Choosing Your Heater Wheels: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for heater wheels

In the competitive landscape of outdoor heating solutions, sourcing high-quality heater wheels can be a daunting task for international B2B buyers. As businesses expand their operations across diverse markets in Africa, South America, the Middle East, and Europe, the challenge of finding durable and reliable heater wheels that meet specific operational needs becomes paramount. This guide is designed to navigate the complexities of the heater wheels market, providing you with critical insights into various types, applications, and essential features that can enhance mobility and functionality.

Throughout this comprehensive resource, we will explore the different styles of heater wheels available, from heavy-duty plastic options to specialized locking casters that ensure stability during use. We will also delve into supplier vetting processes, helping you identify reputable manufacturers and distributors who can deliver consistent quality and service. Additionally, we will discuss cost considerations, allowing you to make informed purchasing decisions that align with your budget and operational requirements.

By equipping you with the knowledge necessary to evaluate and select the best heater wheels for your business, this guide empowers you to streamline your procurement process. Whether you are operating in bustling urban centers or remote areas, our insights will help you enhance your outdoor heating solutions, ensuring a comfortable experience for your customers while optimizing your investment.

Understanding heater wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Wheels | Lightweight, hollow design, available in various colors | Outdoor heaters, patio heaters | Pros: Cost-effective, easy to install. Cons: Less durable than metal options. |

| Locking Caster Wheels | Equipped with a locking mechanism to prevent movement | Commercial heaters, industrial applications | Pros: Enhanced stability, prevents accidental movement. Cons: Can be more expensive than non-locking options. |

| Heavy-Duty Wheels | Made from durable materials, larger diameter | Heavy-duty outdoor heaters, construction sites | Pros: High load capacity, ideal for rough terrain. Cons: Heavier, may require more effort to maneuver. |

| All-Terrain Wheels | Designed for rugged surfaces, often with tread patterns | Event rentals, outdoor festivals | Pros: Excellent grip, suitable for various terrains. Cons: Higher cost, may not fit all heater types. |

| Universal Replacement Wheels | Compatible with multiple heater models | General replacement for various heater brands | Pros: Versatile, reduces inventory complexity. Cons: Compatibility issues may arise with specific brands. |

What Are Plastic Wheels and Their B2B Suitability?

Plastic wheels are lightweight and often hollow, making them a cost-effective choice for outdoor and patio heaters. Typically available in black or white, they offer decent maneuverability for lighter units. However, while they are easy to install and replace, their durability may be a concern for B2B buyers dealing with heavy usage or challenging environments. Businesses should consider their specific needs regarding mobility and longevity when opting for plastic wheels.

How Do Locking Caster Wheels Enhance Stability?

Locking caster wheels feature a mechanism that allows users to secure the heater in place, preventing unwanted movement. This is particularly beneficial in commercial settings where stability is crucial, such as restaurants or event venues. While they provide enhanced safety and stability, buyers should weigh the additional cost against the operational needs of their business. Locking casters are ideal for environments where heaters are frequently moved but must remain stationary during use.

What Are the Advantages of Heavy-Duty Wheels?

Heavy-duty wheels are crafted from robust materials and typically feature a larger diameter to accommodate heavier loads. They are perfect for outdoor heaters used in construction sites or other rugged applications. The increased load capacity and durability make them a preferred choice for B2B buyers in demanding environments. However, the added weight may require more effort to maneuver, which is an important consideration for businesses focused on efficiency.

Why Choose All-Terrain Wheels for Outdoor Events?

All-terrain wheels are specifically designed to navigate rugged surfaces, making them ideal for outdoor events and festivals. Their tread patterns provide excellent grip, ensuring that heaters remain stable on uneven ground. While these wheels can be more costly, their performance in challenging conditions can justify the investment for businesses in the event rental industry. Buyers should assess the terrain where the heaters will be used to determine if all-terrain wheels are necessary.

What Makes Universal Replacement Wheels a Smart Choice?

Universal replacement wheels are compatible with a wide range of heater models, making them a versatile option for businesses that manage multiple brands. This compatibility simplifies inventory management and reduces the need for specialized parts. However, buyers should ensure that the universal wheels meet their specific requirements, as compatibility issues can arise. For businesses looking to streamline their operations, these wheels can be a practical solution.

Key Industrial Applications of heater wheels

| Industry/Sector | Specific Application of Heater Wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Mobility for outdoor patio heaters in restaurants | Enhances guest comfort by providing flexible heating options | Durability to withstand outdoor conditions; easy installation |

| Construction | Portable heating solutions for construction sites | Improves worker productivity by maintaining optimal temperatures | Compatibility with various heater types; safety certifications |

| Event Management | Transportable heaters for outdoor events and exhibitions | Ensures comfort for attendees and staff during events | Lightweight design; ease of maneuverability |

| Agriculture | Heating solutions for greenhouses and livestock facilities | Supports growth and welfare in cold climates | Resistance to moisture; reliability under variable conditions |

| Retail | Mobile heating for outdoor retail spaces | Attracts customers and extends shopping seasons | Cost-effectiveness; aesthetic compatibility with store design |

How Are Heater Wheels Utilized in the Hospitality Sector?

