand Out for Medical Applications?

Liquid Silicone Rubber (LSR) is characterized by its closed system, which significantly minimizes contamination risks during production. This makes it an ideal choice for medical devices and consumer products that require high purity and precision. The rapid curing process allows for quick production cycles, which is essential for meeting market demands. However, buyers should be prepared for higher initial costs and the need for specialized machinery. LSR’s benefits in terms of detail and safety make it a valuable investment for companies in regulated industries.

What Are the Benefits of Thermoplastic Rubber Injection in Consumer Goods?

Thermoplastic Rubber Injection processes elastomers similarly to plastics, allowing for easy recycling and color customization. This method is ideal for producing consumer goods, toys, and automotive parts where versatility and aesthetic appeal are crucial. The process eliminates the need for mixing or vulcanization, streamlining production. However, it is important for buyers to note that this method is best suited for high-temperature applications, which may limit its use in certain environments. Its adaptability and efficiency can lead to significant cost savings in the long run.

Why Choose Compression Molding for Low Volume Production?

Compression Molding is a traditional technique that relies on pre-formed rubber placed in open molds, making it well-suited for low to medium production volumes. This method is commonly used for producing seals, O-rings, and larger rubber parts. While it offers strong materials and is effective for specific applications, buyers should be aware of the longer curing times and the requirement for large, specific molds. This process may be less efficient for high-volume needs but can be advantageous for custom, small-batch orders.

Illustrative image related to injection molding rubber

What Makes Transfer Molding a Preferred Choice for Complex Designs?

Transfer Molding is particularly effective for producing intricate designs and parts with multiple cavities, utilizing a closed mold system. This method ensures high dimensional accuracy and is often used in automotive and aerospace applications where precision is paramount. While it minimizes the need for pre-forms, buyers should consider the potential for increased waste and higher production costs. Transfer Molding is ideal for manufacturers looking to create complex components without compromising on quality.

Key Industrial Applications of injection molding rubber

| Industry/Sector | Specific Application of injection molding rubber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Seals and gaskets for engines | Ensures reliability and performance of vehicle components | Material durability, temperature resistance, and compliance with automotive standards |

| Medical Devices | Custom rubber parts for surgical instruments | Enhances safety and precision in medical procedures | Biocompatibility, sterilization capabilities, and regulatory compliance |

| Consumer Electronics | Shock absorbers for electronic devices | Protects sensitive components from damage | Size specifications, design complexity, and integration with existing systems |

| Aerospace | Vibration dampers for aircraft components | Improves safety and operational efficiency | Weight limitations, heat resistance, and certifications for aerospace applications |

| Industrial Equipment | Hoses and seals for machinery | Prevents leaks and enhances operational reliability | Customization options, resistance to chemicals, and pressure ratings |

How is Injection Molding Rubber Used in the Automotive Industry?

In the automotive sector, injection molding rubber is primarily used to create seals and gaskets that ensure the reliability of engine components. These parts are crucial for preventing leaks and maintaining optimal performance under varying temperature conditions. B2B buyers must consider material durability and compliance with automotive industry standards, as these factors directly affect the longevity and safety of vehicle operations. Suppliers that can provide high-quality, temperature-resistant rubber tailored to specific vehicle designs will be more attractive to manufacturers.

What Role Does Injection Molding Rubber Play in Medical Devices?

Injection molding rubber is vital in the medical device industry, where it is used to produce custom rubber parts for surgical instruments. These components must meet stringent biocompatibility and sterilization requirements to ensure patient safety. International buyers should prioritize suppliers with a proven track record in regulatory compliance and the ability to produce high-precision parts. The ability to customize designs to fit unique medical applications is also essential for meeting specific operational needs.

How is Injection Molding Rubber Beneficial for Consumer Electronics?

In consumer electronics, injection molding rubber is commonly utilized for manufacturing shock absorbers that protect sensitive components from physical damage. This application is particularly crucial in devices that are frequently transported or subjected to vibrations. B2B buyers in this sector must focus on sourcing rubber that meets precise size specifications and design complexities. Suppliers that offer integration capabilities with existing electronic systems can provide added value and ease of implementation.

Why is Injection Molding Rubber Important in Aerospace Applications?

The aerospace industry relies on injection molding rubber for producing vibration dampers that enhance safety and operational efficiency. These components must withstand extreme conditions, making heat resistance and weight limitations critical factors. Buyers in this sector should seek suppliers who can demonstrate compliance with aerospace certifications and provide materials that meet rigorous performance standards. Customization options that allow for tailored solutions can further improve the functionality of aerospace applications.

Illustrative image related to injection molding rubber

How Does Injection Molding Rubber Enhance Industrial Equipment Performance?

In industrial equipment, injection molding rubber is essential for creating hoses and seals that prevent leaks and enhance the overall reliability of machinery. The right rubber materials can withstand harsh environments and resist chemicals, ensuring longevity and reducing maintenance costs. B2B buyers should prioritize suppliers that offer customization capabilities to meet specific operational requirements, including pressure ratings and resistance to various substances. This focus on tailored solutions can significantly impact the efficiency and effectiveness of industrial operations.

3 Common User Pain Points for ‘injection molding rubber’ & Their Solutions

Scenario 1: Challenges with Material Consistency and Quality Control

The Problem: B2B buyers often face issues with inconsistent material quality when sourcing injection molding rubber. This inconsistency can lead to defects in the final products, such as dimensional inaccuracies and compromised mechanical properties. For companies that rely on precision components—such as automotive parts or medical devices—this variability can result in production delays, increased costs due to rework, and potential damage to their reputation among customers.

The Solution: To mitigate these risks, buyers should prioritize sourcing rubber from reputable suppliers with established quality control processes. This includes asking for detailed material certifications and ensuring that the supplier adheres to industry standards such as ISO 9001. Additionally, buyers should conduct regular audits of their suppliers’ production facilities to verify that their quality assurance measures are effective. Engaging in a collaborative relationship with suppliers can also help in developing specific formulations that meet the precise requirements of the application, thus enhancing both quality and performance.

