Choosing Your Heat Exchanger Pics: Key Specs to Compare in 2025

Introduction: Navigating the Global Market for heat exchanger pics

In the fast-evolving global market, sourcing high-quality heat exchanger pictures can be a daunting task for B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the challenge often lies in identifying reliable suppliers and understanding the variety of products available. This guide aims to streamline your purchasing process by offering a comprehensive overview of heat exchanger pics, including different types such as shell and tube, plate, and coil heat exchangers, as well as their diverse applications across industries.

Throughout this guide, we will delve into the nuances of selecting the right heat exchanger images for your business needs. You’ll gain insights into supplier vetting processes, cost considerations, and the significance of visual content in enhancing marketing efforts. By equipping you with the knowledge to make informed decisions, this guide empowers international B2B buyers to navigate the complexities of the heat exchanger market confidently.

With a focus on practical solutions and actionable insights, you will be better positioned to choose high-quality images that resonate with your target audience. Whether you are looking to illustrate technical specifications or showcase product applications, this guide will serve as your go-to resource for optimizing your visual content strategy in the heat exchanger sector.

Understanding heat exchanger pics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Shell and Tube | Composed of a series of tubes, one set carrying the hot fluid and another the cold fluid. | Oil refineries, chemical processing | Pros: High heat transfer efficiency, durable. Cons: Requires significant space, complex maintenance. |

| Plate Heat Exchanger | Made up of multiple thin plates stacked together, allowing for efficient heat transfer. | Food processing, HVAC systems | Pros: Compact design, high efficiency. Cons: Sensitive to fouling, limited pressure capabilities. |

| Air-to-Air Heat Exchanger | Transfers heat between two air streams, often used in ventilation systems. | HVAC systems, industrial air conditioning | Pros: Energy-efficient, reduces heating/cooling costs. Cons: Limited to air applications, may require regular cleaning. |

| Double Pipe Heat Exchanger | Consists of one pipe inside another, with fluids flowing in opposite directions. | Heating and cooling processes in small plants | Pros: Simple design, easy to maintain. Cons: Less efficient for large-scale applications, limited heat transfer area. |

| Coil Heat Exchanger | Features coiled tubes that allow for heat transfer between fluids. | Refrigeration, air conditioning systems | Pros: Compact, flexible installation. Cons: May have higher pressure drops, limited heat transfer efficiency. |

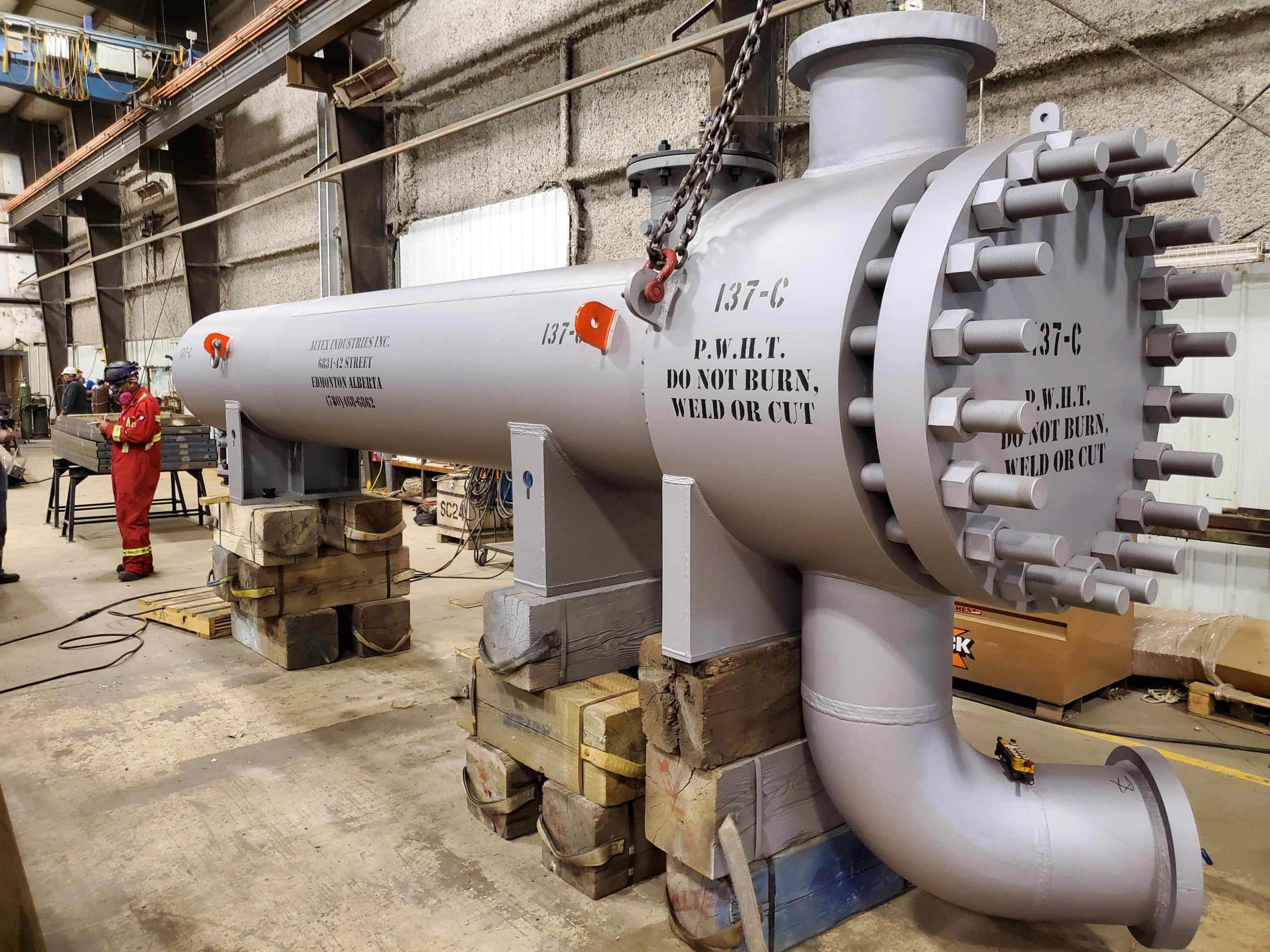

What are the Characteristics of Shell and Tube Heat Exchangers?