In the hospitality industry, heater wheels are essential for enhancing the mobility of outdoor patio heaters used in restaurants and cafes. These wheels allow staff to reposition heaters quickly, ensuring that guests remain comfortable regardless of changing weather conditions. For international buyers, particularly in regions like Saudi Arabia and Nigeria, sourcing durable, weather-resistant wheels is crucial, as they must withstand intense heat or humidity. Additionally, easy installation and compatibility with various heater models are significant factors to consider.

What Role Do Heater Wheels Play in Construction?

Heater wheels are invaluable on construction sites, where portable heating solutions are often required to keep workers warm during colder months. By enabling easy transport of heaters around large job sites, these wheels contribute to improved worker productivity and safety. Buyers in South America and Europe should prioritize wheels that can handle rough terrain and heavy usage while ensuring compliance with safety regulations. The ability to lock in place is also a key feature for stability.

How Are Heater Wheels Important for Event Management?

In event management, heater wheels facilitate the use of portable heaters at outdoor events, exhibitions, and festivals. They allow quick setup and relocation of heating units to adapt to crowd movement or weather changes, ensuring a comfortable environment for attendees. For buyers, particularly in the Middle East, selecting lightweight yet robust wheels that can easily maneuver across various surfaces is critical. The aesthetic appeal of the wheels can also influence their choice, as they need to blend with event decor.

Why Are Heater Wheels Valuable in Agriculture?

In agriculture, heater wheels are used to transport heating solutions for greenhouses or livestock facilities, particularly in colder climates. These wheels allow for easy mobility, ensuring that heating sources can be adjusted as needed to maintain optimal growing conditions or animal welfare. Buyers from Africa and Europe must consider moisture resistance and the durability of materials, as these factors significantly impact the wheels’ longevity in harsh agricultural environments.

How Do Heater Wheels Benefit Retail Spaces?

Retail environments, especially those with outdoor sections, benefit from heater wheels by providing mobile heating solutions that attract customers during colder months. These heaters can be easily moved to optimize customer comfort, extending the shopping season. For B2B buyers, cost-effectiveness and aesthetic compatibility with the store’s design are essential sourcing considerations. Additionally, durability to withstand frequent movement and potential weather exposure is vital for long-term use.

Illustrative image related to heater wheels

3 Common User Pain Points for ‘heater wheels’ & Their Solutions

Scenario 1: Navigating Mobility Restrictions in Large Spaces

The Problem: In expansive commercial settings such as outdoor event venues or large patios, B2B buyers face challenges in maneuvering heavy patio heaters equipped with inadequate wheels. This can lead to operational inefficiencies, as staff struggle to reposition heaters for optimal heating coverage. Additionally, poorly designed wheels may not provide the necessary durability for frequent movement, resulting in damage to the heaters or surrounding areas.

The Solution: To overcome these mobility issues, B2B buyers should invest in high-quality, heavy-duty caster wheels specifically designed for patio heaters. Look for wheels with larger diameters and robust materials that can withstand the weight and frequent movement without compromising stability. When sourcing these wheels, consider suppliers who offer customizable options to fit the specific models of heaters in use. Furthermore, incorporating locking mechanisms on the wheels can enhance safety and stability when the heaters are in position, preventing them from rolling unintentionally during operation.

Scenario 2: Ensuring Compatibility Across Various Heater Models

The Problem: A common pain point arises when B2B buyers attempt to replace or upgrade heater wheels but struggle with compatibility issues. Many heaters come with unique specifications, and mismatched wheels can lead to improper fitting, rendering the heaters unusable. This not only wastes time but also increases costs due to the need for returns or additional purchases.

The Solution: To mitigate compatibility concerns, buyers should conduct thorough research before purchasing replacement wheels. This includes checking the manufacturer’s specifications for both the heater and the wheels. Engaging with suppliers who provide detailed product descriptions, including size, weight capacity, and compatibility information, can save time and resources. Additionally, utilizing a systematic approach, such as maintaining a database of existing heater models and their corresponding wheel specifications, can facilitate future purchases and ensure that the correct components are always sourced.

Scenario 3: Addressing Safety and Stability Concerns

The Problem: B2B buyers often face safety issues when using patio heaters, particularly in areas with high foot traffic. If the wheels are unstable or the heaters are not securely positioned, there is a heightened risk of accidents, which can lead to injuries or property damage. This concern is particularly significant in outdoor settings where uneven surfaces can exacerbate instability.

The Solution: To enhance safety, buyers should prioritize the selection of wheels designed for uneven terrain and those equipped with non-slip features. Heavy-duty wheels with wider bases provide better weight distribution, reducing the likelihood of tipping. Additionally, incorporating features such as anti-tilt mechanisms or adjustable height options can further improve stability. Buyers should also consider implementing regular maintenance checks on the wheels and heaters to ensure they remain in good working condition. This proactive approach not only enhances safety but also extends the lifespan of the equipment, ultimately providing a better return on investment.

By addressing these common pain points with targeted solutions, B2B buyers can ensure that their heater wheels contribute positively to their operations, enhancing both functionality and safety in their outdoor environments.

Strategic Material Selection Guide for heater wheels

When selecting materials for heater wheels, several factors come into play, including performance characteristics, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of heater wheels, along with their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Plastic Wheels for Heater Applications?