Scenario 2: High Production Costs Due to Inefficient Processes

The Problem: Many manufacturers encounter inflated production costs due to inefficient injection molding processes. This inefficiency can stem from several factors, such as poor machine calibration, inappropriate choice of molding technique, or inadequate workforce training. As a result, companies may struggle to remain competitive, especially when dealing with high-volume orders where margins are tight.

The Solution: To address this issue, buyers should invest in optimizing their injection molding operations. This can begin with a thorough assessment of their current processes and equipment to identify areas for improvement. Implementing advanced technologies such as automated monitoring systems can enhance machine performance and reduce cycle times. Furthermore, providing continuous training for staff on best practices in rubber injection molding can lead to better operational efficiency and reduced waste. Finally, considering a shift to more cost-effective molding techniques, such as liquid silicone rubber (LSR) injection for specific applications, can also help in achieving significant savings.

Scenario 3: Difficulty in Meeting Custom Specifications

The Problem: When dealing with injection molding rubber, B2B buyers often face difficulties in obtaining custom parts that meet specific design requirements. This challenge can arise from a lack of understanding of the unique properties of various rubber materials or insufficient communication with manufacturers regarding design specifications. As a result, companies may end up with products that do not fit their intended applications, leading to delays and additional costs.

The Solution: To effectively overcome these challenges, buyers should engage in detailed discussions with their suppliers at the early stages of product development. It is crucial to provide comprehensive design specifications, including dimensions, tolerances, and performance requirements. Utilizing CAD software to create precise models can facilitate clearer communication and ensure that manufacturers fully understand the project needs. Additionally, working with suppliers that offer prototyping services can allow for testing and validation of designs before mass production, ultimately ensuring that the final products meet the desired specifications and performance standards.

Strategic Material Selection Guide for injection molding rubber

What Are the Key Properties of Common Materials Used in Injection Molding Rubber?

When selecting materials for injection molding rubber, it is crucial to consider their properties and how they align with specific application requirements. Here, we analyze four common materials: Natural Rubber, Silicone Rubber, Nitrile Rubber, and Thermoplastic Elastomers (TPE). Each material has unique characteristics that can significantly impact product performance and suitability.

Illustrative image related to injection molding rubber

How Does Natural Rubber Perform in Injection Molding Applications?

Natural rubber is renowned for its excellent elasticity and resilience. It typically operates effectively within a temperature range of -50°C to 100°C and exhibits good tensile strength and abrasion resistance. However, it has limited resistance to heat, oil, and certain chemicals, which can affect its longevity in harsh environments.

Pros: Natural rubber is cost-effective and highly durable, making it suitable for a wide range of applications, including automotive seals and gaskets.

Cons: Its susceptibility to degradation from UV exposure and certain chemicals can limit its use in outdoor applications or where chemical exposure is a concern.

Impact on Application: Natural rubber is ideal for applications requiring flexibility and stretch, but its chemical resistance should be carefully evaluated based on the media it will encounter.

Illustrative image related to injection molding rubber

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM D2000 for rubber materials, particularly in automotive and industrial applications.

What Are the Advantages of Using Silicone Rubber in Injection Molding?

Silicone rubber is highly valued for its thermal stability, operating effectively from -60°C to 200°C, and exceptional resistance to UV light, ozone, and extreme temperatures. Its biocompatibility makes it a preferred choice in medical applications.

Pros: Silicone rubber offers excellent flexibility and can withstand harsh environmental conditions, making it suitable for seals, gaskets, and medical devices.

Cons: The material tends to be more expensive than other rubber types, and its processing can be more complex, requiring specialized equipment.

Impact on Application: Silicone’s compatibility with various media, including food and pharmaceuticals, enhances its suitability for sensitive applications.

Considerations for International Buyers: Compliance with ISO 10993 for medical-grade materials is critical for buyers in the medical sector, particularly in Europe and South America.

Why Choose Nitrile Rubber for Injection Molding Applications?

Nitrile rubber, known for its excellent resistance to oils and fuels, operates effectively within a temperature range of -40°C to 120°C. It also exhibits good abrasion resistance, making it ideal for automotive and industrial applications.

Pros: Nitrile rubber is durable and cost-effective, providing excellent sealing capabilities in oil and fuel applications.

Cons: It has limited performance in extreme temperatures and is not suitable for applications involving strong oxidizing agents.

Illustrative image related to injection molding rubber

Impact on Application: Nitrile rubber is particularly effective in environments where oil and fuel exposure is common, such as in automotive fuel systems.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM D2000 standards, especially in regions like Africa and the Middle East, where oil and gas industries are prevalent.

What Are the Benefits of Using Thermoplastic Elastomers (TPE) in Injection Molding?

Thermoplastic elastomers combine the properties of rubber and plastic, providing flexibility and durability while being easier to process. TPEs typically operate within a temperature range of -40°C to 120°C and can be recycled.

Illustrative image related to injection molding rubber

Pros: TPEs are versatile, offering good chemical resistance and the ability to be colored, making them suitable for consumer products and automotive applications.

Cons: While TPEs are easier to process, they may not perform as well as traditional rubber in high-temperature applications.

Impact on Application: TPEs are suitable for applications requiring flexibility and aesthetic appeal, such as in consumer goods and automotive interiors.

Considerations for International Buyers: Buyers should ensure that TPEs meet relevant standards, such as DIN EN 45545 for fire safety in rail applications, particularly in Europe.

Summary Table of Material Selection for Injection Molding Rubber

| Material | Typical Use Case for injection molding rubber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Automotive seals and gaskets | Cost-effective and highly durable | Limited chemical resistance | Low |

| Silicone Rubber | Medical devices and seals | Excellent thermal stability | Higher processing complexity | High |

| Nitrile Rubber | Oil and fuel seals in automotive applications | Excellent oil resistance | Limited performance in extreme temps | Med |

| Thermoplastic Elastomers | Consumer products and automotive interiors | Versatile and recyclable | Lower performance in high temps | Med |

This strategic material selection guide provides essential insights for international B2B buyers in understanding the properties, advantages, and limitations of various rubber materials used in injection molding, enabling informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for injection molding rubber

What Are the Key Stages in the Manufacturing Process of Injection Molding Rubber?

