Choosing Your Hub P: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for hub p

In today’s interconnected world, sourcing the right components like hub p fittings can be a daunting task for international B2B buyers. As businesses expand their operations across borders, they often encounter challenges in finding reliable suppliers, ensuring product quality, and navigating regulatory requirements. This guide aims to simplify the procurement process by providing a comprehensive overview of hub p fittings, including types, applications, and the critical aspects of supplier vetting. Whether you are in Africa, South America, the Middle East, or Europe, understanding these elements is essential for making informed purchasing decisions.

This guide delves into the various types of hub p fittings, their specific applications in plumbing and construction, and the best practices for evaluating potential suppliers. Additionally, it addresses cost considerations and provides insights into market trends that can influence pricing and availability. By equipping B2B buyers with actionable insights and strategies, this resource empowers you to make confident and informed decisions that align with your business needs.

Navigating the global market for hub p fittings requires a keen understanding of both local and international dynamics. As you explore the contents of this guide, you will find valuable information tailored to help you overcome common challenges and seize opportunities in your sourcing endeavors.

Understanding hub p Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

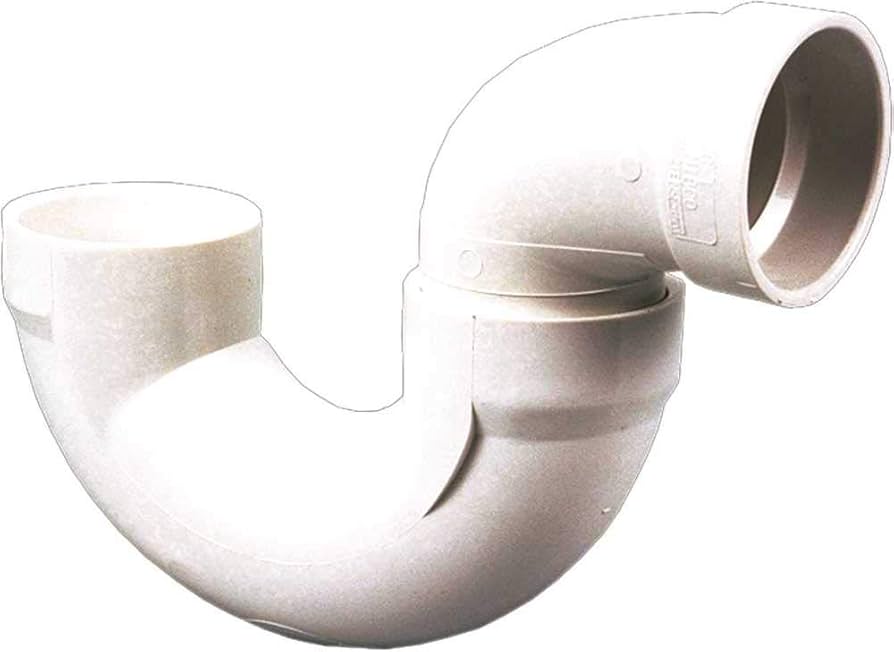

| PVC P-Trap | Made of PVC, hub x hub connections, union joint | Plumbing systems in residential and commercial | Pros: Corrosion resistant, easy installation. Cons: Limited temperature tolerance. |

| DWV Hub | Designed for drainage, waste, and vent systems | Wastewater management in construction | Pros: Durable, effective water seal. Cons: Can be less flexible than other materials. |

| Hub and Spigot | Features a spigot end for easy connection to pipes | Infrastructure projects, drainage systems | Pros: Secure fit, minimizes leaks. Cons: Requires precise alignment during installation. |

| P-Hub Centre Routing | Focuses on optimizing routing with emissions budgets | Logistics and supply chain management | Pros: Reduces costs, enhances efficiency. Cons: Complexity in implementation and planning. |

| Hub P (Entertainment) | Digital media hub for video streaming | Content distribution in digital marketing | Pros: Wide reach, diverse content options. Cons: High competition, potential content regulation issues. |

What are the Characteristics and Suitability of PVC P-Traps for B2B Buyers?

PVC P-Traps are essential components in plumbing systems, known for their durability and resistance to corrosion. They feature a union joint, allowing for easy disassembly and maintenance. Suitable for both residential and commercial applications, these P-Traps are ideal for environments where waste management is critical. Buyers should consider the installation environment and local building codes, as PVC may not withstand extreme temperatures or chemical exposure.

How Do DWV Hubs Serve Waste Management Needs in B2B Applications?

DWV (Drainage, Waste, and Vent) hubs are specifically engineered for effective waste management. They create a reliable water seal, preventing sewer gases from entering buildings. This type is commonly used in construction and renovation projects, making it a staple for contractors. When purchasing DWV hubs, buyers must evaluate the material’s compatibility with existing plumbing systems and the specific requirements of their projects.

What Benefits Do Hub and Spigot Connections Offer for Infrastructure Projects?