Plastic (Polypropylene or Polyethylene)

Plastic wheels, particularly those made from polypropylene or polyethylene, are widely used due to their lightweight nature and resistance to moisture. These materials typically have a temperature rating of up to 80°C (176°F) and are resistant to corrosion from various chemicals.

Pros & Cons:

– Pros: They are cost-effective, lightweight, and provide good maneuverability. Additionally, they are resistant to rust and corrosion, making them suitable for outdoor environments.

– Cons: However, plastic wheels may not withstand high temperatures or heavy loads as effectively as metal options, leading to potential deformation over time.

Impact on Application: Plastic wheels are ideal for portable heaters used in residential settings, where mobility is essential. However, they may not be suitable for industrial heaters that require heavy-duty performance.

Illustrative image related to heater wheels

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local regulations regarding material safety and environmental impact, as well as consider the availability of replacement parts.

How Do Metal Wheels Compare for Heater Mobility?

Metal (Steel or Aluminum)

Metal wheels, particularly those made from steel or aluminum, offer superior strength and durability. Steel wheels can handle higher weight loads and have a temperature tolerance up to 200°C (392°F). Aluminum wheels are lighter but still provide good strength and corrosion resistance.

Pros & Cons:

– Pros: Metal wheels are robust, offering excellent load-bearing capabilities and resistance to wear and tear. They are suitable for both indoor and outdoor applications.

– Cons: The primary drawback is their higher cost compared to plastic options, and they may require additional coatings to prevent rust, especially in humid environments.

Impact on Application: Metal wheels are well-suited for commercial and industrial heaters that operate in demanding environments where durability is critical.

Illustrative image related to heater wheels

Considerations for International Buyers: Compliance with standards such as ASTM for metal products is crucial. Buyers should also consider the potential for corrosion in coastal areas, necessitating the use of stainless steel or aluminum alloys.

What Role Do Rubber Wheels Play in Heater Design?

Rubber

Rubber wheels are often used in applications where traction and shock absorption are important. They can withstand temperatures up to 100°C (212°F) and provide excellent grip on various surfaces.

Pros & Cons:

– Pros: Rubber wheels offer superior shock absorption and traction, making them ideal for uneven surfaces. They are also quieter during movement.

– Cons: They may wear out faster than plastic or metal wheels, particularly in abrasive environments, and can be more expensive.

Impact on Application: Rubber wheels are often found on heaters that need to be moved frequently across different terrains, such as outdoor events or construction sites.

Considerations for International Buyers: Buyers should ensure that rubber wheels meet local safety and environmental standards, especially in regions with stringent regulations regarding synthetic materials.

How Do Composite Materials Enhance Wheel Performance?

Composite Materials

Composite wheels, made from a blend of materials (such as plastic reinforced with fiberglass), offer a balance of weight, strength, and resistance to environmental factors. They typically have a temperature tolerance similar to that of plastic but with enhanced durability.

Pros & Cons:

– Pros: Composites can provide a lightweight yet strong solution, resisting both corrosion and impact damage. They are often designed for specific applications, enhancing performance.

– Cons: The manufacturing process can be complex and costly, which may lead to a higher price point.

Impact on Application: Composite wheels are suitable for specialized heaters that require unique performance characteristics, particularly in high-demand environments.

Considerations for International Buyers: Buyers should be aware of the certifications for composite materials, as they may vary significantly by region, affecting marketability and compliance.

Summary Table

| Material | Typical Use Case for heater wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Residential portable heaters | Lightweight and corrosion-resistant | Limited load capacity | Low |

| Metal | Commercial/industrial heaters | High strength and durability | Higher cost and rust potential | High |

| Rubber | Outdoor event heaters | Excellent traction and shock absorption | Faster wear in abrasive environments | Medium |

| Composite | Specialized high-performance heaters | Balance of weight and strength | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for heater wheels, helping B2B buyers make informed decisions based on their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for heater wheels

What Are the Key Stages in the Manufacturing Process of Heater Wheels?

The manufacturing process for heater wheels involves several critical stages that ensure durability, functionality, and safety. Understanding these stages can help B2B buyers make informed decisions regarding suppliers.

Material Preparation: What Materials Are Used for Heater Wheels?

Typically, heater wheels are constructed from heavy-duty plastics or metals. The choice of material significantly impacts the wheel’s strength, weight capacity, and resistance to outdoor elements. For example, high-density polyethylene (HDPE) is commonly used for its durability and resistance to UV rays, while metals like steel or aluminum provide added strength.

Before manufacturing, raw materials undergo thorough inspection to ensure they meet specified standards. This includes checking for impurities, assessing the material’s physical properties, and verifying compliance with international standards like ISO 9001.

Illustrative image related to heater wheels

Forming: How Are Heater Wheels Shaped and Molded?

Once materials are prepared, the forming process begins. For plastic wheels, injection molding is a prevalent technique, where heated plastic is injected into a mold to create the desired shape. This method allows for precise dimensions and uniformity across batches.

For metal wheels, processes such as stamping or die-casting may be employed. These techniques involve shaping the metal under high pressure to achieve the required specifications. Throughout this stage, manufacturers monitor temperature, pressure, and material flow to maintain quality.