Shell and tube heat exchangers are characterized by their robust construction, featuring a series of tubes housed within a cylindrical shell. This design allows for effective heat transfer between two fluids, typically with one fluid flowing through the tubes and the other around them. These exchangers are particularly suitable for high-pressure applications, such as oil refineries and chemical processing facilities. When purchasing, B2B buyers should consider the required size, material compatibility, and maintenance needs, as these units can be complex and space-consuming.

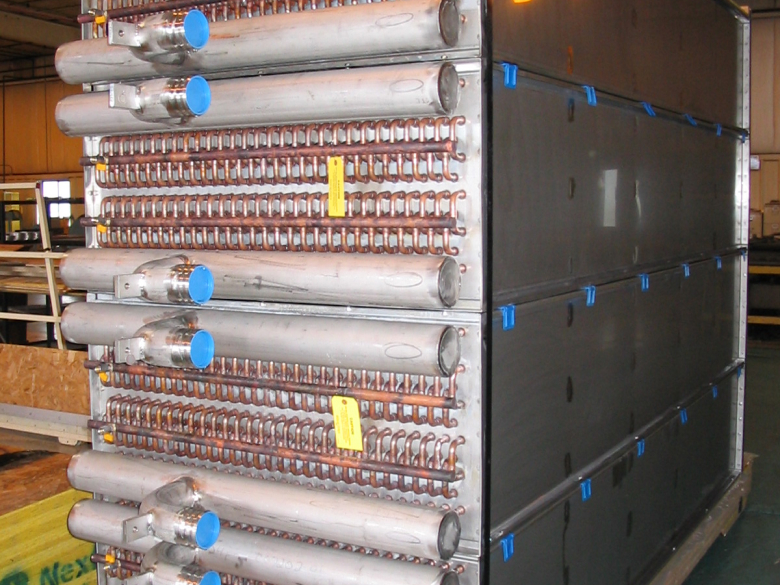

How Do Plate Heat Exchangers Stand Out in Efficiency?

Plate heat exchangers are known for their high efficiency, thanks to the large surface area provided by multiple thin plates stacked together. This design maximizes heat transfer while minimizing the space required, making them ideal for applications in food processing and HVAC systems. However, buyers should be aware of their sensitivity to fouling, which can impact performance and necessitate regular cleaning. Additionally, understanding pressure limitations is essential for ensuring the right fit for their specific applications.

What Makes Air-to-Air Heat Exchangers Energy Efficient?

Air-to-air heat exchangers effectively transfer heat between two air streams, making them a popular choice in HVAC systems and industrial air conditioning. Their design promotes energy efficiency, significantly reducing heating and cooling costs. However, B2B buyers must consider that these units are limited to air applications and may require routine maintenance to prevent fouling and ensure optimal performance. Evaluating the potential energy savings against maintenance requirements can help buyers make informed decisions.

Illustrative image related to heat exchanger pics

Why Choose Double Pipe Heat Exchangers for Simplicity?

Double pipe heat exchangers feature a straightforward design with one pipe inside another, allowing fluids to flow in opposite directions. This simplicity makes them easy to install and maintain, making them suitable for smaller heating and cooling processes. However, they may not be as efficient for larger applications due to their limited heat transfer area. Buyers should assess their specific needs, including flow rates and temperature differentials, to determine if this type meets their operational requirements.

What are the Advantages of Coil Heat Exchangers in Compact Spaces?

Coil heat exchangers utilize coiled tubes to facilitate heat transfer between fluids, making them an excellent choice for refrigeration and air conditioning systems where space is limited. Their compact design allows for flexible installation, which can be advantageous in tight environments. However, potential buyers should consider the pressure drops associated with coils and how these might affect overall efficiency. Understanding the specific application and installation constraints is crucial for selecting the right coil heat exchanger.

Key Industrial Applications of heat exchanger pics

| Industry/Sector | Specific Application of heat exchanger pics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Heat exchangers in refineries | Enhanced efficiency in crude oil processing | Material durability, corrosion resistance, and compliance with safety standards. |

| Chemical Processing | Plate heat exchangers for chemical reactions | Improved heat transfer efficiency and process control | Customization options for specific chemical properties and regulatory compliance. |

| Food & Beverage | Heat exchangers for pasteurization | Extended shelf life and quality assurance | Hygiene standards, ease of cleaning, and material certifications. |

| HVAC & Refrigeration | Air-cooled heat exchangers in commercial buildings | Energy savings and improved climate control | Energy efficiency ratings and compatibility with existing systems. |

| Power Generation | Heat recovery steam generators | Increased energy efficiency and reduced emissions | Design specifications for high-temperature applications and regulatory compliance. |

How Are Heat Exchanger Pics Used in the Oil & Gas Industry?

In the oil and gas sector, heat exchangers are crucial for refining processes, where they facilitate the transfer of heat between fluids without mixing them. Heat exchanger pictures can illustrate the intricate designs of shell and tube heat exchangers, which are often used to manage the high temperatures and corrosive environments typical in refineries. For international buyers, sourcing heat exchangers requires a focus on materials that can withstand harsh conditions, such as high-nickel alloys or duplex stainless steel, while also ensuring compliance with industry safety standards.