Hub and spigot connections are designed to provide a secure fit between pipes, minimizing the risk of leaks. This design is particularly beneficial in infrastructure projects that require a strong and reliable drainage system. The ease of installation is a significant advantage for contractors, though precise alignment is crucial to ensure functionality. Buyers should assess the environmental conditions and longevity of materials when selecting this type.

How Can P-Hub Centre Routing Improve Logistics and Supply Chain Management?

The P-Hub Centre Routing approach optimizes logistics by planning routes that consider emissions budgets. This innovative solution is vital for businesses looking to enhance efficiency while reducing their carbon footprint. Although implementing this strategy can be complex, the potential for significant cost savings and operational improvements makes it an attractive option for B2B buyers focused on sustainability.

What Should B2B Buyers Know About Hub P in Digital Content Distribution?

Hub P, in the context of digital media, refers to platforms that facilitate video streaming and content distribution. This type is increasingly relevant for businesses in the entertainment and marketing sectors. While it offers a broad reach and diverse content options, buyers must navigate a competitive landscape and be aware of content regulation issues. Evaluating the platform’s audience engagement metrics and distribution capabilities is essential for effective investment.

Key Industrial Applications of hub p

| Industry/Sector | Specific Application of hub p | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Plumbing | Use in drainage, waste, and vent systems | Ensures efficient wastewater management and prevents leaks | Compliance with local plumbing codes and standards; quality certifications |

| Manufacturing | Integration in industrial water recycling systems | Reduces water waste and operational costs | Durability under high pressure; availability of replacement parts |

| Food and Beverage | Application in sanitary drainage systems | Maintains hygiene and prevents contamination | Food-grade materials; resistance to chemical corrosion |

| Oil and Gas | Utilization in pipeline systems for fluid transport | Enhances operational efficiency and reduces downtime | High pressure tolerance; compatibility with various fluids |

| Telecommunications | Use in cable management systems | Improves organization and ease of maintenance | Compatibility with existing infrastructure; ease of installation |

How is hub p Applied in Construction and Plumbing?

In the construction and plumbing sectors, hub p is primarily utilized in drainage, waste, and vent (DWV) systems. This application is crucial for ensuring that wastewater is efficiently managed, thereby preventing leaks and potential health hazards. For international buyers, especially in developing regions, sourcing reliable hub p components that comply with local plumbing codes is essential to avoid costly reworks. Quality certifications can also ensure that the products meet international standards, enhancing project reliability.

What Role Does hub p Play in Manufacturing?

In manufacturing, hub p is integrated into industrial water recycling systems, which are increasingly important for sustainability. By effectively managing and recycling water, businesses can significantly reduce operational costs associated with water usage. Buyers in this sector should prioritize sourcing durable hub p components that can withstand high pressure and continuous use, along with ensuring the availability of replacement parts to minimize downtime.

Why is hub p Important for the Food and Beverage Industry?

In the food and beverage industry, the application of hub p in sanitary drainage systems is critical for maintaining hygiene and preventing contamination. These systems are designed to handle food waste and ensure that wastewater is disposed of safely. Buyers need to ensure that the materials used in hub p products are food-grade and resistant to chemical corrosion, which is vital for compliance with health regulations and to protect public safety.

How is hub p Utilized in Oil and Gas Operations?

The oil and gas industry employs hub p in pipeline systems for fluid transport, which enhances operational efficiency and minimizes downtime. The robustness of these components is vital as they must withstand high pressures and corrosive environments. B2B buyers in this sector should focus on sourcing hub p that meets stringent industry standards for pressure tolerance and compatibility with various fluids, ensuring reliable performance in demanding conditions.

What Benefits Does hub p Provide in Telecommunications?

In telecommunications, hub p is utilized for cable management systems, improving the organization and maintenance of infrastructure. This application ensures that cables are protected and easily accessible for repairs or upgrades. For international buyers, especially in regions undergoing rapid technological development, sourcing compatible hub p products that can integrate seamlessly with existing systems is crucial for maximizing efficiency and reducing installation complexities.

3 Common User Pain Points for ‘hub p’ & Their Solutions

Scenario 1: Navigating Complex Sizing and Compatibility Issues

The Problem: B2B buyers often face challenges when selecting ‘hub p’ components due to a lack of clear specifications and compatibility information. For instance, a plumbing contractor may receive a project requiring a specific type of hub, only to discover that the fittings do not match existing infrastructure or that the dimensions are not suitable for the application. This can lead to costly delays and project overruns, frustrating both the contractor and the client.

The Solution: To mitigate sizing and compatibility issues, it is crucial for buyers to conduct thorough research and utilize detailed product specifications. Before purchasing, buyers should consult technical data sheets and installation guides available on manufacturer websites. Moreover, engaging with suppliers who offer expert consultations can provide valuable insights into the correct dimensions and types of ‘hub p’ required. Utilizing CAD software or BIM (Building Information Modeling) can also assist in visualizing how the components will fit within the existing system, ensuring a seamless installation process.