Assembly: What Comes Next in the Wheel Manufacturing Process?

After forming, the wheels undergo assembly. This stage may include attaching components like bearings, axles, or locking mechanisms. Quality assurance checks are integral at this point to ensure that all parts fit correctly and function as intended.

Illustrative image related to heater wheels

Assembly may also involve integrating safety features, such as locking casters, which provide stability during use. Suppliers should have clear protocols for assembly to minimize errors and ensure each product meets safety standards.

Finishing: How Are Heater Wheels Completed?

The finishing stage enhances both the aesthetic and functional aspects of heater wheels. This may involve surface treatments such as painting, coating, or polishing to improve corrosion resistance and visual appeal. For plastic wheels, UV stabilizers may be added to prevent fading and degradation.

Quality control during finishing ensures that all products meet the visual and performance standards expected by customers. This stage often includes visual inspections and tests for durability.

Illustrative image related to heater wheels

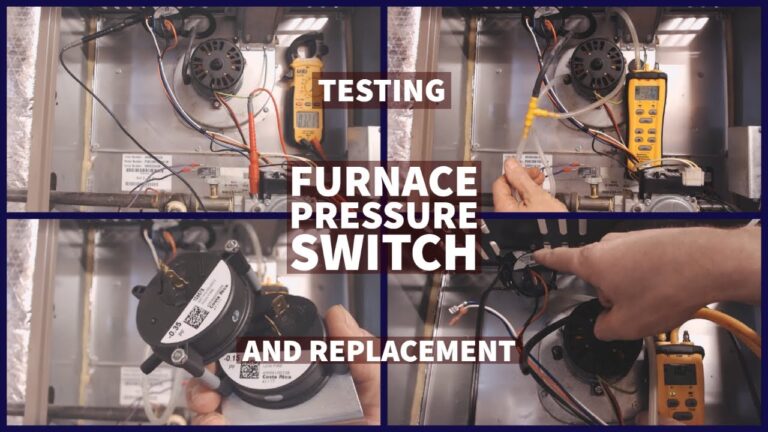

What Quality Assurance Measures Are Essential for Heater Wheels?

Quality assurance (QA) is vital to ensure that heater wheels are safe and reliable. B2B buyers must be aware of the standards and practices that govern this process.

Which International Standards Should B2B Buyers Look For?

B2B buyers should prioritize suppliers who comply with international standards like ISO 9001, which outlines criteria for a quality management system. Additionally, compliance with industry-specific certifications such as CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for products related to gas heaters is crucial.

These certifications demonstrate that the manufacturer has implemented rigorous quality controls and has a commitment to continuous improvement.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including checks on forming, assembly, and finishing stages, to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of finished products, ensuring they meet all specifications and are free from defects.

Buyers should inquire about the specific QC checkpoints their suppliers implement, as this can directly impact the reliability of the products.

Illustrative image related to heater wheels

What Common Testing Methods Are Used for Heater Wheels?

Testing methods for heater wheels can include:

- Load Testing: Assessing the weight capacity and durability under stress.

- Environmental Testing: Evaluating how materials perform under varying temperature and humidity conditions.

- Safety Testing: Ensuring that any locking mechanisms function correctly and that there are no sharp edges or hazardous features.

B2B buyers should request documentation on testing procedures and results, as this information provides insights into the product’s reliability.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a supplier adheres to quality standards, B2B buyers can take several steps:

What Actions Can Buyers Take to Ensure Supplier Compliance?

-

Conduct Audits: Regular audits of the manufacturing facility can provide firsthand insight into the production processes and quality control measures.

-

Request Quality Reports: Buyers should ask for detailed quality assurance reports, including results from testing and inspections.

-

Engage Third-Party Inspectors: Employing independent inspectors can offer an unbiased assessment of the supplier’s quality practices.

-

Review Certifications: Buyers should verify that the supplier holds valid certifications relevant to the product and market.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate specific regulatory requirements. Understanding the import/export laws, customs regulations, and safety standards in their respective markets is critical.

For instance, products entering the European market must comply with CE marking requirements, while those destined for the Middle East may need to meet Gulf Cooperation Council (GCC) standards.

By being proactive and thoroughly vetting potential suppliers, B2B buyers can ensure they receive high-quality heater wheels that meet their operational needs and regulatory standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heater wheels’

In today’s competitive B2B marketplace, sourcing the right heater wheels is critical for ensuring the functionality and mobility of heating equipment. This checklist serves as a practical guide for international buyers looking to procure heater wheels, particularly in regions like Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your sourcing process and ensure you acquire high-quality components that meet your operational needs.

Step 1: Define Your Technical Specifications

Before starting your search, clearly define the technical specifications of the heater wheels you require. Consider factors such as wheel diameter, load capacity, material (plastic, metal, etc.), and whether you need features like locking mechanisms. This clarity will help you communicate effectively with suppliers and ensure that the wheels you select are compatible with your heating equipment.

Illustrative image related to heater wheels

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of heater wheels. Look for manufacturers and distributors with a strong reputation in the industry, especially those experienced in your specific market region. Utilize online resources, industry directories, and trade shows to compile a list of viable candidates.