What Role Do Heat Exchanger Pics Play in Chemical Processing?

In chemical processing, plate heat exchangers are widely utilized for their superior heat transfer capabilities and compact design. Images of these systems can highlight their application in various chemical reactions, where maintaining precise temperatures is vital for product quality. Buyers from regions like Africa and South America must consider customization options to meet specific chemical properties and ensure that the equipment adheres to local regulatory requirements, which may differ significantly from European standards.

Illustrative image related to heat exchanger pics

How Are Heat Exchanger Pics Beneficial in the Food & Beverage Sector?

Heat exchangers are essential in the food and beverage industry, particularly for pasteurization processes that ensure food safety and extend shelf life. Visual representations of these systems can help buyers understand the importance of hygiene and ease of cleaning. International B2B buyers should prioritize sourcing heat exchangers that meet stringent hygiene standards, with certifications that guarantee safety and quality, especially in markets with strict food safety regulations.

Why Are Heat Exchanger Pics Important for HVAC & Refrigeration?

In the HVAC and refrigeration sectors, air-cooled heat exchangers play a significant role in maintaining optimal indoor climates in commercial buildings. Pictures showcasing these systems can demonstrate their design and energy efficiency, which are critical for reducing operational costs. Buyers in the Middle East and Europe should focus on the energy efficiency ratings of these systems and ensure compatibility with existing HVAC setups to optimize performance and sustainability.

How Do Heat Exchanger Pics Enhance Power Generation Efficiency?

Heat exchangers are pivotal in power generation, particularly in heat recovery steam generators (HRSG) that improve overall energy efficiency. Visuals of these systems can illustrate their complex design and operational mechanics. For international buyers, understanding the specific design requirements for high-temperature applications is essential, along with ensuring compliance with environmental regulations aimed at reducing emissions. This focus not only enhances operational efficiency but also aligns with global sustainability goals.

3 Common User Pain Points for ‘heat exchanger pics’ & Their Solutions

Scenario 1: Difficulty in Visualizing Complex Heat Exchanger Designs

The Problem: B2B buyers often struggle to visualize and understand the intricate designs and variations of heat exchangers when reviewing images. This challenge is exacerbated by the technical nature of the products, where different configurations—such as shell and tube, plate, or coil designs—offer varying benefits for specific applications. Without a clear visual reference, buyers may find it difficult to ascertain which type of heat exchanger best meets their operational needs, leading to potential misalignment in procurement decisions.

The Solution: To overcome this challenge, buyers should seek out high-quality, labeled images that highlight the key features and functions of different heat exchanger designs. Utilizing resources from reputable manufacturers or stock photo libraries that specialize in industrial equipment can provide clarity. When sourcing images, look for those that include annotations or descriptions detailing the applications, advantages, and operational principles of each design. Additionally, participating in webinars or virtual tours of manufacturing facilities can provide context and depth beyond static images, helping buyers make informed decisions based on their specific requirements.

Illustrative image related to heat exchanger pics

Scenario 2: Misinterpretation of Heat Exchanger Condition in Photos

The Problem: Buyers frequently encounter images of heat exchangers that may not accurately represent their current condition. Poor-quality photos, or those taken from unhelpful angles, can mislead buyers regarding the integrity and usability of the equipment. This misinterpretation can result in costly purchasing decisions, as buyers may invest in equipment that appears functional in pictures but is, in fact, degraded or unsuitable for their processes.

The Solution: To mitigate the risk of misinterpretation, buyers should prioritize sourcing images from trusted suppliers who provide a detailed context for each heat exchanger, including recent inspection reports and maintenance histories. It’s advisable to request high-resolution images taken from multiple angles, including close-ups of critical components like tube sheets and connections. Moreover, engaging directly with manufacturers or suppliers to obtain real-time images or videos during site visits can ensure that buyers are receiving accurate depictions of the heat exchanger’s condition. This proactive approach can help avoid unexpected repairs or replacements post-purchase.

Scenario 3: Lack of Context for Application-Specific Heat Exchanger Images

The Problem: Many heat exchanger images are presented without sufficient context, leaving buyers uncertain about their suitability for specific applications. This lack of application-specific detail can lead to confusion, especially for buyers in diverse industries such as petrochemical, HVAC, or food processing. Without understanding how a particular heat exchanger design functions within their operational environment, buyers may struggle to justify their investment.

The Solution: Buyers should look for images accompanied by detailed descriptions that explain the specific applications of each heat exchanger type. This can include case studies or example scenarios that illustrate how the equipment performs under various conditions. Additionally, collaborating with suppliers who offer comprehensive product documentation, including technical specifications and performance benchmarks, can provide the necessary context. Buyers may also benefit from engaging in online forums or industry-specific networks where they can discuss practical applications and share insights with peers who have faced similar decisions. This collaboration can enhance their understanding and lead to more informed purchasing choices that align with their operational goals.

Strategic Material Selection Guide for heat exchanger pics

When selecting materials for heat exchangers, various factors come into play, including the specific application, environmental conditions, and regulatory compliance. Below, we analyze four common materials used in heat exchanger construction, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to heat exchanger pics

What Are the Key Properties of Stainless Steel in Heat Exchangers?

Stainless steel is a popular choice for heat exchangers due to its excellent corrosion resistance and high-temperature performance. Typically, grades such as 304 and 316 are used, with 316 offering superior resistance to chlorides. These materials can withstand pressures up to 1500 psi and temperatures of around 1000°F, making them suitable for a wide range of applications.

Pros: Stainless steel is durable and has a long service life. It is also relatively easy to fabricate and weld, allowing for complex designs.