The manufacturing process of injection molding rubber involves several critical stages that ensure the production of high-quality rubber components. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

1. Material Preparation: How Is Rubber Prepared for Injection Molding?

Material preparation is the foundational step in rubber injection molding. This involves mixing rubber compounds in bulk to achieve the desired properties, such as hardness, elasticity, and durability. The raw materials are typically blended with additives, including curing agents and colorants, to enhance performance and aesthetics.

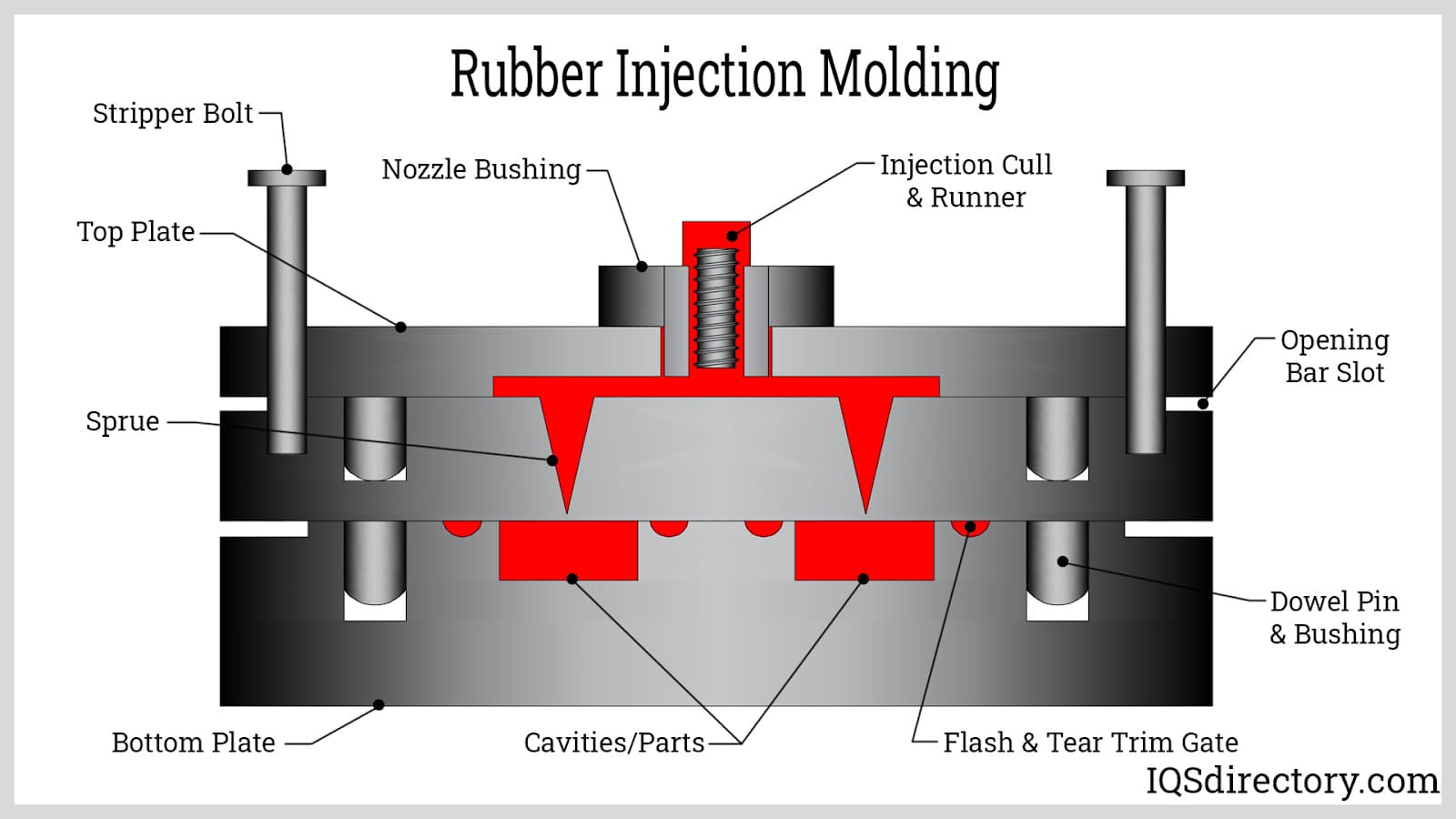

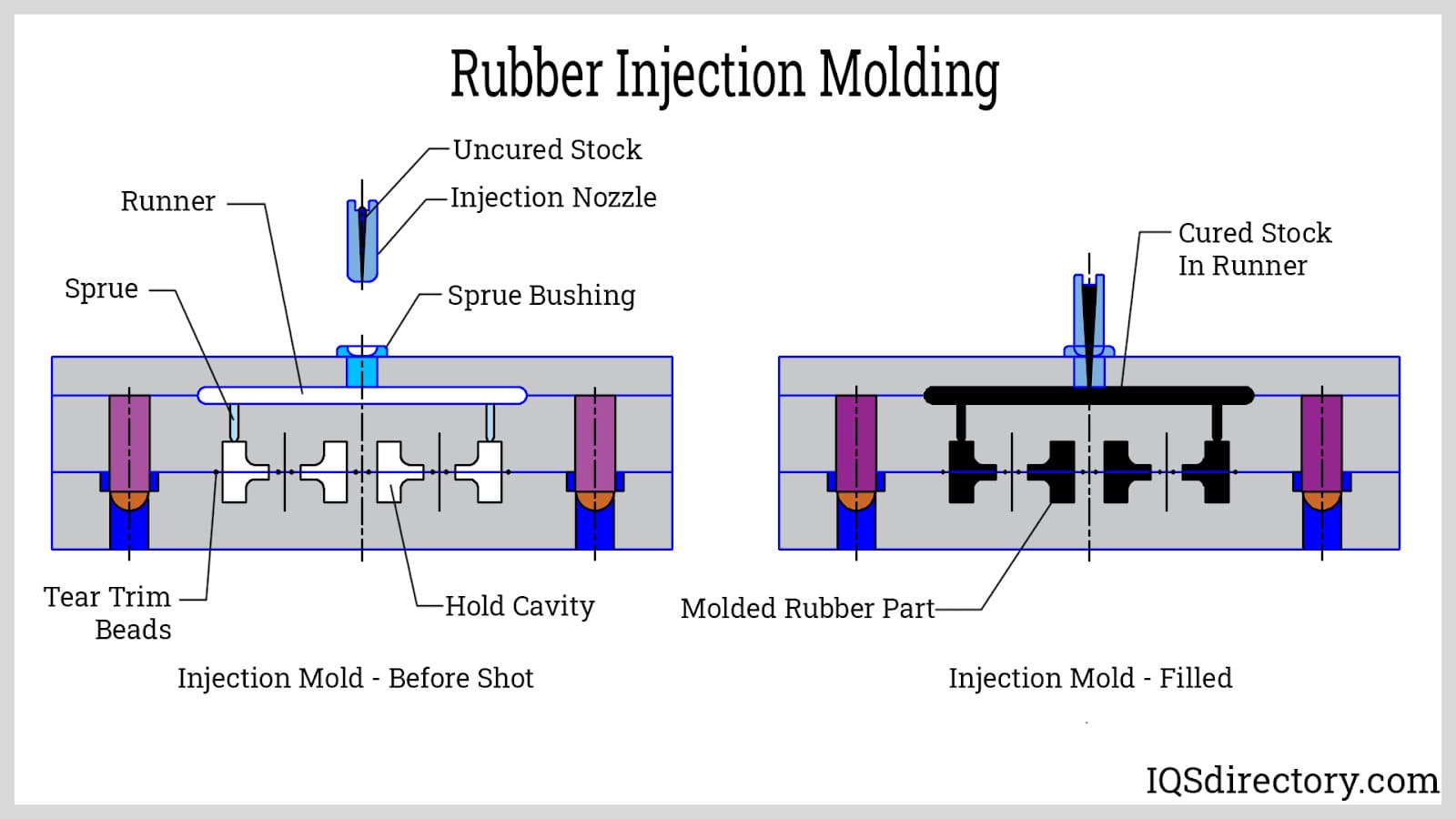

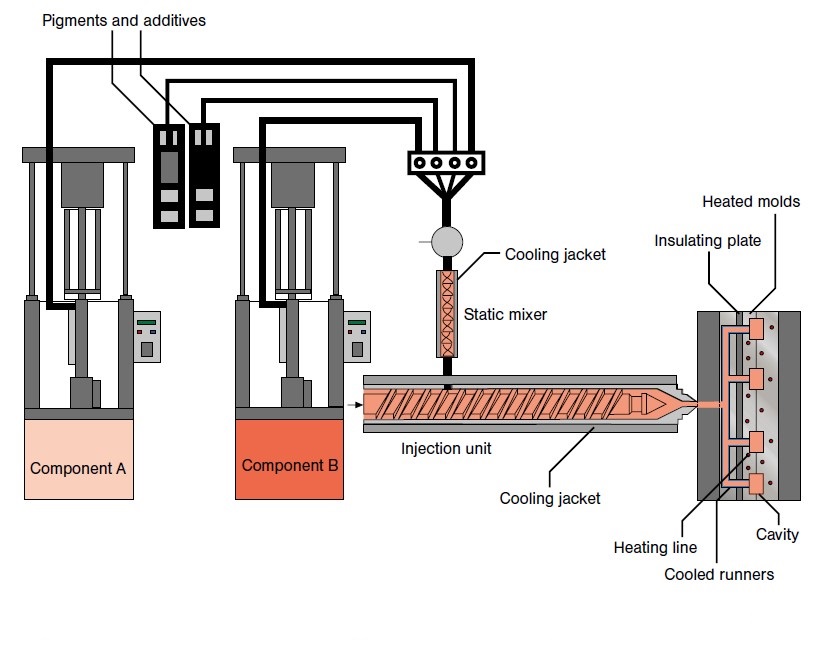

Once mixed, the rubber is stripped into continuous strips, typically around 1.25 inches wide and 0.375 inches thick. These strips are then fed into a screw extruder, where they are heated and pressurized. The pre-heating process reduces the viscosity of the rubber, allowing for easier flow into the mold cavities during the injection stage. This preparation phase is crucial for ensuring consistency in the final product.

2. Forming: What Techniques Are Used in the Injection Molding Process?

The forming stage is where the prepared rubber is transformed into the desired shape. This typically involves the following techniques:

-

Injection Molding: The primary technique used, where the heated and pressurized rubber is injected into a mold cavity. This method is favored for its efficiency, as it eliminates the need for pre-forms, reducing labor costs and potential variability in product quality.

-

Liquid Silicone Rubber (LSR) Injection: Often used for applications requiring high precision and cleanliness, such as medical devices. The two-part liquid silicone is mixed and injected into molds, where it cures, ensuring minimal contamination and faster cycle times.

-

Thermoplastic Rubber (TPR) Injection: In this process, elastomers are treated similarly to thermoplastics, allowing for easy processing and recycling. This method is particularly advantageous for high-volume production where color and design flexibility are important.

These techniques not only enhance production speed but also allow for the creation of complex geometries, which are often required in specialized applications.

3. Assembly: How Are Different Rubber Components Assembled?

In cases where multiple rubber parts are required for a final assembly, the assembly stage becomes crucial. This may involve processes such as bonding rubber to metal or other substrates, often using specialized adhesives or techniques like rubber-to-metal bonding.

Automated assembly lines can increase efficiency and ensure consistent quality in the final products. B2B buyers should inquire about the assembly capabilities of their suppliers, particularly if they require integrated solutions that combine rubber parts with other materials.