- Key Resources: Supplier directories, industry trade shows, and online marketplaces.

Step 3: Evaluate Supplier Certifications

It’s essential to verify the certifications and compliance of your potential suppliers. Check if they meet international quality standards (such as ISO 9001) and safety regulations applicable to your region. This step is crucial not only for ensuring product quality but also for mitigating risks associated with sourcing from non-compliant manufacturers.

- What to Look For: ISO certifications, safety compliance documents, and product testing reports.

Step 4: Request Samples for Testing

Before making a bulk purchase, always request samples of the heater wheels. Testing samples allows you to evaluate their performance under real-world conditions and ensure they meet your specifications. Pay attention to aspects such as durability, ease of movement, and noise levels during operation.

Step 5: Assess Pricing and Payment Terms

Gather detailed pricing information from your shortlisted suppliers. Compare not just the base price but also consider shipping costs, bulk discounts, and payment terms. Understanding these factors will help you make a cost-effective decision while ensuring that you don’t compromise on quality.

- Considerations: Total landed cost, payment methods (e.g., letters of credit, advance payments), and potential for future discounts.

Step 6: Check References and Reviews

Seek references from other businesses that have purchased heater wheels from your chosen suppliers. Customer reviews and testimonials can provide valuable insights into the reliability of the supplier, the quality of their products, and their customer service. This step can help you avoid potential pitfalls in your procurement process.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that you finalize a comprehensive purchase agreement. This agreement should detail the specifications, pricing, delivery timelines, and warranty terms. Having a clear contract helps protect both parties and ensures accountability throughout the transaction.

By following this checklist, you can effectively navigate the sourcing process for heater wheels, ensuring that you make informed decisions that align with your operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for heater wheels Sourcing

When sourcing heater wheels for patio heaters or industrial applications, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. The following analysis outlines the key components that influence costs, pricing strategies, and negotiation tips tailored for buyers from diverse regions including Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Heater Wheels Manufacturing?

Materials: The primary cost driver in heater wheel production is the choice of materials. Common options include heavy-duty plastics and metals. Plastic wheels, for example, are generally less expensive but may offer lower durability compared to metal alternatives. Buyers should weigh the cost against the required longevity and application of the wheels.

Labor: Labor costs can vary significantly based on the region of manufacture. Countries with lower labor costs may provide cheaper wheels, but this can sometimes compromise quality. It’s essential to consider the balance between labor costs and the skill level required for quality production.

Manufacturing Overhead: This includes expenses related to facility operation, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, but any inefficiencies may inflate the final product price.

Tooling: Custom tooling for specialized wheel designs adds to the initial investment. For bulk orders, suppliers often amortize these costs over the production run, making it essential to consider minimum order quantities (MOQs).

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can also raise costs. Buyers should inquire about certification standards (e.g., ISO) that suppliers adhere to, as these can influence pricing.

Logistics: Shipping and handling costs depend on the delivery location, which can significantly affect the total cost. International shipping may involve tariffs and duties that should be accounted for in the final pricing.

Margin: Suppliers typically apply a margin based on production costs, market demand, and competitive pricing. Understanding the standard margins in different regions can aid buyers in evaluating fair pricing.

How Do Pricing Influencers Affect Heater Wheels Costs?

Volume/MOQ: Bulk purchasing often leads to reduced per-unit costs. Suppliers are generally willing to negotiate better pricing for larger orders, which can substantially lower the overall expenditure.

Specifications/Customization: Unique designs or specific performance requirements can elevate costs. Buyers seeking custom wheels should be prepared for higher prices and longer lead times.

Material Quality and Certifications: High-quality materials and compliance with international safety standards can increase costs. However, investing in certified products may reduce maintenance and replacement costs in the long run.

Supplier Factors: The supplier’s reputation, location, and production capabilities play a significant role in pricing. Established suppliers with proven quality may charge a premium, whereas newer or less-known manufacturers might offer lower prices but with potential quality risks.

Incoterms: Understanding shipping terms is vital in international transactions. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the shipping costs and risks, directly impacting the final price.

What Are Effective Buyer Tips for Negotiating Heater Wheel Prices?

Negotiate Wisely: Leverage your purchasing volume to negotiate better pricing. Initiating discussions early in the procurement process can provide room for adjustments.

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, replacement, and operational costs. Higher quality wheels may have a higher upfront cost but can lead to savings in the long run.

Understand Regional Pricing Nuances: Prices can vary widely across different markets. Buyers should conduct regional market research to gauge fair pricing and identify any additional costs related to import duties or local taxes.

Establish Long-term Relationships: Building strong relationships with suppliers can lead to more favorable terms and pricing over time. Trust can facilitate better negotiation outcomes and potential discounts for future orders.

Disclaimer on Indicative Prices

Prices for heater wheels can fluctuate based on market conditions, material costs, and supplier pricing strategies. It is advisable for buyers to obtain multiple quotes and perform due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing heater wheels With Other Solutions

Introduction: Exploring Alternatives to Heater Wheels

In the realm of outdoor heating solutions, mobility plays a crucial role in usability and efficiency. While heater wheels enhance the portability of patio heaters, it is essential to consider alternative solutions that can offer similar benefits. This analysis will compare heater wheels against two viable alternatives: portable heater stands and built-in mobility features in heaters, helping B2B buyers make informed decisions tailored to their specific needs.