Cons: The primary drawback is its cost, which is higher than carbon steel. Additionally, it can be susceptible to stress corrosion cracking in certain environments.

Impact on Application: Stainless steel is compatible with a variety of media, including water, oils, and chemicals. However, care must be taken in acidic environments.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel sheets and plates is crucial. Buyers should also consider local availability and pricing, which can vary significantly across regions like Africa and Europe.

How Does Copper Perform as a Heat Exchanger Material?

Copper is another widely used material, particularly in smaller heat exchangers and residential applications. It has excellent thermal conductivity, significantly outperforming stainless steel and aluminum. Copper can handle temperatures up to 400°F and pressures around 300 psi.

Illustrative image related to heat exchanger pics

Pros: The primary advantage of copper is its superior heat transfer efficiency, which can lead to reduced energy costs.

Cons: However, copper is more expensive than carbon steel and is prone to corrosion in certain environments, particularly when in contact with acidic substances.

Impact on Application: Copper is best suited for applications involving water and low-pressure systems. Its high thermal conductivity makes it ideal for applications requiring rapid heat exchange.

Considerations for International Buyers: Buyers should be aware of the standards governing copper materials, such as ASTM B280. Additionally, the price volatility of copper can impact project budgets, especially in developing markets.

What Are the Advantages of Carbon Steel in Heat Exchangers?

Carbon steel is often used for heat exchangers in industrial applications due to its strength and cost-effectiveness. It can typically handle pressures up to 2000 psi and temperatures around 800°F.

Pros: Carbon steel is relatively inexpensive and widely available, making it a go-to option for many applications.

Cons: Its primary limitation is poor corrosion resistance, which can lead to premature failure in corrosive environments.

Impact on Application: Carbon steel is suitable for applications involving non-corrosive fluids, such as water and certain oils. It is not recommended for use with aggressive chemicals.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A106 for seamless carbon steel pipes. Understanding local corrosion conditions is also essential for ensuring longevity.

How Does Titanium Compare in Heat Exchanger Applications?

Titanium is a high-performance material known for its exceptional corrosion resistance and strength-to-weight ratio. It can withstand high temperatures (up to 1000°F) and pressures (up to 1500 psi), making it suitable for harsh environments.

Pros: Titanium is highly resistant to corrosion, even in seawater and acidic conditions, making it ideal for offshore and chemical processing applications.

Cons: The primary disadvantage is its high cost and manufacturing complexity, which can make it less accessible for some projects.

Illustrative image related to heat exchanger pics

Impact on Application: Titanium is suitable for applications involving aggressive media, including seawater and certain chemicals.

Considerations for International Buyers: Buyers should be aware of the specific standards for titanium, such as ASTM B338. The high initial investment may be justified in applications where longevity and reliability are critical.

Summary Table of Material Selection for Heat Exchanger Pics

| Material | Typical Use Case for heat exchanger pics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, oil and gas | Excellent corrosion resistance | Higher cost and susceptibility to cracking | High |

| Copper | Residential heating, small applications | Superior thermal conductivity | Prone to corrosion in acidic media | Medium |

| Carbon Steel | Industrial applications, water systems | Cost-effective and widely available | Poor corrosion resistance | Low |

| Titanium | Offshore, chemical processing | Exceptional corrosion resistance | High cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for heat exchangers, enabling international B2B buyers to make informed decisions based on their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for heat exchanger pics

What Are the Key Stages in the Manufacturing Process of Heat Exchanger Pictures?

Manufacturing heat exchangers involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these stages is essential for B2B buyers who seek reliable and efficient heat exchangers for their operations.

Material Preparation: What Materials Are Used in Heat Exchanger Manufacturing?

The manufacturing process begins with the selection and preparation of materials. Commonly used materials include stainless steel, copper, titanium, and high-nickel alloys, which are chosen for their thermal conductivity and corrosion resistance. For specialized applications, materials like tantalum and zirconium may also be used.

Illustrative image related to heat exchanger pics

Before fabrication, these materials undergo a thorough inspection to ensure they meet required specifications and quality standards. This includes checking for any surface imperfections and verifying material certifications to ensure compliance with international standards.

How Are Heat Exchangers Formed and Assembled?

Once materials are prepared, the next step is forming. This process can involve various techniques, including welding, bending, and machining, depending on the specific design of the heat exchanger. For instance, shell and tube heat exchangers require precise welding techniques to ensure the integrity of the tube sheets and shell.

After forming, the assembly phase begins. This involves fitting together the various components, such as tubes, shells, and headers, in accordance with engineering specifications. Techniques like hydro-expansion and roller expansion are often employed to secure the tubes within the shell, enhancing thermal efficiency and structural stability.

What Finishing Processes Are Essential for Quality Heat Exchangers?

Finishing processes play a crucial role in the durability and performance of heat exchangers. This may include surface treatments, such as passivation or coating, to enhance corrosion resistance. Additionally, thorough cleaning processes are implemented to remove any contaminants that may affect performance.

Final assembly and finishing stages are followed by rigorous testing to ensure that the heat exchangers meet the operational requirements and industry standards.

Illustrative image related to heat exchanger pics

What Quality Control Measures Are Essential in Heat Exchanger Manufacturing?

Quality control (QC) is integral to the manufacturing process, ensuring that every unit meets the necessary standards for performance and safety. For B2B buyers, understanding these QC measures can be critical when selecting a supplier.

What International Standards Should B2B Buyers Be Aware Of?

Heat exchangers must comply with various international standards, such as ISO 9001 for quality management systems. Additionally, industry-specific certifications like CE marking in Europe or API standards for the oil and gas industry are essential. These certifications indicate that the manufacturer adheres to high-quality production practices and regulatory requirements.

How Are QC Checkpoints Structured in the Manufacturing Process?