4. Finishing: What Are the Final Steps in Rubber Injection Molding?

Finishing processes are essential for enhancing the appearance and performance of molded rubber products. This can include:

- Trimming: Excess rubber (flash) is removed from the molded parts to achieve the desired dimensions.

- Surface Treatments: Depending on the application, surface treatments may be applied to improve aesthetics or functionality, such as texturing or coating.

- Quality Control Inspections: Final inspections ensure that the products meet specified tolerances and quality standards before shipping to customers.

How Is Quality Assurance Managed in Rubber Injection Molding?

Quality assurance is a critical component in the injection molding process, ensuring that products meet both international standards and customer expectations.

What International Standards Are Relevant for Injection Molding Rubber?

Many B2B buyers prioritize suppliers who adhere to recognized international quality standards. The following standards are particularly relevant:

-

ISO 9001: This standard outlines requirements for a quality management system (QMS) and is crucial for ensuring consistent quality across production processes. Suppliers certified under ISO 9001 demonstrate their commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be necessary, ensuring that rubber components can withstand harsh operating conditions.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control is integrated into various stages of the manufacturing process, typically involving the following checkpoints:

-

Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials before production begins. Ensuring high-quality inputs is vital for achieving superior outputs.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of the molded products. This includes measuring dimensions and inspecting for defects.

-

Final Quality Control (FQC): Once production is complete, a final inspection ensures that the products meet all specified requirements before shipping. This is critical for maintaining the trust of B2B clients.

What Common Testing Methods Are Used to Ensure Product Quality?

Several testing methods are employed to verify the quality of rubber injection molded products:

-

Mechanical Testing: This includes tensile, compression, and hardness tests to evaluate the physical properties of the rubber.

-

Visual Inspection: A thorough visual check for defects such as bubbles, discoloration, or irregularities in the surface finish.

-

Dimensional Inspection: Using calipers and other measuring tools to ensure that products meet the specified dimensions and tolerances.

-

Environmental Testing: Assessing the rubber’s performance under various environmental conditions, such as temperature extremes and exposure to chemicals.

How Can B2B Buyers Verify a Supplier’s Quality Assurance Practices?

For international B2B buyers, verifying a supplier’s quality assurance practices is crucial for mitigating risks. Here are several strategies to consider:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes and quality control systems. This is an effective way to assess their capabilities and commitment to quality.

-

Requesting Quality Reports: Suppliers should be willing to provide documentation of their quality control processes, including inspection reports and certifications.

-

Third-Party Inspections: Engaging independent inspectors can add an additional layer of assurance. These inspectors can verify compliance with international standards and assess overall product quality.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control when dealing with suppliers in different countries. These include:

-

Cultural Differences: Understanding the cultural context can help buyers navigate communication and negotiation processes effectively.

-

Regulatory Requirements: Different regions may have varying regulatory requirements that impact product quality. Buyers must ensure that suppliers comply with the relevant regulations in their target markets.

-

Logistical Considerations: Quality assurance processes can be affected by logistics, including transportation and storage conditions. Buyers should discuss these factors with suppliers to ensure product integrity upon arrival.

In conclusion, understanding the manufacturing processes and quality assurance measures in rubber injection molding is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions and select suppliers that align with their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘injection molding rubber’

Introduction

Sourcing injection molding rubber can be a complex process, especially for international B2B buyers. This guide provides a step-by-step checklist to streamline your procurement process, ensuring that you select the right materials and suppliers to meet your specific production needs. By following these actionable steps, you can mitigate risks and enhance the efficiency of your sourcing activities.

Step 1: Define Your Technical Specifications

Clearly defining your technical specifications is crucial for successful sourcing. This includes understanding the size, geometry, weight, and material requirements of the rubber parts you need.

Illustrative image related to injection molding rubber

- Material Type: Determine whether you require organic rubber, liquid silicone rubber (LSR), or thermoplastic rubber (TPR) based on your application.

- Volume Needs: Assess your production volume to choose a suitable molding process, as different methods cater to varying quantities.

Step 2: Research Potential Suppliers

Conduct thorough research on potential suppliers to identify those with a strong reputation in rubber injection molding.

- Industry Experience: Look for suppliers with significant experience in your specific industry, as they will be more familiar with your unique challenges and requirements.

- Geographical Considerations: Given your target regions (Africa, South America, the Middle East, and Europe), ensure that the suppliers can efficiently handle logistics and delivery to your location.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure quality and compliance with industry standards.

- Quality Management Systems: Check for certifications such as ISO 9001, which indicate a commitment to quality management practices.

- Material Certifications: Ensure that the rubber materials meet relevant safety and environmental regulations pertinent to your industry.

Step 4: Request Prototypes or Samples

Before making a large commitment, request prototypes or samples of the rubber parts.

- Testing Fit and Function: This step allows you to assess whether the supplier can meet your design and performance specifications.

- Quality Assurance: Evaluate the quality of the sample to determine if it aligns with your expectations and standards.

Step 5: Assess Production Capabilities

Evaluate the production capabilities of your shortlisted suppliers to ensure they can meet your volume and timeline requirements.

- Machinery and Technology: Inquire about the types of injection molding machines and technologies used, as advanced equipment often results in better precision and efficiency.

- Flexibility in Production: Assess whether the supplier can adapt to changes in demand or specifications, which is vital for dynamic markets.

Step 6: Review Pricing Structures

Understanding the pricing structure is key to ensuring that your sourcing decision aligns with your budget.

- Cost Breakdown: Request detailed quotes that break down costs for materials, labor, and any additional services such as design or prototyping.

- Long-term Agreements: Consider negotiating long-term contracts that may provide better pricing and stability in supply.

Step 7: Establish Clear Communication Channels

Effective communication is essential throughout the sourcing process.

- Point of Contact: Ensure that you have a dedicated point of contact within the supplier’s organization for streamlined communication.

- Regular Updates: Set expectations for regular updates on production status, potential delays, and any other critical information to avoid misunderstandings.