Comparison Table

| Comparison Aspect | Heater Wheels | Portable Heater Stands | Built-in Mobility Features |

|---|---|---|---|

| Performance | Enhances maneuverability | Fixed positioning; limited mobility | Excellent mobility; no extra parts |

| Cost | Low-cost accessory ($3 – $10) | Moderate cost ($30 – $150) | Generally included in heater price |

| Ease of Implementation | Simple installation | Requires assembly | Ready-to-use; no installation needed |

| Maintenance | Low; occasional checks needed | Moderate; checks for stability | Very low; built-in components |

| Best Use Case | Outdoor events, temporary setups | Long-term setups, stationary use | Frequent repositioning in various settings |

Detailed Breakdown of Alternatives

1. Portable Heater Stands

Portable heater stands offer a versatile solution for outdoor heating by providing a stable base for heaters. They are typically made from durable materials and can support various heater models. However, while they offer some mobility, they are often designed for stationary use, making them less suitable for dynamic outdoor events. Their moderate cost may be a consideration for budget-conscious buyers, but the assembly required can be a drawback for those looking for quick setup options.

2. Built-in Mobility Features

Many modern patio heaters come equipped with built-in mobility features, such as integrated wheels or lightweight designs that allow for easy repositioning. This option eliminates the need for additional accessories, providing a seamless user experience. The main advantage is convenience, as these heaters can be easily moved without the hassle of attaching or detaching wheels. However, the initial investment might be higher compared to standalone heater wheels, making it essential for buyers to evaluate their budget against the benefits of convenience and efficiency.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the ideal mobility solution for outdoor heaters, B2B buyers must consider various factors, including cost, ease of use, and specific use cases. Heater wheels offer a cost-effective and straightforward option for enhancing the mobility of existing heaters, making them suitable for temporary setups. In contrast, portable stands and heaters with built-in mobility features present more integrated solutions that may better serve long-term outdoor environments. By understanding the unique benefits and limitations of each option, buyers can make strategic decisions that align with their operational requirements and budgetary constraints.

Essential Technical Properties and Trade Terminology for heater wheels

What Are the Key Technical Properties of Heater Wheels in B2B Transactions?

Understanding the technical specifications of heater wheels is crucial for B2B buyers looking to optimize functionality and performance in their heating solutions. Here are some essential properties to consider:

1. Material Grade

The material used in heater wheels significantly impacts durability and mobility. Common materials include heavy-duty plastic, rubber, and metal. Plastic wheels are often lightweight and cost-effective, while metal wheels provide superior strength and longevity. For buyers, selecting the right material can influence maintenance costs and the lifespan of the product.

2. Diameter and Width

The dimensions of heater wheels, typically expressed in inches, affect both stability and maneuverability. For instance, a wheel diameter of 2-3/8″ and a width of 1-1/4″ might be standard for many models. A larger diameter can enhance rolling capability on uneven surfaces, which is particularly important in outdoor settings. Buyers should consider how wheel size aligns with their specific operational needs.

3. Load Capacity

The load capacity indicates how much weight the wheels can support. This is especially important for commercial applications where heaters may need to support substantial weight. Ensuring that the wheels can handle the intended load without compromising safety is vital for operational efficiency and risk management.

4. Locking Mechanism

A locking mechanism on caster wheels allows for enhanced stability when the heater is in use. This feature prevents unwanted movement, which is crucial in environments where safety is a concern. Buyers should look for wheels with reliable locking systems to enhance safety during operation.

5. Tread Design

The tread pattern on the wheels affects traction and maneuverability. A textured tread can provide better grip on various surfaces, reducing the risk of slipping. For B2B buyers, selecting the right tread design can improve the mobility of heaters in diverse operational environments.

6. Corrosion Resistance

Wheels that feature corrosion-resistant coatings or materials are essential in humid or outdoor environments. Corrosion can lead to failure or increased maintenance costs. Buyers should prioritize wheels with suitable protective features to ensure long-term functionality.

What Are Common Trade Terms Related to Heater Wheels?

Navigating the B2B landscape requires familiarity with industry jargon. Here are some key terms that are often encountered in transactions involving heater wheels:

Illustrative image related to heater wheels

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of heater wheels, buyers should understand whether they are sourcing from OEMs to ensure compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest number of units a supplier is willing to sell. This is crucial for B2B buyers as it affects inventory management and cost efficiency. Understanding MOQ helps in budgeting and determining the feasibility of large purchases.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For heater wheels, submitting an RFQ allows buyers to compare offers and negotiate better terms, ensuring they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B transactions involving heater wheels across borders.

5. Lead Time

Lead time refers to the duration from placing an order to delivery. Understanding lead time is essential for planning and inventory management, especially for companies needing heater wheels to meet seasonal demands.

6. Warranty

A warranty is a promise from the manufacturer regarding the quality and longevity of the product. Buyers should consider warranty terms when purchasing heater wheels to safeguard against potential defects and ensure reliability in their operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and operational efficiency in utilizing heater wheels.