Quality control is typically structured around several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials before they enter the manufacturing process. It ensures that all materials meet predefined specifications and standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to monitor the quality of the work being performed. This may include checking weld integrity, dimensional accuracy, and surface finishes.

-

Final Quality Control (FQC): Once the heat exchanger is fully assembled, it undergoes final inspections and testing. This may involve pressure testing, thermal performance assessments, and visual inspections for any defects.

What Testing Methods Are Commonly Used for Heat Exchangers?

Common testing methods for heat exchangers include:

-

Hydrostatic Testing: This involves filling the heat exchanger with water and pressurizing it to check for leaks. It is a critical test that ensures the integrity of the unit under operational pressures.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and dye penetrant testing are used to detect internal and surface defects without damaging the heat exchanger.

-

Performance Testing: This assesses the heat exchanger’s thermal efficiency and capacity under simulated operational conditions, ensuring it meets the specified performance criteria.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are some strategies to ensure reliability:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, QC measures, and adherence to international standards. This direct observation can provide valuable insights into the supplier’s capabilities.

-

Requesting Quality Reports: Buyers should request detailed QC reports that outline inspection results, testing methodologies, and compliance with industry standards. These documents serve as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing and QC processes. This can be particularly beneficial for buyers in regions with stringent regulatory requirements.

What Are the Nuances in Quality Control for International Buyers?

International buyers should be aware of specific nuances related to quality control. Different regions may have varying standards, and understanding these can aid in selecting the right supplier. For instance, buyers from Europe may prioritize CE marking, while those from the Middle East might focus on compliance with local regulatory bodies.

Illustrative image related to heat exchanger pics

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. It is advisable for buyers to establish clear, written agreements outlining quality standards and inspection protocols to mitigate misunderstandings.

Conclusion: Ensuring Quality in Heat Exchanger Procurement

For B2B buyers, understanding the manufacturing processes and quality assurance measures for heat exchangers is vital to ensuring that they procure reliable and efficient equipment. By focusing on material preparation, forming, assembly, and finishing stages, along with robust quality control practices, buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heat exchanger pics’

Introduction

Sourcing high-quality images of heat exchangers is essential for businesses involved in manufacturing, engineering, or marketing related to thermal management solutions. This guide will walk you through a step-by-step checklist to ensure you procure the most relevant and high-quality visuals that meet your specific needs.

Illustrative image related to heat exchanger pics

Step 1: Identify Your Visual Requirements

Before beginning your search, clarify what types of heat exchanger images you need. Consider the specific designs, applications, and contexts that are relevant to your industry, such as shell and tube, plate, or air-to-air heat exchangers. This initial definition will streamline your sourcing process and ensure that you acquire images that directly support your business objectives.

Step 2: Research Reputable Image Sources

Not all image repositories are created equal. Focus on well-established platforms known for industrial and technical images, such as Adobe Stock, iStock, or specialized galleries like TITAN Metal Fabricators. Make sure to check their licensing agreements to understand usage rights, especially if you plan to use these images for commercial purposes.

Step 3: Evaluate Image Quality and Relevance

When browsing potential images, prioritize high-resolution files that clearly depict the details of the heat exchangers. Look for images that showcase various angles, operational settings, and applications. This will not only enhance your marketing materials but also provide clarity in technical documentation or training resources.

Step 4: Consider Custom Photography Options

If your needs are highly specific or if you require images of proprietary designs, consider commissioning a professional photographer. This option allows for tailored visuals that highlight your unique products and applications. When approaching photographers, provide them with detailed specifications and examples of what you’re looking for to ensure the final images align with your vision.

Step 5: Verify Licensing and Usage Rights

Before finalizing your selection, review the licensing terms associated with each image. Ensure that the usage rights align with your intended applications, whether for digital marketing, print materials, or internal use. This step is crucial to avoid legal complications down the road.

Step 6: Collect Feedback from Stakeholders

Engage with your marketing, engineering, and sales teams to gather feedback on the selected images. Their insights can help refine your choices and ensure that the visuals resonate well with your target audience. Collaboration at this stage can lead to a more cohesive brand presentation.

Step 7: Document Your Findings and Source URLs

Maintain a detailed record of the images you consider, including their source URLs, licensing details, and any notes on how they might be used. This documentation will facilitate easier access in the future and assist in budgeting for potential purchases.

By following this checklist, B2B buyers can effectively source high-quality heat exchanger images that enhance their product representation and marketing strategies.

Illustrative image related to heat exchanger pics

Comprehensive Cost and Pricing Analysis for heat exchanger pics Sourcing

Analyzing the cost structure and pricing for heat exchanger pictures sourcing is essential for B2B buyers looking to optimize their procurement strategy. Understanding the various cost components and price influencers can help buyers make informed decisions, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Heat Exchanger Pics?

-

Materials: The choice of materials significantly affects the cost of heat exchanger images. Premium-grade materials such as titanium or high-nickel alloys may command higher prices due to their durability and resistance to corrosion. Additionally, the complexity of the heat exchanger design—be it shell and tube, plate, or coil—can also influence material costs.

-

Labor: Labor costs encompass the expenses associated with capturing high-quality images, including photographer fees, editing, and post-production. Skilled professionals may charge a premium for their expertise, especially when specialized equipment or techniques are required to showcase intricate designs.

-

Manufacturing Overhead: This includes all indirect costs related to the production of heat exchanger images, such as studio rental, equipment maintenance, and utilities. These costs are typically spread across all images produced, impacting the overall pricing.

-

Tooling: If custom setups or specialized equipment are needed to capture specific heat exchanger designs, tooling costs can increase. This is particularly relevant for unique or large-scale heat exchangers that require tailored photographic techniques.