Scenario 2: Dealing with Quality Assurance and Performance Reliability

The Problem: Another significant pain point for B2B buyers is ensuring the quality and reliability of ‘hub p’ products, particularly in high-demand environments. For example, a facility manager may select a lower-cost option to cut expenses, only to experience frequent failures, leaks, or maintenance issues, leading to increased operational costs and safety concerns. This not only affects productivity but also damages the reputation of the company.

The Solution: To address quality assurance concerns, buyers should prioritize sourcing products from reputable manufacturers known for their rigorous testing and quality control measures. Implementing a supplier evaluation process that includes reviewing certifications, testing results, and customer testimonials can help identify reliable vendors. Additionally, establishing long-term relationships with these suppliers can facilitate better service and access to high-quality materials. Conducting regular audits and performance reviews of the installed products can also help in early detection of potential issues, thereby maintaining operational efficiency.

Scenario 3: Streamlining Procurement Processes for Hub P Components

The Problem: Many B2B buyers struggle with inefficient procurement processes, leading to delays in acquiring necessary ‘hub p’ components. For instance, a contractor may find themselves scrambling for parts at the last minute due to poor inventory management or a lack of pre-ordering systems. This not only disrupts project timelines but can also escalate costs due to expedited shipping or last-minute purchases at inflated prices.

The Solution: To streamline procurement, implementing an integrated inventory management system can significantly improve efficiency. Buyers should consider adopting technology that allows for real-time tracking of stock levels and automated reordering processes. Establishing partnerships with suppliers for bulk purchasing agreements can also ensure that essential components are readily available, reducing the need for rush orders. Additionally, utilizing e-procurement platforms can facilitate easier access to a broader range of suppliers, enabling buyers to compare prices and terms effectively. This proactive approach not only enhances operational efficiency but also contributes to better budget management and project planning.

Strategic Material Selection Guide for hub p

When selecting materials for hub p applications, it is essential to consider various factors such as performance characteristics, environmental conditions, and compliance with international standards. Below, we analyze four common materials used in hub p systems, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of PVC in Hub P Applications?

Polyvinyl Chloride (PVC) is widely used in plumbing and drainage systems due to its excellent chemical resistance and lightweight nature. PVC can typically withstand temperatures up to 140°F (60°C) and pressure ratings of up to 150 psi, making it suitable for various applications. Its resistance to corrosion ensures longevity in systems exposed to moisture and chemicals.

Pros: PVC is cost-effective, easy to install, and requires minimal maintenance. Its smooth interior surface reduces friction, enhancing flow rates.

Cons: While PVC is durable, it can become brittle over time when exposed to UV light and extreme temperatures. Additionally, it may not be suitable for high-temperature applications.

Impact on Application: PVC is compatible with a wide range of media, including wastewater and chemicals, making it a versatile choice for hub p systems.

Considerations for International Buyers: Compliance with standards such as ASTM D1784 is crucial. Buyers should also consider local regulations regarding material use, especially in regions like Africa and South America, where specific environmental conditions may apply.

How Does Stainless Steel Perform in Hub P Systems?

Stainless steel is renowned for its strength and corrosion resistance, making it a preferred material for high-pressure applications. It can withstand temperatures up to 1,500°F (815°C) and is suitable for environments where chemical exposure is a concern.

Pros: The durability of stainless steel ensures a long service life, even in harsh conditions. Its aesthetic appeal also makes it suitable for visible installations.

Cons: The primary disadvantage is its higher cost compared to other materials like PVC. Additionally, stainless steel can be more challenging to work with due to its weight and the need for specialized tools.

Impact on Application: Stainless steel is ideal for transporting aggressive media and can handle high-pressure systems effectively.

Considerations for International Buyers: Compliance with standards such as ASTM A312 is important. Buyers in Europe and the Middle East should also consider local certifications for food-grade applications.

What Are the Advantages of Using Copper in Hub P Applications?

Copper is another material commonly used in plumbing and hub p systems due to its excellent thermal conductivity and antimicrobial properties. It can handle temperatures up to 400°F (204°C) and is resistant to corrosion in most environments.

Pros: Copper’s antimicrobial properties make it an excellent choice for potable water systems. It is also highly durable and can last for decades with proper maintenance.

Cons: The primary limitation is its cost, which is generally higher than PVC and some stainless steel options. Additionally, copper can be prone to corrosion in acidic environments.

Impact on Application: Copper is well-suited for applications involving drinking water and heating systems, providing reliability and safety.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B88 and local regulations regarding the use of copper in drinking water systems, particularly in regions with stringent health codes.

What Role Does Polypropylene Play in Hub P Systems?

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight properties. It can withstand temperatures up to 200°F (93°C) and is often used in applications involving aggressive chemicals.