Navigating Market Dynamics and Sourcing Trends in the heater wheels Sector

What Are the Current Market Dynamics and Key Trends Influencing Heater Wheels?

The heater wheels market is experiencing significant growth driven by several global factors. Increasing demand for outdoor heating solutions in regions with colder climates, particularly in Europe, North America, and parts of the Middle East, is pushing manufacturers to innovate. In Africa and South America, where outdoor gatherings are prevalent, the need for portable heating solutions is also on the rise. Additionally, the shift towards e-commerce and digital platforms has revolutionized how buyers source heater wheels, allowing for greater price comparison and accessibility to a wider range of suppliers.

Emerging technologies are reshaping sourcing trends, with manufacturers increasingly utilizing advanced materials such as high-density polyethylene and reinforced plastics. These materials not only enhance the durability of heater wheels but also reduce production costs, making them more appealing to B2B buyers. Furthermore, automation in manufacturing processes is leading to quicker turnaround times and reduced lead times for bulk orders. As international B2B buyers, particularly from regions like Saudi Arabia and Nigeria, seek to optimize their supply chains, understanding these dynamics is essential for making informed purchasing decisions.

How Does Sustainability and Ethical Sourcing Impact the Heater Wheels Market?

Sustainability is becoming a cornerstone of supply chain management in the heater wheels sector. The environmental impact of manufacturing processes, particularly those involving plastic materials, has prompted buyers to seek suppliers who adhere to sustainable practices. This includes the use of recycled materials, energy-efficient production methods, and minimizing waste during manufacturing. B2B buyers are increasingly prioritizing suppliers who can demonstrate a commitment to environmental stewardship, often looking for certifications such as ISO 14001 or other green certifications.

Ethical sourcing is also gaining traction, with buyers focusing on the transparency of their suppliers’ supply chains. Companies that prioritize fair labor practices and responsible sourcing of raw materials are becoming preferred partners. This shift not only enhances brand reputation but also aligns with the growing consumer demand for ethically produced products. For B2B buyers in regions like Europe, where sustainability regulations are stringent, aligning with suppliers who prioritize these values can be crucial for compliance and market competitiveness.

What Is the Historical Context Behind Heater Wheels Development?

The evolution of heater wheels can be traced back to the increasing popularity of outdoor heating solutions in the late 20th century. Initially, these wheels were simple designs made from metal or basic plastic, primarily aimed at providing mobility for portable heaters. Over the years, advancements in materials science led to the development of more sophisticated, durable, and lightweight options.

Manufacturers began integrating features such as locking mechanisms for stability and enhanced designs for aesthetic appeal, catering to both commercial and residential markets. As the global focus shifted towards energy efficiency and sustainability, the heater wheels sector adapted by incorporating eco-friendly materials and manufacturing processes. This historical context not only highlights the adaptability of the industry but also underscores the importance of staying abreast of technological advancements and market demands for B2B buyers looking to source heater wheels effectively.

By understanding the current market dynamics, sustainability trends, and the historical evolution of heater wheels, international B2B buyers can make informed decisions that align with their operational goals and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of heater wheels

-

How do I choose the right heater wheels for my application?

Selecting the right heater wheels involves assessing the type of heater, its weight, and the intended surface for mobility. Consider whether you need heavy-duty wheels for outdoor use or lighter options for indoor settings. Additionally, evaluate the wheel diameter and width, as these factors influence maneuverability and stability. Contact suppliers for guidance on compatibility and features that suit your specific heating equipment. -

What are the benefits of using locking caster wheels for heaters?

Locking caster wheels provide enhanced stability by preventing unwanted movement of the heater when in use. This feature is particularly crucial in environments with high foot traffic or on uneven surfaces. Locking mechanisms ensure safety, allowing users to secure the heater in place while maximizing heat distribution. For commercial settings, this can lead to improved operational efficiency and safety compliance. -

What is the minimum order quantity (MOQ) for heater wheels?

Minimum order quantities for heater wheels can vary widely depending on the supplier and the specific product type. Typically, MOQs range from 50 to 500 units, particularly for custom designs. When negotiating with suppliers, clarify MOQ requirements upfront and explore options for bulk purchases to take advantage of lower pricing. Some suppliers may offer flexibility for first-time buyers or pilot orders. -

How can I ensure the quality of heater wheels before purchasing?

To ensure quality, request samples from potential suppliers to assess materials and construction. Look for certifications or compliance with international quality standards, such as ISO or CE markings. Additionally, seek references or testimonials from other clients in similar markets to gauge reliability. Conducting a factory audit or visiting the supplier’s facility can also provide insights into their production processes. -

What payment terms should I expect when sourcing heater wheels internationally?

Payment terms can vary based on the supplier’s policies and the nature of the transaction. Common options include advance payment, letters of credit, or payment upon delivery. For larger orders, consider negotiating favorable terms, such as partial upfront payments with the balance due upon shipment. Ensure that payment methods are secure and provide adequate buyer protection, particularly for international transactions. -

What logistics considerations should I keep in mind for importing heater wheels?

When importing heater wheels, consider shipping methods, customs regulations, and import duties. Collaborate with a logistics provider experienced in international trade to navigate these complexities. Additionally, factor in lead times for production and delivery, as well as potential delays at customs. Having a clear understanding of these logistics will help streamline the purchasing process and minimize unexpected costs. -

Can I customize the heater wheels for my specific needs?