-

Quality Control (QC): Ensuring that images meet industry standards for quality and clarity incurs additional costs. QC processes may involve multiple revisions and checks, particularly for images intended for marketing or technical documentation.

-

Logistics: This covers the costs associated with delivering the final images to the client. For international buyers, logistics can include shipping charges for physical media or costs related to digital delivery platforms.

-

Margin: Suppliers typically add a profit margin to cover their expenses and ensure profitability. This margin can vary significantly based on the supplier’s market positioning and the perceived value of the images.

How Do Price Influencers Impact Heat Exchanger Pics?

-

Volume/MOQ: Buyers can often negotiate better pricing based on the volume of images ordered. Higher quantities may reduce per-image costs, making it more cost-effective for bulk purchases.

-

Specifications and Customization: Custom requests for specific angles, lighting, or settings can lead to increased costs. Buyers should clearly outline their requirements to receive accurate quotes.

-

Quality and Certifications: Images that require certification (e.g., for technical publications) may come at a premium. Suppliers offering certified images can justify higher prices based on the added value of compliance.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more due to perceived quality and service reliability.

-

Incoterms: Understanding the terms of trade is crucial for international buyers. Different Incoterms can affect the total cost by defining who is responsible for shipping, insurance, and tariffs.

What Buyer Tips Can Enhance Cost-Efficiency?

-

Negotiation: Engage in discussions with suppliers to explore discounts based on volume or long-term contracts. Suppliers may be willing to adjust prices to secure repeat business.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just upfront costs. Evaluate factors such as image usage rights, potential re-edits, and the longevity of the images in your marketing materials.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that may affect the final price. Establishing relationships with local suppliers can mitigate some of these issues.

-

Due Diligence: Research multiple suppliers to compare prices and quality. Request samples when possible to ensure the images meet your expectations before committing to larger orders.

Disclaimer

The prices discussed in this analysis are indicative and can vary widely based on specific requirements, regional factors, and supplier negotiations. Buyers are encouraged to conduct thorough market research and engage directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing heat exchanger pics With Other Solutions

Introduction: Understanding Alternatives in Heat Exchange Solutions

In the realm of industrial processes, selecting the right heat exchange solution is paramount. While ‘heat exchanger pics’ offer a visual representation of heat exchangers and their designs, it is essential for B2B buyers to evaluate various alternatives that might better suit their operational needs. This section will compare heat exchanger pics to two viable alternatives: Plate Heat Exchangers and Air-Cooled Heat Exchangers. Each option has unique features that cater to different applications, performance requirements, and budget constraints.

Comparison Table

| Comparison Aspect | Heat Exchanger Pics | Plate Heat Exchangers | Air-Cooled Heat Exchangers |

|---|---|---|---|

| Performance | Visual representation only | High efficiency, compact design | Lower efficiency, larger footprint |

| Cost | Varies based on imagery | Generally higher upfront cost | Lower initial investment |

| Ease of Implementation | Easy to source images | Moderate complexity in installation | Simple installation |

| Maintenance | N/A | Requires regular cleaning | Minimal maintenance needed |

| Best Use Case | Design inspiration | HVAC and food processing | Outdoor applications, cooling towers |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of Plate Heat Exchangers?

Plate heat exchangers are known for their high thermal efficiency due to their large surface area and compact design. They are ideal for applications where space is limited and energy efficiency is critical, such as in HVAC systems and food processing industries. However, the initial cost can be higher than traditional heat exchangers, and they require regular maintenance to prevent fouling. Their complex design may also complicate installation, making it crucial for buyers to consider their specific needs and capabilities.

How Do Air-Cooled Heat Exchangers Compare?

Air-cooled heat exchangers utilize ambient air to cool fluids, making them an excellent choice for outdoor applications. They are generally less expensive to install compared to liquid-cooled systems and require less maintenance, as they do not involve cooling towers or extensive piping. However, their performance can be lower than that of plate heat exchangers, especially in high-temperature environments. Additionally, they typically have a larger footprint, which may not be suitable for all facilities.

Conclusion: Making the Right Choice for Your Business Needs

When selecting a heat exchange solution, B2B buyers must weigh the pros and cons of each alternative against their specific operational requirements. Heat exchanger pics serve as a valuable resource for visualizing designs, but practical considerations such as performance, cost, and maintenance must guide the decision-making process. By understanding the strengths and limitations of options like Plate Heat Exchangers and Air-Cooled Heat Exchangers, businesses can make informed choices that optimize efficiency and cost-effectiveness in their operations.

Essential Technical Properties and Trade Terminology for heat exchanger pics

What Are the Key Technical Properties of Heat Exchanger Pics?

Understanding the technical specifications of heat exchangers is crucial for B2B buyers, especially when selecting equipment that meets specific operational needs. Here are some essential properties to consider:

Illustrative image related to heat exchanger pics

-

Material Grade

The materials used in heat exchangers significantly affect their performance and longevity. Common materials include stainless steel, copper, and high-nickel alloys. For industries dealing with corrosive fluids, selecting the right material grade ensures resistance to corrosion and minimizes maintenance costs. For example, titanium is preferred in marine applications due to its excellent corrosion resistance. -

Heat Transfer Area

This specification refers to the surface area available for heat exchange between the two fluids. A larger heat transfer area generally improves efficiency, allowing for better thermal performance. B2B buyers should assess their process requirements to determine the optimal size, as this can impact energy consumption and overall operational costs. -

Pressure Rating

The pressure rating indicates the maximum pressure the heat exchanger can withstand during operation. It is critical for ensuring safety and reliability in high-pressure applications, such as in petrochemical or power generation industries. Selecting a heat exchanger with an appropriate pressure rating minimizes the risk of leaks and failures, which can lead to costly downtimes. -

Tolerance

Tolerance levels refer to the allowable variation in dimensions and specifications of the heat exchanger components. This is particularly important in applications where precise fitting is necessary. Inaccuracies can lead to inefficiencies or potential failures, making it vital for buyers to verify that tolerances align with their installation requirements. -

Flow Configuration

Heat exchangers can have various flow configurations, such as counterflow, parallel flow, or crossflow. The choice of configuration affects the thermal performance and efficiency. Buyers should evaluate the specific process conditions to select a configuration that optimizes heat transfer and minimizes energy loss.