Pros: Polypropylene is highly resistant to a wide range of chemicals, making it ideal for industrial applications. Its lightweight nature simplifies installation and reduces shipping costs.

Cons: The material’s lower temperature resistance compared to stainless steel and copper may limit its use in high-heat applications. Additionally, it may not be as robust as metal options.

Impact on Application: Polypropylene is particularly effective in applications involving wastewater and chemical processing, providing reliable performance.

Considerations for International Buyers: Compliance with standards such as ASTM D4101 is essential. Buyers should also consider the material’s compatibility with local environmental regulations.

Summary Table of Material Selection for Hub P

| Material | Typical Use Case for hub p | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Drainage and plumbing | Cost-effective and easy to install | Brittle over time, UV sensitivity | Low |

| Stainless Steel | High-pressure applications | High durability and corrosion resistance | Higher cost and weight | High |

| Copper | Potable water systems | Antimicrobial properties | Higher cost, prone to corrosion | Med |

| Polypropylene | Chemical processing | Excellent chemical resistance | Lower temperature resistance | Low |

This analysis provides a comprehensive overview of material options for hub p applications, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hub p

What Are the Typical Manufacturing Processes for Hub P?

Manufacturing processes for hub p products involve several critical stages that ensure quality and efficiency. The main stages include material preparation, forming, assembly, and finishing. Each of these stages plays a pivotal role in the final quality of the product.

How Is Material Prepared for Hub P Manufacturing?

Material preparation is the initial step in the manufacturing process. For hub p, materials like PVC, metal, or composite substances are often utilized. This stage involves sourcing high-quality raw materials that meet international standards and specifications. Suppliers must ensure that the materials are free from defects and suitable for the intended application.

Typically, the materials undergo inspections to confirm their chemical composition, mechanical properties, and compliance with industry standards. This may involve reviewing material safety data sheets (MSDS) and certification documents from suppliers. Additionally, proper storage conditions are maintained to prevent contamination or degradation of the materials before processing.

What Techniques Are Used in the Forming Stage of Hub P Production?

The forming stage is where raw materials are transformed into specific shapes required for hub p products. This can include processes like extrusion, injection molding, or stamping.

-

Extrusion: This technique is commonly used for creating continuous shapes, such as pipes or profiles. The raw material is heated until it becomes pliable and is then forced through a die to achieve the desired shape.

-

Injection Molding: For more complex shapes, injection molding is used. In this process, heated material is injected into a mold, where it cools and solidifies into the final product.

-

Stamping: Metal components may be produced through stamping, where sheets of metal are cut and shaped using high-pressure presses.

Each of these techniques requires skilled operators and precise machinery to ensure accuracy and consistency in the final products.

How Are Hub P Products Assembled?

After forming, the next stage is assembly. This involves joining various components to create the final hub p product. Techniques for assembly can include welding, adhesive bonding, or mechanical fastening, depending on the materials and design specifications.

Quality control during assembly is critical. Teams often use jigs and fixtures to ensure that components are aligned correctly and that tolerances are maintained. Automated assembly lines may also be employed to enhance efficiency and reduce human error.

What Finishing Processes Are Involved in Hub P Manufacturing?

Finishing is the final stage in the manufacturing process, where products are treated to improve appearance, durability, and performance. This may include processes such as surface treatment, painting, or coating.

Surface treatments like anodizing or galvanizing can protect metal parts from corrosion, while coatings may enhance aesthetic appeal or provide additional functionality (e.g., UV protection). Quality checks during this stage are vital to ensure that the finished products meet the required specifications and standards.

What Quality Assurance Measures Are Essential for Hub P?

Quality assurance (QA) is integral to the manufacturing of hub p products. Implementing robust QA measures helps ensure that products meet international standards and customer expectations.

Which International Standards Are Relevant for Hub P Quality Assurance?

International standards such as ISO 9001 play a significant role in guiding quality management systems for manufacturers. Compliance with ISO 9001 ensures that organizations consistently provide products that meet customer and regulatory requirements.

Industry-specific standards, such as CE marking for products sold in Europe or API standards for oil and gas applications, may also apply. These standards dictate specific performance and safety criteria that products must meet to gain certification.

What Are the Key Quality Control Checkpoints in Hub P Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors the manufacturing process to identify any deviations or defects as they occur.

- Final Quality Control (FQC): Conducts comprehensive testing and inspection of finished products before they are dispatched.

Common testing methods may include dimensional checks, pressure testing, and material property assessments. These measures help identify and rectify any issues before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure reliable product sourcing.

What Steps Should Buyers Take to Verify Supplier Quality Assurance?

-

Conduct Audits: Regular supplier audits can provide insights into the manufacturer’s processes and adherence to quality standards. Audits may include reviewing documentation, interviewing staff, and observing manufacturing practices.