By following this checklist, B2B buyers can navigate the complexities of sourcing injection molding rubber with confidence, ensuring that they select the best materials and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for injection molding rubber Sourcing

What Are the Key Cost Components in Injection Molding Rubber Sourcing?

When analyzing the cost structure for injection molding rubber, several components come into play, each influencing the overall pricing. Understanding these elements is critical for B2B buyers looking to optimize their sourcing strategies.

-

Materials: The type of rubber used significantly impacts costs. Organic rubber, liquid silicone rubber (LSR), and thermoplastic elastomers (TPEs) each have different price points. Additionally, sourcing high-quality materials that meet specific certifications can lead to increased costs but may be necessary for industries such as medical or automotive.

-

Labor: Labor costs vary by region and depend on the complexity of the molding process. Skilled labor is essential for tasks such as machine operation and quality control, and this can be a significant portion of the overall manufacturing cost, especially in regions with higher wage expectations.

-

Manufacturing Overhead: This includes costs related to facility maintenance, equipment depreciation, utilities, and other indirect expenses. Efficient production processes, such as those employed in injection molding, can help reduce overhead by maximizing output.

-

Tooling: Tooling costs can be substantial, particularly for custom molds that require precision engineering. The design and fabrication of molds are critical investments that affect both the initial and long-term costs of production. Buyers should consider the expected lifecycle of the molds when evaluating tooling expenses.

-

Quality Control (QC): Implementing a robust QC system is essential to ensure product consistency and compliance with industry standards. While it adds to the cost, effective QC can prevent costly reworks and product failures, making it a worthwhile investment.

-

Logistics: Shipping and handling costs can vary widely based on location, shipping method, and Incoterms. Understanding the logistics involved in transporting rubber components from the supplier to the buyer’s location is crucial for accurate cost assessments.

-

Margin: Suppliers will factor in their profit margins, which can vary based on market conditions, competition, and the perceived value of their products. B2B buyers should be aware of typical margins in the industry to negotiate effectively.

How Do Price Influencers Affect Injection Molding Rubber Costs?

Several factors can influence the final price of injection molding rubber components:

-

Volume/MOQ: Higher order volumes often result in lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to align with their production needs and budget.

-

Specifications/Customization: Custom parts designed for specific applications can significantly increase costs. Buyers should weigh the benefits of customized solutions against their budget constraints.

-

Materials: The choice of rubber material directly impacts pricing. Specialty materials or those with specific certifications may command higher prices.

-

Quality/Certifications: Products that meet international quality standards or certifications (e.g., ISO, RoHS) may have higher costs but can ensure compliance and reliability, particularly for sectors like automotive and medical.

-

Supplier Factors: The supplier’s experience, reputation, and production capabilities can influence pricing. Established suppliers may charge a premium but often provide better quality assurance and reliability.

-

Incoterms: The agreed-upon Incoterms can affect logistics costs and responsibilities, impacting the total cost of ownership. Understanding these terms is essential for international buyers.

What Are Some Negotiation and Cost-Efficiency Tips for B2B Buyers?

-

Leverage Volume Discounts: Consider consolidating orders to meet higher MOQs for better pricing. Long-term contracts can also provide stability and cost predictability.

-

Evaluate Total Cost of Ownership (TCO): Don’t just focus on the initial purchase price. Consider long-term costs, including maintenance, replacement, and quality issues that may arise from lower-quality materials.

-

Research Market Prices: Stay informed about market trends and pricing benchmarks in your region. This knowledge will empower you during negotiations.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down each cost component. This transparency can reveal areas for potential savings.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better terms, priority service, and insights into upcoming pricing changes.

-

Consider Local Suppliers: For buyers in Africa, South America, and the Middle East, sourcing from local suppliers can reduce logistics costs and lead times.

Disclaimer on Pricing

Prices for injection molding rubber components can vary significantly based on numerous factors, including market conditions, material availability, and specific project requirements. The information provided here is indicative and should be used as a guideline rather than a fixed pricing model. Always consult directly with suppliers for accurate quotes tailored to your specific needs.

Alternatives Analysis: Comparing injection molding rubber With Other Solutions

Introduction: Exploring Alternatives to Injection Molding Rubber

When considering manufacturing solutions for rubber parts, injection molding rubber stands out for its efficiency and precision. However, various alternative methods may also meet specific production needs and constraints. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their operational goals.

Comparison Table

| Comparison Aspect | Injection Molding Rubber | Compression Molding | Transfer Molding |

|---|---|---|---|

| Performance | High precision, minimal waste | Moderate precision, longer cycle times | High precision, good for complex shapes |

| Cost | Economical for high volumes | Lower tooling costs, but higher labor costs | Moderate to high, depending on complexity |

| Ease of Implementation | Complex setup, requires specialized machinery | Simple, requires less complex tooling | Moderate complexity, requires specific molds |

| Maintenance | Low maintenance, automated processes | Moderate maintenance, depends on manual handling | Moderate maintenance, involves careful mold management |

| Best Use Case | High volume, precision parts | Low to medium volume, simpler parts | Complex shapes, multiple cavities |

Detailed Breakdown of Alternatives

Compression Molding

Compression molding is a traditional method where pre-formed rubber is placed in an open mold, which is then closed and heated. This process is particularly effective for low to medium production volumes and is well-suited for simpler parts like seals and gaskets. The main advantage of compression molding is its lower tooling costs, making it an attractive option for startups and smaller manufacturers. However, it comes with longer cycle times and requires manual handling, which can introduce variability in product quality.

Transfer Molding

Transfer molding is an advanced method ideal for producing intricate rubber components. In this process, rubber is heated and transferred into a closed mold via a piston mechanism, allowing for precise control over material flow. Transfer molding excels in applications that require high dimensional tolerances and complex geometries, such as automotive parts and medical devices. While it can produce high-quality parts, the setup can be more costly and time-consuming than other methods, making it best suited for specific high-precision applications rather than general production.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right manufacturing method involves a careful analysis of performance, cost, and specific application requirements. Injection molding rubber offers high precision and efficiency, particularly for large-scale production. However, alternatives like compression and transfer molding can provide cost-effective solutions for lower volumes or more complex designs. Ultimately, understanding each method’s strengths and limitations will enable buyers to align their manufacturing strategy with their operational goals, ensuring they achieve optimal results for their projects.