Which Trade Terms Should B2B Buyers Know for Heat Exchanger Purchases?

Familiarity with industry terminology can streamline the procurement process and enhance communication between buyers and suppliers. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed by another company. Understanding OEM relationships helps buyers ensure they are sourcing high-quality components that meet industry standards. Engaging with reputable OEMs can also facilitate better warranty and support options. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate MOQs based on their projected usage and financial constraints to avoid excess inventory costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of goods or services. This process helps buyers compare offers and make informed decisions. A well-structured RFQ can also clarify technical requirements, ensuring that suppliers provide accurate quotes. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and duties. Familiarity with these terms is crucial for managing logistics and avoiding unexpected costs. Buyers should clearly specify the desired Incoterms in their contracts to prevent misunderstandings. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times helps buyers manage project schedules and avoid delays. It is advisable to discuss lead times upfront with suppliers to align expectations and ensure timely delivery of heat exchangers.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of heat exchanger procurement more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the heat exchanger pics Sector

What Are the Key Market Dynamics and Trends Influencing the Heat Exchanger Sector?

The heat exchanger market is experiencing robust growth driven by several global factors, particularly in developing regions such as Africa and South America, as well as established markets like Europe. The increasing demand for energy-efficient solutions across industries, including oil and gas, chemical processing, and HVAC systems, is propelling innovations in heat exchanger technology. For B2B buyers, understanding these dynamics is crucial. For instance, the rise of smart manufacturing and IoT technologies is transforming heat exchanger designs, allowing for real-time monitoring and predictive maintenance, which can significantly reduce operational costs.

Emerging trends include the adoption of advanced materials, such as titanium and high-nickel alloys, to enhance corrosion resistance and extend the lifespan of heat exchangers. Additionally, regulatory pressures are pushing manufacturers to prioritize efficiency and sustainability, thereby reshaping sourcing strategies. International buyers should be aware of how local regulations in their regions influence the types of heat exchangers they procure, particularly as European standards become increasingly stringent.

The market is also witnessing a shift towards modular and compact designs, which are particularly appealing in urban settings where space is limited. This trend is not only about efficiency but also aligns with the growing emphasis on reducing the carbon footprint of industrial operations. For buyers in regions like Brazil, where infrastructure development is booming, leveraging these advancements can lead to significant competitive advantages.

Illustrative image related to heat exchanger pics

How Does Sustainability and Ethical Sourcing Impact the Heat Exchanger Industry?

The environmental impact of heat exchangers is increasingly under scrutiny, making sustainability a vital consideration for B2B buyers. The production and operation of heat exchangers can result in considerable energy consumption and waste generation. As such, many companies are now prioritizing sustainability in their sourcing decisions, seeking suppliers that offer eco-friendly materials and processes.

Ethical sourcing is paramount, particularly in regions with stringent environmental regulations. Buyers are encouraged to look for certifications that verify sustainable practices, such as ISO 14001 for environmental management systems or certifications indicating the use of recycled materials. This not only helps in complying with local regulations but also enhances the brand reputation among environmentally conscious consumers.

Moreover, the integration of sustainable practices can lead to cost savings in the long run. For instance, selecting heat exchangers designed for higher thermal efficiency can reduce energy consumption, leading to lower operational costs. Buyers should also consider the lifecycle of heat exchangers, opting for products that are designed for easy maintenance, repair, and recycling, thus minimizing environmental impact.

Illustrative image related to heat exchanger pics

What Is the Historical Context of Heat Exchangers and Their Evolution?

The evolution of heat exchangers can be traced back to the early industrial revolution when the need for efficient energy transfer became apparent. Initially, designs were rudimentary and often limited to basic tube and shell configurations. However, as industries evolved, so did the technology behind heat exchangers. Innovations such as plate heat exchangers emerged in the mid-20th century, allowing for increased surface area and improved heat transfer efficiency.

Over the decades, advancements in materials science have played a crucial role in the development of heat exchangers. The introduction of corrosion-resistant materials has expanded their applicability in harsh environments, particularly in the oil and gas sector. Today, the focus is on integrating digital technologies, which not only enhance operational efficiency but also facilitate predictive maintenance—signifying a shift from reactive to proactive management in industrial processes.

As a result, today’s heat exchangers are not only more efficient but also more adaptable, capable of meeting the demands of various industries worldwide. For B2B buyers, understanding this evolution helps in making informed decisions about the types of heat exchangers that will best meet their operational needs while aligning with sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of heat exchanger pics

-

How can I ensure I’m sourcing high-quality heat exchanger images?

To source high-quality heat exchanger images, start by identifying reputable stock photo providers that specialize in industrial imagery. Look for platforms that offer a diverse range of heat exchanger types, including shell and tube, plate, and air-to-air exchangers. Evaluate the resolution and licensing options of images to ensure they meet your specific needs. Additionally, consider requesting samples or previews and checking user reviews to gauge the quality and reliability of the supplier. -

What are the best platforms for finding heat exchanger images?