Yes, many suppliers offer customization options for heater wheels, including material selection, size, and color. Custom designs can enhance functionality and branding, making your products stand out in the market. Discuss your requirements with the supplier to explore available customization options and any associated costs. Keep in mind that custom orders may have longer lead times and higher MOQs. -

What should I do if I receive defective heater wheels?

If you receive defective heater wheels, promptly contact the supplier with details of the issue. Most reputable suppliers have a return policy or warranty that covers defective products. Document any defects with photos and provide a clear description of the problem. Understanding the supplier’s return process beforehand can facilitate a smoother resolution, whether it involves replacement, repair, or refund.

Top 7 Heater Wheels Manufacturers & Suppliers List

1. Hiland – Plastic Wheels

Domain: azpatioheaters.com

Registered: 2008 (17 years)

Introduction: {“name”: “Hiland Plastic Wheels”, “category”: “Tall Patio Heater Parts”, “price”: “$23.99”, “availability”: “IN STOCK”, “weight”: “0.00 lbs”, “sku”: “THP-PW-BK”, “colors”: [“Black”, “White”], “description”: “Enhance the mobility of your patio heater with the Hiland Plastic Wheels. Available in both black and white options, these hollow wheels offer seamless movement for your heater. The set includ…

2. Balkene Home – Set of 2 Heavy Duty Wheels

Domain: balkenehome.com

Registered: 2019 (6 years)

Introduction: {“item_number”: “61980”, “price”: “$7.71”, “availability”: “In Stock”, “quantity”: “Set of 2 wheels”, “wheel_diameter”: “2-3/8 inch”, “wheel_width”: “1 1/4 inch”, “material”: “Heavy duty black plastic”, “warning”: “WARNING: Cancer and Reproductive Harm – www.P65Warnings.ca.gov”}

3. Mr. Heater – Locking Caster Wheel for MH18CH

Domain: mrheater.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Locking Caster Wheel for MH18CH”, “SKU”: “27514”, “description”: “Replacement Locking Caster Wheel for Cabinet Heater MH18CH”, “price”: “$3.15”, “availability”: “In stock”}

4. DR Heater – Caster Wheel for Models DR-968, DR-998, DR-968H, ILG-918

Domain: drheaterusa.com

Registered: 2009 (16 years)

Introduction: Caster wheel for models DR-968, DR-998, DR-968H, ILG-918. Price: $7.99. Requires selection of Serial No. prefix before ordering. Available for recurring or deferred purchase.

5. Fuel Offroad – Fuel Heater

Domain: fueloffroad.com

Registered: 2008 (17 years)

Introduction: Product Name: Fuel Heater

Starting Price: $426.00

Sizes Available: 17″, 18″, 20″

Offsets: -24mm to +20mm

Configurations: 5, 6, and 8-lug

Compatible Vehicles: Jeep Wranglers, Toyota Tacomas, Ford F-150s, Silverado 1500s, Ford F-250, F-350, RAM 2500, 3500, Silverado 2500, 3500

Warranty: Limited Warranty covering structural failure under normal use

Specifications:

– Model: D720 HEATER MATTE BLACK DDT…

6. Replacement Black Plastic Wheels – Set of 2

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Replacement Black Plastic Wheels for Patio Heaters – Set of 2”, “Condition”: “Open box”, “Condition Description”: “An item in excellent, new condition with no wear. The item may be missing the original packaging or protective wrapping, or may be in the original packaging but not sealed. The item includes original accessories. The item may be a factory second.”, “Quantity Availabl…

7. Heater Parts Central – Kerosene Forced Air Heater Wheels

Domain: heaterpartscentral.com

Registered: 2017 (8 years)

Introduction: Kerosene Forced Air Heater Wheels: 1. Model 21-6022 – MSRP: $49.95, fits select kerosene forced air models (DFA400/650T). 2. Model 21-1272 – MSRP: $29.88, fits select kerosene forced air models. Both products carry a warning for cancer and reproductive harm (www.P65Warnings.ca.gov).

Strategic Sourcing Conclusion and Outlook for heater wheels

In today’s competitive market, effective strategic sourcing of heater wheels is essential for optimizing supply chains and enhancing product offerings. By understanding the diverse options available, international B2B buyers can make informed decisions that align with their operational needs and customer expectations. Quality, durability, and mobility are crucial factors to consider, especially in regions with varying climates and usage scenarios, such as Africa, South America, the Middle East, and Europe.

Building strong relationships with reliable suppliers can lead to cost savings, improved product availability, and access to the latest innovations in heater wheel technology. As businesses increasingly prioritize sustainability, sourcing wheels made from eco-friendly materials can also enhance brand reputation and appeal to environmentally-conscious consumers.

Looking ahead, the demand for versatile and high-quality heater wheels is set to rise, driven by the growing popularity of outdoor heating solutions across various sectors. To stay ahead, international buyers should actively seek partnerships with manufacturers who can provide tailored solutions, ensuring their offerings meet both market demands and operational requirements. Embrace strategic sourcing today to secure a competitive edge in the dynamic heater wheel market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.