Illustrative image related to injection molding rubber

Essential Technical Properties and Trade Terminology for injection molding rubber

What Are the Key Technical Properties of Injection Molding Rubber?

When engaging in rubber injection molding, understanding specific technical properties is crucial for ensuring that the final product meets your business needs. Here are some critical specifications to consider:

-

Material Grade

Material grade refers to the specific formulation and quality of rubber used in the injection molding process. Different grades exhibit varying physical properties, such as hardness, flexibility, and temperature resistance. For B2B buyers, selecting the right material grade is essential for achieving the desired performance characteristics in their applications, whether for automotive parts, seals, or medical devices. -

Dimensional Tolerance

Dimensional tolerance indicates the allowable variation in the dimensions of a molded part. This specification is critical for ensuring that components fit precisely within larger assemblies. In industries such as automotive and aerospace, where precision is paramount, understanding the required tolerances can help buyers avoid costly rework or product failures. -

Cure Time

Cure time is the duration required for the rubber to undergo chemical curing within the mold. This property directly impacts production efficiency and cycle times. For B2B buyers, minimizing cure time while ensuring optimal part quality can lead to significant cost savings and improved time-to-market for their products. -

Hardness (Shore Durometer)

Hardness, measured using the Shore durometer scale, determines the rubber’s resistance to indentation. Different applications require different hardness levels; for example, softer rubber may be necessary for vibration dampening, while harder rubber is better for structural applications. Understanding hardness is vital for buyers to ensure that the rubber components will perform as intended in their specific applications. -

Volume Production Capability

Volume production capability refers to the ability of a manufacturing process to produce large quantities of molded parts efficiently. This property is particularly important for businesses with high demand for rubber components, as it influences cost per unit and supply chain management. Buyers should assess the production capabilities of their suppliers to ensure they can meet their volume requirements without compromising quality.

What Are Common Trade Terms in Rubber Injection Molding?

Familiarizing yourself with industry jargon can enhance communication and negotiation with suppliers. Here are some essential trade terms used in rubber injection molding:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In rubber injection molding, OEMs often require custom rubber components that integrate seamlessly into their products. Understanding OEM dynamics can help buyers align their needs with manufacturer capabilities. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can affect inventory costs and production planning. Knowing the MOQ can help buyers determine if a supplier is a viable partner for their needs, especially for custom parts. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. In the context of injection molding rubber, submitting an RFQ helps buyers obtain competitive pricing and understand the lead times and material options available from different suppliers. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risk transfer, and delivery obligations, which can significantly affect the total cost of procurement for rubber components. -

Vulcanization

Vulcanization is a chemical process that enhances the properties of rubber by cross-linking polymer chains. This term is important for buyers to understand the production methods used by suppliers and the implications for durability and performance of the final product.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that ensure the successful procurement of rubber injection-molded components, aligning supplier capabilities with their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the injection molding rubber Sector

What Are the Key Market Dynamics and Trends in the Injection Molding Rubber Sector?

The injection molding rubber sector is experiencing significant growth, driven by the increasing demand for custom rubber components across various industries such as automotive, healthcare, and consumer goods. Globalization and technological advancements are facilitating international trade, enabling buyers from regions like Africa, South America, the Middle East, and Europe to access high-quality rubber products. Notably, the rise of Industry 4.0 technologies, such as IoT and AI, is transforming manufacturing processes, allowing for real-time monitoring and predictive maintenance, which enhances production efficiency and reduces downtime.

Emerging trends in sourcing include a shift towards just-in-time manufacturing, which minimizes inventory costs and promotes lean operations. This approach is particularly beneficial for B2B buyers looking to optimize cash flow and improve responsiveness to market changes. Additionally, there is a growing interest in automation and robotics in the injection molding process, which not only increases precision but also reduces labor costs. These trends are crucial for international buyers aiming to maintain competitive advantages in a rapidly evolving marketplace.

Furthermore, the demand for sustainable and eco-friendly rubber products is on the rise. Buyers are increasingly seeking suppliers that can provide sustainable materials and practices, reflecting a broader shift towards responsible sourcing. This trend is particularly pertinent for companies in Europe and the Middle East, where regulatory frameworks are becoming more stringent regarding environmental impacts.

How Is Sustainability Shaping Sourcing Practices in the Injection Molding Rubber Industry?

Sustainability is now a pivotal consideration in the injection molding rubber sector, significantly influencing sourcing decisions. As environmental awareness grows, businesses are under pressure to reduce their carbon footprints and adopt ethical sourcing practices. This is especially relevant for international B2B buyers who must navigate various regulatory landscapes across regions like Africa, South America, the Middle East, and Europe.

The environmental impact of rubber production is a critical concern, as traditional methods can lead to deforestation and significant waste generation. Therefore, sourcing from suppliers that prioritize sustainable practices—such as using recycled materials, eco-friendly production methods, and obtaining certifications like ISO 14001—has become increasingly important. Buyers should also look for manufacturers that offer ‘green’ materials, such as bio-based elastomers, which can help mitigate environmental impacts.

Moreover, ethical supply chains are gaining prominence, with buyers seeking transparency and accountability from their suppliers. This includes understanding the sourcing of raw materials and ensuring fair labor practices. By aligning with suppliers committed to sustainability and ethical practices, B2B buyers can enhance their brand reputation while meeting the growing consumer demand for responsible products.

What Is the Historical Context of Injection Molding Rubber That Influences Today’s Market?

The history of injection molding rubber dates back to the mid-20th century when the process was adapted from plastic injection molding techniques. Initially, rubber injection molding was limited in scope and primarily used for simple parts. However, advancements in technology and material science have significantly transformed the landscape, leading to the development of various molding techniques, such as liquid silicone rubber (LSR) injection and thermoplastic rubber (TPR) injection.