-

Request Quality Reports: Buyers should ask for documented evidence of quality control measures, including inspection reports and certification documents. This transparency helps in assessing the supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide unbiased evaluations of manufacturing processes and final products. This can be especially useful for international transactions where buyers may not have direct oversight.

What Nuances Should International Buyers Consider in Quality Control?

International buyers must navigate various regulatory and cultural nuances when assessing quality control. Understanding the specific standards applicable in their regions can help buyers better evaluate suppliers. For instance, while CE marking is essential in Europe, different certifications might be required in Africa or South America.

Additionally, language barriers and differing business practices may affect communication regarding quality expectations. Establishing clear communication channels and expectations from the outset can mitigate potential misunderstandings.

Conclusion

The manufacturing processes and quality assurance measures for hub p products are essential components of ensuring product reliability and customer satisfaction. By understanding these processes and implementing rigorous quality checks, B2B buyers can make informed decisions, ultimately leading to successful business partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hub p’

Introduction

This practical sourcing guide provides a systematic checklist for B2B buyers interested in procuring ‘hub p’ products. Whether you’re looking for plumbing solutions, components for HVAC systems, or other industrial applications, this guide will help you navigate the procurement process effectively. By following these steps, you can ensure that you make informed decisions that align with your technical and operational requirements.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in sourcing ‘hub p’ products. This includes understanding the dimensions, materials, and performance standards that your application requires. Precise specifications will help you communicate effectively with suppliers and avoid costly mistakes during installation or operation.

- Consider factors such as pressure ratings, temperature tolerances, and compatibility with existing systems.

- Document any industry standards or certifications that are mandatory for your project.

Step 2: Research Potential Suppliers

A thorough market analysis is essential to identify potential suppliers that meet your specifications. Focus on suppliers who specialize in ‘hub p’ products and have a strong reputation in the industry. Utilize online databases, industry forums, and trade shows to gather information.

- Look for suppliers that have experience in your specific region, as local expertise can facilitate smoother logistics.

- Check online reviews and testimonials to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with industry standards. This step is crucial to ensure that the products you procure meet safety and quality benchmarks.

- Request copies of certifications such as ISO, CE, or other relevant compliance documents.

- Ensure that the supplier has a robust quality management system in place.

Step 4: Request Samples and Prototypes

Obtaining samples or prototypes of ‘hub p’ products can provide valuable insights into their quality and compatibility with your requirements. This hands-on evaluation can help you make more informed decisions before placing larger orders.

- Pay attention to the material quality, finish, and any unique features that may affect performance.

- Use this opportunity to test the product in real-world applications to assess its functionality.

Step 5: Negotiate Pricing and Terms

Once you’ve shortlisted suppliers, it’s time to negotiate pricing and contractual terms. Effective negotiation can lead to cost savings and favorable conditions that benefit your organization.

- Be clear about your budget constraints and look for volume discounts or long-term partnership opportunities.

- Discuss payment terms, delivery timelines, and warranties to ensure they align with your operational needs.

Step 6: Confirm Logistics and Delivery Options

Understanding the logistics involved in the delivery of ‘hub p’ products is essential for timely project execution. Confirm shipping methods, lead times, and any potential customs issues if sourcing internationally.

- Ensure that the supplier can meet your delivery timelines and has a reliable logistics partner.

- Discuss the possibility of drop shipping or direct deliveries to reduce handling times.

Step 7: Establish a Feedback Loop

After procurement, establish a feedback loop to assess the performance of the supplier and the product. This step is vital for ongoing supplier relationships and for improving future sourcing strategies.

- Collect feedback from your team regarding the product’s performance and any issues encountered.

- Use this information to refine your sourcing criteria and to make adjustments in future procurement efforts.

By following these steps, B2B buyers can streamline their sourcing process for ‘hub p’ products and ensure they select the best suppliers for their needs.

Comprehensive Cost and Pricing Analysis for hub p Sourcing

What Are the Key Cost Components in Hub P Sourcing?

When analyzing the cost structure for sourcing hub P, several components come into play. Materials represent a significant portion of the overall expenses, with the type of material impacting both price and performance. Common materials include PVC and other durable plastics, which must meet certain industry standards.

Labor costs account for the workforce needed to manufacture hub P products. This includes not only direct labor but also the costs associated with skilled technicians, especially if customization is required. Manufacturing overhead, which includes utilities, equipment depreciation, and facility costs, also contributes to the total cost.

Moreover, tooling expenses for molds and dies can be substantial, particularly for custom designs. Ensuring quality control (QC) throughout the production process is essential and adds another layer of cost. Finally, logistics costs such as transportation, warehousing, and insurance are critical, especially for international shipments. Each of these components must be considered to get an accurate picture of sourcing costs.

How Do Price Influencers Affect Hub P Pricing?

Several key factors influence the pricing of hub P products. Volume and minimum order quantities (MOQ) play a crucial role; larger orders often lead to price reductions due to economies of scale. Furthermore, specifications and customization can significantly impact pricing. Customized solutions typically require more resources and thus are priced higher than standard offerings.