The best platforms for finding heat exchanger images include stock photography websites such as Adobe Stock, iStock, and specialized sites like TITAN Metal Fabricators. These platforms often provide extensive galleries and categorization, allowing for easy navigation. Additionally, consider industry-specific resources that may offer unique images not found on general stock sites, ensuring you have access to specialized visuals that cater to your business needs. -

How do I verify the credibility of a supplier for heat exchanger images?

To verify the credibility of a supplier for heat exchanger images, conduct thorough research by checking their online presence, including reviews and testimonials from previous clients. Look for industry certifications or memberships in relevant organizations, which can indicate reliability. Request references from the supplier and verify their previous work, ensuring that they have experience in providing images for industrial applications, particularly heat exchangers. -

Can I customize heat exchanger images for my branding needs?

Many stock image providers offer customization options, allowing you to adapt heat exchanger images for your branding needs. This can include adding your logo, changing colors, or modifying backgrounds. Before purchasing, confirm with the supplier about customization possibilities and any associated fees. Customization can enhance brand recognition and ensure that the imagery aligns with your marketing strategy. -

What is the minimum order quantity (MOQ) for purchasing heat exchanger images?

Minimum order quantities for purchasing heat exchanger images can vary significantly between suppliers. Some stock photo websites operate on a pay-per-image basis with no MOQ, while others may require a subscription or bulk purchase for discounts. It’s crucial to clarify these terms with the supplier prior to making a commitment, especially if you are looking to acquire a large number of images for a project. -

What payment terms should I expect when buying heat exchanger images?

Payment terms for purchasing heat exchanger images typically depend on the supplier’s policies. Most stock photo websites offer various payment methods, including credit cards and PayPal. Some suppliers may offer subscription models with monthly payments or one-time fees for image packs. Always review the payment terms, including refund policies and any additional costs, to avoid unexpected charges. -

How can I ensure the quality assurance of heat exchanger images?

To ensure the quality assurance of heat exchanger images, request high-resolution files and check for image clarity and detail. Look for images that provide clear depictions of different heat exchanger types and their components. Additionally, inquire whether the supplier conducts quality checks on their images for technical accuracy and relevance, which is particularly important for industrial applications. -

What logistics considerations should I be aware of when sourcing heat exchanger images internationally?

When sourcing heat exchanger images internationally, consider logistics related to digital delivery and licensing rights. Ensure that the supplier can provide images in formats compatible with your intended use. Additionally, be aware of any geographic restrictions on image usage and confirm that the licensing allows for international distribution if needed. Clear communication with the supplier about delivery timelines and formats will help streamline the acquisition process.

Top 7 Heat Exchanger Pics Manufacturers & Suppliers List

1. Adobe Stock – Heat Exchanger Assets

Domain: stock.adobe.com

Registered: 1986 (39 years)

Introduction: Heat Exchanger Images – 17,690 Stock Photos, Vectors, and Videos available on Adobe Stock. Includes options for images, videos, audio, templates, and 3D assets. Offers a free trial to access 10 images or 1 video, and options to unlock over 200 million assets. Various filters and sorting options available for browsing.

2. TITAN – Heat Exchangers

Domain: titanmf.com

Registered: 1999 (26 years)

Introduction: TITAN’s Heat Exchanger product line includes various designs from the Shell and Tube Heat Exchanger family and TEMA designs, such as Fixed Tube Sheet, U-Bundle, Packed Head, Floating Tube Sheet, Kettle Reboilers, Falling Film Evaporators / Absorbers, Bayonet, Helical Coil, Immersion Coil, and Double Pipe. Options for tube sheets include loose-lined, solid, and explosion-clad. All head and closure …

3. iStock – Heat Exchanger Images

Domain: istockphoto.com

Registered: 2000 (25 years)

Introduction: This company, iStock – Heat Exchanger Images, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Getty Images – Heat Exchanger Stock Photos

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: This company, Getty Images – Heat Exchanger Stock Photos, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Heat Exchanger Manufacturers – Tube Heat Exchangers

Domain: heatexchangermanufacturers.com

Registered: 2001 (24 years)

Introduction: Tube heat exchangers are designed with bundles of tubes to efficiently transfer heat between two fluids. They feature sturdy, pressure-resistant construction, making them ideal for industrial systems requiring long-term thermal performance and durability. Types include shell and tube, U-tube, and straight-tube designs, serving various performance needs. Common applications are in chemical processi…

6. Pixabay – Free Heat Exchanger Images

Domain: pixabay.com

Registered: 2010 (15 years)

Introduction: 10,000+ Free Heat Exchangers & Fire Images – Pixabay. 10,112 Free images of Heat Exchangers available for download and use in projects. Royalty-free images. Limited deal: 20% off with PIXABAY20 coupon.

7. Freepik – Heat Exchanger Graphics

Domain: freepik.com

Registered: 2010 (15 years)

Introduction: This company, Freepik – Heat Exchanger Graphics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for heat exchanger pics

In the ever-evolving landscape of industrial equipment, heat exchangers remain a pivotal component across various sectors, including petrochemical, HVAC, and energy. Strategic sourcing of heat exchanger images not only facilitates enhanced marketing efforts but also aids in the effective communication of product capabilities and applications. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging high-quality visuals can significantly influence purchasing decisions and brand perception.

Understanding the diverse types and designs of heat exchangers, such as shell and tube or plate heat exchangers, enables buyers to make informed choices tailored to their specific operational needs. By sourcing images that accurately represent these products, companies can better showcase their offerings and improve customer engagement.

As we look ahead, the demand for sustainable and efficient heat exchange solutions will only increase. International buyers should seize this opportunity to enhance their marketing strategies through effective visual storytelling. Embrace the power of strategic sourcing to elevate your brand and connect with potential customers on a deeper level. Invest in high-quality heat exchanger images today to position your business for success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to heat exchanger pics

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.