Illustrative image related to injection molding rubber

These innovations have allowed for greater precision, efficiency, and versatility in the manufacturing of rubber components. As businesses increasingly seek custom solutions to meet specific operational needs, the evolution of injection molding rubber has paved the way for tailored applications across multiple industries. This historical context is essential for B2B buyers, as understanding the evolution of the technology can inform their sourcing strategies and help them leverage the latest advancements for competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of injection molding rubber

-

How do I solve quality issues with injection molded rubber products?

To address quality issues in injection molded rubber, start by conducting a thorough inspection of both raw materials and the manufacturing process. Implement quality control measures such as regular testing for hardness, tensile strength, and elasticity. Collaborate closely with your supplier to establish clear specifications and standards. Consider utilizing third-party quality assurance services to ensure compliance with international standards. Establishing a feedback loop with your supplier can also help in quickly resolving any recurring issues. -

What is the best type of injection molding for my specific application?

The best type of injection molding for your application depends on several factors, including the complexity of the part, production volume, and material requirements. For intricate designs or multi-cavity parts, rubber transfer molding may be ideal. If high precision and efficiency are paramount, injection molding—especially liquid silicone rubber (LSR) injection—is recommended. Consult with your supplier to assess the specific needs of your project, including material characteristics and cost considerations. -

How can I ensure my supplier complies with international standards?

To ensure your supplier complies with international standards, request certifications such as ISO 9001 or ISO 13485, depending on your industry. Conduct thorough due diligence by reviewing their quality management systems and operational practices. Engaging in regular audits and assessments can provide insight into their compliance and manufacturing capabilities. Additionally, consider suppliers with a proven track record in international trade and certifications relevant to your target market. -

What are the typical minimum order quantities (MOQs) for injection molded rubber parts?

Minimum order quantities for injection molded rubber parts can vary significantly based on the supplier and the complexity of the part. Generally, MOQs range from 500 to 1,000 units for standard products, while custom designs may require higher quantities. Discuss your specific needs with potential suppliers, as many are willing to accommodate lower MOQs for initial orders or prototypes. Always factor in the cost implications of lower quantities against potential savings from larger orders. -

What payment terms should I expect when sourcing injection molded rubber?

Payment terms for sourcing injection molded rubber typically vary by supplier and can include options like net 30, net 60, or payment upon delivery. Many suppliers may request a deposit of 30-50% upfront, especially for custom orders. It’s essential to negotiate terms that align with your cash flow and project timelines. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings later in the transaction. -

How do I vet potential suppliers for injection molding rubber?

Vetting potential suppliers involves assessing their manufacturing capabilities, quality control processes, and industry experience. Begin by reviewing their portfolio and client testimonials to gauge reliability. Request samples of previous work to evaluate quality. Additionally, consider conducting site visits if feasible, or utilizing third-party inspection services. Establishing clear communication and understanding their lead times and customer service practices is also crucial in your vetting process. -

What logistics considerations should I keep in mind for international shipping of rubber products?

When planning for the logistics of international shipping of rubber products, consider factors such as shipping costs, customs regulations, and lead times. Work closely with your supplier to understand packaging requirements that minimize damage during transit. Additionally, familiarize yourself with import/export duties and tariffs specific to your country. Engaging a logistics partner with experience in international trade can streamline the shipping process and ensure compliance with all regulations. -

How can I customize injection molded rubber products to meet my specifications?

Customizing injection molded rubber products starts with clearly defining your requirements, including dimensions, material properties, and intended use. Collaborate with your supplier to develop prototypes and conduct tests to ensure the product meets your specifications. Many suppliers offer design assistance and can help you refine your concept for optimal manufacturability. Be prepared to provide detailed drawings or CAD models to facilitate the customization process and ensure accuracy in production.

Top 2 Injection Molding Rubber Manufacturers & Suppliers List

1. Protolabs – Liquid Silicone Rubber Injection Molding

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Liquid Silicone Rubber (LSR) Injection Molding produces custom prototypes and end-use production parts in 15 days or less. The process utilizes aluminum molds for cost-efficient tooling and accelerated manufacturing cycles. Various grades and durometers of LSR materials are available. Common applications include low-volume production, bridge tooling, pilot runs, and functional prototyping. Certifi…

2. Da/Pro Rubber – Rubber Injection Molding

Domain: daprorubber.com

Registered: 1998 (27 years)

Introduction: Da/Pro Rubber specializes in rubber injection molding, offering high precision, tolerance, and low flash in the industry. Their expertise includes plastic injection and liquid silicone rubber injection molding. Key features include:

– Custom molding of components using various materials such as buna rubber, butyl rubber, fluorosilicone, natural rubber, synthetic rubbers, silicones, plastics, TPE, …

Strategic Sourcing Conclusion and Outlook for injection molding rubber

What Are the Key Takeaways for B2B Buyers in Injection Molding Rubber?

In conclusion, the strategic sourcing of injection molding rubber is pivotal for businesses seeking to enhance operational efficiency and product quality. By understanding the distinct molding processes—transfer, compression, and injection molding—buyers can make informed decisions that align with their specific needs. Custom solutions, particularly in high-demand markets such as automotive, medical, and industrial sectors, allow for tailored applications that optimize performance and cost-effectiveness.

How Can Strategic Sourcing Enhance Your Supply Chain?

Leveraging strategic sourcing not only streamlines procurement but also fosters strong supplier relationships, ensuring consistency in product delivery and quality. International buyers from Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia, should prioritize partnerships with manufacturers who demonstrate innovation and adaptability in their rubber molding capabilities.

What’s Next for International Buyers in the Injection Molding Rubber Market?

As the demand for high-quality rubber components continues to rise, the outlook for injection molding rubber remains robust. Embrace the opportunity to explore custom solutions and engage with suppliers who are committed to sustainable practices and technological advancements. Take proactive steps today to secure your supply chain and remain competitive in an ever-evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.