The quality and certifications of materials also affect pricing. Suppliers offering certified products may charge a premium, but this can translate into long-term savings for buyers through reduced failure rates and lower maintenance costs. Additionally, supplier factors such as reputation, reliability, and geographical location can influence pricing dynamics.

Finally, understanding Incoterms is vital for international buyers. These terms dictate who is responsible for shipping costs, insurance, and customs clearance, which can significantly affect the total landed cost of products.

What Negotiation Tips Can Help International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, negotiation is key to achieving favorable pricing. Start by conducting thorough market research to understand prevailing prices and identify potential suppliers. This knowledge will empower you during negotiations.

Focusing on total cost of ownership (TCO) rather than just the initial purchase price can lead to better long-term value. TCO considers all costs associated with a product over its lifecycle, including maintenance, operational efficiency, and disposal costs.

Be prepared to discuss pricing nuances, such as payment terms and delivery schedules. Offering to pay upfront or negotiating longer payment terms can sometimes yield discounts. Additionally, building a relationship with suppliers can lead to better pricing and service, as trust and reliability often foster more favorable business arrangements.

What Should International Buyers Know About Pricing Nuances?

International buyers should be aware of specific pricing nuances that can affect their sourcing strategies. Currency fluctuations can impact costs, so consider negotiating prices in your local currency to mitigate risks.

Customs duties and tariffs must also be factored into the pricing equation, as these can vary widely based on the country of origin and destination. Understanding local regulations can help avoid unexpected costs that might arise during importation.

Lastly, always ask for indicative prices and be aware that these can fluctuate based on market conditions. Keeping an open line of communication with suppliers can help you stay informed about any changes in pricing or availability.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing influencers for hub P sourcing is essential for international B2B buyers. By strategically addressing the various cost components, leveraging negotiation tactics, and staying informed about pricing nuances, buyers can optimize their purchasing decisions and enhance their overall procurement strategy.

Alternatives Analysis: Comparing hub p With Other Solutions

Exploring Alternatives to Hub P: A Comprehensive Comparison

In the dynamic landscape of B2B solutions, understanding alternatives to existing products or methods is crucial for informed decision-making. This section focuses on comparing ‘Hub P’ against other viable solutions, highlighting key aspects that can guide international buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Hub P | Alternative 1: Solution X | Alternative 2: Solution Y |

|---|---|---|---|

| Performance | High efficiency in data routing | Moderate efficiency; suitable for smaller operations | High scalability, but may be overkill for small projects |

| Cost | Competitive pricing | Higher initial investment | Subscription model may increase costs over time |

| Ease of Implementation | User-friendly setup | Requires extensive training | Straightforward integration, but initial setup can be complex |

| Maintenance | Low maintenance needs | Moderate maintenance required | High maintenance; regular updates necessary |

| Best Use Case | Ideal for medium to large businesses | Best for startups or small businesses | Suitable for large-scale operations with complex needs |

In-Depth Analysis of Alternatives

Alternative 1: Solution X

Solution X offers moderate efficiency and is well-suited for smaller operations. Its competitive pricing makes it attractive for startups, but the higher initial investment can be a barrier for some. Implementation requires extensive training, which may prolong the onboarding process. While it has moderate maintenance needs, businesses must allocate resources for regular updates and troubleshooting. This solution is best for companies looking for a cost-effective option without the need for high performance.

Alternative 2: Solution Y

Solution Y stands out for its scalability, making it an excellent choice for large-scale operations. However, it may be overkill for smaller projects, leading to unnecessary complexity. While its straightforward integration is appealing, the initial setup can be intricate, requiring specialized knowledge. The subscription model can lead to escalating costs over time, especially for businesses with fluctuating demands. Maintenance is high, as regular updates are essential to keep the system running optimally. This solution is ideal for enterprises with complex requirements that can justify the investment.

Conclusion: Making the Right Choice for Your Business Needs

When considering alternatives to Hub P, B2B buyers should evaluate their specific needs, including operational scale, budget constraints, and technical expertise. A thorough understanding of each solution’s strengths and weaknesses will empower decision-makers to select the most appropriate option. Whether prioritizing cost, ease of implementation, or long-term scalability, aligning the chosen solution with business goals is essential for maximizing operational efficiency and achieving sustainable growth.

Essential Technical Properties and Trade Terminology for hub p

What Are the Key Technical Properties of Hub P?

Understanding the technical properties of hub P is essential for B2B buyers, especially those involved in plumbing and construction industries. Here are some critical specifications:

-

Material Grade

Hub P components are typically made from materials like PVC (Polyvinyl Chloride) or ABS (Acrylonitrile Butadiene Styrene). The material grade affects durability, resistance to chemicals, and temperature tolerance. Higher-grade materials ensure longer service life and lower maintenance costs, which are crucial for commercial applications. -

Pressure Rating

The pressure rating indicates the maximum pressure the hub P can withstand without failure. This specification is vital for ensuring that the plumbing systems operate efficiently under varying pressure conditions, particularly in commercial buildings where water supply can be inconsistent. -

Size and Diameter

Hub P fittings come in various sizes, typically ranging from 1 inch to 6 inches in diameter. Selecting the appropriate size is critical to ensure compatibility with existing plumbing systems and to prevent leaks or blockages, which can lead to costly repairs. -

Connection Type

The connection type—be it hub x hub, hub x slip, or slip x slip—determines how the hub P integrates with other plumbing components. Understanding these connections helps in making informed decisions about installation and future upgrades. -

Tolerance Levels

Tolerance refers to the allowable variation in dimensions. Precise tolerances are essential to ensure proper fit and function, preventing leaks and ensuring system integrity. Tighter tolerances often indicate higher quality and reliability. -

Temperature Resistance

Different materials and fittings can handle varying temperature ranges. For instance, PVC is typically rated for temperatures up to 140°F (60°C), while ABS can handle slightly higher temperatures. This property is essential for applications involving hot water or steam.

What Are Common Trade Terms Related to Hub P?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several key terms related to hub P:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. Understanding whether a supplier is an OEM can influence purchasing decisions, especially regarding quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their purchases efficiently. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process is vital for comparing costs and negotiating favorable terms, particularly in bulk purchasing situations. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for determining who bears the risk and costs associated with shipping and delivery. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is crucial for planning projects and managing timelines, especially when dealing with international suppliers. -

Warranty Period

The warranty period specifies the duration for which a product is covered against defects or failures. Knowing the warranty terms helps buyers assess the reliability and risk associated with their purchases.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their plumbing and construction projects.

Navigating Market Dynamics and Sourcing Trends in the hub p Sector

What Are the Key Market Dynamics and Sourcing Trends in the Hub P Sector?

In the rapidly evolving hub p sector, international B2B buyers face a complex landscape shaped by various global drivers. Increased demand for efficient supply chain solutions, driven by the growth of e-commerce and the need for faster delivery times, is a significant trend. Moreover, advancements in technology, such as automation and data analytics, are transforming logistics operations, allowing companies to optimize their routing and inventory management. Buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for suppliers who can provide real-time tracking and robust data insights, enabling them to make informed decisions and enhance operational efficiency.

Emerging trends also include the integration of artificial intelligence and machine learning in sourcing strategies. These technologies offer predictive analytics that can help businesses anticipate market changes and adjust their sourcing strategies accordingly. In addition, the rise of digital platforms is facilitating better communication and collaboration between suppliers and buyers, streamlining the procurement process. For instance, platforms that support vendor management and performance tracking are becoming vital tools for B2B buyers seeking to maintain competitive advantages.

How Is Sustainability Impacting Sourcing Decisions in the Hub P Sector?

Sustainability has emerged as a crucial factor influencing sourcing decisions in the hub p sector. The environmental impact of sourcing practices is under increasing scrutiny, prompting businesses to reassess their supply chains. Ethical sourcing, which prioritizes sustainability and social responsibility, is becoming a prerequisite for many buyers. This shift is particularly evident among companies that operate in regions where environmental regulations are stringent and consumer preferences lean towards sustainable products.

The importance of ethical supply chains cannot be overstated, as they not only mitigate risks associated with environmental degradation but also enhance brand reputation. Buyers are increasingly seeking suppliers who can provide ‘green’ certifications and sustainable materials, demonstrating compliance with environmental standards. Certifications such as ISO 14001 for environmental management systems or LEED for sustainable building practices are gaining traction. These certifications can significantly influence purchasing decisions, as they assure buyers of the supplier’s commitment to sustainability.

What Is the Evolution of the Hub P Sector in the B2B Context?

The hub p sector has undergone significant evolution over the years, driven by technological advancements and changing market demands. Initially focused on traditional logistics and transportation methods, the sector has shifted towards more integrated and technology-driven solutions. The emergence of digital platforms and advanced analytics has transformed how companies approach sourcing and supply chain management.

As globalization increased, so did the complexity of supply chains, prompting businesses to adopt more sophisticated routing and distribution strategies. The introduction of eco-friendly practices has further reshaped the sector, as companies strive to meet both regulatory requirements and consumer expectations for sustainability. This evolution highlights the need for international B2B buyers to stay informed about market dynamics and adapt their sourcing strategies accordingly to remain competitive in a fast-paced environment.

By understanding these trends and their implications, buyers can make informed decisions that align with both their operational goals and sustainability commitments, ultimately leading to a more resilient and responsible sourcing strategy.

Frequently Asked Questions (FAQs) for B2B Buyers of hub p

-

How do I solve issues related to sourcing hub p?

When facing challenges in sourcing hub p, start by identifying your specific needs, such as material specifications, dimensions, and application requirements. Research potential suppliers through trade platforms, industry directories, and trade shows. Establish direct communication with shortlisted vendors to discuss your requirements and assess their capabilities. It’s also beneficial to request samples and verify their certifications to ensure compliance with international standards. Finally, leverage local representatives or agents familiar with the market to navigate logistics and regulations. -

What is the best hub p for commercial plumbing applications?

The best hub p for commercial plumbing applications typically features durable materials like PVC or CPVC, designed for heavy-duty use. Look for products that comply with local plumbing codes and have reliable water seal capabilities. Additionally, consider options with union joints for easier installation and maintenance. It’s essential to assess the specific requirements of your project, such as pipe diameter and system pressure, to select the most suitable hub p for your needs. -

How can I vet suppliers for hub p products?

To vet suppliers for hub p products, conduct thorough research to verify their business credentials and reputation. Request references from previous clients and check online reviews or ratings. Evaluate their production capabilities, quality control processes, and compliance with industry standards. It’s advisable to visit their manufacturing facilities if possible. Additionally, inquire about their experience in international trade, particularly with buyers from your region, to ensure they understand the specific requirements of your market. -

What are typical minimum order quantities (MOQ) for hub p products?

Minimum order quantities (MOQ) for hub p products can vary significantly based on the supplier and product type. Typically, manufacturers may set MOQs ranging from 100 to 500 units for standard items. However, for customized solutions or specialized products, MOQs might be higher. It’s essential to discuss MOQs upfront with potential suppliers to understand their policies and explore options for smaller trial orders, especially if you are entering a new market or testing a new product line. -

What payment terms should I expect when sourcing hub p internationally?

Payment terms for international sourcing of hub p products often include options such as advance payment, letters of credit, or net 30/60 days after shipment. Suppliers may require a deposit to initiate production, especially for large orders. Always clarify payment terms during negotiations and ensure they align with your cash flow capabilities. It’s also prudent to consider using secure payment methods that offer buyer protection, such as escrow services, to mitigate risks in international transactions. -

How do I ensure quality assurance for hub p products?

To ensure quality assurance for hub p products, establish clear specifications and standards before placing an order. Request samples and conduct quality checks upon receipt. Collaborate with suppliers who offer certifications or third-party testing to validate product quality. Regularly communicate with your suppliers regarding production processes and quality control measures. Additionally, consider implementing a quality audit system to monitor supplier performance over time, ensuring consistency and compliance with your standards. -

What logistics considerations should I keep in mind when importing hub p?

When importing hub p, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose a reliable freight forwarder experienced in handling similar products and understand the specific import duties and tariffs that may apply. Ensure that your supplier provides the necessary documentation for customs clearance, including invoices and certificates of origin. It’s also wise to plan for potential delays and have contingency strategies in place to manage supply chain disruptions effectively. -

Are there customization options available for hub p products?

Many suppliers offer customization options for hub p products, including variations in size, material, and design to meet specific project requirements. When discussing customization, provide detailed specifications and any relevant standards your project must comply with. Be aware that customized products may come with higher MOQs and longer lead times. Always confirm the supplier’s capability to deliver customized solutions and request prototypes or samples to evaluate before full-scale production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Hub P Manufacturers & Suppliers List

1. THE HUB COMMUNITY HEALTHCARE P FINANCE LIMITED – Company Information

Domain: find-and-update.company-information.service.gov.uk

Introduction: This company, THE HUB COMMUNITY HEALTHCARE P FINANCE LIMITED – Company Information, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Facebook – Quality Control CEO

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Quality Control CEO P owns 100% of Lil Baby’s masters.

Strategic Sourcing Conclusion and Outlook for hub p

How Can Strategic Sourcing Enhance Your Business’s Efficiency?

In today’s competitive landscape, strategic sourcing for hub p offers B2B buyers a pathway to optimize procurement processes, reduce costs, and enhance supply chain resilience. By leveraging data-driven insights and fostering relationships with reliable suppliers, businesses can ensure they secure high-quality products while adapting to fluctuating market demands.

The strategic sourcing approach not only streamlines operations but also aligns purchasing strategies with broader business objectives, promoting sustainability and innovation. This is particularly critical for international buyers from regions like Africa, South America, the Middle East, and Europe, where diverse markets present unique challenges and opportunities.

What Should International Buyers Consider Moving Forward?

As you navigate the complexities of sourcing hub p products, consider investing in robust supplier partnerships that prioritize transparency and communication. Embrace technological advancements that facilitate real-time data sharing and analytics, enabling informed decision-making.

Looking ahead, the demand for strategic sourcing will only grow. Engage proactively with suppliers and industry networks to stay ahead of trends and challenges. By prioritizing strategic sourcing, your organization can not only enhance operational efficiency but also position itself for long-term success in a dynamic global marketplace. Start today—your future procurement strategies depend on it.